Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139 results about "Ion beam-assisted deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ion beam assisted deposition or IBAD or IAD (not to be confused with ion beam induced deposition, IBID) is a materials engineering technique which combines ion implantation with simultaneous sputtering or another physical vapor deposition technique. Besides providing independent control of parameters such as ion energy, temperature and arrival rate of atomic species during deposition, this technique is especially useful to create a gradual transition between the substrate material and the deposited film, and for depositing films with less built-in strain than is possible by other techniques. These two properties can result in films with a much more durable bond to the substrate. Experience has shown that some meta-stable compounds like cubic boron nitride (c-BN), can only be formed in thin films when bombarded with energetic ions during the deposition process.

Rechargeable thin film battery and method for making the same

InactiveUS6982132B1Improve lithium ion mobilityHigh voltageElectrode thermal treatmentFinal product manufactureElectrical batteryHigh energy

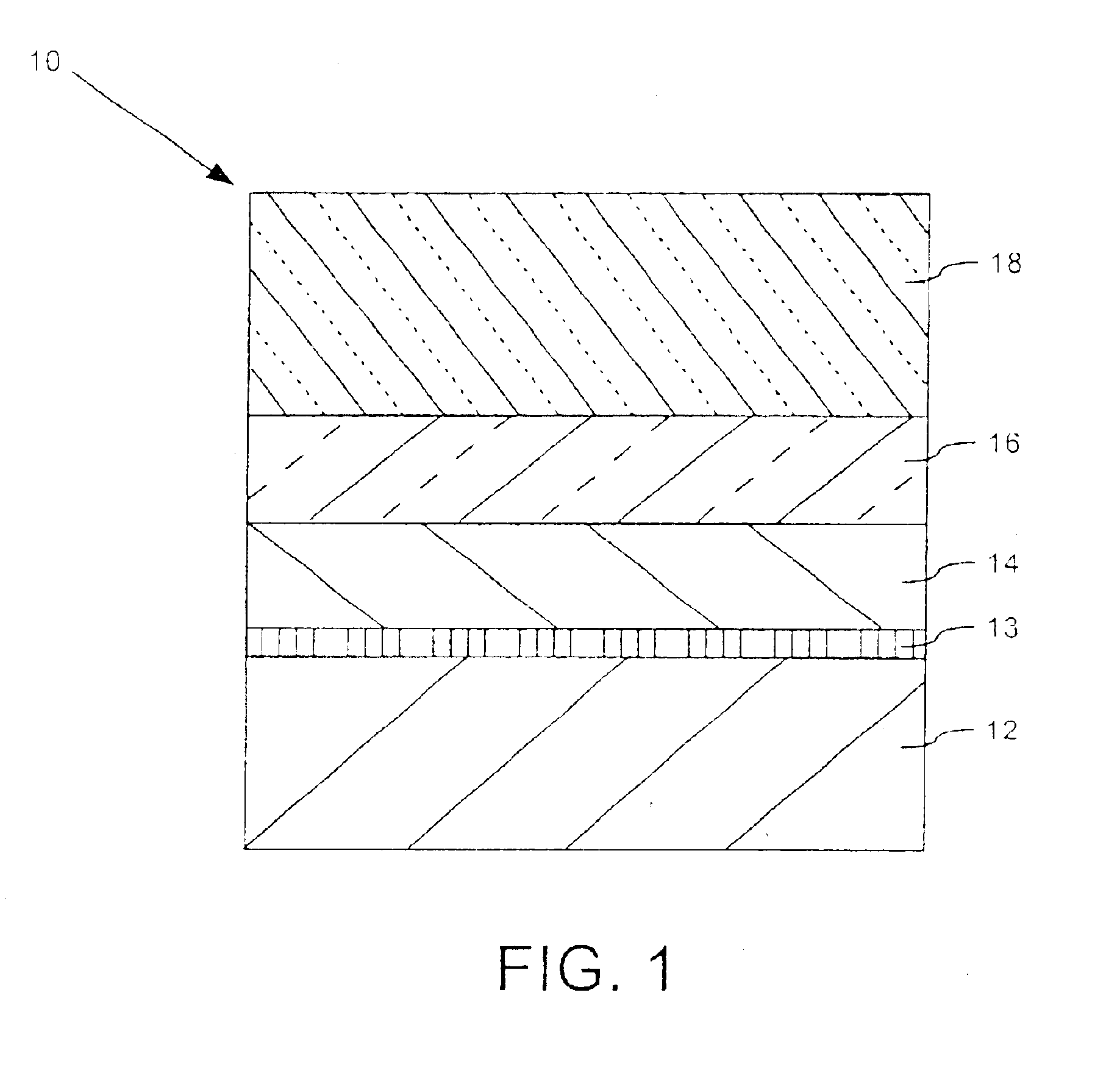

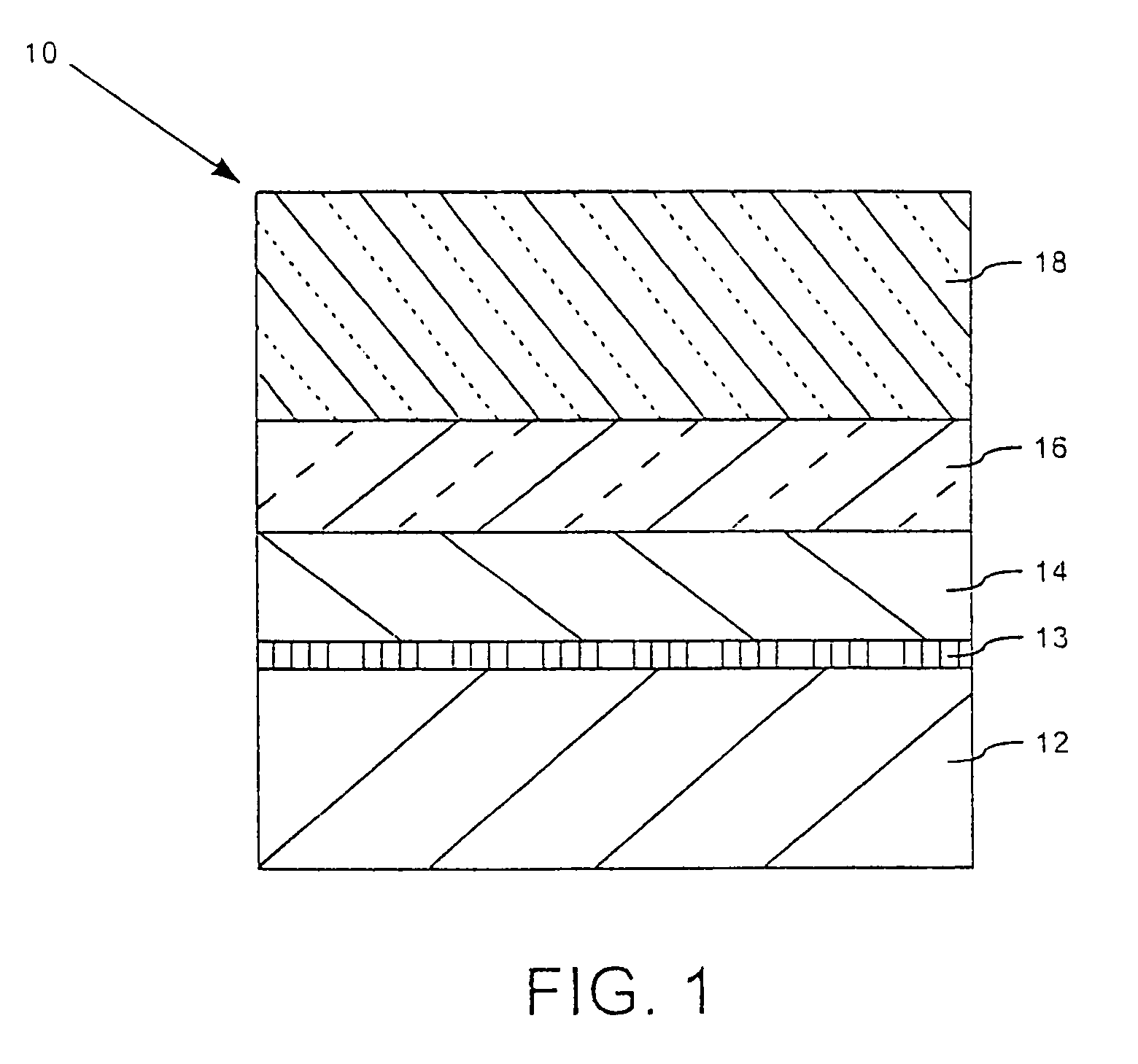

A rechargeable, stackable, thin film, solid-state lithium electrochemical cell, thin film lithium battery and method for making the same is disclosed. The cell and battery provide for a variety configurations, voltage and current capacities. An innovative low temperature ion beam assisted deposition method for fabricating thin film, solid-state anodes, cathodes and electrolytes is disclosed wherein a source of energetic ions and evaporants combine to form thin film cell components having preferred crystallinity, structure and orientation. The disclosed batteries are particularly useful as power sources for portable electronic devices and electric vehicle applications where high energy density, high reversible charge capacity, high discharge current and long battery lifetimes are required.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

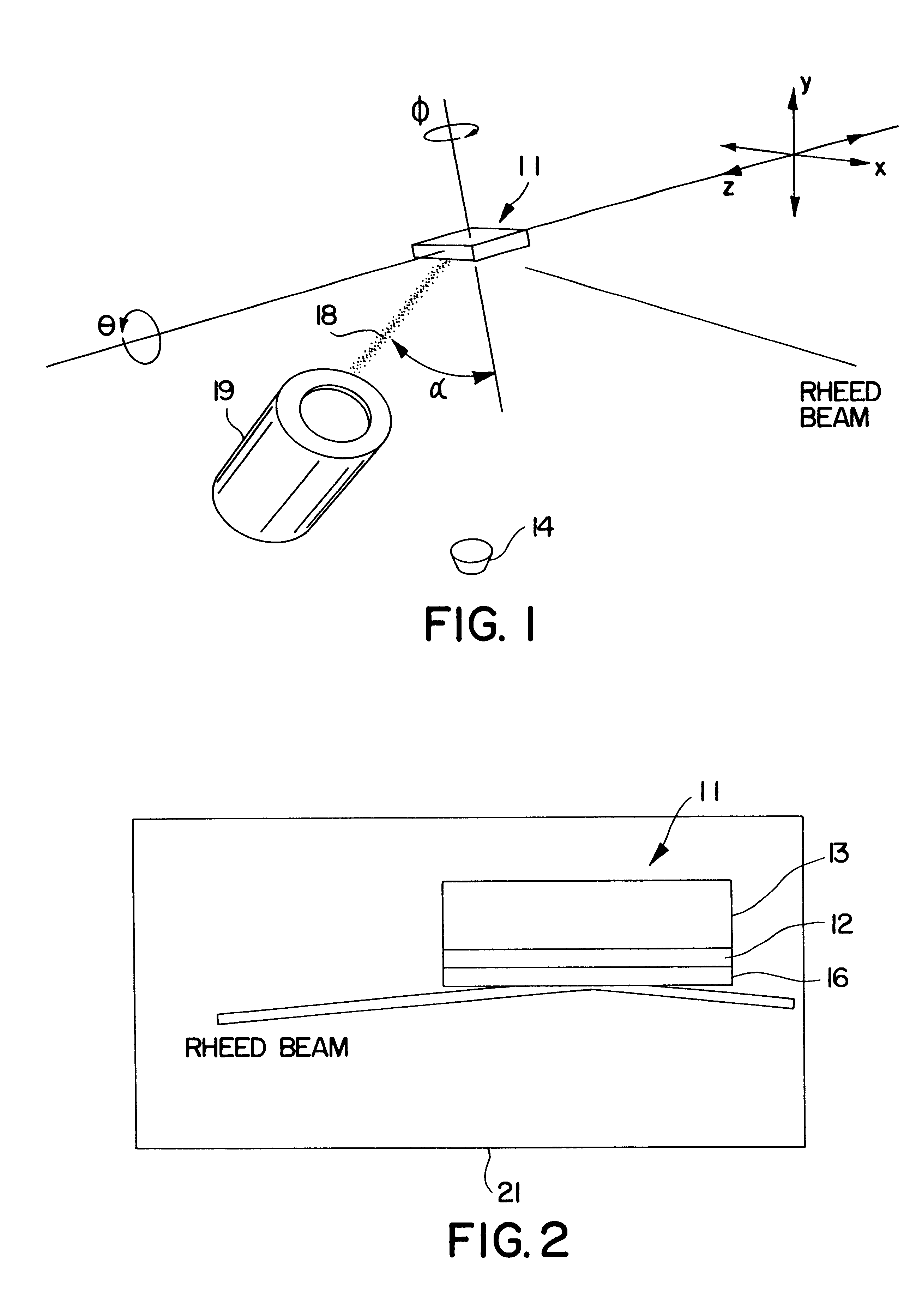

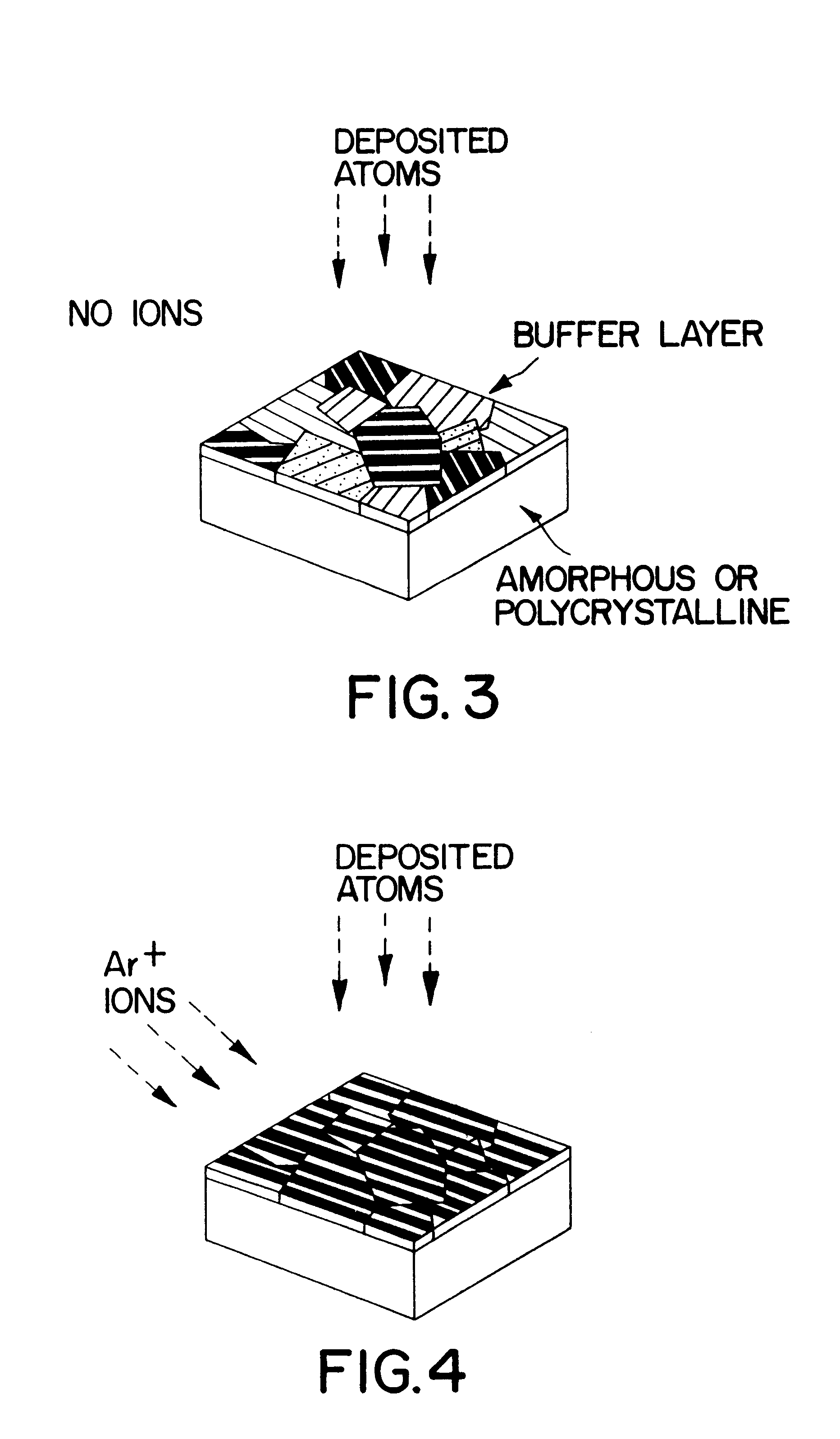

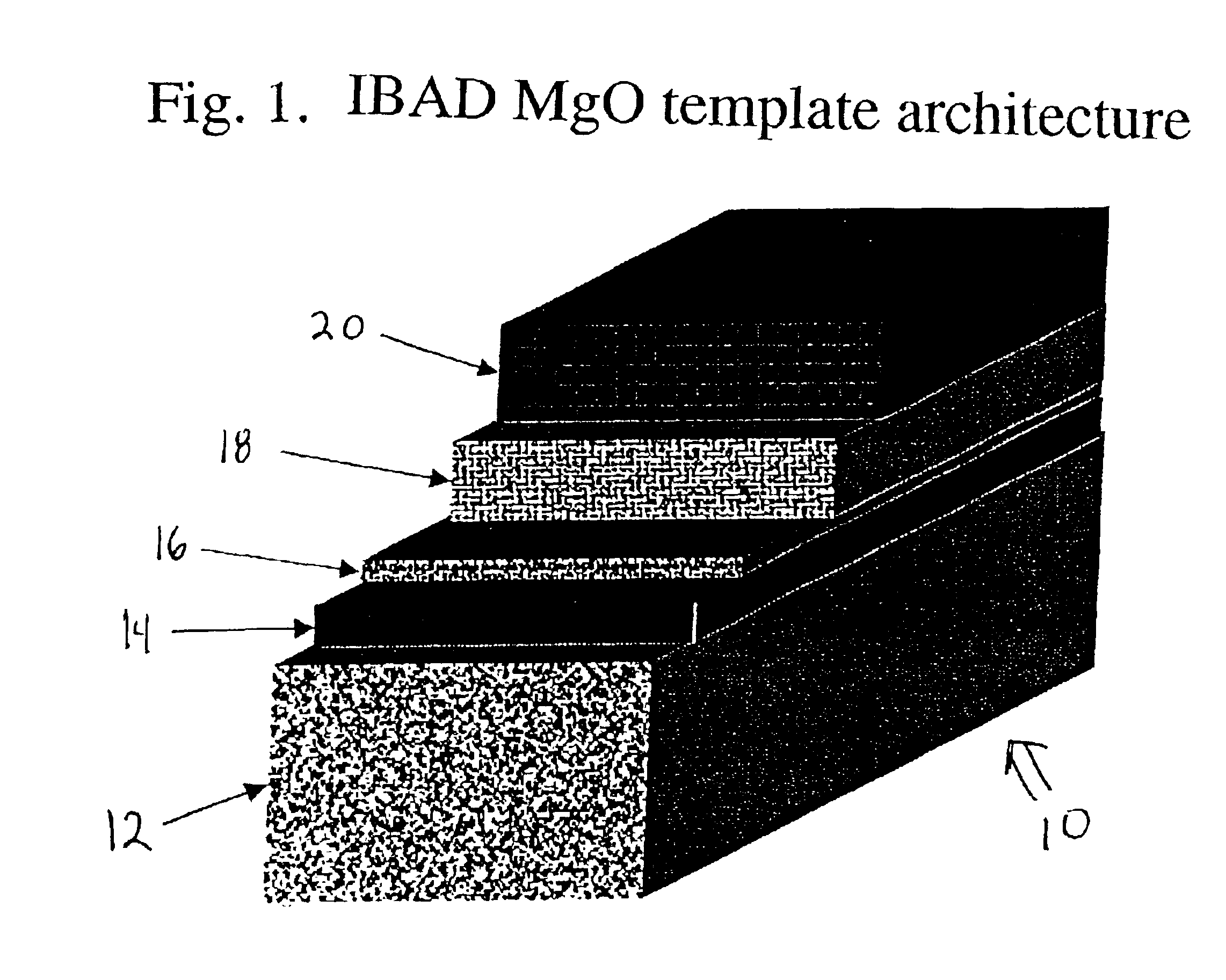

Thin films having rock-salt-like structure deposited on amorphous surfaces

InactiveUS6190752B1Simple technologyLow production costVacuum evaporation coatingSputtering coatingIon beam-assisted depositionOptoelectronics

A thin film of material having a rock-salt-like structure is deposited on a smooth amorphous substrate surface by ion beam assisted deposition.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

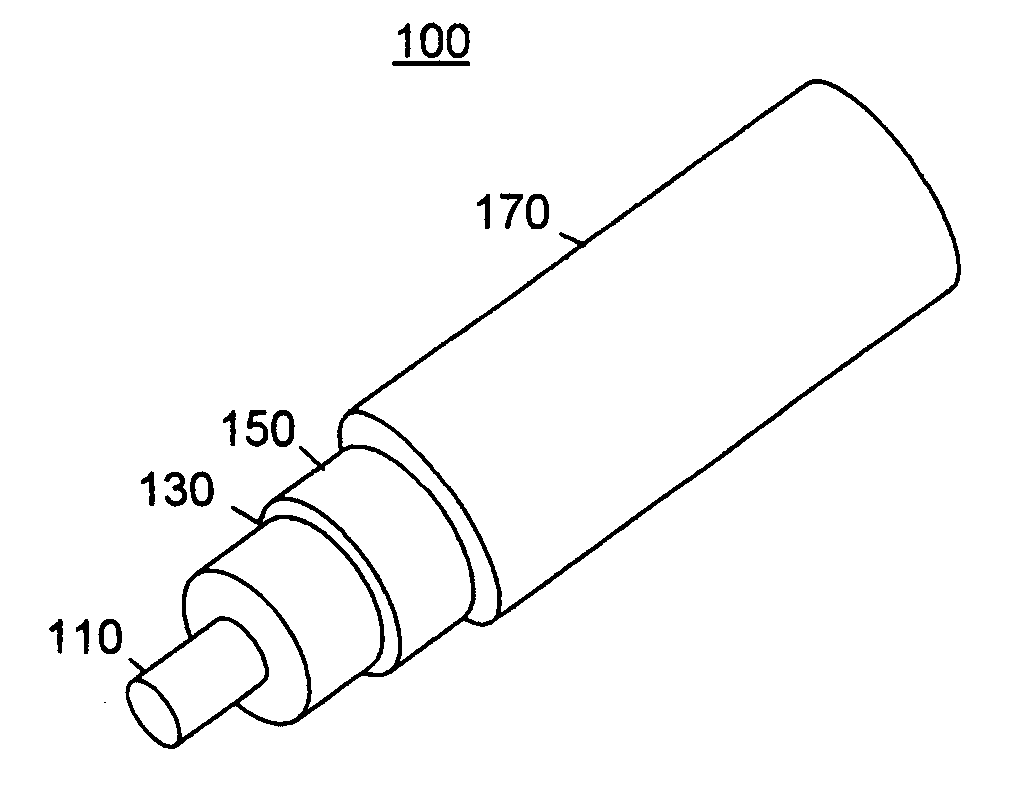

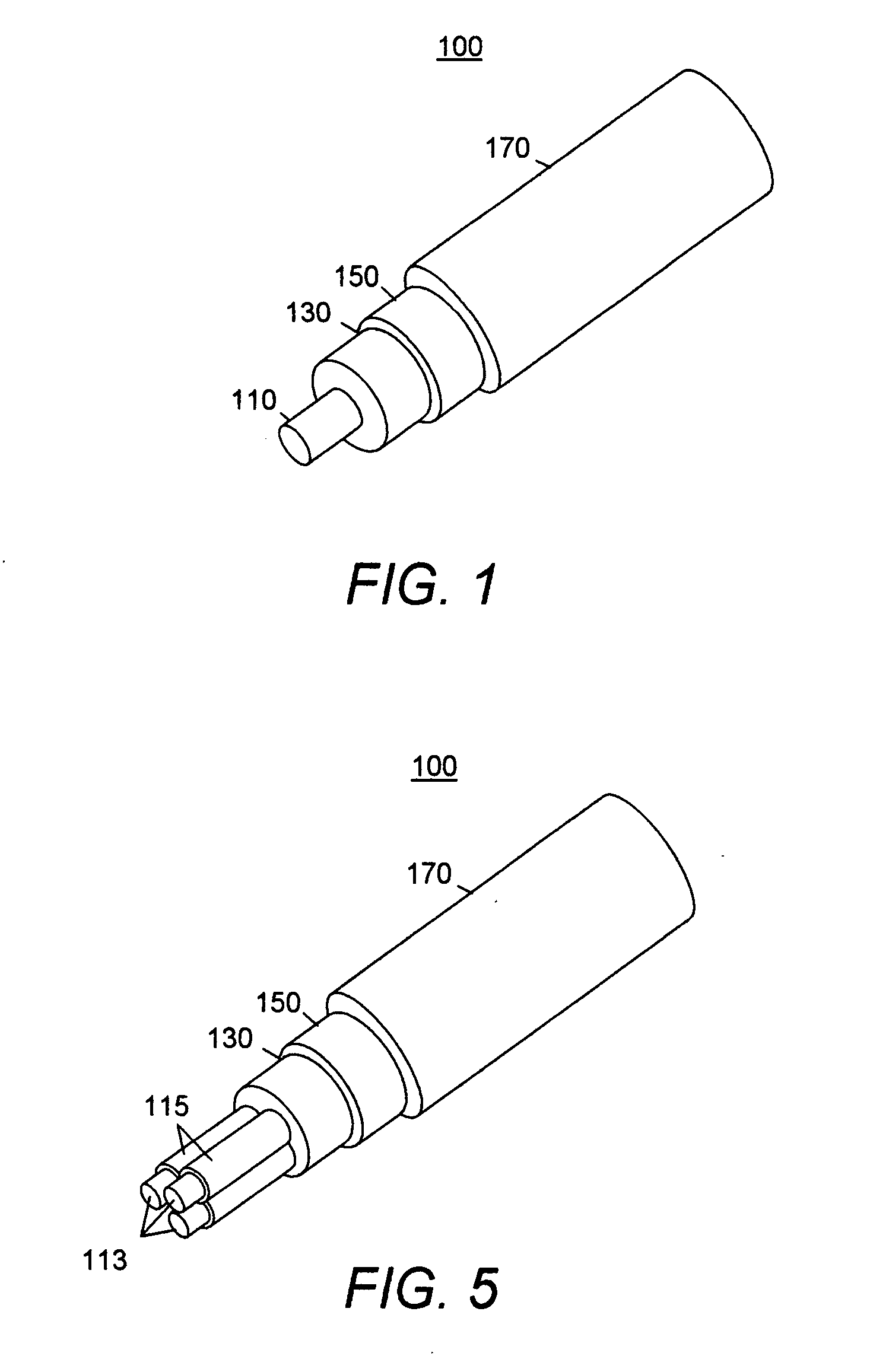

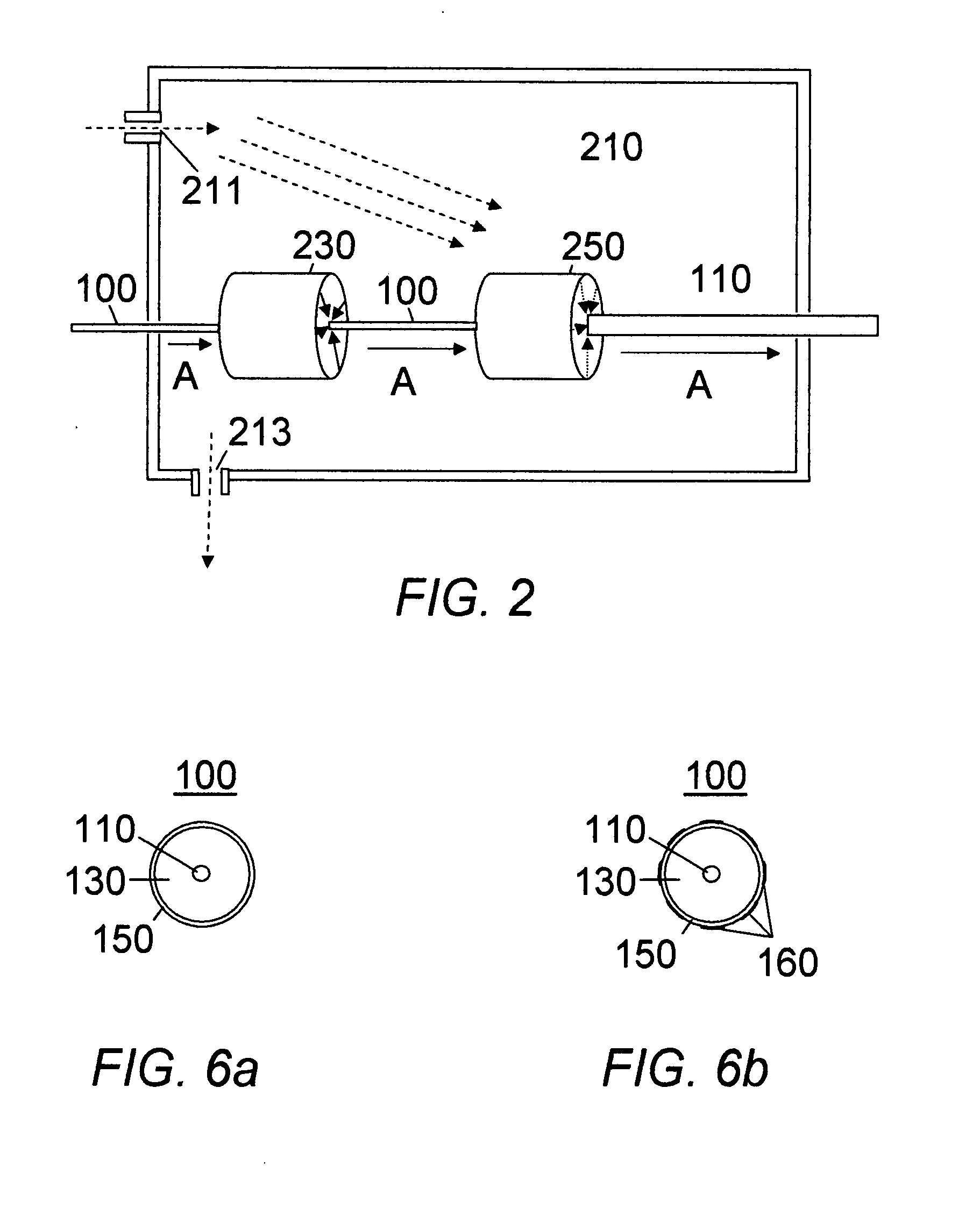

Multi-layer cable design and method of manufacture

InactiveUS20080060832A1Economically manufacturedVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsCathodic arc depositionFiber

