Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

365 results about "Vacuum electronics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

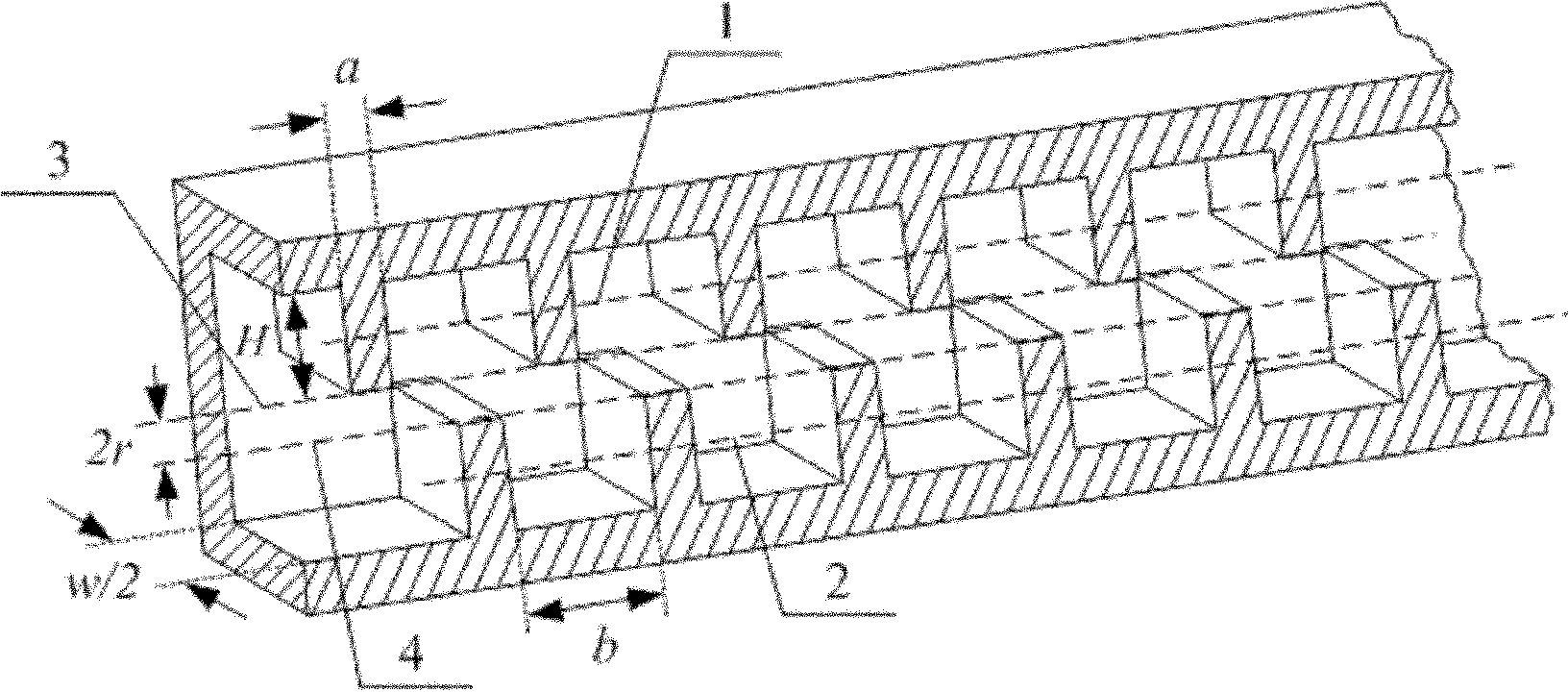

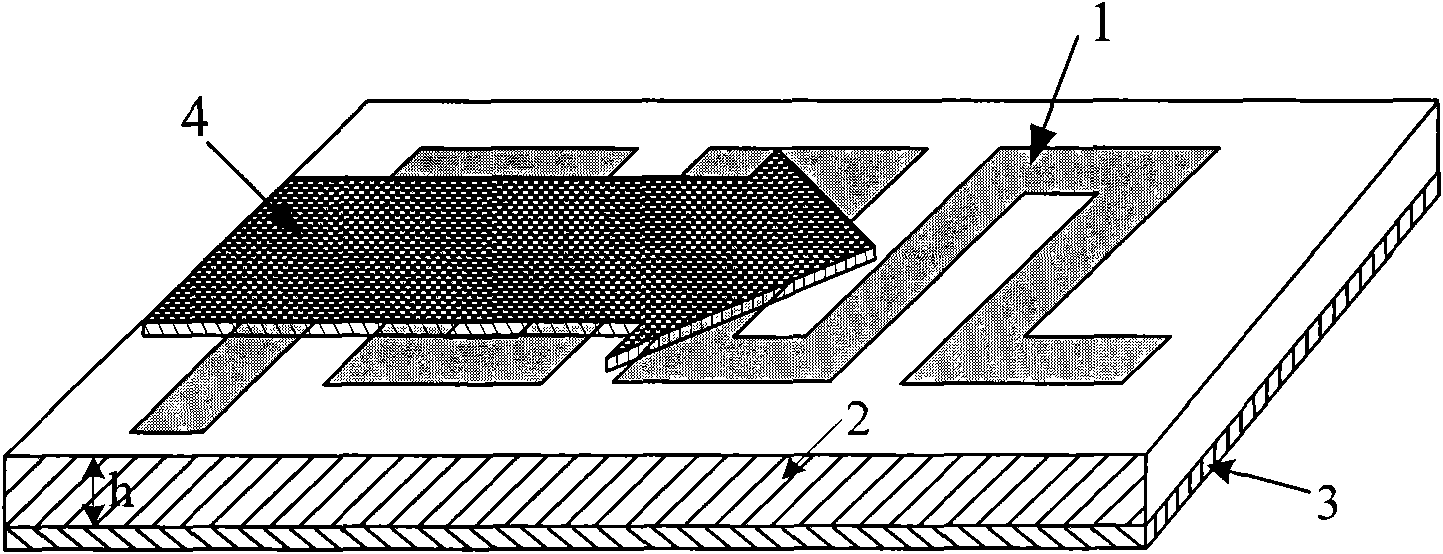

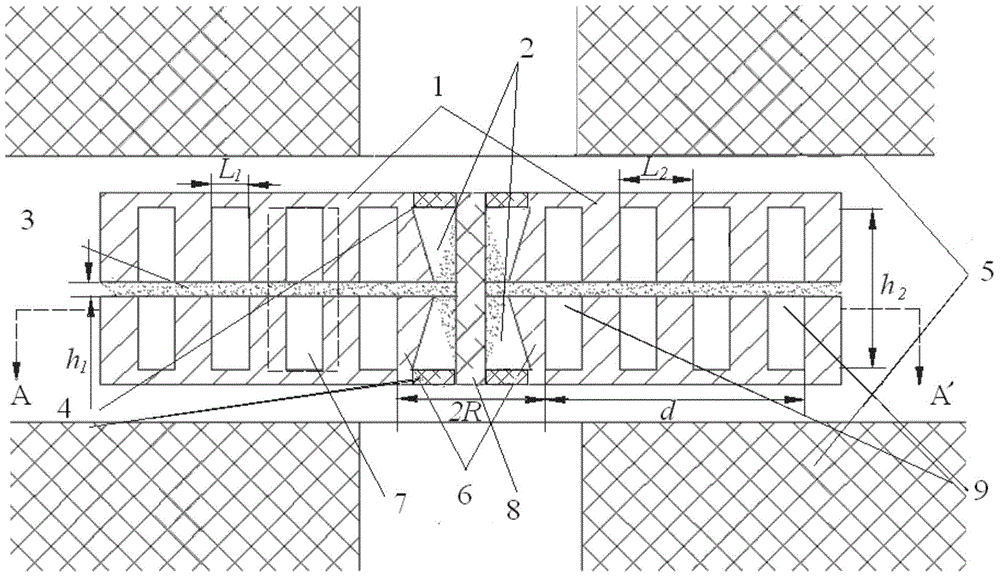

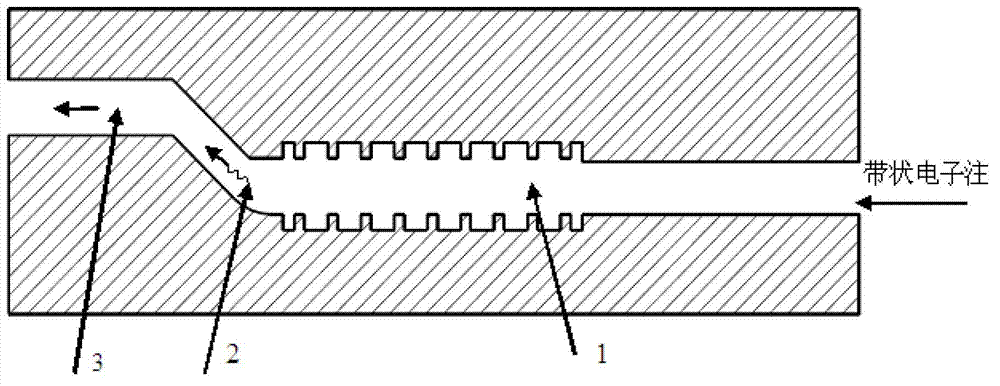

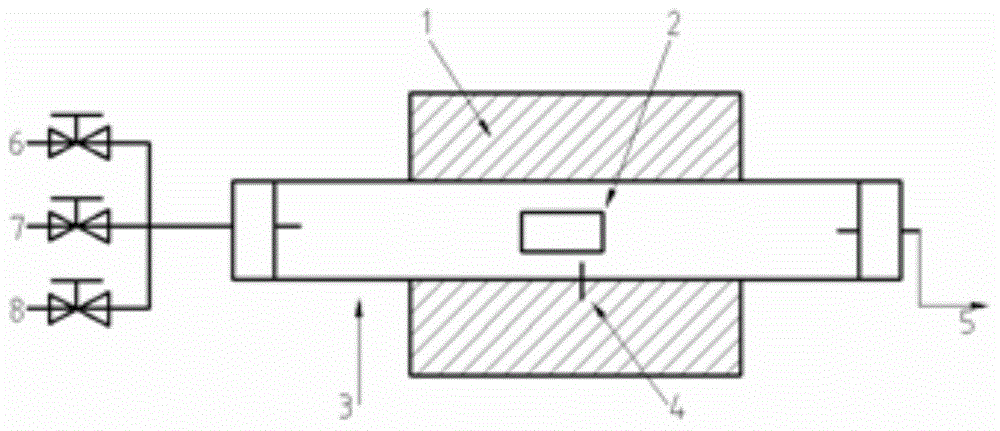

Energy coupling device suitable for rectangular-crossed double-gate slow-wave structure

InactiveCN102064069APromote circulationEnhanced couplingTransit-tube coupling devicesWave structureEnergy coupling

The invention relates to an energy coupling device suitable for a rectangular-crossed double-gate slow-wave structure, belonging to the technical field of vacuum electronics. One end of the device is connected with a rectangular waveguide, and the other end is connected with a rectangular-crossed double-gate slow-wave structure; the part connected with the rectangular-crossed double-gate slow-wave structure comprises an upper row and a lower row of rectangular gate waveguide structures which are mutually staggered and distributed and have gradually changed height; the half-height positions of the rectangular gates at the upper row are in an upper datum plane (1); all half-height positions of the rectangular gates at the lower row are in a lower datum plane (2); counted from a port connected with the rectangular-crossed double-gate slow-wave structure, the heights of the upper row and the lower row of rectangular gates are gradually reduced to zero; and the maximum height of the rectangular gates does not exceed the rectangular gate height of the rectangular-crossed double-gate slow-wave structure. The invention has the advantages of favorably coupling a microwave signal into the rectangular-crossed double-gate slow-wave structure, favorably extracting the amplified microwave signal from the rectangular-crossed double-gate slow-wave structure and being easy to connect with a traditional standard waveguide device.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

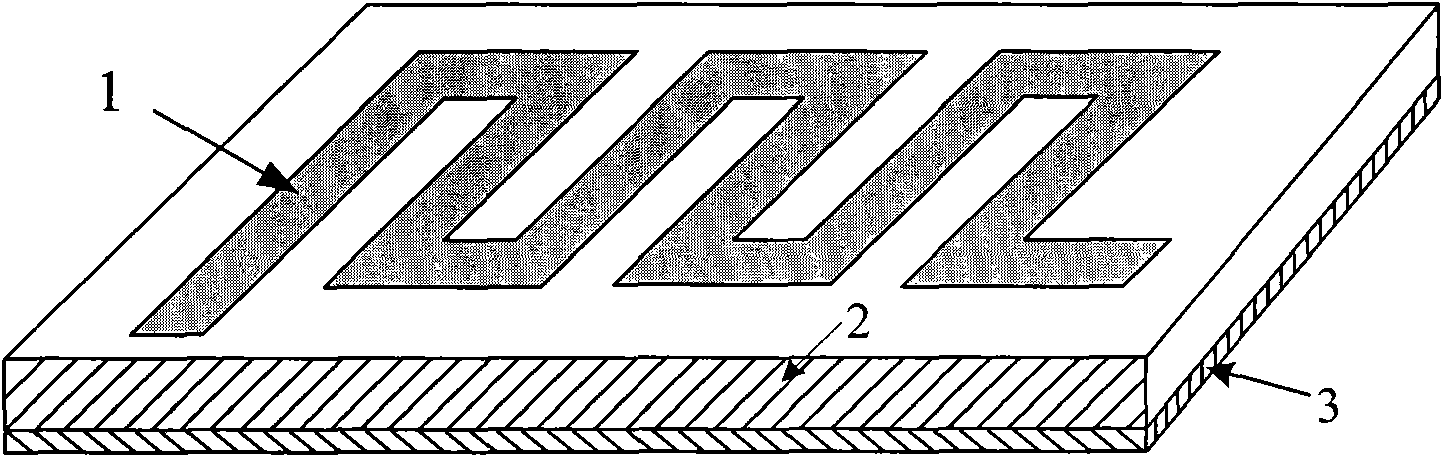

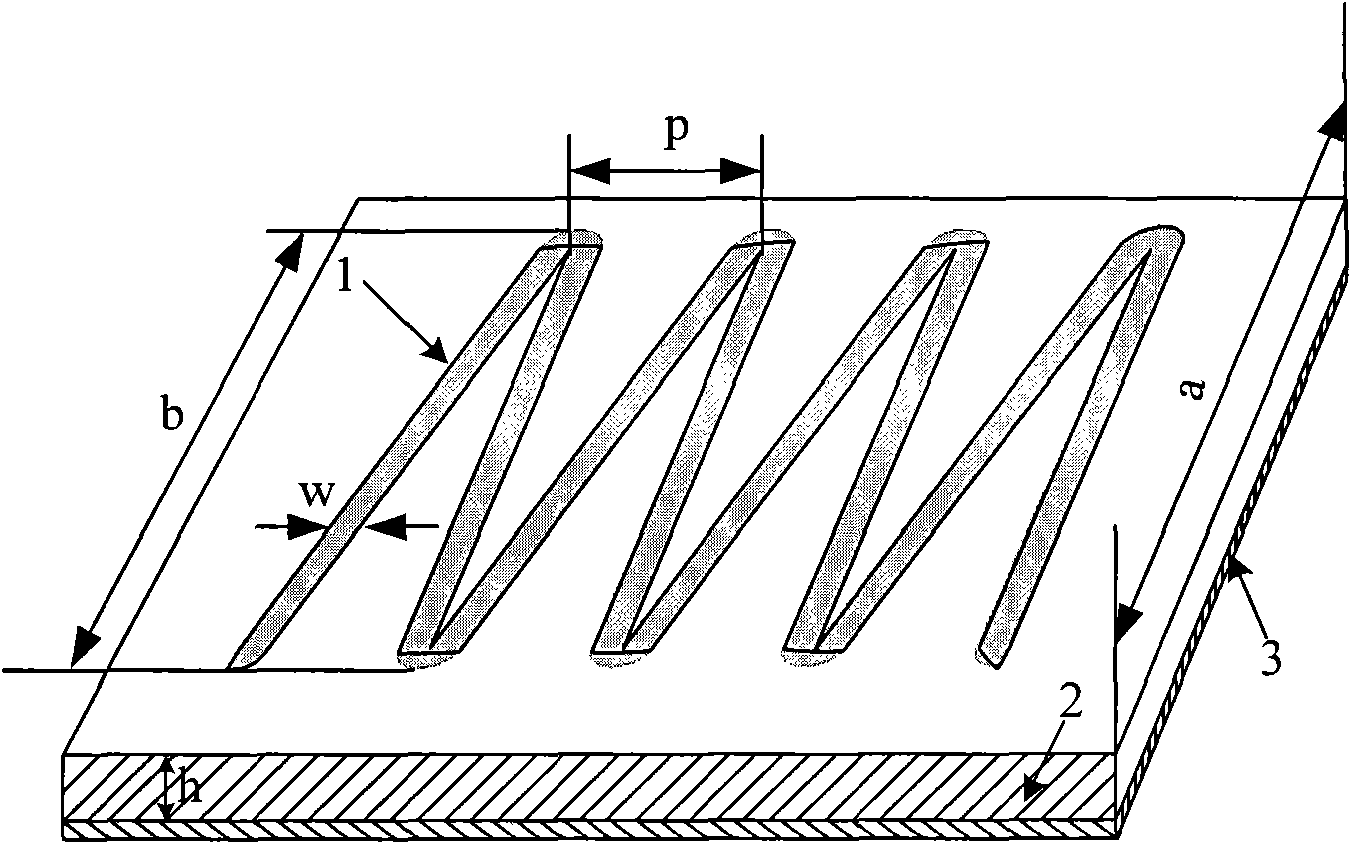

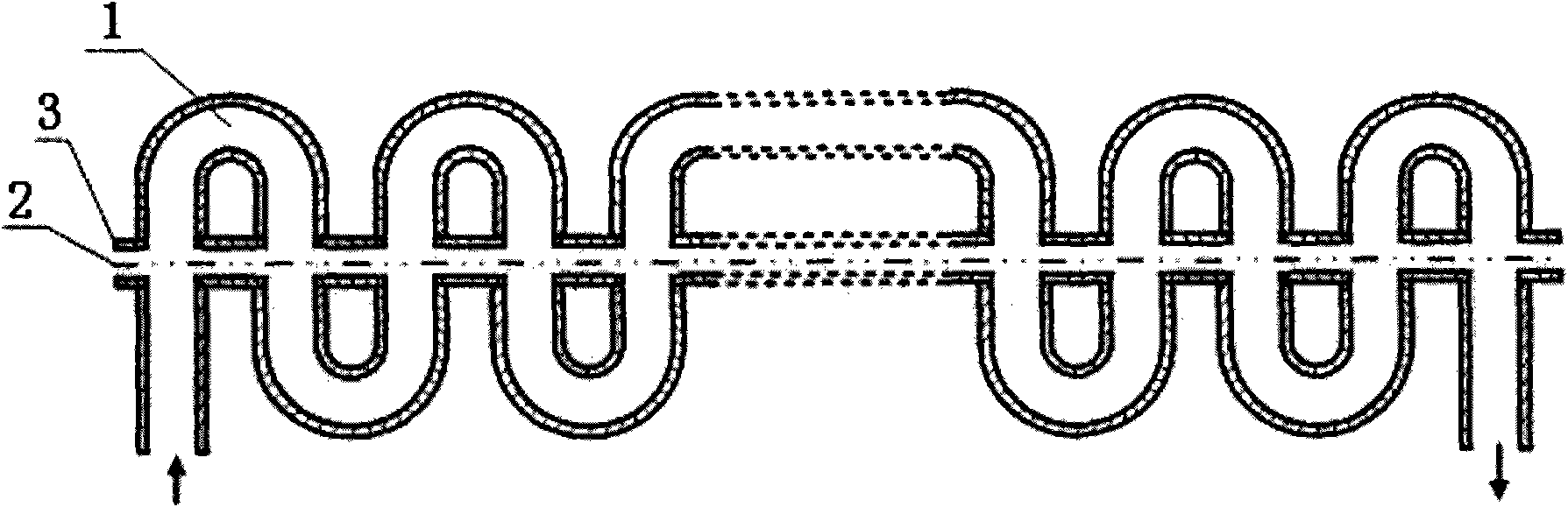

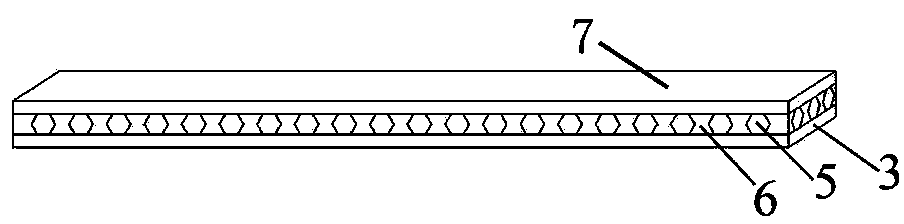

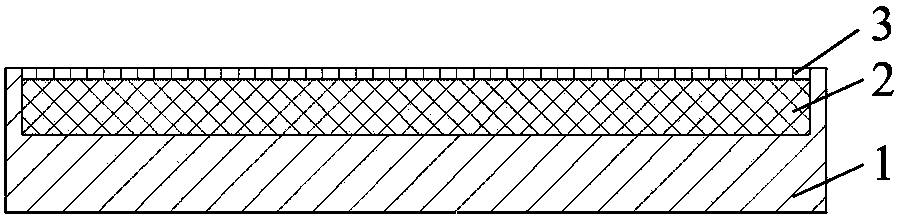

V-shaped micro-strip meander-line slow wave structure

InactiveCN101894724AImprove working bandwidthHigh coupling impedanceTransit-tube circuit elementsWave structureVacuum electronics

The invention discloses a V-shaped micro-strip meander-line slow wave structure, belongs to the technical field of microwave vacuum electronics, and relates to a traveling wave tube amplifier. The V-shaped micro-strip meander-line slow wave structure comprises a micro-strip transmission line structure consisting of a metal bottom plate (3), a dielectric layer (2) and a planar metal wire (1) and is characterized in that: the dielectric layer (2) is positioned between the metal bottom plate (3) and the planar metal wire (1); the planar metal wire (1) has a zigzag structure formed by connecting a plurality of sections of planar metal wires which have the same shape and dimension end to end; and the adjacent two sections of planar metal wires constitute a V shape or a reverse V shape, and the included angle 2theta of the V shape or reverse V shape is less than 180 degrees. The shape of the dielectric layer (2) can be the same as that of the metal bottom plate (3) or the planar metal wire (1). Compared with the conventional right-angle micro-strip meander-line slow wave structure, the V-shaped micro-strip meander-line slow wave structure has wider working band and higher coupling impedance and can further meet the requirements of an equipment system on the device in aspects of working bandwidth, output power, weight and volume.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

