Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "Release internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-loss large-effective-area fiber and preparation technology therefor

ActiveCN106125192AImprove roundnessIncrease the effective areaGlass optical fibreOptical fibre with multilayer core/claddingRelative refractive indexLength wave

The invention relates to a low-loss large-effective-area fiber and a preparation technology therefor. The low-loss large-effective-area fiber comprises a core layer, wrapping layers and coating layers from inside to outside in sequence. The core layer is a pure silica glass layer with the radius of 5-7 [mu]m. An inner wrapping layer is a fluorine-doped inner wrapping layer with the radius r2 of 5-12 [mu]m and the relative refractive index difference of from -0.4% to -0.2%. The radius r3 of a middle wrapping layer is 12-25 [mu]m. An outer layer is a pure quartz glass layer with the radius r4 of 25-45 [mu]m. The coating layers adopt polyacrylate and comprise an inner coating layer and an outer coating layer, the diameter of the inner coating layer is 192 [mu]m, and the diameter of the outer coating layer is 245 [mu]m. The preparation technology comprises a perform rod preparation process, a fiber fusion annealing process and a fiber drawing and curing process. The fiber provided by the invention is advantaged in that comprehensive properties such as cut-off wavelength, bending loss and dispersion are good in an application waveband; the fiber can be used in long-distance fiber communication by crossing bad conditions of gobi, deep sea and the like; the roundness of each layer of the fiber is good, so that the appearance is enabled to be round; and the strain of the fiber can reach 2% or more.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

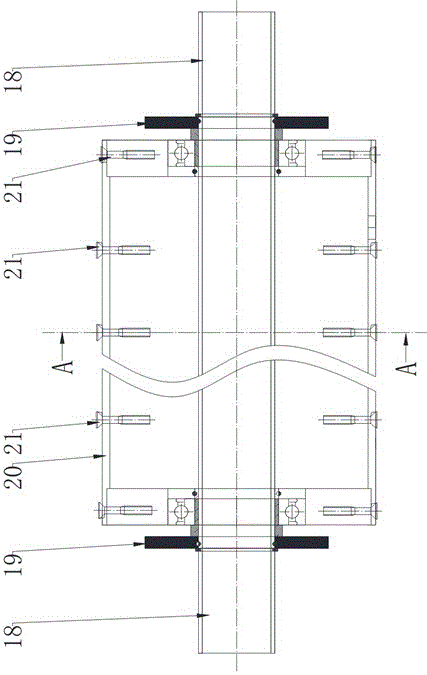

Pre-straightener for medium and thick plates

ActiveCN102248029AGuaranteed uptimeMeet the straightening process requirementsThick plateWater source

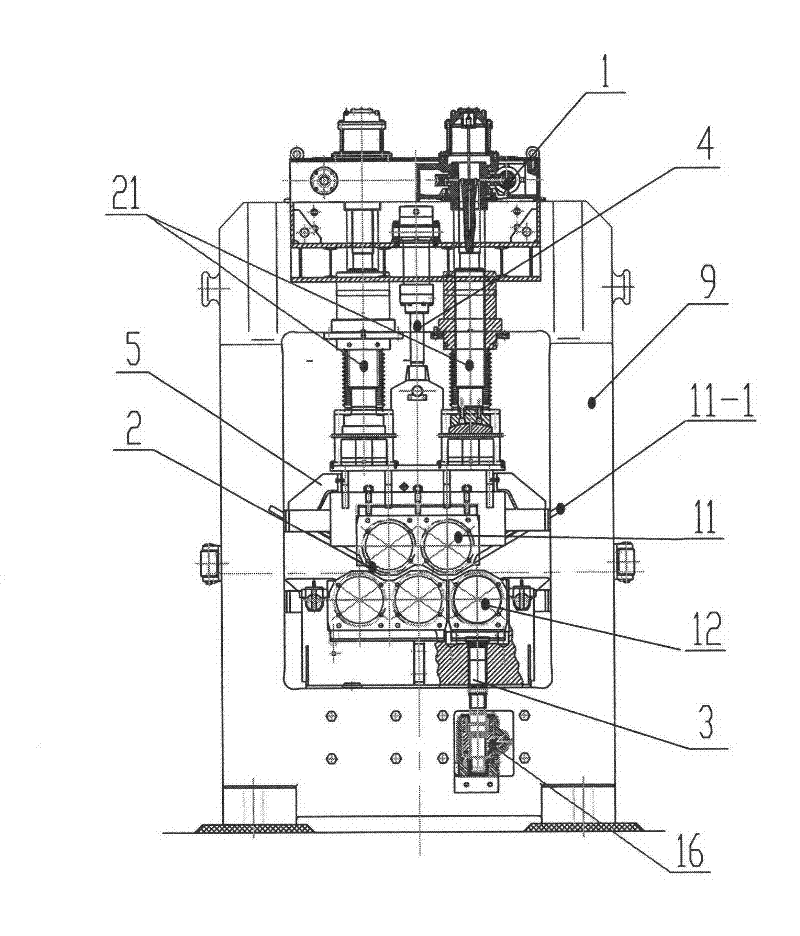

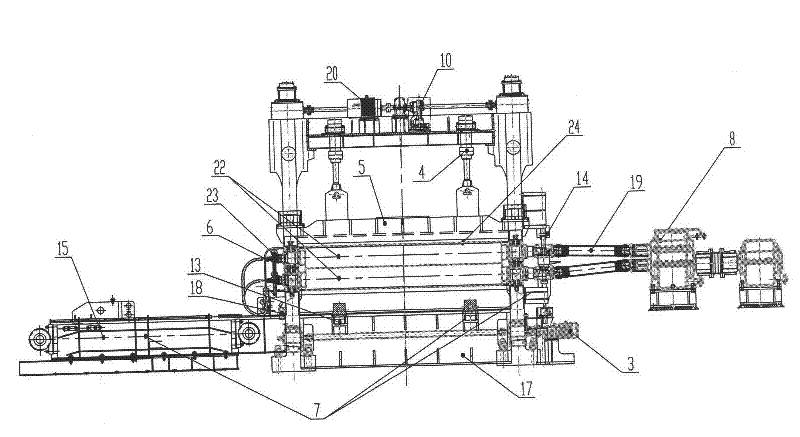

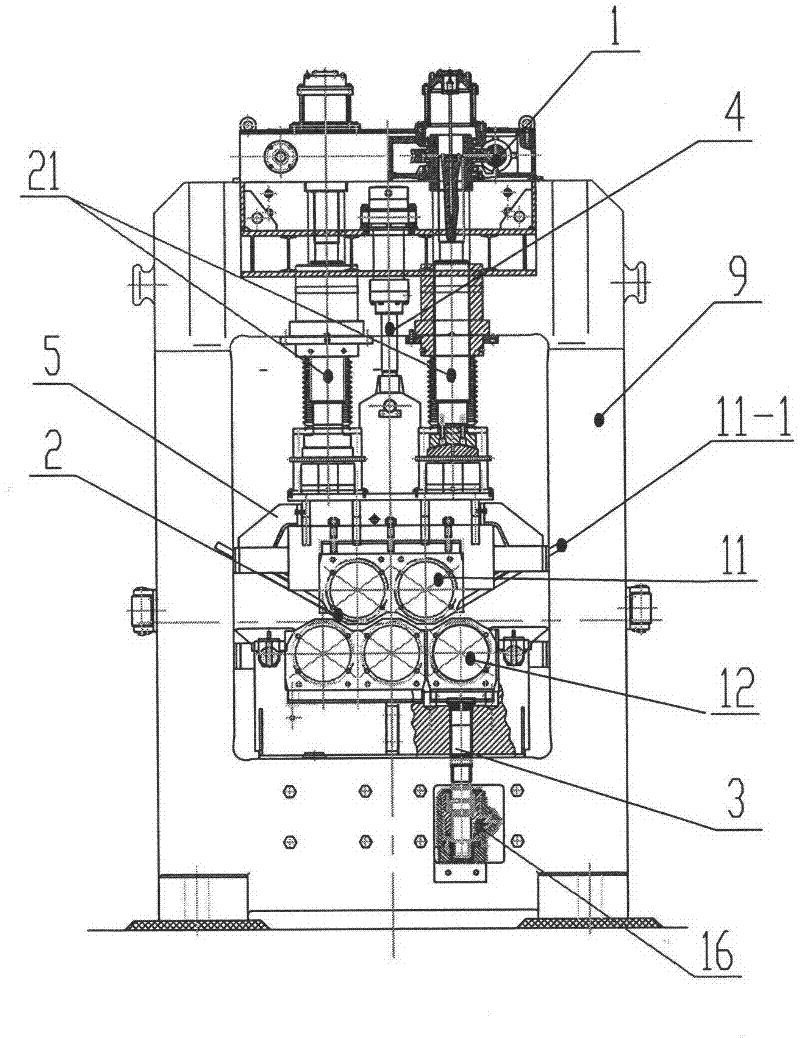

The invention discloses a pre-straightener for medium and thick plates, and relates to a thermal straightener. The invention solves the problems that the conventional thermal straightener has an unreasonable structure, is provided with a large number of rolls and has overhigh straightening force. The thermal straightener is characterized in that: a frame is fixed on a foundation through foundation bolts, a fast screwdown system is arranged on the upper part of the frame, and a balancing device is connected with the frame and a movable beam through hinged earrings respectively; an outlet edge roll lifting system is arranged inside the outlet side of the frame, and is connected with outlet edge rolls of a five-roll system device through a screw elevator; a high-efficiency cooling system is arranged inside the five-roll system device and on the upper part of the movable beam, and is connected with an external water source through a pipeline; a fast roll replacement device consists of a roll system lifting device, a connecting shaft positioning and clamping device, and a roll system dragging device; and a main transmission device is arranged on the foundation, and is connected with the five-roll system device through a universal spindle. The thermal straightener can continuously pre-straighten hot-rolled high-temperature steel plates; and equipment guarantee is provided for the progress of a medium and thick plate production process and the development of novel varieties of steel.

Owner:TAIYUAN HEAVY IND

Method for preparing radiation oriental magnetic ring and radiation multipolar magnetic ring

ActiveCN101770862AGood orientationImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureAlicyclic HydrocarbonsNitrogen gas

The invention provides a method for preparing a radiation oriental magnetic ring and a radiation multipolar magnetic ring. The method comprises the following steps of: melting and casting raw material of alloy in a vacuum furnace; carrying out coarse / hydrogen decrepitation on the ingots in the inert atmosphere; adding matters into the powder subject to coarse / hydrogen decrepitation to mix; carrying out micro crushing on the alloy coarse powder by an airflow mill in the nitrogen atmosphere; annealing the alloy powder in the inert gas, vacuum or reduction atmospheres; adding carbonyl iron powder and at least one type of alicyclic hydrocarbon into the annealed alloy powder to mix; carrying out preorientation operation on the mixing powder; enabling the mixing powder to form a circular former in the magnetic field; carrying out integral grinding treatment on the inner wall of the circular former; and sintering the circular former in the vacuum or inert gas atmosphere. The invention has the advantages of effectively decreasing the oriental field required in forming, enhancing the oriental degree of the magnetic rings and improving the property of the magnetic rings.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

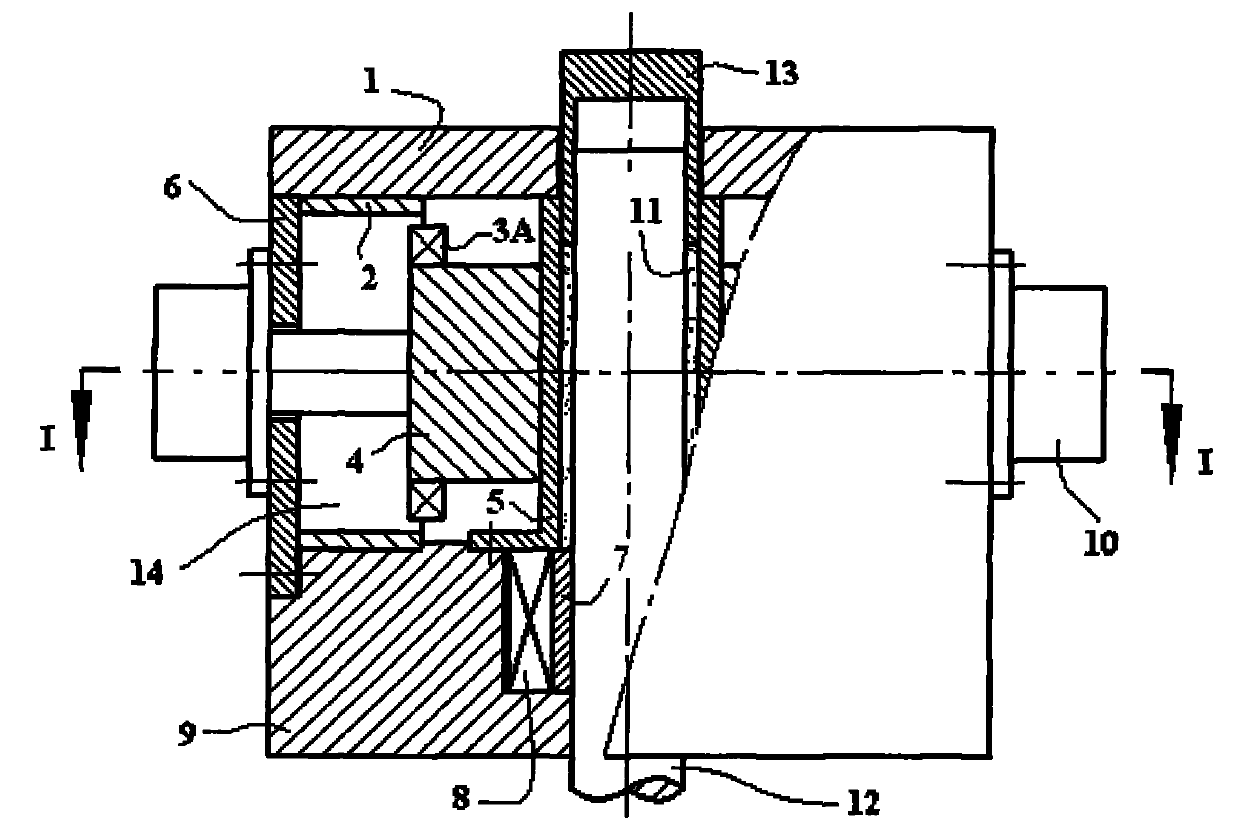

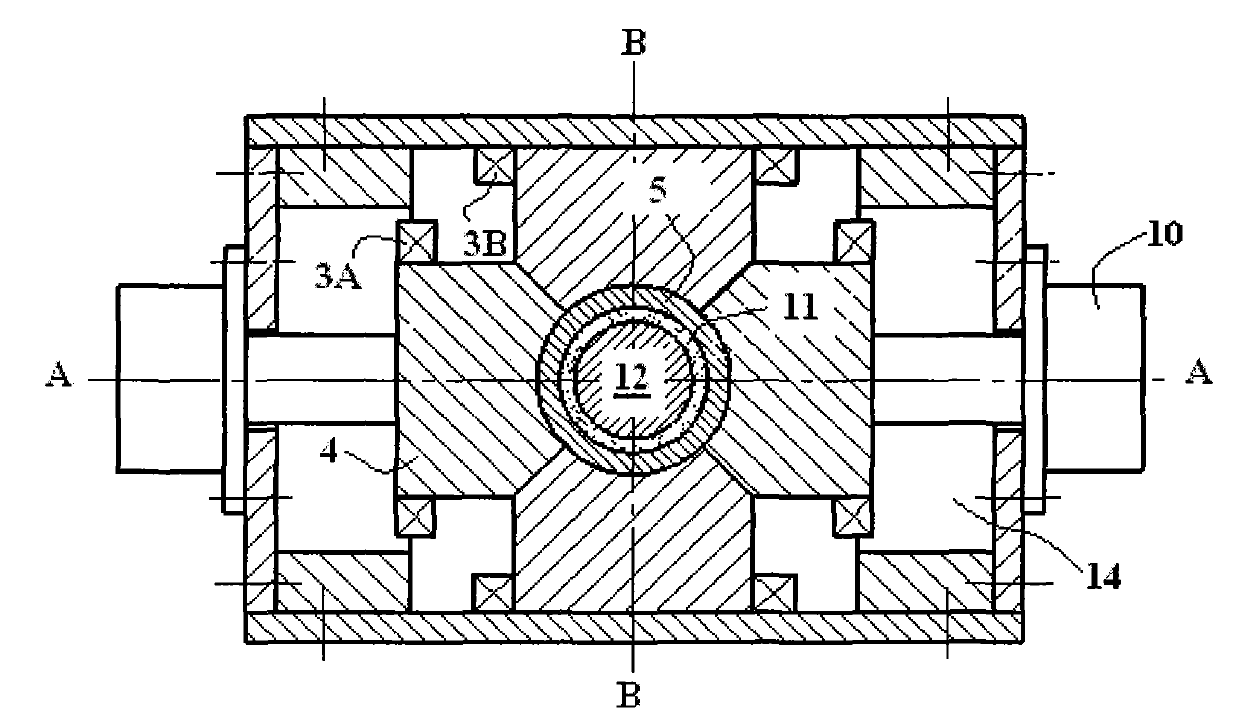

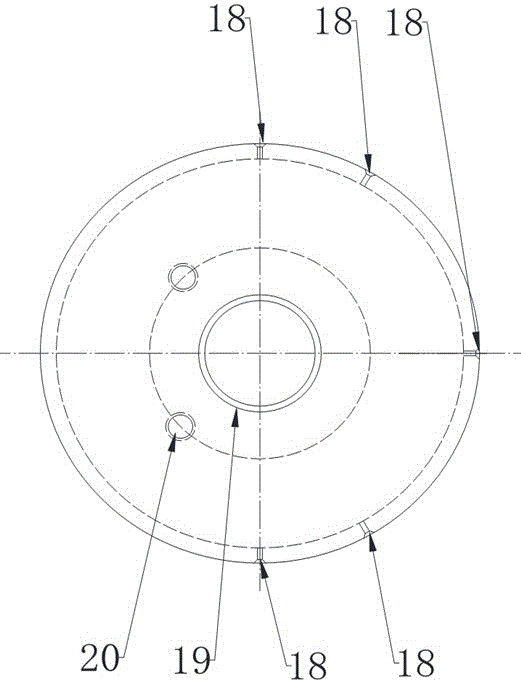

Preparation method and pressing device for radiation-oriented magnet ring or multipolar magnet ring

