The structure and method of layered ceramic raw materials are continuously turned and folded and rubbed

A technology of ceramic raw materials and raw materials, applied in the direction of supply devices, manufacturing tools, etc., to achieve the effect of simplified structure, good physical and chemical properties, and coordinated pattern effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical process of a layered ceramic raw material continuous falling and stacking cloth structure and method according to an embodiment of the present invention will be introduced below.

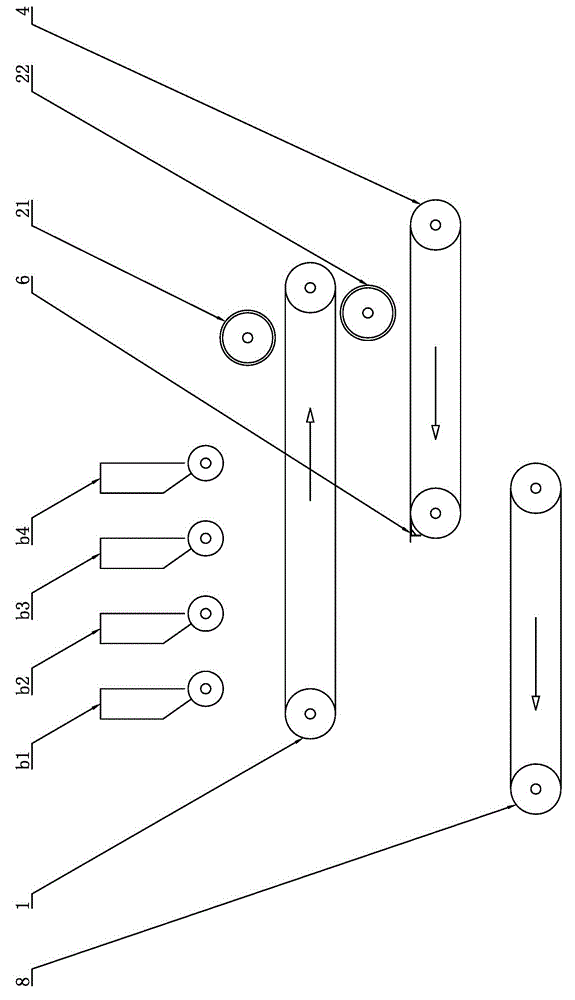

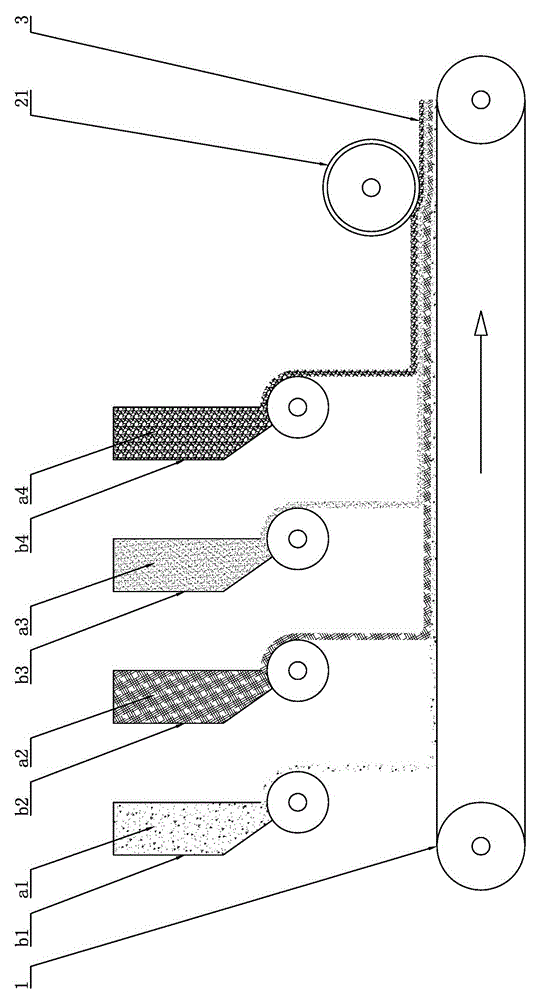

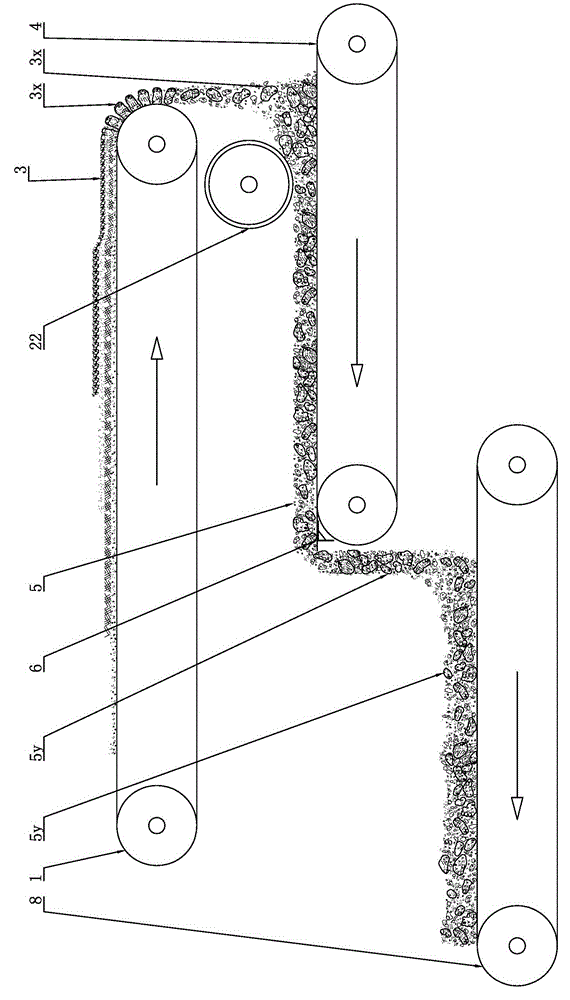

[0024] see figure 1 As shown, it is a kind of layered ceramic raw material of the present invention, which is continuously turned and folded and rubbed. figure 1 Among them, there are four unloading devices b, which are respectively the first, second, third, and fourth unloading devices b1, b2, b3, and b4; it also includes the first belt 1 for receiving the raw materials from the unloading device b and the device The first rolling device 21 on the first belt. The above-mentioned unloading device may be a roller hopper device for controlling unloading through a roller, or a belt type hopper device for controlling unloading through a belt. The first rolling device may be an outsourcing sponge type or a belt type or a resin roller; the second rolling device may also be an outsour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com