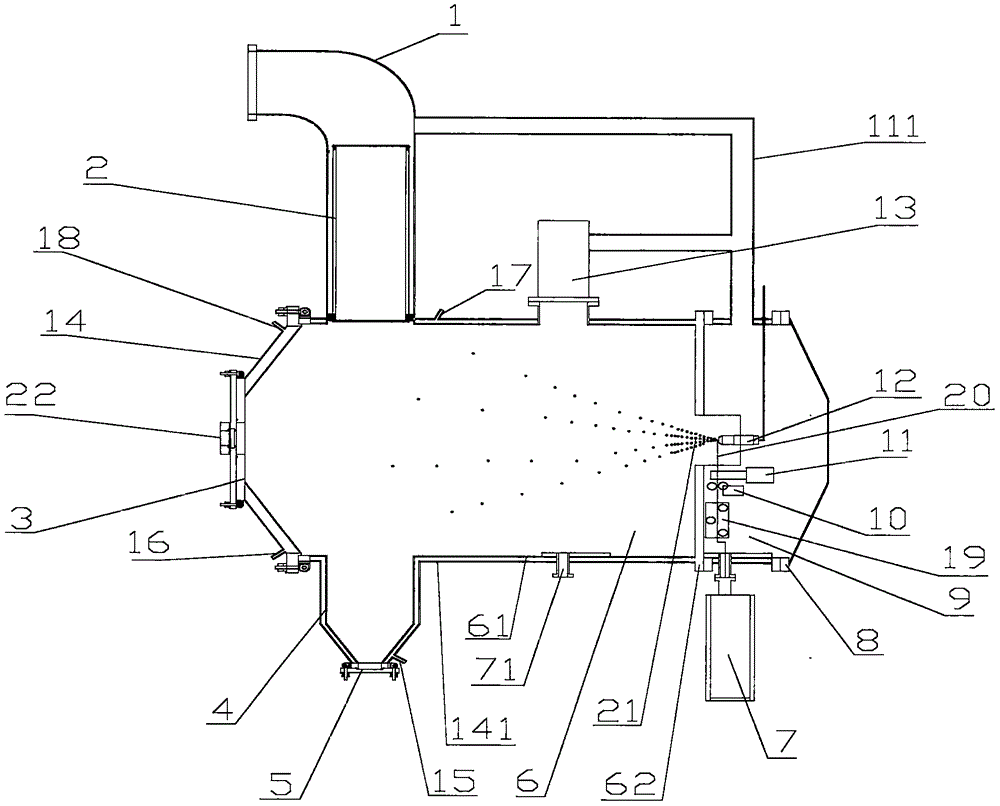

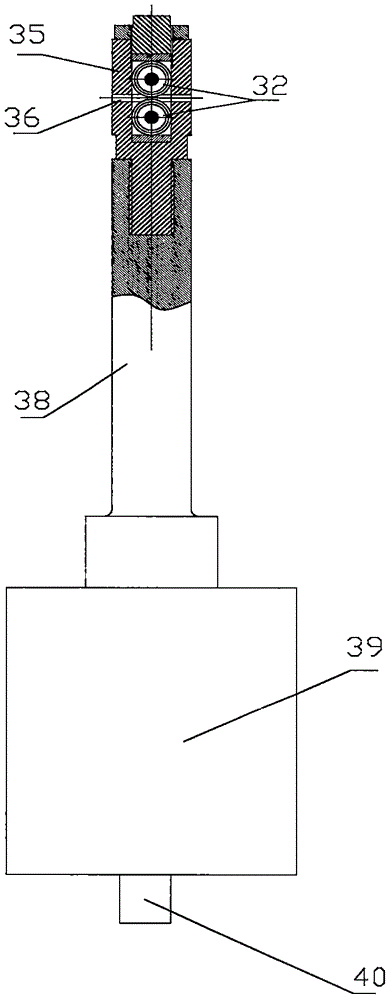

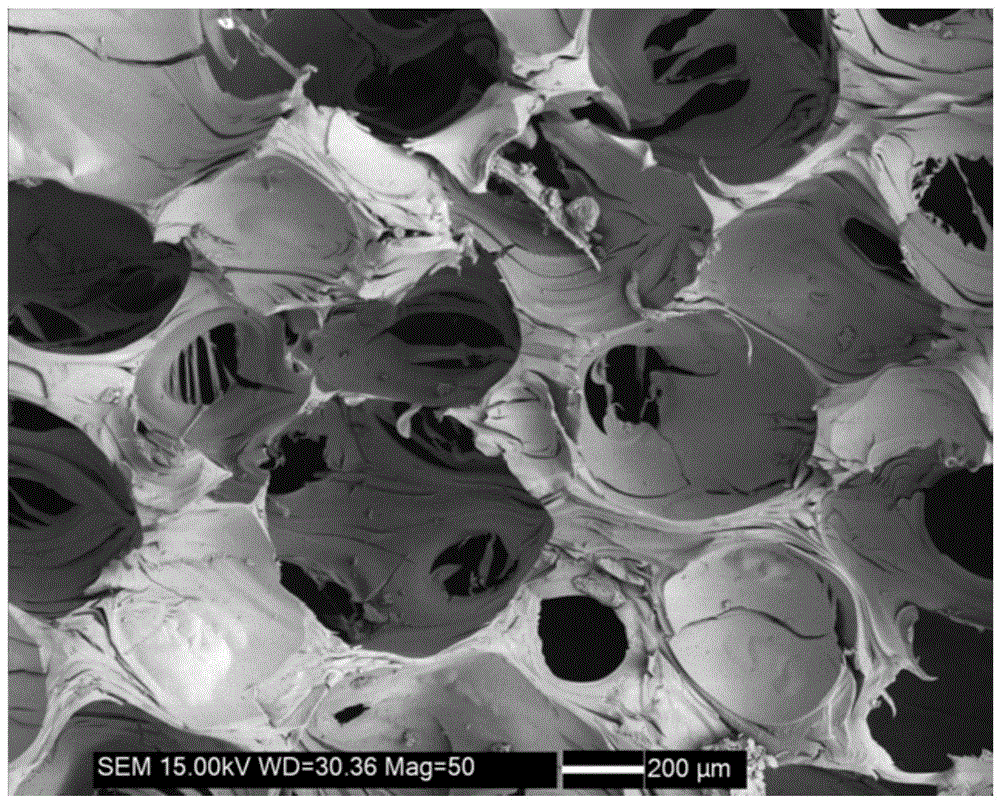

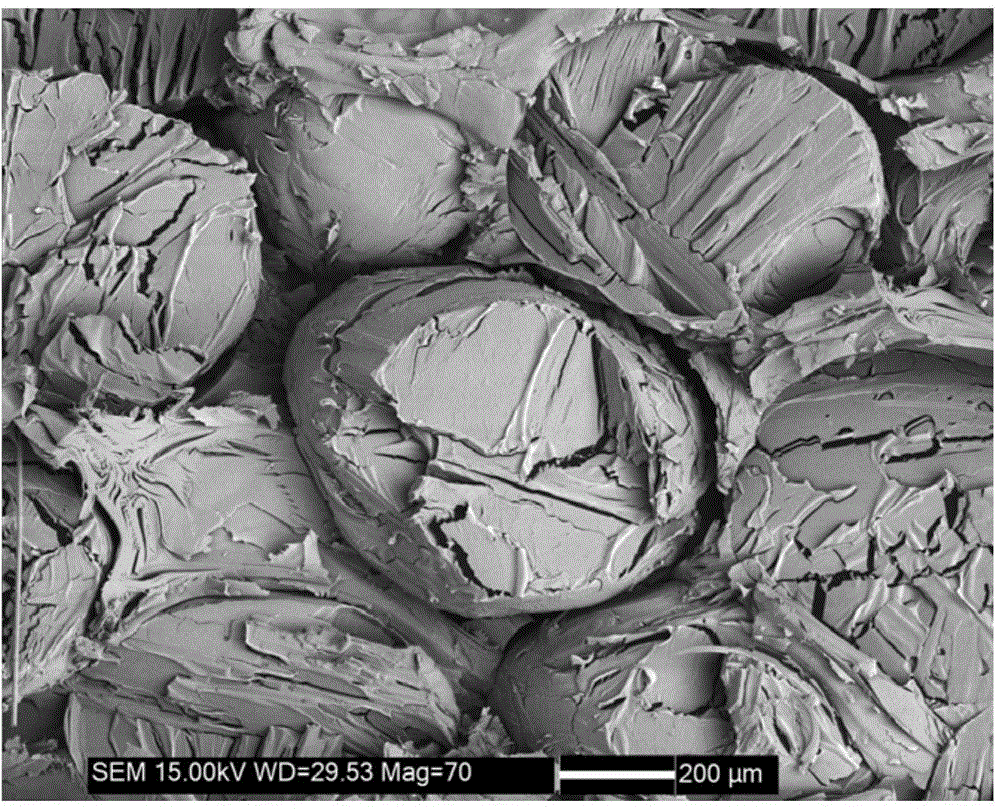

Equipment and technology for preparing superfine spherical metal powder by means of ultrasonic vibration and atomization

ActiveCN105855558ARealize large-capacity productionHigh purityTransportation and packagingMetal-working apparatusVacuum pumpingPlasma generator

The invention provides an equipment and technology for preparing superfine spherical metal powder by means of ultrasonic vibration and atomization. The metal powder is prepared by adopting a stepless speed-regulation ultrasonic vibration wire feeding system and a vacuum electron beam generator or multiple plasma generators to melt and atomize metal materials in a combined mode. The equipment comprises a vacuum atomizing chamber and a barrel thereof, the upper portion of the barrel is communicated with a vacuum pumping exhaust pipeline and the electron beam generator, the left end of the barrel is provided with a front door, the right end of the barrel is provided with a vacuum atomizing chamber rear door, the outer surface of a powder accumulation hopper, the outer surface of the barrel and the outer surface of the vacuum atomizing chamber front door are each coated with a cooling water jacket, and an auxiliary mechanical chamber is defined by an atomizing chamber interlayer arranged inside the barrel and the vacuum atomizing chamber rear door. According to the equipment and technology for preparing the superfine spherical metal powder by means of ultrasonic vibration and atomization, two metal powder preparation methods are combined into a whole and selectively used, continuous long-time large-capacity production can be achieved through only one-time starting, and the produced powder is high in purity, fine in particle size, centralized in distribution and significant in spherical appearance characteristic; the equipment occupied space is small, operation is easy, the investment is low, and the running cost is low.

