Equipment and technology for preparing superfine spherical metal powder by means of ultrasonic vibration and atomization

A metal powder, vibration atomization technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of coarse metal powder particles, impossibility of large-scale industrialization, large equipment investment, etc., achieve fine particle size, small footprint, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

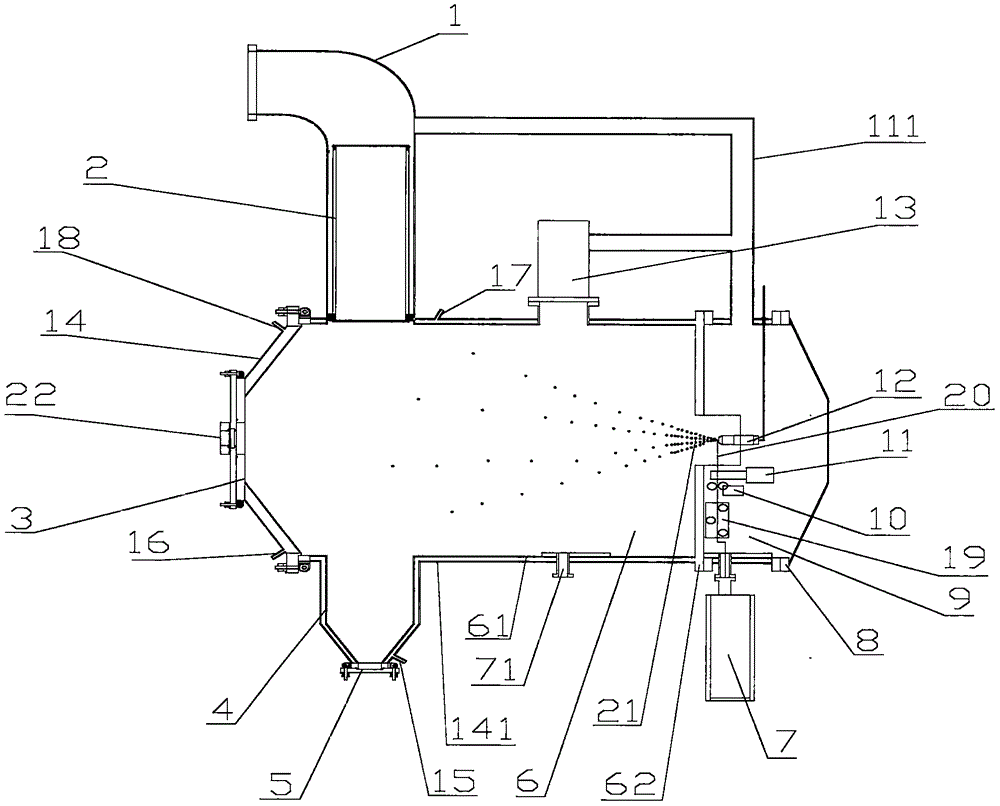

[0038] The equipment and process of this embodiment will be described in detail below with reference to the accompanying drawings.

[0039] One, such as figure 1 As shown, it is a schematic structural diagram of the equipment for preparing fine spherical metal powder by ultrasonic vibration atomization in the present invention. It includes a vacuum atomization chamber (6) and its cylinder (61). The upper part of the cylinder (61) is connected with a vacuum exhaust pipe (1) and an electron beam generator (13) is installed; The powder hopper (4), the lower end of the powder accumulation hopper (4) is also connected with a powder outlet (5), which is convenient to open and discharge metal powder; the left end is provided with a vacuum atomization chamber front door (3), and the vacuum atomization chamber front door ( 3) There is also an observation window (22) on the top to facilitate the observation of the internal working conditions of the vacuum atomization chamber (6); the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com