ActiveCN102087917AGood orientationImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureFirst FillIngot

The invention provides a preparation method for a radiation-oriented magnet ring or a multipolar magnet ring, which comprises the following operation steps of: preparing an alloy ingot, cracking the alloy ingot, pressing under a radiation-oriented magnet field, sintering the magnet ring and subsequently machining and is characterized in that a powder pre-orientation step is also arranged before the step of pressing under the radiation-oriented magnet field, powder is first filled in a die cavity of a forming press, and pre-orientation operation is then carried out on the powder. Before the step of sintering the magnet ring, a step of preprocessing a blank is also arranged. Preprocessing operation is carried out on the blank magnet ring under protective atmosphere. The orientation degree of the magnet ring can be further improved under the condition that the die structure is not changed, so that the purpose for improving the magnetic performance of the magnet ring is achieved. Meanwhile, sintering crack problems resulting from nonuniform contraction caused by the internal stress of the magnet ring in the sintering process can be effectively solved, and the sintering finished product rate of the magnet ring can be obviously improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

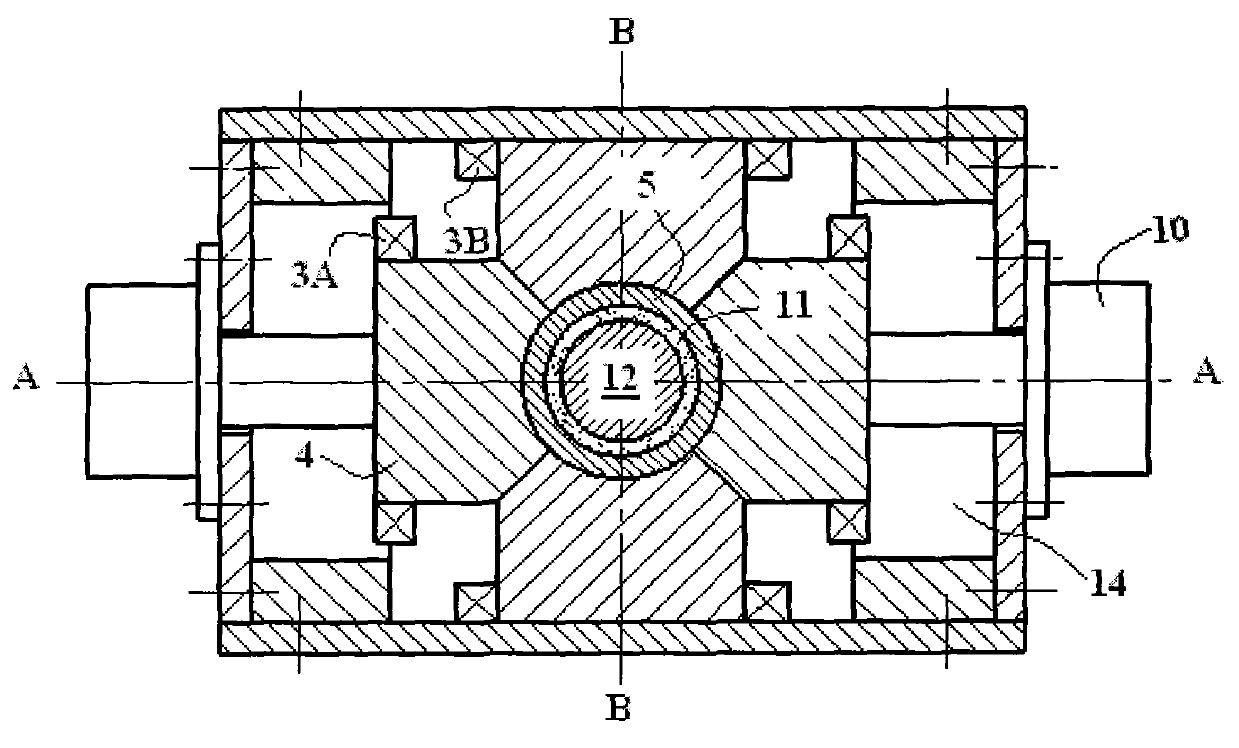

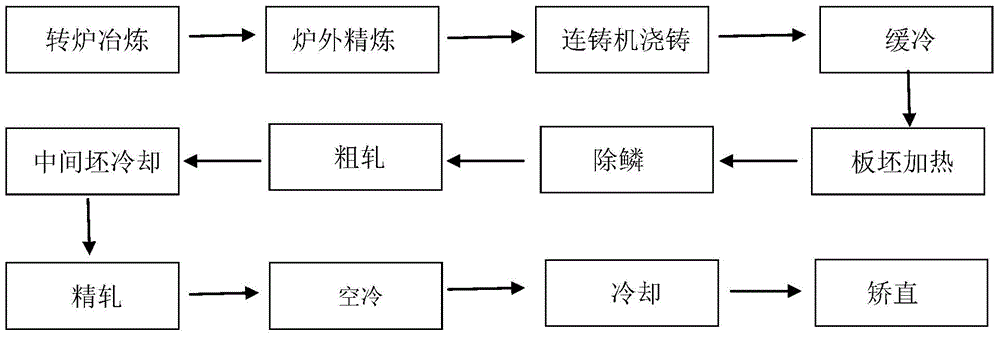

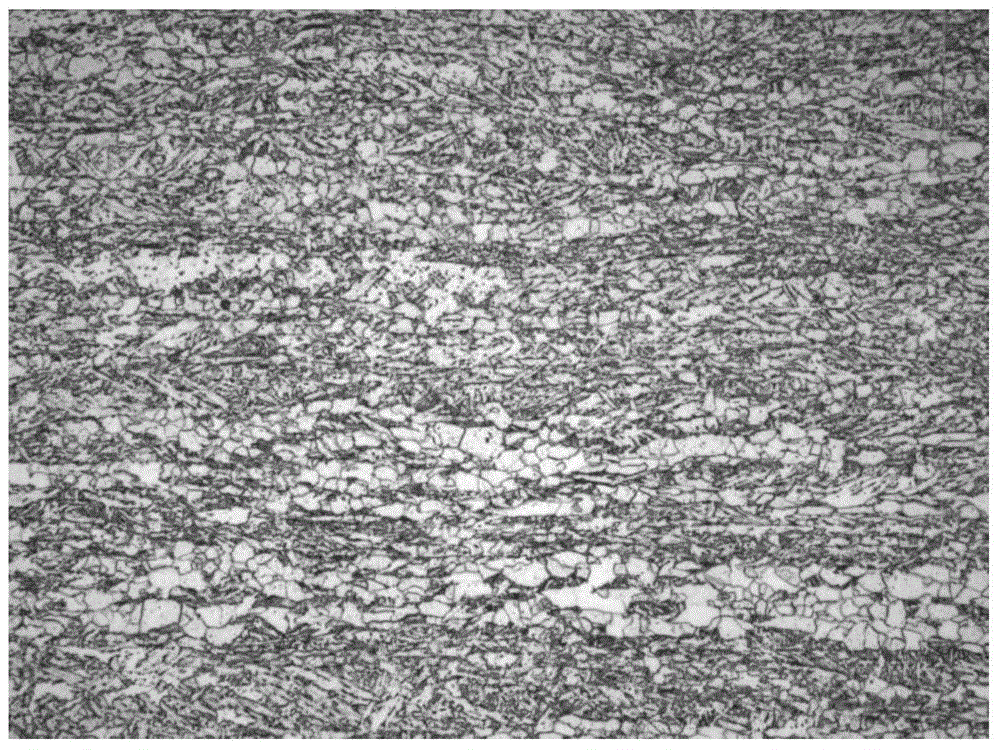

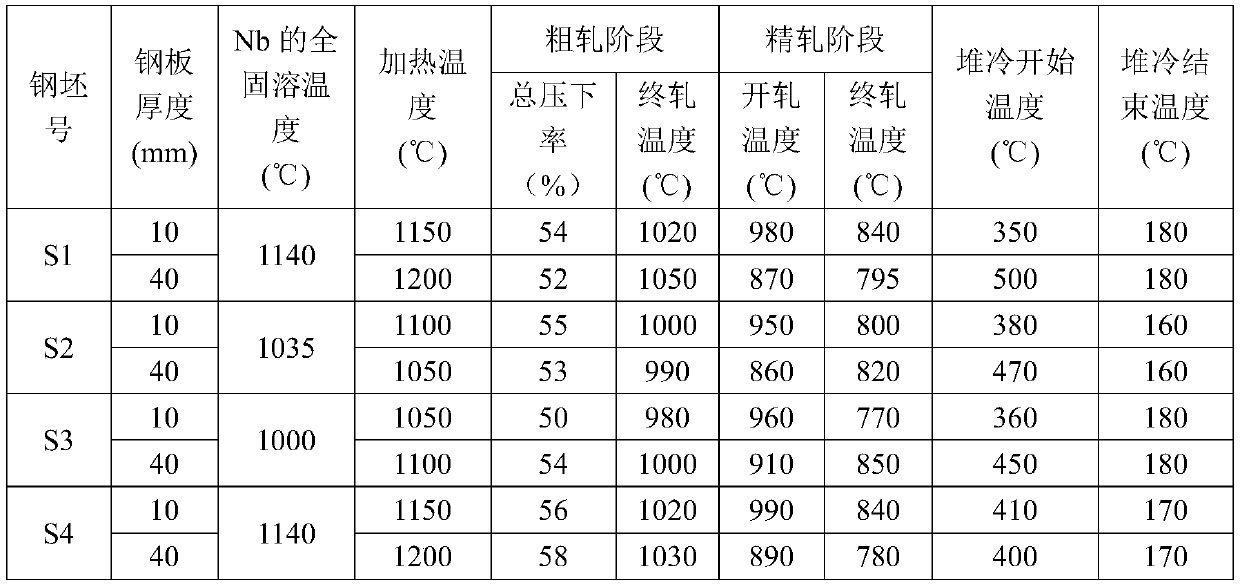

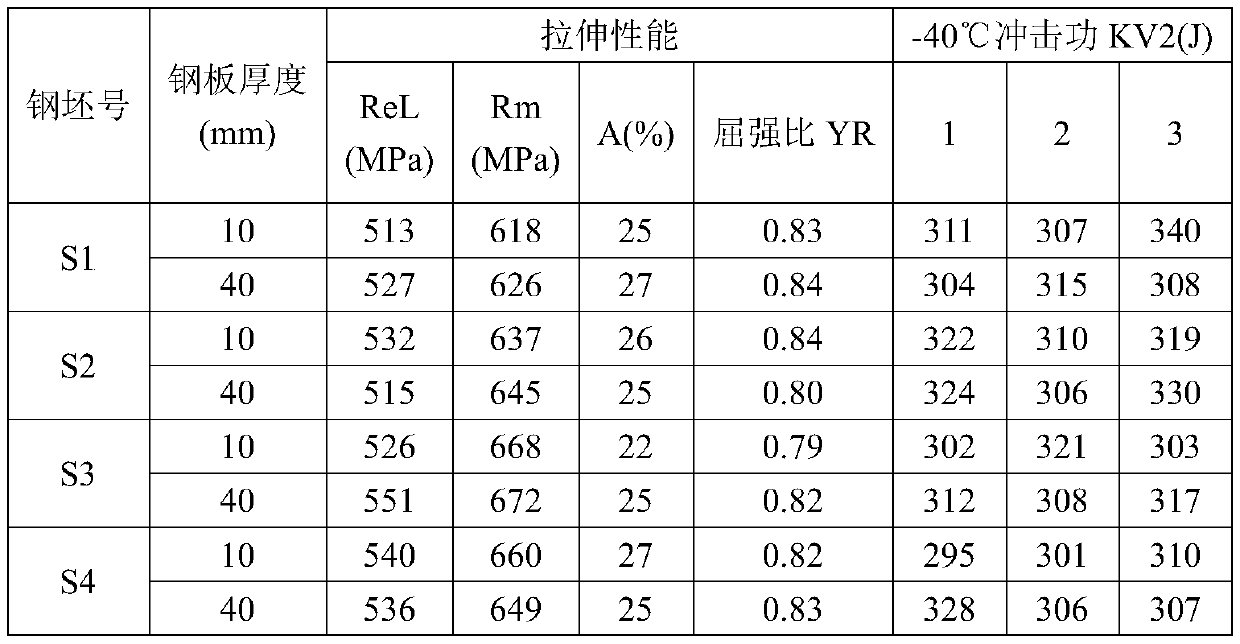

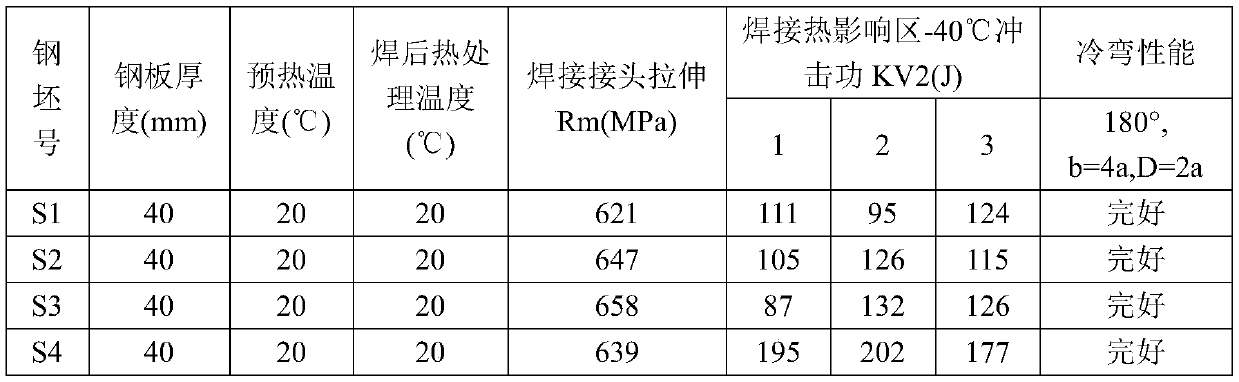

X80 pipeline steel with high stress ratio and high arrest toughness and preparation method and application of X80 pipeline steel