Owner:深圳市恒歌科技有限公司

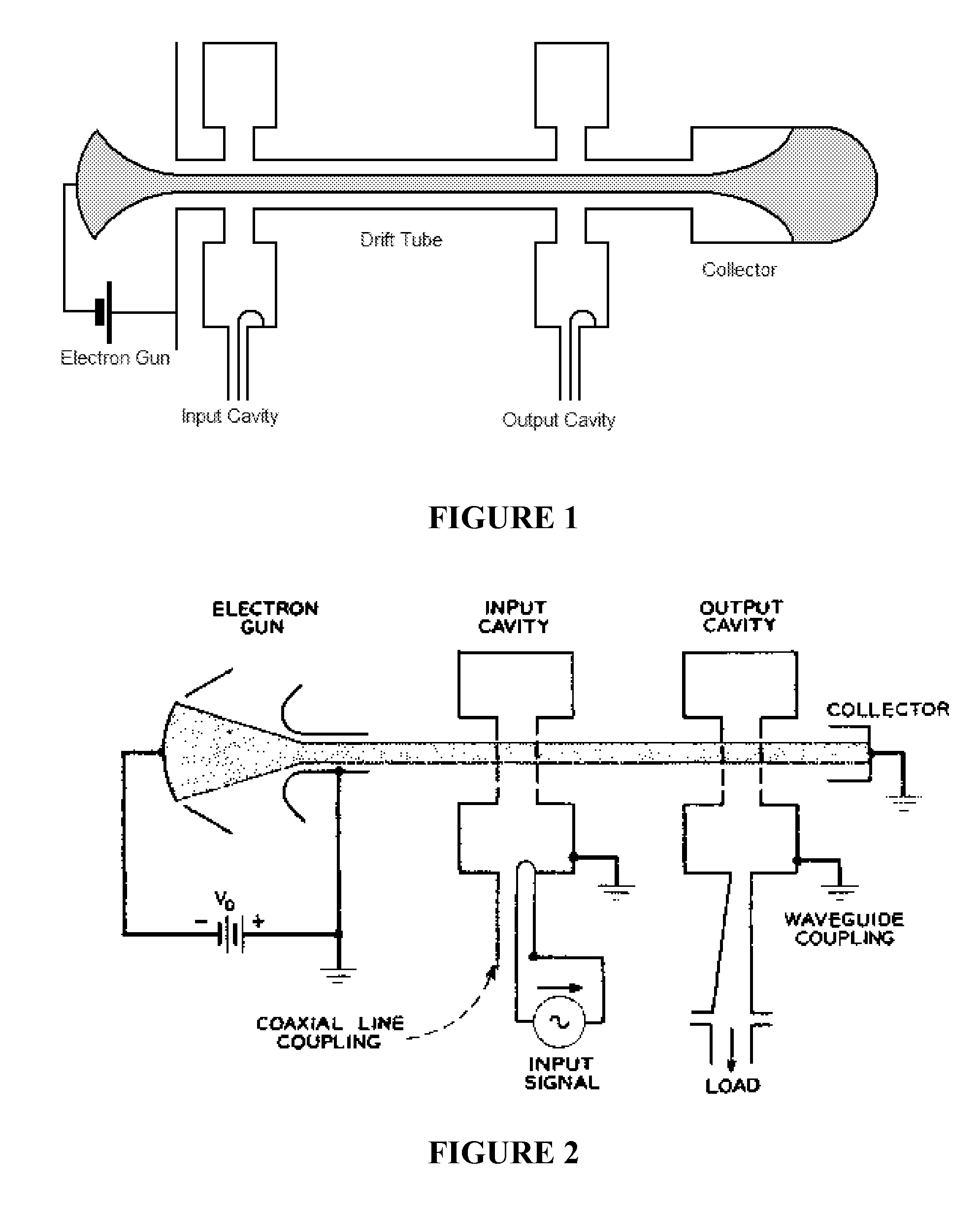

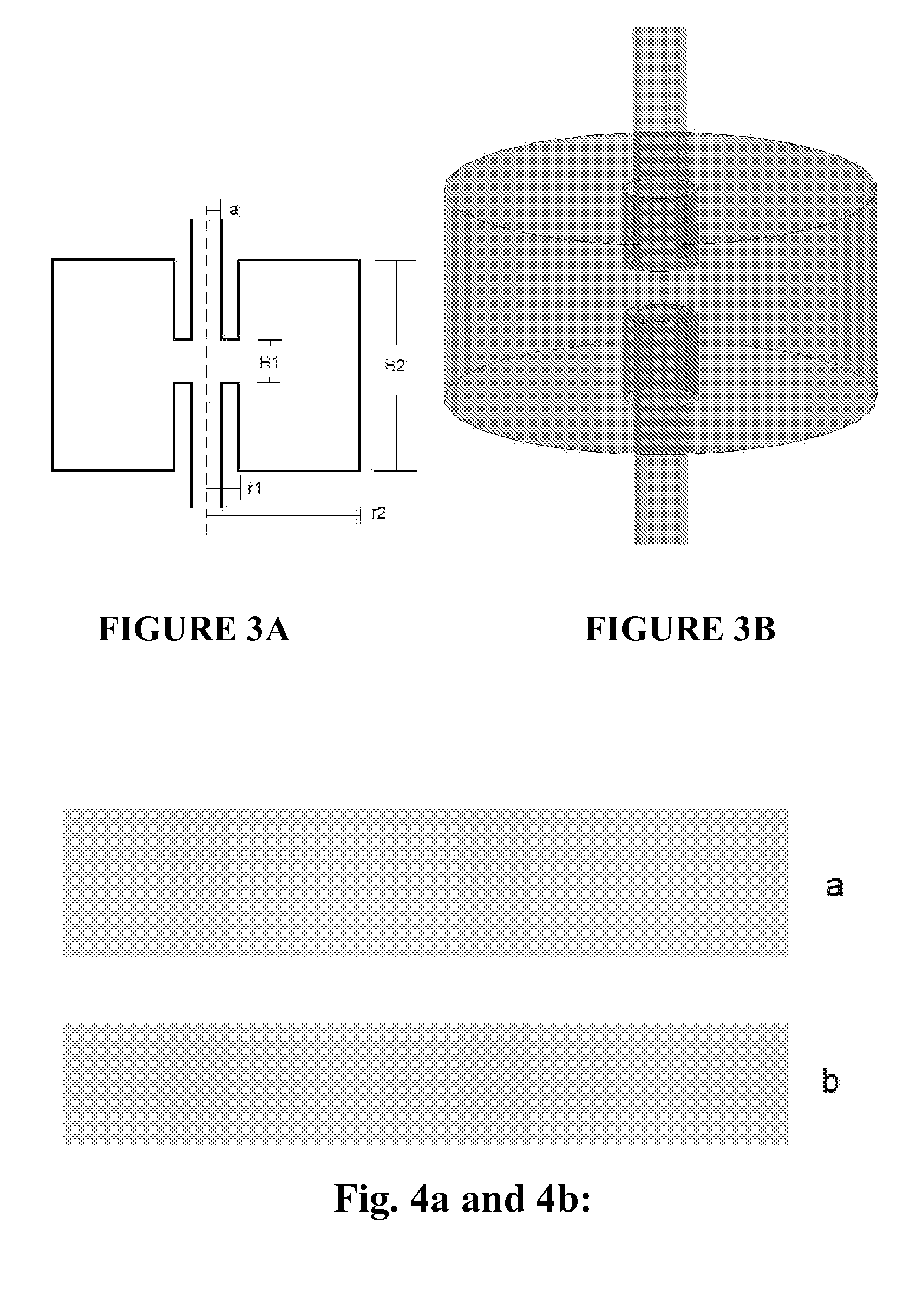

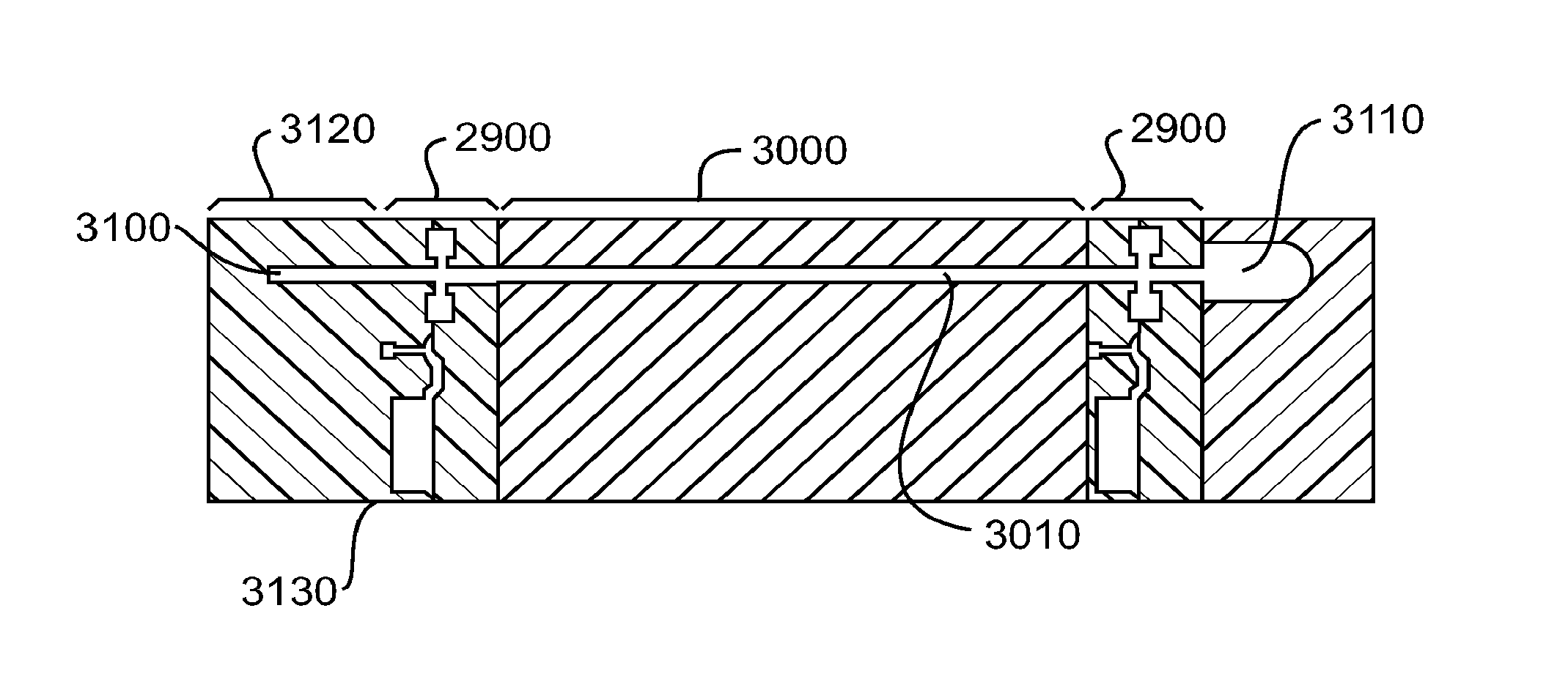

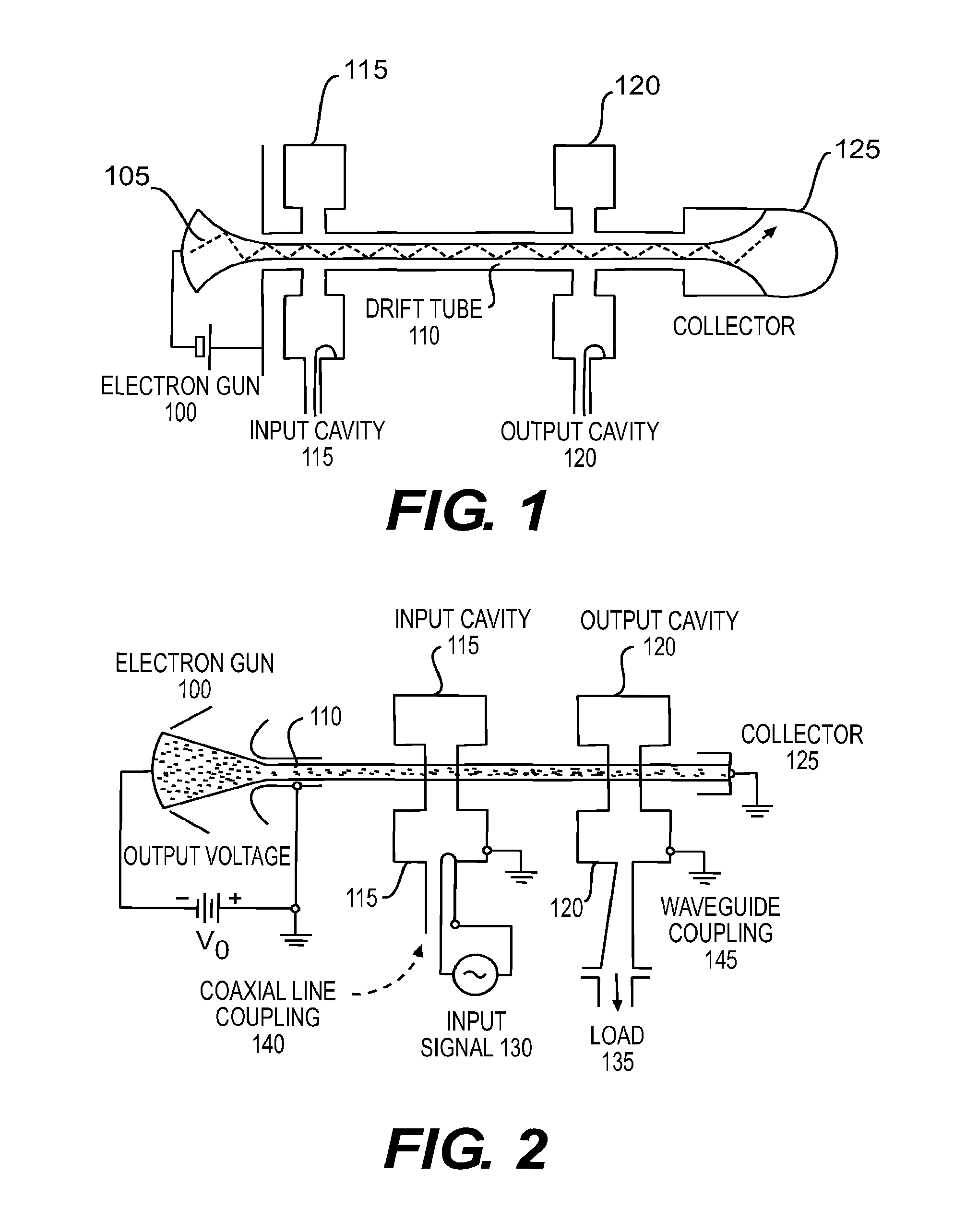

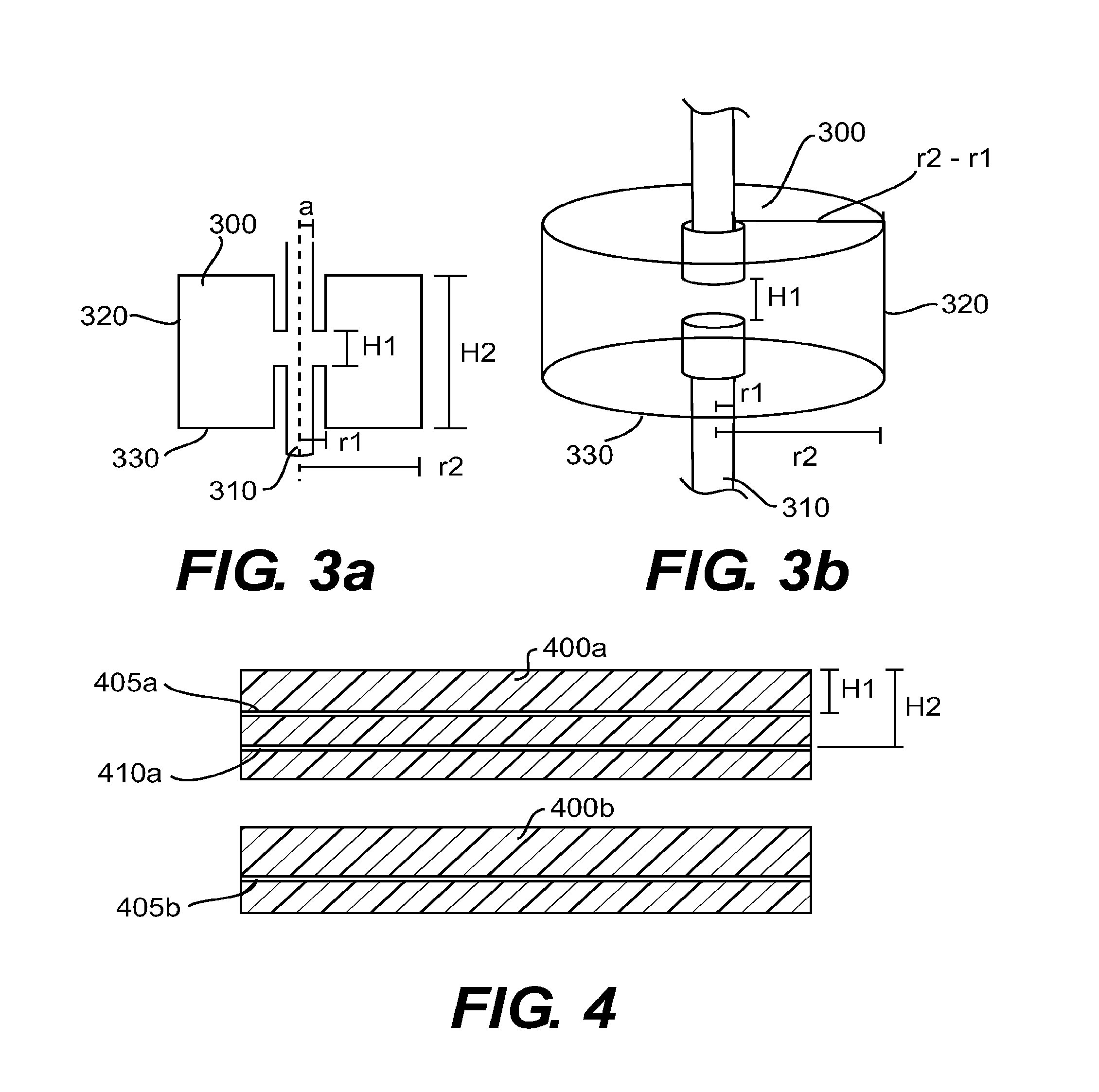

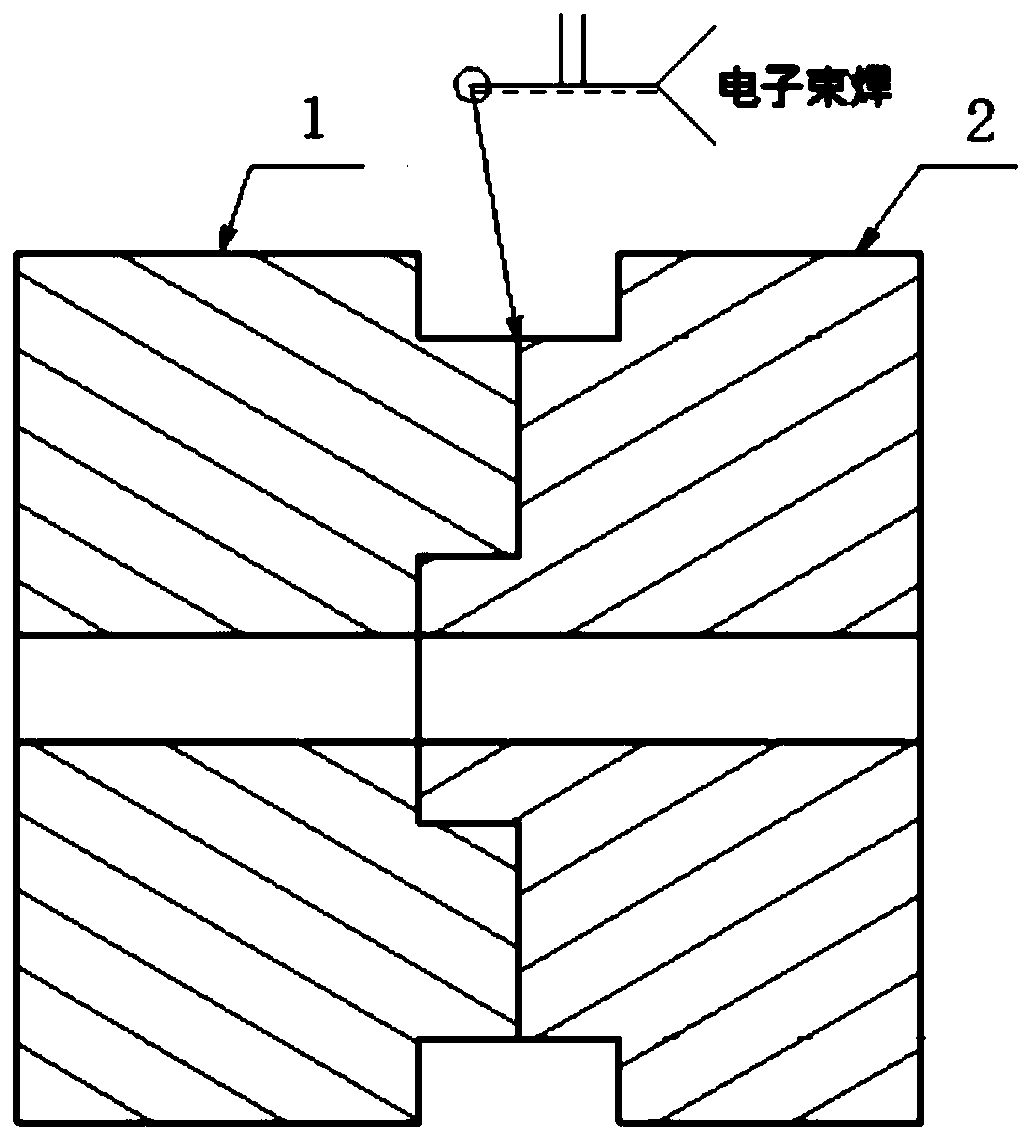

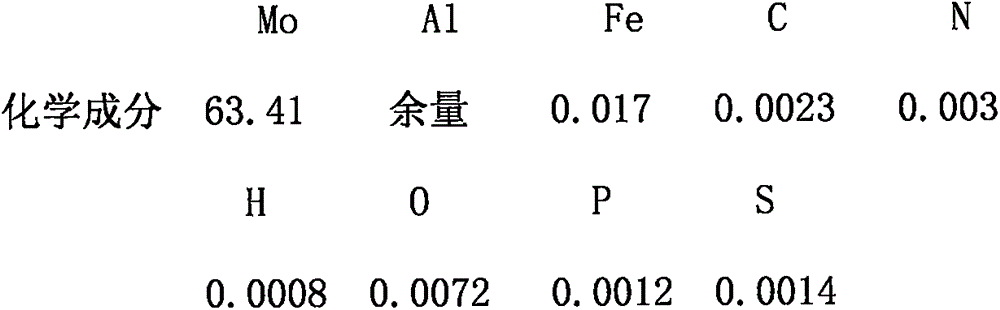

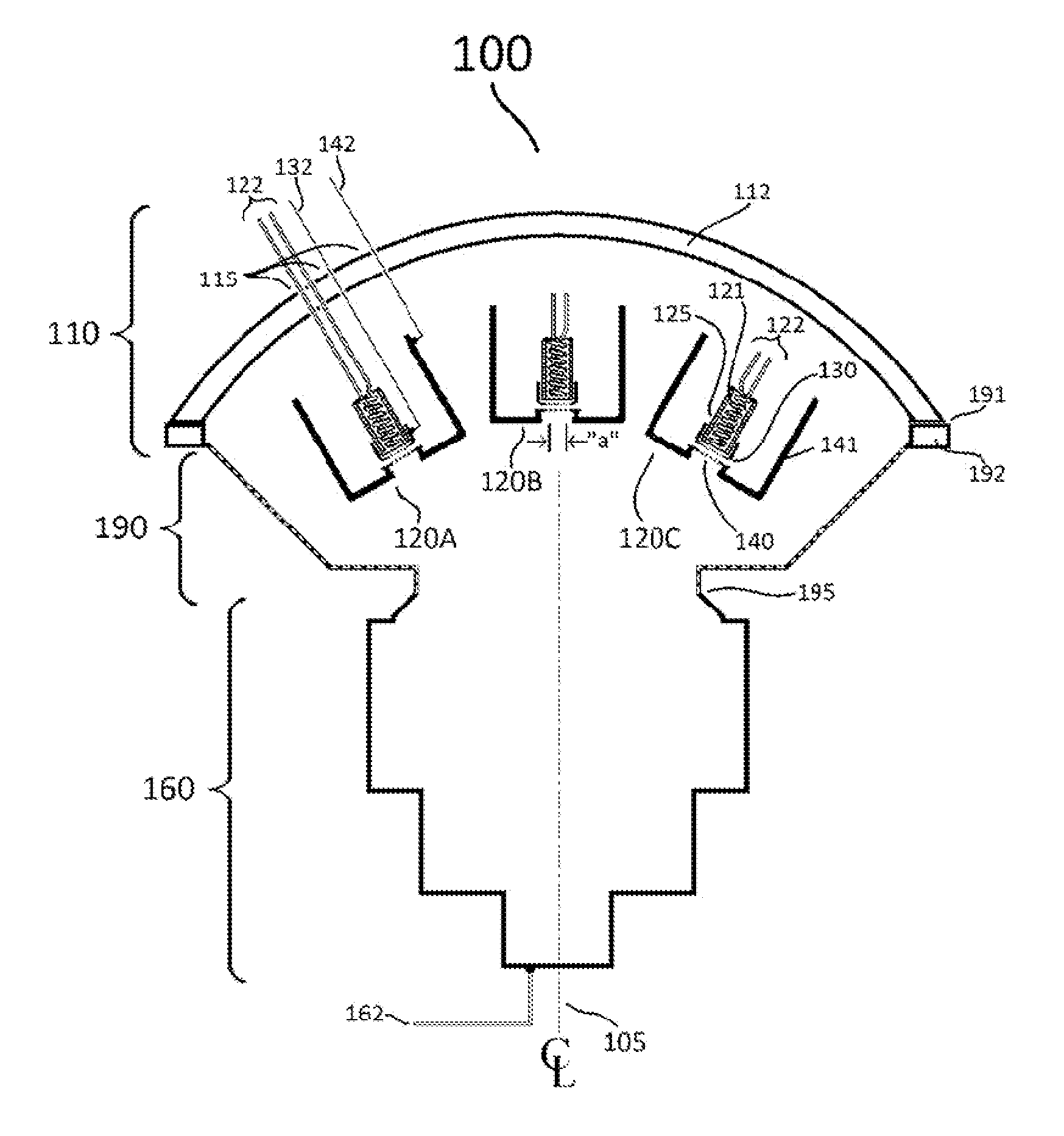

Vacuum Electronic Devices and Cavities and Fabrication Methods Therefor

The present invention relates to the formation of a vacuum electronics circuit by the fusion bonding of multiple substrate wafers, e.g., silicon, copper, or other suitable conductive material, each etched using DRIE, cut using EDM, or machined by other suitable means. Other aspects of the invention relate to the alignment of a cathode with tube by fusion bonding the cathode wafer to a tube built using the fabrication methods described herein. Yet other aspects involve the alignment of dies or wafers during the fabrication of a vacuum electronics device using the “lego” technique outlined herein. In yet other aspects, fabrication methods are described.

Owner:LOGOS TECH HOLDCO INC

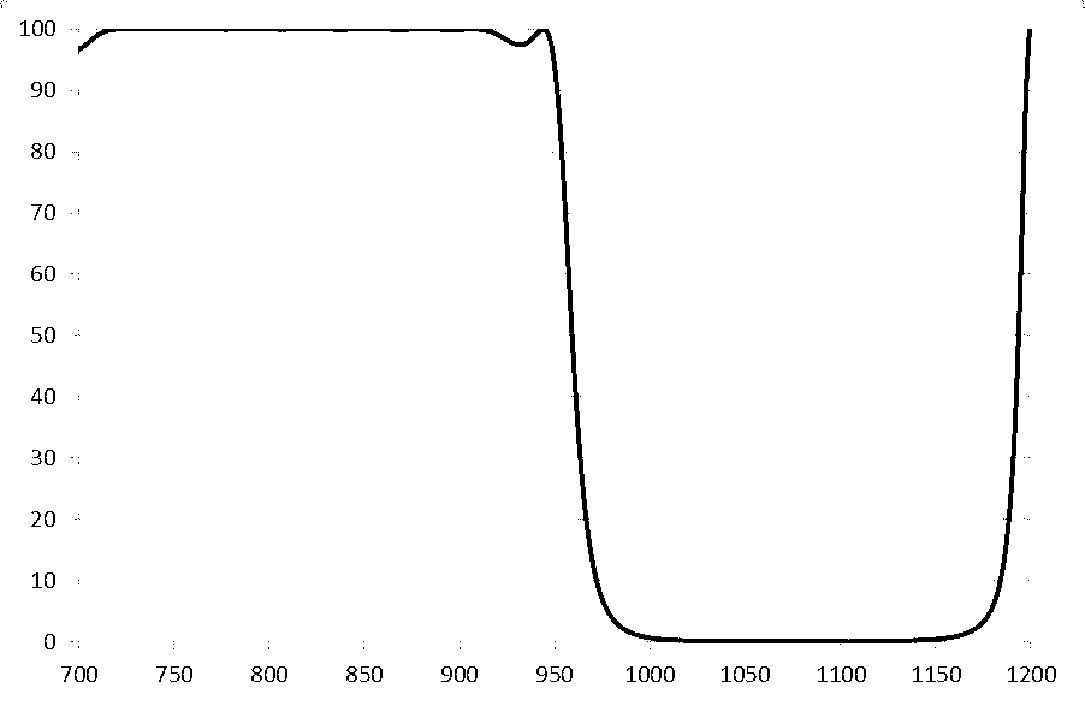

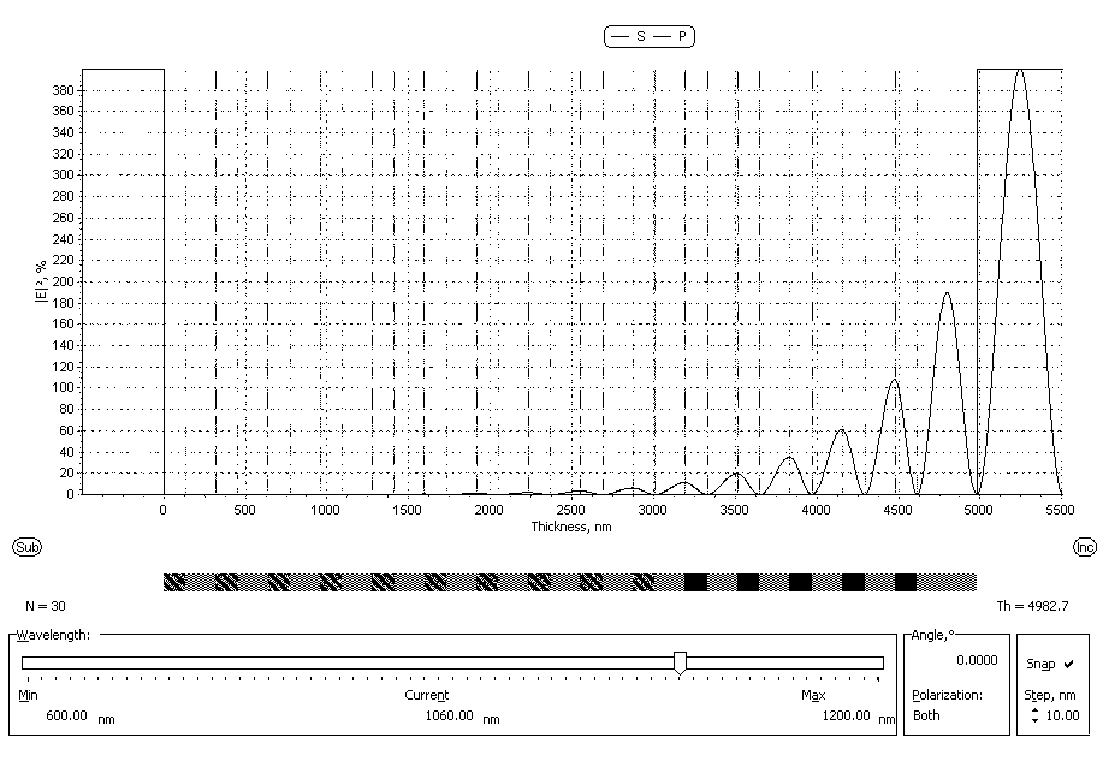

Preparation method for waterproof laser film

ActiveCN103173720AImprove transmittanceImprove reflectivityVacuum evaporation coatingSputtering coatingDiode-pumped solid-state laserRefractive index

The invention relates to a preparation method for a waterproof laser film. According to the requirement in practical application of normal incidence 800nm pumping transmission and back incidence 1064nm fundamental frequency light reflection, an HfO2 and SiO2 film is prepared by a vacuum electron beam evaporation sedimentation technology and is taken as the film which has a large electric filed and is easy to damage due to being close to a base plate when being used as the back incidence, so as to obtain higher laser damage resistance threshold; aiming at the working condition of a water cooling system, for the films close to the water side and easy to be permeated and corroded, Ta2O5 and SiO2 films are prepared by an ion beam auxiliary sedimentation technology, so that the microstructure of the film is improved, higher stacking density is obtained, and good waterproof performance is realized; HfO2, Ta2O5 and SiO2 of high or low refractive index are deposited alternately so as to form a multi-layer film, and the optical thickness of each layer is controlled so as to obtain the needed spectral characteristic. The preparation method can well take advantages of the three characteristics and can apply the characteristics to a neodymium glass substrate of a diode pumping solid laser system, so that the diode pumping solid laser system can work in a water cooing system normally, and has good laser damage resistance performance and the spectral characteristic needed by the system.

Owner:润坤(上海)光学科技有限公司

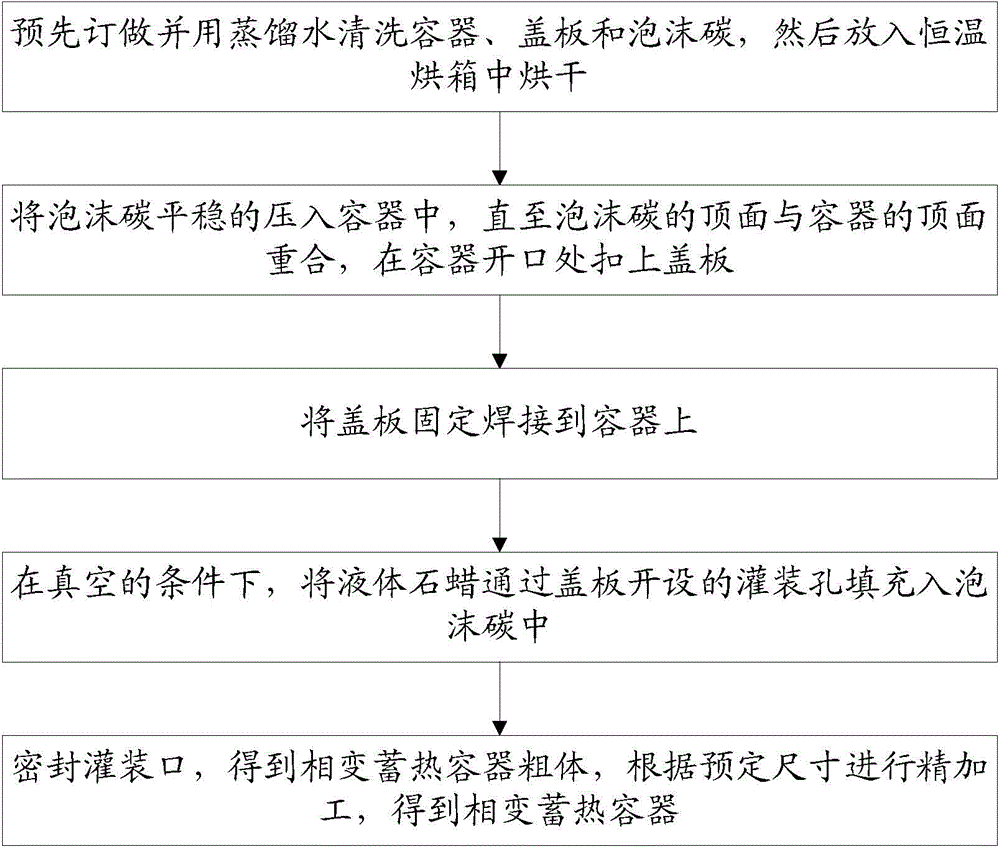

Foamy carbon/paraffin type phase-change composite material and encapsulation method thereof

ActiveCN104893674AImprove heat transfer performanceImprove thermal conductivityHeat-exchange elementsElectron beam welding apparatusParaffin waxParaffin oils

The invention discloses a foamy carbon / paraffin type phase-change composite material and an encapsulation method thereof, and relates to the technical field of phase-change energy storage. The phase-change composite material comprises foamy carbon and paraffin filling holes of the foamy carbon, wherein the weight ratio of the foamy carbon to the paraffin is 1:1.2-1:3.1; and the mass fraction of hydrocarbon in the paraffin is more than 98%, and the hydrocarbon is solid at normal temperature. The encapsulation method comprises the following steps: 1, cleaning a container, a cover plate and the foamy carbon; 2, filling the foamy carbon; 3, welding the cover plate; 4, filling with liquid paraffin; and 5, sealing a filling opening and performing finish machining. The phase-change heat-storage composite material disclosed by the invention is high in heat conductivity and good in heat transfer performance, and can realize control of the distribution of cavity positions; and vacuum electron beams are adopted to seal and weld the filling opening, thereby ensuring that a paraffin phase-change material is absolutely sealed in a cavity of a container.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

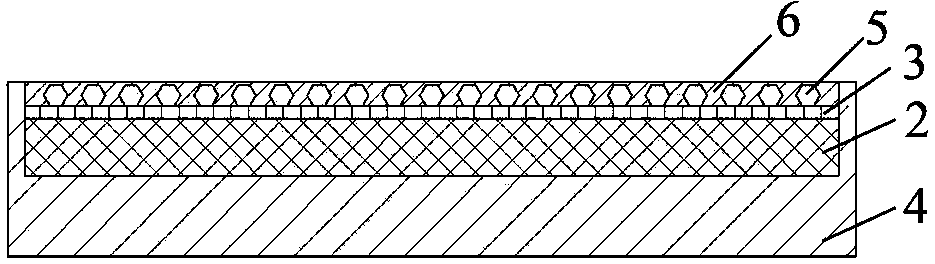

A mipm type internal field emission cathode

InactiveCN102280332AGuaranteed Emission EfficiencyGuaranteed DensityDischarge tube/lamp detailsPower flowAlternating current

A cathode of the invention belongs to the field of vacuum electronics and the materials science, and in particular relates to an MIPM (multum in parvo mapping)-type internal field emitting cathode. The MIPM-type internal field emitting cathode is composed of a bottom electrode layer, an insulating layer, an electronic storage transmission layer and a top electrode layer; the emitting cathode is mainly characterized in that the electronic storage transmission layer adopts a porous silicon film material. In an alternating current AC driving mode, a functional layer not only can transport electrons, but also can store the electrons so as to improve the emitting efficiency. Compared with the prior art, the MIPM-type internal field emitting cathode has the advantages of great emitting current and good stability; and due to the strong environment adaptability, the cathode not only can work in the gas, but also can work in the liquid.

Owner:SICHUAN UNIV

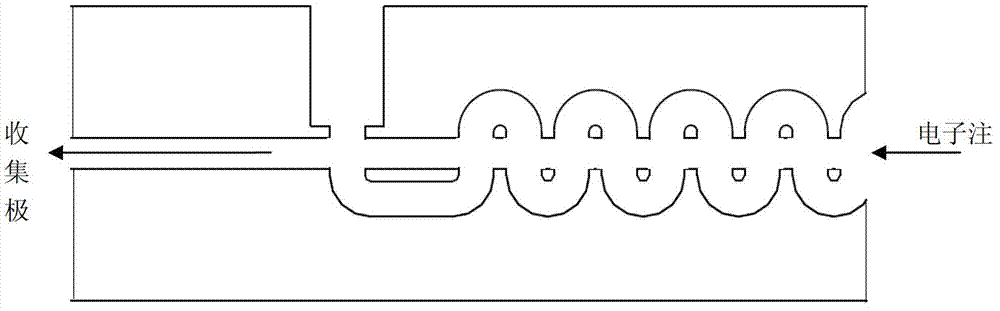

Rectangular-grooved loading winding waveguide slow wave line

InactiveCN101615553AIncrease output powerHigh coupling impedanceTransit-tube circuit elementsMicrowaveClassical mechanics

The invention provides a rectangular-grooved loading winding waveguide slow wave line, relating to a travelling wave tube amplifying device in the technical field of microwave vacuum electronics. A series of arc (or right-angle) bend waveguides and straight waveguides are connected end to end to form a winding waveguide structure; each bend waveguide is inboard provided with an opening along the broadside direction of the waveguides; each opening position is connected with a rectangular groove; the whole winding waveguides and the chambers of the rectangular-grooves are mutually communicated; the central axis symmetric line of the winding waveguide structure, the straight waveguides walls and the rectangular-grooved walls are provided with circular through holes at the points of intersection thereof; then two through holes of all adjacent straight waveguide walls and rectangular-grooved walls are connected by metal tubes with the same aperture size as the aperture size of the circular through holes to form an electron bunch channel. In the invention, the rectangular grooves featuring periodic loading are used for improving field distribution in conventional winding waveguide slow wave line; the slow wave line of the invention, compared with ordinary slow wave line, has higher coupling impedance, higher power gain and output power and smaller volume.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

