Method for producing jet fuel

A technology for jet fuel and raw material, which is applied in the petroleum industry, hydrotreating process, processing of hydrocarbon oil, etc., can solve the problems of large circulation of kerosene fractions, increased equipment investment, complicated operation, etc., and achieves increased yield and improved selectivity. , reduce the effect of secondary cracking reaction

Active Publication Date: 2018-05-25

CHINA PETROLEUM & CHEM CORP +1

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method needs to increase more equipment, and the circulation of kerosene fraction is relatively large, which increases the investment of the device, and the operation is more complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~4

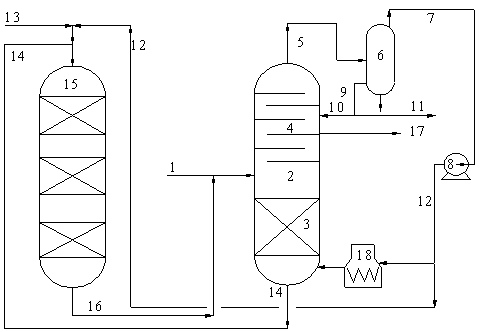

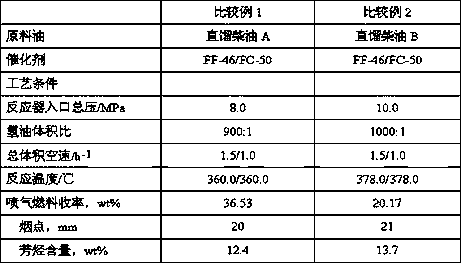

[0031] Example process as the present invention figure 1 As shown, the properties of the used feedstock oils are shown in Table 1, and the properties of the used catalysts are shown in Table 2. Process conditions, product distribution and main properties are shown in Tables 3-4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for producing jet fuel. The method comprises the following contents: a straight-run diesel oil raw material and hydrocracking generated oil are mixed, heated and / or subjected to heat exchange and enter a reaction rectification tower from the middle, and a product descends into a catalytic reaction zone filled with a hydrofining catalyst in the tower for hydrofiningreaction, wherein light components rise to the rectification section of the reaction rectification tower for fractionation, one part of the liquid phase as overhead reflux flows into the reaction rectification tower, and the other part comprising naphtha, jet fuel and the like as products is discharged out of the system; heavy components continue to descend in a stripping section, are dischargedfrom the bottom of the tower, and enter a hydrocracking reactor filled with a hydrocracking catalyst for hydrocracking reaction. According to the method, the straight-run diesel oil is taken as a mainraw material, the reaction process and the reaction depth are adjusted and controlled by selecting a proper process flow and catalyst system, more components in the straight-run diesel oil raw material are converted into jet fuel products, and accordingly, the yield of the jet fuel products is increased, and the quality of the jet fuel products is improved.

Description

technical field [0001] The invention relates to a method for producing jet fuel, in particular to a method for producing high-quality jet fuel by using straight-run diesel oil fractions as raw materials. Background technique [0002] With the continuous expansion of the international air transport industry, the global demand for jet fuel has increased year by year, with an annual growth rate of about 5.0%, which is much higher than the annual growth rate of gasoline and diesel of 1.0% to 1.5%, which has greatly driven the global demand for jet fuel. The demand for high-quality jet fuel products in the oil market has also contributed to the rapid development of jet fuel production technology in the refining industry. Worldwide, the existing jet fuel production technologies are mainly straight-run jet fuel fraction hydrorefining technology and hydrocracking technology. Compared with diesel or gasoline products, jet fuel products have more advantages in profit, which greatly ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G67/02

Inventor 彭冲曾榕辉郭蓉吴子明白振民方向晨

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com