System and method for rectifying and purifying dimethyl oxalate synthesized through carbonylation of glycol from coal

A technology for dimethyl oxalate and coal-to-ethylene glycol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low purity of dimethyl oxalate, improve market competitiveness, solve the The effect of low purity and extended useful life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

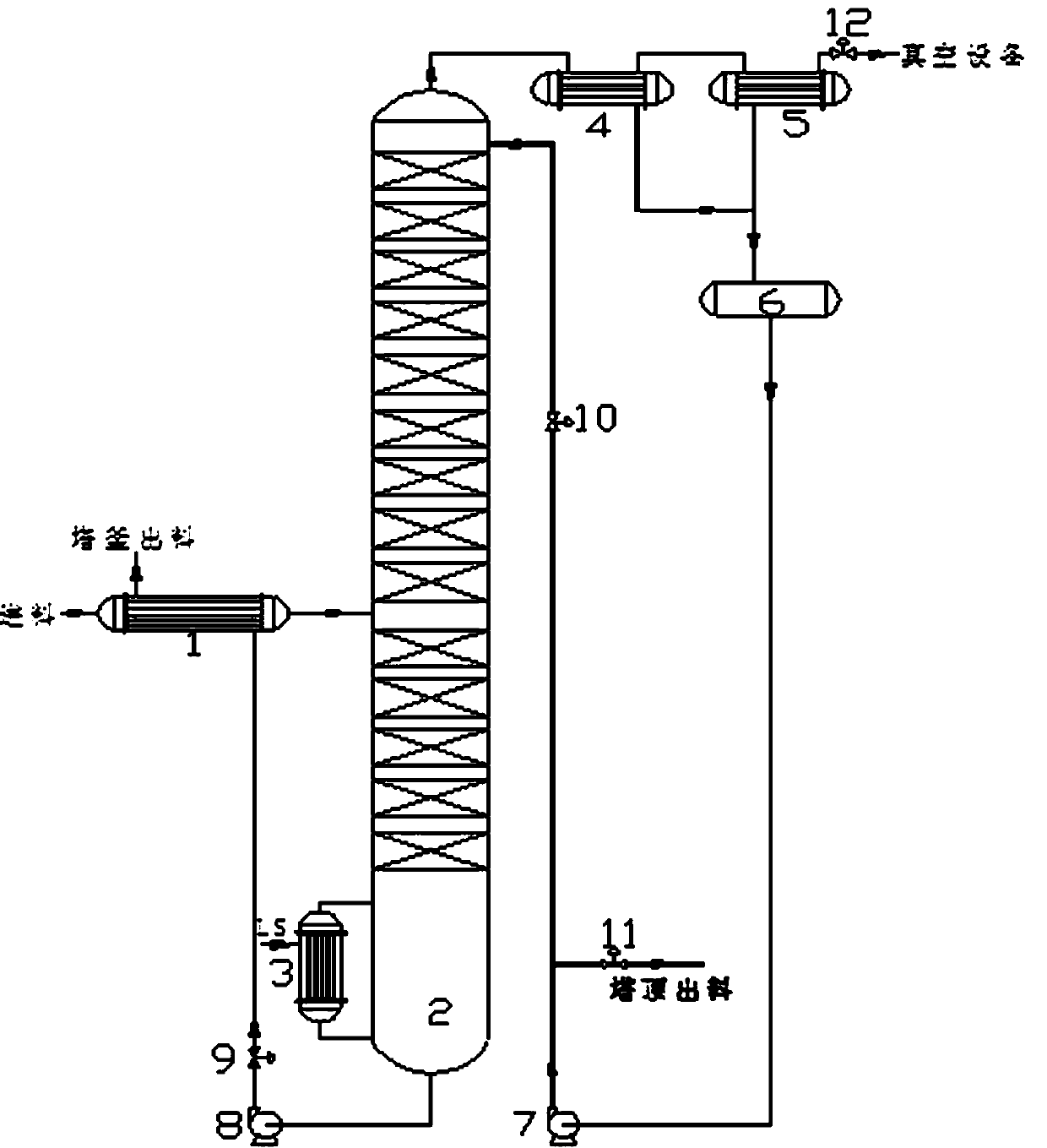

[0034] Coal-to-ethylene glycol carbonylation synthesis product dimethyl oxalate rectification purification process system, such as figure 1 As shown, it includes dimethyl oxalate feed heat exchanger 1, vacuum rectification tower 2, reboiler 3, tower top condenser 4, tail cooler 5, reflux tank 6, reflux pump 7, heavy component discharge pump 8. Tower still liquid level regulating valve 9, reflux flow regulating valve 10, tower top production flow regulating valve 11, vacuum degree regulating valve 12.

[0035] The vacuum rectification tower is one of the main equipments for rectification operation. A reboiler is installed in its tower kettle. The distillation tower provides rising steam; the discharge pump of the tower kettle is connected to the bottom of the rectification tower, and the output flow is controlled through the outlet regulating valve; The high-temperature pure dimethyl oxalate in the tower is exchanged for heat exchange, increasing the temperature of the feed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com