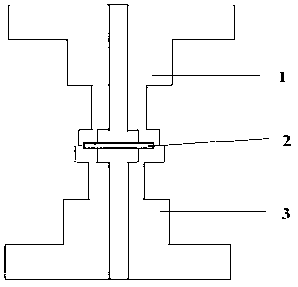

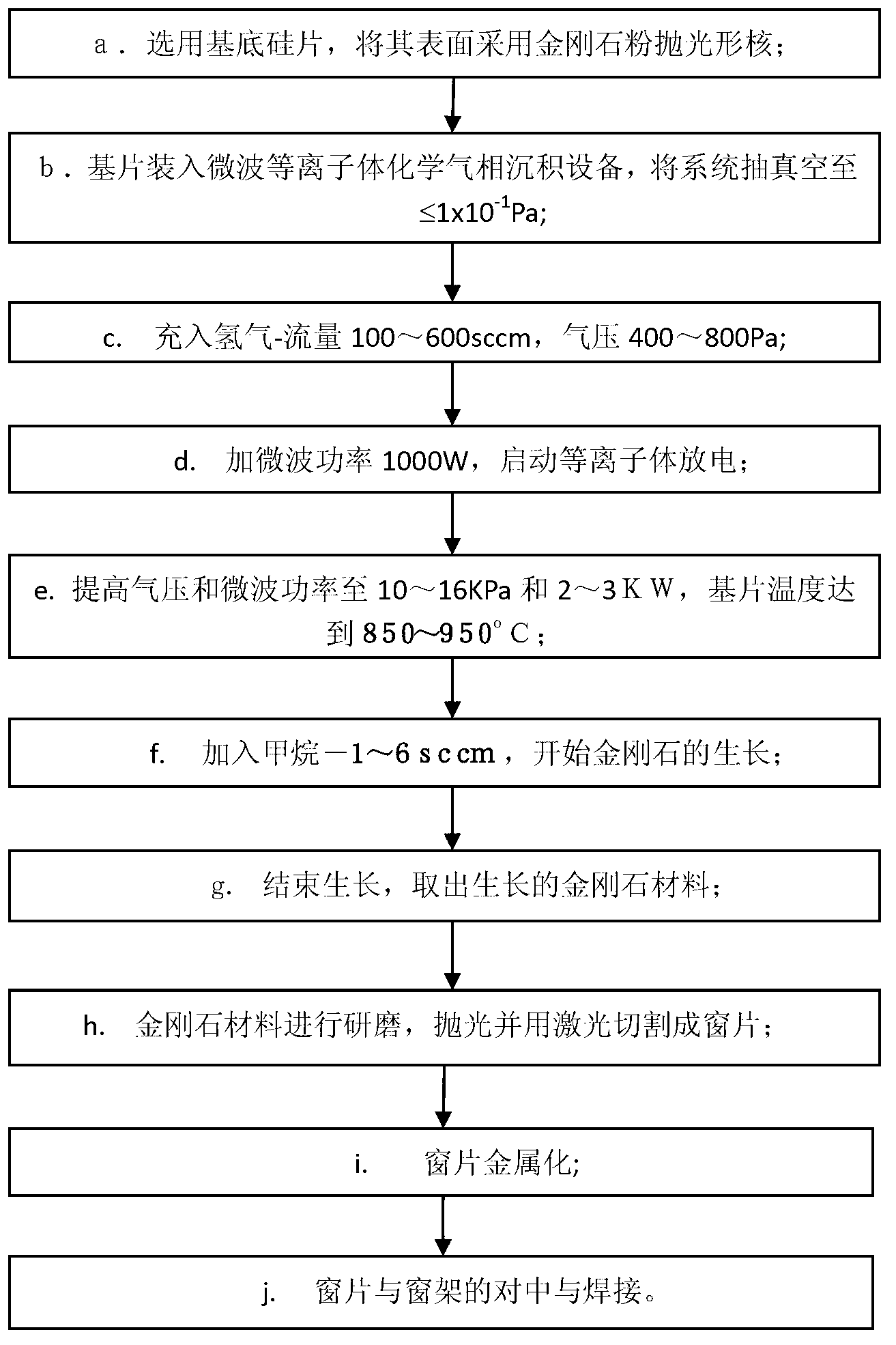

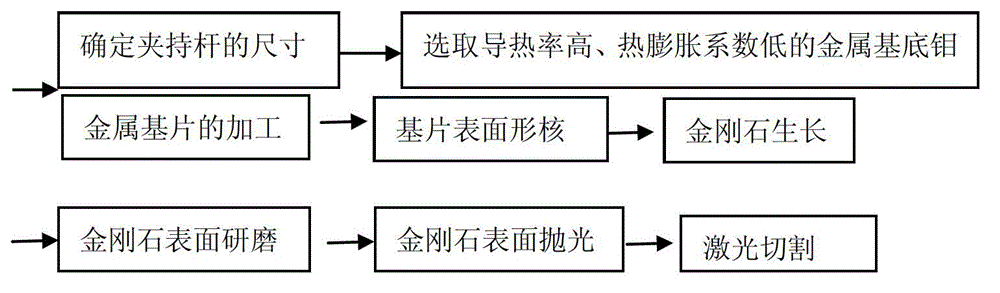

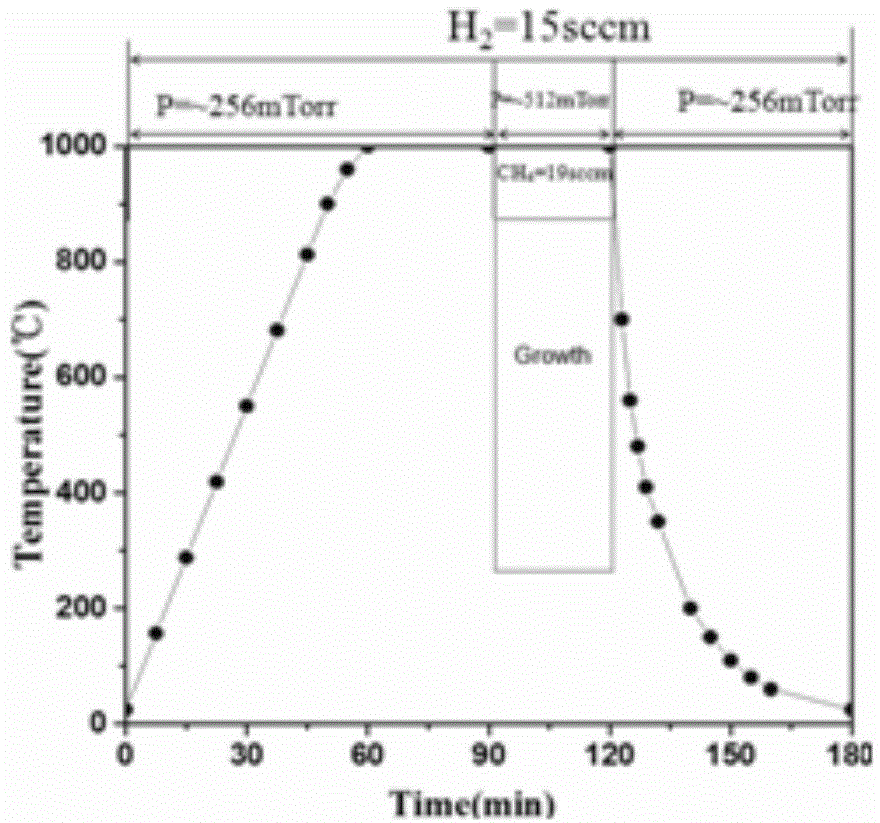

Diamond energy transmission window for short millimeter wave traveling tubes and manufacturing method of diamond energy transmission window

ActiveCN103236390AIncrease output powerSuppression of reflection oscillationsTransit-tube coupling devicesCold cathode manufactureSapphire windowEngineering

The invention discloses a diamond energy transmission window for short millimeter wave traveling tubes and a manufacturing method of the diamond energy transmission window and belongs to the technical field of vacuum electronics. The diamond energy transmission window comprises an energy transmission window leaf, a connecting wave guide and sealing window frames. The sealing window frames connected with the waveguide are symmetrically arranged on the upper and lower portion of the diamond energy transmission window, and the diamond window leaf is hermetically clamped between the window frames. The manufacturing method of the diamond energy transmission window includes: a, selecting a substrate silicon wafer; b, installing the substrate silicon wafer in a microwave plasma chemical vapor deposition device; c, inflating hydrogen gas; d, starting plasma discharging; e, increasing air pressure and microwave power and increasing substrate temperature to 850-950 DEG C; f, adding methane and starting growing diamond; g, finishing growing and taking out of diamond materials; h, grinding, polishing and cutting to obtain the window leaf by laser; i, metalizing the window leaf; and j, welding the window leaf and the window frames by centering. The diamond energy transmission window is superior to sapphire windows in both matching performance and transmission loss.

Owner:NO 12 RES INST OF CETC

Small all-metal slow wave device

ActiveCN104064422AIncrease output powerImprove output efficiencyTransit-tube circuit elementsElectrical conductorVacuum electronics

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

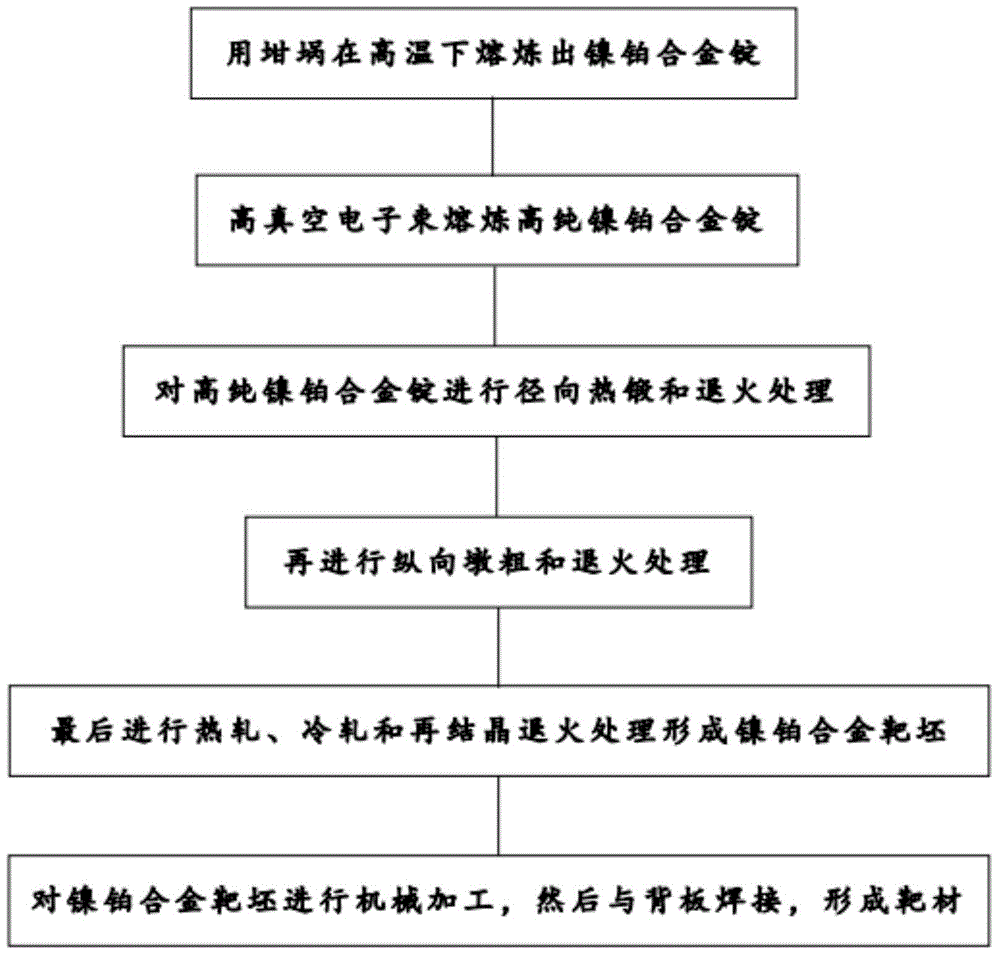

Nickel-platinum alloy target and preparation method thereof

InactiveCN104018120AUniform compositionUniform thicknessVacuum evaporation coatingSputtering coatingPlatinumCrucible

The invention relates to a preparation method of a nickel-platinum alloy target. The preparation method comprises the following steps in sequence: smelting raw materials including nickel and platinum in a crucible at high temperature to obtain a nickel-platinum alloy ingot; smelting the nickel-platinum alloy ingot by adopting a vacuum electron beam to obtain a high-purity nickel-platinum alloy ingot; carrying out radial hot forging and annealing treatment on the high-purity nickel-platinum alloy ingot; carrying out longitudinal heading and annealing treatment on the high-purity nickel-platinum alloy ingot; carrying out hot rolling, cold rolling and re-crystallization annealing treatment on the high-purity nickel-platinum alloy ingot to form a nickel-platinum alloy target blank; machining the nickel-platinum alloy target blank to form the nickel-platinum alloy target. The preparation method has the advantages that the nickel-platinum alloy target with uniform components, high purity, fine crystal grains and low oxygen content is obtained through the steps of high temperature smelting, smelting with the vacuum electron beam, radial hot forging and annealing treatment, longitudinal heading and annealing treatment, hot rolling, cold rolling and re-crystallization annealing treatment and the like; the target is beneficial for obtaining films with uniform thickness, few grains and high quality.

Owner:郑州海普电子材料研究院有限公司

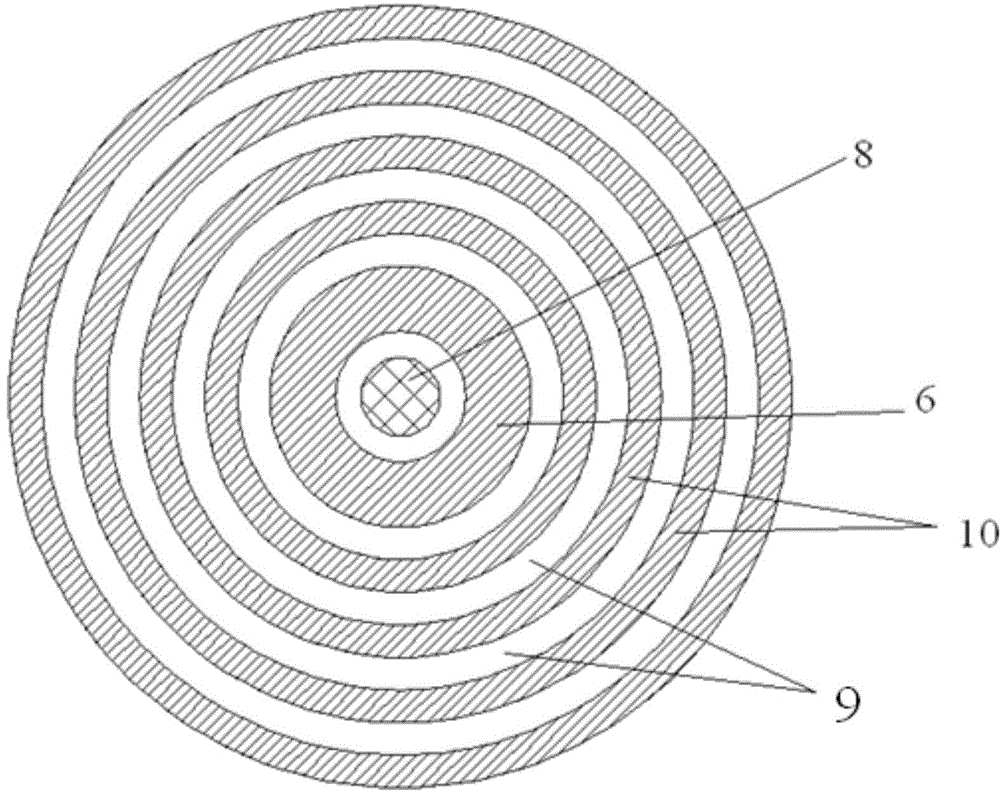

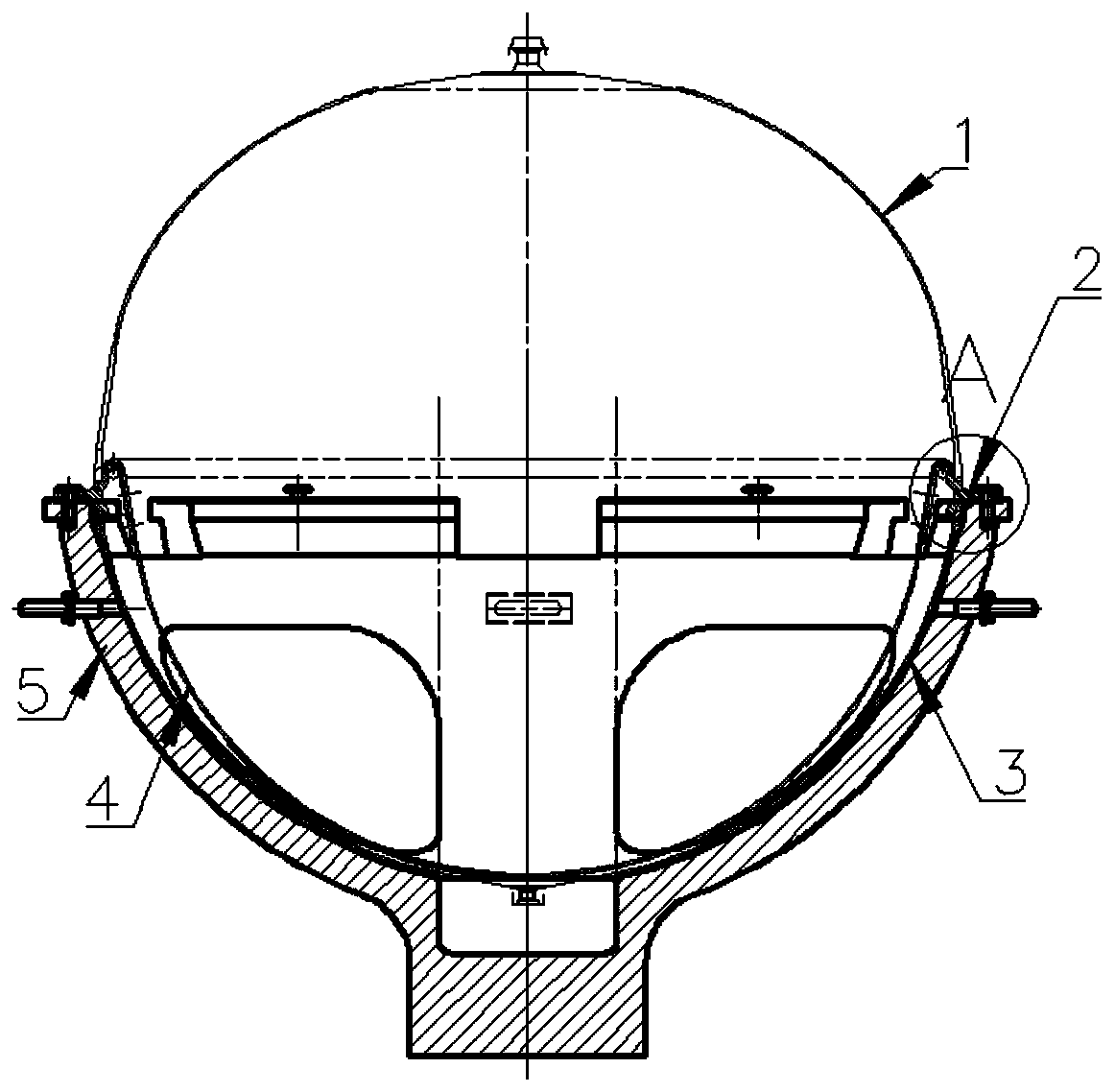

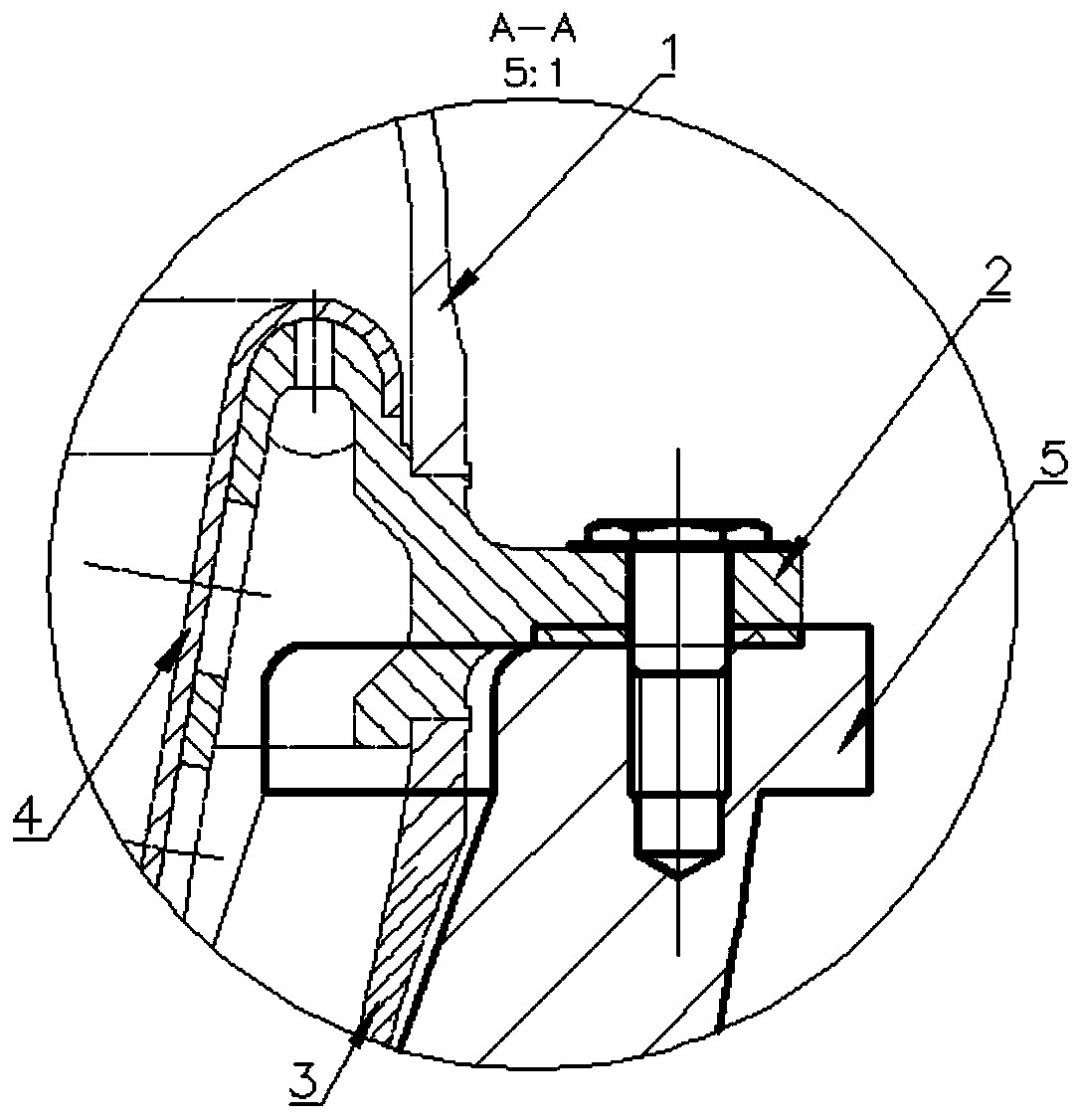

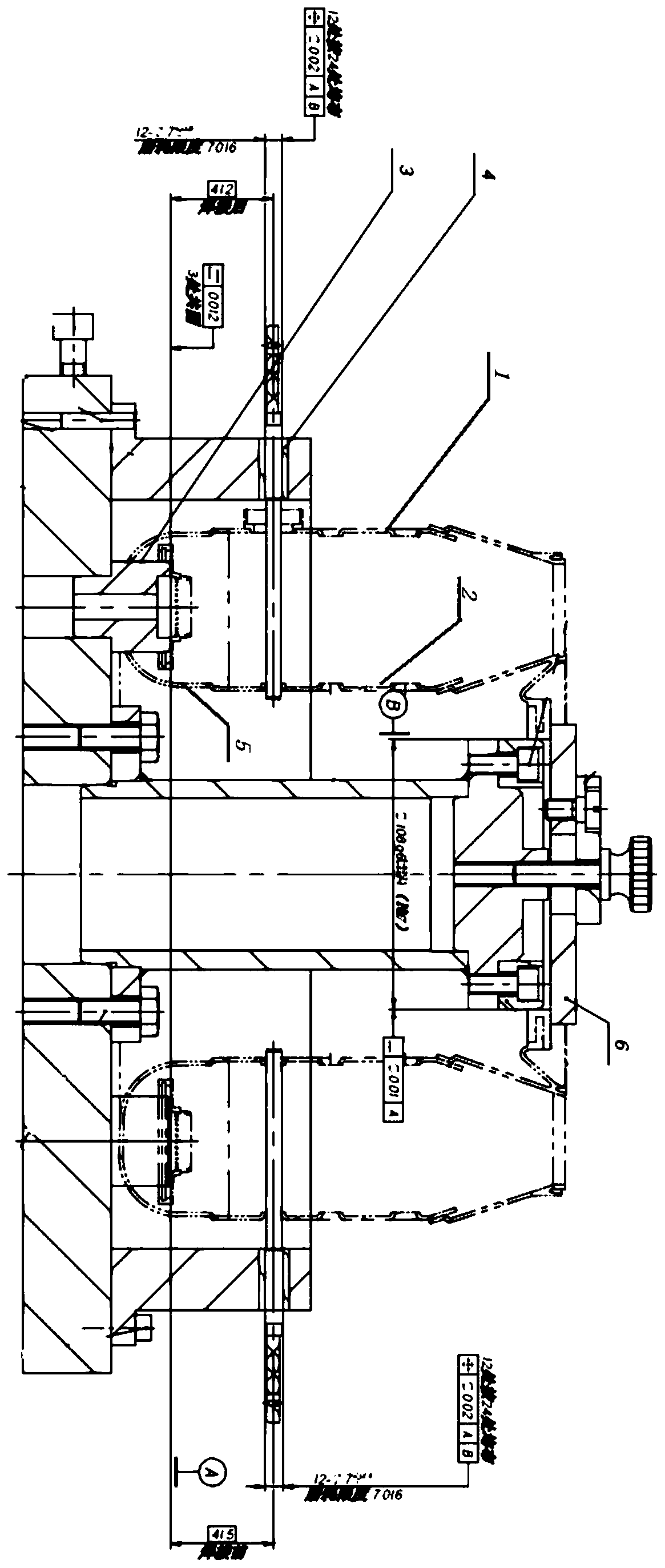

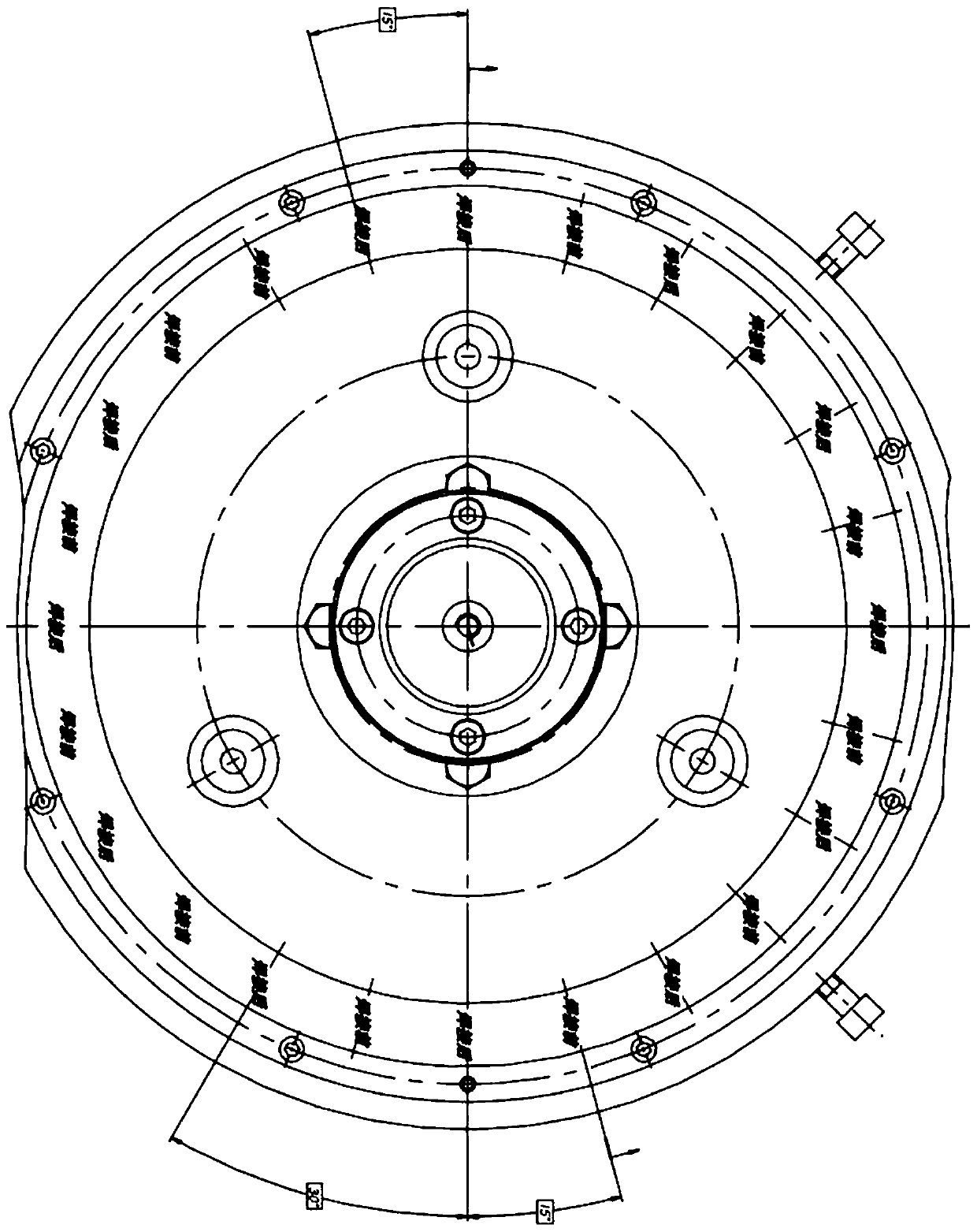

Radial EIO (extended interaction oscillator) for high-power source

InactiveCN104658838ALarge power capacityIncrease working currentKlystronsTransit-tube circuit elementsCooling capacityVacuum electronics