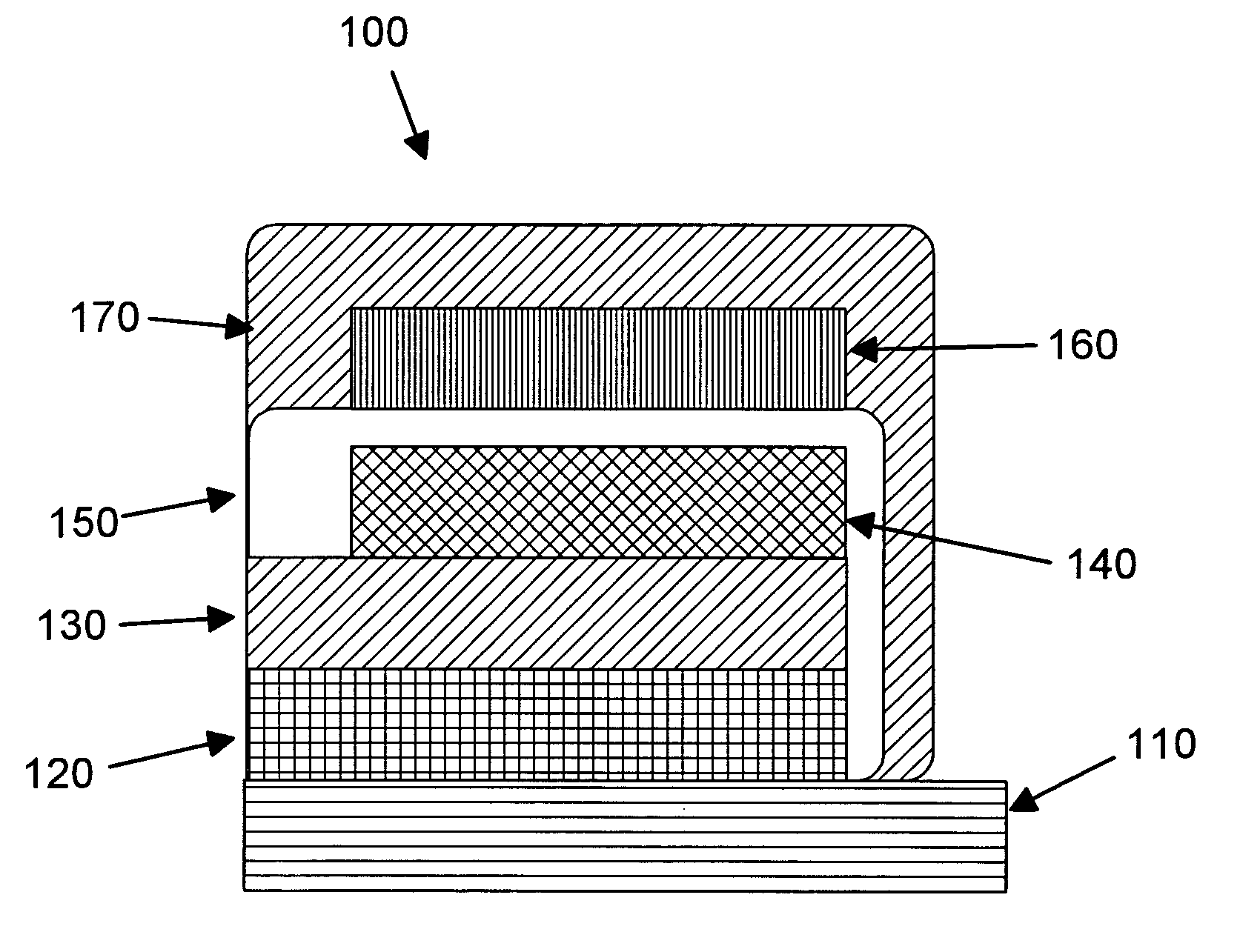

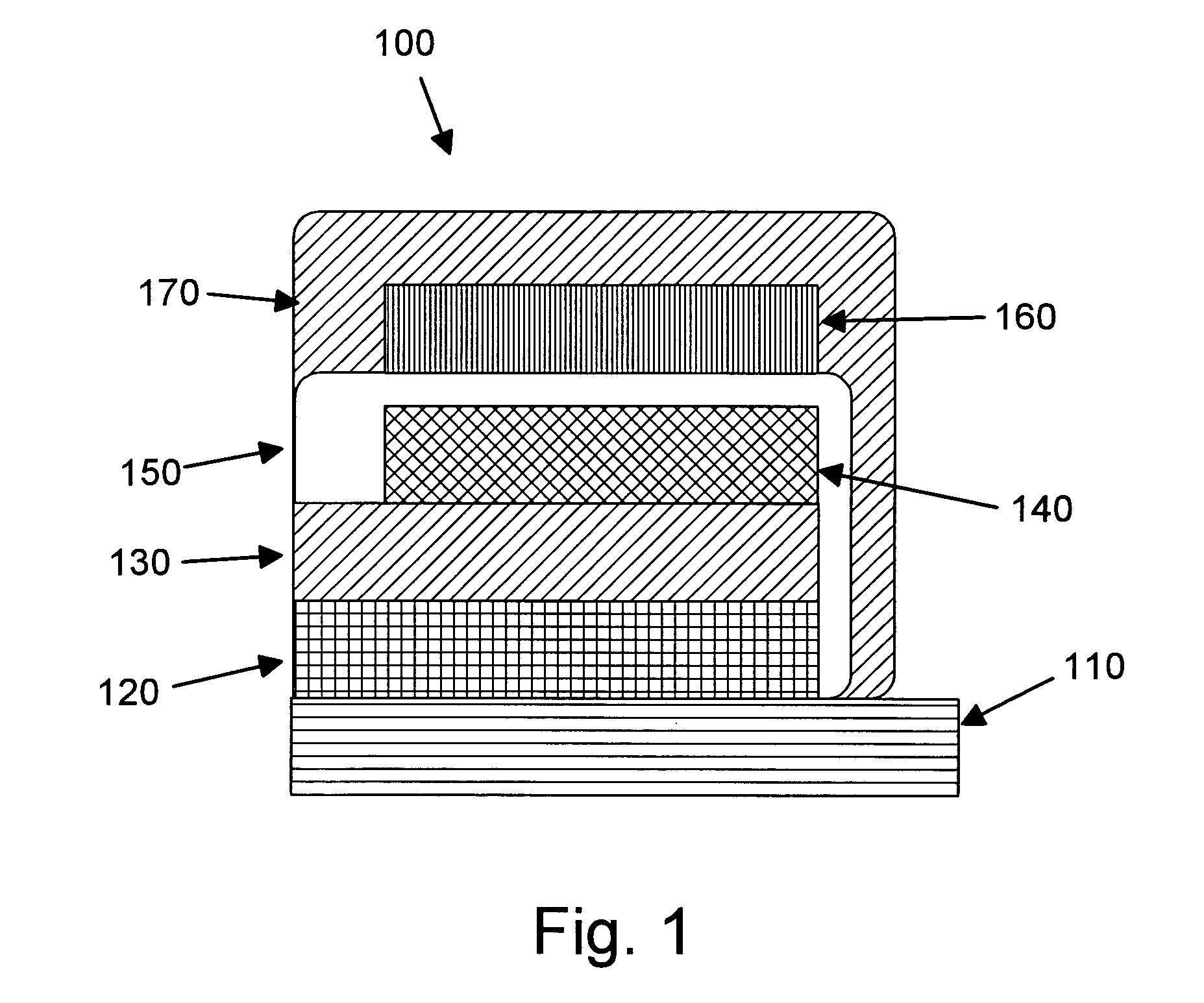

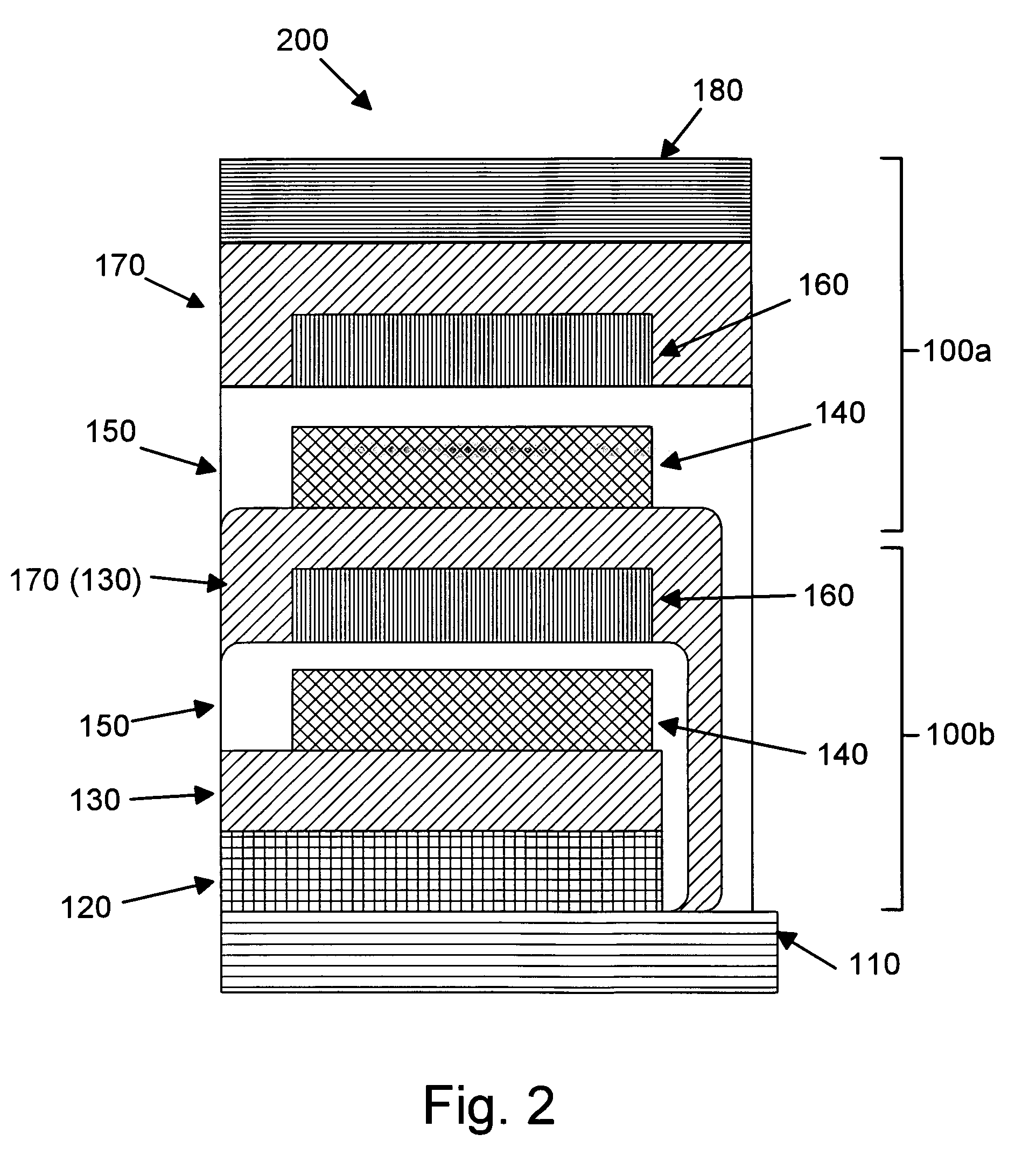

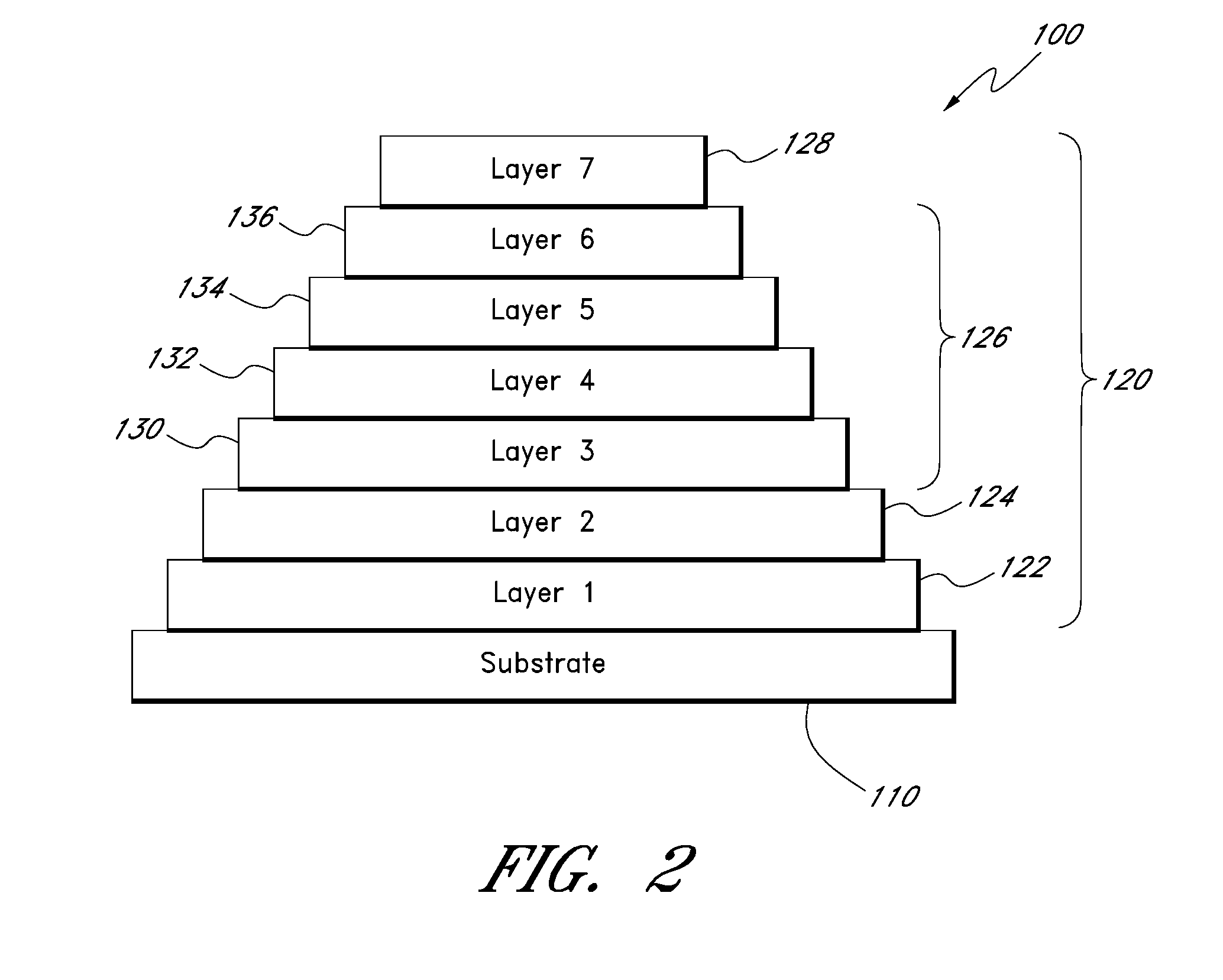

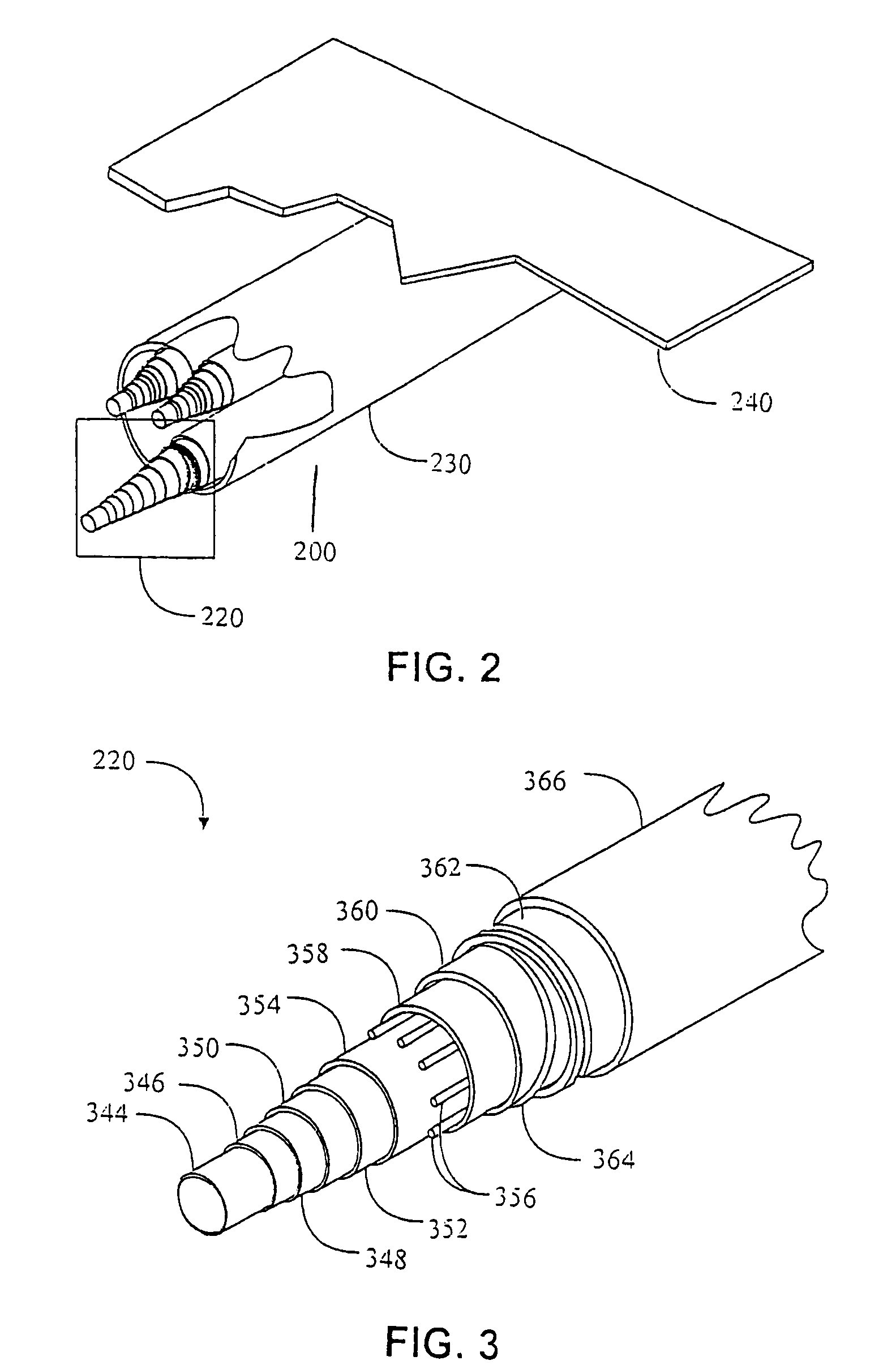

A novel method of designing and fabricating flexible and lightweight cable [100] having a central conductor [110], a dielectric layer [130], an outer conductor [150] and an insulation coating [170] using thin film technology is disclosed. The dielectric layer [130] is ‘grown’ on dielectric layer [130] using electrophoretic deposition to a specified thickness, based upon its intended use. It may include nano-diamonds. Ion beam assisted deposition is used to metalize the cable dielectric layer [130]. This may be ion beam assisted sputtering, ion beam assisted evaporative deposition or ion beam assisted cathodic arc deposition. In an alternative embodiment, the outer conductor may be etched to provide greater flexibility, or to add a piezoelectric layer. The central conductor [110] may be created from dielectric fibers [113] which are metalized as described above. The piezoelectric layer added to create ultrasonic transducer cables.

Owner:RAZAVI ALI

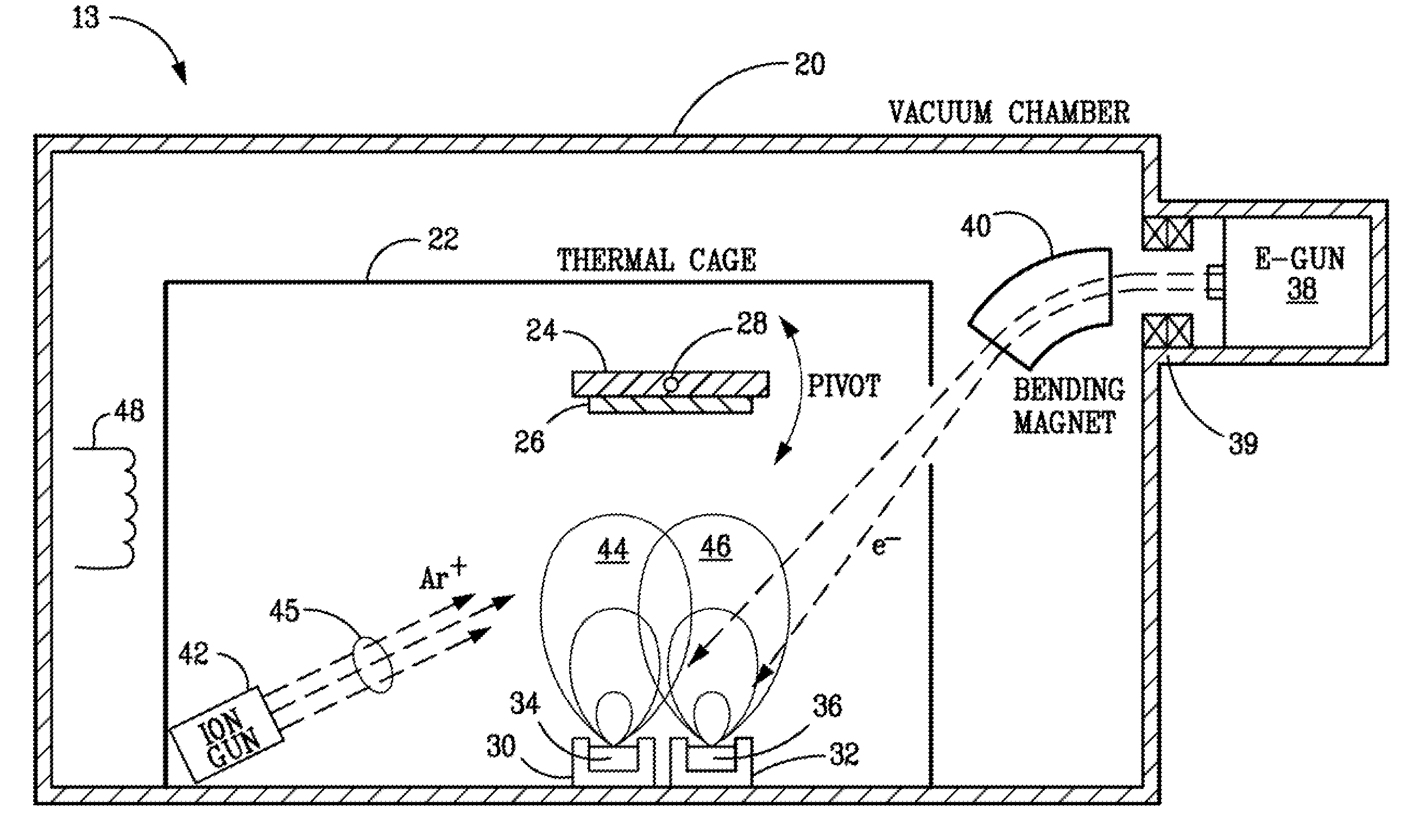

Ion beam assisted deposition of thermal barrier coatings

InactiveUS7838083B1Engine manufactureVacuum evaporation coatingElectron beam physical vapor depositionIon beam-assisted deposition

Methods and apparatus for depositing thermal barrier coatings on gas turbine blades and vanes using Electron Beam Physical Vapor Deposition (EBPVD) combined with Ion Beam Assisted Deposition (IBAD).

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

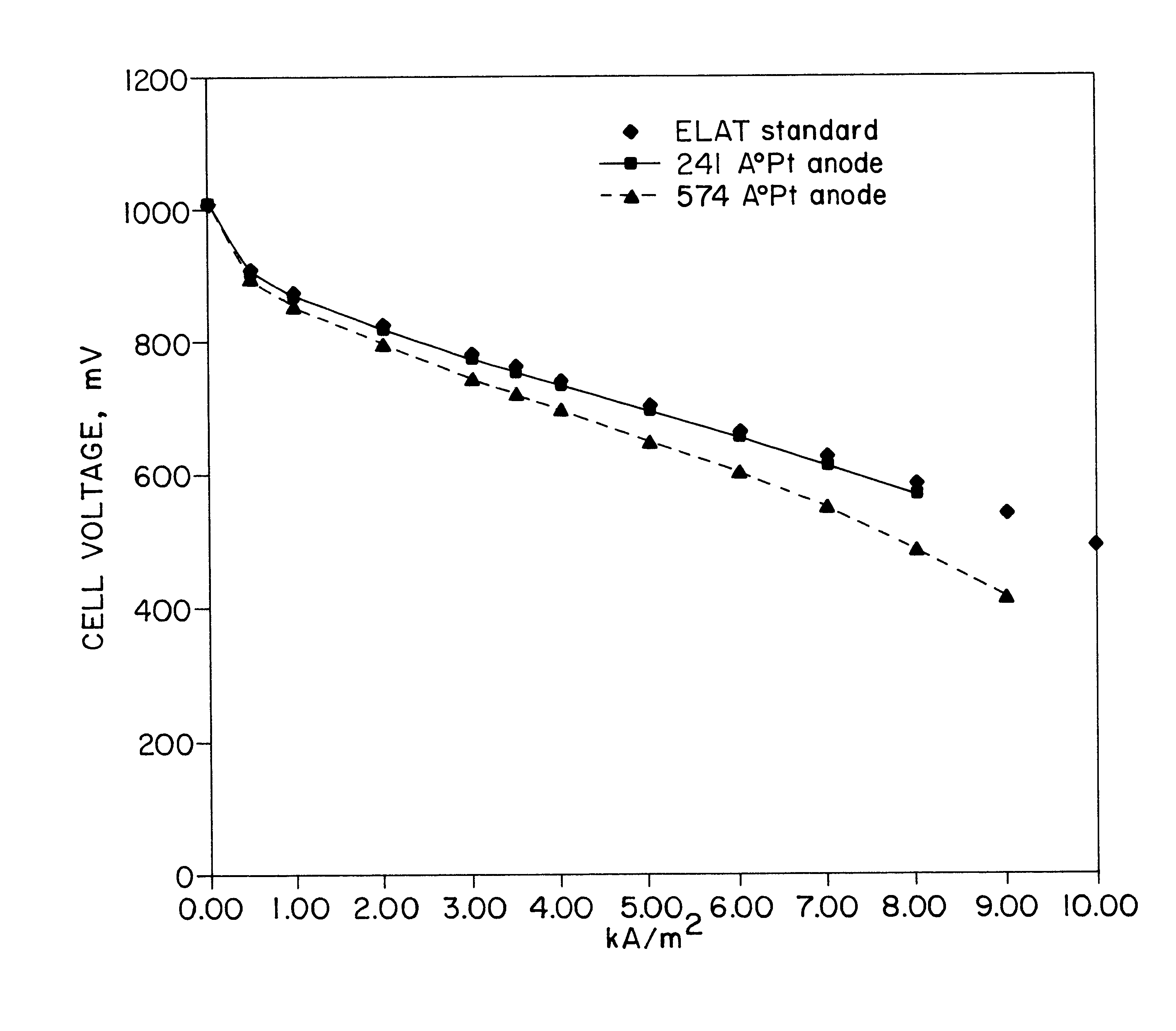

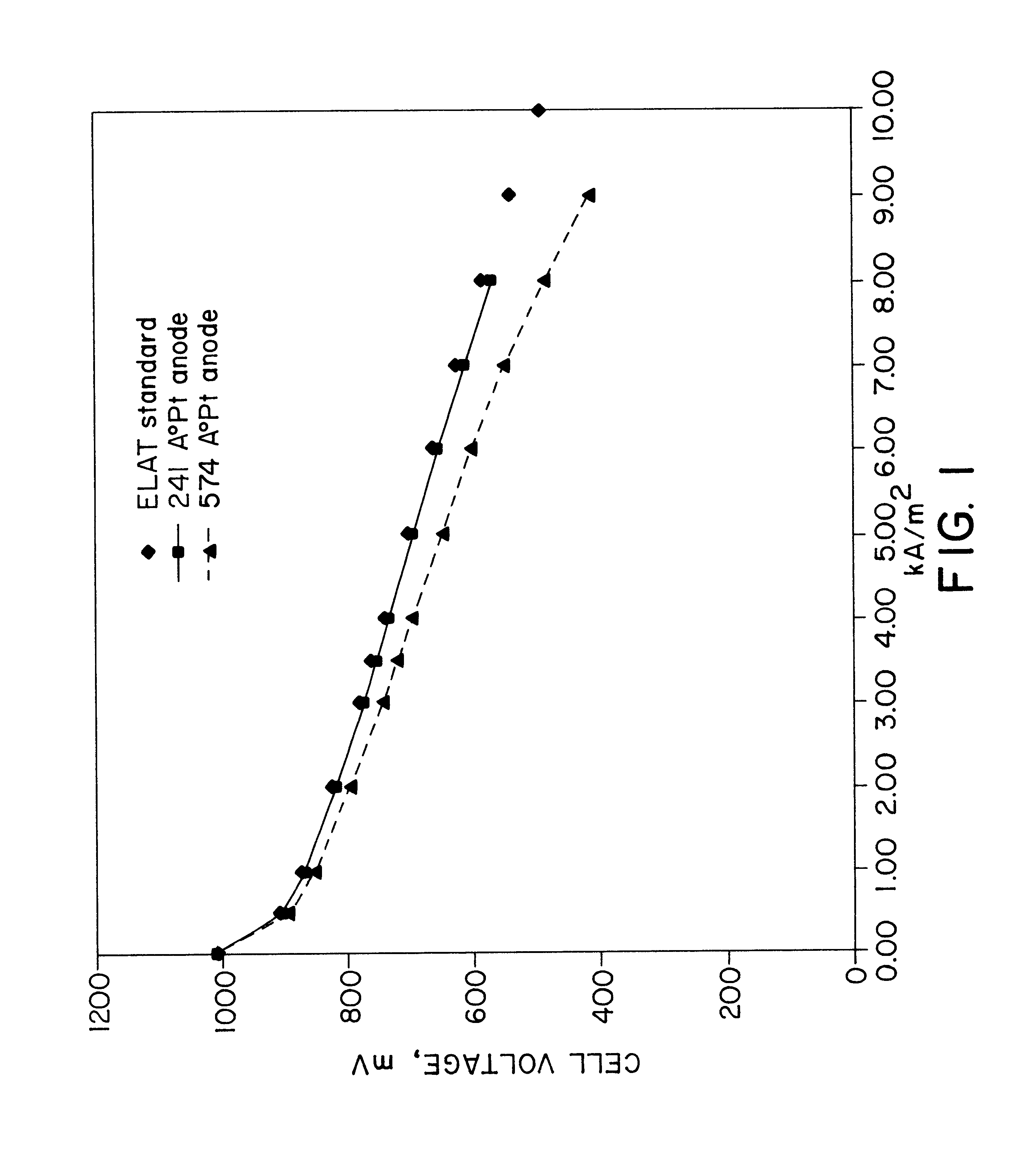

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

An ion beam-assisted deposition process for preparing a membrane-electrode structure is described wherein a layer of liquid ionomer is applied to the surface of a carbon cloth gas diffusion electrode structure. The coated structure is heated to form an ionomer film on the cloth electrode and the resulting structure is treated with a metal or metal oxide ion-beam having an energy between 500-2000 eV. The process forms a carbon cloth supported metal or a carbon metal oxide ionomer film membrane-electrode structure.

