Wafer bonding structure and preparation method thereof

A wafer and bonding technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high porosity and low bonding strength, and achieve the effect of high bonding strength, improved strength, and reduced bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

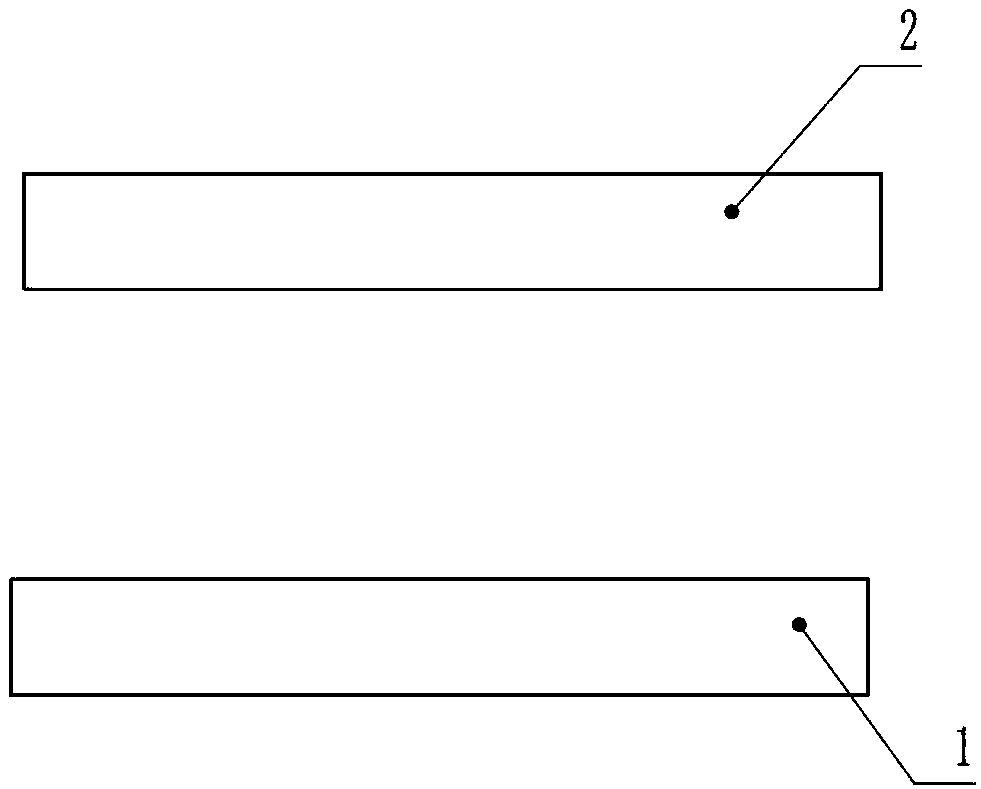

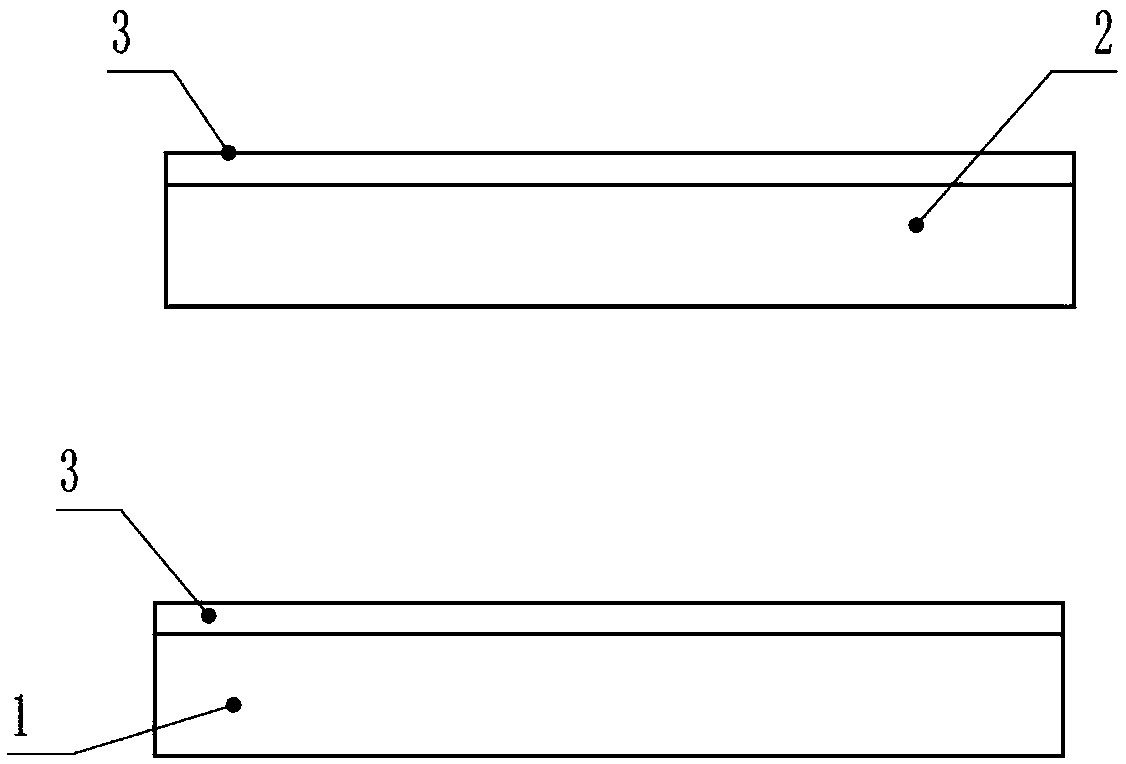

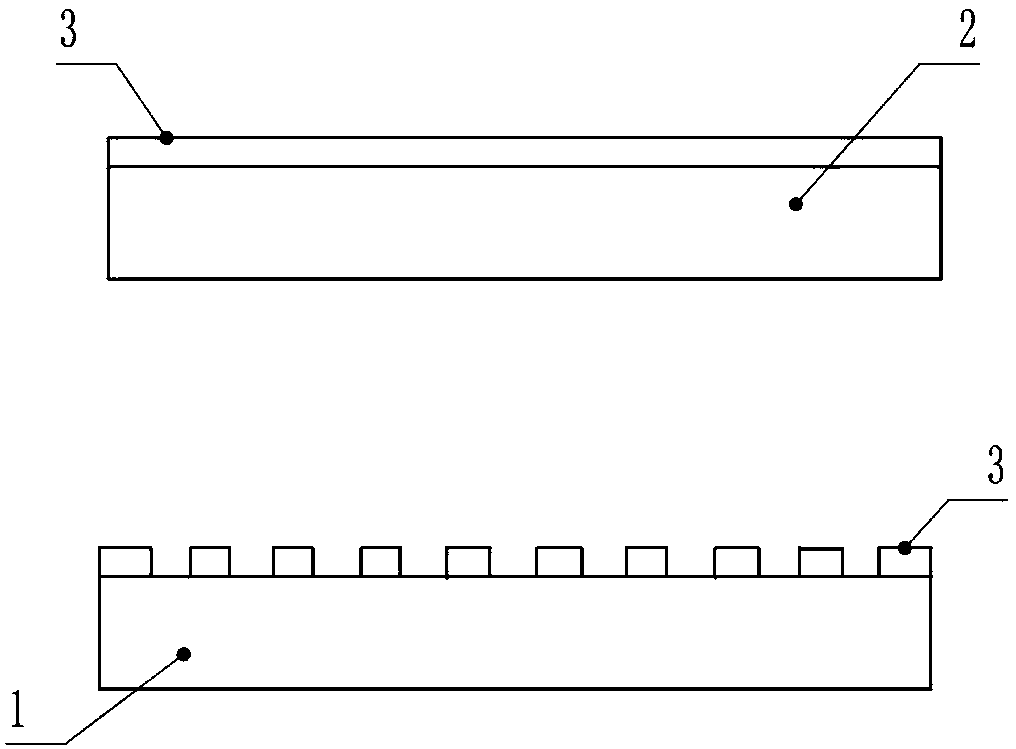

[0049] Such as figure 1 As shown, this embodiment provides a structure of bonded wafers, including a first wafer 1 and a second wafer 2, the first wafer 1 is located at the bottom layer, the top of the first wafer 1 is an intermediate layer, and the intermediate layer It includes a gas channel 9 and an aluminum oxide layer 8, and the second wafer 2 is above the intermediate layer; the gas channel 9 is a groove-shaped gas channel with equal intervals formed by etching with a mixed gas.

[0050] The preparation method of the bonded wafer structure comprises the following steps:

[0051] A. Both the first wafer 1 and the second wafer 2 are cleaned and dried; RCA wet chemical cleaning method is used for cleaning, and the cleaning solution used in the RCA wet chemical cleaning method includes a mixed solution of organic solvent, sulfuric acid and hydrogen peroxide And a mixed solution of ammonia, hydrogen peroxide and deionized water; the organic solvent includes one or more of is...

Embodiment 2

[0059] Such as figure 1 As shown, this embodiment provides a structure of bonded wafers, including a first wafer 1 and a second wafer 2, the first wafer 1 is located at the bottom layer, the top of the first wafer 1 is an intermediate layer, and the intermediate layer It includes a gas channel 9 and an aluminum oxide layer 8, and the upper part of the intermediate layer is the second wafer 2; the gas channel 9 is a groove-shaped gas channel with equal intervals formed by etching with a mixed gas.