The invention discloses a radial EIO (extended interaction oscillator) for a high-power source, belongs to the technical field of vacuum electronics, and relates to a high-power micro-wave and millimeter wave source technology. The invention designs a radial EIO adopting circular sheet electron beam under the limit of the cathode current emission density. The radial EIO comprises two disk bodies, a cathode, an insulated circular ring-shaped piece and an electron beam channel, wherein the disk bodies are symmetrically arranged in the longitudinal direction, and each disk body is provided with a control anode head and circular ring-shaped grooves. The EIO can obtain higher power under small current density by increasing the electron emission area and an electron beam channel area; compared with EIOs adopting other structures, the EIO can meet the requirement for high-power output; the EIO has better cooling capacity, and meanwhile, due to the specific cylindrical symmetry structure, machining becomes simple, and the assembly error can be effectively reduced; the cathode of an electron-optical system is located in the center of a device, the structure is compact, and the shock-proof performance is better.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

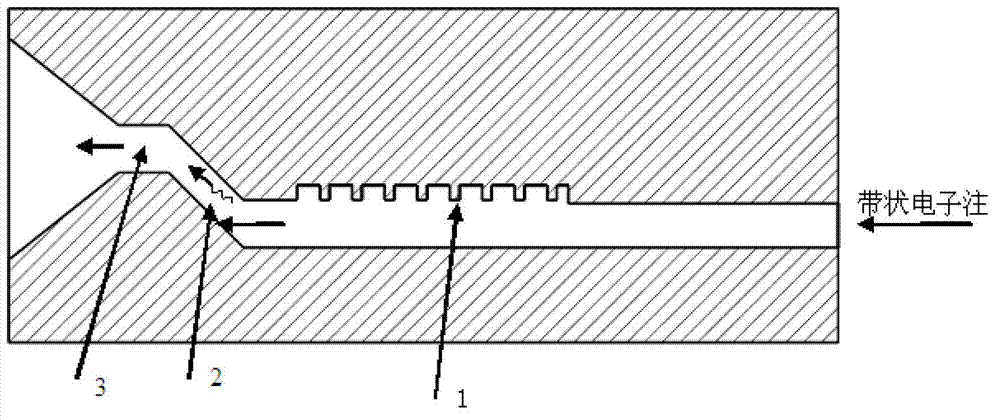

Energy output structure of panel vacuum electron device

InactiveCN102789939AResolve electronic collectionSolve the problem of energy outputTravelling-wave tubesTransit-tube circuit elementsWave structureVacuum electronics

An energy output structure of a panel vacuum electron device belongs to the technical field of vacuum electronics. The energy output structure of the panel vacuum electron device comprises a panel slow wave structure (1), rectangular inclined waveguide (2) and rectangular straight waveguide (3). The sizes of narrow sides and wide sides of the panel slow wave structure (1), the rectangular inclined waveguide (2) and the rectangular straight waveguide (3) are uniform, the rectangular straight waveguide (3) is parallel to the panel slow wave structure (1), and two ends of the rectangular inclined waveguide (2) are connected with the rectangular straight waveguide (3) and the panel slow wave structure (1) respectively in inclined mode. The energy output structure solves the problems of electron collection and energy output of the high-power panel vacuum electron device, achieves integration of a collector and the energy output structure, and is simple in structure, easy to machine and high in output efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Vacuum electron beam welding method for aluminum alloy metal diaphragm storage tank

ActiveCN111037083AAchieve staggerImprove welding strengthWelding/cutting auxillary devicesPipeline systemsVacuum electronicsUltimate tensile strength

The invention discloses a vacuum electron beam welding method for an aluminum alloy metal diaphragm storage tank. The method comprises the following steps of (1) processing two hemispherical electronbeam welding tools, wherein six notches are uniformly distributed on the hemispherical electron beam welding tools; (2) clamping a support ring, a metal diaphragm and an air cavity shell by utilizinga first electron beam welding tool; (3) firstly, positioning and welding the support ring and the metal diaphragm in a segmented mode, secondly, positioning and welding the support ring and the air cavity shell through the gap of a tool, and finally, welding the support ring and the metal diaphragm through electron beams in the whole circumference; (4) removing the first electron beam welding tool, clamping all the components on the second electron beam welding tool, wherein a liquid cavity shell is located below the second electronic beam welding tool, firstly positioning and welding the support ring and the liquid cavity shell through the gap of the tool at first, and welding the support ring and the air cavity shell by the electron beams in the whole circumference; and (5) removing thesecond electron beam welding tool, clamping the product by using the first electron beam welding tool, and welding the support ring and the liquid cavity shell by using the electron beams in the wholecircumference. Through the method disclosed by the invention, the internal quality qualification rate and the welding line strength of the electron beam welding line of the aluminum alloy metal diaphragm storage tank are improved.

Owner:XIAN SPACE ENGINE CO LTD

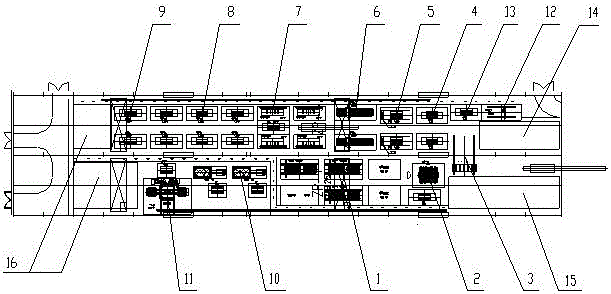

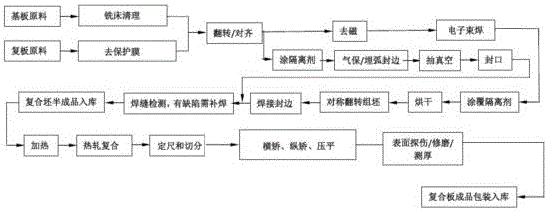

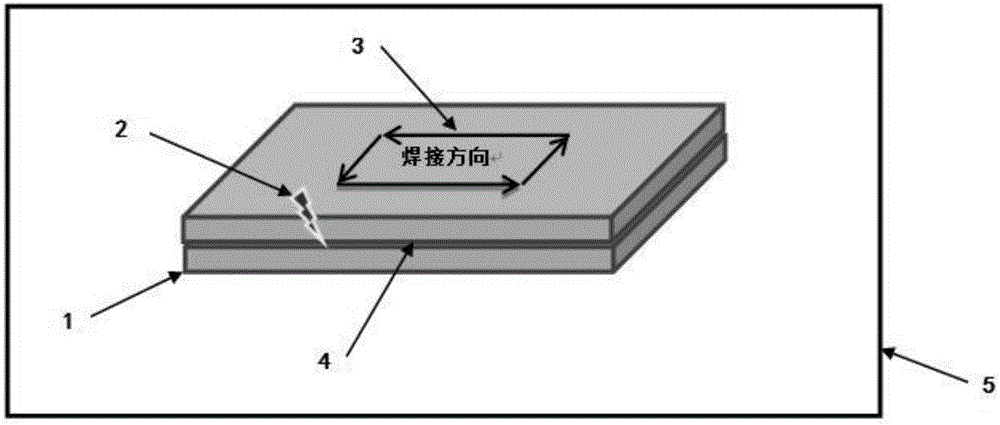

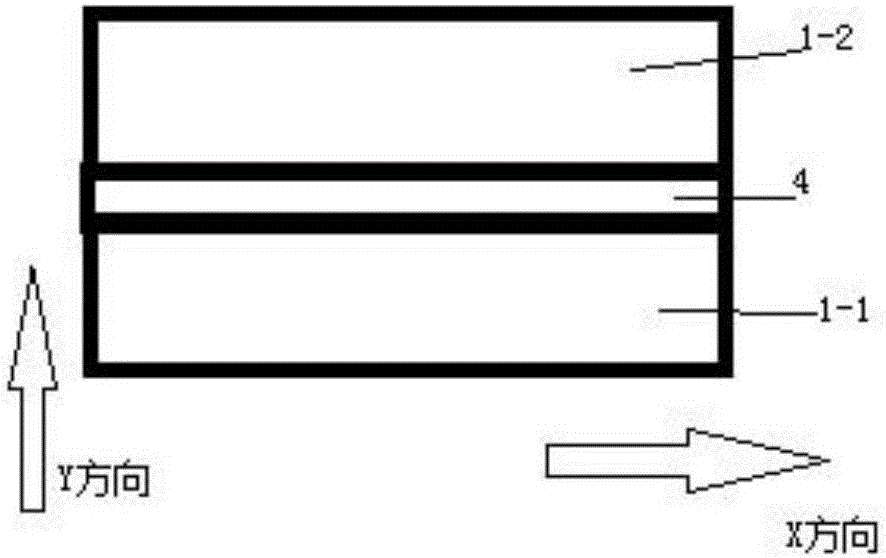

Dissimilar metal lamination composite complete blank assembly equipment and blank assembly method

InactiveCN106808212AAvoid Package SolderingReduce cut lossOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a complete set of blank assembly equipment for lamination and compounding of dissimilar metals. Workshop No. 1 is sequentially equipped with double plate turnover warehouse, plasma welding splicing equipment, weld seam grinding table, surface grinding table, coating table, and pressure assembly recording unit, narrow gap automatic gas-shielded welding long-side edge-banding unit, gas-shielded welding short-side edge-banding unit, flaw detection and inspection unit, turnover warehouse for finished welded slabs, workshop No. Plate alignment device, CNC gantry surface milling device, isolating agent drying device, vacuum electronic welding unit, and finished welded billet turnover warehouse; the dissimilar metal lamination composite complete set of billet assembly equipment of the present invention has high production efficiency, energy saving and environmental protection, and adopts advanced production methods It is in line with the development direction and trend of the future metal composite material production field.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

Vacuum electron beam welding method and application of vacuum electron beam welding method to welding of hydroelectric steel

InactiveCN106695106AMeet stability requirementsGuaranteed PenetrationElectron beam welding apparatusWelding/soldering/cutting articlesSlow coolingUltimate tensile strength

The invention discloses a vacuum electron beam welding method and the application of the vacuum electron beam welding method to welding of the hydroelectric steel. The vacuum electron beam welding method comprises the steps of surface treatment, combination, vacuum electron beam defocusing blowing, vacuum electron beam preheating welding, vacuum electron beam fusion welding, vacuum electron beam local heat treatment and vacuum-keeping slow cooling. The vacuum electron beam welding method aims to achieve vacuum electron beam welding of two pieces of hydroelectric steel, the welding efficiency is high, the welding performance is stable, the welding quality is excellent, the weld joint quality meets the GJB 1718-2005 I-level requirement, the strength coefficient of the welded joint is larger than or equal to 0.91, the requirement for welding of large-thickness hydroelectric steel billets can be completely met, and the vacuum electron beam welding method can be applied and popularized to welding of large-size components which are made of other materials, poor in welding performance, complicated in welding technology and large in workload.

Owner:TIANJIN UNIV

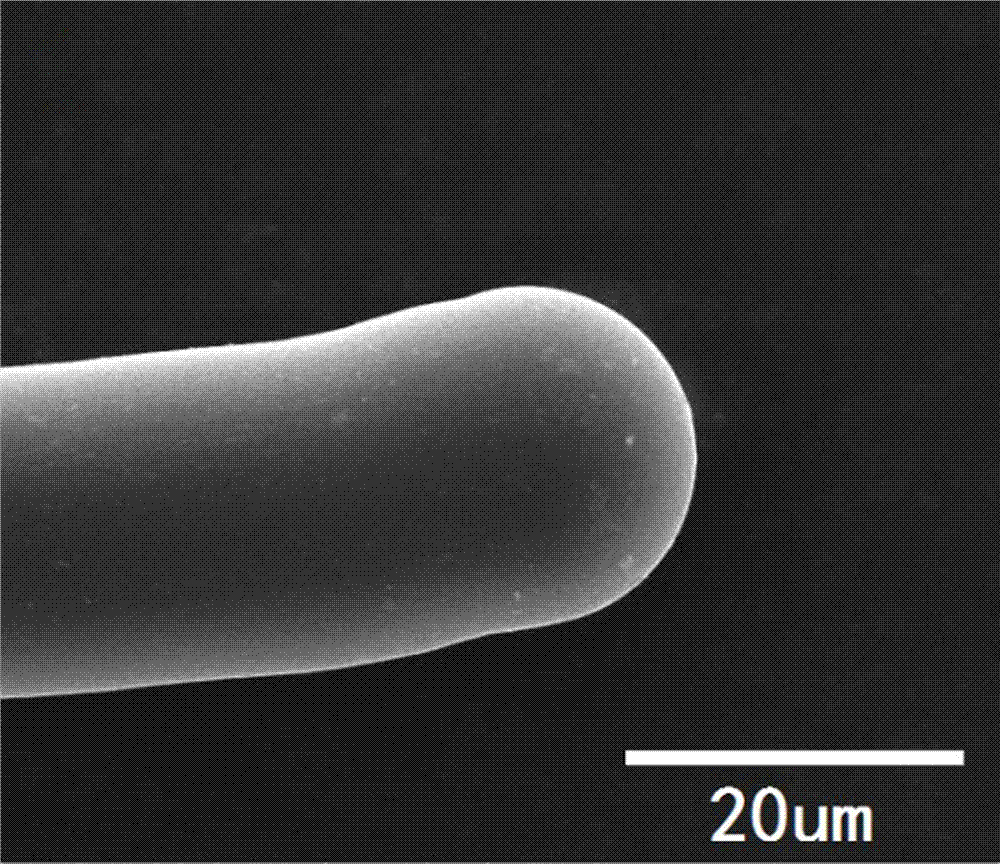

Graphite fiber and preparation method thereof

ActiveCN107119348AHas a large spanHigh purityElectroconductive/antistatic filament manufactureFiberGas phase

The invention relates to a graphite fiber and a preparation method thereof. The graphite fiber serving as a monomer fiber directly grows by adopting a vapor deposition method under the condition of no catalyst; the purity of obtained products is greater than 99.99 percent; the obtained products are straight and filamentous in appearance, the diameter range is 0.1 to 50mu m and the length range is 3 to 100mm; the products are generally parallel to one another; a hemispherical sealing cover is arranged at the top of each product and the interior of the fiber is solid; Raman spectrum shows that the intensity of a G peak is greater than that of a D peak in the graphite fiber; the graphite fiber has a metallic luster under the irradiation of visible light, and the resistivity of the graphite fiber is equivalent to that of graphite. The graphite fiber uses a quartz plate as a substrate, adopts argon and hydrogen as carrier gases, selects methane as a carbon source, and is prepared by cleaning the substrate, charging into a furnace, carrying out vapor deposition growth and sampling. With a special form and physical properties, the performance consistency between devices can be ensured when the graphite fiber prepared by the method is used for producing vacuum electronic devices such as a cold field emission electric gun filament.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

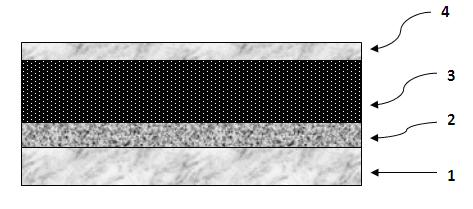

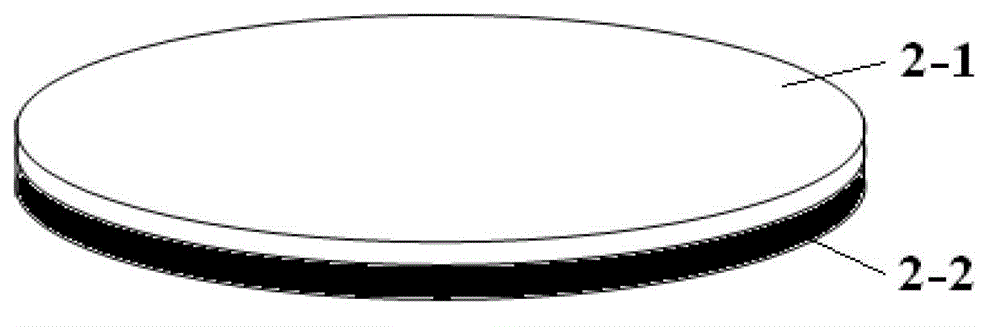

Diamond / metal composite material clamping rod and manufacturing method thereof

ActiveCN103594306AEasy nucleationAvoid deformationVessels or leading-in conductors manufactureTransit-tube circuit elementsCrystal orientationVacuum electronics

The invention discloses a diamond / metal composite material clamping rod and a manufacturing method of the diamond / metal composite material clamping rod, belongs to the technical field of vacuum electronics, and relates to clamping rods for traveling-wave tubes. The diamond / metal composite material clamping rod solves the problems that BeO and other materials can not meet heat dissipation requirements of the traveling-wave tubes, natural and artificial diamond large monocrystal materials are high in cost and difficult to manufacture, and CVD self-supporting thick films are high in cost, prone to brittle failures, and difficult to assemble. The diamond / metal composite material clamping rod comprises three layers, wherein the top layer and the bottom layer are made of CVD diamond films, the middle layer is a metal layer, the metal layer is wrapped by artificial diamond particles which are approximate in particle size and the same in crystal orientation, and the diamond particles are connected with the CVD diamond film on the top layer and the CVD diamond film on the bottom layer. The diamond / metal composite material clamping rod is short in manufacturing period, low in cost, high in toughness, and not prone to brittle failures.

Owner:山西新碳超硬材料科技有限公司

High-voltage lead assembly for ultrahigh vacuum device and manufacture method thereof

InactiveCN102570094ALine/current collector detailsSecuring/insulating coupling contact membersAlloyHigh pressure

The invention discloses a high-voltage lead assembly for an ultrahigh vacuum device and a manufacture method thereof, which relate to vacuum electronic technology. The high-voltage lead assembly comprises a metal lead, insulation porcelain, ceramic sealing alloy and a lead flange. The high-voltage lead assembly has the advantages of being high in structure strength, compact in size, good in voltage withstanding effect and favorable for improving reliability and high voltage application range of the ultrahigh vacuum device. The structure design, the materials, the manufacture process and the like of the high-voltage lead assembly are provided.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Multi-cavity vacuum electron beam device for operating at terahertz frequencies

The present invention relates to the formation of a vacuum electronics circuit by the fusion bonding of multiple substrate wafers, e.g., silicon, copper, or other suitable conductive material, each etched using DRIE, cut using EDM, or machined by other suitable means. Other aspects of the invention relate to the alignment of a cathode with tube by fusion bonding the cathode wafer to a tube built using the fabrication methods described herein. Yet other aspects involve the alignment of dies or wafers during the fabrication of a vacuum electronics device using the “lego” technique outlined herein. In yet other aspects, fabrication methods are described.

Owner:LOGOS TECH HOLDCO INC

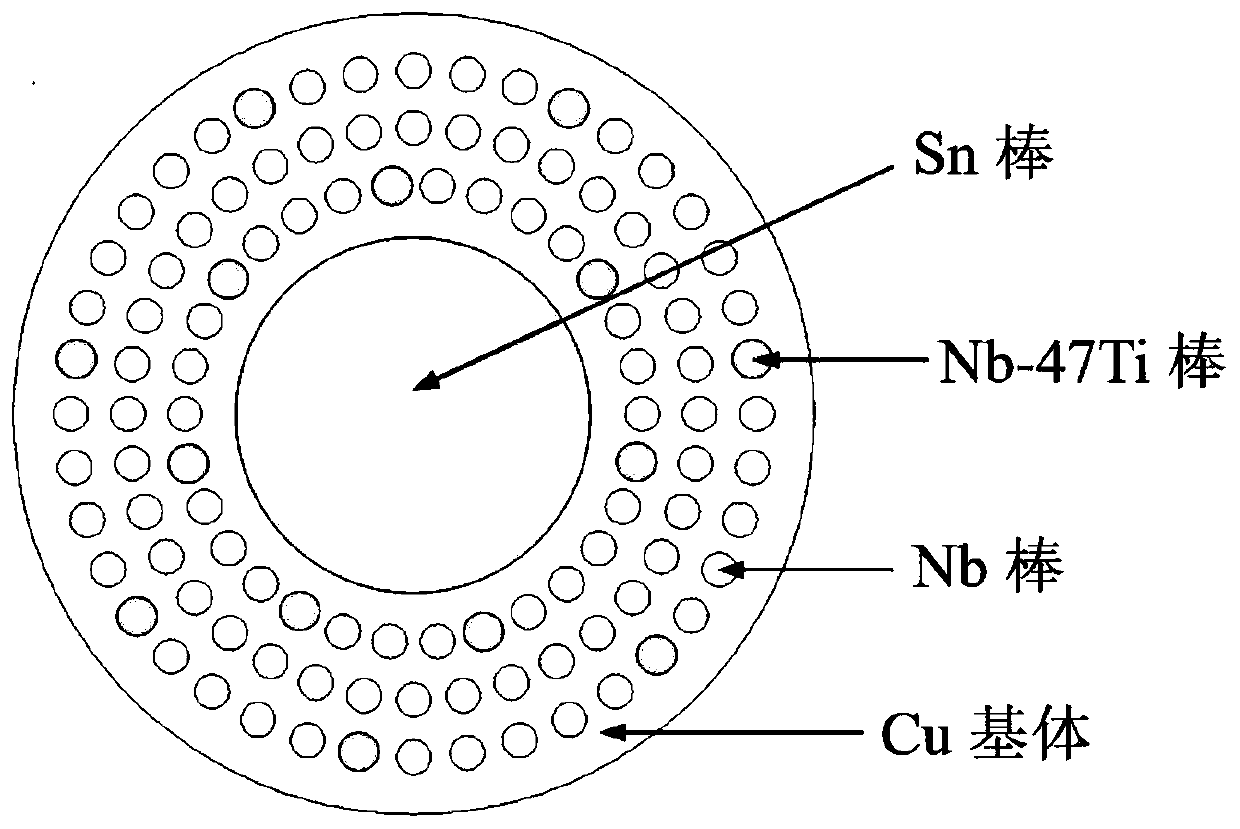

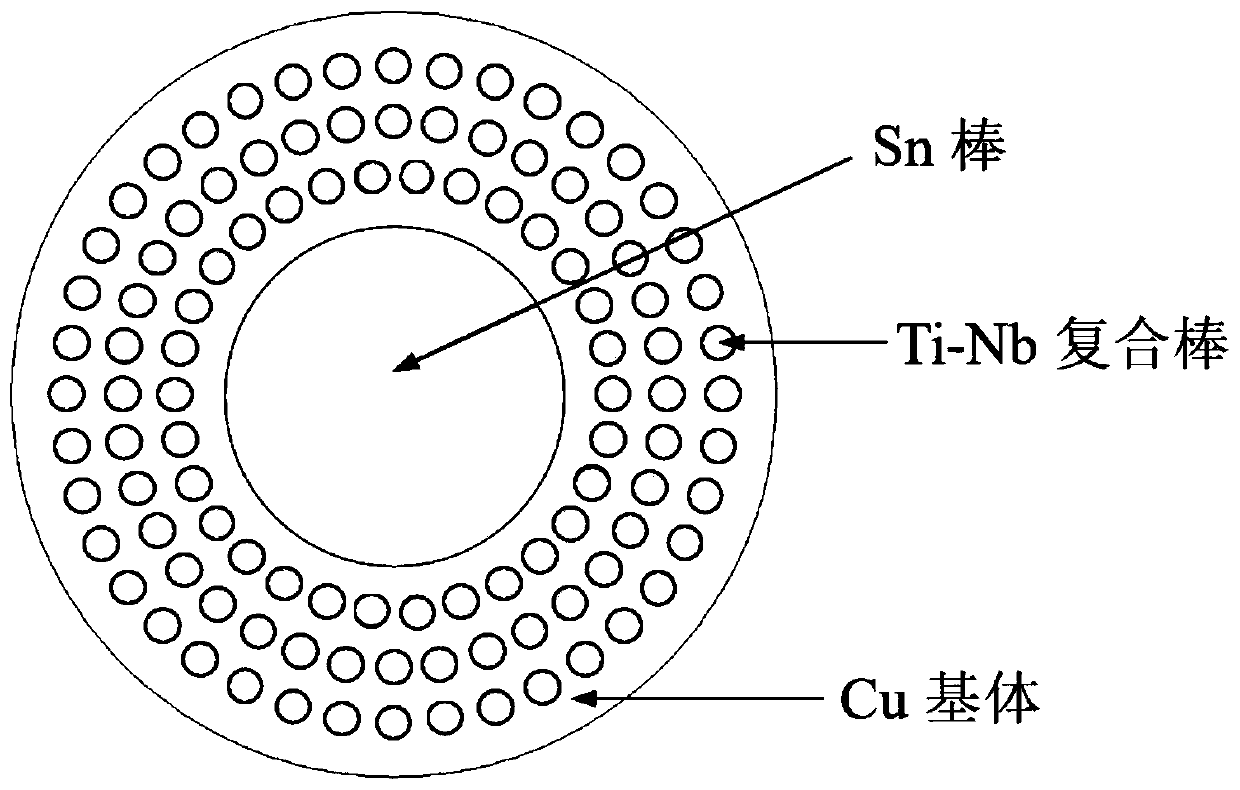

Preparation method of Ti-doped internal tin method Nb3Sn precursor wire

ActiveCN110993185AEasy compound processingReduce manufacturing costSuperconductors/hyperconductorsSuperconductor devicesVacuum electronicsElectron bunches

The invention belongs to the technical field of superconducting material processing. The invention relates to a preparation method of a Ti-doped internal tin method Nb3Sn precursor wire. The method comprises the steps that hexagonal Cu / Nb-Ti / Nb composite bars are manufactured, the multiple Cu / Nb-Ti / Nb composite bars and a center Cu bar are arranged in a primary copper sheath containing a barrier layer, and the multi-core composite bars are machined through the procedures of vacuum electron beam welding sealing, hot isostatic pressing, hot extrusion and the like; the multi-core composite bar issubjected to center drilling, Sn or Sn alloy bars are inserted into the multi-core composite bar, Cu-Nb-Sn sub-components are machined, the multiple sub-components are arranged in a secondary copper-clad sleeve, plastic machining such as drawing and rolling is conducted, and finally the Ti-doped Nb3Sn precursor wire with the internal tin method is machined. The Nb3Sn wire rod prepared by the method is not easy to break in the plastic processing process, each performance index is equivalent to each performance index of the wire rod prepared by a conventional method, the rate of finished products of wires is higher, and the preparation cost of the wire rod is lower.