Owner:BASF FUEL CELL

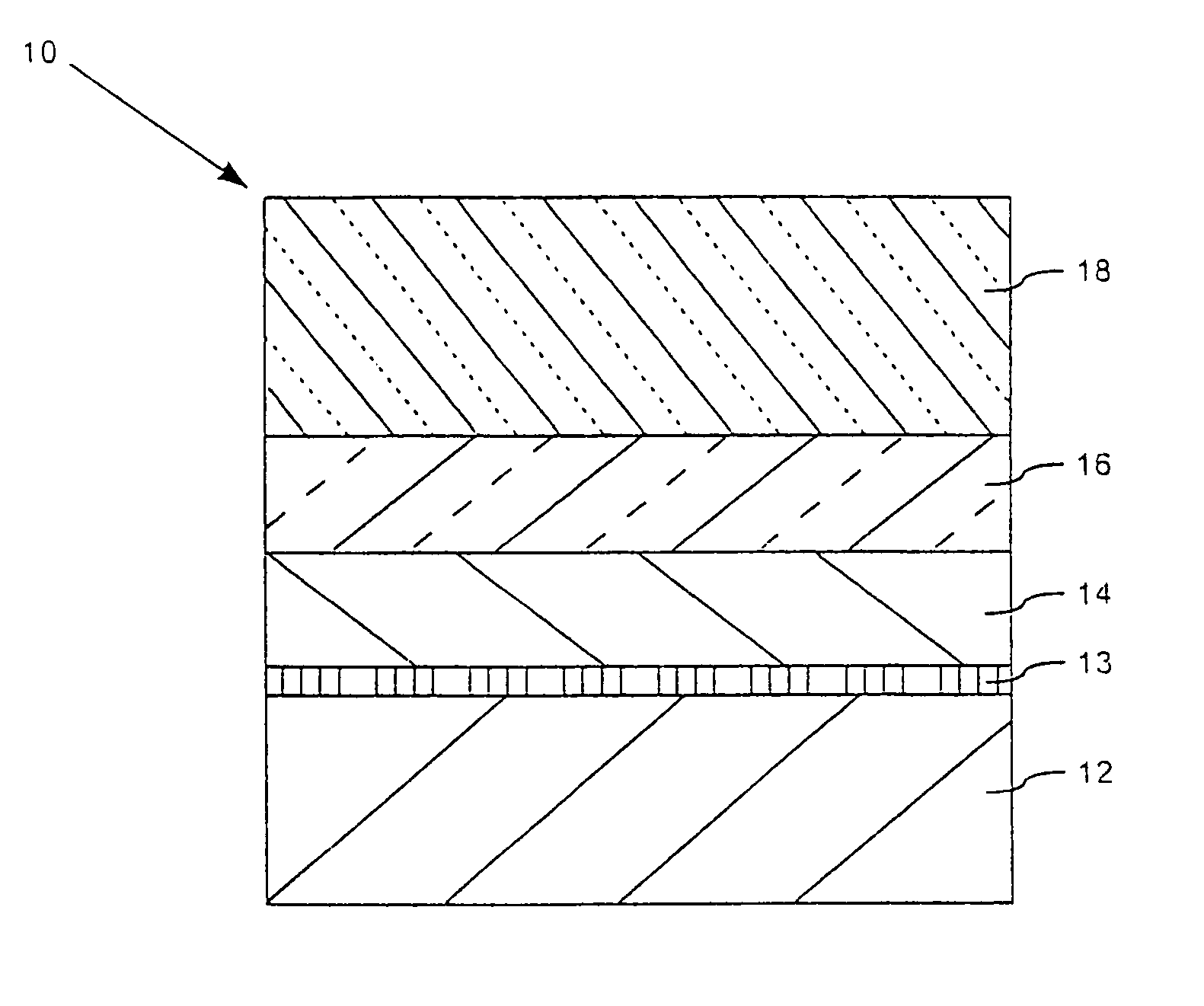

Implantable microelectronic device and method of manufacture

InactiveUS20070096281A1Lateral dimension be relatively largeElectrotherapySemiconductor/solid-state device detailsContact padTitanium

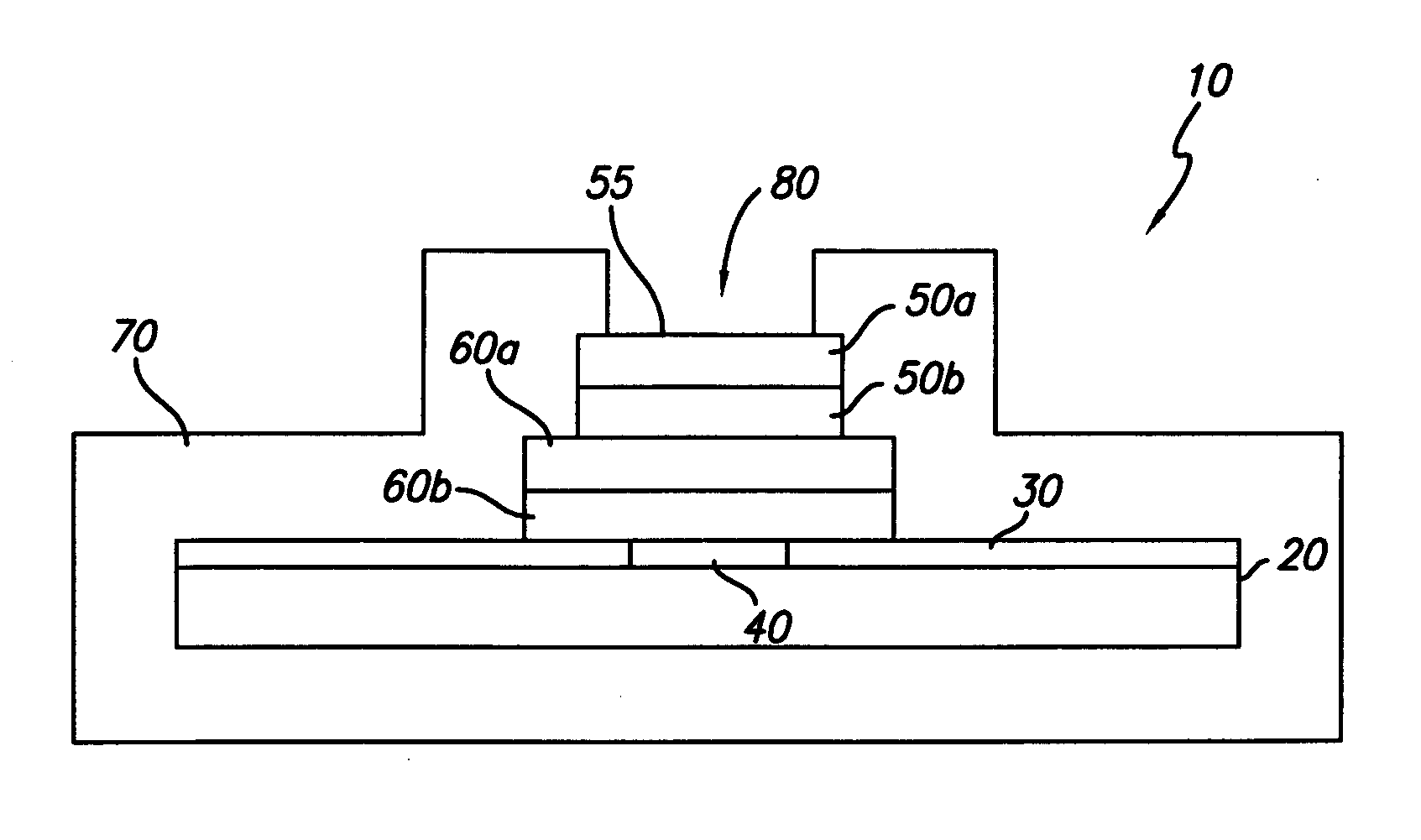

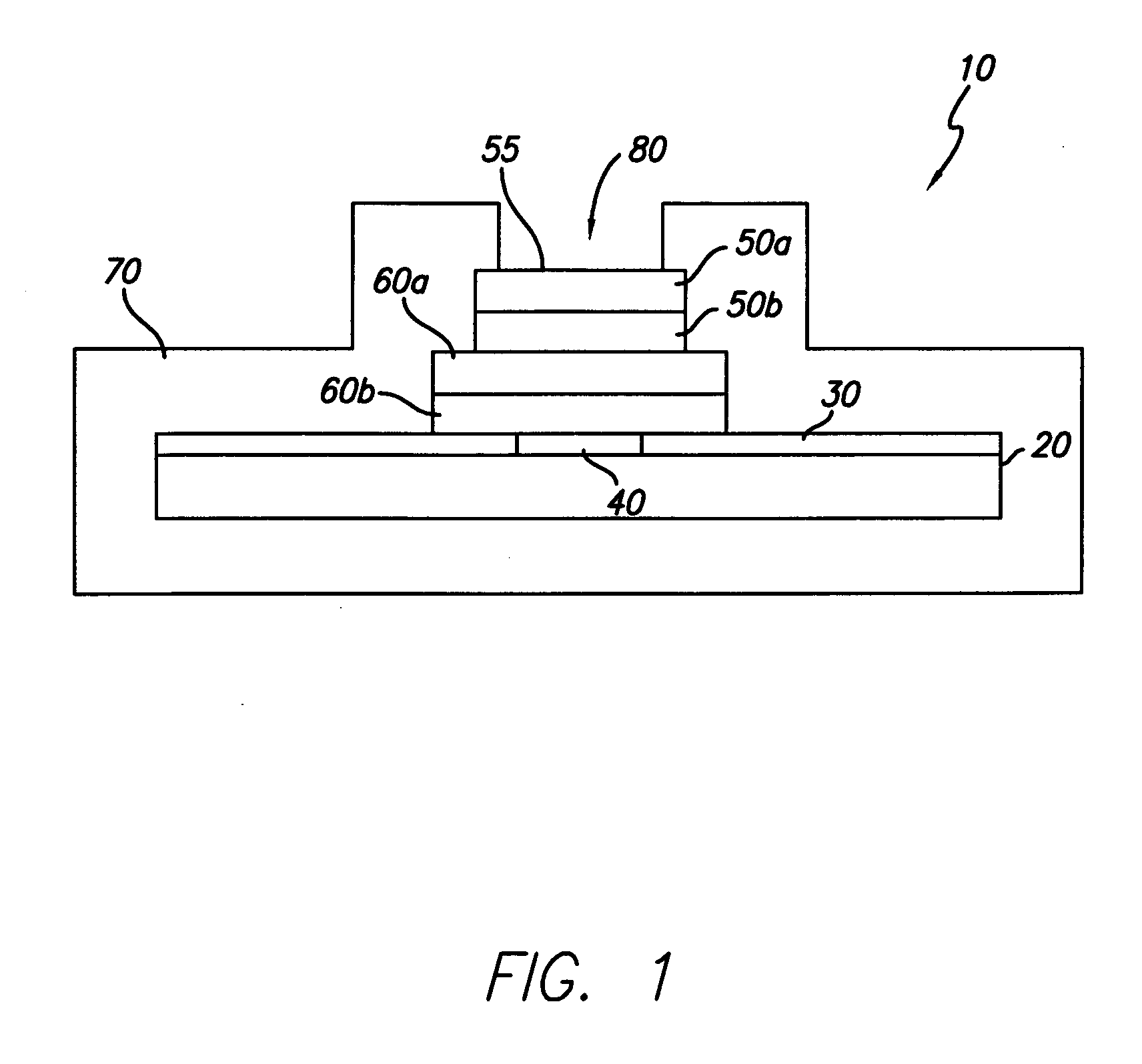

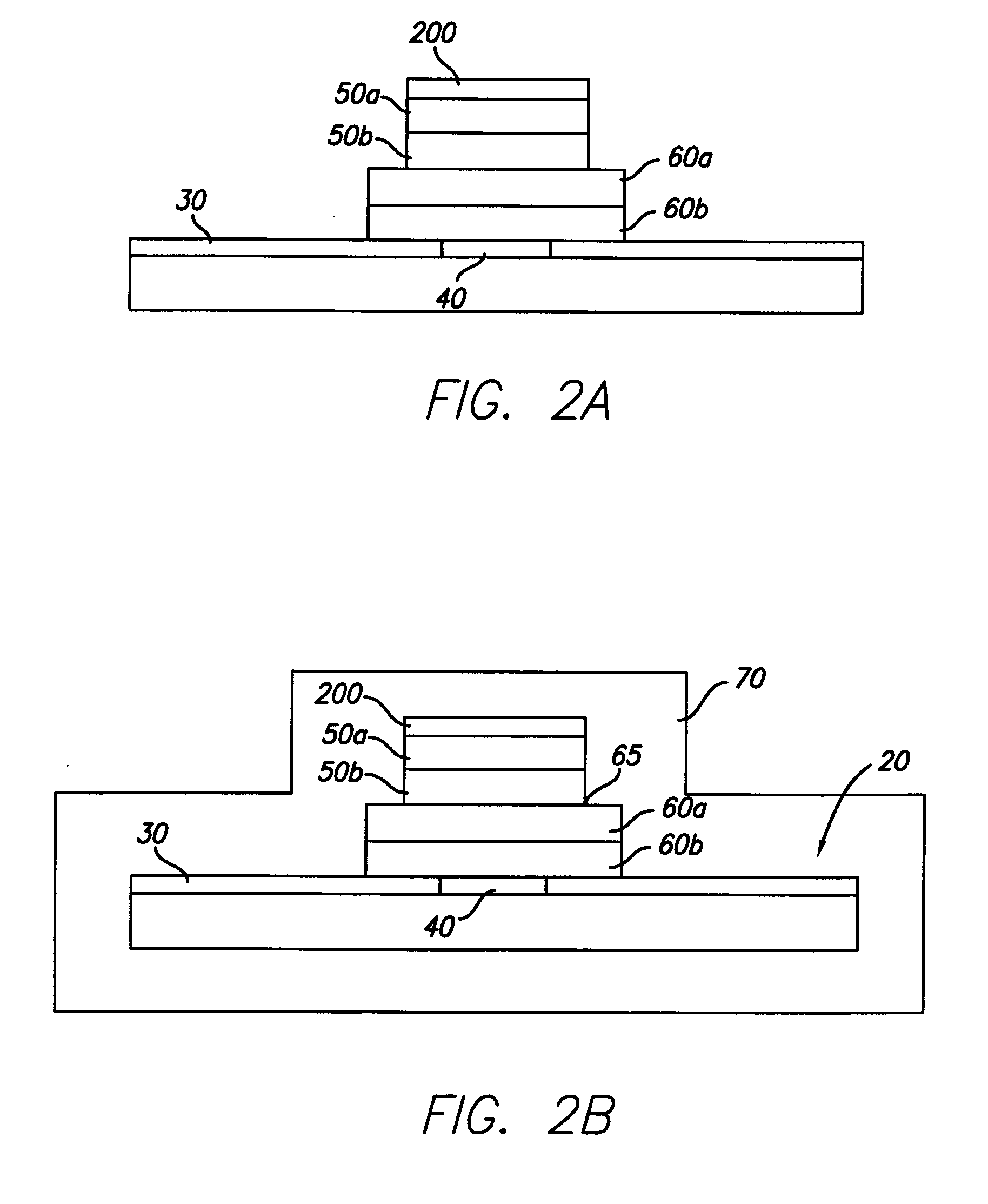

An implantable hermetically sealed microelectronic device, and method of manufacture are disclosed. The microelectronic device of the present invention is hermetically encased in a insulator, such as alumina formed by ion bean assisted deposition (“IBAD”), with a stack of biocompatible conductive layers extending from a contact pad on the device to an aperture in the hermetic layer. In a preferred embodiment, one or more patterned titanium layers are formed over the device contact pad, and one or more platinum layers are formed over the titanium layers, such that the top surface of the upper platinum layer defines an external, biocompatible electrical contact for the device. Preferably, the bottom conductive layer is larger than the contact pad on the device, and a layer in the stack defines a shoulder.

Owner:SECOND SIGHT MEDICAL PRODS

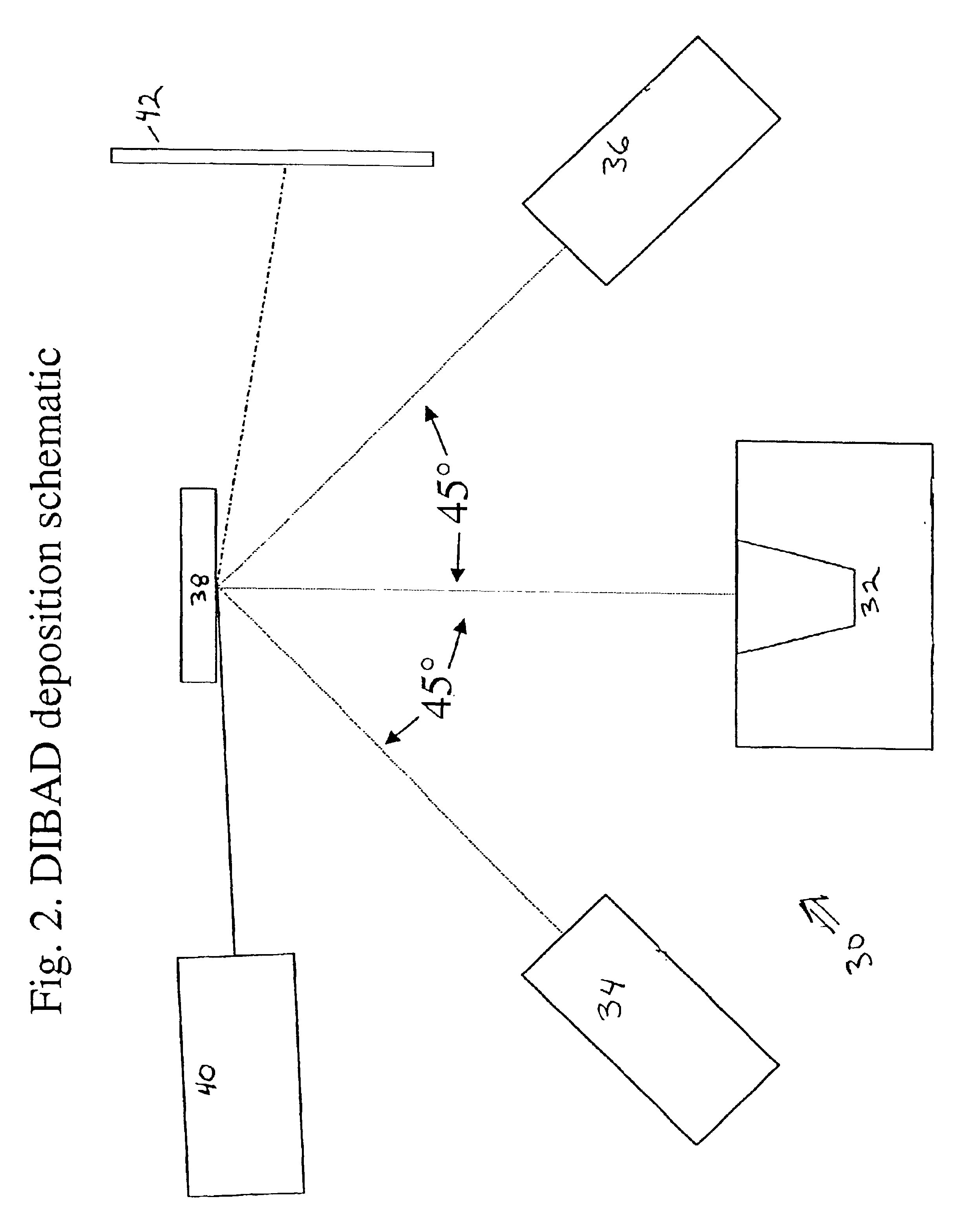

Dual ion beam assisted deposition of biaxially textured template layers

InactiveUS6899928B1Polycrystalline material growthVacuum evaporation coatingIon beam-assisted depositionMetal substrate

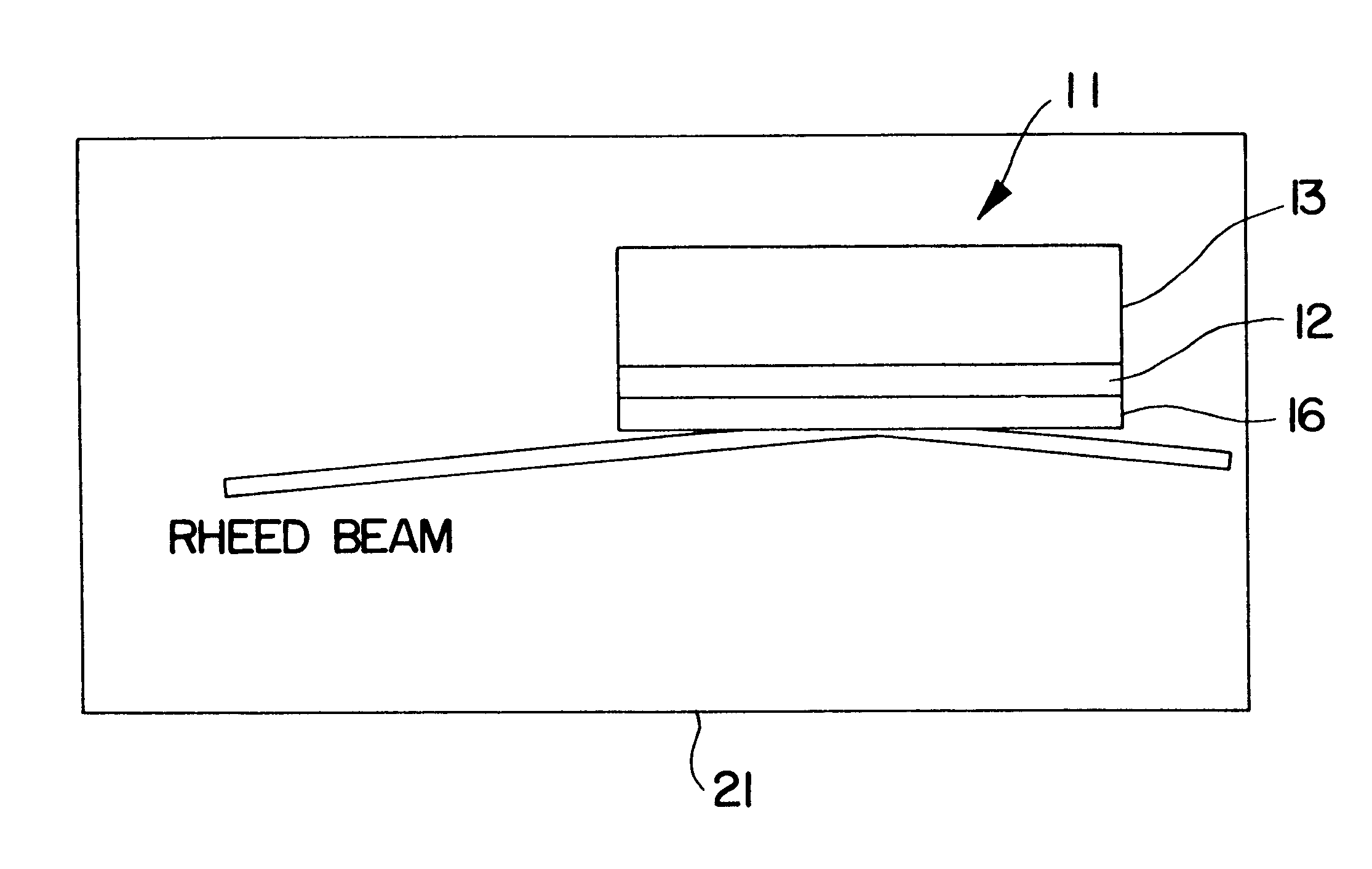

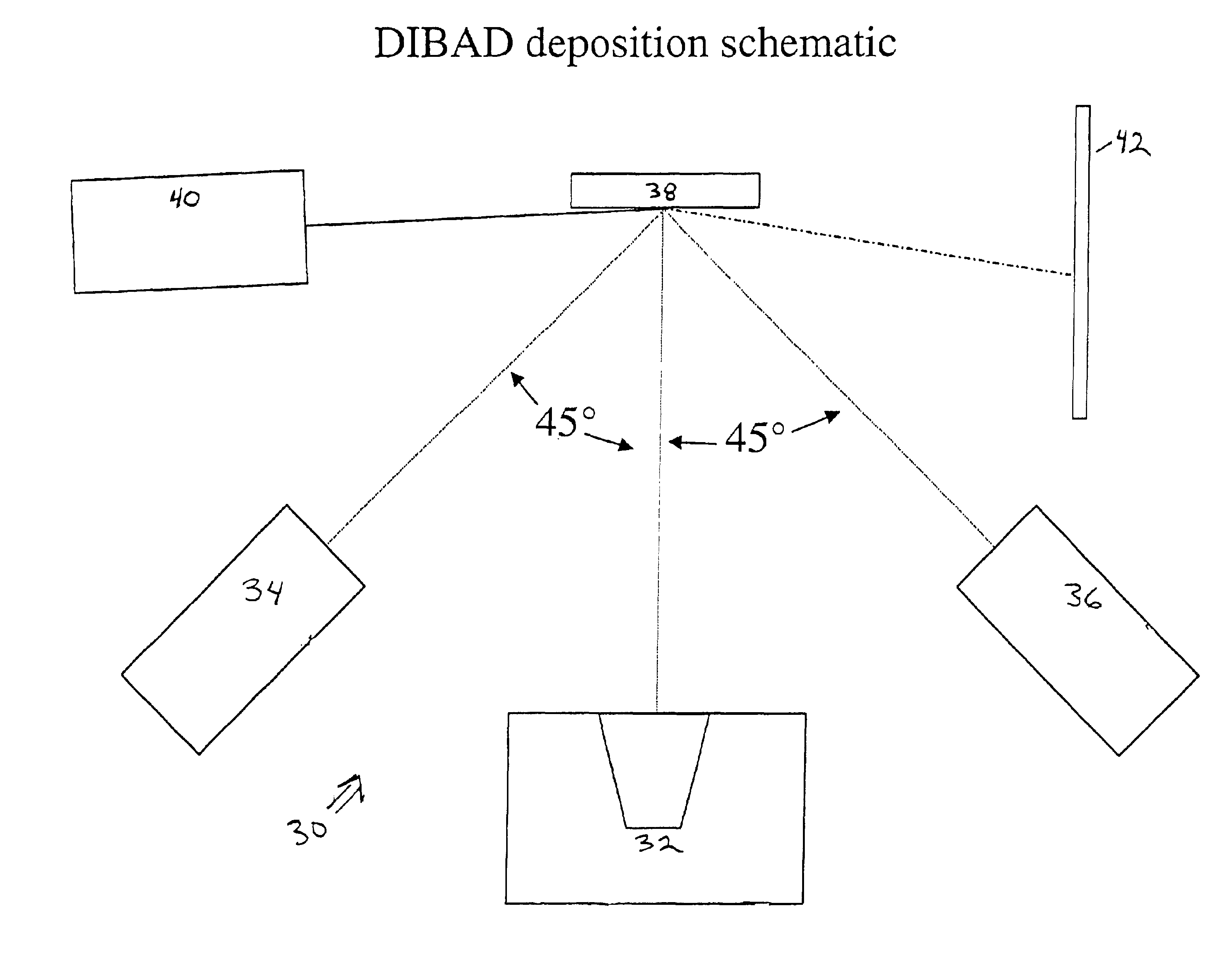

The present invention is directed towards a process and apparatus for epitaxial deposition of a material, e.g., a layer of MgO, onto a substrate such as a flexible metal substrate, using dual ion beams for the ion beam assisted deposition whereby thick layers can be deposited without degradation of the desired properties by the material. The ability to deposit thicker layers without loss of properties provides a significantly broader deposition window for the process.

