EPDM (ethylene propylene diene monomer) rubber sealing strip compatible with silicone rubber and productive technology thereof

A technology of EPDM rubber and silicone glue, which is applied in the field of EPDM rubber sealing strips, can solve the problem of the decrease of the bonding performance between silicone and curtain wall rubber strips and glass, the hardening and brittle sealing strips, and the Problems such as yellowing of the glue color, to achieve the effect of cost reduction, improvement of adhesive strength and prolongation of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

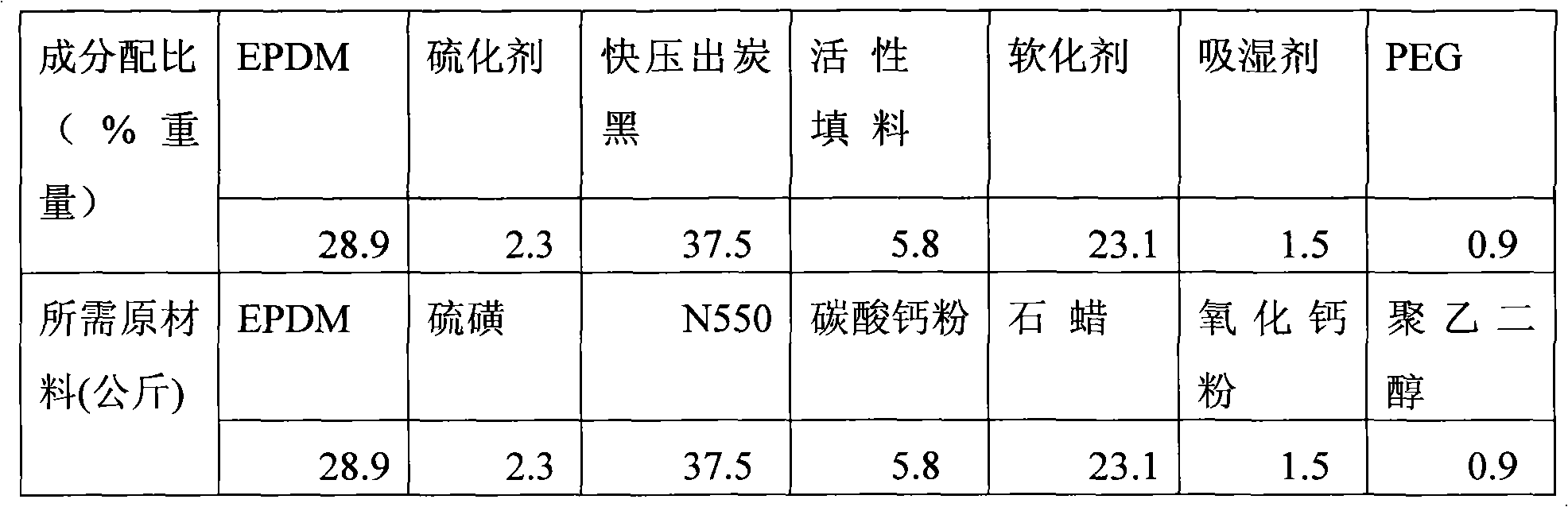

[0023] Ingredients: According to the following composition ratio weight ingredients, take 100KG rubber compound as an example:

[0024]

[0025] Mixing: According to the technical requirements, put EPDM rubber, quick-extrusion carbon black, active filler, paraffin softener, hygroscopic agent and polyethylene glycol into a 55L bottom-opening internal mixer, and the pressure on the top bolt is 0.39 ~0.49MPa, under the condition of mixing temperature 110±5℃, the first mixing time is 280-300 seconds, then add sulfur, and under the same conditions, the second mixing time is 100-120 seconds;

[0026] Parking: Park the rubber compound obtained from mixing at room temperature 23°C and relative temperature 25% for 24 hours, and at the same time take samples from the rubber compound to test the hardness, tensile strength, elongation, specific gravity and Mooney viscosity. ;

[0027] Extrusion: TreeterΦ90 vacuum extruder, length-to-diameter ratio 1:20, set the temperature of the extr...

