Ethyl acetate-water system supergravity distillation separation method

A technology of ultra-gravity rectification and ethyl acetate, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of low separation efficiency, low separation purity, bulky volume, etc., and achieves a simple process. , improve the purity and recovery efficiency, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

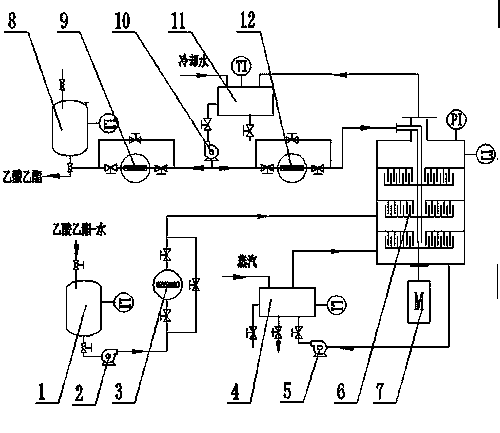

[0025] A kind of ethyl acetate-water system high-gravity rectification recovery device, such as figure 1 Shown, by ethyl acetate-water storage tank 1, ethyl acetate-water pump 2, ethyl acetate-water flow meter 3, reboiler 4, separating liquid pump 5, baffle type supergravity rectification machine 6, regulator Speed motor 7, finished product storage tank 8, finished product flow meter 9, finished product pump 10, condenser 11, return flow meter 12 and corresponding connecting pipelines.

[0026] A kind of ethyl acetate-water system high-gravity rectification separation method adopts figure 1 The separation process shown:

[0027] (1) The separation system is ethyl acetate-water with a volume fraction of 10-45%, which is transported from the ethyl acetate-water storage tank 1 to the baffle type high-gravity rectifier 6 through the ethyl acetate-water pump 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com