Hot melt polyester-polyamide, preparation method and application thereof

A polyester polyamide, hot-melt technology, applied in the field of composite material compatibilizers, can solve the problems of no separation method, environmental pollution, low recovery rate, etc., to promote sustainable development of resources and ecological environment, durable The effect of excellent performance and cost reduction of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

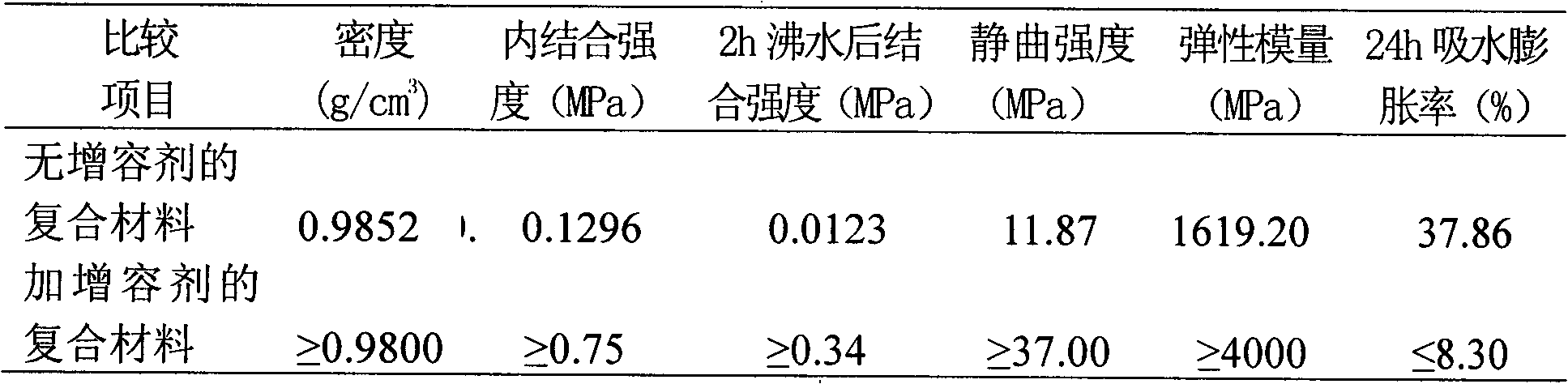

Examples

Embodiment 1

[0051] Crushing the recovered PET, air drying, reducing the moisture to below 1.0%, sieving to remove solids such as sand, stones, metals; crushing nylon acid, air drying, reducing the moisture to below 1.0%, sieving to remove sand, Solids such as stones and metals; Add 400g of reclaimed PET, 150g of diglycolamine to the flask, and use 500W microwave radiation for 40min to make the PET aminolysis; Add 170g of nylon acid to the flask, and carry out esterification reaction with 500W microwave radiation; Add 1.3g of polycondensation catalyst monobutyltin oxide and 1.3g of heat stabilizer trimethyl phosphate into the flask, heat to a temperature of 220-240°C until anhydrous distills out, and at a temperature of 220-240°C, the vacuum degree is 300mHg Distill under reduced pressure for 0.5h, then distill under reduced pressure at a vacuum degree of 90mmHg until the acid value drops to 1.7mgKOH / g, press the melt material into a water tank in granular form while it is hot, and obtain a...

Embodiment 2

[0054] Crushing the recovered PET, air drying, reducing the moisture to below 1.0%, sieving to remove solids such as sand, stones, metals; crushing nylon acid, air drying, reducing the moisture to below 1.0%, sieving to remove sand, Solids such as stones and metals; add 400g of recycled PET and 250g of diglycolamine to the flask, and use 700W microwave radiation for 6min to degrade PET; add 270g of nylon acid to the flask, and carry out esterification reaction with 700W microwave radiation; Add polycondensation catalyst monobutyltin oxide and antimony trioxide blend 2.4g in mass ratio 1:1, heat stabilizer trimethyl phosphate and 2,6-di-tert-butyl-4-methylphenol 1.5g of the blend with a mass ratio of 1:1 is heated to a temperature of 220-240°C until anhydrous is distilled off, and at a temperature of 220-240°C, a vacuum of 350mHg is used for distillation under reduced pressure for 1h, and then the vacuum is Distill under reduced pressure at 100mmHg until the acid value drops to...

Embodiment 3

[0057] Crushing the recovered PET, air drying, reducing the moisture to below 1.0%, sieving to remove solids such as sand, stones, metals; crushing nylon acid, air drying, reducing the moisture to below 1.0%, sieving to remove sand, Solids such as stones and metals; add 400g of recovered PET and 200g of diglycolamine to the flask, and use 600W microwave radiation for 30min to make PET ammonylysis; add 220g of nylon acid to the flask, and carry out esterification reaction with 600W microwave radiation; Add 2.0g of polycondensation catalyst antimony trioxide and tetrabutyl titanate in a mass ratio of 1:1, heat stabilizer triphenyl phosphite 1.7g, heat to a temperature of 220-240°C until anhydrous distilled , at a temperature of 220-240°C, vacuum distillation at 332mHg for 0.8h, and then vacuum distillation at a vacuum of 75mmHg until the acid value drops to 2.1mgKOH / g, and the melt material is pressed into granular form while it is hot. In the human sink, a hot-melt polyester po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com