Liquid blast furnace slag pelletizing method and apparatus for heat recovering process

A technology of heat recovery and blast furnace slag, which is applied in heating devices, recycling technology, and other non-combustion heat generation, can solve the problems of high heat recovery efficiency and liquid slag granulation, and achieve water conservation, good physical and chemical properties, Effect of saving cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

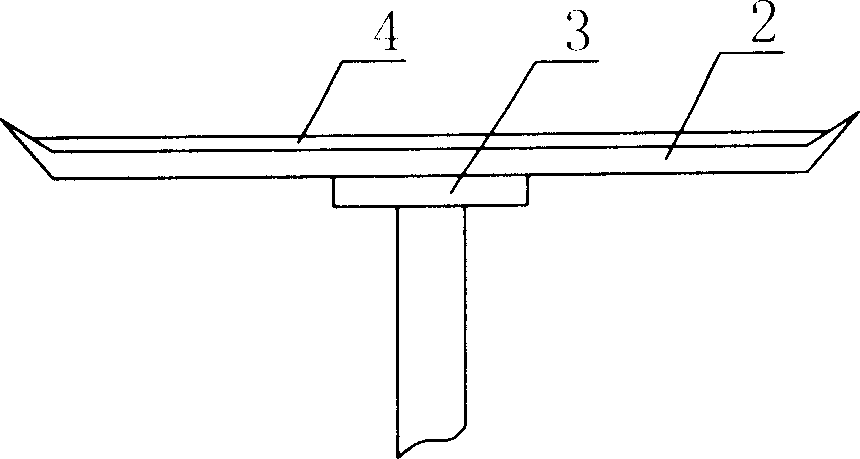

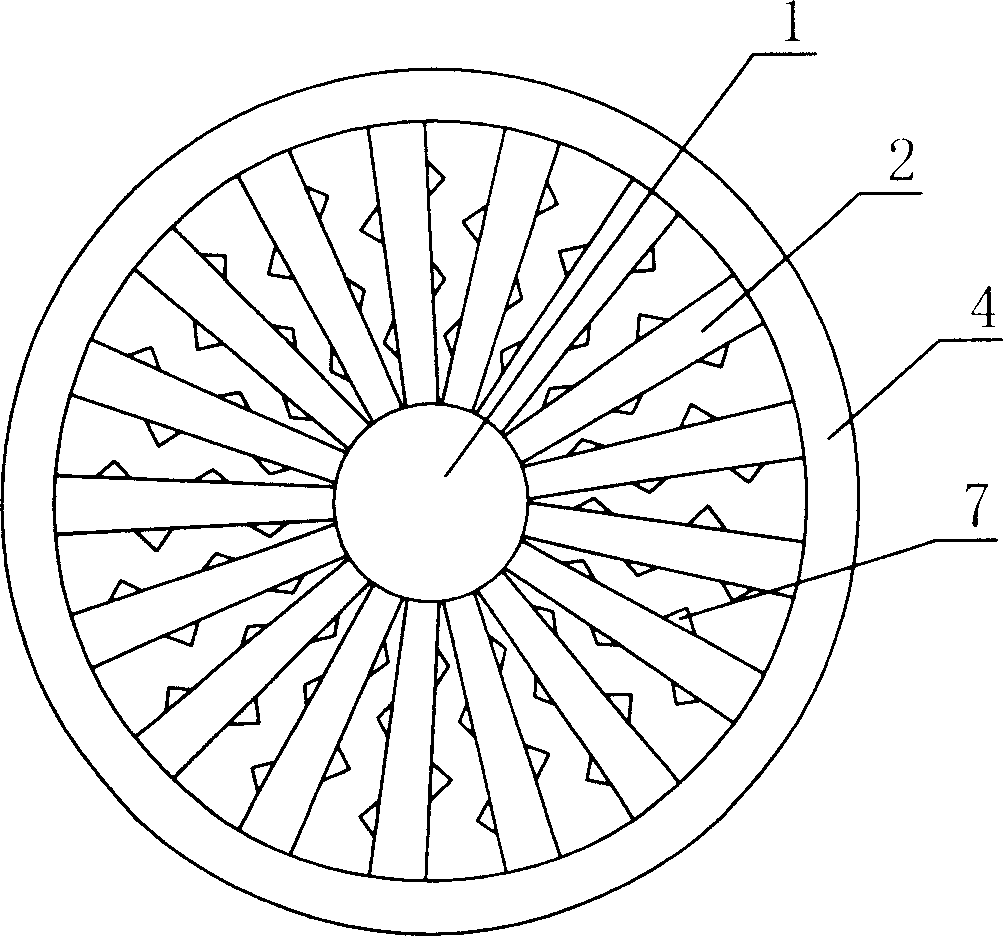

[0030] Implementation Option 1: If figure 1 , figure 2 As shown, the central part of the spoke of the wheel-spoke granulation device is a solid disc 1, and diamond bars 2 are arranged radially around the disc 1; there are gaps for slag particles to pass between two adjacent diamond bars 2, and the discs 1. The center of the entire spoke rhombus 2 is concave; the bottom of the disk 1 is connected to the motor through the transmission shaft 3; the outermost edge of the disk is provided with a baffle 4, the main purpose of which is to prevent the granulated high-temperature slag from hitting the inner wall of the container , and stick to the wall. There is a smooth transition from the solid disc 1 to the spoke part. The purpose of this design is twofold: one is to protect the lower rotating shaft to avoid damage to the rotating shaft by liquid slag or high-temperature slag; Break up liquid slag well.