Owner:LOS ALAMOS NATIONAL SECURITY

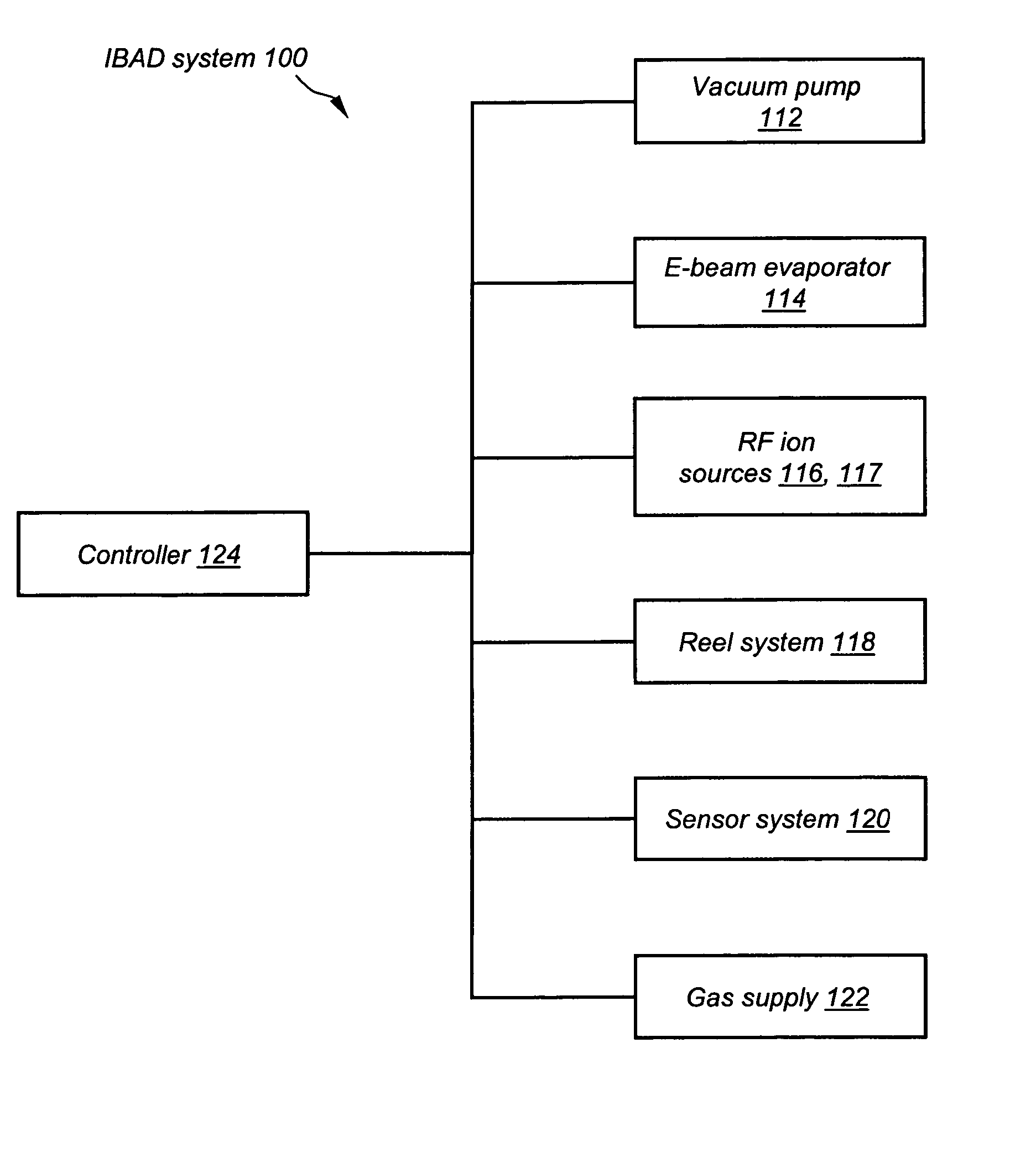

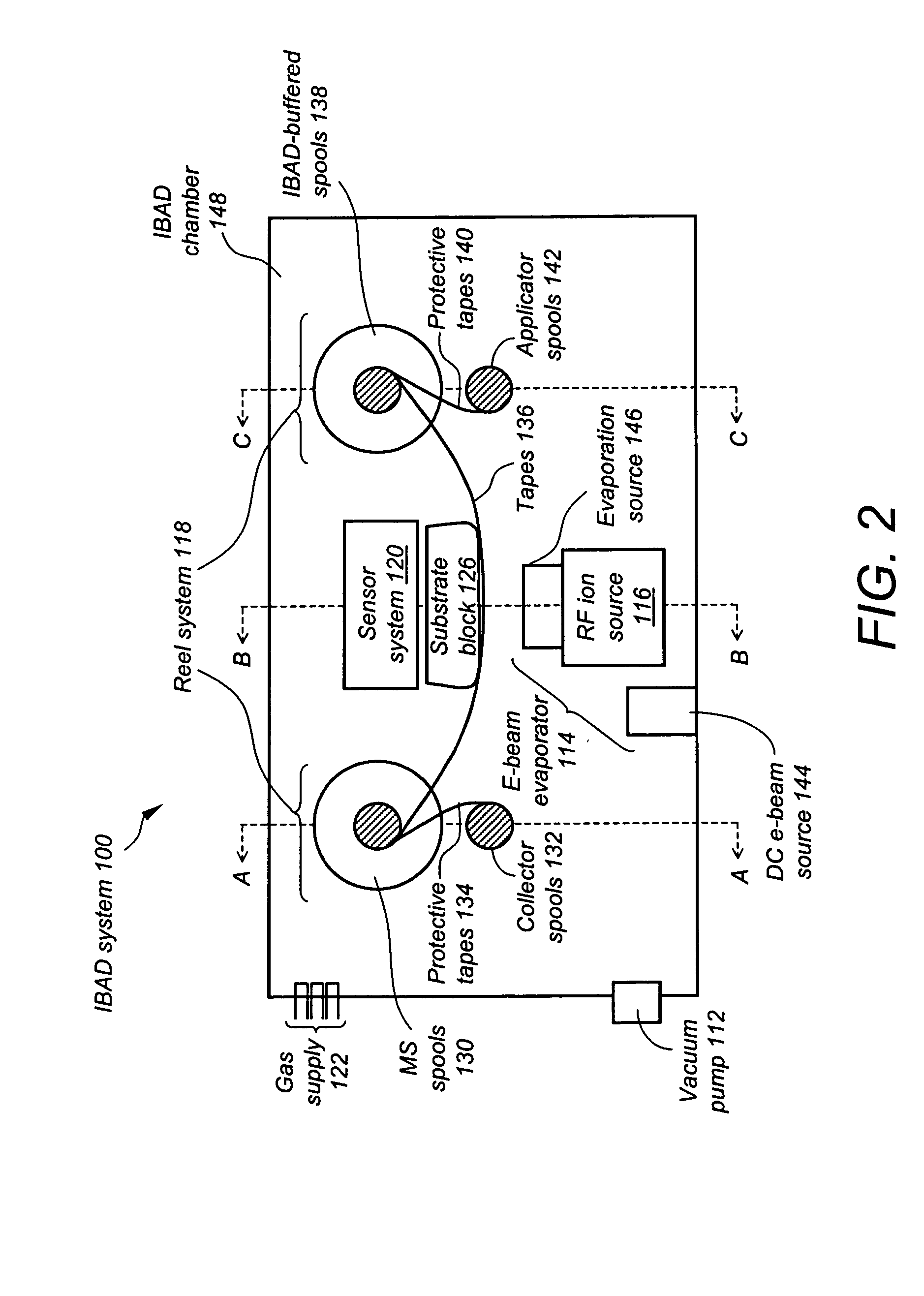

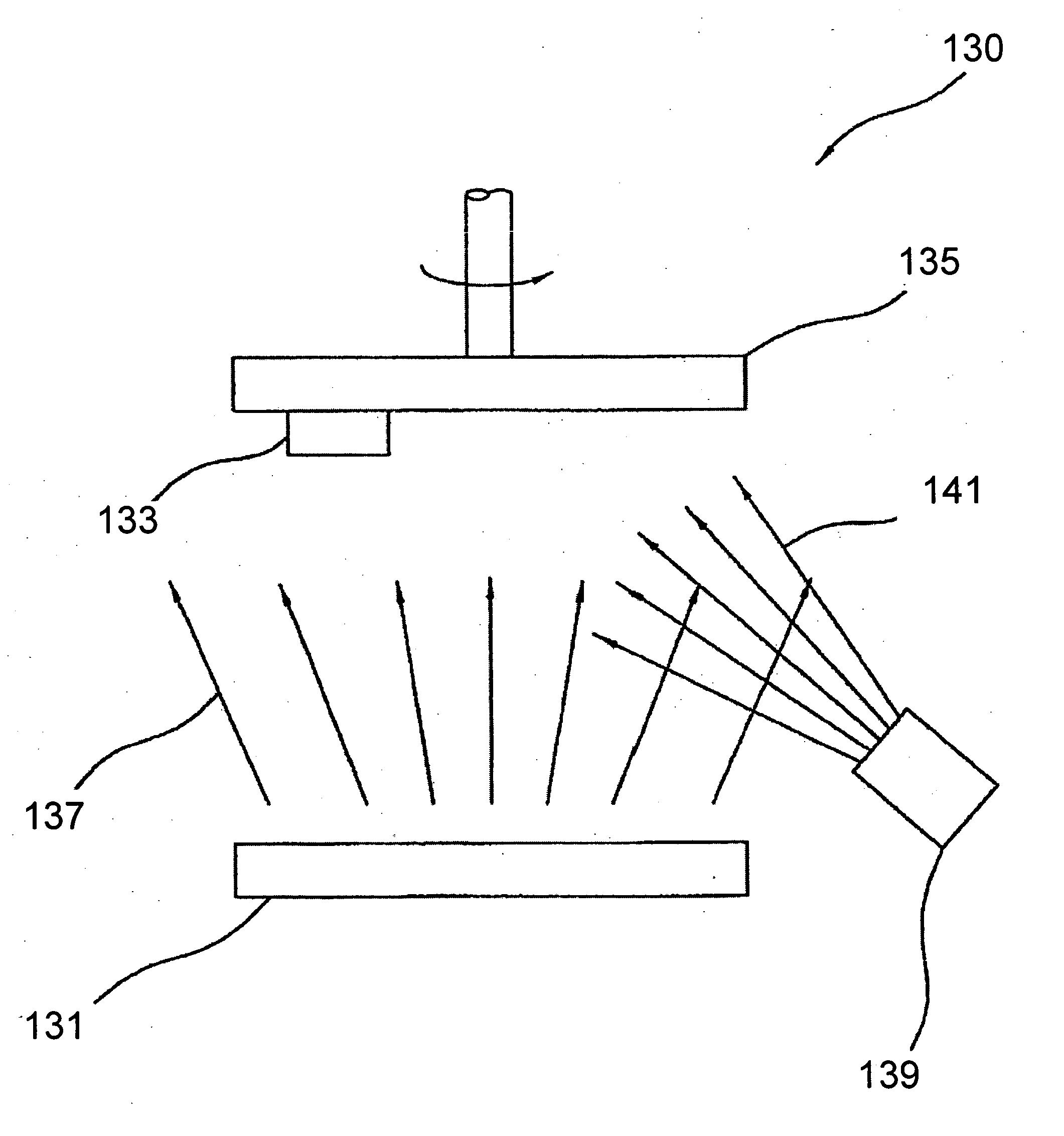

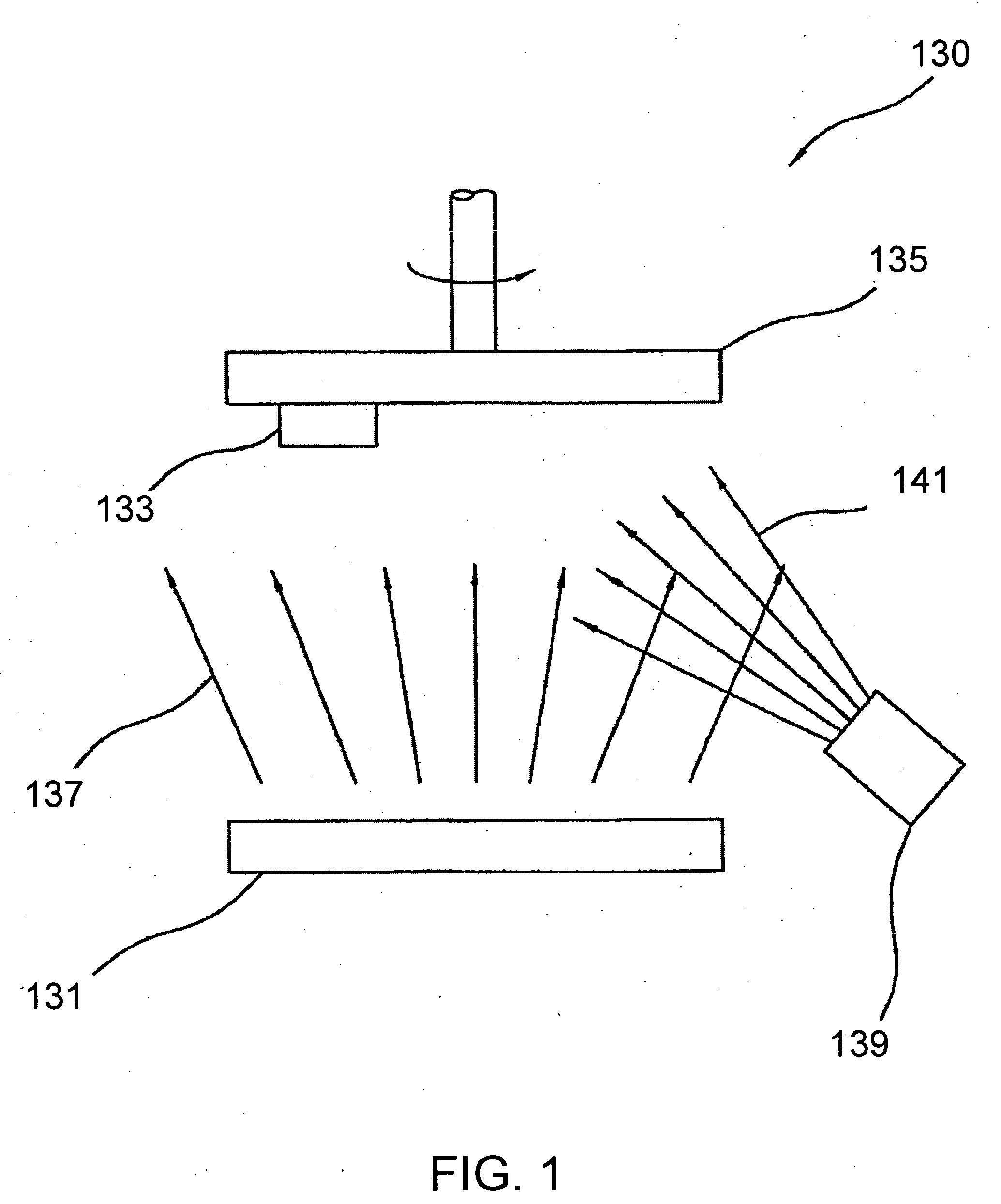

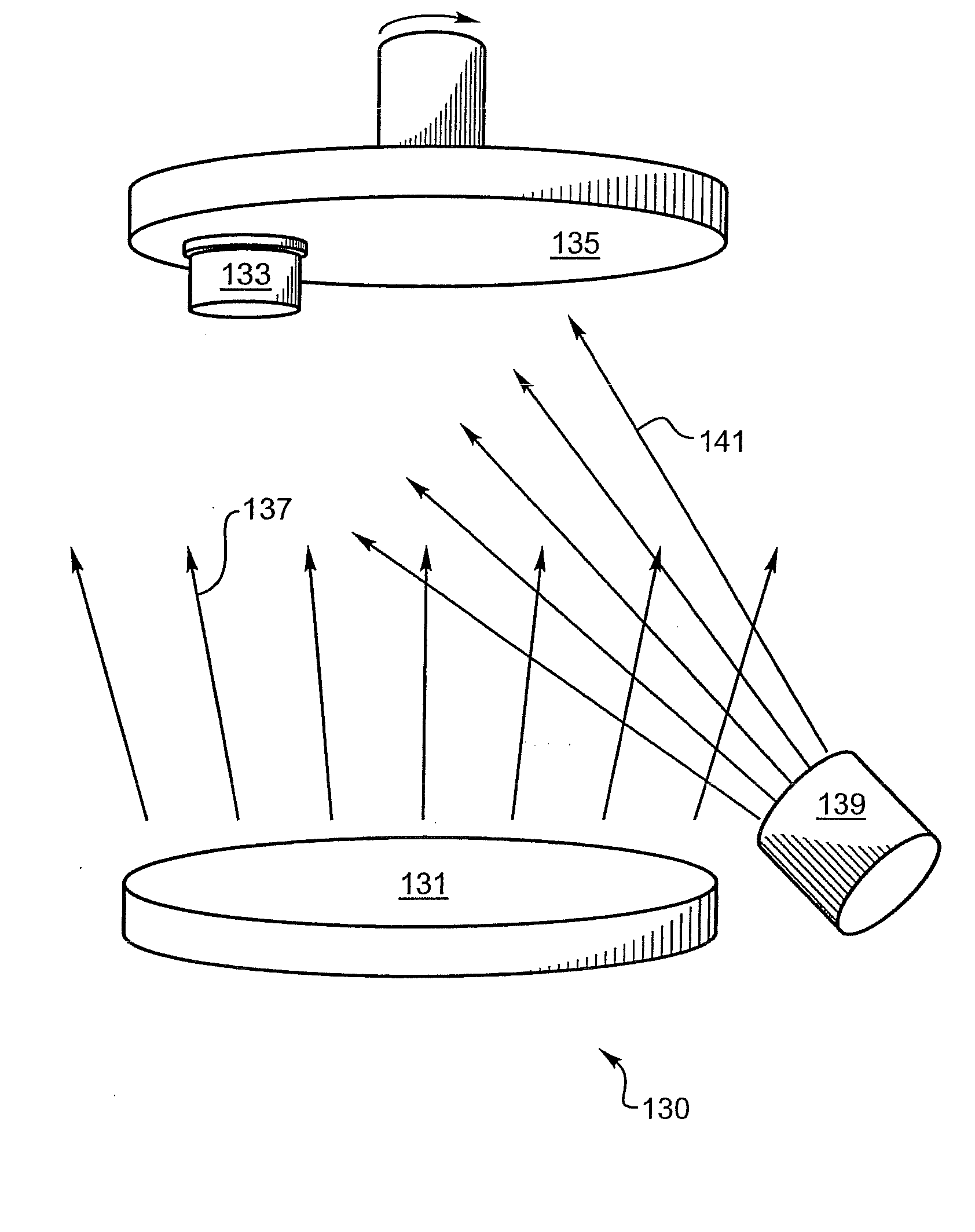

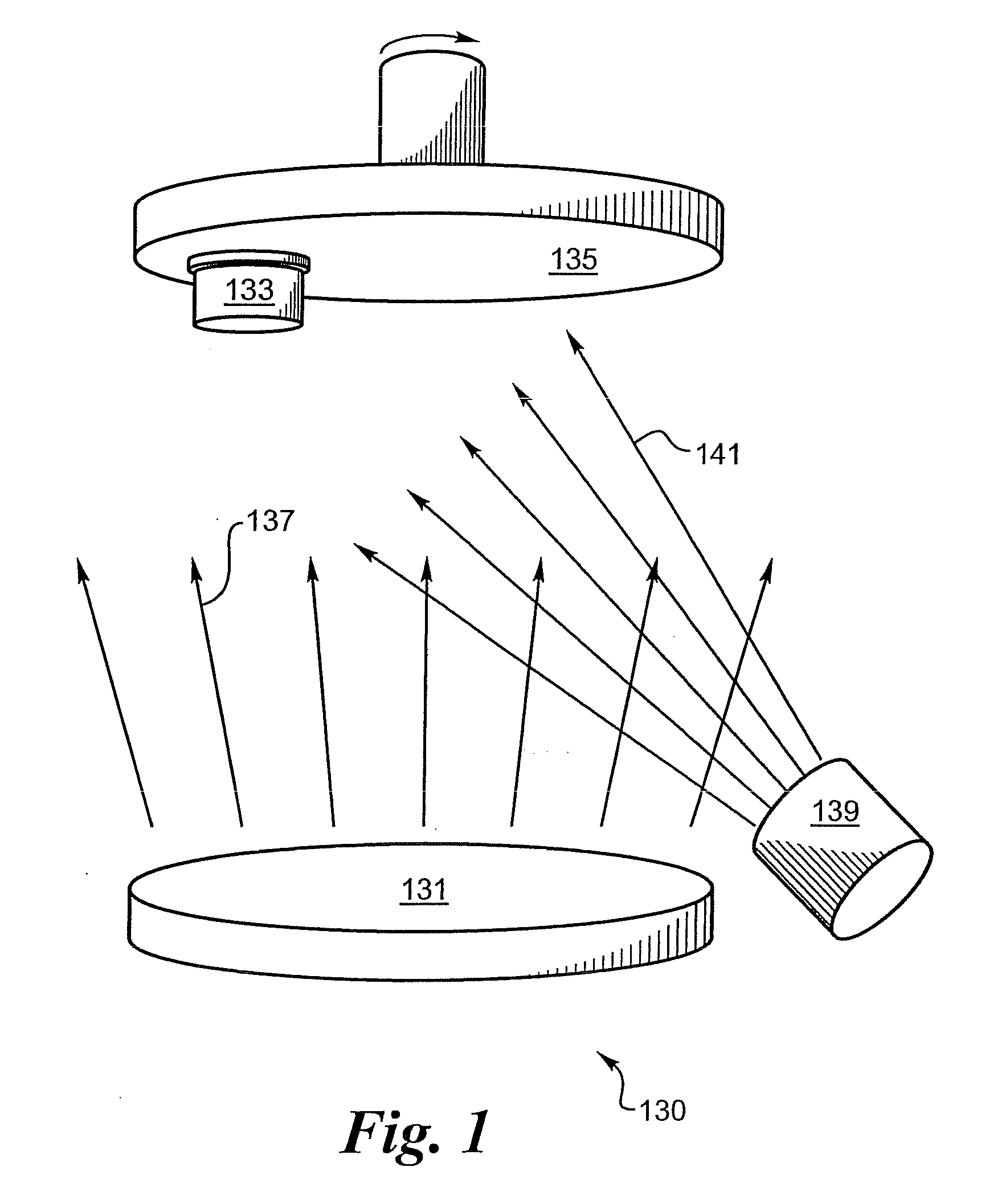

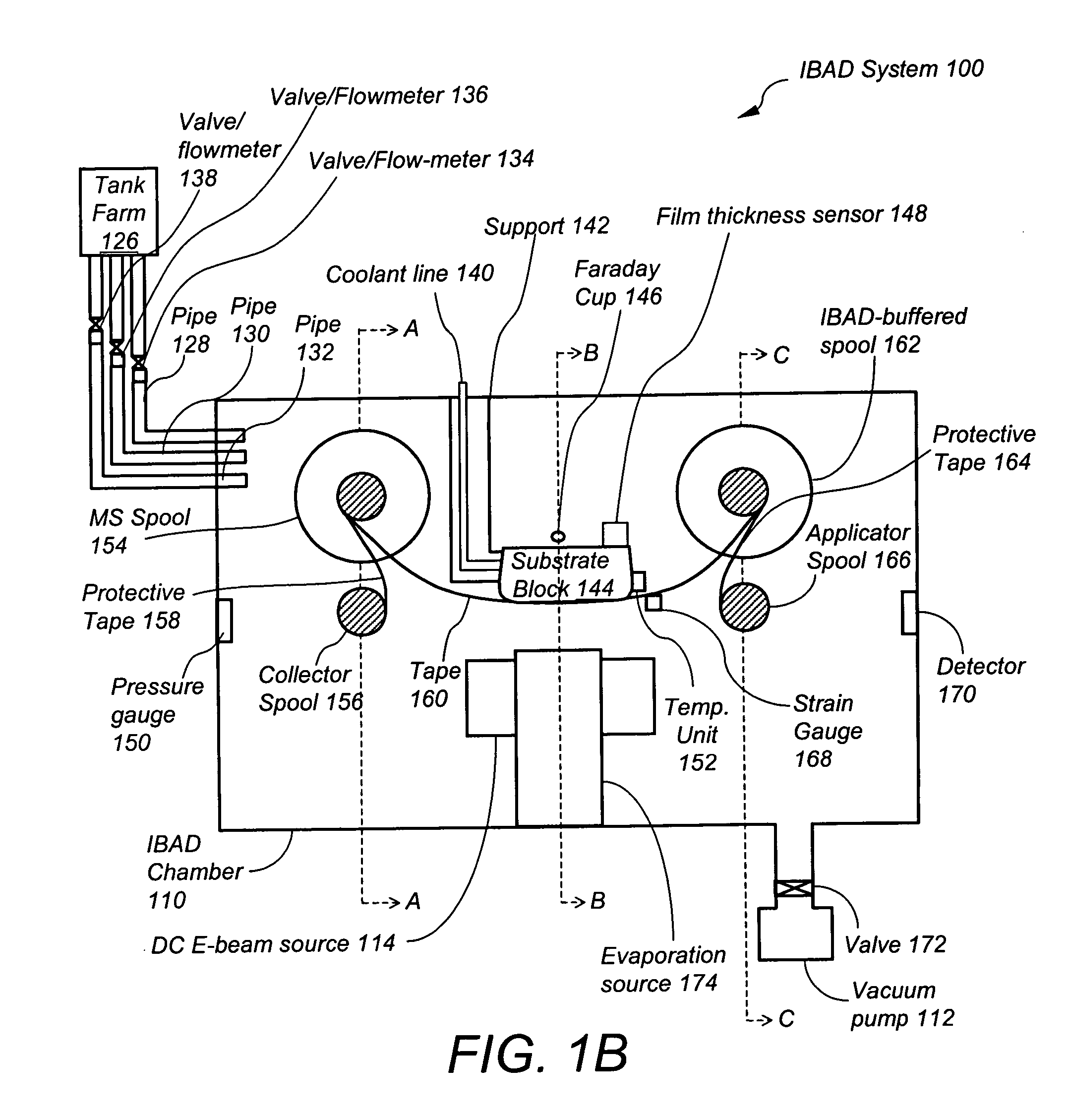

Apparatus for high-throughput ion beam-assisted deposition (IBAD)

Disclosed is an ion beam-assisted deposition system that includes a bi-lateral RF ion source system that, when used in conjunction with an electron beam, magnetron or ion beam evaporator assembly, creates a deposition zone of sufficient width to enable simultaneous deposition onto a plurality of parallel-arranged translating metal substrate tapes. The arrangement of the bilateral RF ion source is such that a pair of RF ion sources is arranged on opposite sides of an evaporation source in such a manner that a pair of ion beams is directed toward a translating set of parallel-arranged substrate tapes at incident angles of, for example, 55 degrees.