Owner:FUJIAN NORMAL UNIV

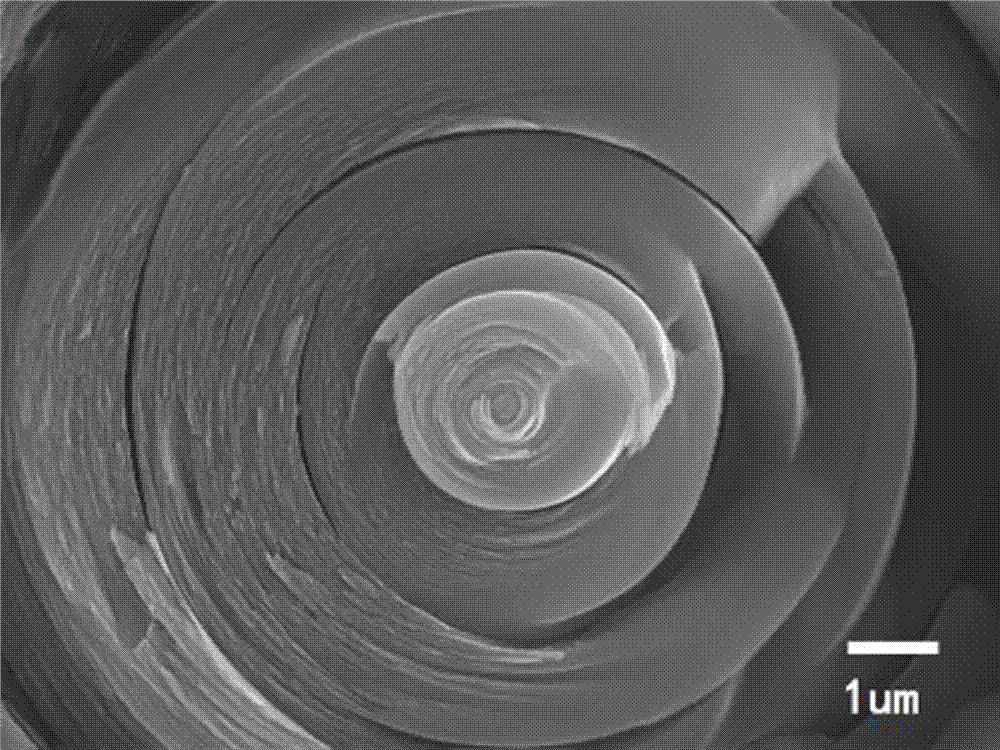

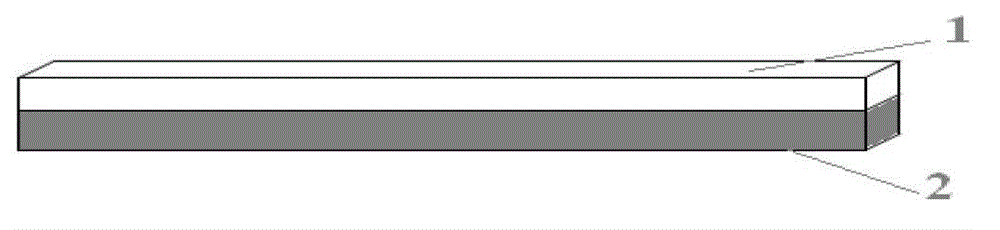

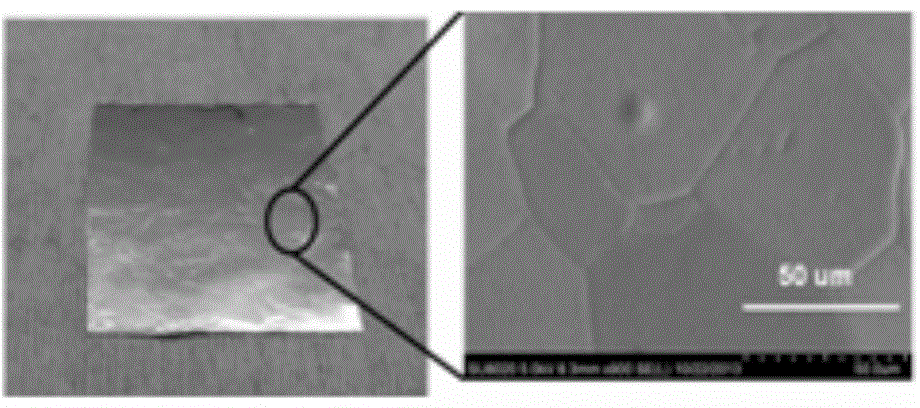

Diamond-metal compound type clamping rod for travelling wave tube and manufacture method of diamond-metal compound type clamping rod

InactiveCN102867716AHigh strengthIncrease output powerTransit-tube vessels/containersVessels or leading-in conductors manufactureGas phaseChemical vapor deposition

The invention discloses a diamond-metal compound type clamping rod for a travelling wave tube and a manufacture method of the diamond-metal compound type clamping rod, belonging to the technical field of vacuum electronics. The diamond-metal compound type clamping rod is used as one part in a travelling wave tube and high-frequency structure and comprises an artificially synthesized diamond and a metal substrate. The manufacture method of the diamond-metal compound type clamping rod comprises the following steps of: firstly forming a diamond crystal nucleus on the surface of the metal substrate, then artificially synthesizing a diamond layer by using a chemical vapor deposition method, then grinding and polishing the surface of the diamond, and cutting and processing into the diamond-metal compound type clamping rod by using laser. The diamond-metal compound type clamping rod has the advantages of greatly shortening the growing time of diamond, reducing the cost, improving the strength of the clamping rod, and remarkably improving the output power of the travelling wave tube compared with that when a beryllium oxide clamping rod is used.

Owner:NO 12 RES INST OF CETC

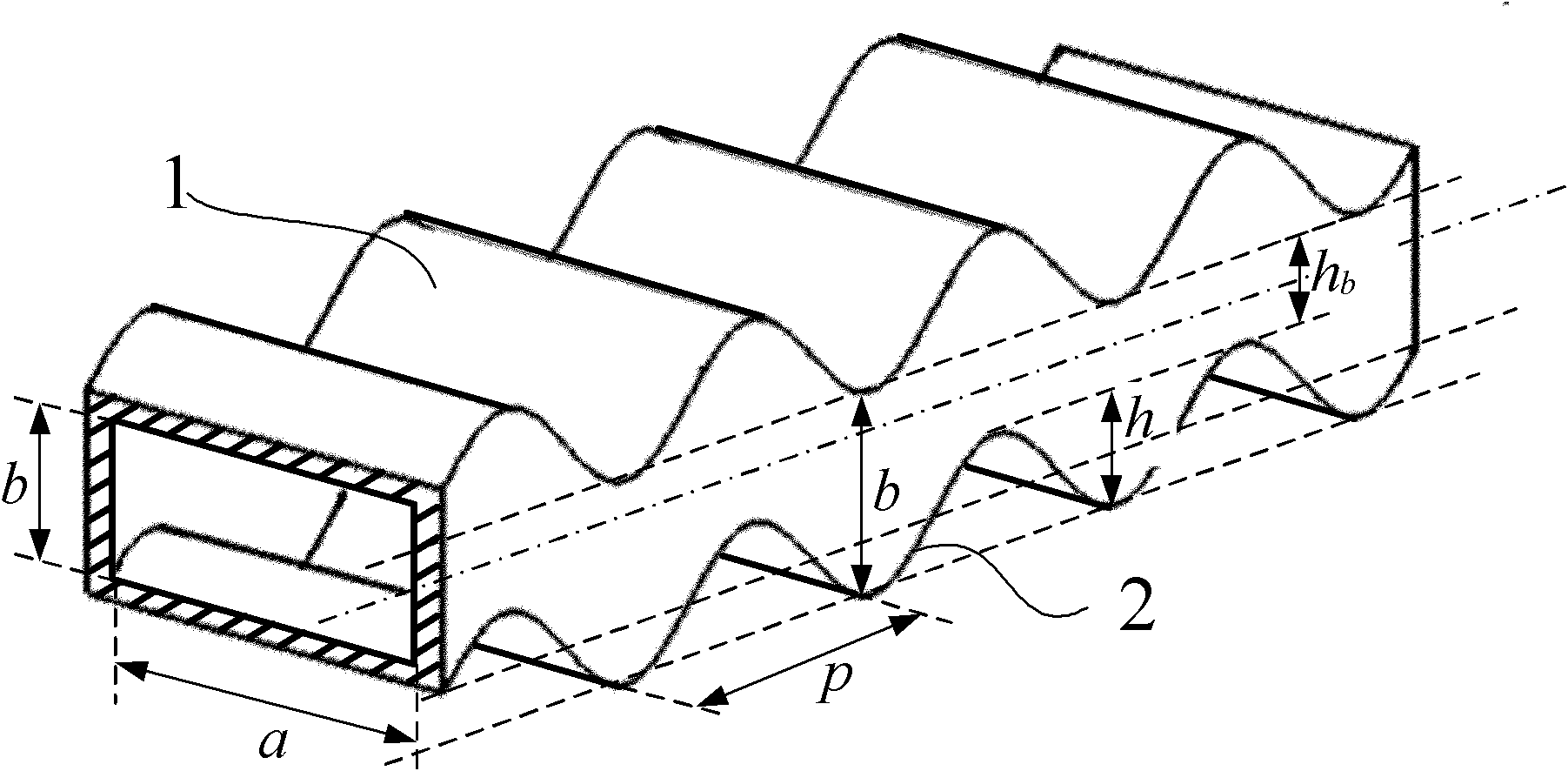

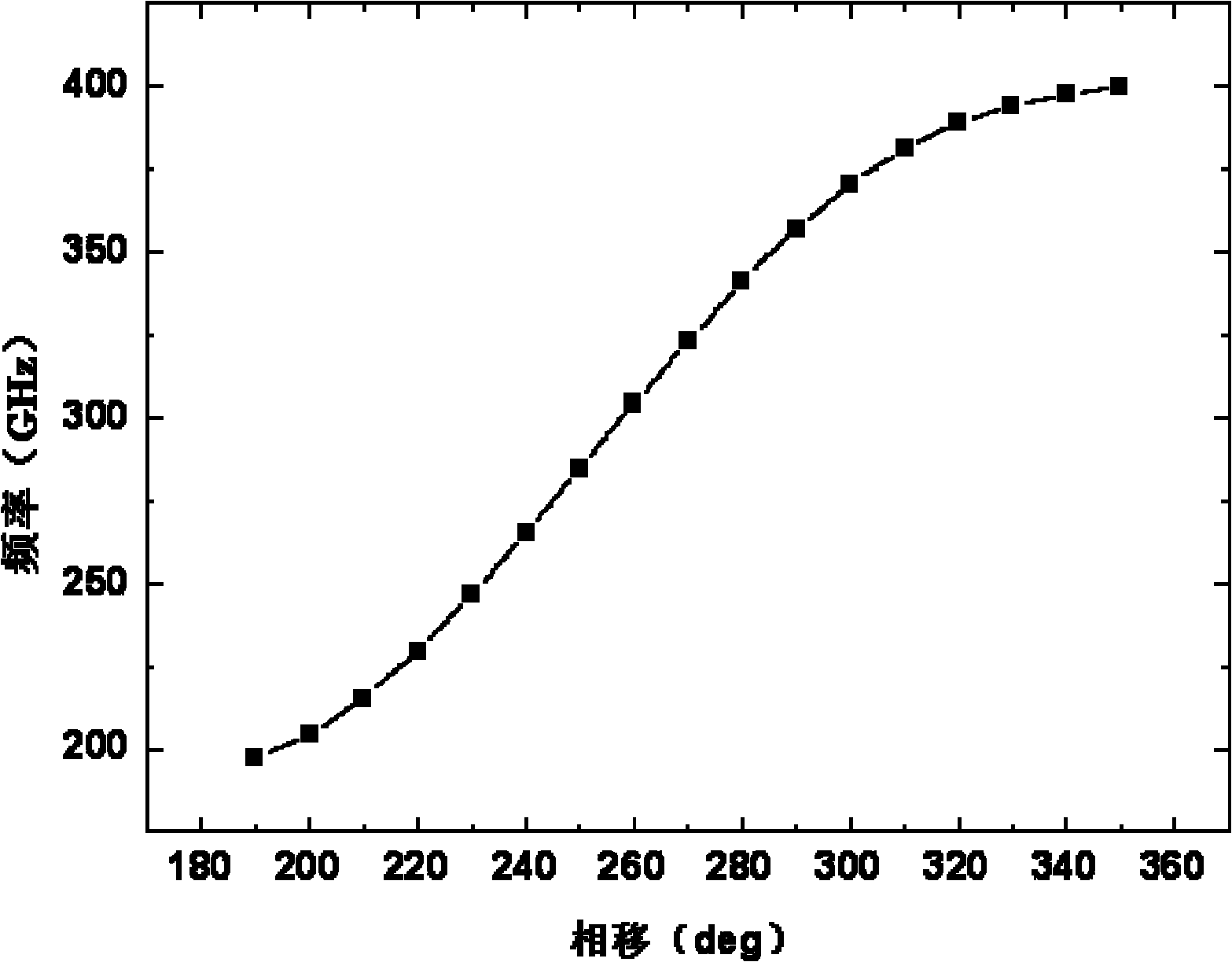

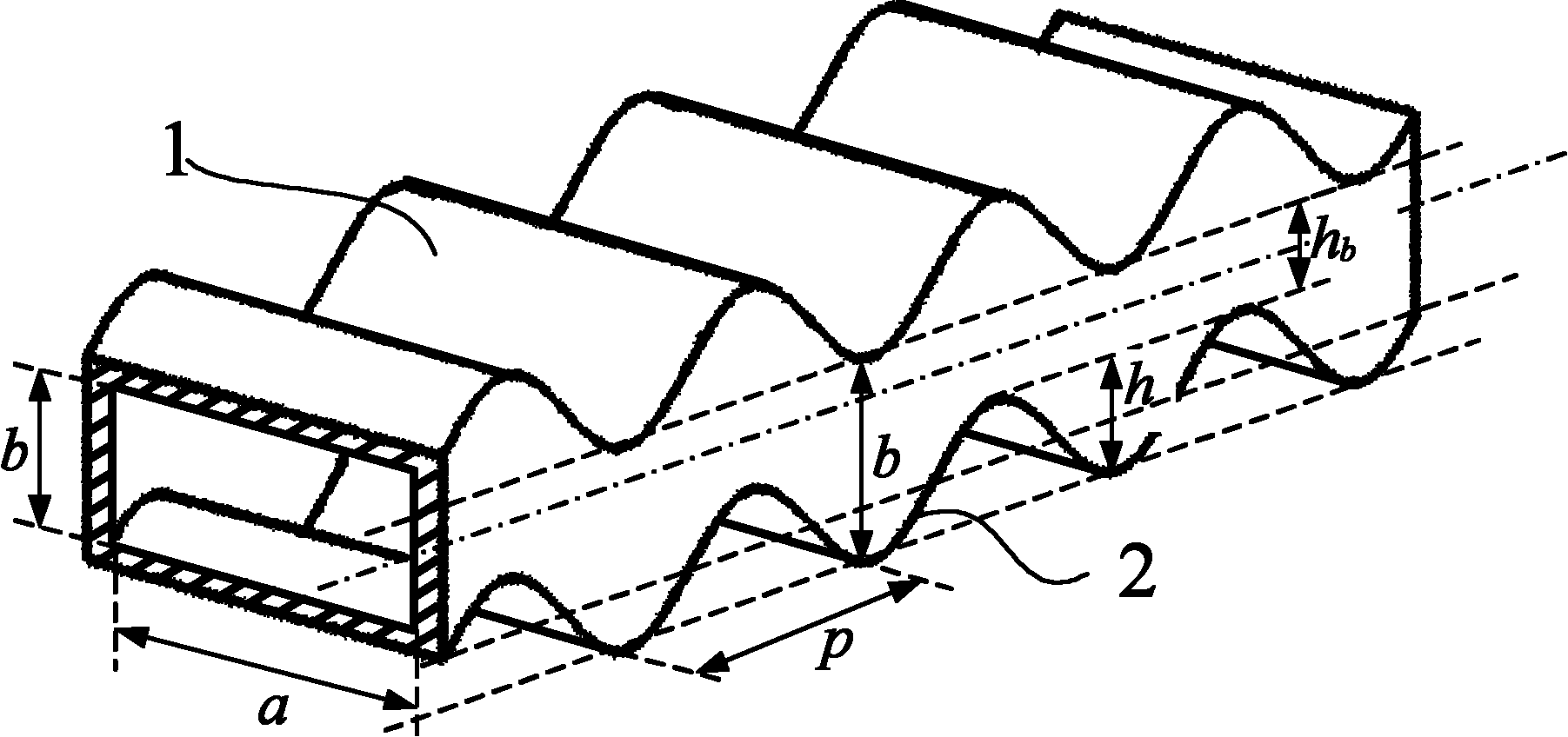

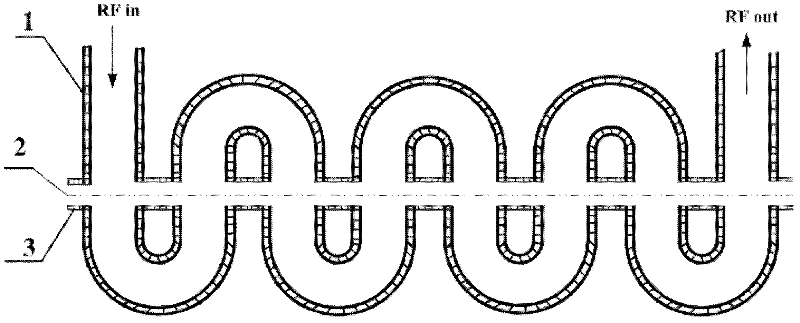

Fluctuant waveguide slow wave structure

InactiveCN102054644AThe main structure is simpleReduce processing difficultyTravelling-wave tubesTransit-tube circuit elementsWave structureBand shape

The invention provides a fluctuant waveguide slow wave structure, belonging to the technical field of vacuum electronics. The structure is formed by deforming a conventional rectangular waveguide of which the size of wide edges is a, and the size of narrow edges is b; the E face of the fluctuant waveguide slow wave structure is regularly fluctuant; the H face of the fluctuant waveguide slow wave structure is a plane; crossed contour lines of the E face and the H face are regularly-changed wavy lines; the period length of the regularly-changed wavy lines is p; and the fluctuant height h of the regularly-changed wavy lines is a difference of the size b of the narrow edges for the rectangular waveguide and the height hb of an electron beam channel. The fluctuant waveguide slow wave structure is simple in main structure and easy to process, has the characteristics of low high-frequency loss, small reflection and wide frequency band, is suitable for using banded electron beam to operate, and the like. The fluctuant waveguide slow wave structure is completely applied to travelling wave tubes (TWT) which work in a terahertz wave band, and is a novel slow wave structure with great application potential.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