The invention specifically relates to X80 pipeline steel with the high stress ratio and high arrest toughness and a preparation method and application of the X80 pipeline steel. The X80 pipeline steel is composed of, by weight, 0.03% to 0.08% of C, 0.15% to 0.35% of Si, 1.50% to 2.00% of Mn, not larger than 0.010% of P, not larger than 0.003% of S, 0.04% to 0.08% of Nb, 0.015% to 0.025% of Ti, 0.015% to 0.025% of Zr, not larger than 0.03% of Mo, not larger than 0.35% of Cu, not larger than 0.30% of Ni, not larger than 0.30% of Cr and the balance Fe and inevitable impurities. Zirconium is added to promote precipitation of proeutectoid ferrite, the banded structure level is reduced, and the stress ratio and the arrest toughness of a steel plate are effectively improved. The heating temperature is strictly controlled, and the recrystallization deformation temperature section in a rough rolling stage and the rolling reduction and the temperature of the last phase of rough rolling are reasonably matched, so that the austenite grain size is reduced to the maximum degree; and a rough-rolled intermediate billet is cooled, so that grain growth generated after recrystallization deformation is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

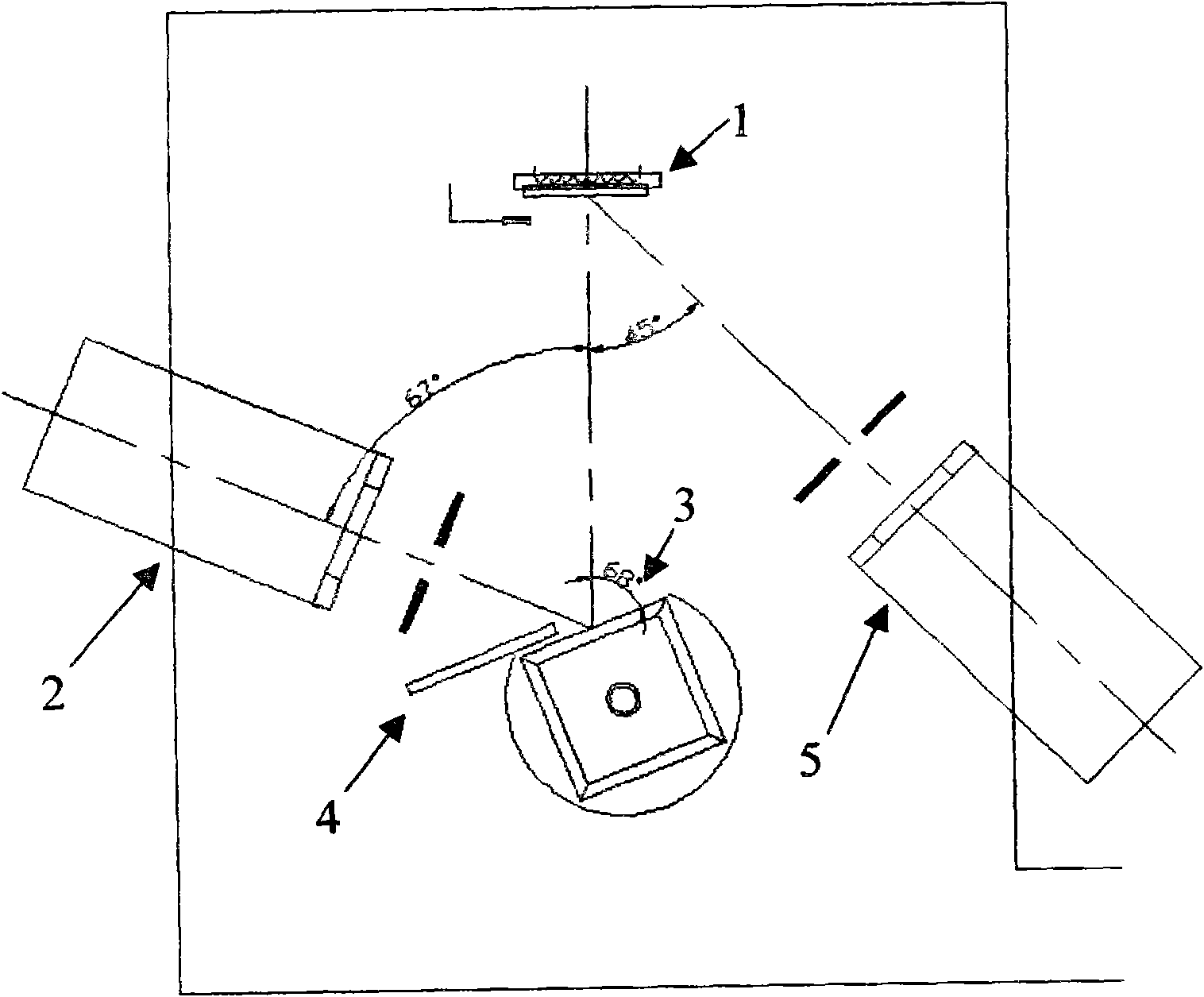

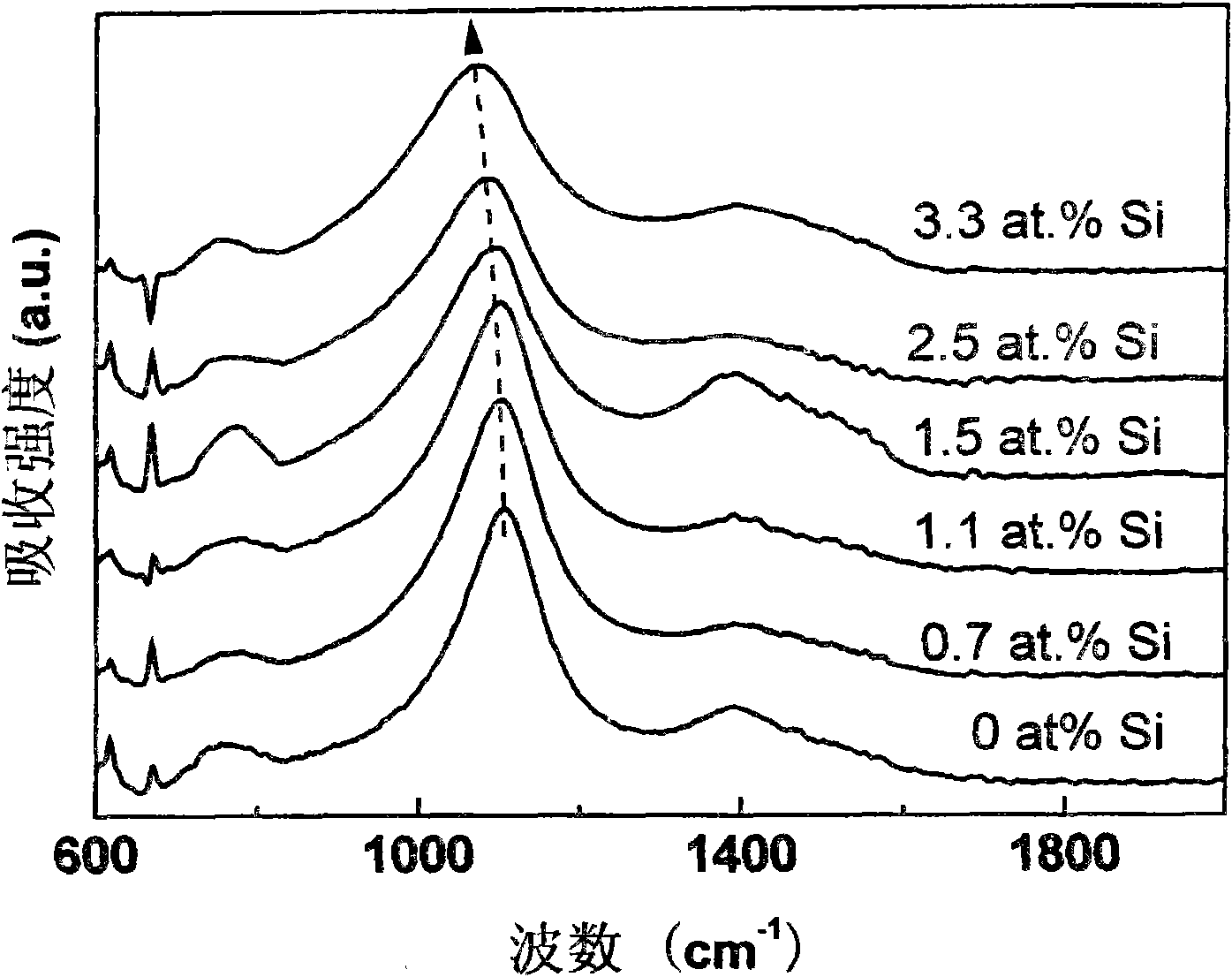

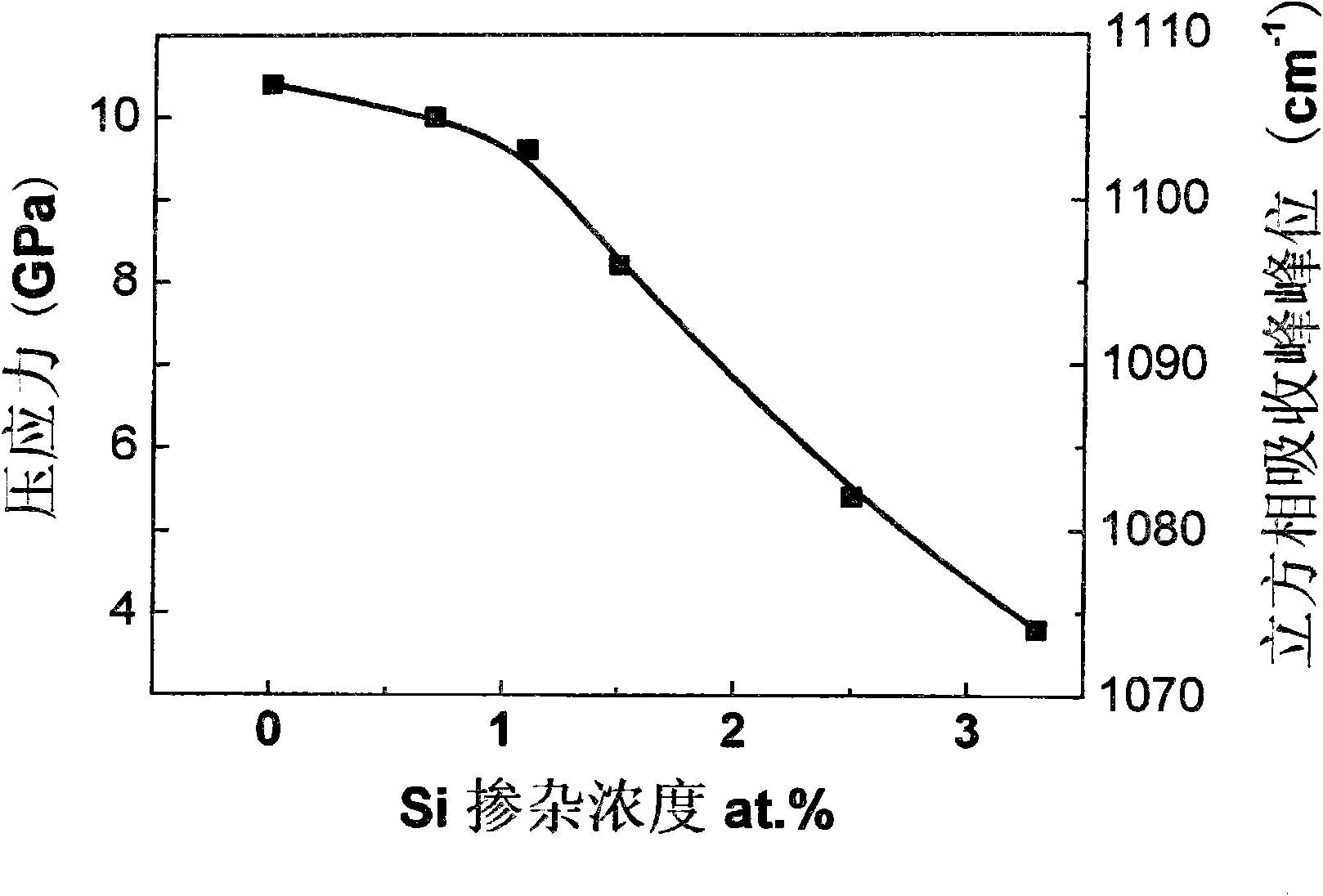

Method for reducing stress of cubic boron nitride thin film

InactiveCN101671846ARelease internal stressReduce internal stressPolycrystalline material growthDiffusion/dopingIon bombardmentIon beam-assisted deposition

The invention discloses a preparation method for reducing the stress of a cubic boron nitride thin film, which comprises the following steps: 1, taking a silicon substrate; 2, placing the silicon substrate on an ion beam assisted deposition system, taking a highly-pure boron target as a sputtering target deposited by the cubic boron nitride thin film, and taking a silicon target as a doped source;3, heating the substrate; 4, adopting two independently adjustable Kaufman broad beam ion sources of which a main ion source adopts Ar<+> ions to bombard the boron target and the silicon target, andsimultaneously taking mixed ion beams of Ar<+> and N2<+> as an auxiliary ion source to bombard the substrate so as to deposit and form the cubic boron nitride thin film on the substrate by the ion beam assisted deposition system; 5, cooling the substrate down in the ion beam assisted deposition system; and 6, taking the prepared substrate out, and performing stress parameter testing to finish thepreparation.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of silicon-aluminum sputtering target material

InactiveCN106498350AImprove and enhance key quality indicatorsImprove key quality indicatorsMolten spray coatingVacuum evaporation coatingSputteringSand blasting

The invention discloses a preparation method of a silicon-aluminum sputtering target material high in density, low in oxygen content and not prone to embrittlement. The preparation method comprises the following steps of target material base tube preparing, wherein a stainless steel base tube of the required type is selected and checked; base tube surface pretreatment, wherein the base tube is made to enter base tube pretreatment equipment to be subjected to sand-blasting roughening, a nickel-aluminum alloy wire is utilized, a bottoming combination layer is sprayed through an arc spray method, and a target material base tube to be sprayed is obtained; raw material preparing, wherein 50 kg of silicon powder with the content ranging from 99.9% to 99.95%, the oxygen content being smaller than or equal to 1,000 ppm and the particle size ranging from 45 micrometers to 150 micrometers and 6.6 kg of high-purity spherical aluminum powder with the content ranging from 99.9% to 99.95%, the oxygen content being smaller than or equal to 1,500 ppm and the particle size ranging from 45 micrometers to 100 micrometers are weighed; powder mixing, wherein two obtained raw materials are put into a V-shaped powder mixer to be mixed for 5 hours to 6 hours; and drying, wherein an evenly-mixed silicon-aluminum powder raw material is put in a drying furnace to be dried for 2 hours to 3 hours, and the temperature is 60 DEG C.