Owner:SUPERPOWER INC

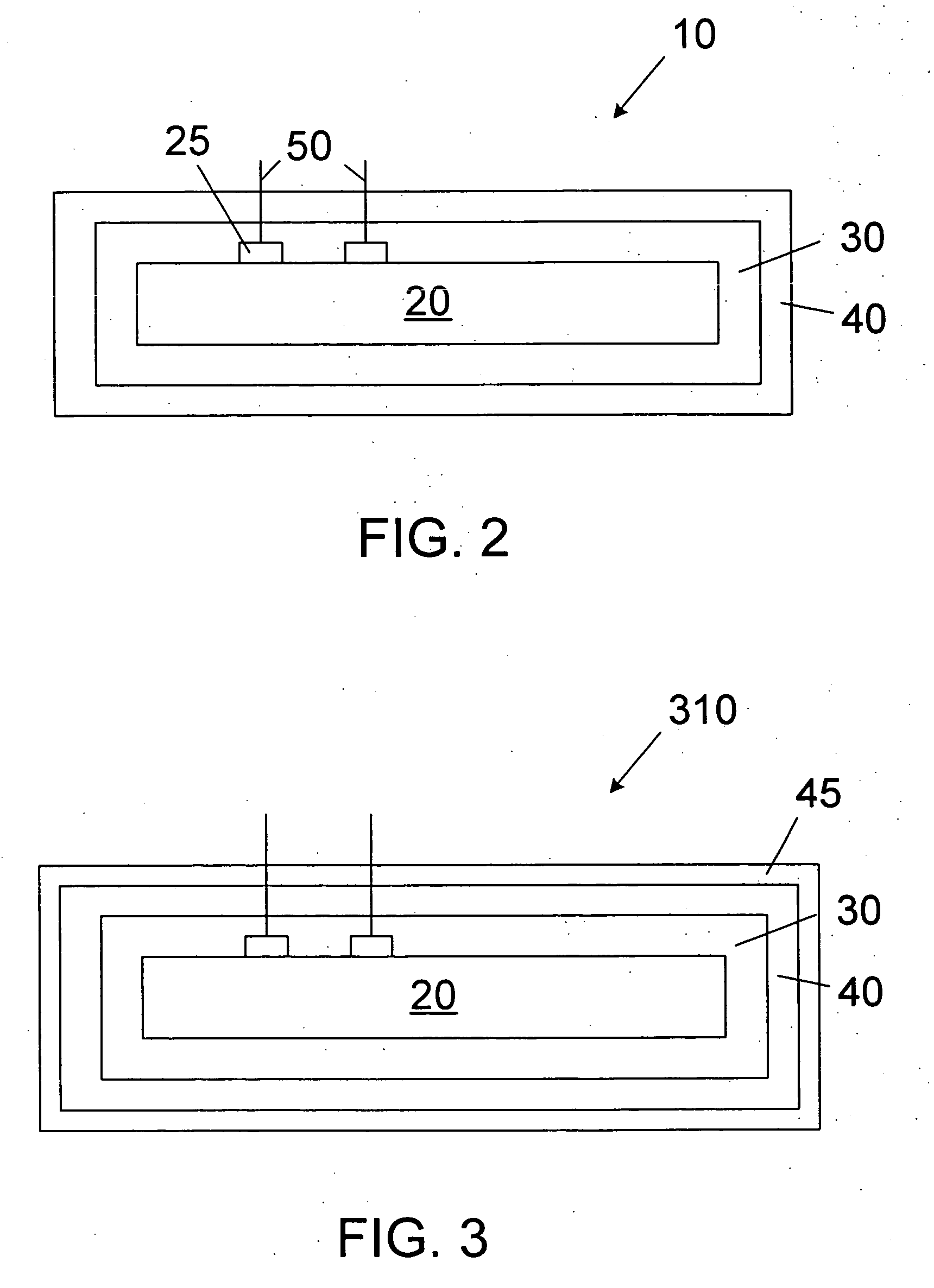

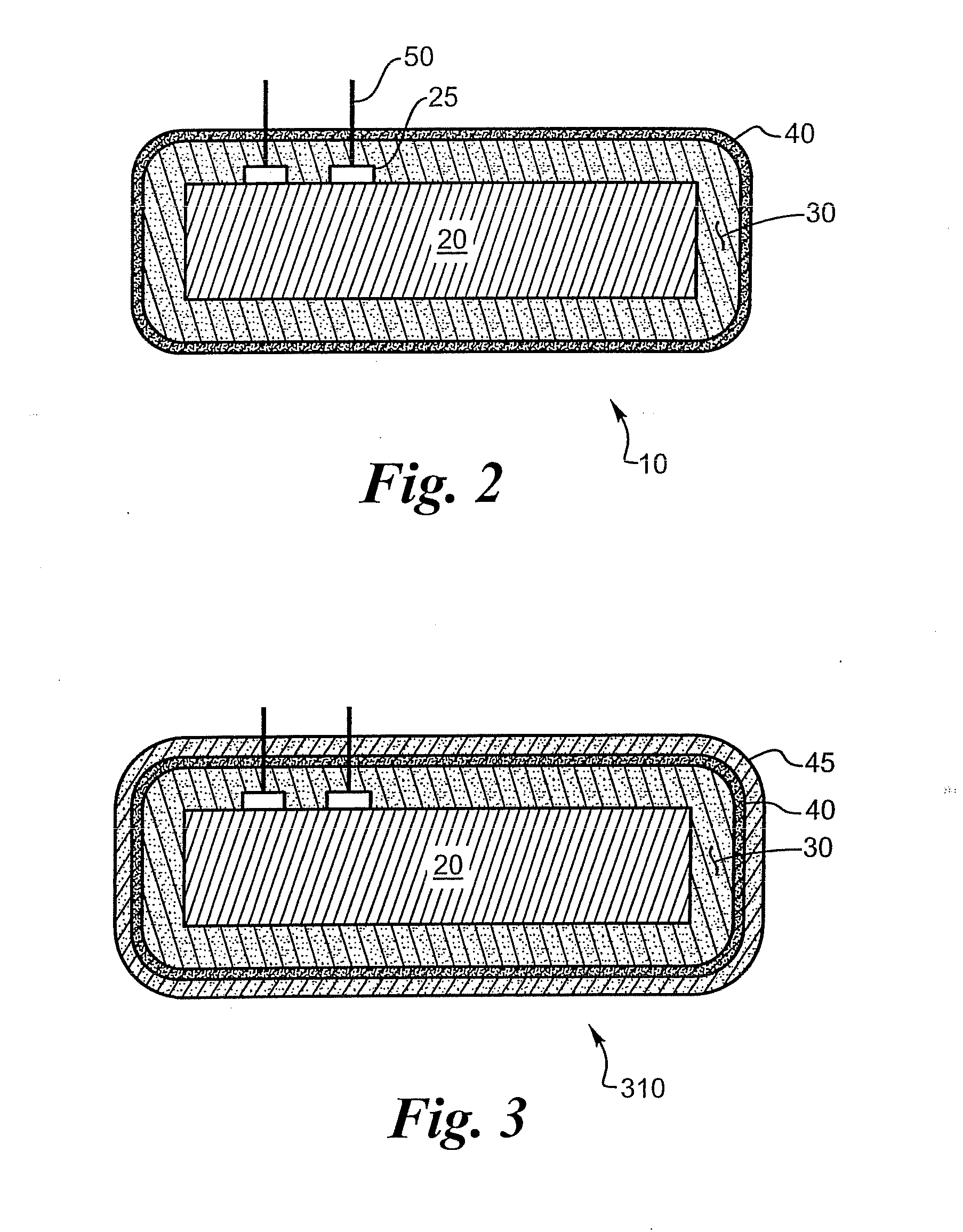

Micro-miniature implantable coated device

ActiveUS20060173497A1Internal electrodesVacuum evaporation coatingParyleneIon beam-assisted deposition

An implantable micro-miniature device is disclosed. The device comprises a thin hermetic insulating coating and at least one thin polymer or metal secondary coating over the hermetic insulating layer in order to protect the insulating layer from the erosive action of body fluids or the like. In one embodiment the insulating layer is ion beam assisted deposited (IBAD) alumina and the secondary coating is a parylene polymer. The device may be a small electronic device such as a silicon integrated circuit chip. The thickness of the insulating layer may be ten microns or less and the thickness of the secondary layer may be between about 0.1 and about 15 microns.

Owner:SECOND SIGHT MEDICAL PRODS +1

Method of producing biaxially textured buffer layers and related articles, devices and systems

ActiveUS6849580B2Polycrystalline material growthSuperconductors/hyperconductorsIon beam-assisted depositionOut of plane

A superconductor article includes a substrate and a first buffer film disposed on the substrate. The first buffer film has a uniaxial crystal texture characterized (i) texture in a first crystallographic direction that extends out-of-plane of the first buffer film with no significant texture in a second direction that extends in-plane of the first buffer film, or (ii) texture in a first crystallographic direction that extends in-plane of the first buffer film with no significant texture in a second direction that extends out-of-plane of the first buffer film. A second buffer film is disposed on the first buffer film, the second buffer film having a biaxial crystal texture. A superconductor layer can be disposed on the second buffer film. Ion-beam assisted deposition (IBAD) can be used to deposit the second buffer film.

Owner:FLORIDA UNIV OF A FLORIDA +1

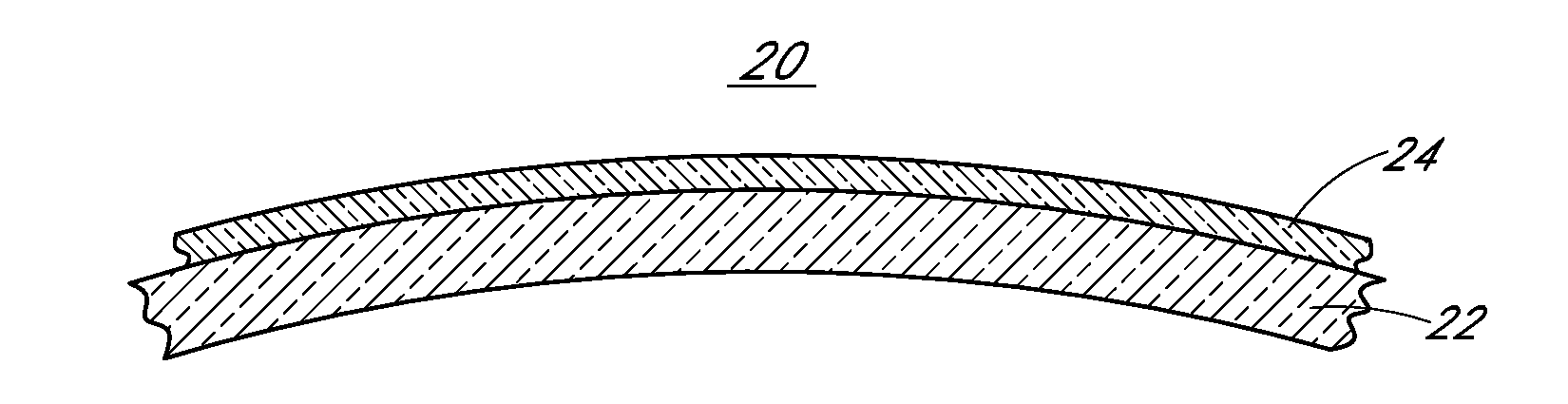

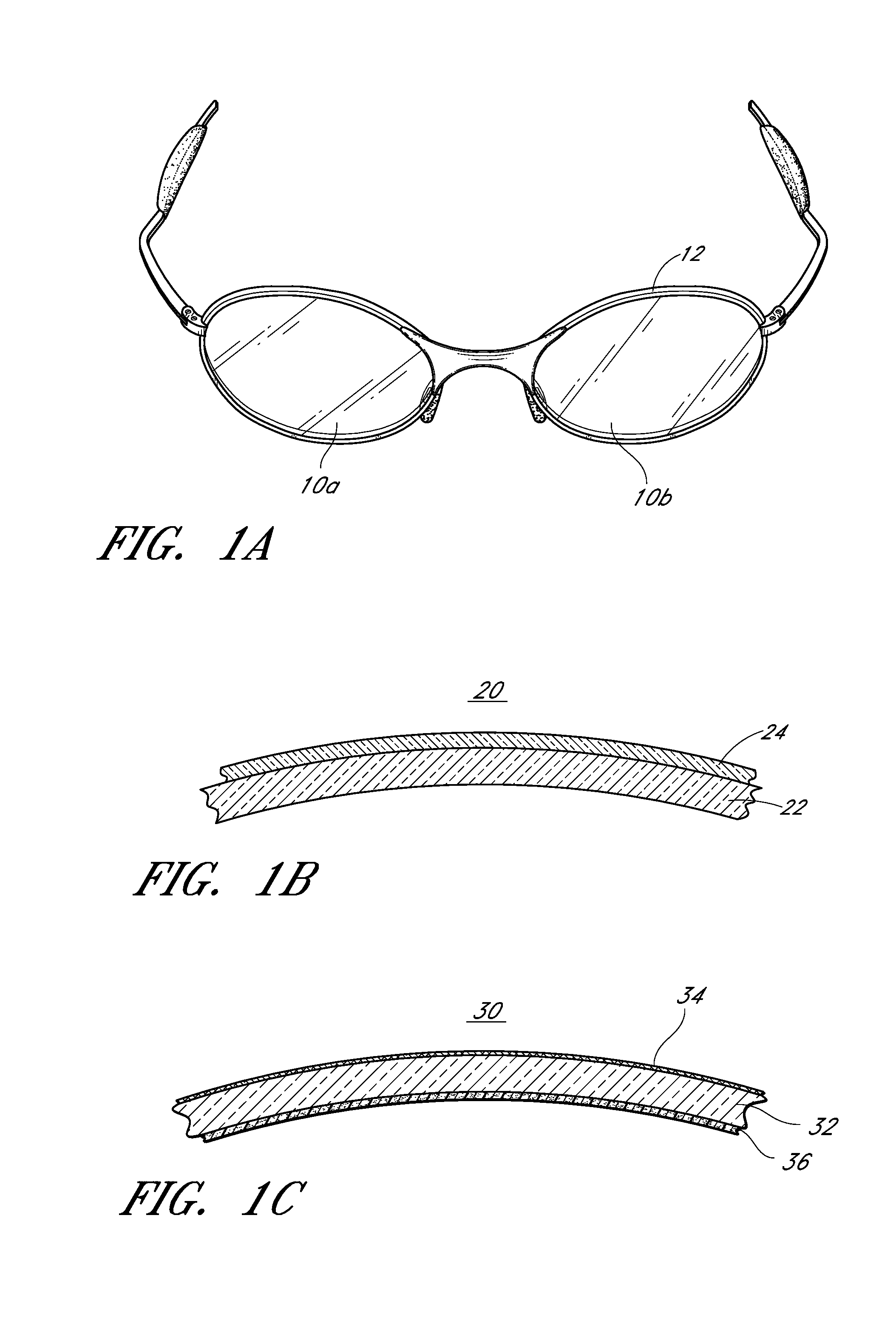

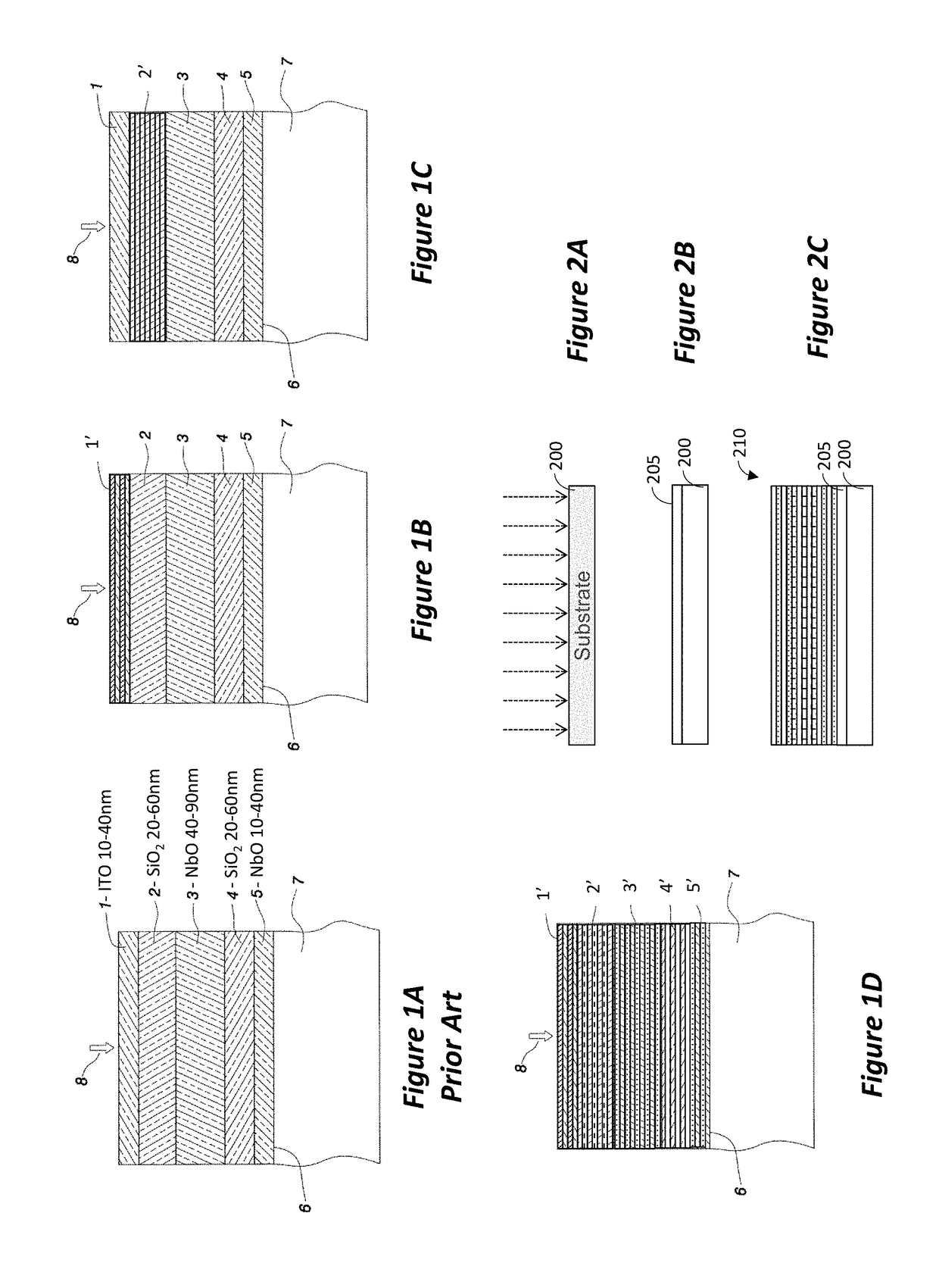

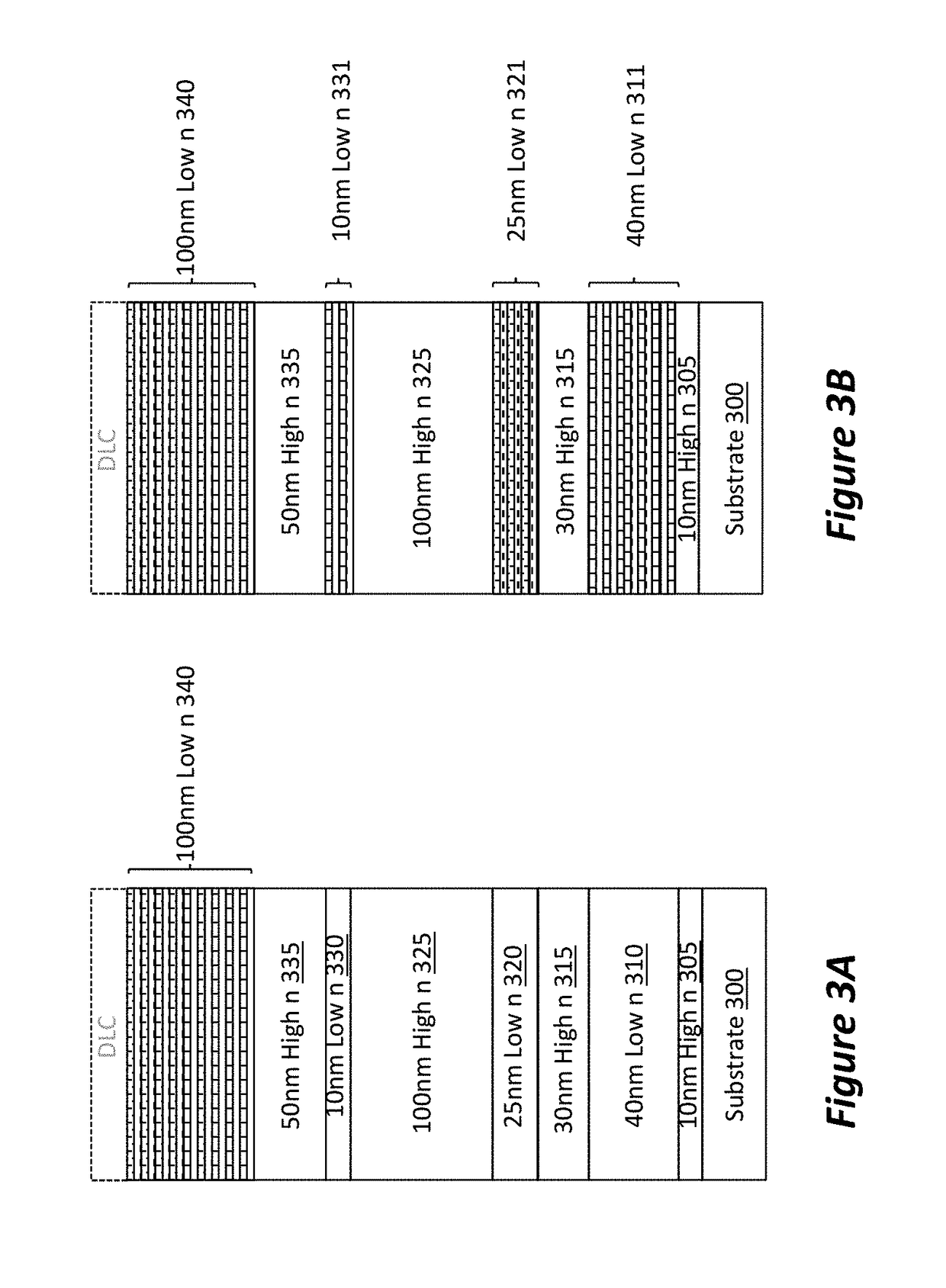

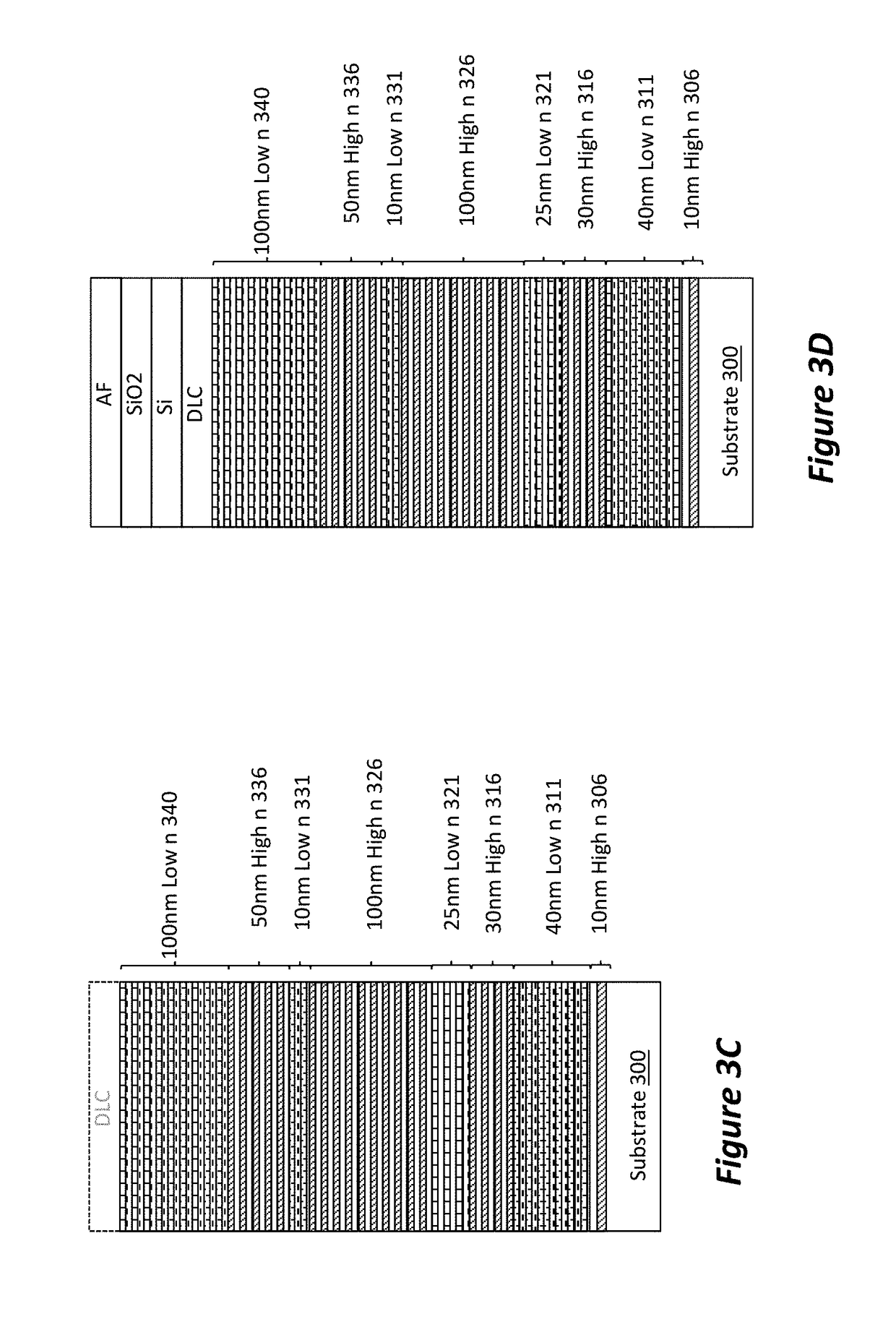

Ion beam assisted deposition of ophthalmic lens coatings

InactiveUS20110229660A1Reduce and prevent accumulationImprove the level ofVacuum evaporation coatingSputtering coatingGas phaseRefractive index

Some embodiments provide a physical vapor deposition process for forming a coating on a substrate of an ophthalmic lens in a vacuum deposition chamber. The process can include depositing a multilayer interference stack having a plurality of low refractive index layers and a plurality of high refractive index layers on the substrate by: depositing one or more of the plurality of high refractive index layers by contacting the substrate with a vapor phase pulse of one or more high refractive index source chemicals simultaneously while contacting the substrate with an energetic ion beam generated by an ion source; and depositing each of the plurality of low refractive index layers by contacting the substrate with a vapor phase pulse of one or more low refractive index source chemicals.