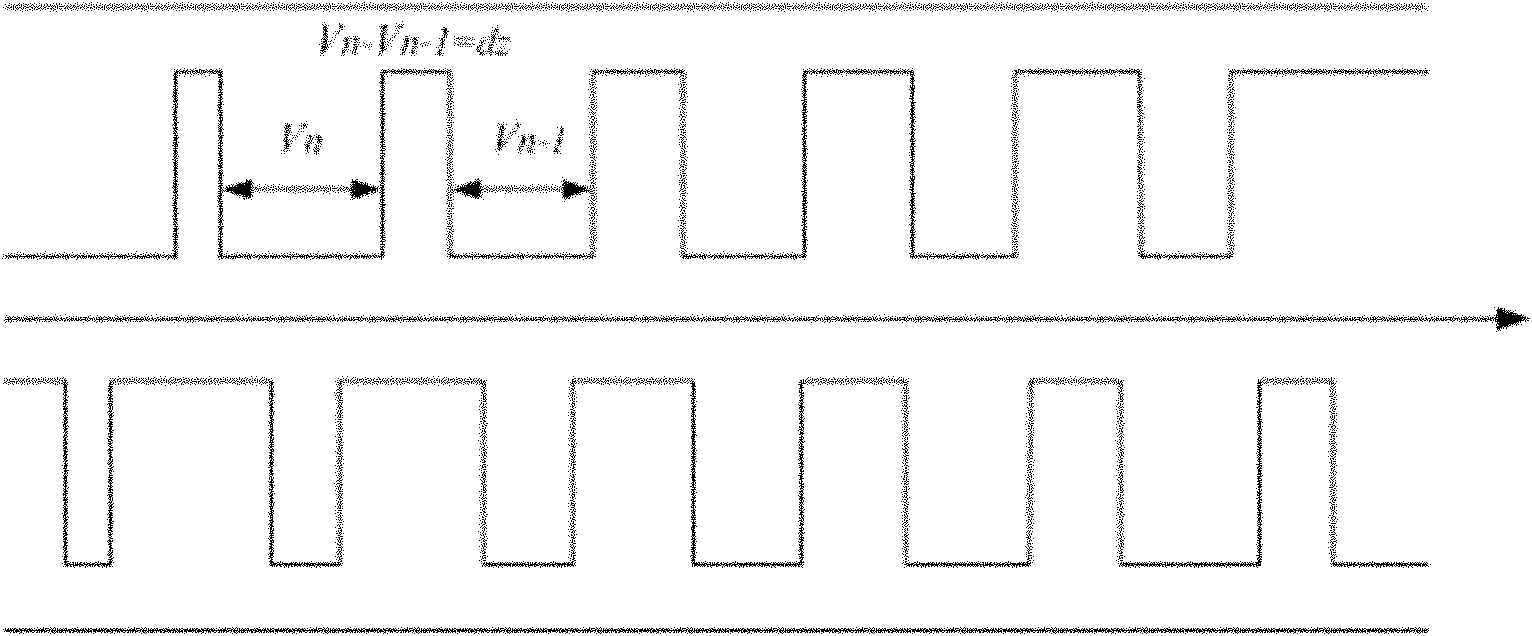

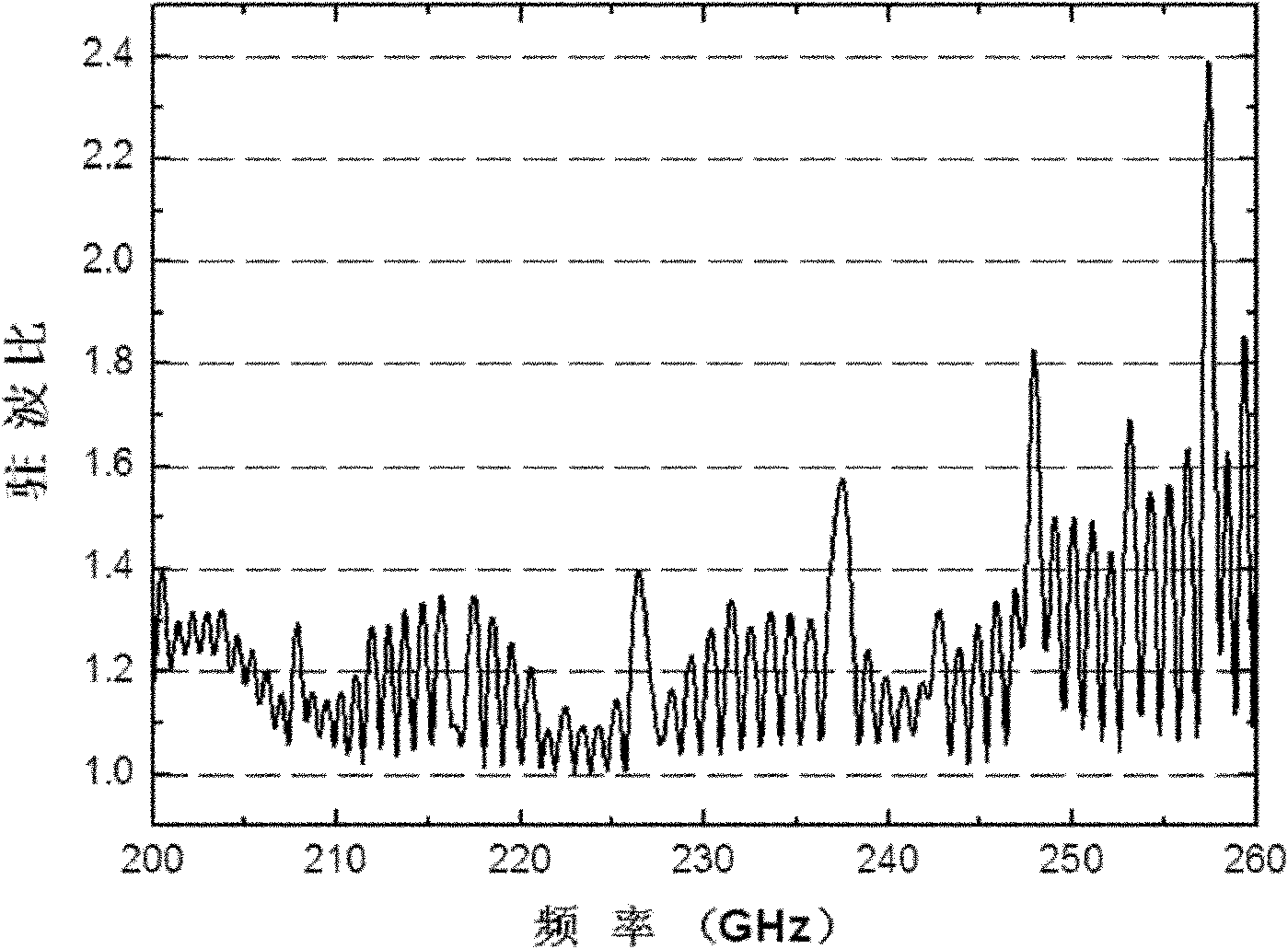

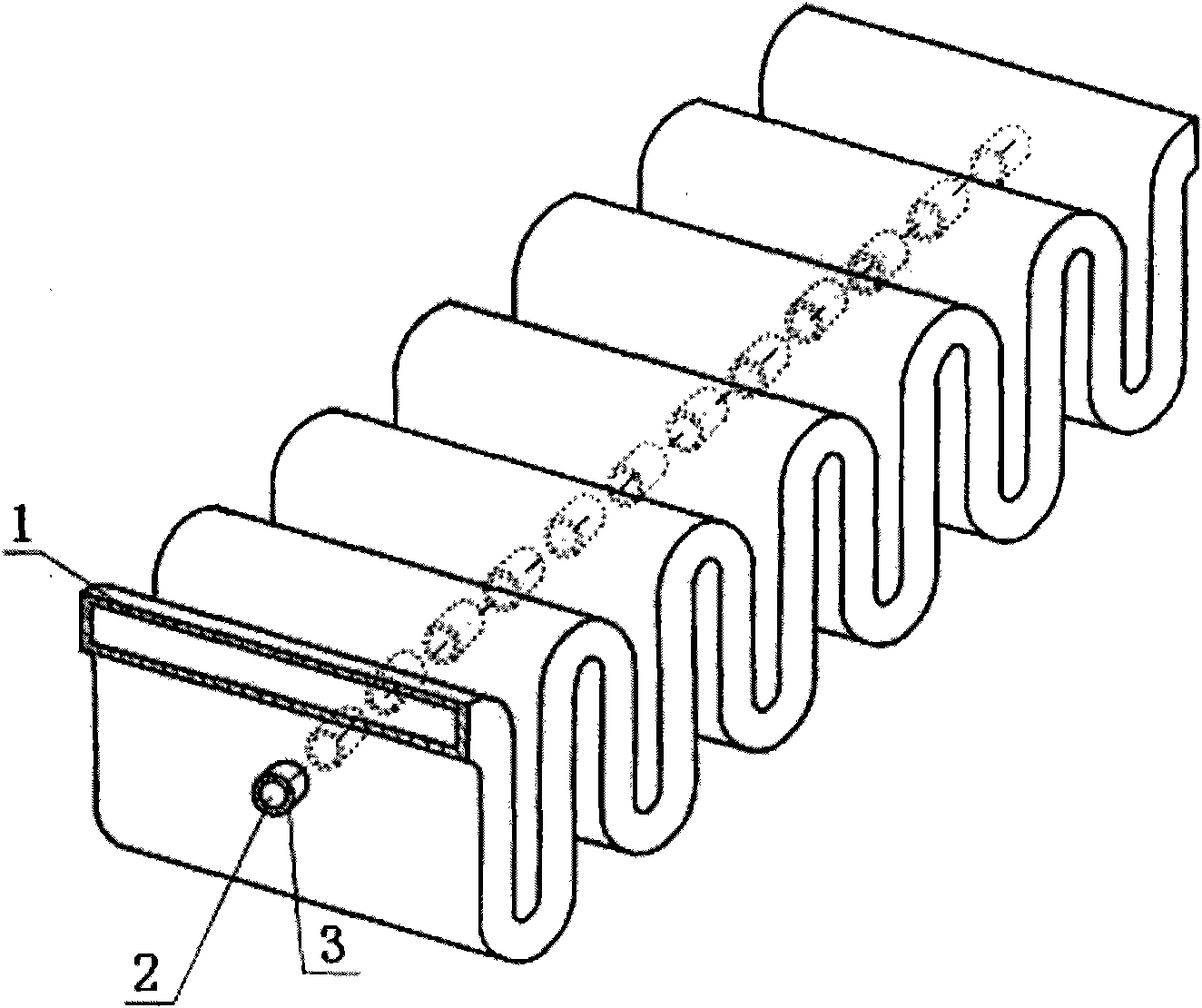

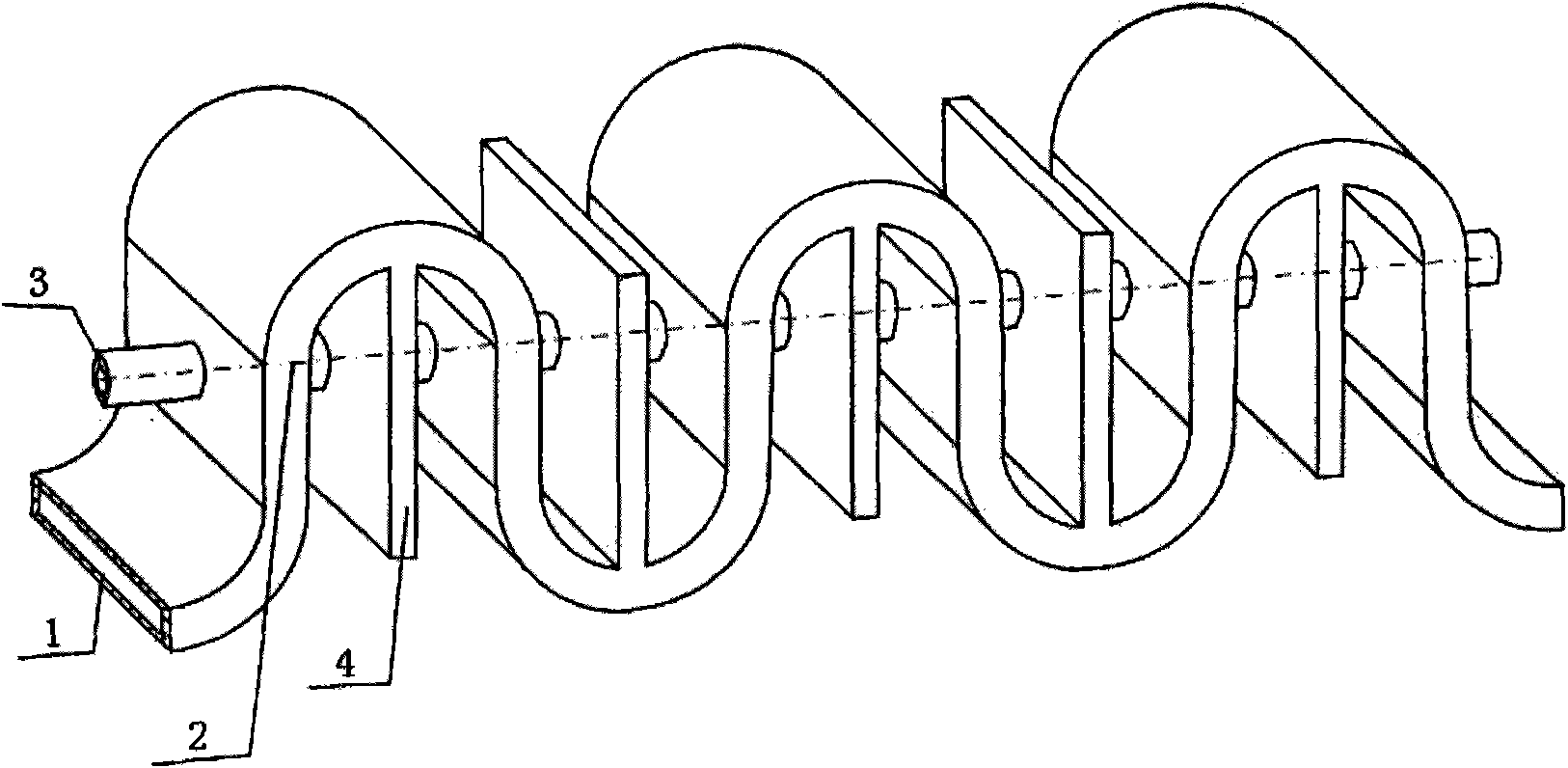

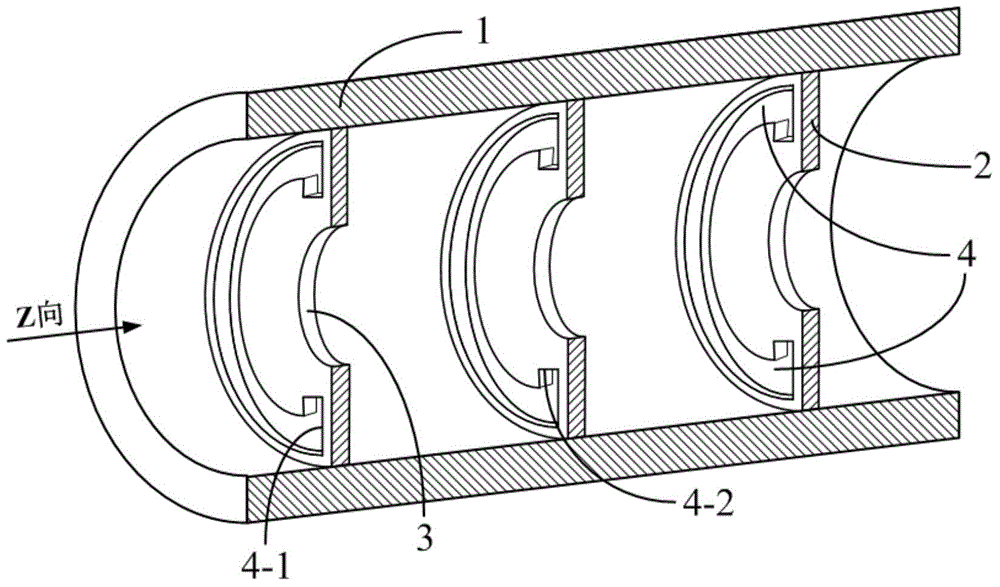

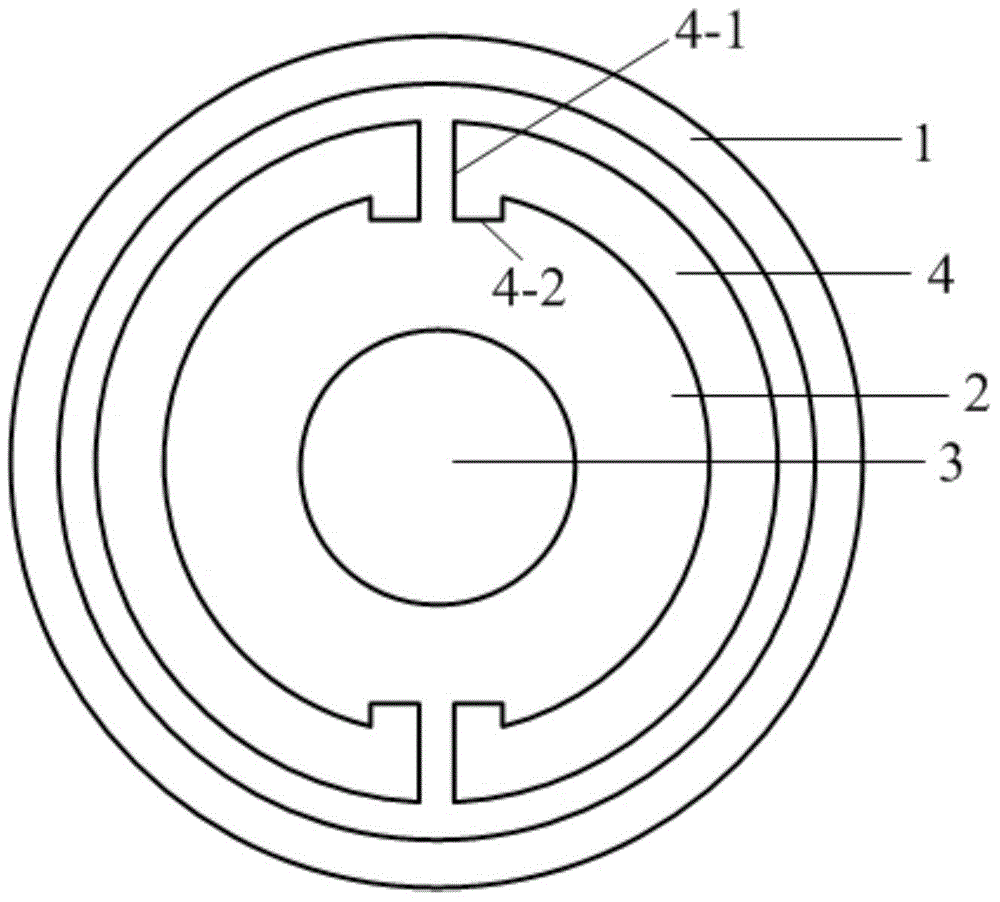

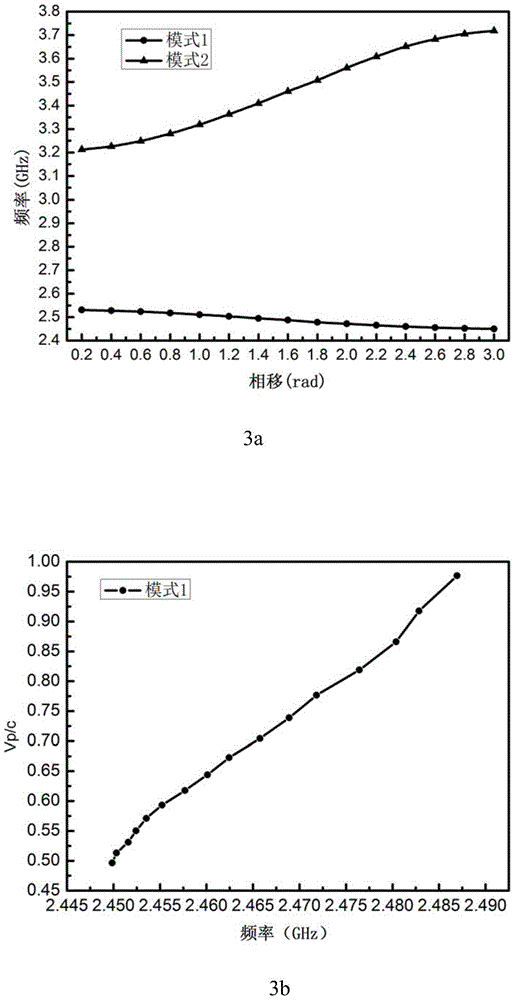

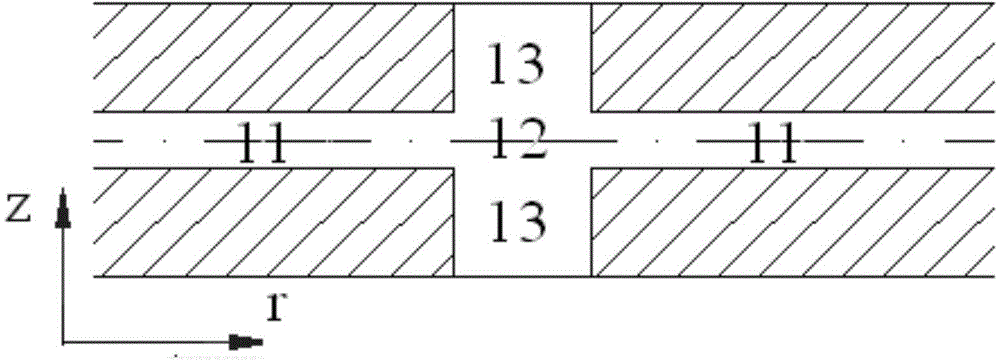

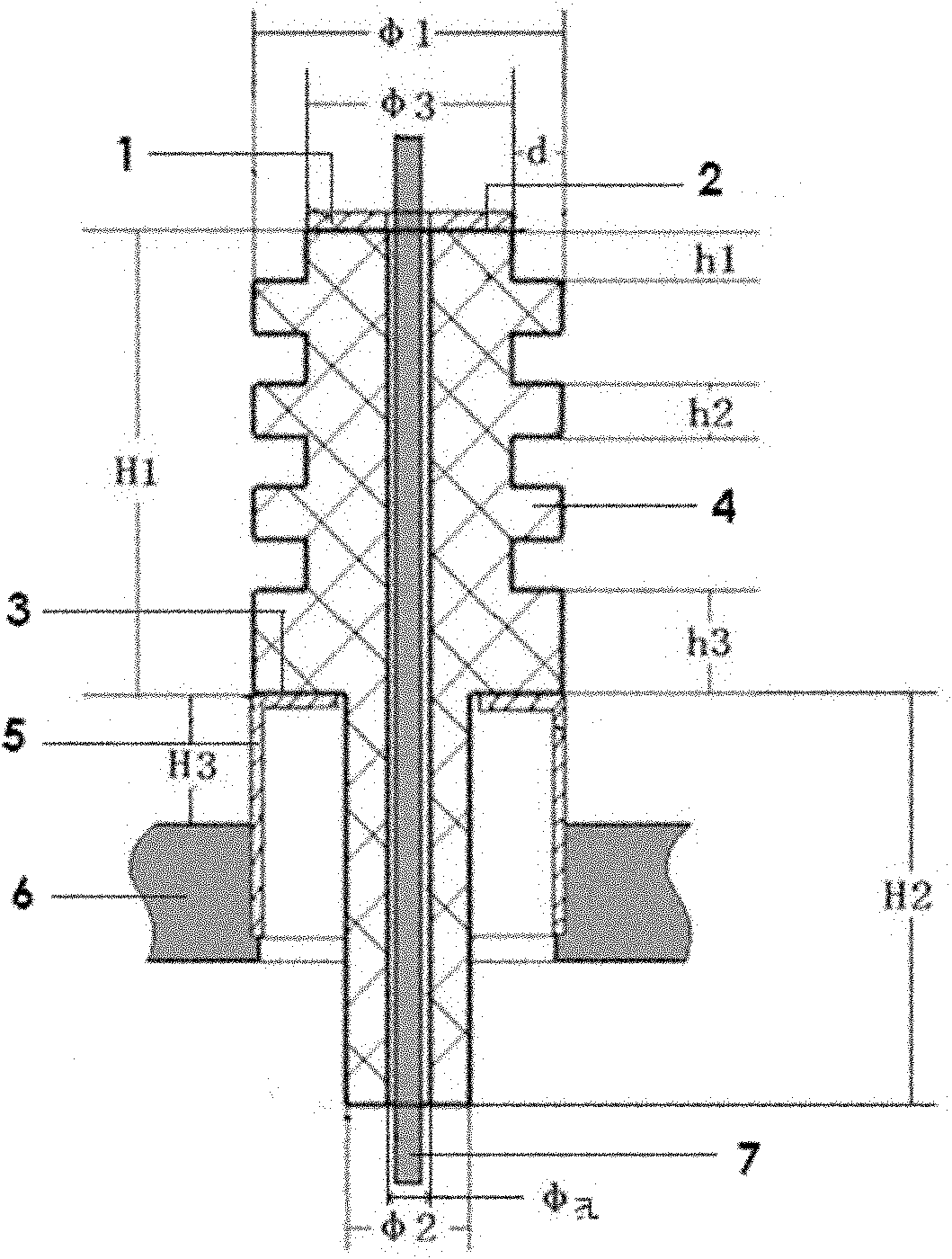

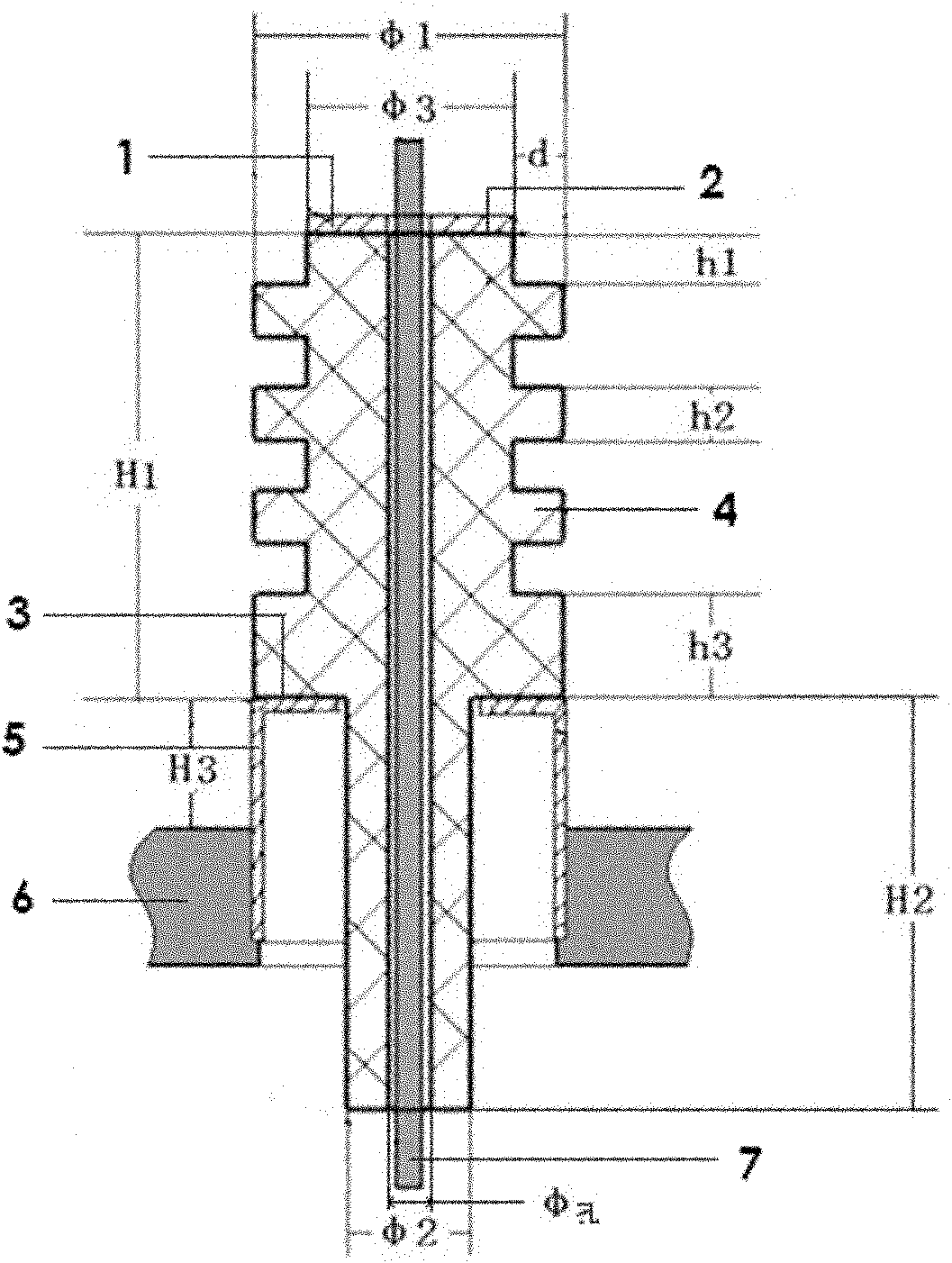

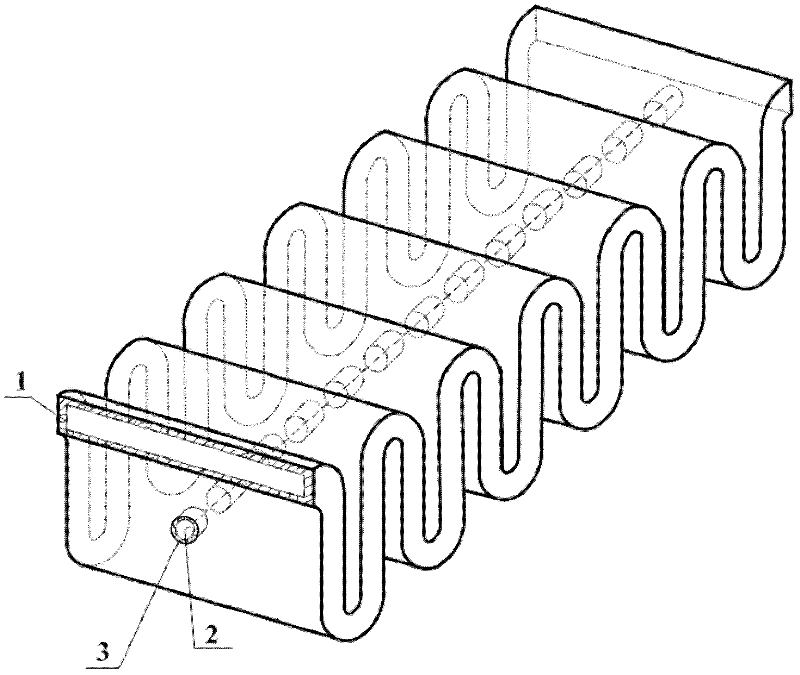

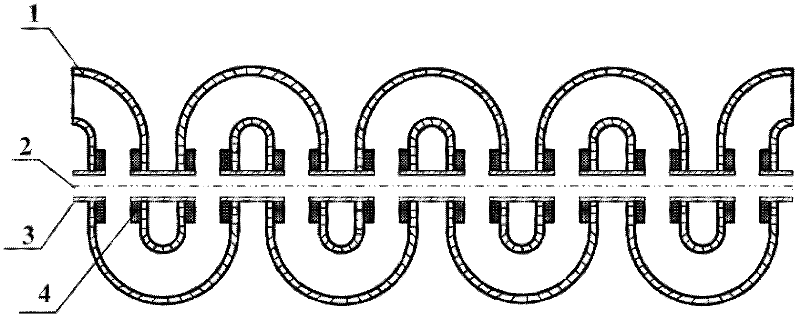

Gradient ridge loading tortuous waveguide slow wave line

The invention discloses a gradient ridge loading tortuous waveguide slow wave line, and belongs to the technical field of microwave vacuum electronics. The slow wave line is formed by alternately connecting a series of arc bent waveguides (or right-angled bent waveguides) and straight waveguides end to end, equivalently a rectangular waveguide (1) is periodically bent into a tortuous waveguide structure along an electric field surface. A gradient metal ridge sheet (4) is loaded on the inner wall of the straight waveguide of each tortuous unit; and a circular through hole is formed in a middle axis symmetric line (2) on the waveguide wall and the metal ridge sheet along the slow wave structure, and the circular through holes of the straight waveguides of the two adjacent tortuous units are connected by adopting a metal pipe (3) with the same size as the apertures of the circular through holes to form an electron injection channel. When relatively high coupling impedance of the ridge loading tortuous waveguide slow wave line is kept, the standing wave coefficient of the ridge loading tortuous waveguide slow wave line can be reduced, and the transmission property of the slow wave line is improved; and the reflecting oscillation of a ridge loading tortuous waveguide traveling wave tube is inhibited, so that the ridge loading tortuous waveguide traveling wave tube has higher gain and efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Hollow oxygen-free copper bar vacuum electron beam welding method, current lead and nuclear fusion device