Owner:FAKETE TECH JIANGSU

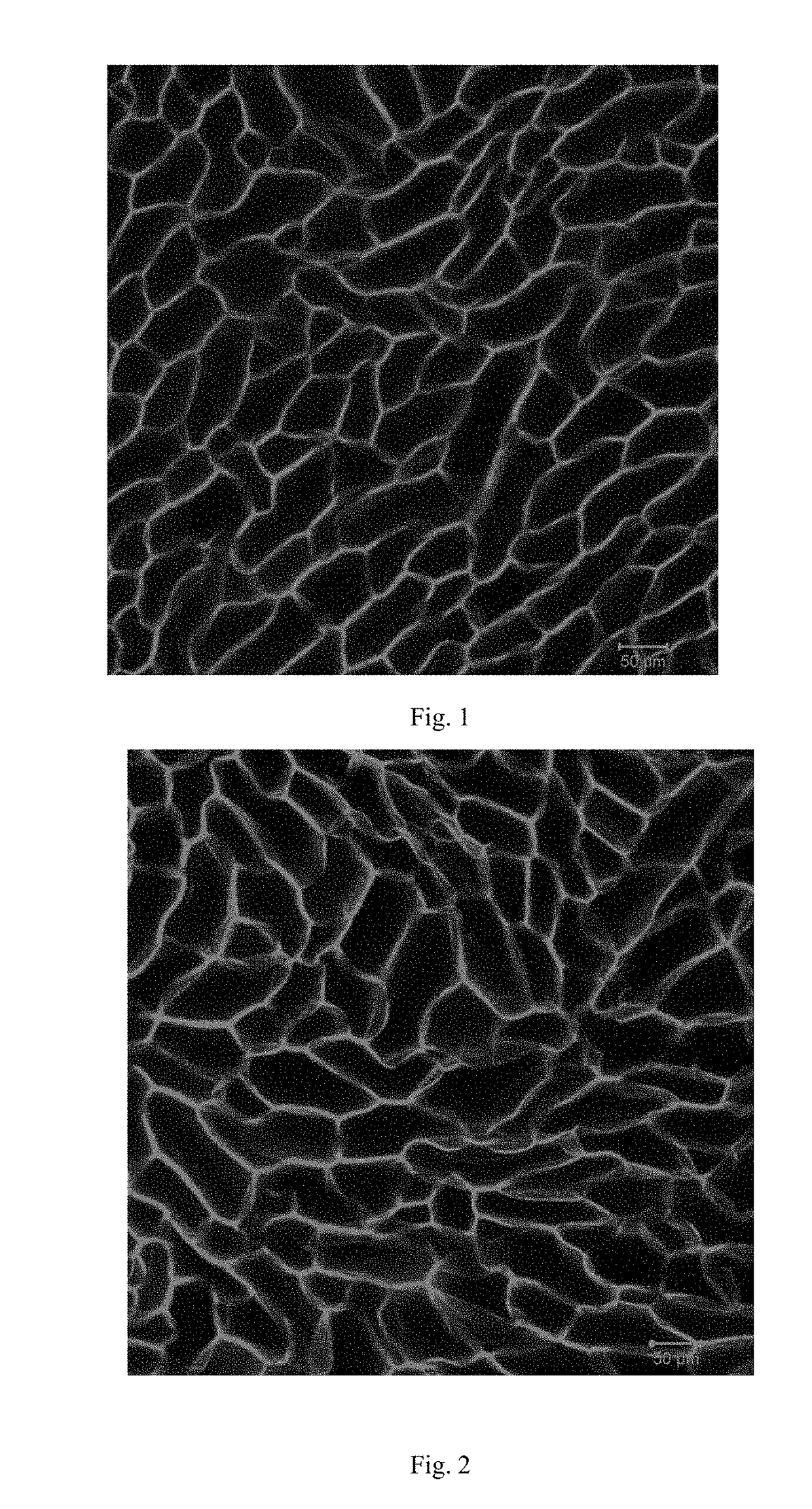

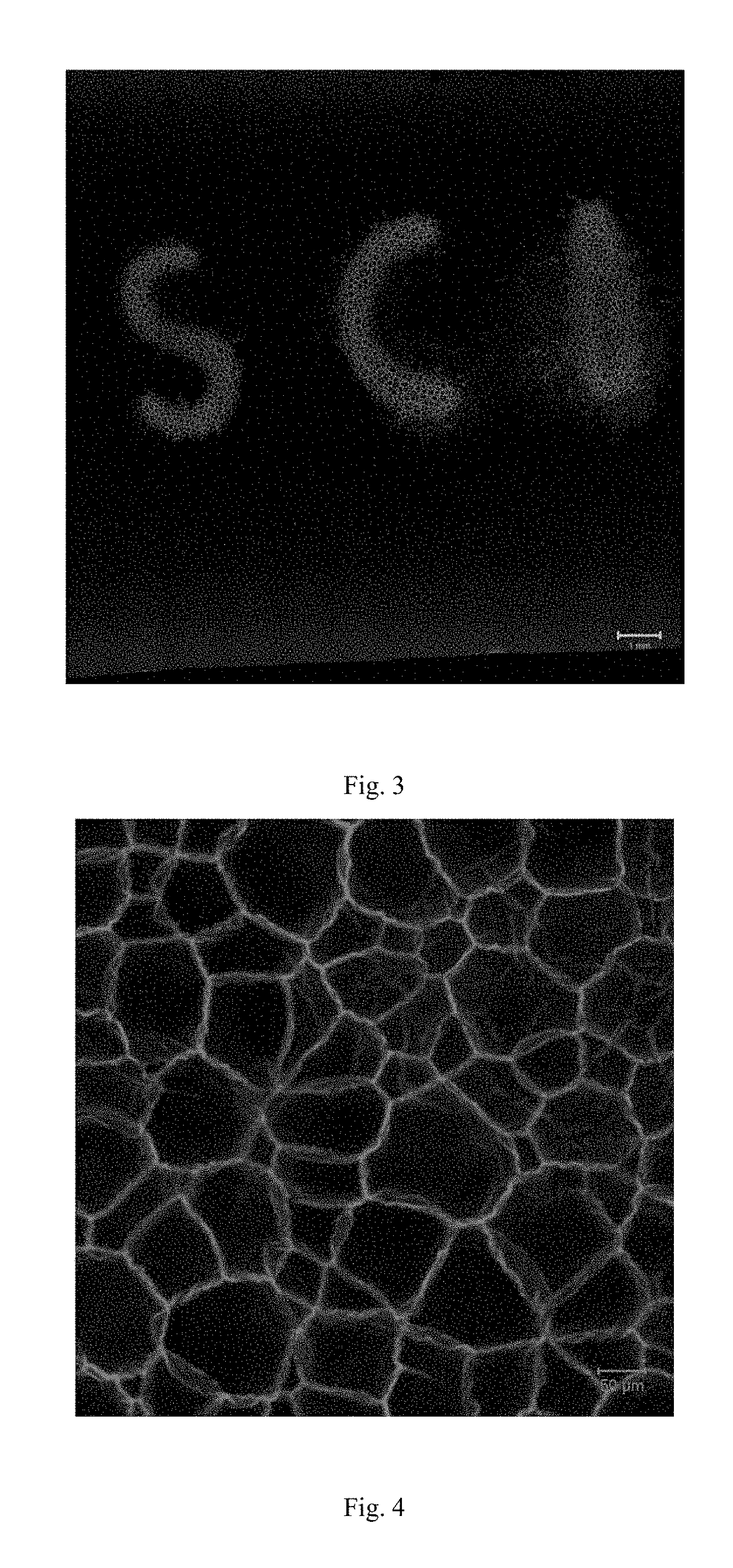

Method for preparing porous hydrogel through freezing-illumination

ActiveUS20170210864A1Convenient and efficient controlRegulate the spatial distribution of the pore structure within a gelSulfurWavelength

The present invention discloses a freezing-illumination method for preparing porous gels, comprising the steps of: (a) synthesizing the gels containing dynamic exchangeable bonds; (b) illuminating the gels under frozen state by certain wavelength light source; (c) elevating the temperature and melt the ice crystals within the gels to get the porous structure. The dynamic exchangeable bonds existing in the gels include double / multi-sulfur bond, hydrazine bond, boronic ester bond. Catalyst is also included in the gel composition to activate the bond exchange reactions under illumination. This new method for preparing porous gels is easy to operate and suitable for most kinds of gels. Meanwhile, it can spatially control the pore structure within the gels by local illumination.

Owner:ZHEJIANG UNIV

Preparation method for anti-aging composite materials of sleepers

The invention belongs to the technical field of track materials, and particularly relates to a preparation method for anti-aging composite materials of sleepers. According to the preparation method, bentonite, mica and titanium dioxide are mixed and ball-milled, dispersed into modified liquid and then stirred at a high speed to uniformly fill wood fiber cells subjected to enzymolysis treatment, the interiors of the wood fiber cells are fully swelled and filled, and therefore the effect of physically shielding ultraviolet light is achieved, the penetration rate of the ultraviolet light in the wood is effectively reduced, and the anti-aging performance of the wood material in an ultraviolet light environment is improved. Meanwhile, the wood material is subjected to hot pressing treatment, and due to high temperature and enzymolysis treatment, fibers of wood residues are fully hydrolyzed; and due to the fact that the internal cellulose cells are filled with the filler, the thickness swelling rate of water absorption is effectively reduced, redundant internal stress in the materials is released, and the aging resistance of the composite materials of the sleepers is greatly enhanced.

Owner:赖尚辉

Method for preparing high-strength carbon fibers

InactiveCN101560701AImprove microstructureLower exotherm onset temperatureFibre chemical featuresCarbon fibersCarbonization

The invention discloses a method for preparing high-strength carbon fibers, and belongs to the filed of new material preparation. The invention aims to provide the method for preparing the high-strength carbon fibers. The method prepares the high-strength carbon fibers from polyacrylonitrile precursor fibers through sulfanilamide solution chemical modification, physical modification, preoxidation, low temperature carbonization and high temperature carbonization in turn. The method provided by the invention has simple and convenient operation and low cost, and the prepared carbon fibers have high tensile strength.

Owner:BEIJING UNIV OF CHEM TECH

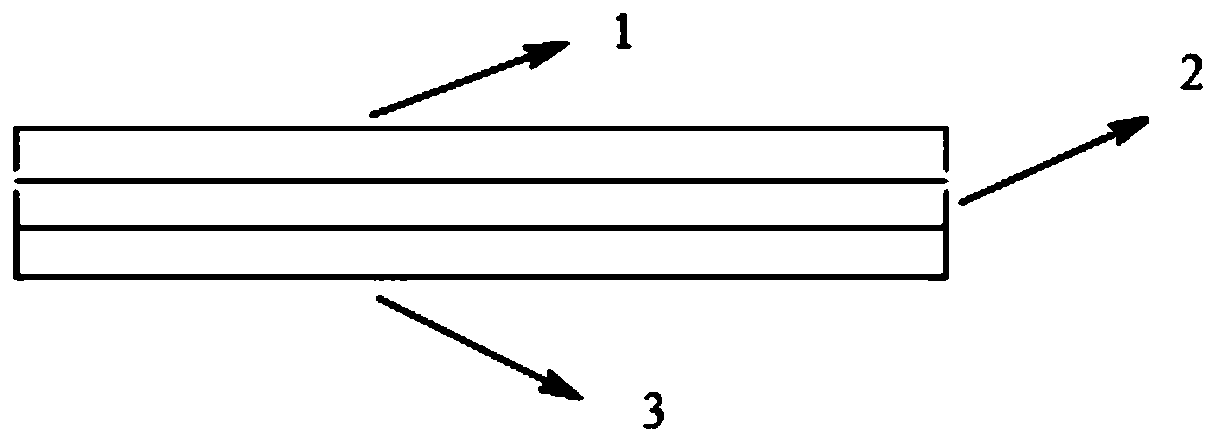

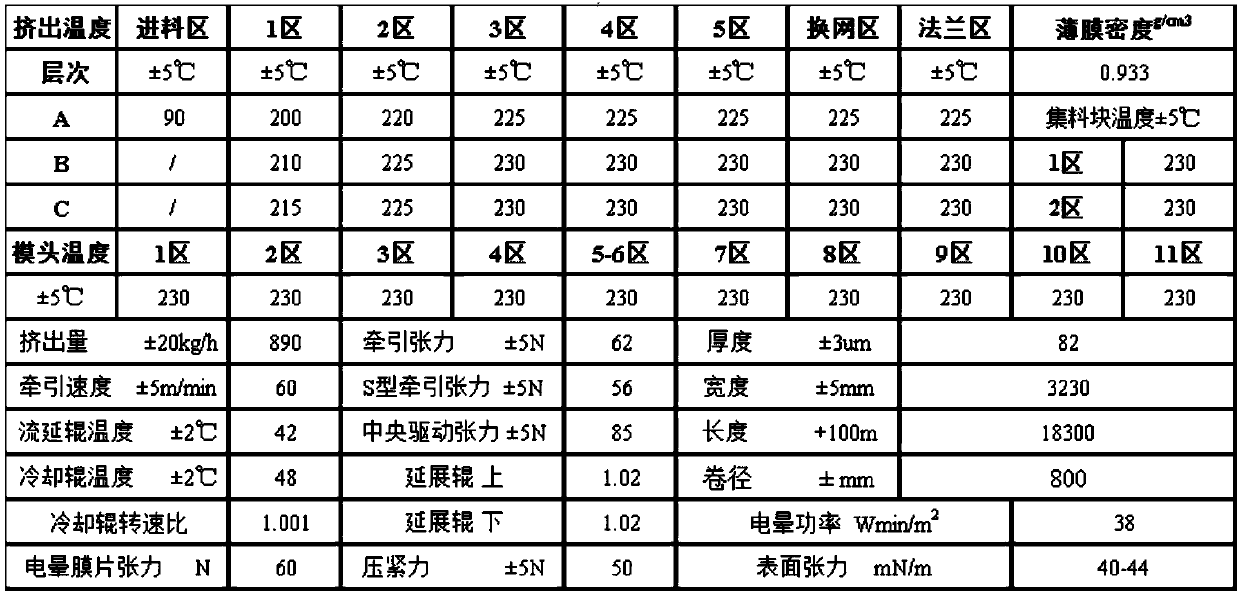

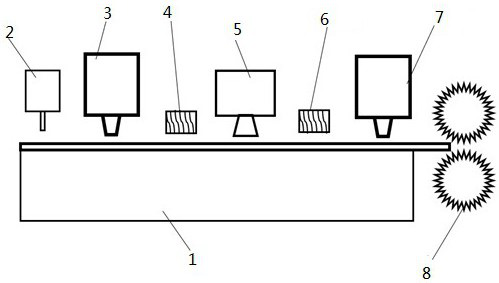

Production method of crossed multi-barrier-layer co-extruded film

InactiveCN105058825AMeet production needsImprove barrier propertiesFlat articlesEngineeringDouble barrier

The invention relates to a production method of a crossed multi-barrier-layer co-extruded film. The production method comprises the following steps: blowing out a film bulb through an extruder and a die head, wherein the innermost layer material of the film bulb is a self-adhesive material, feeding the film bulb into a heating pinch roller, pressing the cylindrical film bulb into a double-layer flaky structure, sticking the double-layer flaky structure into an integral structure through the self-adhesive material after heating the double-layer flaky structure through the heating roller, and then, cooling and rolling so as to obtain the crossed multi-barrier-layer co-extruded film. The thickness of the crossed multi-barrier-layer co-extruded film, namely a sheet material, prepared by the production method is even, and production requirements and quality requirements are met. Surface treatment including gravure, flexographic printing, offset printing, gold stamping and the like can be carried out. A symmetrical structure is formed in each layer, so that barrier layers and functional layers are all doubled, the thickness is doubled, and the sheet material meeting the production requirements is prepared. The doubled barrier layers and functional layers can promote the sheet material to have better barrier performance, and the product performance of the sheet material is improved.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