Owner:LUXOTTICA US HLDG CORP

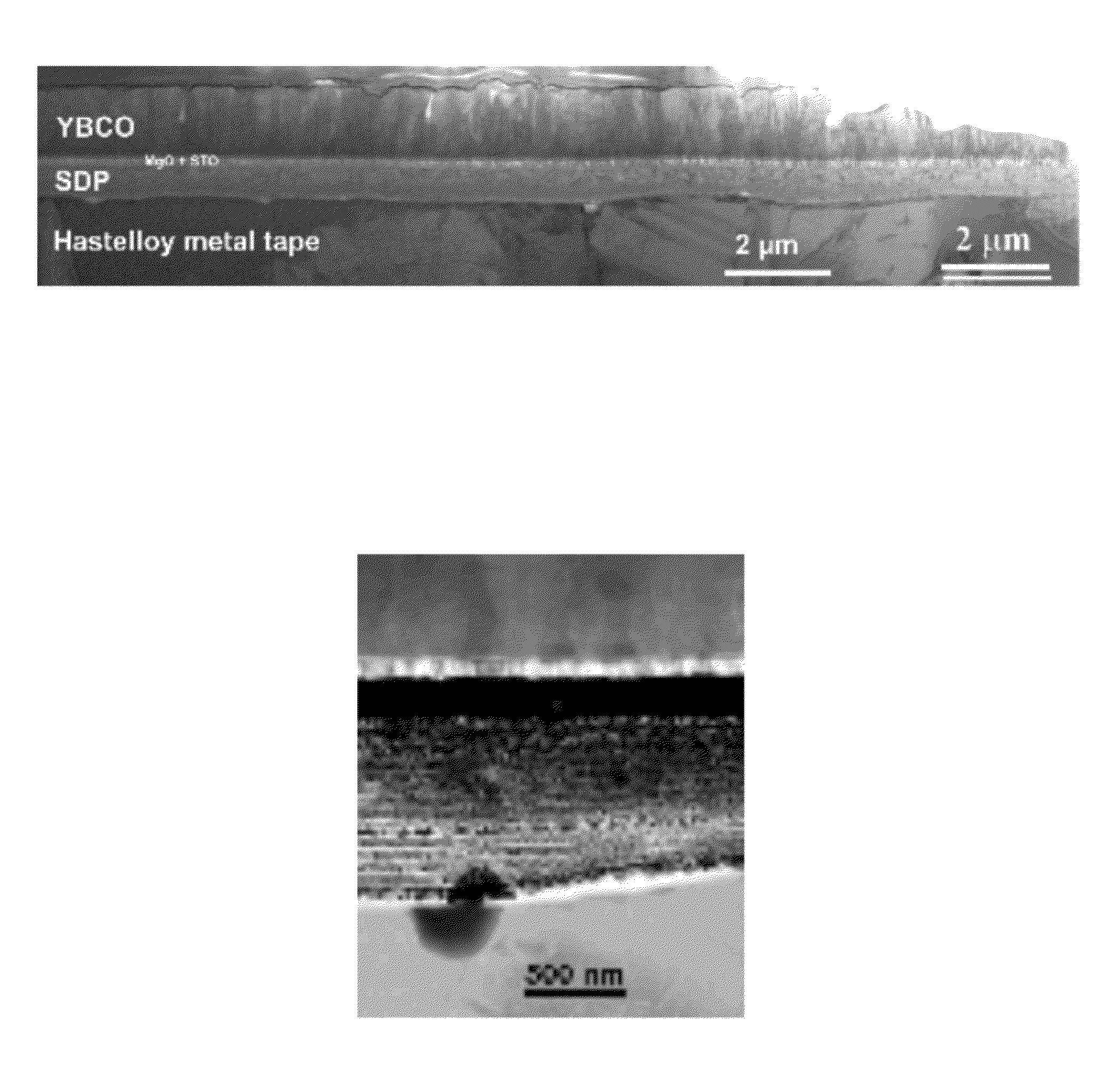

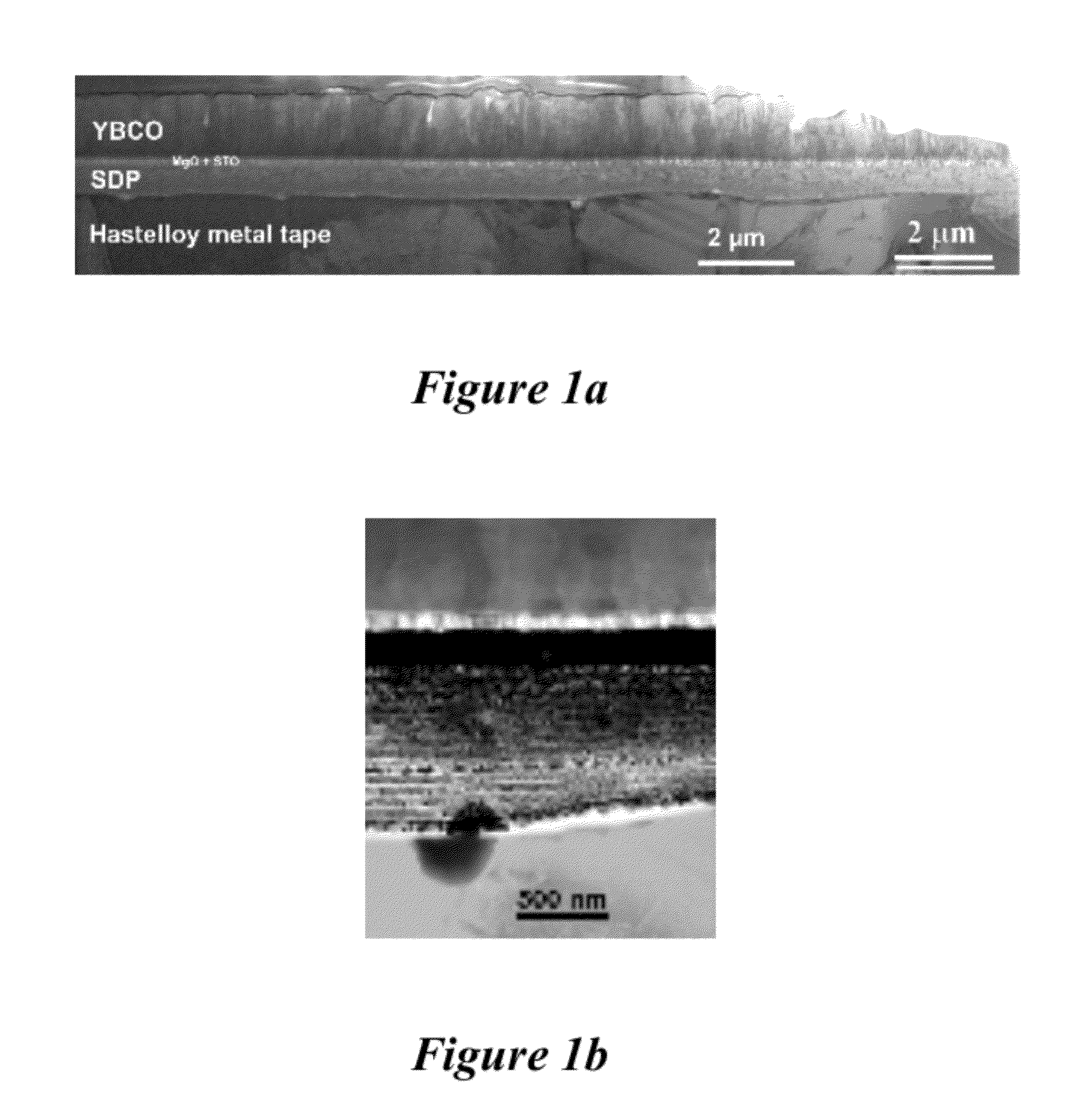

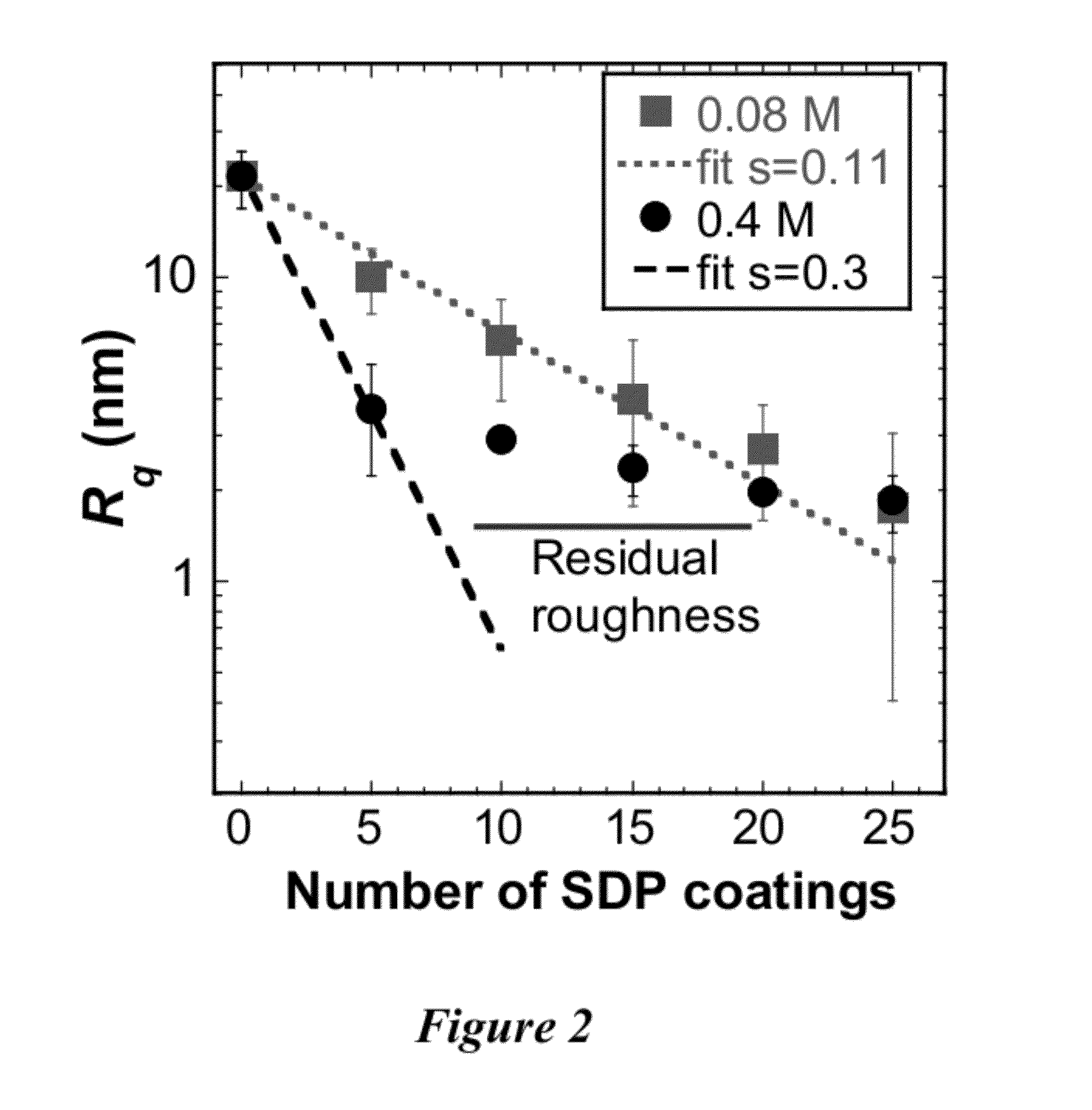

Solution deposition planarization method

A process for planarizing a substrate involves applying a coating of a first solution of yttrium oxide precursor to a rough substrate surface and heating to remove solvent and convert the yttrium oxide precursor to yttrium oxide. This is repeated with the first solution and then with the second solution. A final surface roughness less than 1 nm RMS may be obtained. In addition, a process for preparing a layered structure includes solution deposition planarization of a rough substrate using different concentrations of metal oxide precursor to provide a metal oxide surface having a surface roughness, and then depositing MgO by IBAD (ion beam assisted deposition). A benefit of a better in plane MgO texture was observed for lower molarities, and when two solutions of different concentrations was employed for coating the rough substrate prior to IBAD-MgO.

Owner:LOS ALAMOS NATIONAL SECURITY +1

Multi-ion-beam sputter-deposition technology for doping with diamond-like carbon (DLC) coating

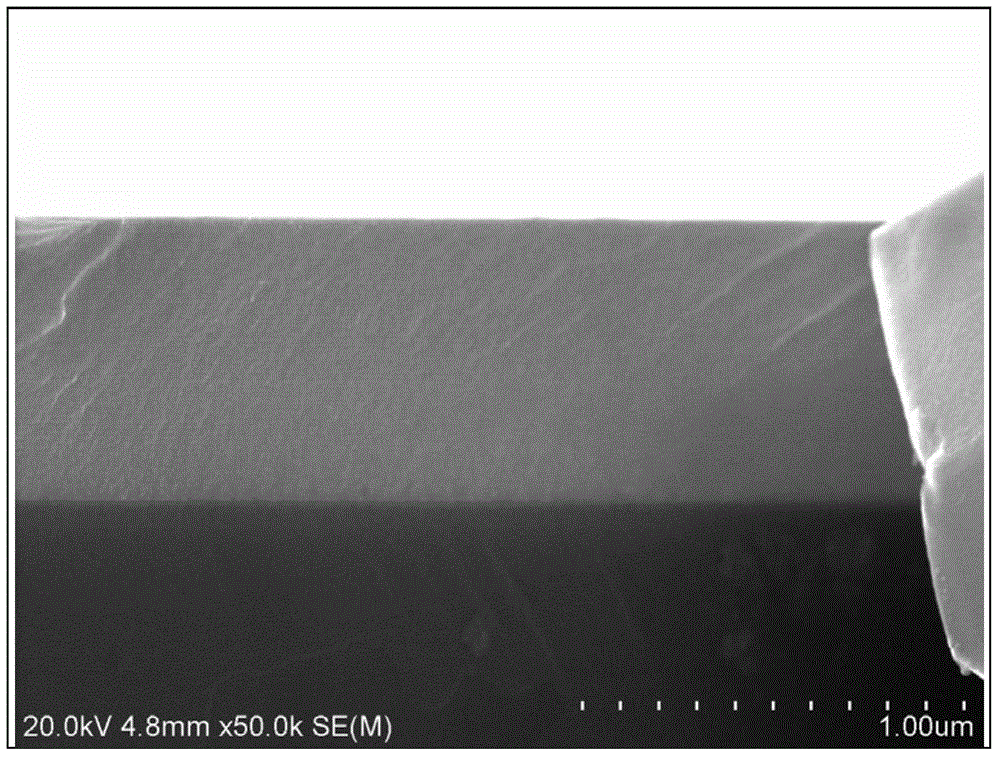

InactiveCN101787518AImprove performanceRealize complementary advantagesVacuum evaporation coatingSputtering coatingDlc coatingGrown film

The invention relates to a multi-ion-beam sputter-deposition technology for doping a diamond-like carbon (DLC) coating. The technology is characterized by comprising the following steps of: firstly, washing to removing a polluted layer on the surface of a workpiece by utilizing ultrasonic waves, and carrying out ion beam bombardment washing on the surface of the workpiece by utilizing an argon-ion beam generated by an ion source to obtain an atomic scale clean surface; then preparing a gradient transition layer by utilizing an auxiliary ion beam sputter-deposition method; and finally, synthesizing a multi-element doped DLC coating on the gradient transition layer by utilizing multi-ion-beam sputtering and low-energy ion beam auxiliary deposition. In the process of synthesizing the multi-element doped DLC coating by utilizing the multi-ion-beam sputtering and the low-energy ion beam auxiliary deposition, carbon particles and metallic particles which are generated by bombarding a graphite target and a metallic target are deposited by using a sputtering ion source, and gas ions generated by an auxiliary deposition ion source continuously bombard the surface of a grown film layer to regulate and control the microstructure of the film layer and realize multi-element doping.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

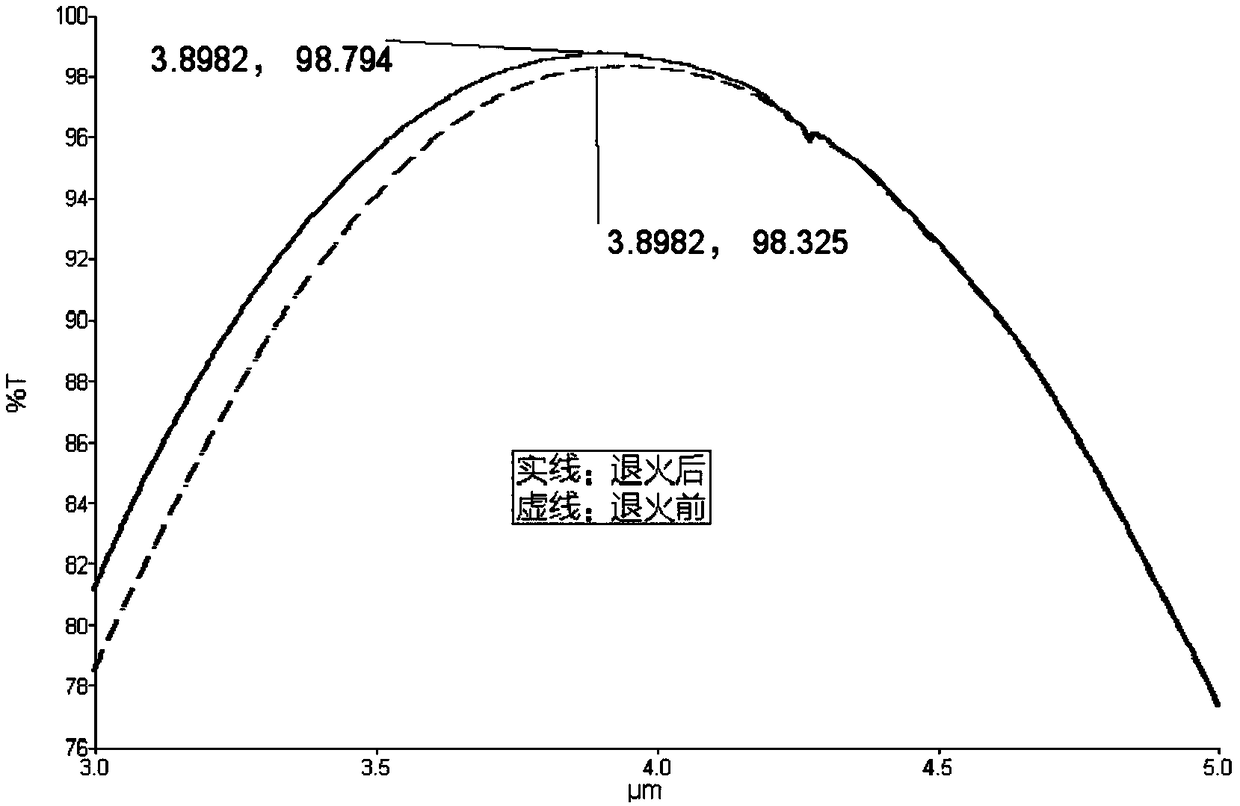

Large-size sapphire substrate multi-spectral hard antireflection film and preparation method thereof

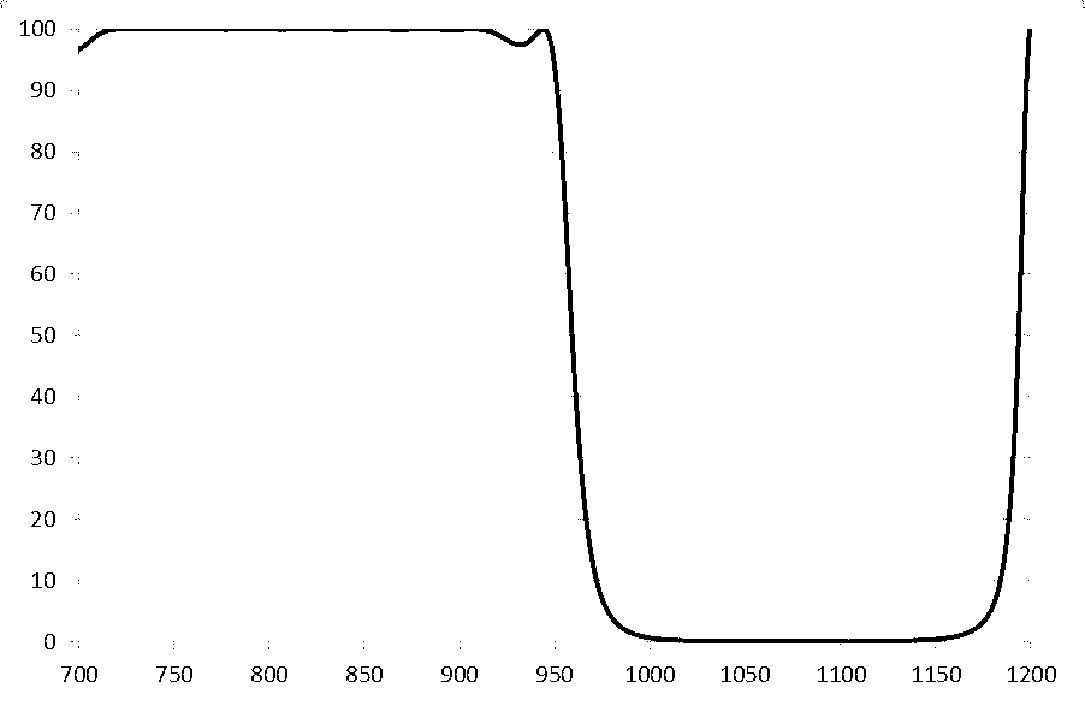

ActiveCN109182972AStress minimizationReduce stress valueVacuum evaporation coatingSputtering coatingRefractive indexIon beam-assisted deposition

The invention discloses a large-size sapphire substrate multi-spectral hard antireflection film and a preparation method thereof. The film comprises a sapphire substrate, a stress matching layer, an oxide material multilayer antireflection film system and a hard wear-resisting protective layer in sequence from bottom to top; the oxide material multilayer antireflection film system is formed by alternated plating of high / low refractive index materials, and ion beam assisted deposition is adopted. Ti3O5 or ZrO2 or Ta2O5 is selected as the high refractive index material, and SiO2 is selected as the low refractive index material. According to the invention, a conventional oxide film material is adopted, and the related technique is easy for transplanting, so that the film coating and film forming quality of the large-size sapphire substrate multi-spectral hard antireflection film does not depend on the hardware state of coating machine strongly, and the optical performance and the mechanical and physical performance of the film are substantially promoted.

Owner:HUAZHONG PHOTOELECTRIC TECH INST (CHINA SHIPBUILDING IND CORP THE NO 717 INST)

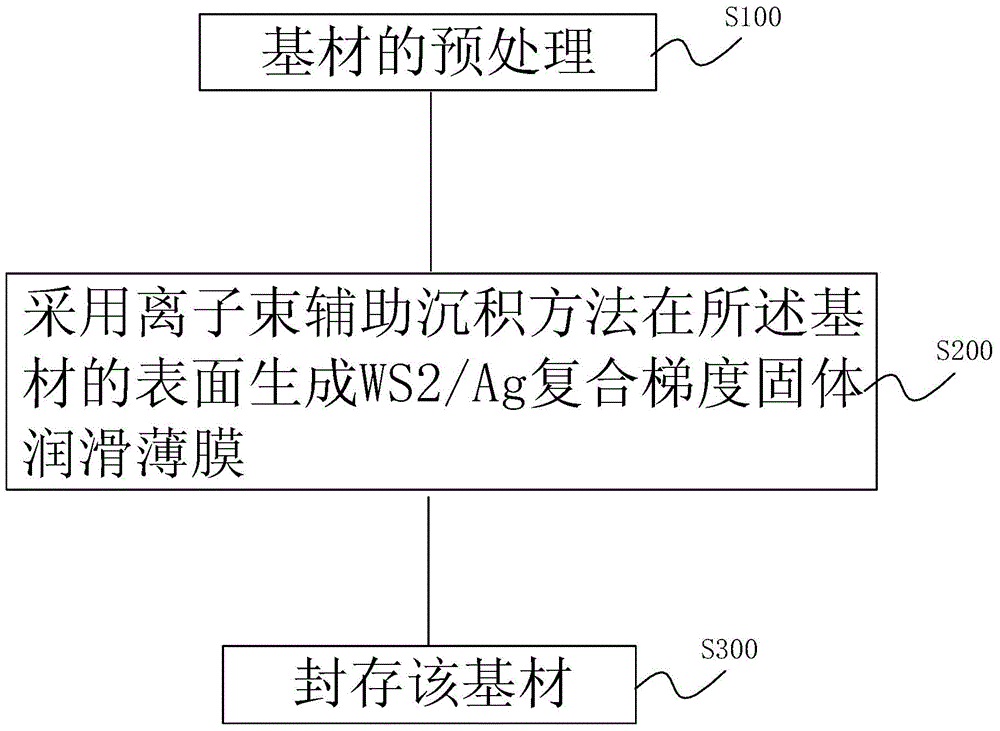

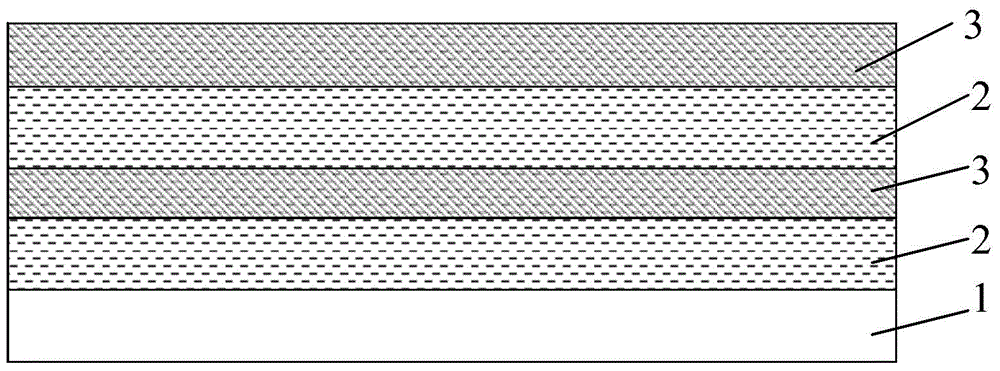

Method for preparing WS2/Ag compositional gradient solid lubrication film

ActiveCN104962859AImprove performanceReduce coefficient of frictionVacuum evaporation coatingSputtering coatingVacuum pumpingHigh energy

The invention discloses a method for preparing a WS2 / Ag compositional gradient solid lubrication film. The WS2 / Ag compositional gradient solid lubrication film is formed on the surface of a base material in an ion beam assisted deposition method. The method for preparing the WS2 / Ag compositional gradient solid lubrication film includes the steps that the baser material is preprocessed; the solid lubrication film is generated, the base material is put into a vacuum chamber, and vacuum pumping is conducted; surface modification is conducted on the base material through a low-energy ion source and a high-energy ion source in an alternate mode, so that the WS2 / Ag compositional gradient solid lubrication film is generated on the surface of the base material, and the proportion of W to S in the WS2 / Ag compositional gradient solid lubrication film is 1:0.8; and the base material with the WS2 / Ag compositional gradient solid lubrication film generated on the surface is put into an acetone solution to be cleaned and the dried, and the dried base material is sealed and stored in a vacuum mode.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

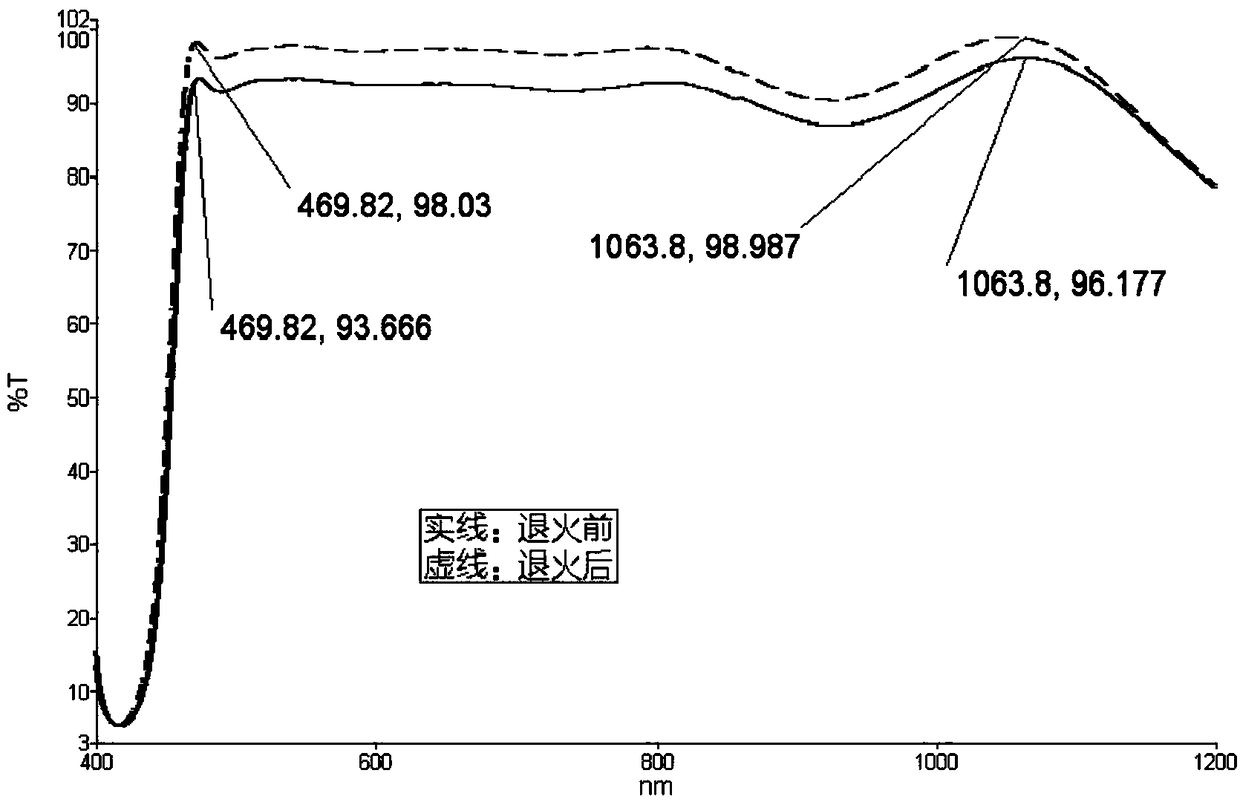

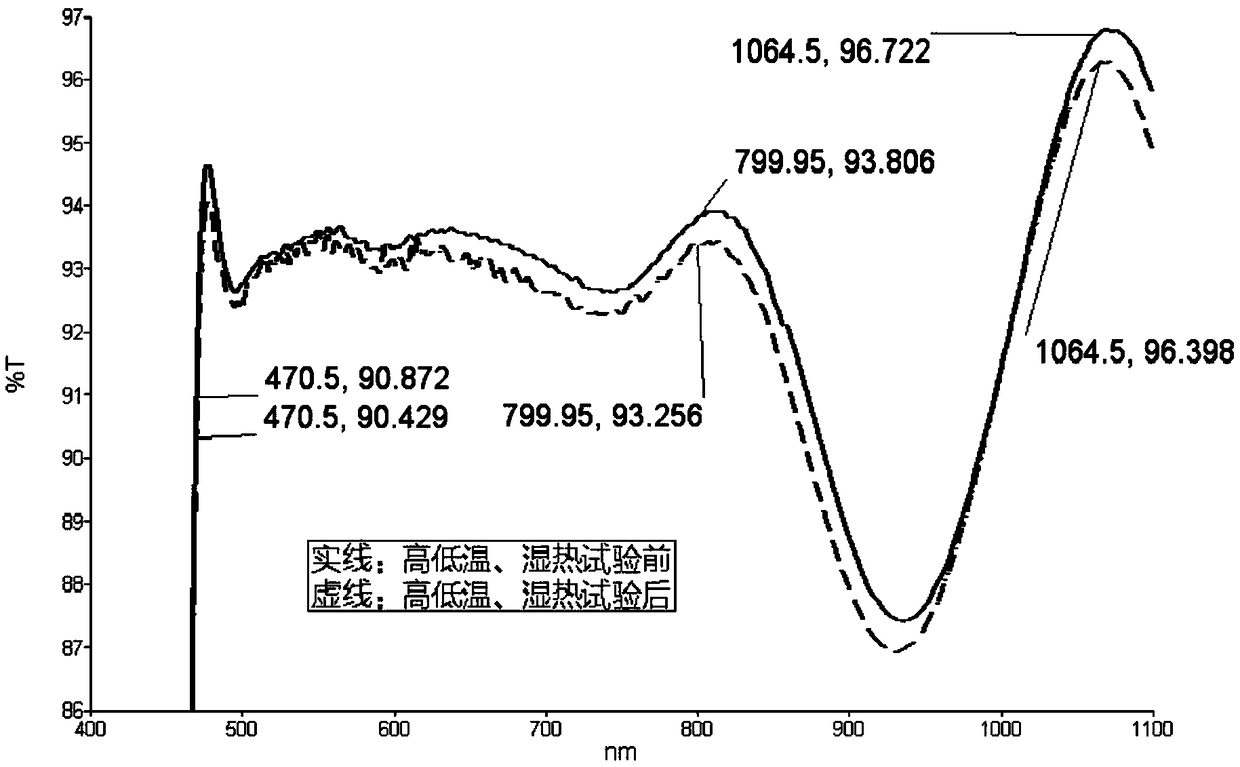

Preparation method for waterproof laser film

ActiveCN103173720AImprove transmittanceImprove reflectivityVacuum evaporation coatingSputtering coatingDiode-pumped solid-state laserRefractive index

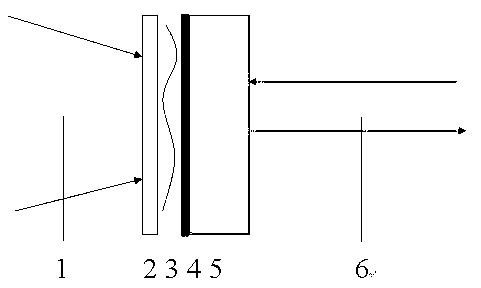

The invention relates to a preparation method for a waterproof laser film. According to the requirement in practical application of normal incidence 800nm pumping transmission and back incidence 1064nm fundamental frequency light reflection, an HfO2 and SiO2 film is prepared by a vacuum electron beam evaporation sedimentation technology and is taken as the film which has a large electric filed and is easy to damage due to being close to a base plate when being used as the back incidence, so as to obtain higher laser damage resistance threshold; aiming at the working condition of a water cooling system, for the films close to the water side and easy to be permeated and corroded, Ta2O5 and SiO2 films are prepared by an ion beam auxiliary sedimentation technology, so that the microstructure of the film is improved, higher stacking density is obtained, and good waterproof performance is realized; HfO2, Ta2O5 and SiO2 of high or low refractive index are deposited alternately so as to form a multi-layer film, and the optical thickness of each layer is controlled so as to obtain the needed spectral characteristic. The preparation method can well take advantages of the three characteristics and can apply the characteristics to a neodymium glass substrate of a diode pumping solid laser system, so that the diode pumping solid laser system can work in a water cooing system normally, and has good laser damage resistance performance and the spectral characteristic needed by the system.

