Structure for reducing back pressure of air inlet channel of inspiration type impulse knocking engine

A pulse detonation, engine technology, applied in engine components, air inlets of turbine/propulsion, combustion air/combustion-air processing, etc. The valve structure is complicated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention below in conjunction with specific embodiment:

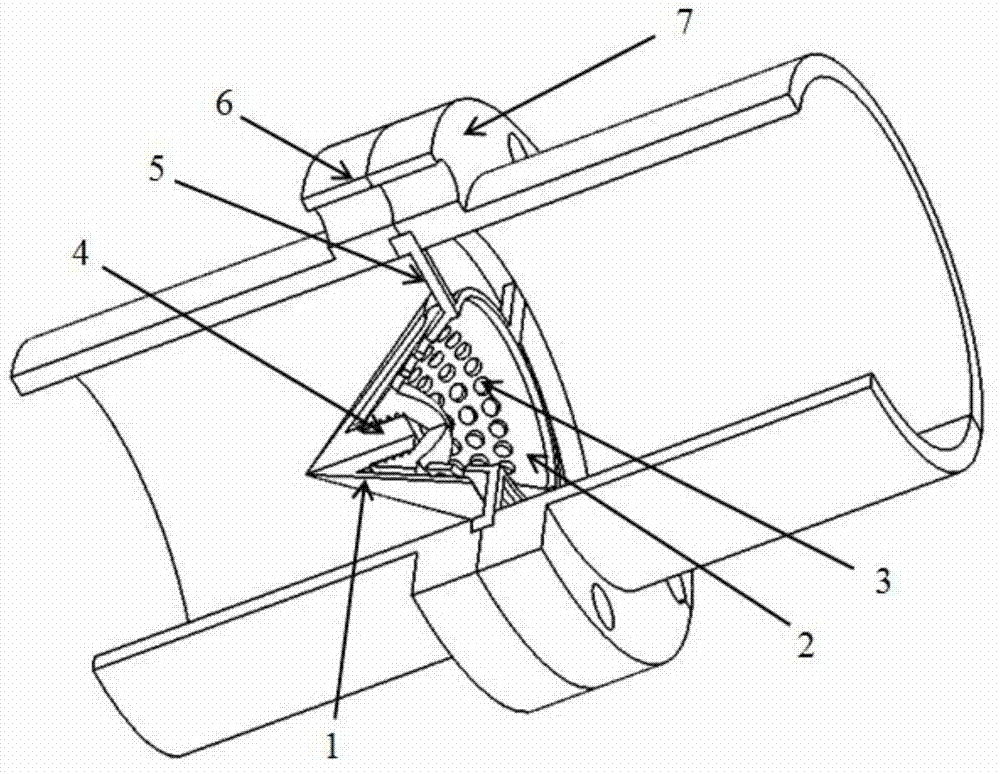

[0024] Refer to attached Figure 5 , the structure proposed by the present invention to reduce the intake port back pressure of an air-breathing pulse detonation engine is applied in the mixing chamber and ignition chamber of the engine in this embodiment.

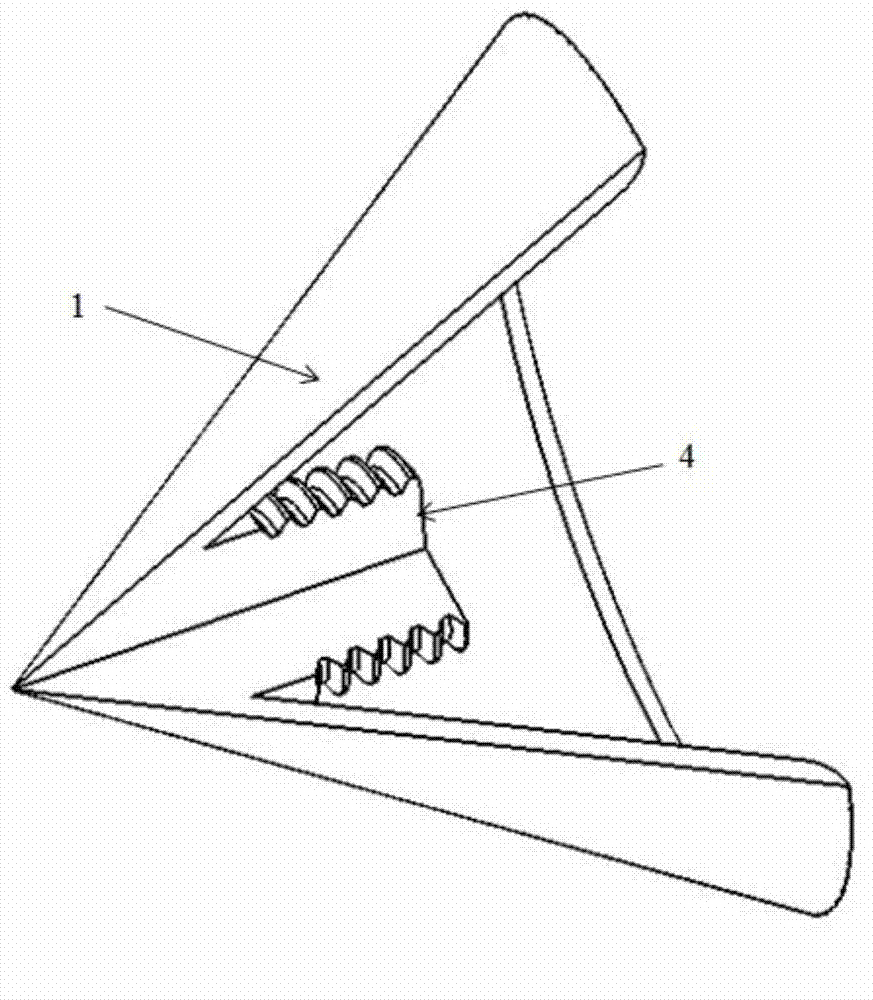

[0025] Refer to attached figure 1 , the structure for reducing the backpressure of the air intake pulse detonation engine consists of a front cone 1 and a rear cone 2 .

[0026] Refer to attached figure 2 , the front cone 1 is a thin-walled conical structure, and there is an axial cylinder 4 with external threads on the inner surface of the front cone head, and the axis of the cylinder 4 coincides with the axis of the front cone.

[0027] Refer to attached image 3 , the back cone 2 is a thin-walled conical structure, with an axial boss on the inner surface of the back cone head, and an axial blind hole with internal threads on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com