Preparation method of heat-resistant CrMoV steel casting part and heat-resistant CrMoV steel casting material

A steel casting and heat-resistant technology, which is applied in the field of preparation of heat-resistant CrMoV steel castings, can solve the problems of plastic toughness not meeting standard requirements, high temperature durability performance degradation and other problems, so as to achieve no deterioration of metallographic structure and eliminate residual Stress, effect of reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

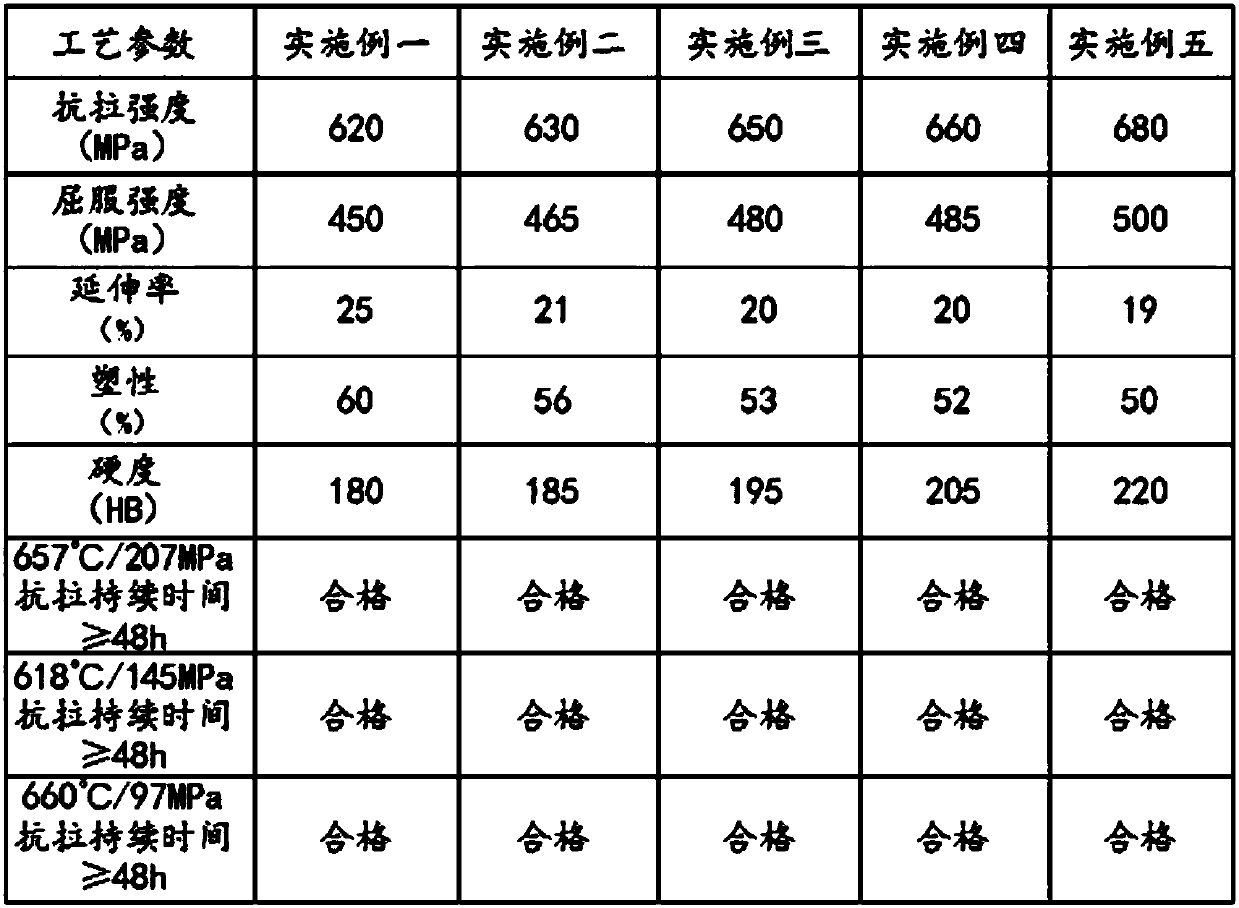

[0051] Select the disclosed chemical composition and content range in the scheme of the present invention, and adopt the heat treatment process in the first invention scheme to formulate the following examples. Each embodiment produces the same type of gas turbine castings. The maximum wall thickness of the castings is 220mm. The castings have Trapezoidal attached casting test block, the cross section of the test block is trapezoidal, the cross-sectional dimensions are: upper bottom width: 70m, lower bottom width: 100mm, height: 100mm, and the overall length of the test block is 220mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com