Embodiment 2

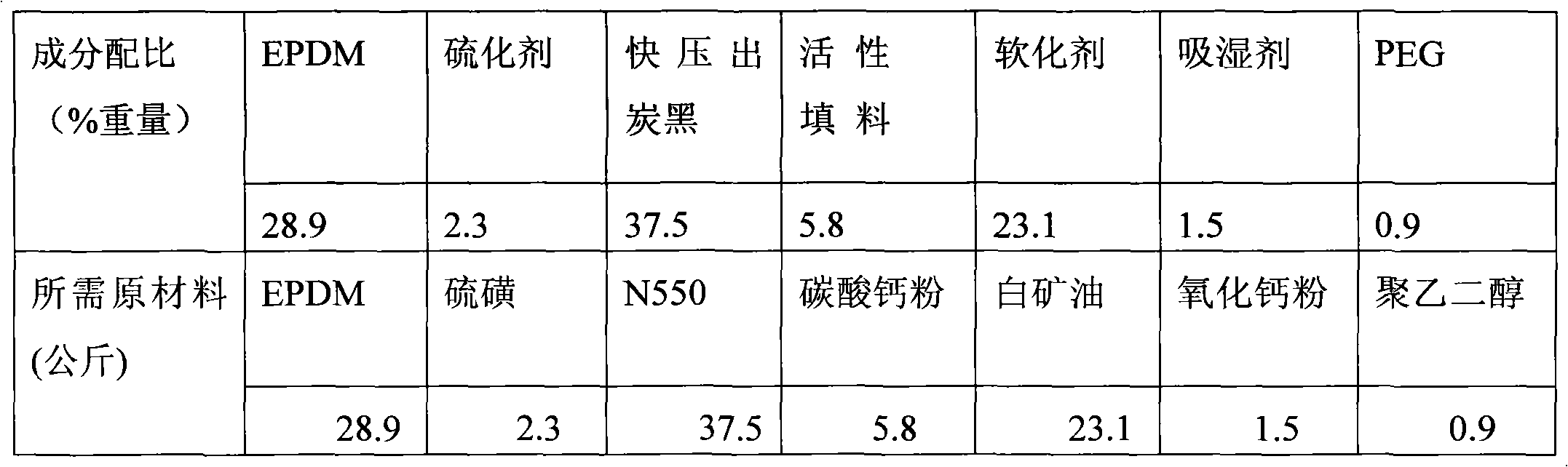

[0033] Ingredients: According to the following composition ratio weight ingredients, take 100KG rubber compound as an example:

[0034]

[0035] Mixing: According to the process requirements, 55L of EPDM rubber, quick extruded carbon black, active filler, white mineral oil, moisture absorbent and polyethylene glycol are thrown into the internal mixer, and the pressure of the top bolt is 0.39~0.49MPa, under the condition of mixing temperature 110±5℃, the first mixing time is 280-300 seconds, then add sulfur, under the same conditions, the second mixing time is 100-120 seconds;

[0036] Parking: Park the rubber compound obtained from mixing at room temperature 23°C and relative temperature 25% for 24 hours, and at the same time take samples from the rubber compound to test the hardness, tensile strength, elongation, specific gravity, Mooney viscosity and other items ;

[0037] Extrusion: TreeterΦ90 vacuum extruder, the ratio of length to diameter is 1:20, the temperature of ...

Embodiment 3

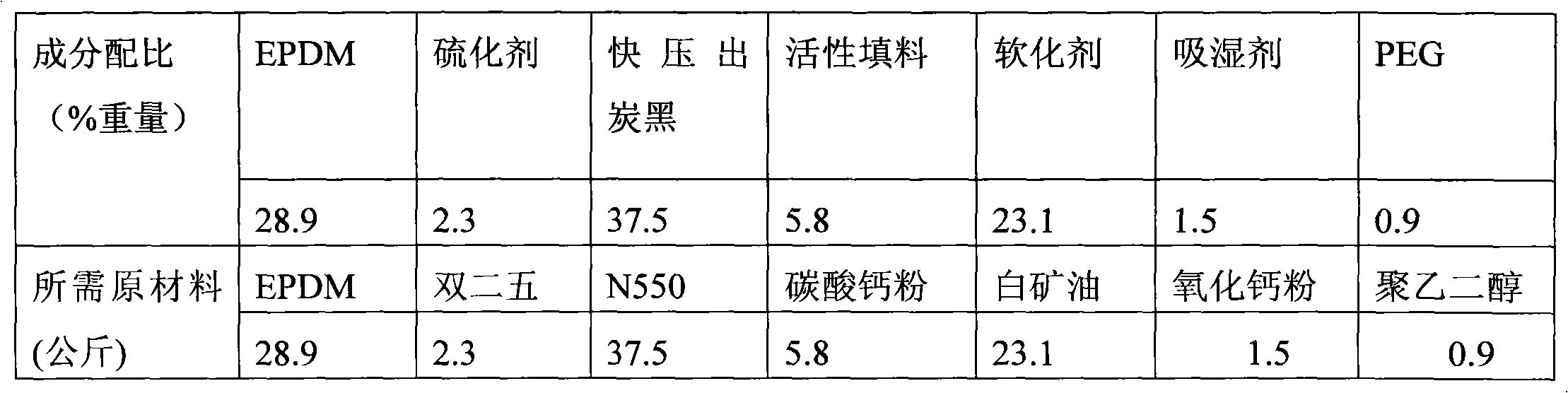

[0044] Ingredients: according to the following ingredients proportioning weight ingredients,

[0045] Take 100KG rubber compound as an example:

[0046]

[0047] Mixing: According to the technical requirements, put EPDM rubber, quick-extruded carbon black, active filler, white mineral oil, moisture absorbent and polyethylene glycol into a 55L bottom-opening internal mixer, and the pressure on the top bolt is 0.39 ~0.49MPa, under the condition of mixing temperature 100-110℃, the first kneading is 280-300 seconds, and then the double 25 is put in. Under the same conditions, the second kneading is 100-120 seconds;

[0048] Parking: Park the rubber compound obtained from mixing at room temperature 23°C and relative temperature 25% for 20-24H, and at the same time take samples from the masterbatch to measure hardness, tensile strength, elongation, specific gravity, Mooney viscosity, etc. project test

[0049] Extrusion: TreeterΦ90 vacuum extruder, the ratio of length to diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com