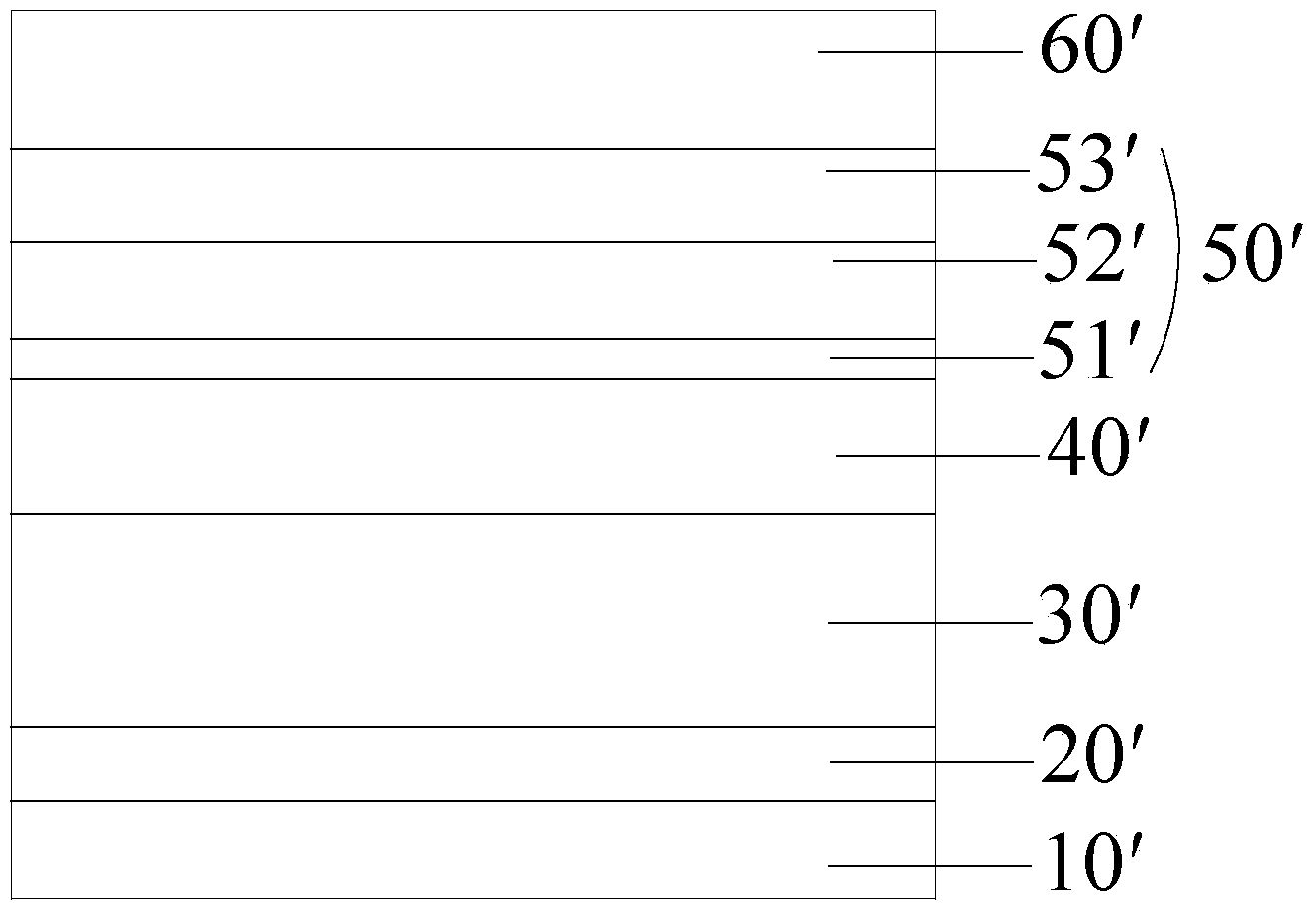

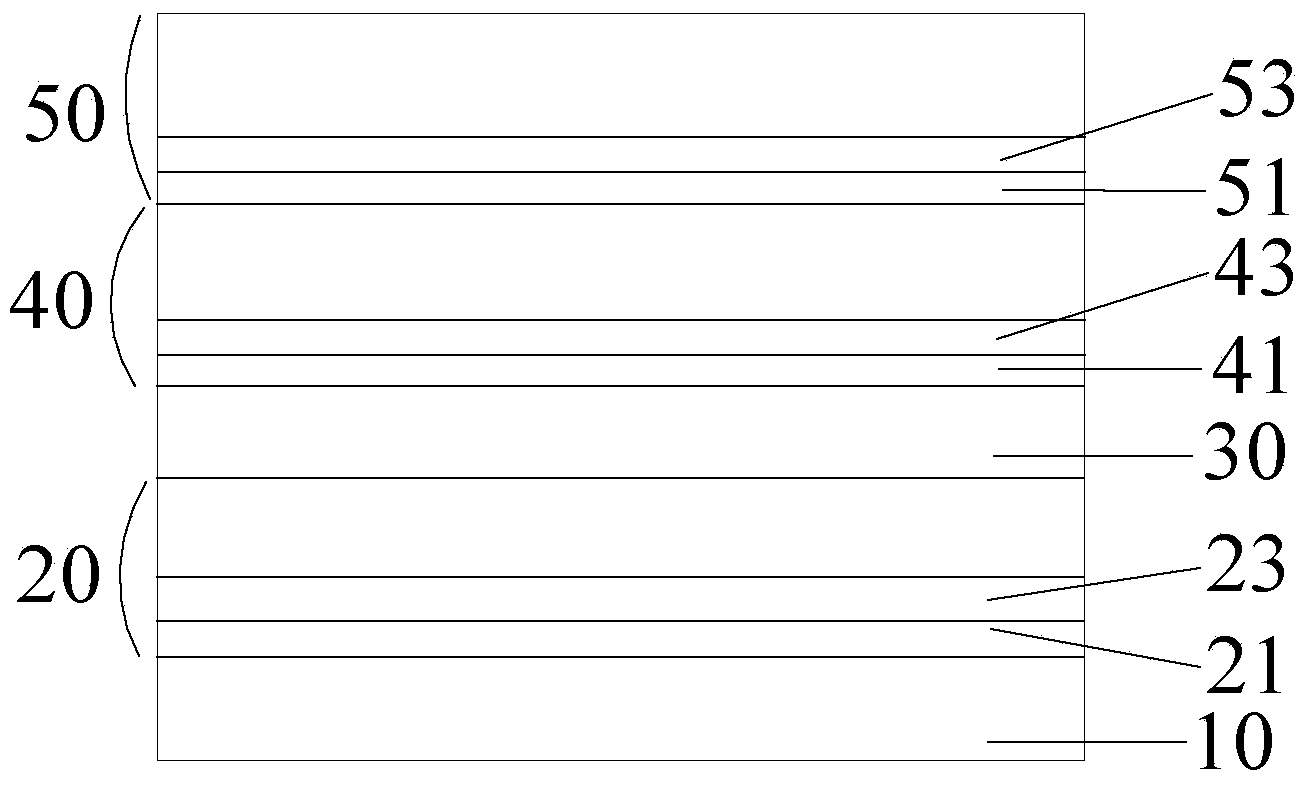

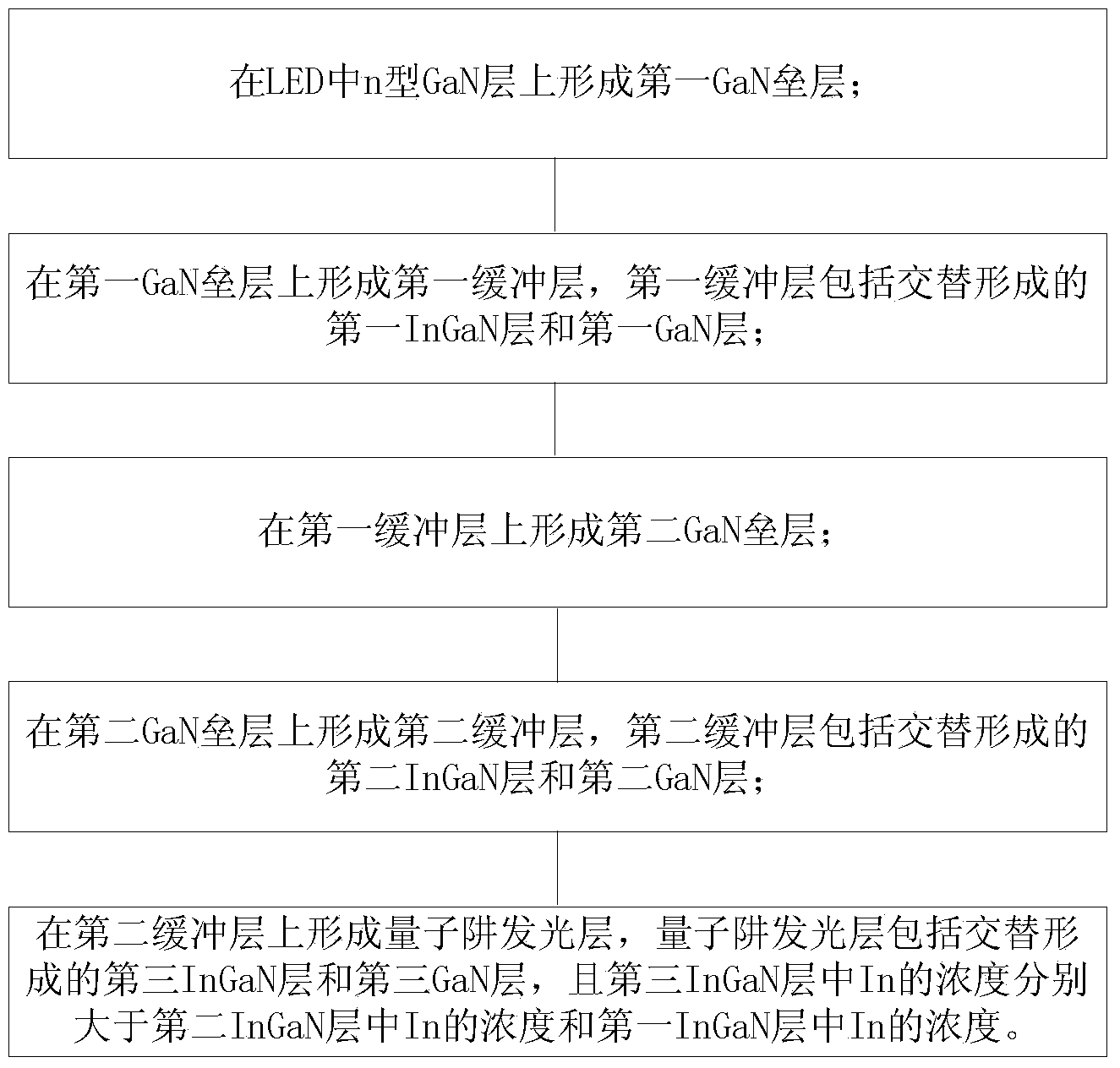

LED quantum well structure, manufacture method of the same, and LED epitaxial wafer comprising the same

ActiveCN104064644AImprove crystal qualityImprove luminous efficiencySemiconductor devicesQuantum wellOptoelectronics

The invention discloses an LED quantum well structure, a manufacture method of the same, and an LED epitaxial wafer comprising the same. The structure comprises: a first GaN barrier layer arranged on an n-type GaN layer in an LED; a first buffer layer arranged on the first GaN barrier layer and including a first InGaN layer and a first GaN layer arranged alternately; a second GaN barrier layer arranged on the first buffer layer; a second buffer layer arranged on the second GaN barrier layer and including a second InGaN layer and a second GaN layer arranged alternately; and a quantum well light emitting layer arranged on the second buffer layer and including a third InGaN layer and a third GaN layer arranged alternately. The In concentration of the third InGaN layer is greater than that of the second InGaN layer and greater than that of the first InGaN layer. The crystal quality of the quantum well light emitting layer of the structure is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

PVC plastic plate special for stone compounding and production method thereof

The invention discloses a PVC plastic plate special for stone compounding. The PVC plastic plate is prepared from, by weight, 100 parts of PVC, 20-90 parts of light calcium carbonate, 0.1-30 parts of wood flour, 0.001-20 parts of polylactic acid and 20-50 parts of PVC processing agents; the PVC processing agents include a lubricating agent, an anti-shocking modifier, a foaming agent and a foaming modifier and further include one or more of a lubricity processing agent, a PVC processing modifier, a stabilizer, a reinforcing agent, barium sulfate and titanium dioxide. The wood flour and polylactic acid are added and have a synergistic effect of improving tenacity and brittleness of the PVC plate, and in addition, polylactic acid is beneficial for improving the tensile strength of the PVC plate. The invention further discloses a production method for the PVC plastic plate special for stone compounding and a natural stone plastic compound plate produced from the PVC plastic plate.

Owner:JIANGYIN YUANSHI BUILDING MATERIAL TECH CO LTD

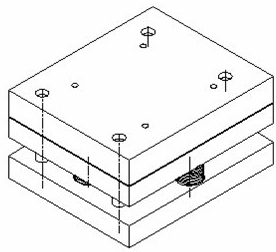

PET (polyethylene) sheet three-dimensional molding process and counter pressure thermal molding mould

The invention relates to a PET (polyethylene) sheet three-dimensional molding process and a counter pressure thermal molding mould. By improving a molding mould and adjusting thermal molding machine tool parameter, the PET sheet three-dimensional molding processing is realized. The molding mould comprises an upper module and a lower mould; the lower mould comprises a mould core, a pressure plate and a lower formwork; the mould core is fixed on the lower formwork, the pressure plate is in threaded connection with the lower formwork through an unloading bolt on which a spring is sleeved, the pressure plate is provided with a locating pillar, the lower formwork is provided with a guide pillar, the pressure plate is in sliding fit with the guide pillar and the mould core, the upper mould and the lower mould are in mould assembling or de-mould fit. By heating and assembling the PET sheet, and adopting a step of continuously and repeatedly pressurizing and maintaining pressure, the internal stress of the PET sheet is released to maximally reduce the resilience, thereby solving the problems that the PET sheet is hard to mold and great in resilience; the PET sheet with strong resilience can achieve a stable three-dimensional effect and meets various demands of clients.

Owner:TIANJIN ZHONGHUAN HI TECH

Preparation method for hose sheet by multilayer co-extrusion

InactiveCN105109173AReduce thicknessMeet production needsSynthetic resin layered productsLaminationEngineeringCo extrusion

The present invention relates to a preparation method for a hose sheet by multilayer co-extrusion. The method is characterized by: using an extruder and a die orifice to blow bubble by multilayer co-extrusion, wherein the bubble has a 5-11 layer structure, the bubble at least comprises a self-adhesive material layer, and an innermost layer is the self-adhesive material layer; and a cylindrical bubble being laminated into a double-layer sheet structure when the bubble entering into a heating nip roller, the double-layer sheet structure passing through the self-adhesive material layer to adhere to an integrated structure by a heating roller, and through cooling and rolling to obtain the hose sheet, wherein layer number of the hose sheet is two times of the layer number of the bubble. The hose sheet prepared by the method is uniform in thickness, and components of each layer can be adjusted according to the performance requirements of the hose; each layer of the hose sheet forms a chiral symmetry structure, thereby doubling the quantity of function layers with a better functional property; and the thickness of the film can be doubled to 100-460 [mu]m, and the thickness thereof can meet the hose production requirements.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

Optical fiber with large effective area

InactiveCN106199823AImprove roundnessIncrease the effective areaOptical fibre with multilayer core/claddingOptical waveguide light guideRelative refractive indexSilicon dioxide

The invention relates to optical fiber with a large effective area. The mold field diameter of the optical fiber at the 1550 nm position is 12.0-13.6 micrometers, and the mold field area is larger than or equal to 120 square micrometers; the optical fiber sequentially comprises a core layer, cladding layers and coating layers, the core layer is a silicon dioxide glass layer with the radius of 5-7 micrometers, an inner cladding layer is a fluorine-doped inner cladding layer, the relative refringence difference is -0.4--0.2 %, the radius r3 of the middle cladding layer is 12-25 micrometers, and the outer cladding layer is a quartz glass layer with the radius r4 of 25-45 micrometers; the coating layers include an inner coating layer and an outer coating layer, the diameter of the inner coating layer is 192 micrometers, and the diameter of the outer coating layer is 245 micrometers. The cut-off wavelength, the bending loss, chromatic dispersion and other comprehensive performance parameters in the application wave band are good, the optical fiber can be used as long-distance optical fiber communication under bad conditions such as super crossing gobi and deep sea, the circular degree of all layers of the optical fiber is good, the round formed shape is ensured, and strain of the optical fiber can reach 2% or more.

