Preparation method for waterproof laser film

A technology of laser film and water resistance, which is applied in the field of preparation of waterproof laser film, can solve the problems of difficult application of water cooling system and inability to protect the deliquescent neodymium glass substrate, so as to achieve perfect film shape, improve damage threshold, and safety reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further illustrated below by means of embodiments in conjunction with the accompanying drawings.

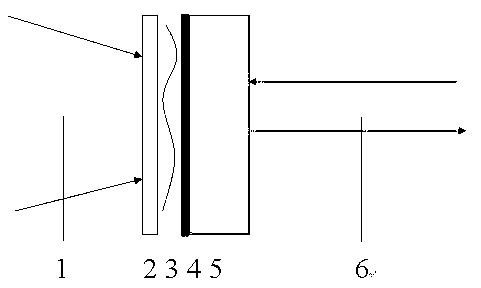

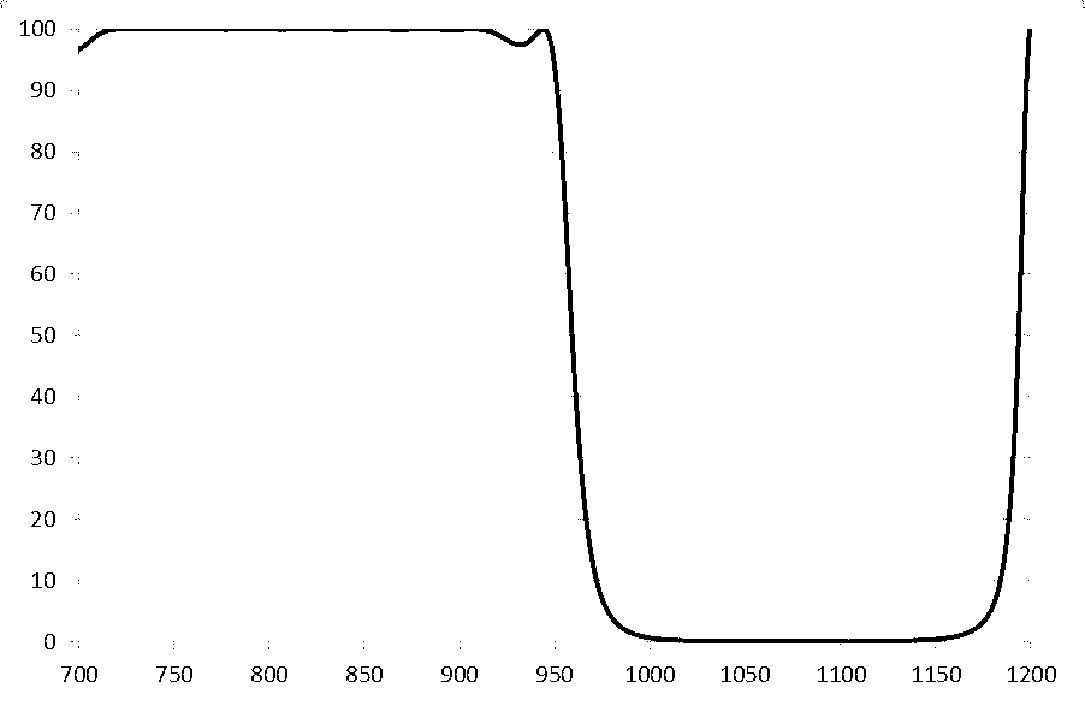

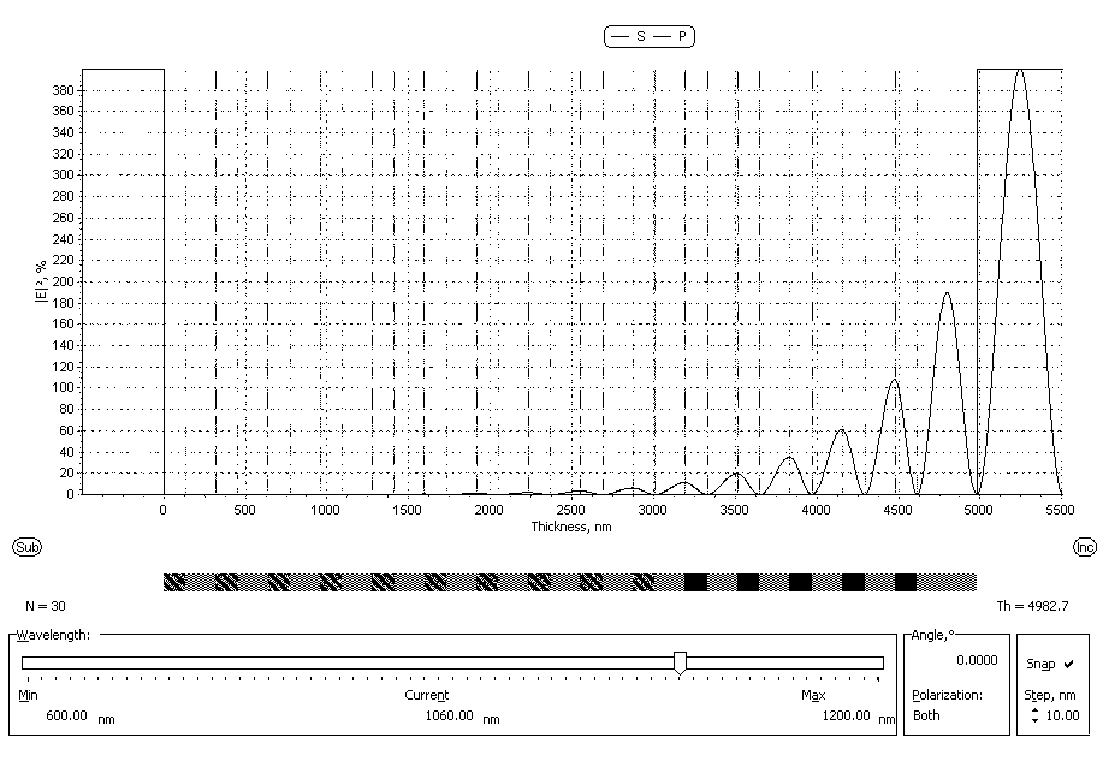

[0043] in the attached figure 1 Among them, 1 is the 802nm pump light, 2 is the sealing water glass of the water cooling system, 3 is the cooling water, 4 is the waterproof laser film, 5 is the neodymium glass substrate, and 6 is the propagation of the 1064nm laser in the resonant cavity. in the attached figure 2 In , the abscissa is the wavelength (nm), and the ordinate is the single-sided transmittance (%). in the attached image 3 In the middle, the air medium is on the left, and the neodymium glass substrate is on the right. The abscissa is the thickness distribution of the film structure, black represents HfO 2 , the oblique bar indicates Ta 2 o 5 , gray indicates SiO 2 . The specific implementation steps are as follows:

[0044] 1. The required spectral requirements are set as follows: the single-sided transmittance at 802nm is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com