ActiveCN110227879AWeld firmlyUniform weld widthElectron beam welding apparatusWelding/soldering/cutting articlesNuclear fusionEngineering

The invention discloses a hollow oxygen-free copper bar vacuum electron beam welding method, a current lead and a nuclear fusion device. The method comprises the steps of positioning welding, penetration fusion welding, modified welding and the like. The current lead comprises an integral hollow oxygen-free copper bar formed through the hollow oxygen-free copper bar vacuum electron beam welding method, and the current lead is adopted in the nuclear fusion device. According to the welding method, welding between hollow oxygen-free copper bars is stable, the welding line width is uniform, splashing is little, arc extinguishing is full, and the characteristics that a welding connector is good in sealing performance and high in tensile strength are achieved; and the current lead manufactured after welding and the nuclear fusion device applying the current lead have the advantages that the performance is stable and the service life is long, wherein the advantages are brought by the above effects.

Owner:淮南新能源研究中心

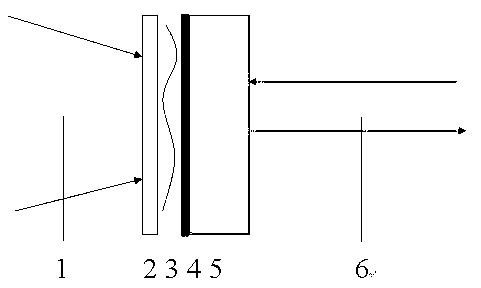

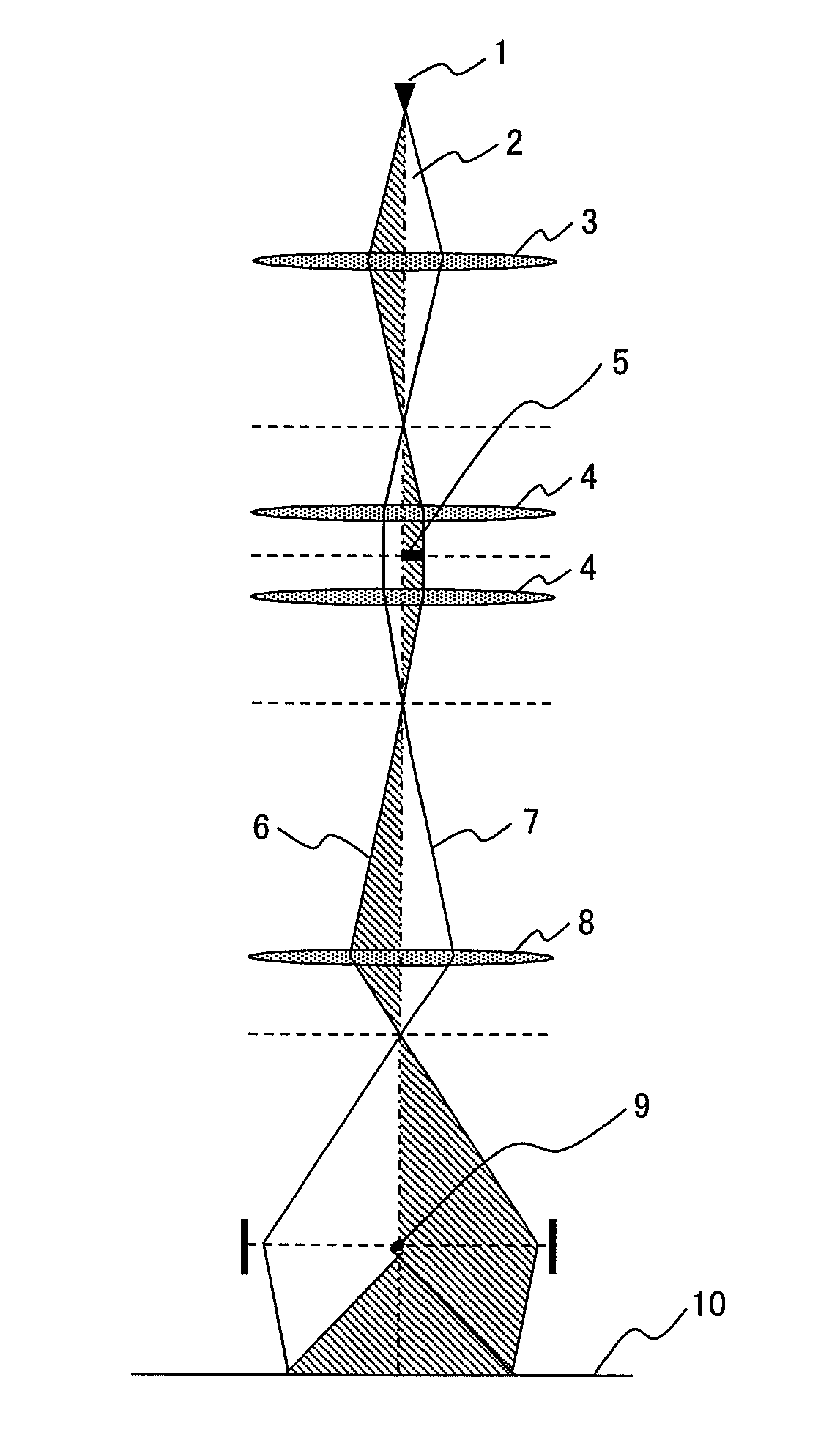

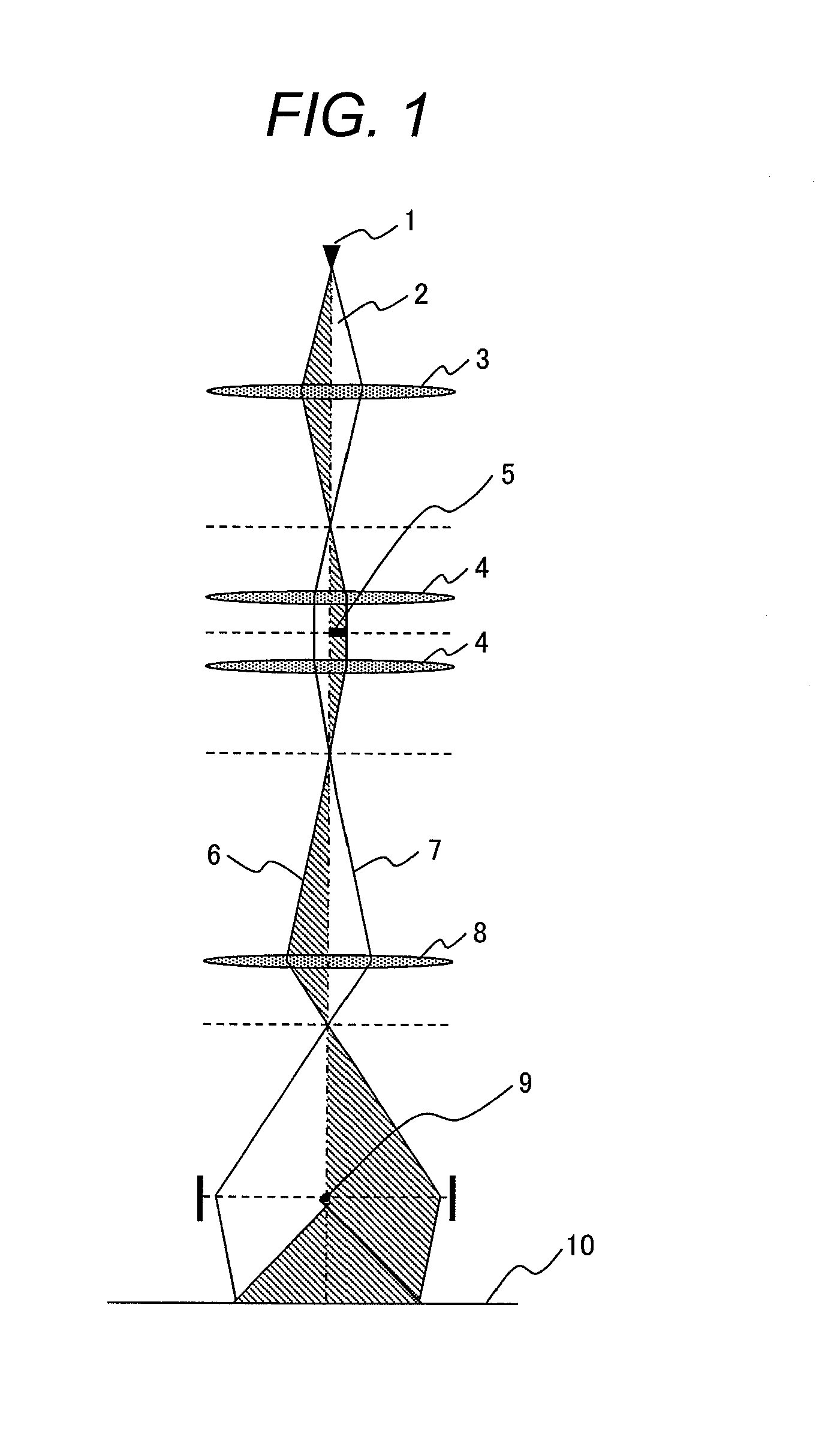

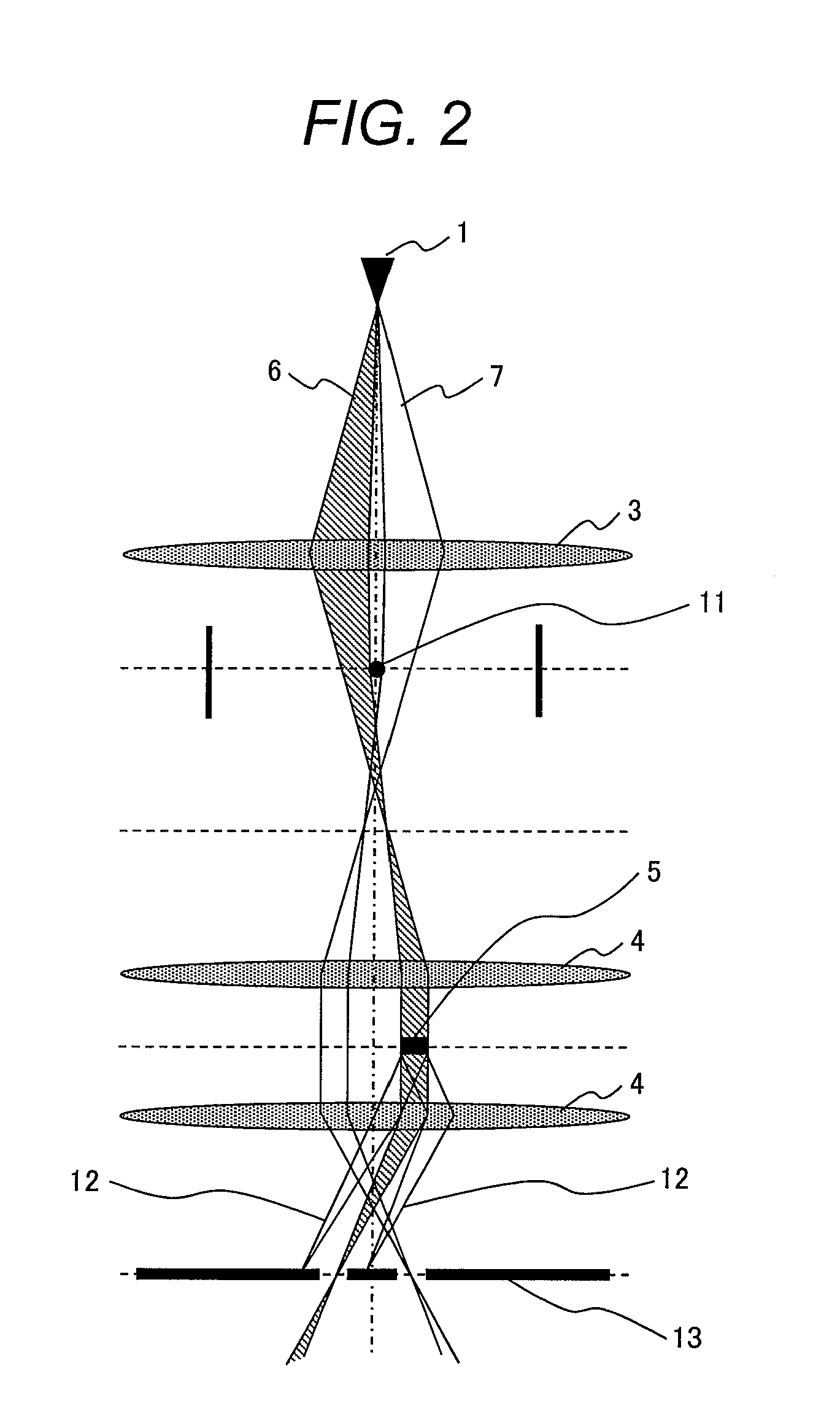

Transmission interference microscope

InactiveUS20130163076A1Accurate imagingHigh magnificationElectric discharge tubesMicroscopesElectron sourceParticle physics

Disclosed is a transmission interference microscope that provides a degree of freedom to a region being observed while obtaining pure transmission information, and obtains highly-accurate interference images at high magnification under optimized radiation conditions. An electron beam emitted from an electron source 1 is split by a biprism 11 positioned under a converging lens 3, and enters objective lenses 4 as an electron beam 6 passing through a sample and an electron beam 7 passing through a vacuum. The electron beams are bent at the front magnetic fields of the objective lenses 4, and are emitted as a collimated beam in a state in which the sample location and vacuum are each appropriately are left a space.

Owner:HITACHI HIGH-TECH CORP

Vacuum electron beam welding deformation control method and device for aero-engine flame tube

ActiveCN110732766AImprove detection efficiencyElectron beam welding apparatusEngineeringDeformation control

The invention discloses a vacuum electron beam welding deformation control method and device for an aero-engine flame tube. Safety pins with the same number of mixing holes in the outer ring or innerring of the flame tube are adopted, and position and detection are carried out three times at two different positions. According to the vacuum electron beam welding deformation control method and device for the aero-engine flame tube, the problem that the position degree is large after the flame tube undergoes vacuum electron beam welding is solved, a device for pre-welding control and post-welding detection is adopted for inspecting an pre-welding butt joint gap and the relative position degree of film holes of the inner and outer ring of the flame tube and detecting the position degree of the film holes of the inner and outer ring of the flame tube after welding is carried out by specific welding parameters.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Method for processing surface of Cu electrode of multistage depressed collector through graphene

ActiveCN104465267ASolve the challenges of successful preparationOvercome the three-dimensional structureTransit-tube collectorsCold cathode manufactureSecondary electronsVacuum electronics

The invention discloses a method for processing the surface of a Cu electrode of a multistage depressed collector through graphene, relates to the technology of vacuum electronics, and provides a novel collector processing technology applicable to a high-efficiency travelling-wave tube. According to the method, a grapheme coating is adopted and can be directly used for processing the oxygen-free copper electrode, secondary electron emission is restrained, the recovery efficiency of the multistage depressed collector is improved, and the overall efficiency of the travelling-wave tube is improved. The method is simple in process, controllable in technology and low in cost, and the processed multistage depressed collector can achieve the same secondary electron emission restraining effect as a collector made of graphite. The processed multistage depressed collector has the advantages of a traditional graphite collector, has higher mechanical performance, electric conduction performance and heat conduction performance, and solves the problems that the structure is loose, strength is low and the graphite collector is prone to generating graphite dust under a long-term bombardment of electron beams, thereby effectively improving the efficiency and reliability of the travelling-wave tube.

Owner:HEFEI UNIV OF TECH

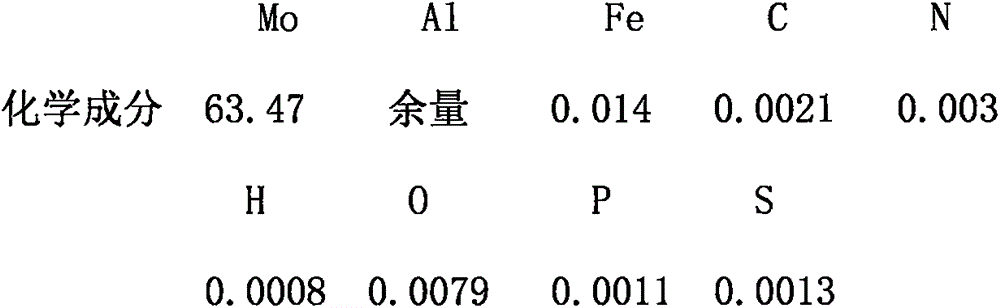

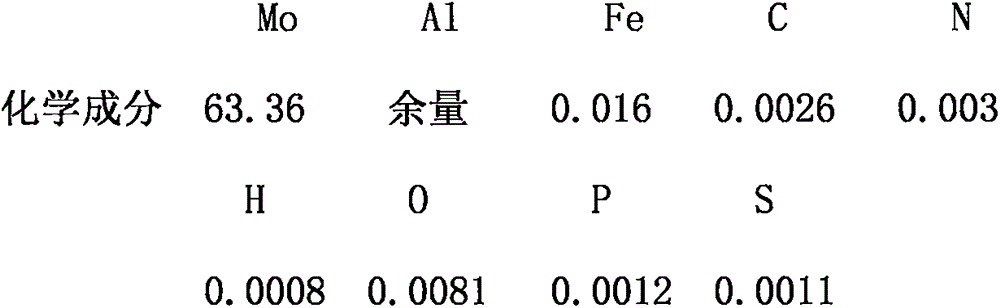

Preparation method of aerospace grade molybdenum and aluminum alloy

The invention relates to the material and metallurgy technology, in particular to a preparation method of an aerospace grade molybdenum and aluminum alloy. The preparation method is characterized in that by controlling vacuum electron beam smelting parameters, the reaction is kept within a reasonable speed range, and uniform distribution of the molybdenum element in the molybdenum and aluminum alloy is facilitated. By adding aluminum shot again before vacuum electron beam smelting, aluminum element losses caused by high temperature are counteracted under the condition of electron beam smelting, and the aluminum element content of the final product reaches a set value. The preparation method of the aerospace grade molybdenum and aluminum alloy has the beneficial effects that the molybdenum element in the produced molybdenum and aluminum alloy is uniform in distribution, the impurity element content is small, the aluminum element content is stable, and the requirement of the aerospace grade molybdenum and aluminum alloy is met.

Owner:宝鸡市嘉诚稀有金属材料有限公司

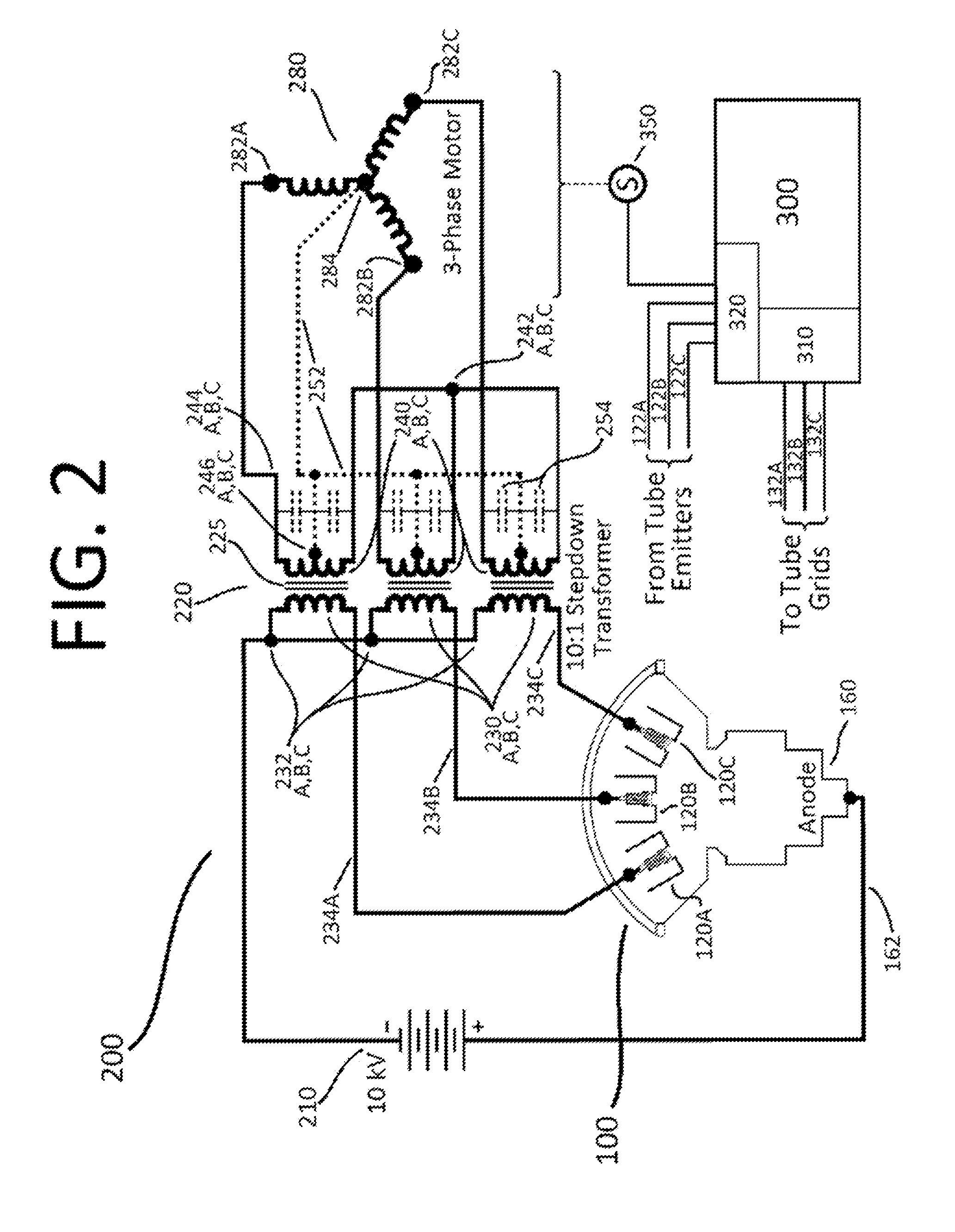

Vacuum electron power tube

A vacuum tube that may include but is not limited to a plurality of electrodes. A first electrode of the plurality of electrodes may be configured to operatively connect to an electrical source. A second electrode of the plurality of electrodes may be configured to operatively connect to a first load of a plurality of loads, wherein the first electrode may be configured to complete a first circuit through the second electrode and the first load. A third electrode of the plurality of electrodes may be configured to operatively connect to a second load of the plurality of loads that is independent from the first load, wherein the first electrode may be configured to complete a second circuit through the third electrode and the second load.

Owner:BALDWIN DAVID A +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com