Owner:润坤(上海)光学科技有限公司

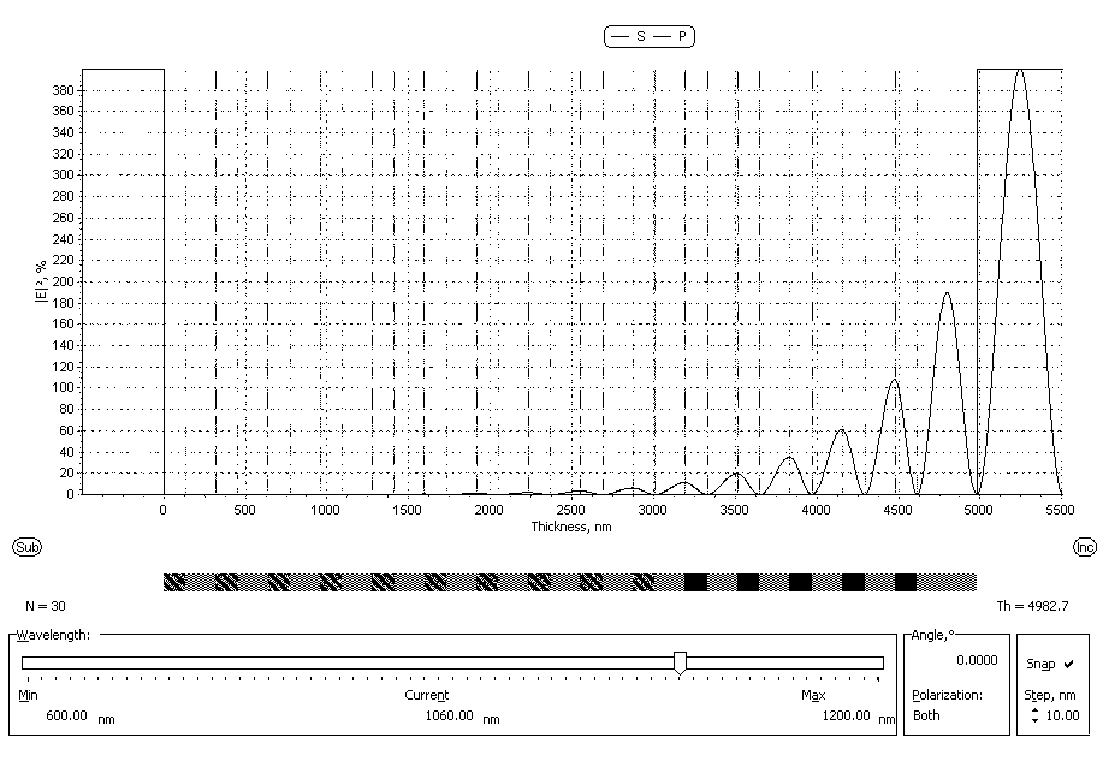

Deposition method capable of enhancing preferred orientation growth of AlN film

ActiveCN101824592AEasy to operateReduce manufacturing costVacuum evaporation coatingSputtering coatingSurface roughnessSurface acoustic wave

The invention relates to a deposition method capable of enhancing the preferred orientation growth of an AlN film. The deposition method comprises the following steps: adopting an ion beam-assisted deposition technique to prepare an AlN homogeneous transition layer: when using an Ar + ion beam of 2.0-2.5keV / 20-50mA for depositing an Al film in a sputtering way on a substrate, using a moderate-energy N+ ion beam of 20-35keV / 2-8mA for bombarding the Al film in an assisting way; and then depositing the AlN film by adopting magnetron sputtering, wherein base pressure is less than or equal to 5x10<-4>Pa, working air pressure is 0.5-10Pa and substrate temperature is 200 DEG C-500 DEG C. Through pre-depositing the homogeneous transition layer, the invention has the advantages that the internal stress between the film and the substrate can be effectively reduced, the full (002) orientation AlN film is formed, the surface roughness of the film is reduced, the bonding strength between the film and the substrate is increased and the film product can satisfy the requirements on the application in surface acoustic wave devices, acoustic bulk wave devices and other microelectronic devices and power devices.

Owner:湖南特瑞精密医疗器械有限公司

Method for manufacturing a tunnel junction magnetic sensor using ion beam deposition

InactiveUS20080152834A1Avoids target poisoningQuality improvementNanomagnetismNanoinformaticsOxygen ionsIon deposition

A method for forming a MgO barrier layer in a tunnel junction magnetoresistive sensor (TMR). The MgO barrier layer is deposited by an ion beam deposition process that results in a MgO barrier layer having exceptional, uniform properties and a well controlled oxygen content. The ion beam deposition of the barrier layer includes placing a wafer into an ion deposition chamber and placing Mg target into the chamber. An ion beam from an ion beam gun is directed at the target thereby dislodging Mg atoms from the target for deposition onto the wafer. Oxygen is introduced into the chamber by one or both of pumping molecular oxygen (O2) into the chamber and / or introducing oxygen ions into the chamber from a second ion beam gun. The use of ion beam deposition avoids oxygen poisoning of the Mg target, such as would occur using a more conventional plasma vapor deposition technique.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Radiographic image conversion panel and method of manufacturing the same

InactiveUS20060060792A1Highly uniform thicknessWithout deteriorationPhotometryFluorescence/phosphorescenceGas phaseFluorescence

There is provided a radiographic image conversion panel having a substrate made of a metal or an alloy, an oxide layer formed on the substrate by a vapor deposition technique such as sputtering, ion plating or ion beam assisted deposition, and a phosphor layer formed on the oxide layer by the vapor deposition technique. A method of manufacturing the radiographic image conversion panel is also provided. The radiographic image conversion panel is capable of suppressing for a long time corrosion of the surface of the substrate due to a reaction between a stimulable phosphor and the substrate through moisture and also capable of providing a radiographic image without any deterioration of the characteristics.

Owner:FUJIFILM CORP +1

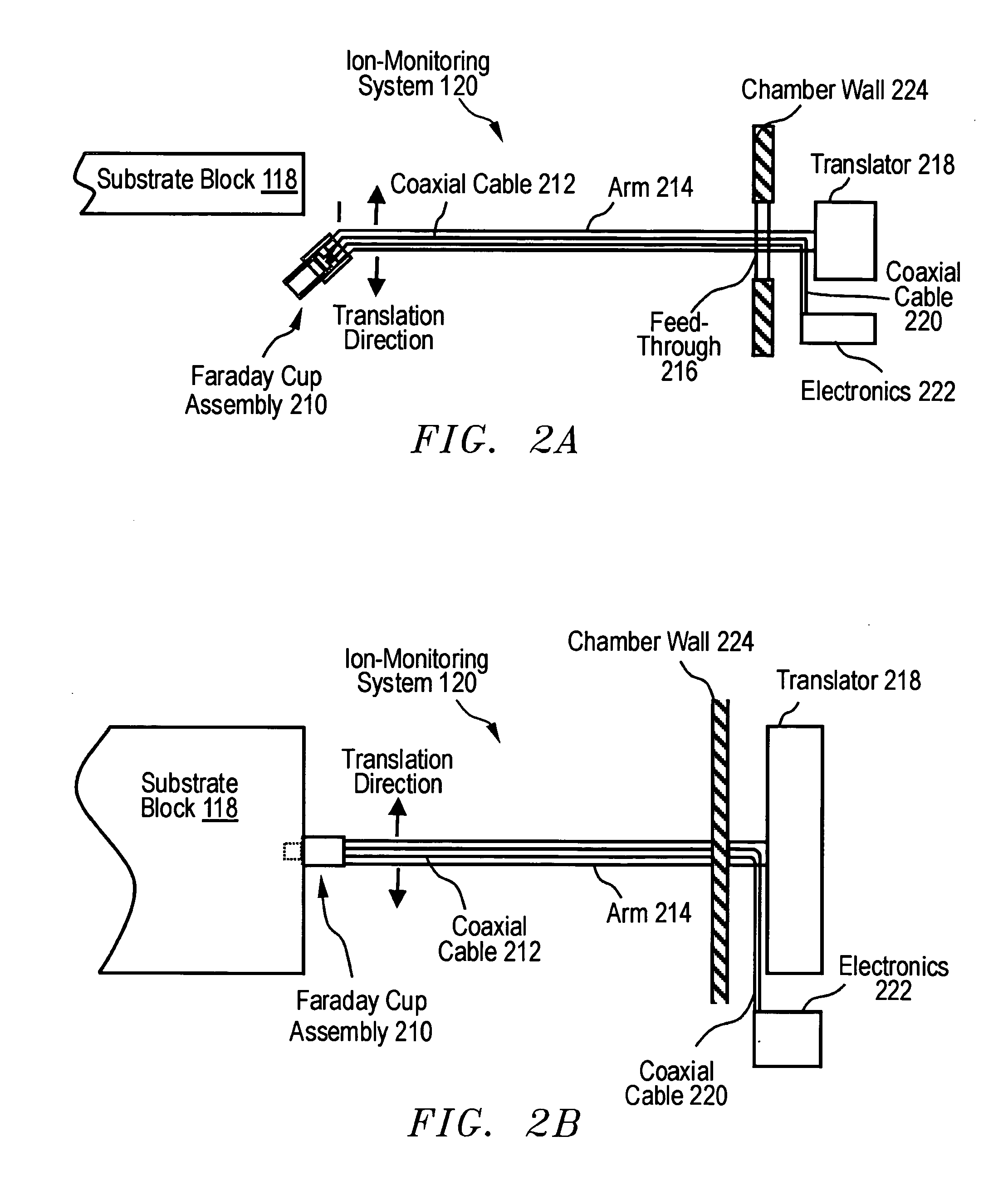

Superconductor fabrication processes

InactiveUS20050249869A1Current/voltage measurementVacuum evaporation coatingVolumetric Mass DensityIon beam-assisted deposition

A method of forming a superconductive device is provided, including providing a substrate having a dimension ratio of not less than about 102, depositing a buffer film to overlie the substrate by ion beam assisted deposition utilizing and ion beam, monitoring spatial ion beam density of the ion beam over a target area, and depositing a superconductor layer to overlie the buffer film. Monitoring may be carried out by utilizing an ion detector having an acceptance angle of not less than 10°.

Owner:SUPERPOWER INC

Micro-Miniature Implantable Coated Device

ActiveUS20080051862A1Internal electrodesVacuum evaporation coatingParyleneIon beam-assisted deposition