[0031] Dozens of rhombus bars are arranged on the spoke part, and the cro...

Embodiment approach 2

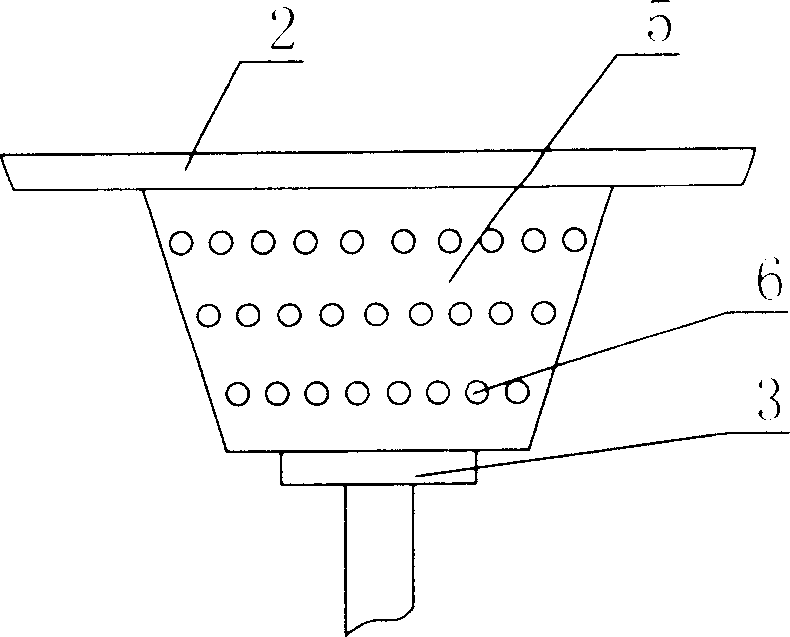

[0033] Implementation Option 2: If image 3 , Figure 4 As shown, the main body of the cup-type granulation device is a cup-shaped structure, and the central part is a circular cup 5 with a large upper part and a smaller lower part. The bottom of the cup 5 and the side wall form an obtuse angle; ; The outer ring of the cup 5 is radially arranged with diamond strips 2, and there is a gap for slag particles to pass between two adjacent diamond strips 2; A thorn 7, to strengthen the crushing effect. The length of the thorns is about 5mm.

[0034] The cup 5 is sunken in the entire spoke rhombus 2; the bottom of the cup 5 is connected with the motor through the transmission shaft 3. The cup can be processed into an integral type, or can be processed into a separate type.

[0035] The height of the cup: if it is too high, it may make it difficult for large sticky slag or solid slag to be thrown out from the upper part of the cup.

[0036] Both the height and diameter of the cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com