Owner:QINGDAO WINCHANCE TECH

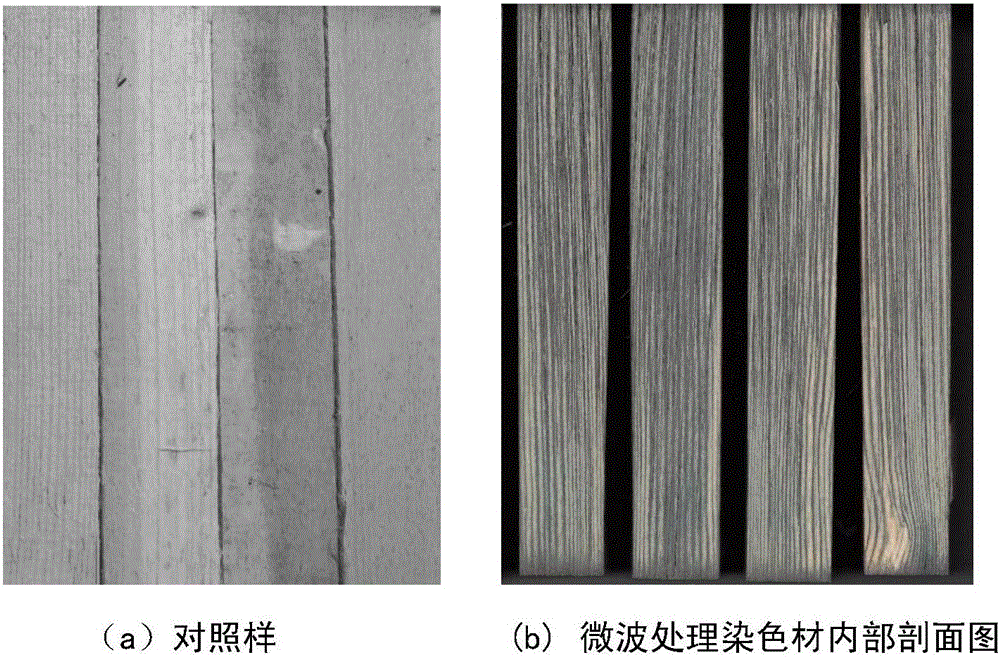

Microwave-treated dyed decorative veneer and preparation method thereof

InactiveCN106182284AImprove permeabilityFacilitate continuous industrial productionRadiation/waves wood treatmentWood treatment detailsMicrowaveAdhesive

The invention discloses microwave-treated dyed decorative veneer and a preparation method thereof. The preparation method comprises the following steps: first performing high-intensity microwave treatment of large-size wood; then dyeing the microwave-treated wood with a dye; drying the dyed wood and then soaking the dried wood in a resin-based adhesive or a bio-based adhesive; next preparing the wood into microwave-treated dyed wood by hot pressing or cold pressing; and finally planning the microwave-treated dyed wood to prepare the microwave-treated dyed decorative veneer. Through the microwave-treated dyed decorative veneer and the preparation method thereof, the difficult problems of poor dye liquor permeability, insufficient dye liquor penetration depth, poor physical and mechanical properties of decorative veneer and poor dyeing effect uniformity in a large-size wood dyeing process are solved. The microwave-treated dyed decorative veneer and the preparation method thereof are applicable to the fields of furniture, floor, decoration and finish.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

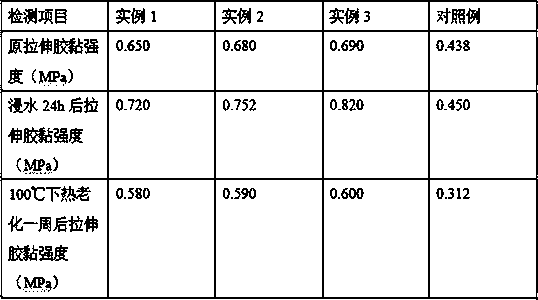

Preparation method of anti-hollowing high-adhesion strength tile adhesive

The invention relates to a preparation method of an anti-hollowing high-adhesion strength tile adhesive, and belongs to the technical field of preparation of decorative materials. The preparation method is characterized by taking ceramic tile polished residue which is prepared from the main components of silicon carbide, magnesium oxide, magnesium chloride and tile fine powder as a raw material, mixing the raw material with absolute ethanol, carrying out wet grinding, oxidizing by using potassium permanganate after wet grinding, fermenting and modifying by using lemon juice, and finally carrying out dehydration reaction, thus obtaining reaction filter residue; then carrying out soda boiling on rice straw by using slaked lime, and sealing for fermenting, thus obtaining rice straw ribs; blending the reaction filter residue, the rice straw ribs and other auxiliary materials, thus finally preparing the anti-hollowing high-adhesion strength tile adhesive. The anti-hollowing high-adhesion strength tile adhesive prepared through the preparation method is very good in adhesion strength and flexibility, is not easy to generate hollowing and has a wide application prospect.

Owner:田秋珍

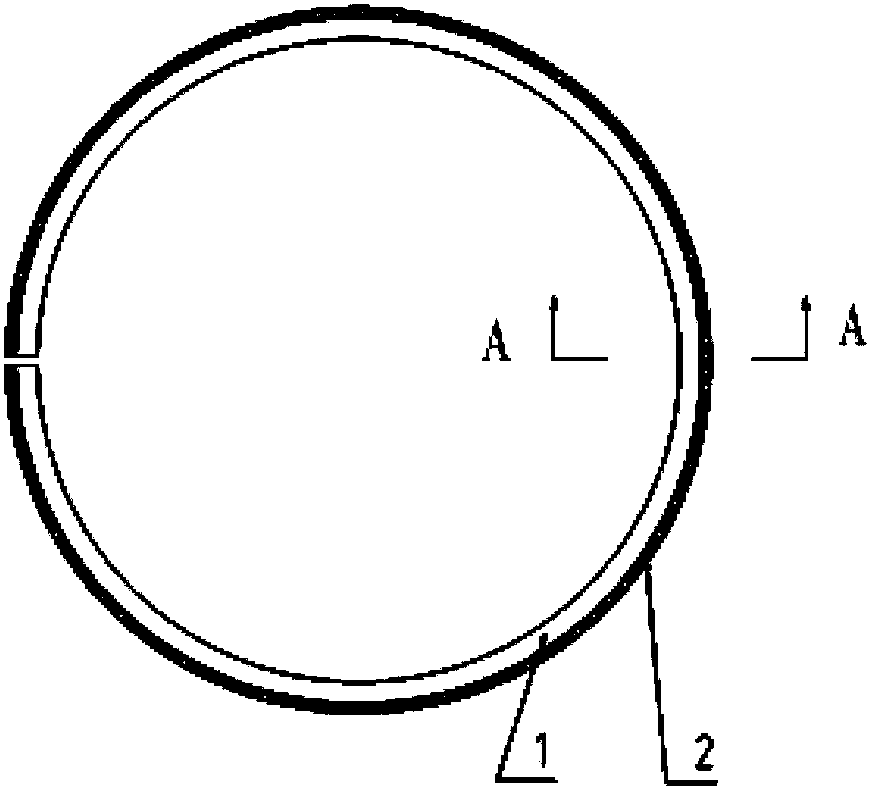

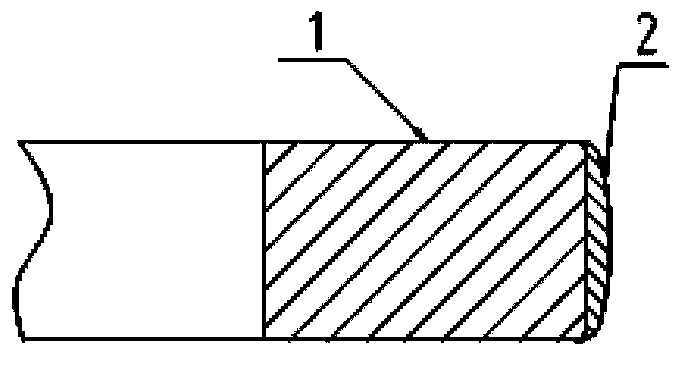

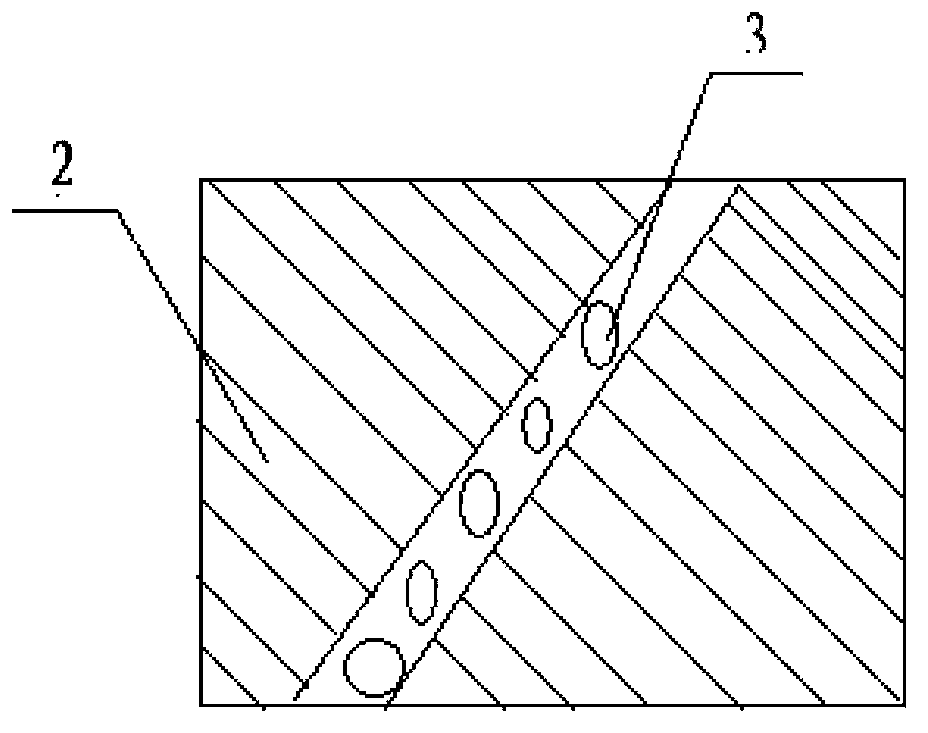

Composite coating piston ring inlaid with wear-resistant particles, and processing method thereof

InactiveCN103469283AImprove wear resistanceReduce coefficient of frictionPiston ringsElectrolytic coatingsBenzoic acidEtching

The invention discloses a composite coating piston ring inlaid with wear-resistant particles. The composite coating piston ring comprises a cast iron body and a composite coating layer plated on the outer circle of the main body, wherein the composite coating layer is a mesh-patterned electroplating coating inlaid with the wear-resistant particles; and the wear-resistant particles are one or more selected from silicon carbide, silicon dioxide, aluminium trioxide and diamond. A processing method of the composite coating piston ring inlaid with the wear-resistant particles comprises the steps of preparing a composite plating solution with a concentration of chromic anhydride being 200-400 g / L, a concentration of sulfuric acid being 2-6 g / L, a concentration of benzoic acid being 4-10 g / L and 100-130 g / L of the wear-resistant particles; forming a hard chrome layer on the surface of the piston main body by applying a forward current; carrying out reverse etching by applying a backward current, the wear-resistant particles being adsorbed to cracks during the reverse etching process; and repeating the reverse etching process, so that the wear-resistant particles are inlaid in the composite plating layer. The composite coating piston ring inlaid with the wear-resistant particles has good wear-resistant performance, high oil storage property and long service life. The production method provided by the invention is simple in operations and is stable.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

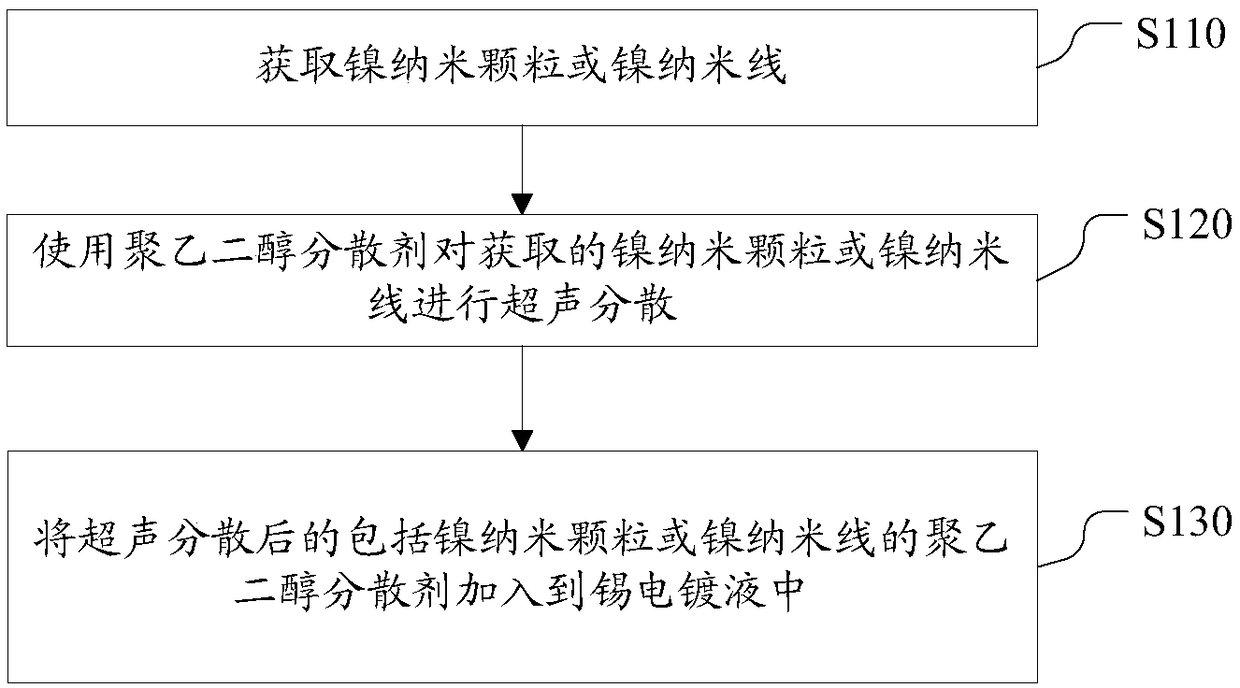

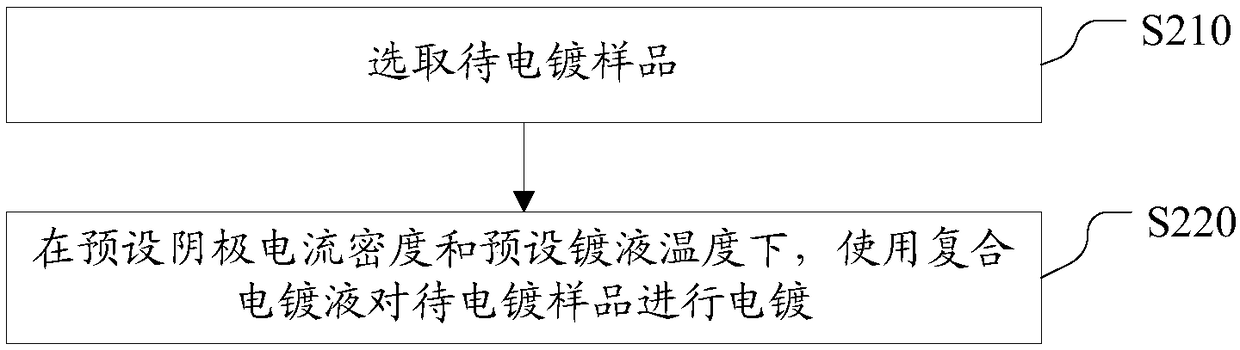

Complex plating solution, preparation method and application thereof

The invention discloses a complex plating solution, and a preparation method and application thereof. The complex plating solution comprises a tin plating solution containing nickel nanoparticles or nickel nanowires. In case of plating by use of the complex plating solution, the nickel nanoparticles or the nickel nanowires are co-deposited with pure tin to form a complex plating. In the complex plating, the nickel nanoparticles or the nickel nanowires can be embedded into the crystal lattices of tin, effectively releasing the internal stress of the plating, thus reducing the internal driving force for tin whiskers to grow to effectively inhibit the growth of the tin whiskers, and with the mature preparation of nickel nanoparticles or nickel nanowires, the complex plating solution is convenient to obtain, and has a good application prospect.

