Residue automatic discharging filter

A filter and automatic technology, which is applied in the direction of filtration separation, filtration circuit, chemical instruments and methods, etc., can solve the problems of large loss of filter elements, low filtration efficiency, easy blockage of filter elements, etc., and achieves improved service life, simple structure, and convenience The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

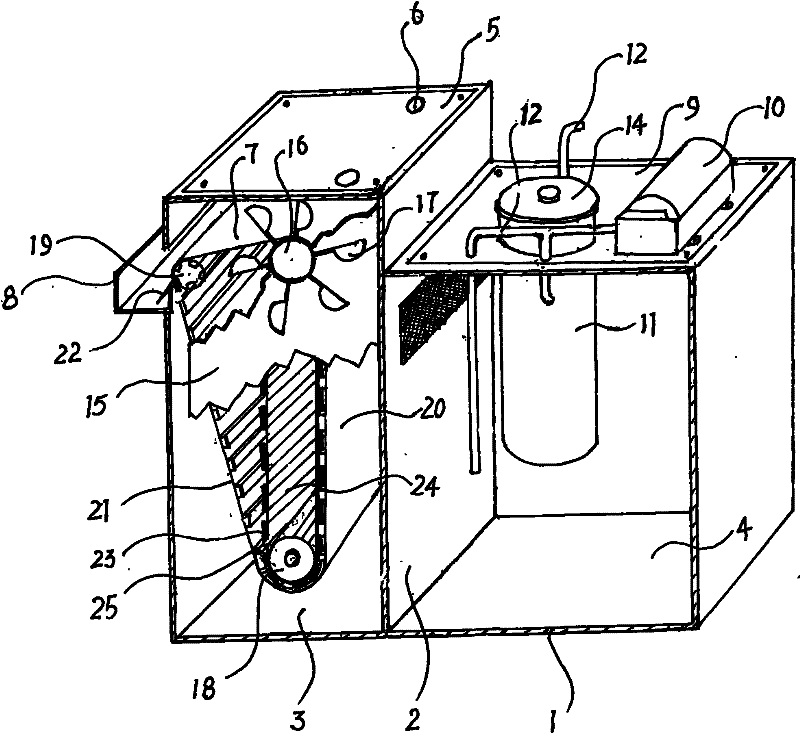

[0009] In the figure, the box body 1 is divided into a liquid inlet chamber 3 and a liquid outlet chamber 4 by a partition plate 2, holes are opened on the partition plate, the inlet and outlet liquid chambers are connected, and the filter screen 2-1 is covered on the holes, and the liquid inlet chamber is as high as In the liquid outlet chamber, a cover 5 is provided at the upper end, and a liquid inlet hole 6 is opened on the cover 5. An automatic slag discharge device 7 is installed in the liquid inlet chamber, and a slag discharge tank 8 is provided on one side of the liquid inlet chamber; Cover 9, on which a water pump 10, a filter cartridge 11, a pipeline 12 and an outlet 13 are installed, and a cover 14 is arranged at the upper end of the filter cartridge. The power shaft 16 of the automatic slag discharge device is installed in the shaft hole on the upper part of the bracket baffle 15, the driven shaft 18 is installed in the shaft hole on the lower part of the baffle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com