Owner:CORTIGENT INC

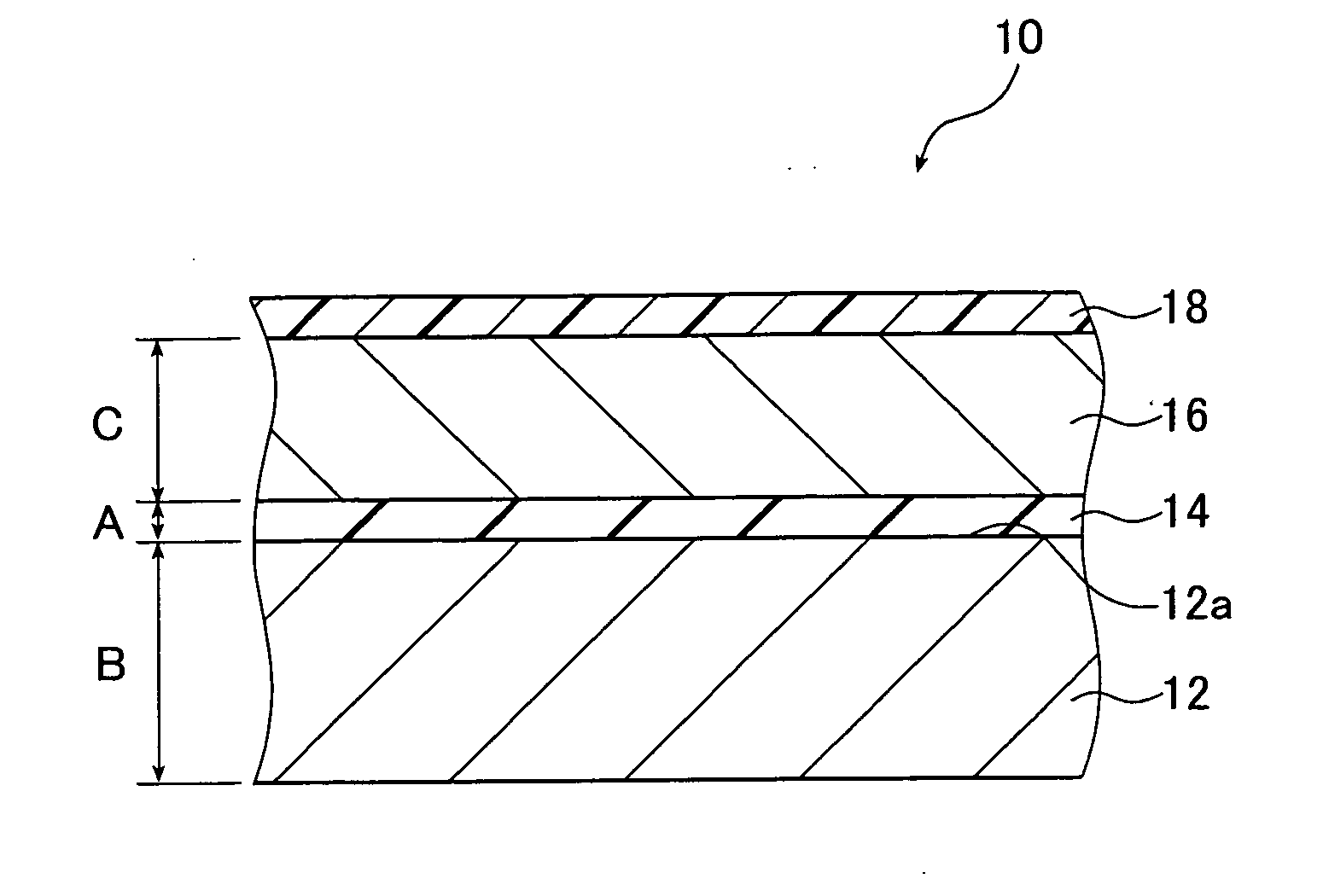

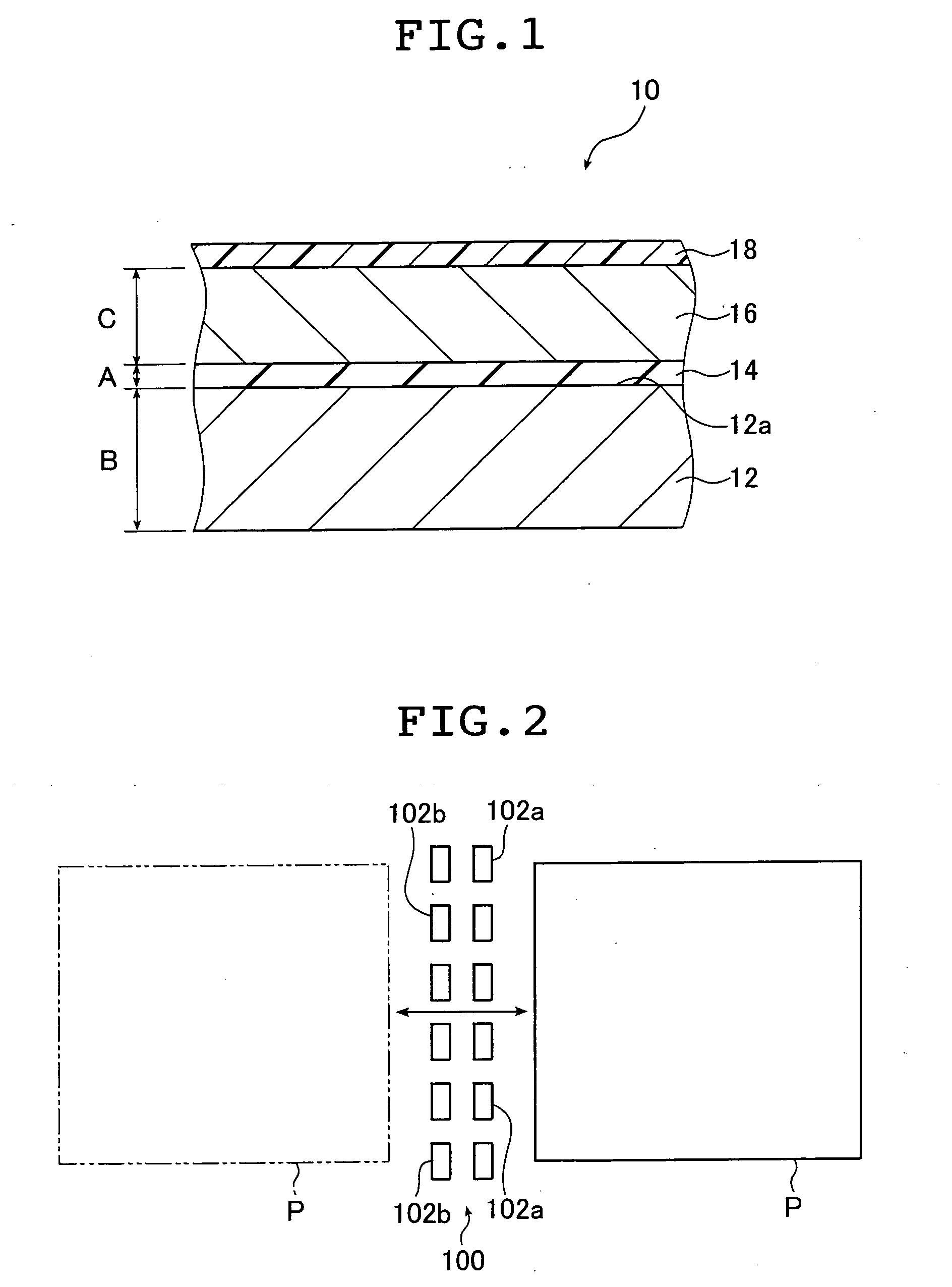

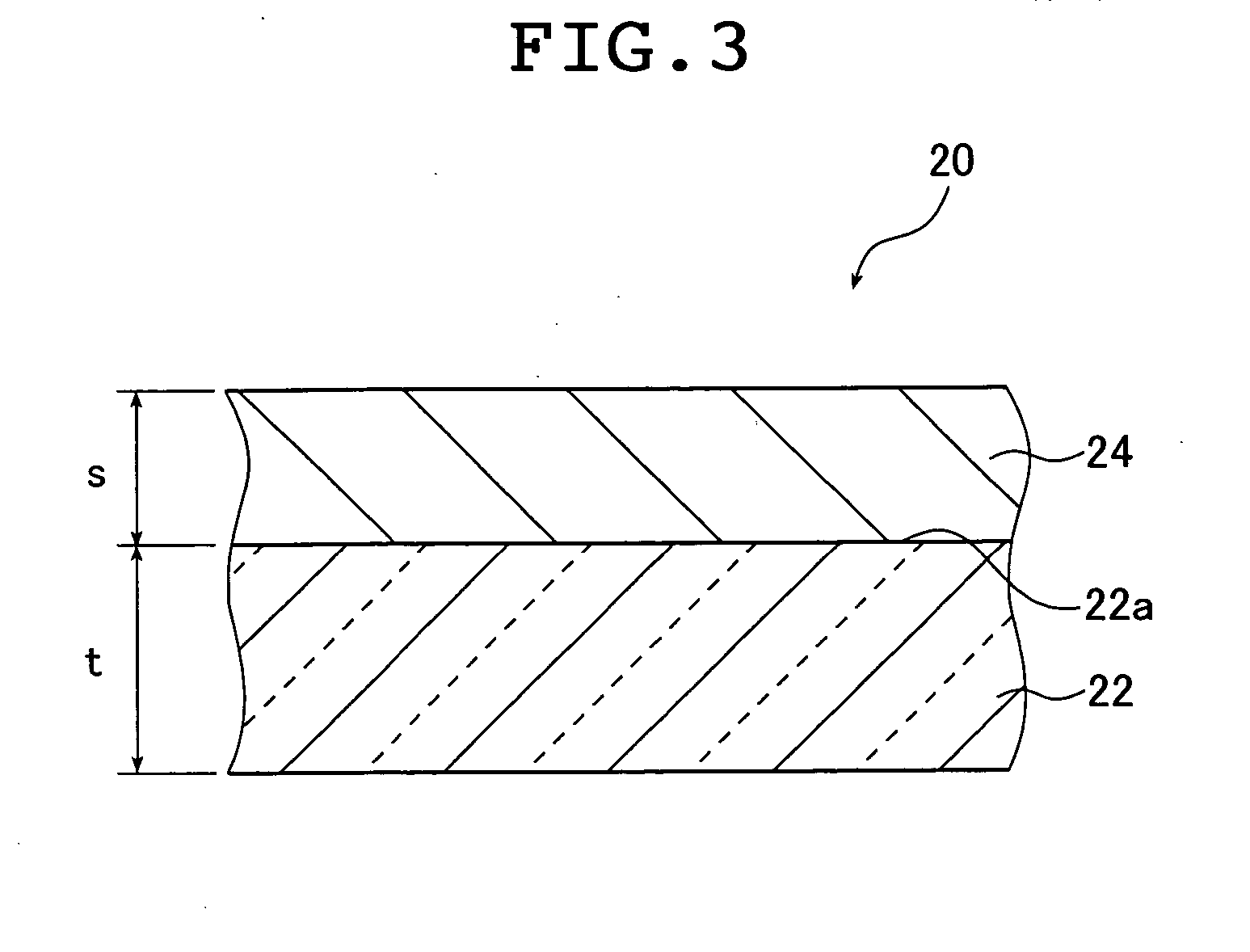

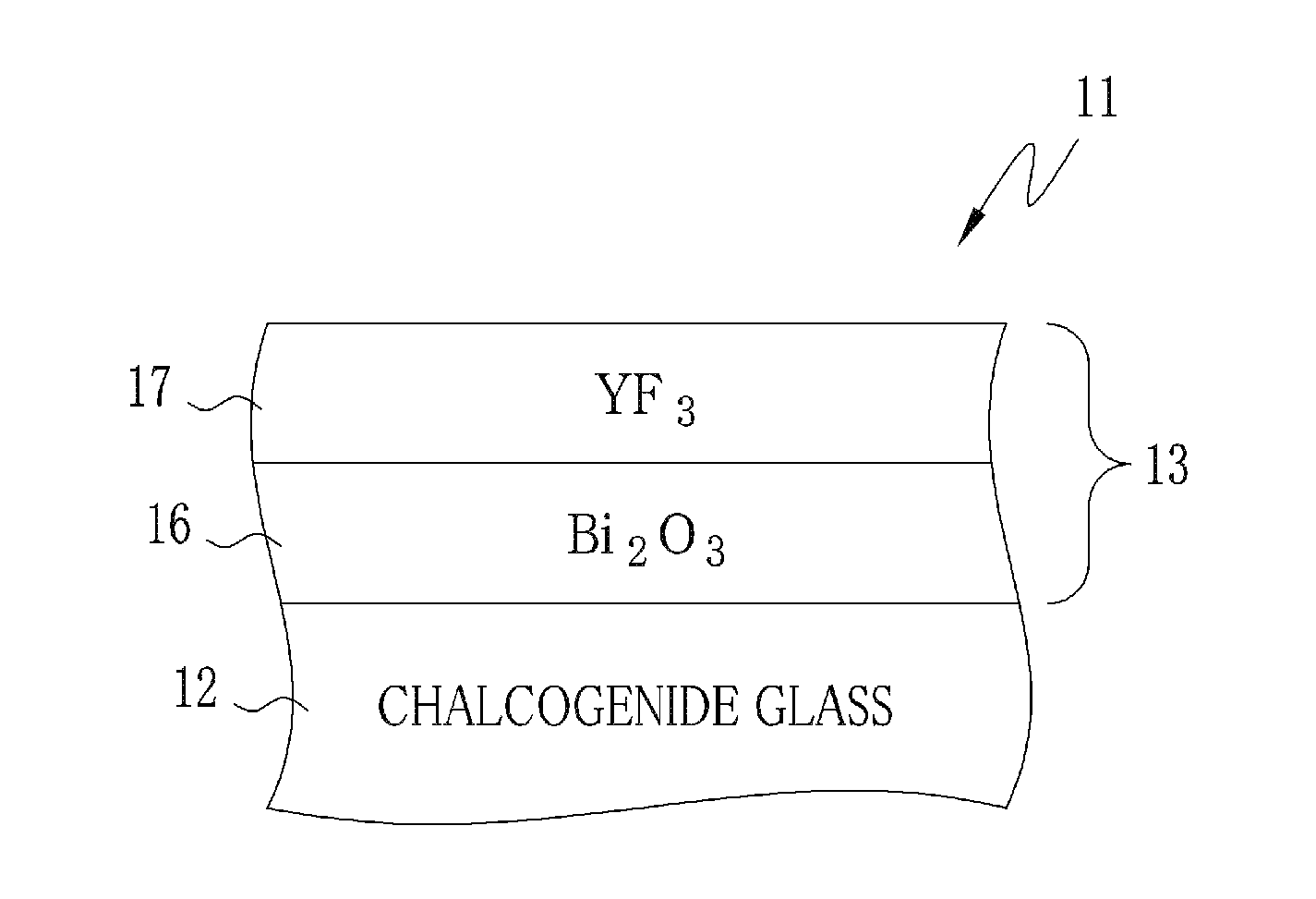

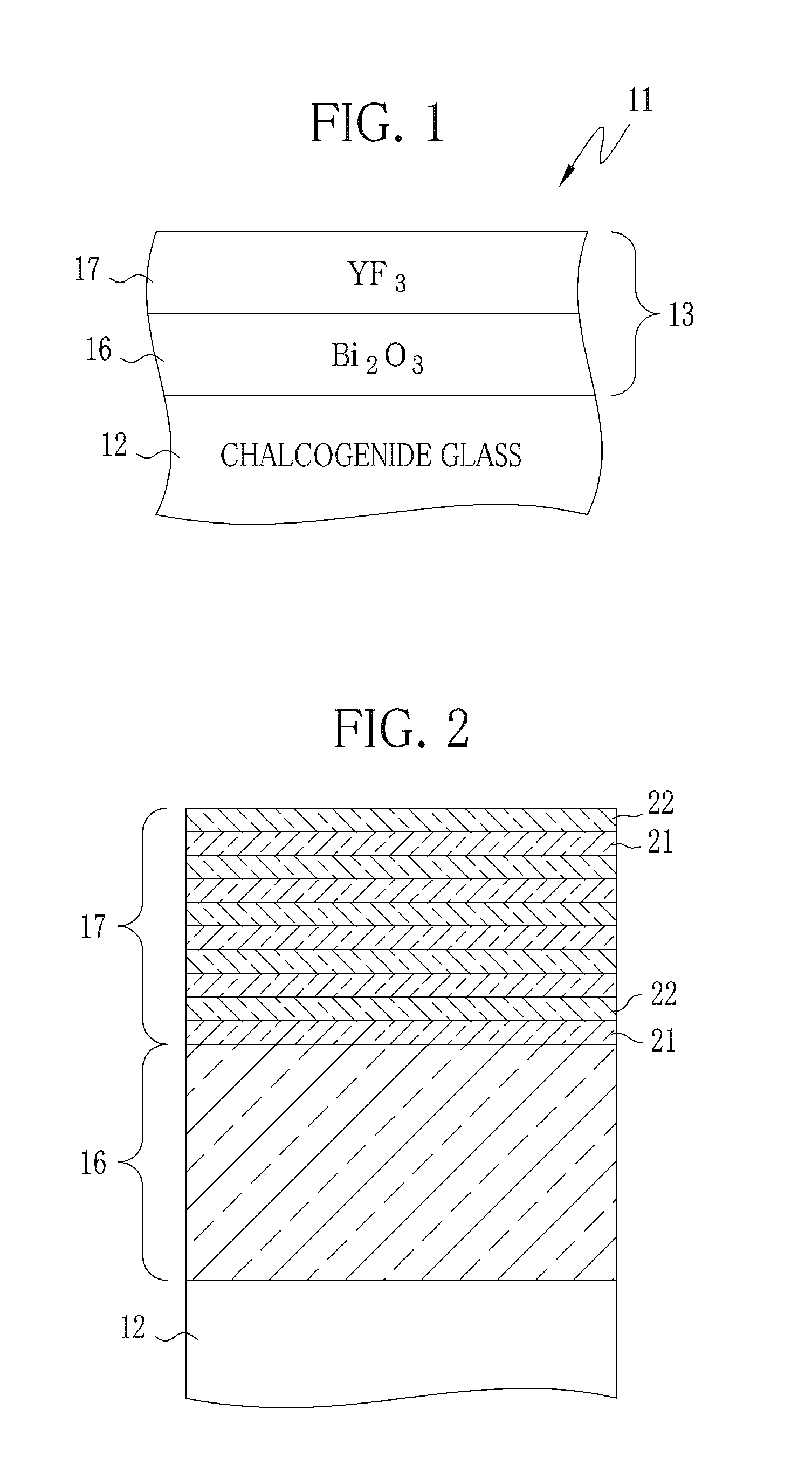

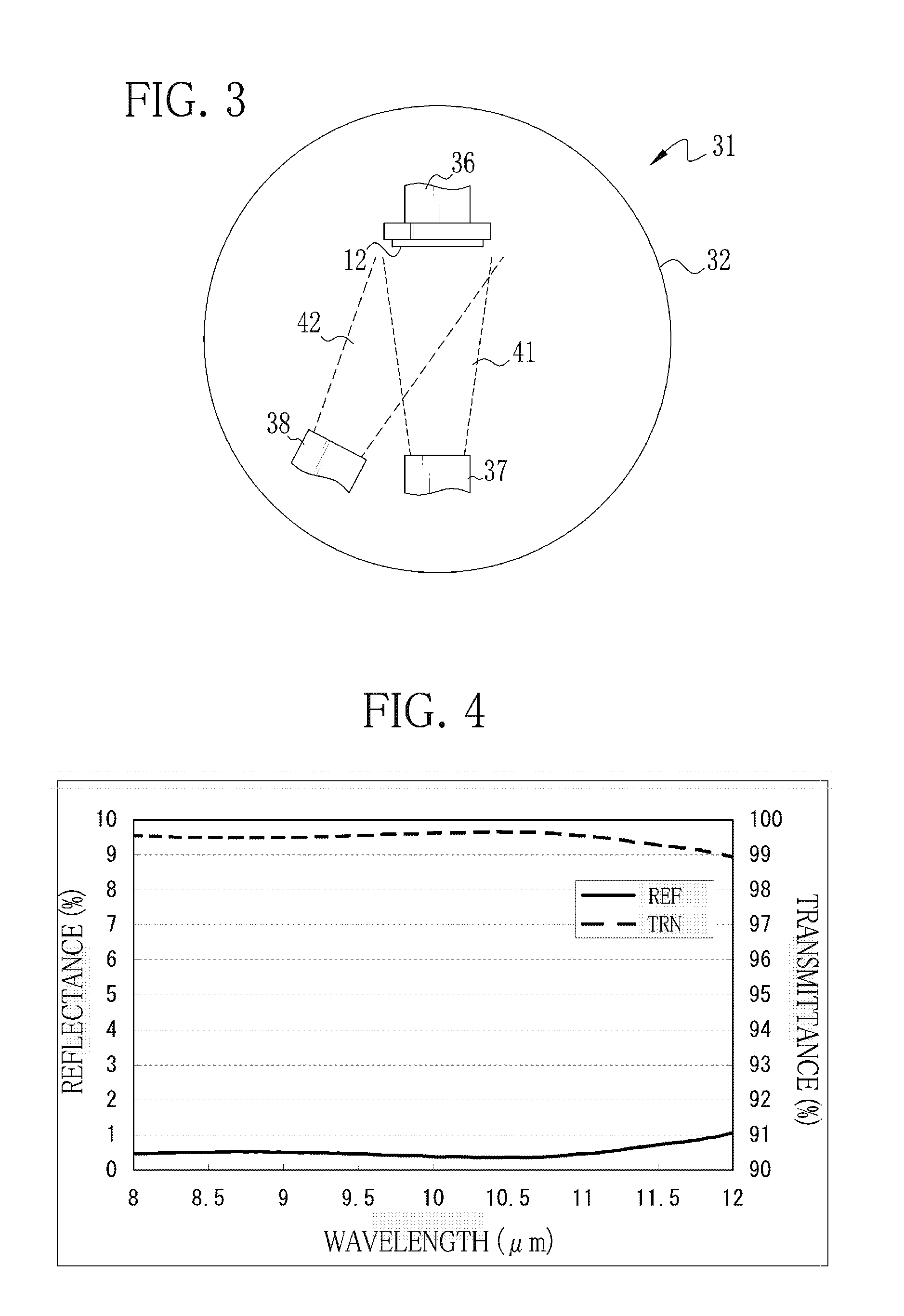

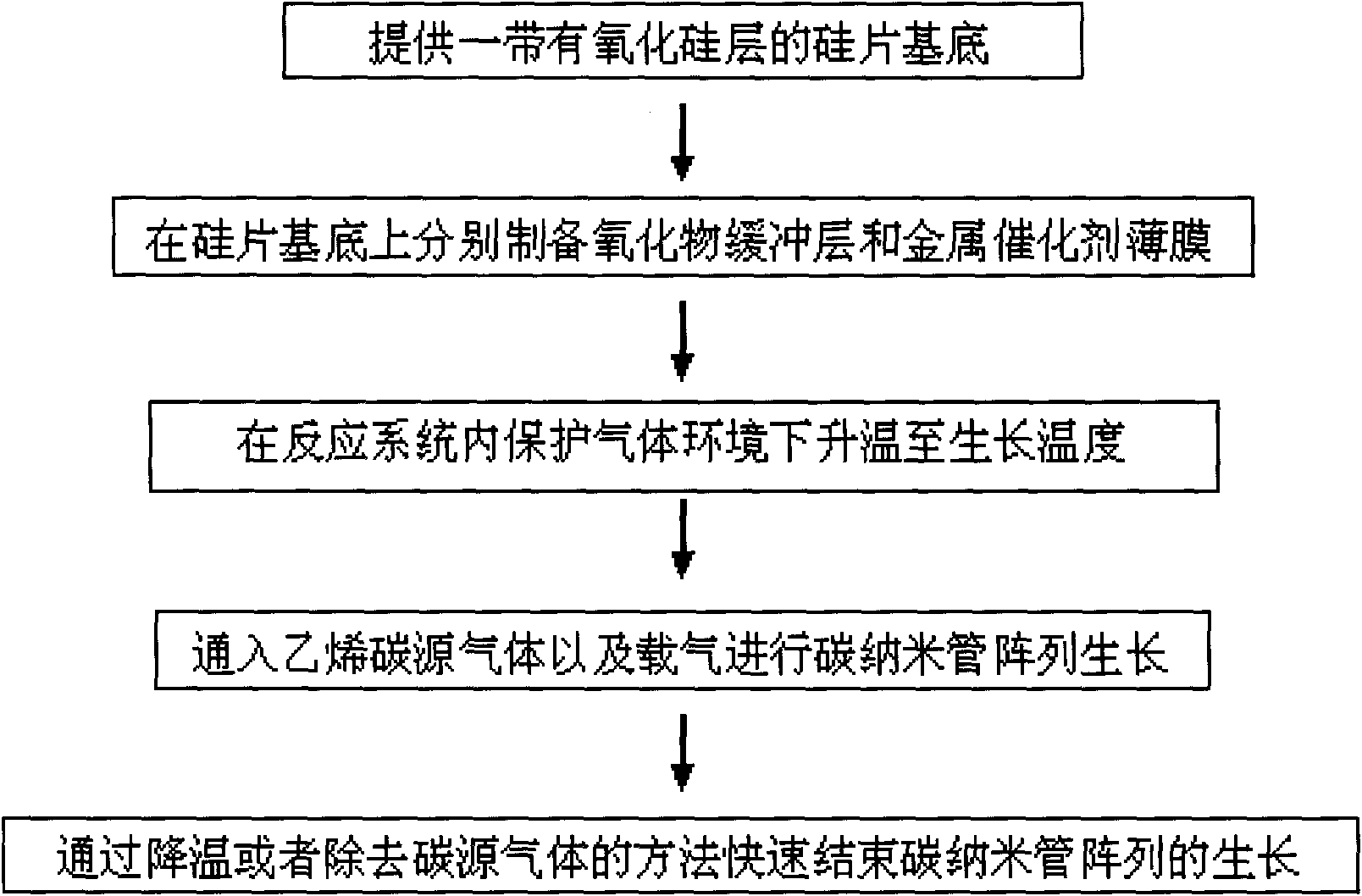

Anti-reflection film and infrared optical element

ActiveUS20110244224A1Improve resistance performanceImprove adhesionVacuum evaporation coatingSputtering coatingChalcogenide glassOptoelectronics

An anti-reflection film provided on a surface of a chalcogenide glass base includes a first thin film layer and a second thin film layer. The first thin film layer is composed of a single layer of Bi2O3 formed by ion beam assisted deposition. The second thin film layer made of YF3 includes assisted layers and non-assisted layers laminated alternately. The assisted layers are formed by the ion beam assisted deposition, while the non-assisted layers are formed without assistance of an ion beam. The assisted layer is superior in adhesion and surface flatness or smoothness. On the other hand, the non-assisted layer has small internal stress. The second thin film layer functions as a buffer to relieve the internal stress of the first and second thin film layers.

Owner:FUJIFILM CORP

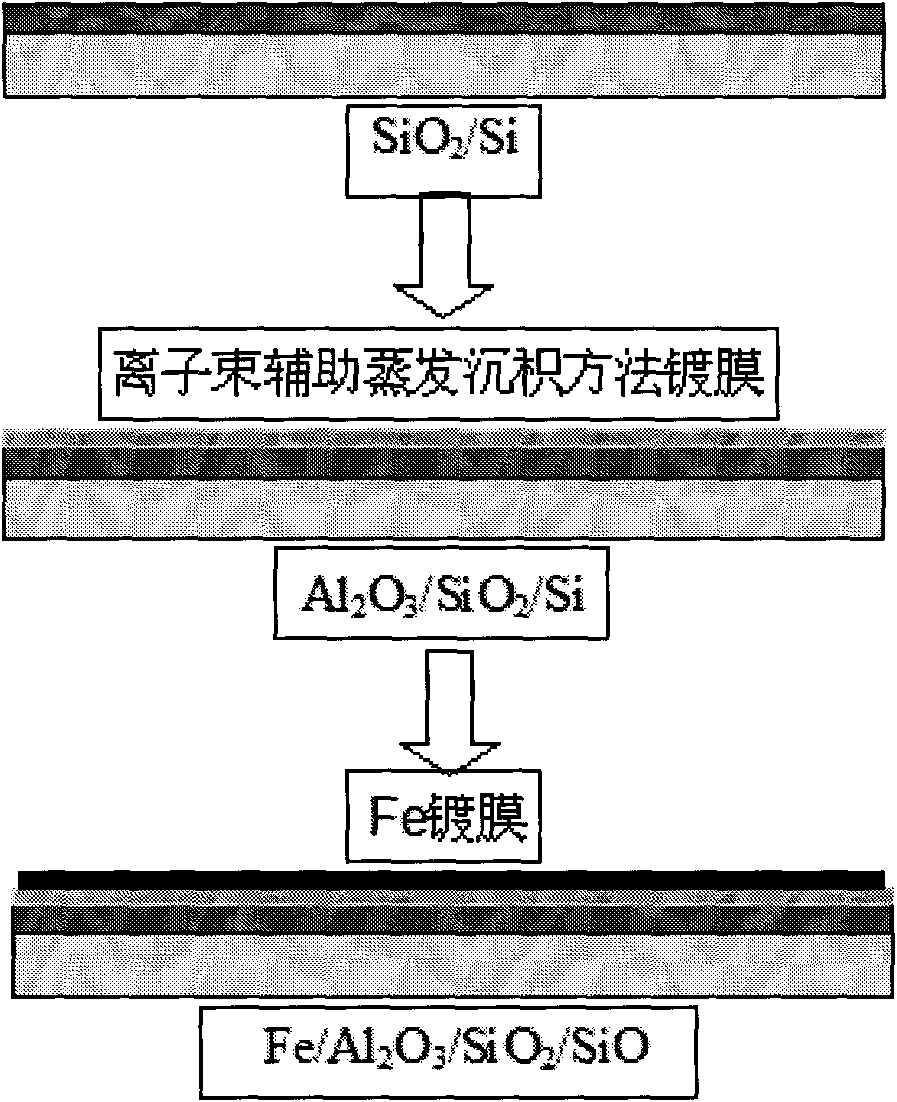

Preparation method of carbon nano tube array for spinning

The invention discloses a preparation method of a carbon nano tube array for spinning, comprising the following steps of: preparing an oxide buffer layer on a precast silicon substrate and depositing a metal catalyst film on the oxide buffer layer to form a carbon nano tube array growth catalytic structure with composite activity; heating a reaction furnace to the growth temperature of the carbon nano tube in an environment of protective gas; introducing ethylene and carrier gas to the reaction furnace by controlling the flow and the proportion to grow the carbon nano tube array under normal pressure; and finally quickly finishing the growth of the carbon nano tube array. By adopting the application of ethylene CVD preparation method, a catalyst buffer layer structure is prepared by an ion beam assistant deposition method, and the metal catalyst film thickness and the growth technological parameter are controlled. The obtained carbon nano tube array has the advantages of small diameter of the carbon nano tube, small number of tube walls, high carbon tube surface distribution density on the substrate and is useful in high-area preparation, therefore, the invention provides possibility for the application of the carbon nano tube in the industrial spinning manufacturing.

Owner:SUZHOU CREATIVE CARBON NANOTECH

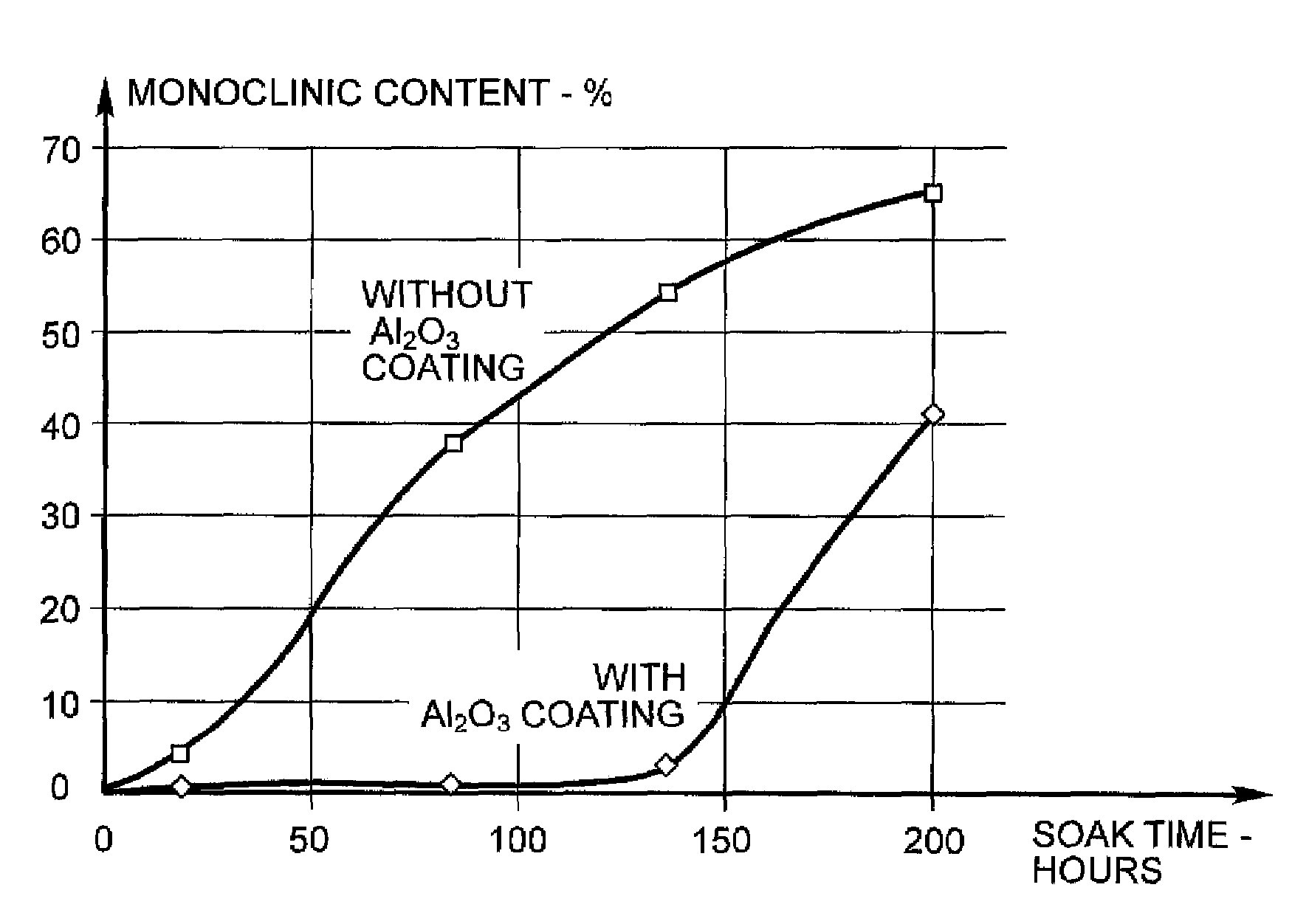

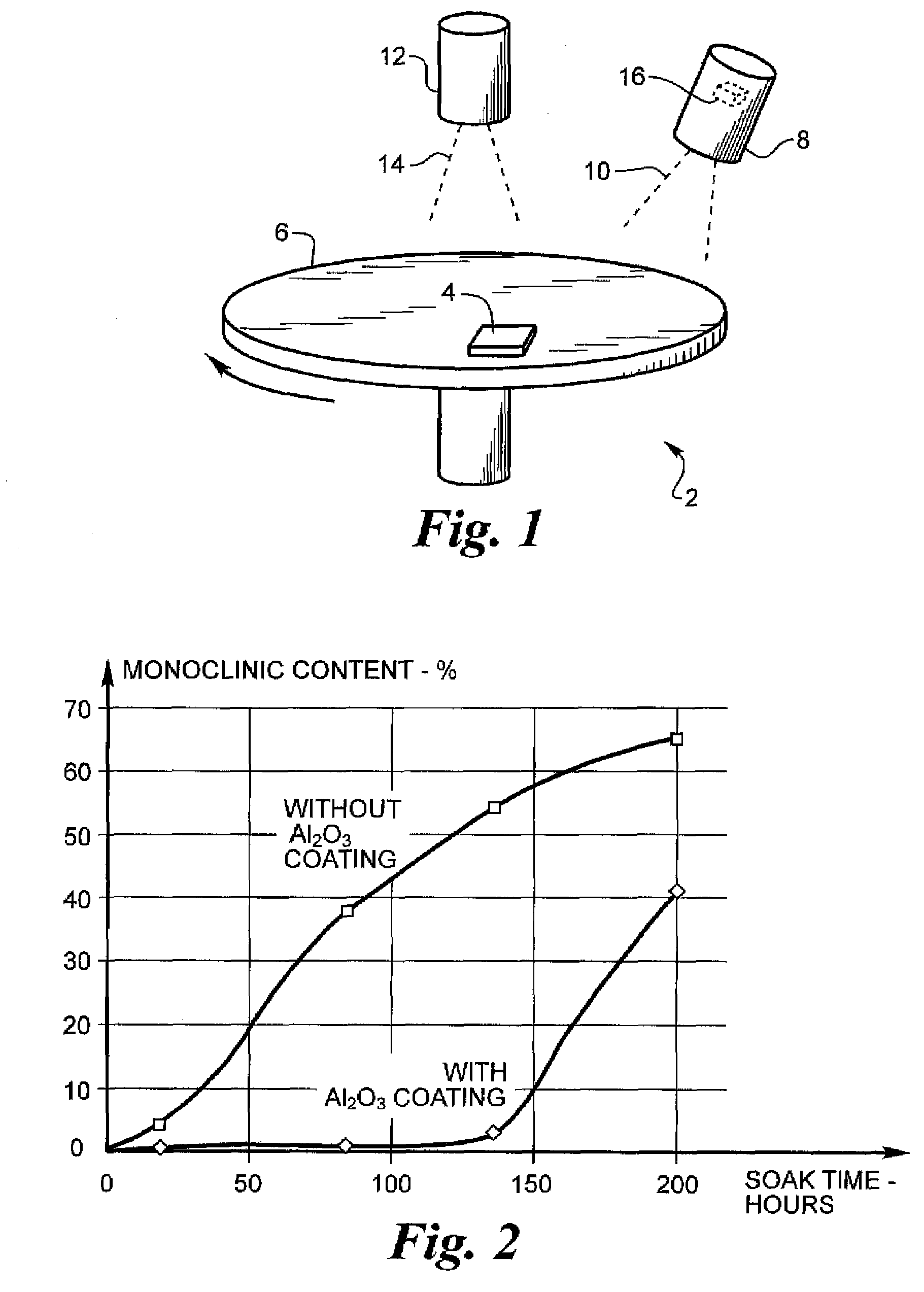

Material to prevent low temperature degradation of zirconia

ActiveUS7297420B2Vacuum evaporation coatingSputtering coatingHigh fractureIon beam-assisted deposition

The invention is directed to a material that is unaffected by the low-temperature degradation, humidity-enhanced phase transformation typical of yttria-stabilized zirconia, as well as of yttria-stabilized tetragonal zirconia polyorystalline ceramic (Y-TZP). Because of the high fracture toughness and high mechanical strength, this class of materials is widely used, including as implants, such as for the packaging material for small implantable neural-muscular sensors and stimulators. The destructive phase transformation rate is dramatically reduced by coating the surface of the Y-TZP component with dense alumina by a physical vapor deposition process, preferably ion beam assisted deposition.

Owner:FOUND FOR SCI RES ALFRED E MANN

Preparation method of metal doped hydrogen-free diamond-like carbon film

InactiveCN102965618AHigh film hardnessImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingDiamond-like carbonIon beam-assisted deposition

The invention discloses a preparation method of a metal doped hydrogen-free diamond-like carbon film which. The method is characterized in that an ion beam assisted deposition technology is utilized to prepare a metal doped hydrogen-free diamond-like film on a workpiece and a metal target and a graphite target are used for carrying out double-target sputtering. The preparation method comprises the following specific steps of: cleaning and activating ions on the surface of the workpiece and depositing to prepare the metal doped hydrogen-free diamond-like film. The prepared metal doped hydrogen-free diamond-like film has relatively higher film hardness, film-matrix binding force, elastic modulus, abrasion resistance, thermal stability and other performances. The preparation method is strong in technological operability and good in repeatability and can be applied to the surface treatment of silicon and various metal workpieces.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method of producing biaxially textured buffer layers and related articles, devices and systems

InactiveUS7071149B2Polycrystalline material growthSuperconductors/hyperconductorsIon beam-assisted depositionPolycrystalline material

A superconductor article includes a substrate and a first buffer film disposed on the substrate. The first buffer film includes a polycrystalline material. An IBAD (ion-beam assisted deposition) second buffer film is disposed on the first buffer film, the second buffer film having a biaxial crystal texture. A superconductor layer can be disposed on the second buffer film.

Owner:SUPERPOWER INC

Preparation method of multi-metal doping hydrogen-free diamond carbon film

InactiveCN102965619AHigh film hardnessImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingSputteringHydrogen

The invention discloses a preparation technology of a multi-metal doping hydrogen-free diamond carbon film. The preparation technology is characterized in that by using an ion beam auxiliary deposition technology, a multi-metal mosaic target (formed by mosaicking a mosaic block 2 in a sputtering region 3 on a base target material 1) and a graphite target are used for double-target sputtering, and the multi-metal doping hydrogen-free diamond film is deposited and prepared on the surface of a workpiece. The preparation technology comprises the following specific steps: preparing the mosaic target, cleaning and activating ions on the surface of the workpiece, and depositing and preparing the multi-metal doping hydrogen-free diamond film. Compared with the prior art, the film prepared by the method has the advantages of higher hardness, film-based bonding force, elasticity modulus, abrasion resistance and hot stability property; and doping components can be adjusted so that the film can meet the requirement of transmission parts of precise instruments for accuracy and increases the reliability of the transmission parts. The film is suitable for surface treatment of silicon and various metal workpieces.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

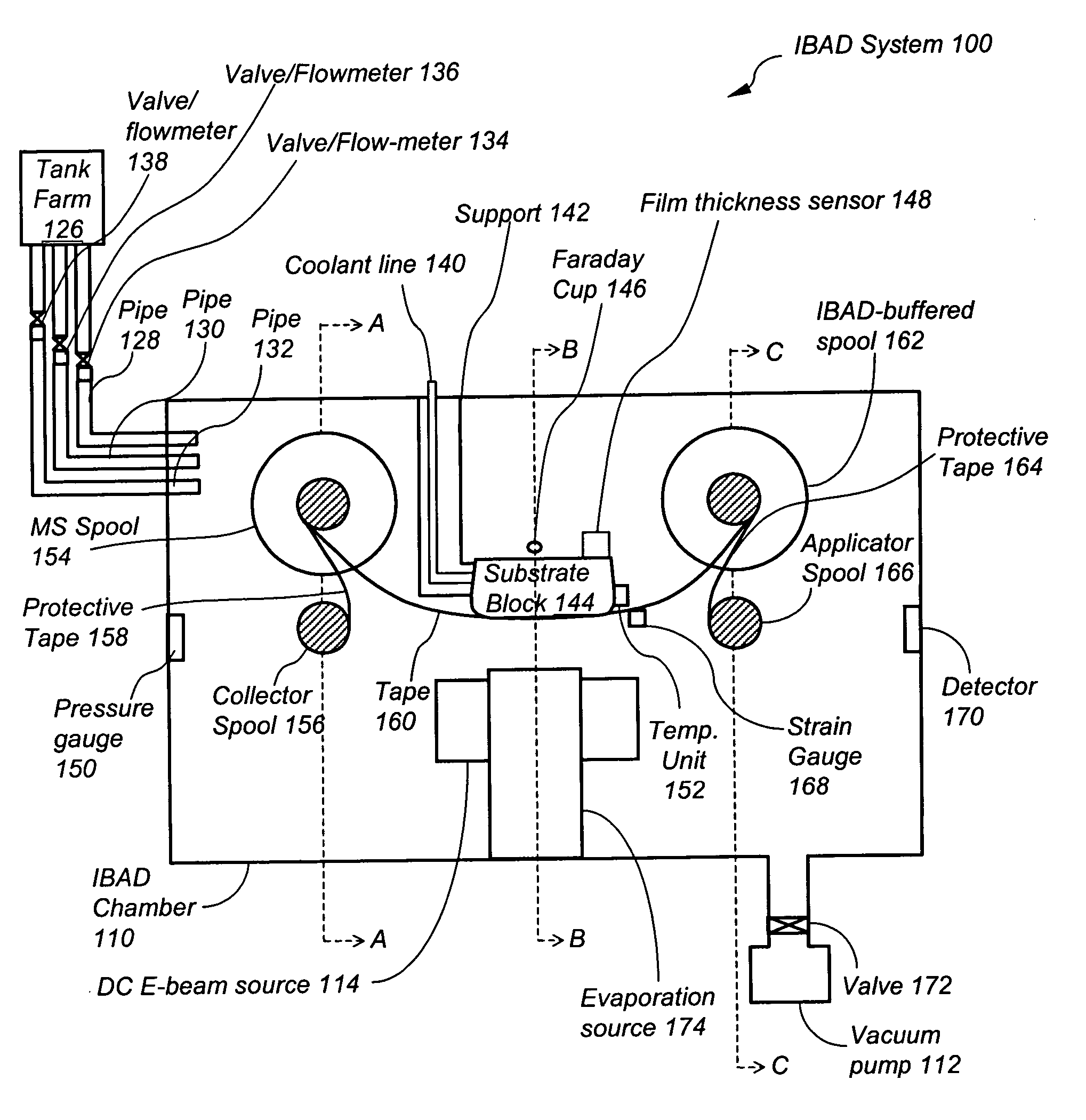

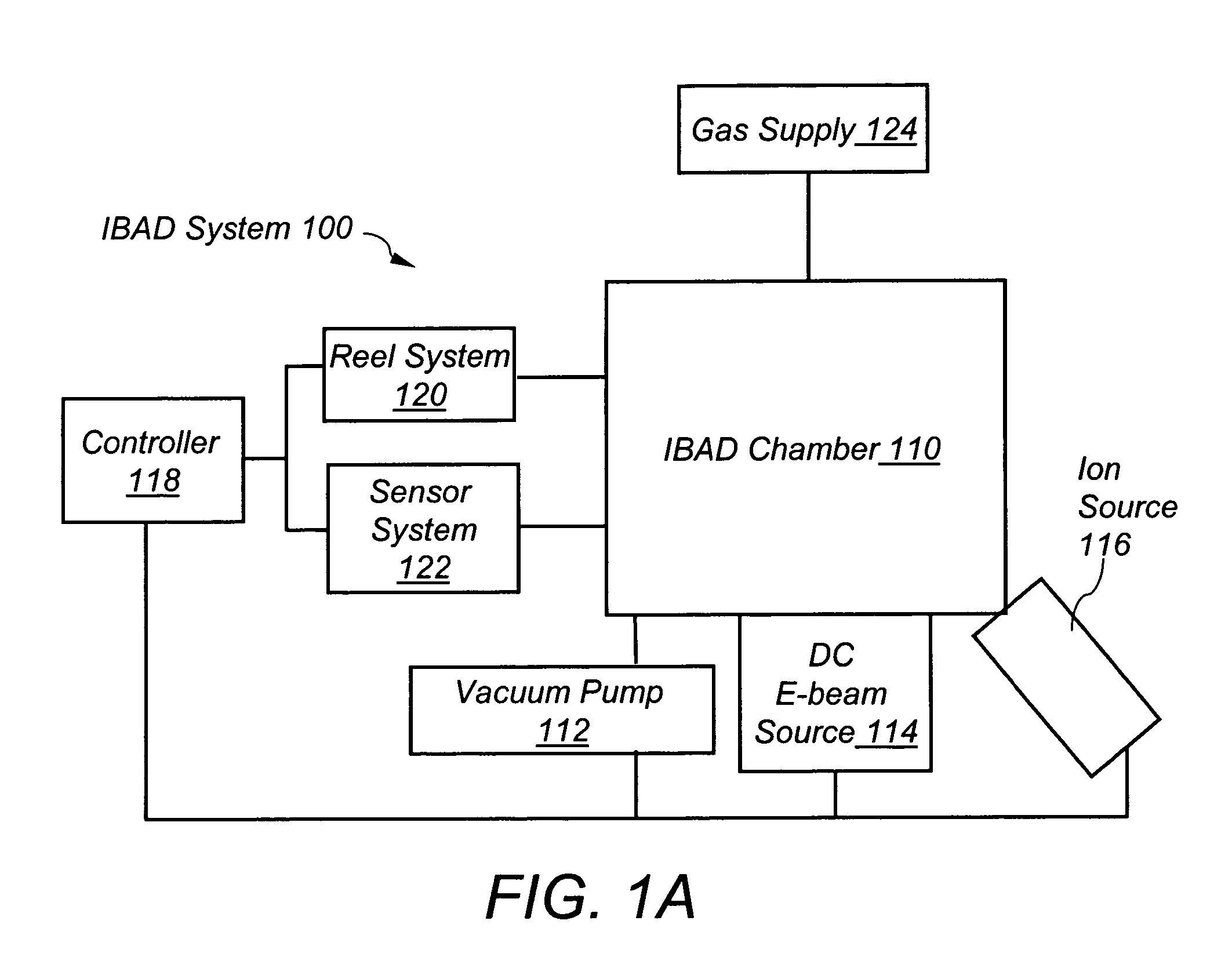

Apparatus for and method of continuous HTS tape buffer layer deposition using large scale ion beam assisted deposition

The present invention is a high-throughput ion beam assisted deposition (IBAD) system and method of utilizing such a system that enables continuous deposition of thin films such as the buffer layers of HTS tapes. The present invention includes a spool-to-spool feed system that translates a metal substrate tape through the IBAD system as the desired buffer layers are deposited atop the translating substrate tape using an e-beam evaporator assisted by an ion beam. The system further includes a control and monitor system to monitor and regulate all necessary system parameters. The present invention facilitates deposition of a high-quality film over a large area of translating substrate.

Owner:SUPERPOWER INC

System for forming nano-laminate optical coating

ActiveUS20190025469A1Improve mechanical propertiesExcellent optical propertiesVacuum evaporation coatingSputtering coatingAnti-reflective coatingBatch processing

A processing system for forming an optical coating on a substrate is provided, wherein the optical coating including an anti-reflective coating and an oleophobic coating, the system comprising: a linear transport processing section configured for processing and transporting substrate carriers individually and one at a time in a linear direction; at least one evaporation processing system positioned in the linear transport processing system, the evaporation processing system configured to form the oleophobic coating; a batch processing section configured to transport substrate carriers in unison about an axis; at least one ion beam assisted deposition processing chamber positioned in the batch processing section, the ion beam assisted deposition processing chamber configured to deposit layer of the anti-reflective coating; a plurality of substrate carriers for mounting substrates; and, means for transferring the substrate carriers between the linear transport processing section and the batch processing section without exposing the substrate carrier to atmosphere.

Owner:INTEVAC

Infrared broadband antireflection microstructure and preparation method thereof

ActiveCN108710164AAddress the needs of large aspect ratiosImprove transmittanceCoatingsRefractive indexEvaporation

The invention provides an infrared broadband antireflection microstructure comprising a substrate, a nanostructure array layer and a low-refractive-index layer which are arranged from the bottom to the top in turn. The nanostructure array layer is provided with nanostructures which are perpendicular to the main axis of the surface of the substrate, and the cross section of the nanostructures has atriangular, conical, parabolic or Gaussian isogradient structure. A layer of low-refractive-index material is added to the nanostructure array, and the low-refractive-index layer is realized by the ion beam sputtering deposition technology or the electron beam evaporation ion beam auxiliary deposition technology so as to avoid water absorption. The thickness of the low-refractive-index layer is adjusted so that the broadband antireflection effect of the nanostructure array layer can be enhanced, high transmittance of broadband range can be realized and the transmitting curve is flatter.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com