Owner:SHANG RUIYUAN CHEM TECH

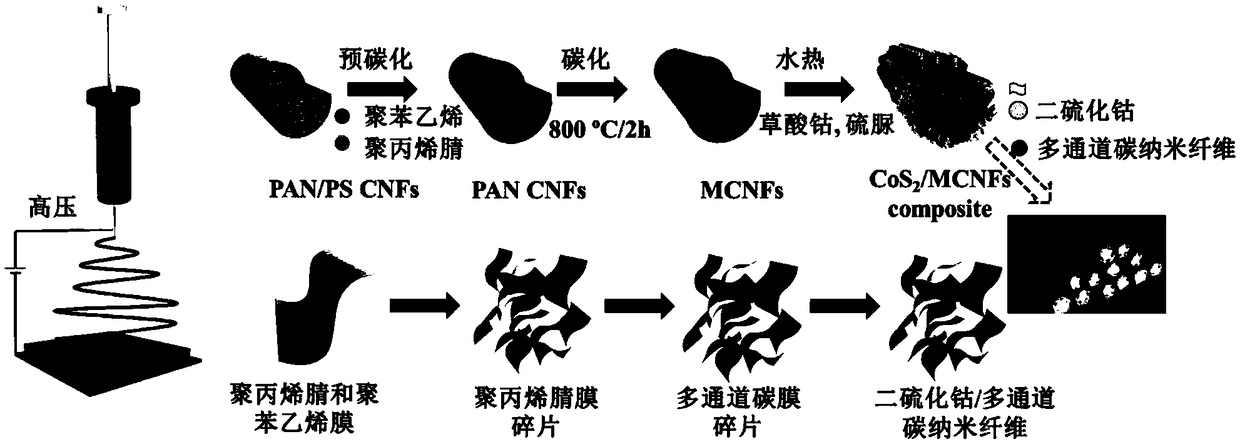

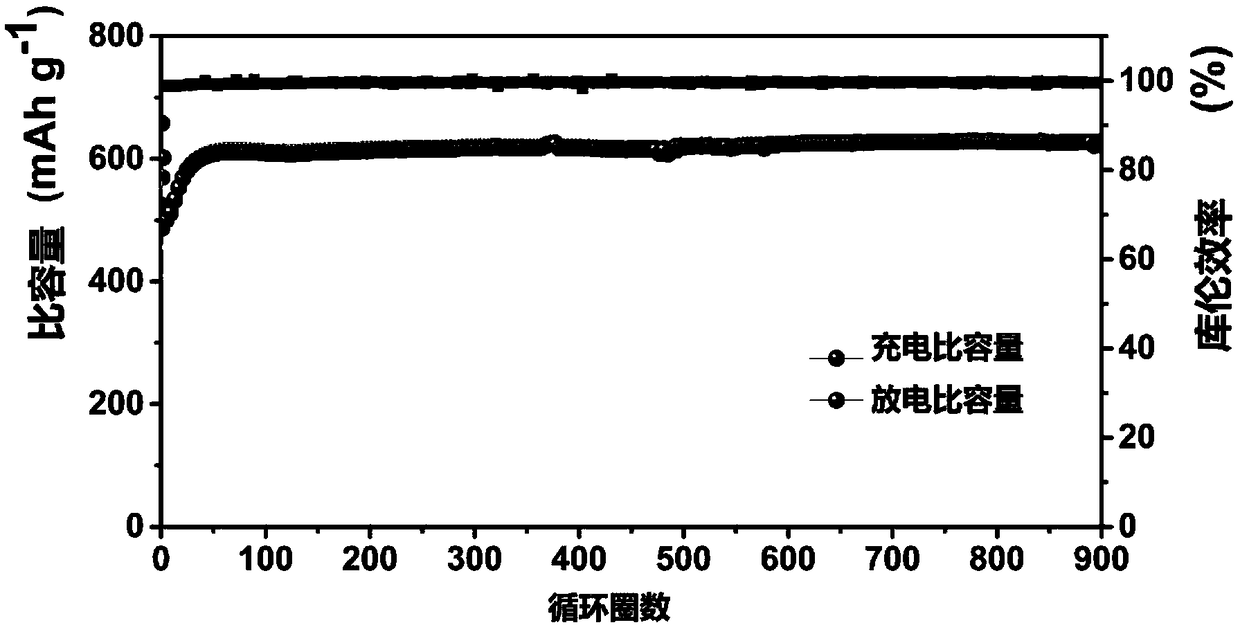

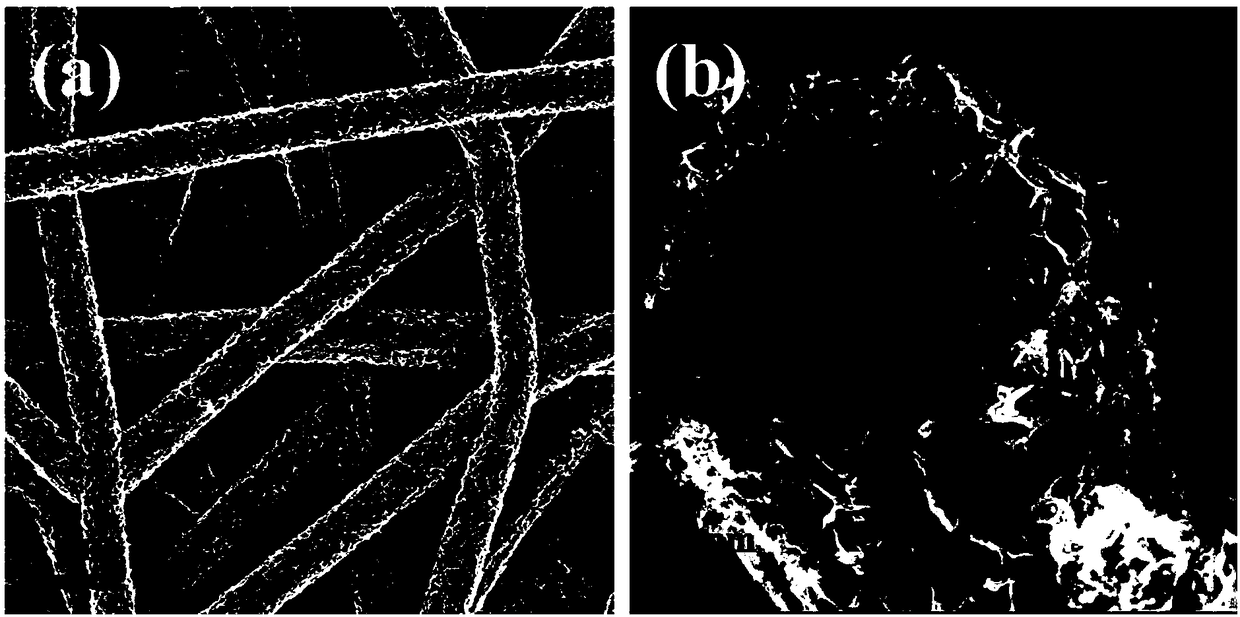

Cobalt disulfide/carbon nanofiber composite material and preparation method thereof

InactiveCN109192952AImprove conductivityLarge specific surface areaMaterial nanotechnologyCell electrodesPolystyreneCarbon nanofiber

The invention provides a preparation method of a cobalt disulfide / carbon nanofiber composite material, comprising the following steps: S1A) carbonizing a polyacrylonitrile / polystyrene composite nanofiber membrane to obtain a carbon nanofiber membrane; S1B) mixing cobalt salt of organic acid, organic sulfur source and diol solvent to obtain mixed solution,the organic sulfur source containing aminogroups; S2) mixing the carbon nanofiber membrane with the mixed solution and hydrothermally reacting to obtain a cobalt disulfide / carbon nanofiber composite material. As that carry of the cobalt disulfide material, the multi-channel carbon nanofibers of the invention can enhance the conductivity of the cobalt disulfide and provide an effective buff space for the volume change of the cobalt disulfide; and compared with the prior art, the multi-channel carbon nanofibers of the invention can enhance the conductivity of the cobalt disulfide and provide an effective buffer space for the volume change of the cobalt disulfide; Moreover, the self-assembled nanofibers formed a wrinkled cobalt disulfide nanolayer structure on the surface of carbon nanofibers, which has a large specific surface area,which is conducive to the exchange and transfer of sodium ions and electrons, and also conducive to the electrolyte immersion, and enhances the electrochemical properties of the composite materials.

Owner:UNIV OF SCI & TECH OF CHINA

Heat-treatment-free monorail turnout weathering steel plate and preparation method thereof

The invention discloses a heat-treatment-free monorail turnout weathering steel plate. The weathering steel plate comprises, by mass, 0.03-0.16% of C, 0.10-0.35% of Si, 0.70-1.60% of Mn, 0.20-0.40% ofCu, 0.35-0.70% of Cr, 0.25-0.60% of Ni, 0.01-0.08% of Alt, 0.01-0.05% of Nb, 0.005-0.020% of Ti and the balance iron and unavoidable impurities. A preparation method comprises the steps of smelting,refining, continuous casting, heating and rolling, and in the heating process, the complete solution temperature of Nb is calculated through a solid solution formula, and a casting slab is heated to the complete solution temperature of Nb or above. The weathering steel plate has excellent welding performance, and also has ultra-high strength, high toughness and high weather resistance; and heat treatment is not required in the production process, the production cost is reduced, and the production cycle is shortened.

Owner:NANJING IRON & STEEL CO LTD

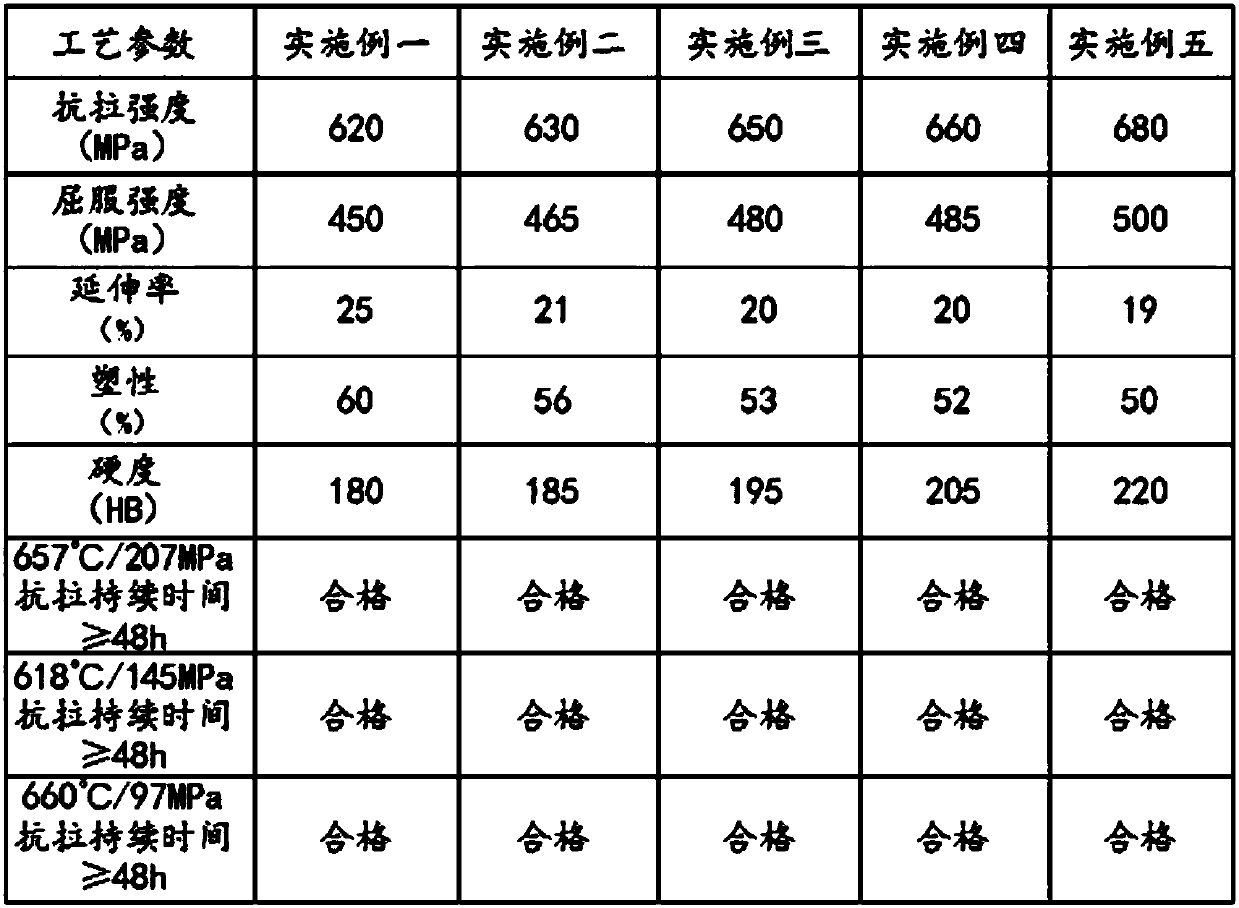

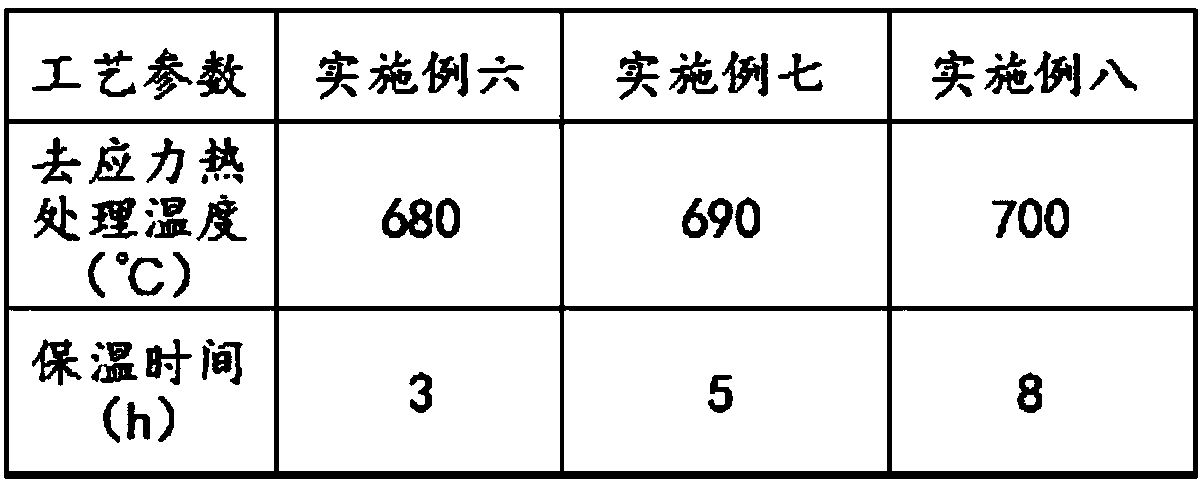

Preparation method of heat-resistant CrMoV steel casting part and heat-resistant CrMoV steel casting material

The invention discloses a preparation method of a heat-resistant CrMoV steel casting part. The steel casting part comprises the following main chemical components in percentage by weight: 0.12-0.20% of C, 0.20-0.60% of Si, 0.5-0.9% of Mn, not greater than 0.020% of P, not greater than 0.012% of S, 1.0-1.5% of Cr, 0.9-1.2% of Mo, 0.1-0.5% of Ni, 0.20-0.35% of V, and the balance iron and residual elements; the steel casting part prepared through the abovementioned components is treated by normalizing and tempering. The method for producing the casting part is applicable to the production of thecasting part used in high-temperature environment, such as a gas turbine casting part; the produced casting part is high in high-temperature lasting mechanical performance and meets the requirements on the mechanical performance under normal temperature and high temperature.

Owner:KOCEL STEEL

Electric inductor and manufacturing method thereof

InactiveCN105679492AImprove qualityImprove manufacturing yieldInductances/transformers/magnets manufactureMagnetic materialsElectrical conductorTin plating

The invention discloses an electric inductor manufacturing method.The method comprises the following steps that 1, an electric conductor is put into a mold; 2, the mold is filled with soft magnetic metal powder, and pressure is applied to integrally press the soft magnetic metal powder and the electric conductor into a pressed body; 3, heat treatment is performed on the pressed body, so that the soft magnetic metal material has the insulation resistance of the preset degree and releases the internal stress generated during pressing forming; 4, an oxidation layer, stretching out of the surface of the electric conductor, of the pressed body subjected to heat treatment is treated, so that welding and tin plating are conveniently achieved; 5, the electric inductor stretching out of a magnet is reshaped, so that needed surface attaching or inserting is conveniently achieved.The invention further discloses an electric inductor which is manufactured through the electric inductor manufacturing method.Accordingly, high-operating temperature, large-current, low-inductance value and high-automation level production of the electric inductor can be achieved, the quality of the electric inductor is improved, and the manufacturing yield of the electric inductor is increased.