[0060] The preparation method of the bonded wafer structure comprises the following steps:

[0061] A. Both the first wafer 1 and the second wafer 2 are cleaned and dried; RCA wet chemical cleaning method is used for cleaning, and the cleaning solution used in the RCA wet chemical cleaning method includes a mixed solution of organic solvent, sulfuric acid and hydrogen peroxide And a mixed solution of ammonia, hydrogen peroxide and deionized water; the organic solvent includes one o...

Embodiment 3

[0070] Such as figure 1 As shown, this embodiment provides a structure of bonded wafers, including a first wafer 1 and a second wafer 2, the first wafer 1 is located at the bottom layer, the top of the first wafer 1 is an intermediate layer, and the intermediate layer It includes gas channels 9 and 8 layers of aluminum oxide, and the upper part of the middle layer is the second wafer 2; the gas channels 9 are groove-shaped gas channels with equal intervals formed by etching with mixed gas.

[0071] The preparation method of the bonded wafer structure comprises the following steps:

[0072] A. Both the first wafer 1 and the second wafer 2 are cleaned and dried; RCA wet chemical cleaning method is used for cleaning, and the cleaning solution used in the RCA wet chemical cleaning method includes a mixed solution of organic solvent, sulfuric acid and hydrogen peroxide And a mixed solution of ammonia, hydrogen peroxide and deionized water; the organic solvent includes one or more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com