Method for reducing stress of cubic boron nitride thin film

A technology of cubic boron nitride and thin film stress, which is applied in chemical instruments and methods, ion implantation plating, crystal growth, etc., can solve problems such as insignificant effects and affecting device structure design, so as to reduce internal stress and effectively release The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

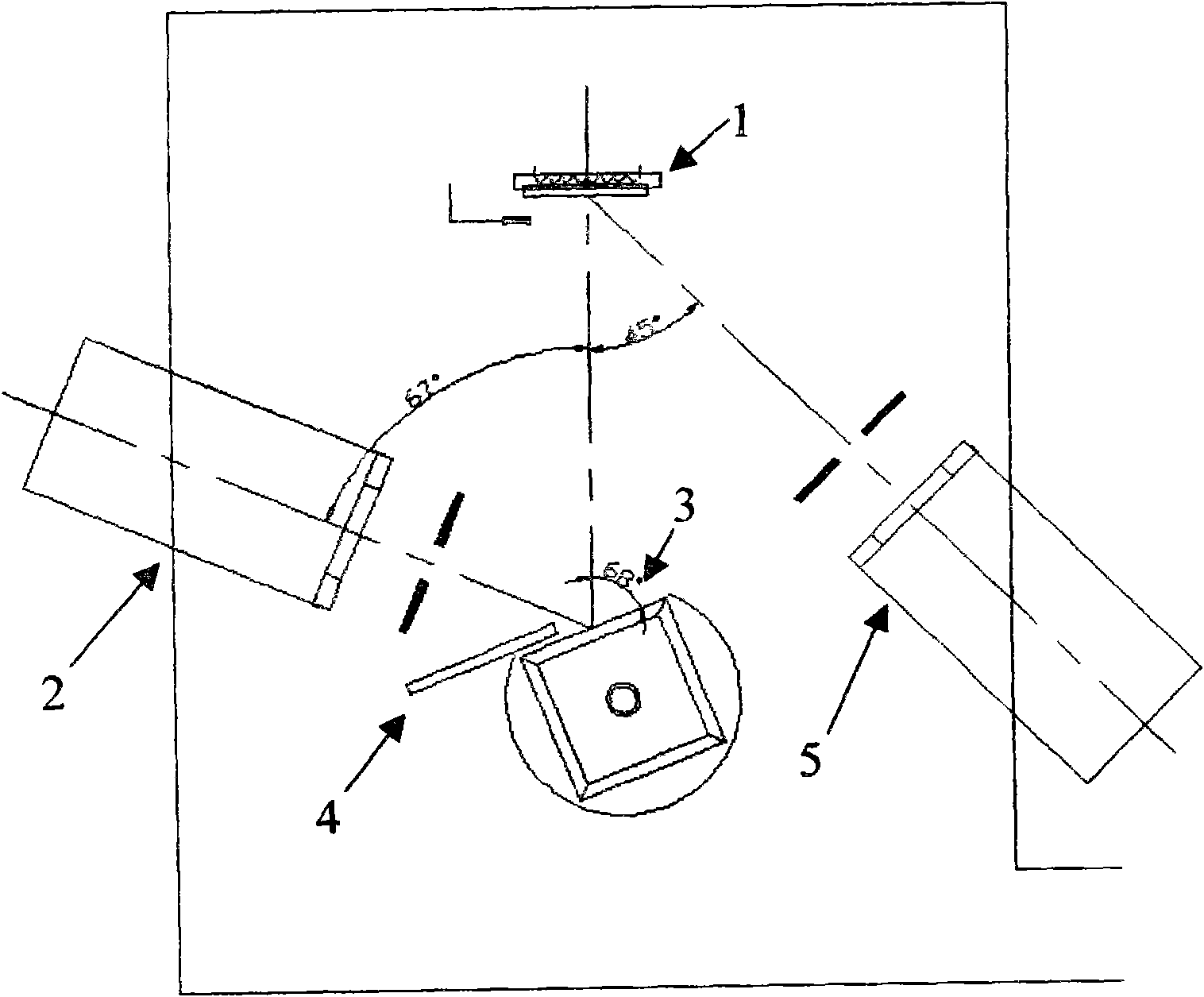

[0025] see figure 1 Shown, a kind of preparation method of the present invention reduces cubic boron nitride film stress, is characterized in that, comprises the steps:

[0026] Step 1: Take a silicon substrate, which is a silicon (001) single crystal substrate;

[0027] Step 2: Place the silicon substrate on the sample carrier 1 of the ion beam assisted deposition system, use the high-purity boron target 2 as the sputtering target for cubic boron nitride film deposition, and use the silicon target as the dopant source;

[0028] Step 3: heating the substrate; substrate temperature T s 200-800℃, working gas pressure P D 1.0-5.0×10 -2 Pa;

[0029] Step 4: The ion beam assisted deposition system uses two Kaufmann wide-beam ion sources that can be adjusted independently, and the main ion source 2 uses Ar + The ions bombard the boron target 3 and the silicon target 4, and at the same time, the Ar + and N 2 + The mixed ion beam is used as the auxiliary ion source 5 to bombar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com