Owner:SHENZHEN SUNLORD ELECTRONICS

Dlp type 3d printing photocuring material for clinical dental temporary crown

InactiveCN112353694AReduce the influence of complex physical and chemical factorsRisk of reduced service lifeAdditive manufacturing apparatusImpression capsPhotopigmentAntibacterial agent

The invention belongs to the field of dentistry, and particularly relates to a dlp type 3d printing photocuring material for a clinical dental temporary crown, which takes nano organic-inorganic hybrid UV resin, high-strength aliphatic urethane acrylate, high-toughness aliphatic urethane acrylate and a free radical acrylate monomer diluent as main bodies and is matched with an inorganic silver antibacterial agent and a pigment, the dLp type 3D printing photocuring material for the clinical dental temporary crown is prepared from a 385nm wavelength free radical system composed of a photoinitiator, and the problems of poor material performance stability, poor size stability, poor toughness, poor mechanical property, medical risk and the like are effectively solved by using a special printingprocess and a post-treatment process.

Owner:WUXI CITY CASHEW NEW MATERIALS CO LTD

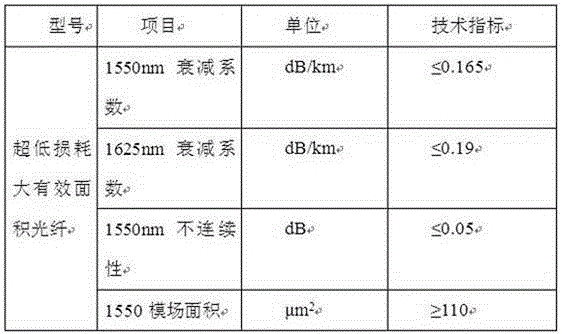

Ultralow-loss and large-effective area optical fiber

InactiveCN106226864AImprove roundnessIncrease the effective areaGlass optical fibreOptical fibre with multilayer core/claddingMicrometerRelative refractive index

An ultralow-loss and large-effective area optical fiber of the present invention comprises, orderly from inside to outside, a core layer, cladding layers and a coating layer. The core layer is a pure quartz glass layer, and the radius of the core layer is between 4 micrometers and 6 micrometers. An inner cladding layer is a fluorine-doped inner cladding layer, the radius r2 of the inner cladding layer is between 6 micrometers and 10 micrometers, and the relative refractive index is between -0.4% and -0.2%. The radius r3 of an intermediate clapping layer is between 12 micrometers and 25 micrometers, and an outer cladding layer is a pure silicon dioxide glass layer, and the radius r4 of the outer cladding layer is between 25 micrometers and 45 micrometers. The coating layer adopts the polyacrylate and comprises an inner coating layer and an outer coating layer, the diameter of the inner coating layer is 192 micrometers, and the diameter of the outer coating layer is 245 micrometers. The advantages of the present invention are that: the comprehensive performance parameters of the optical fiber, such as the cut-off wavelength, the bending loss, the dispersion, etc., are good in an application waveband; the optical fiber can be used for the long-distance optical fiber communication spanning the mal-conditions, such as the gobi, the deep sea, etc.; the layers of the optical fiber are good in roundness, so that the round appearance of the optical fiber is guaranteed; the stress of the optical fiber can reach 2% or even more.

Owner:QINGDAO WINCHANCE TECH

Gallium arsenide semiconductor substrate wet etching process

ActiveCN105762062AEfficient removalRelease internal stressSemiconductor/solid-state device manufacturingManufacturing cost reductionProcess equipment

The invention discloses a gallium arsenide semiconductor substrate wet etching process comprising the following step of: (1) pasting a gallium arsenide semiconductor substrate having subjected to previous processing on a sapphire carrier; (2) mechanically thinning the gallium arsenide semiconductor substrate in the step (1); immersing the gallium arsenide semiconductor substrate in the step (2) in etching liquid to be subjected to chemical corrosion; (4) taking out, cleaning, and drying the chemically corroded gallium arsenide semiconductor substrate and directly performing later photoetching and subsequent processing on the gallium arsenide semiconductor substrate. The gallium arsenide semiconductor substrate wet etching process is simple in steps, good in operability, low in processing cost, may remove damaged crystal processing surface and releasing internal stress, does not need to purchase professional processing equipment and install a matching chemical waste processing system, greatly shortens later processing technological processes, benefits an increase in production power, reduces production cost, and enhances product price competitiveness.

Owner:SUZHOU LIANG DONGXIN MICROELECTRONICS CO LTD

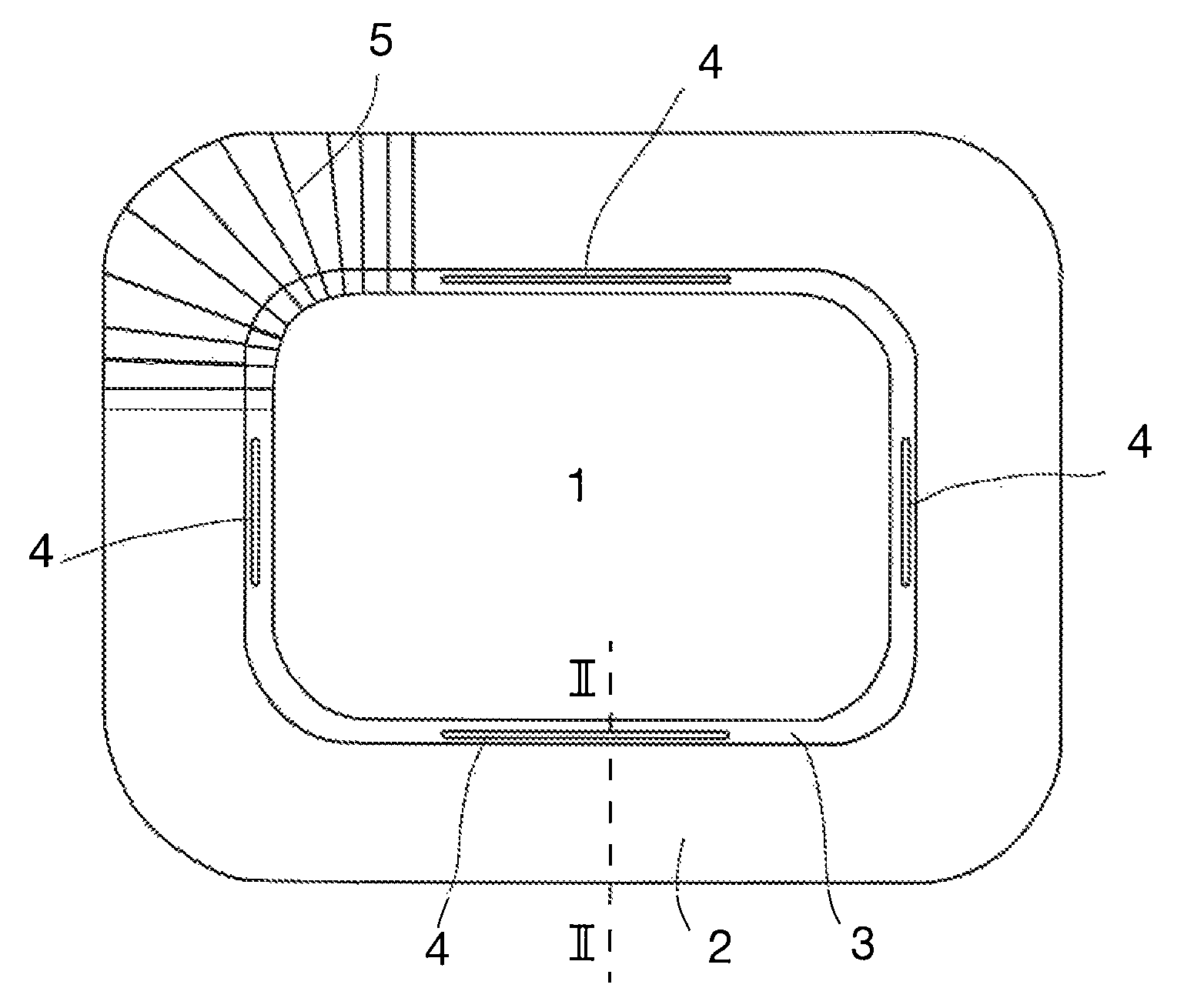

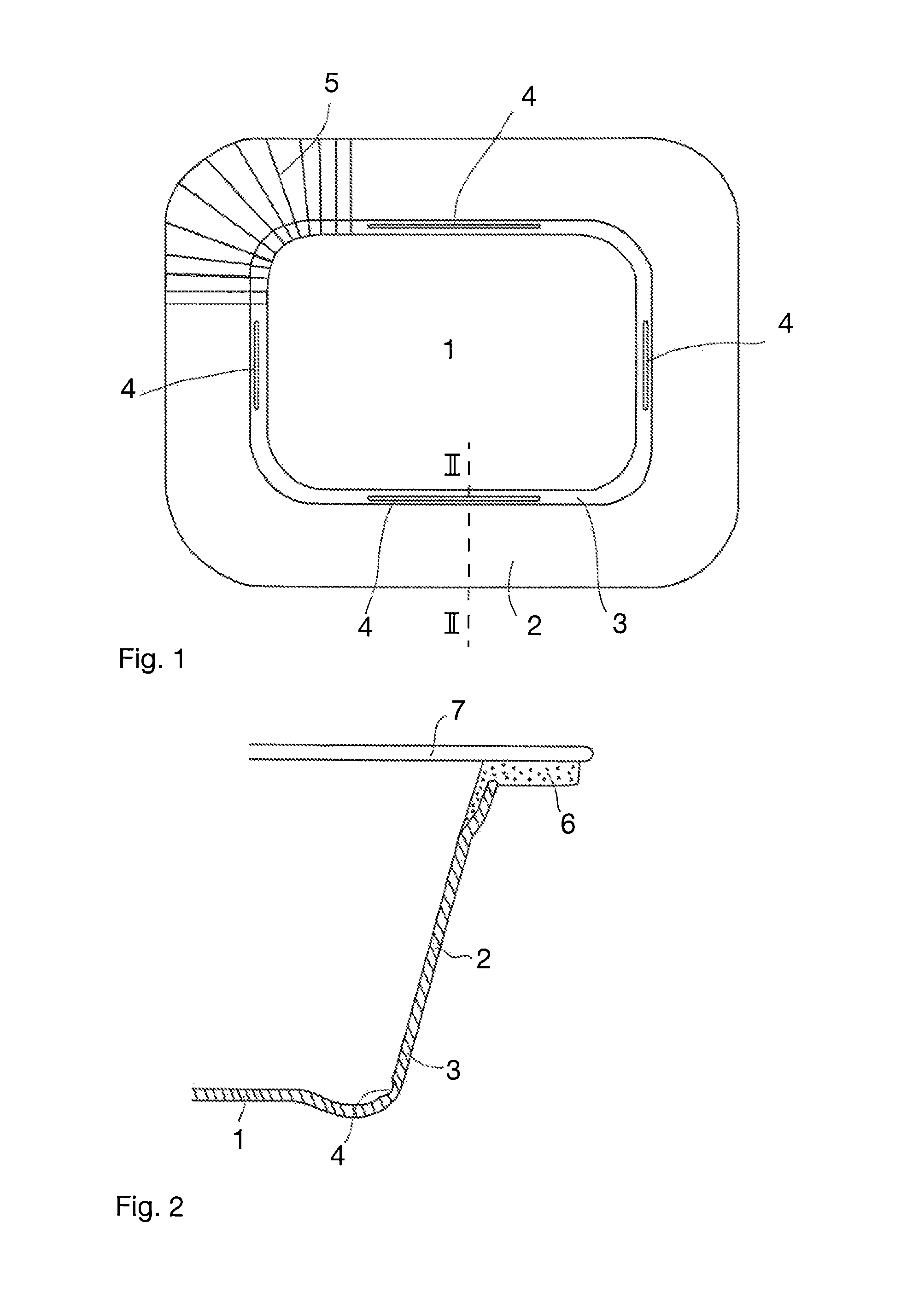

Method for forming a package, a package and a package blank

InactiveUS9016497B2Easy to shapeLow bending stiffnessEnvelopes/bags making machineryBox making operationsCardboardBending stiffness

Owner:NEC CORP +1

High temperature-resistant nanosized self-adhesive optical protective film and production method thereof

PendingCN109605886AImprove transmittanceStable self-adhesiveSynthetic resin layered productsFlat articlesLow-density polyethyleneElastomer

The invention relates to a high temperature-resistant nanosized self-adhesive optical protective film and a production method thereof. The self-adhesive optical protective film comprises a self-adhesive layer, an intermediate layer and an unwinding layer, wherein the self-adhesive layer comprises metallocene polyethylene elastomer resin, soft rubber resin and ternary polymerized polypropylene resin at a mass ratio of (70-80):(10-20):(5-15), the intermediate layer includes high-density polyethylene resin, linear low-density polyethylene resin and low-density polyethylene resin at a mass ratio of (25-35):(35-45):(25-40), and the unwinding layer includes block polypropylene resin and a fluorine-containing auxiliary agent at a mass ratio of (90-98):(2-10). The self-adhesive optical protectivefilm is produced in a multi-layer coextrusion tape-casting mode, and has the excellent properties of high temperature resistance, no shrinkage, repeated sticking and no precipitation.

Owner:永新股份(黄山)包装有限公司

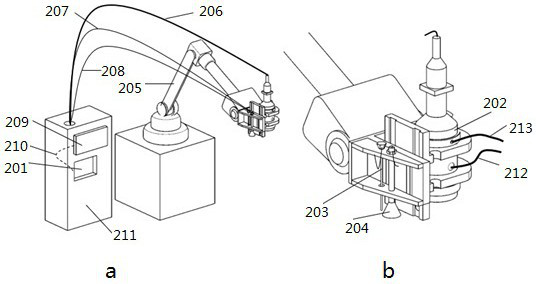

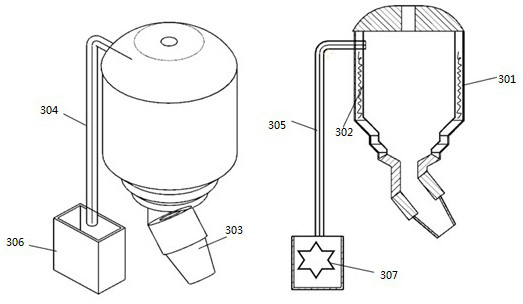

Waste aluminum recycling and direct forming device and method

ActiveCN111979508AReasonable structural designImprove yieldMolten spray coatingMetal rolling stand detailsAluminium recyclingRoll forming

The invention relates to a waste aluminum recycling and direct forming device and method. The waste aluminum recycling and direct forming device comprises an induction heating system, smelting furnaces, temperature adjusting devices, a composite material stirring device, a conveying device and a double-roller rolling device, wherein the heating system, the smelting furnace I, the temperature adjusting device I, the composite material stirring device, the temperature adjusting device II, the smelting furnace II and the double-roller rolling device are all arranged around the conveying device, atreated stainless steel plate is conveyed into the heating system, heated and slightly melted and then conveyed to the smelting furnace, molten waste aluminum is sprayed to the steel plate, temperature measurement and temperature adjustment are carried out, strengthening particles are sprayed to the surface of the waste aluminum, secondary temperature measurement and temperature adjustment are carried out, the surfaces of the strengthening particles are covered with molten aluminum, the strengthening particles are sent into double rollers, rolling forming is carried out to obtain a steel / aluminum / strengthening particle / aluminum wavy composite plate, and laser shock is carried out on the surface of the steel / aluminum / strengthening particle / aluminum wavy composite plate. The wavy compositeplate is directly machined and formed from waste aluminum, the problems of high cost, difficulty in operation, complex structure and the like are solved, the yield is high, the production efficiency and the qualified rate of products are favorably improved, continuous production can be realized, and the wavy composite plate has the advantages of energy conservation and environmental protection.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com