Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1902 results about "Solid of revolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, engineering, and manufacturing, a solid of revolution is a solid figure obtained by rotating a plane curve around some straight line (the axis of revolution) that lies on the same plane.

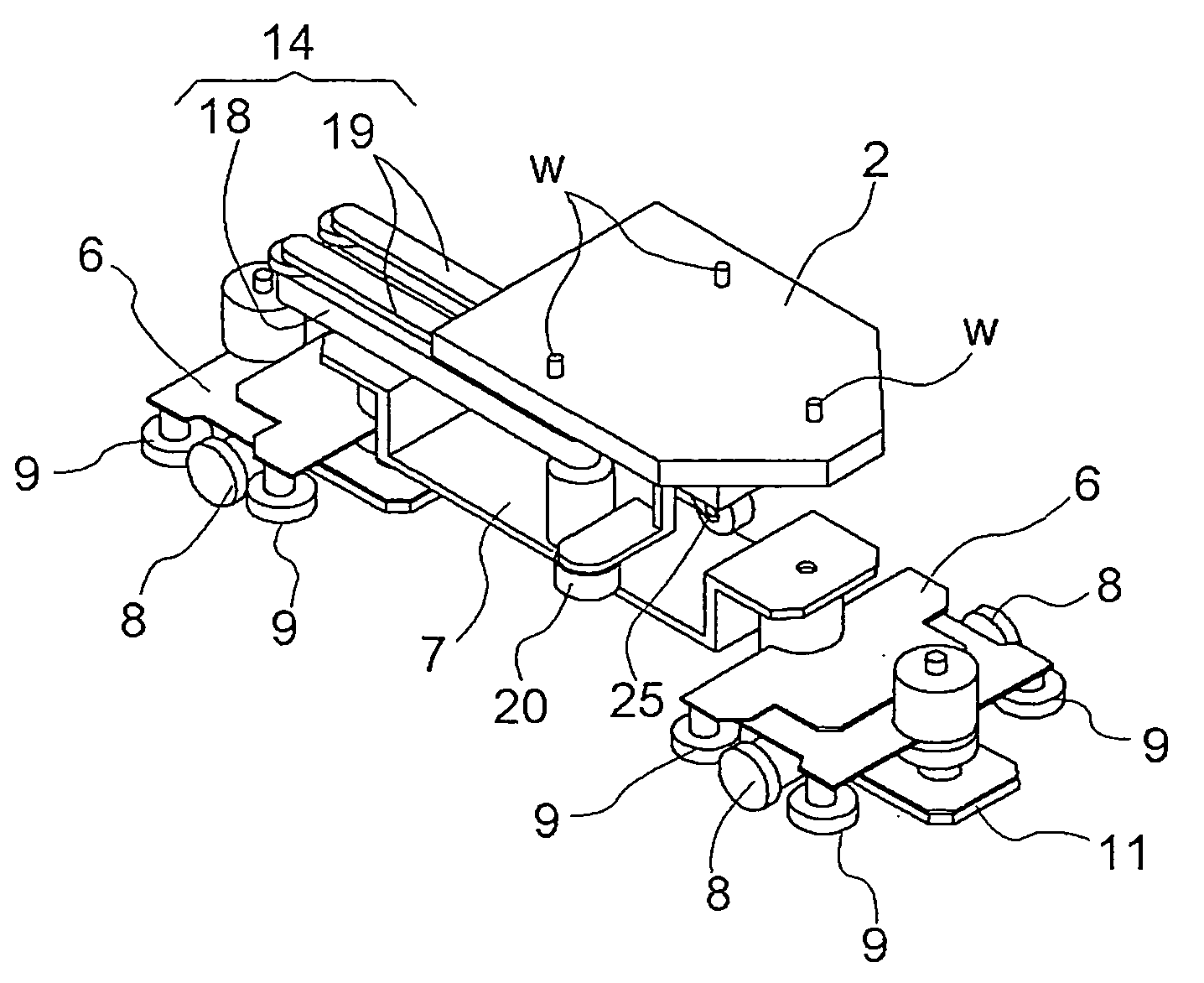

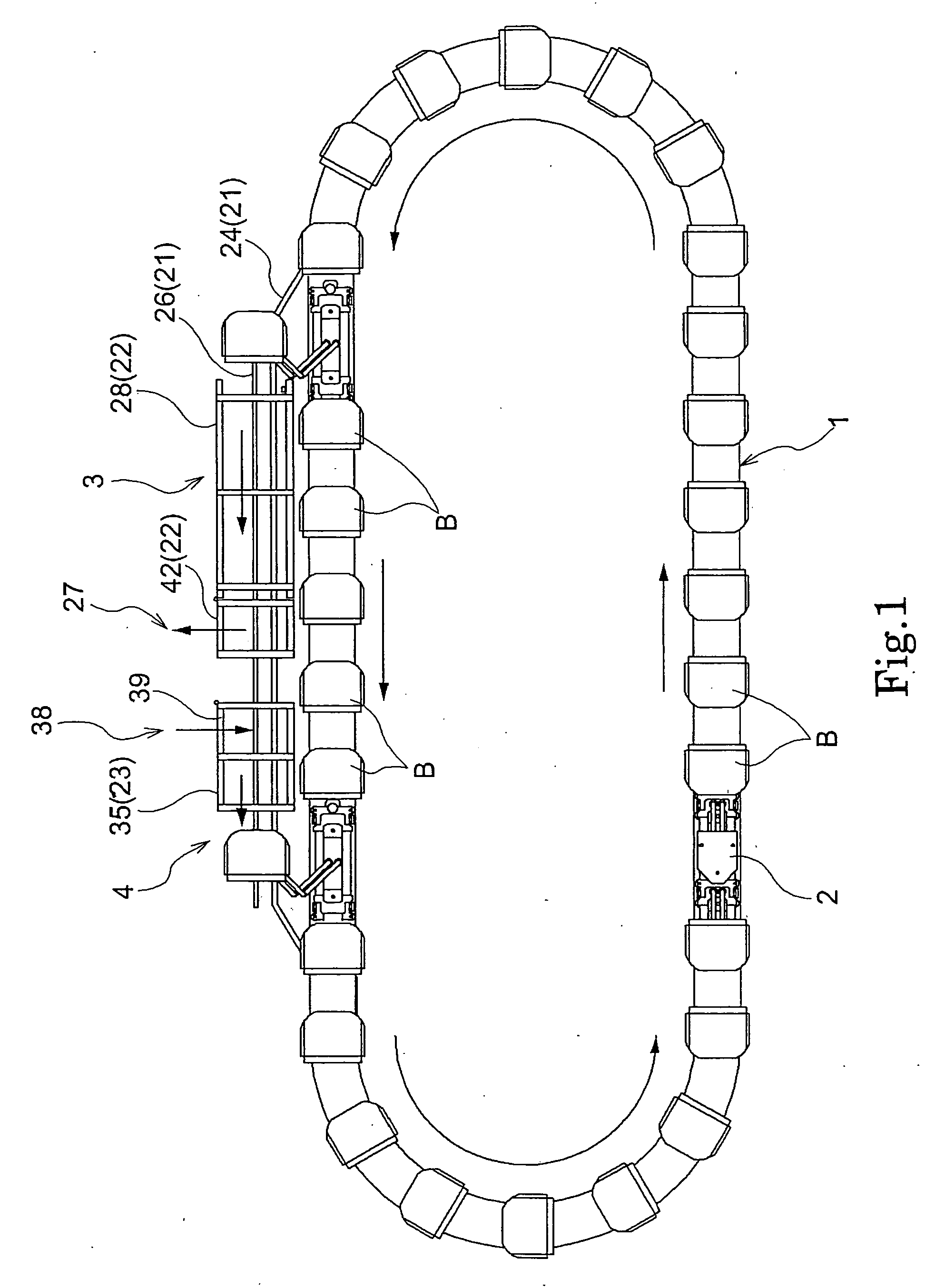

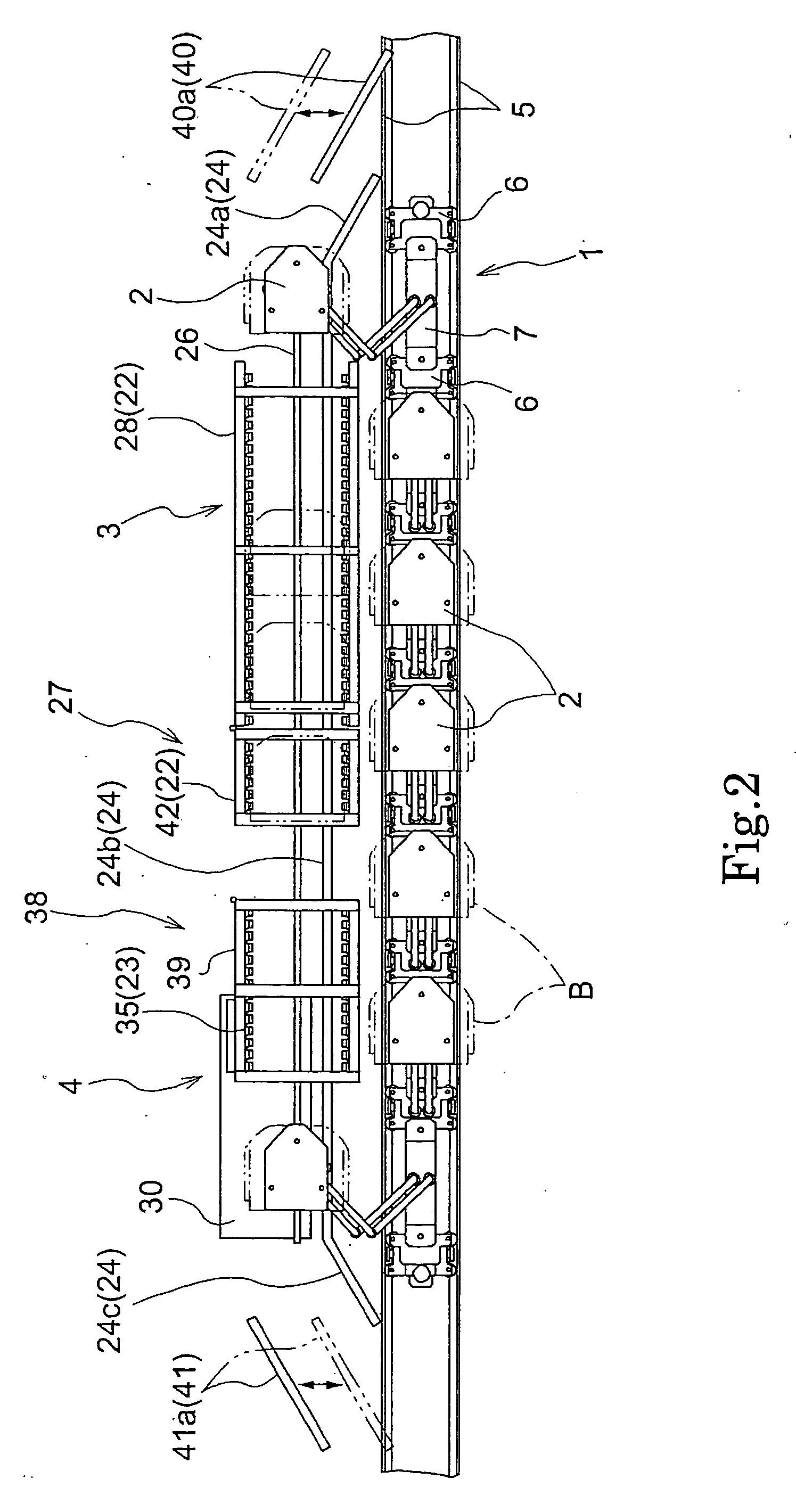

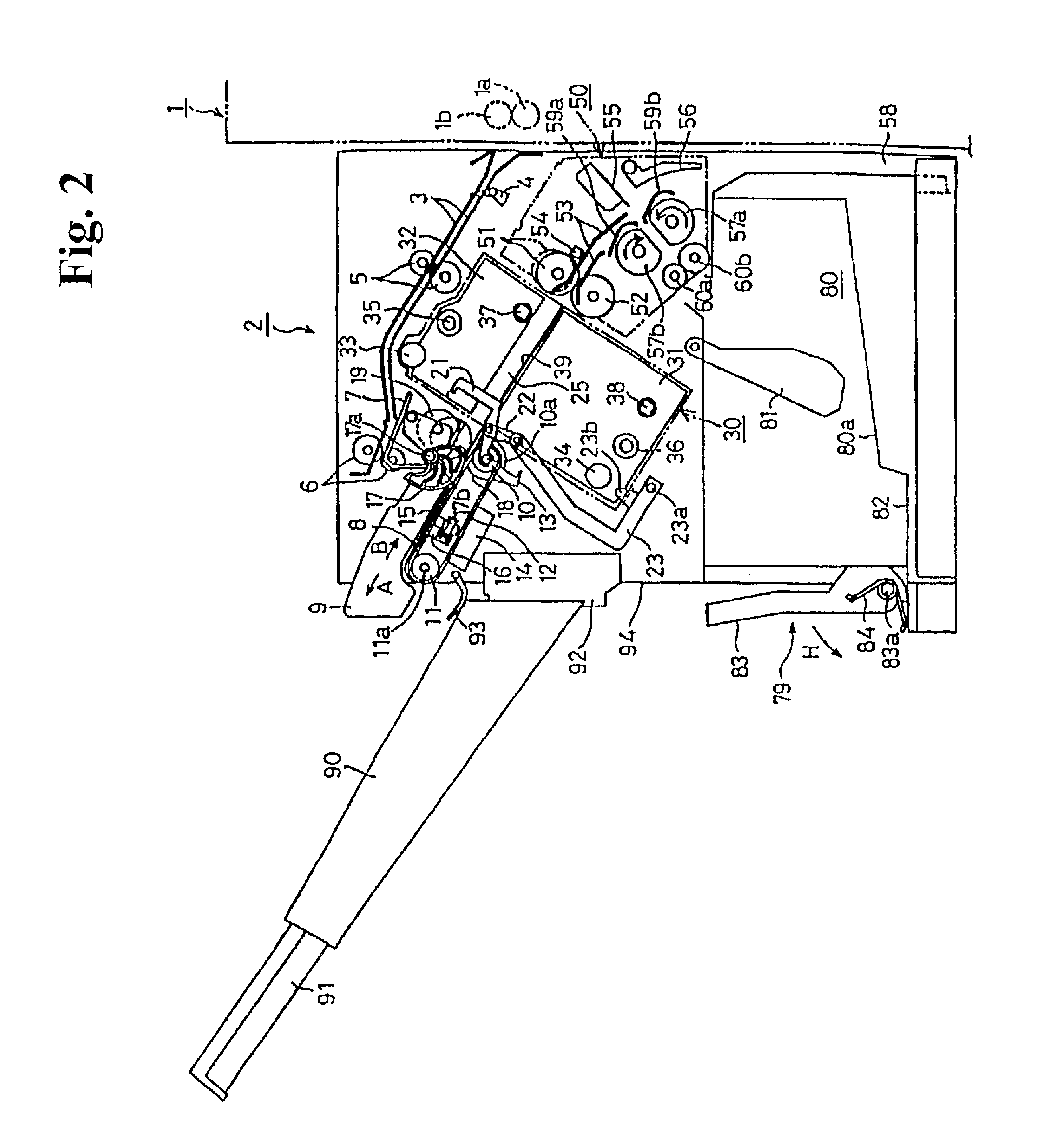

Article transport device

InactiveUS20070034477A1Small and simpleSemiconductor/solid-state device manufacturingControl devices for conveyorsSolid of revolution

Owner:DAIFUKU CO LTD

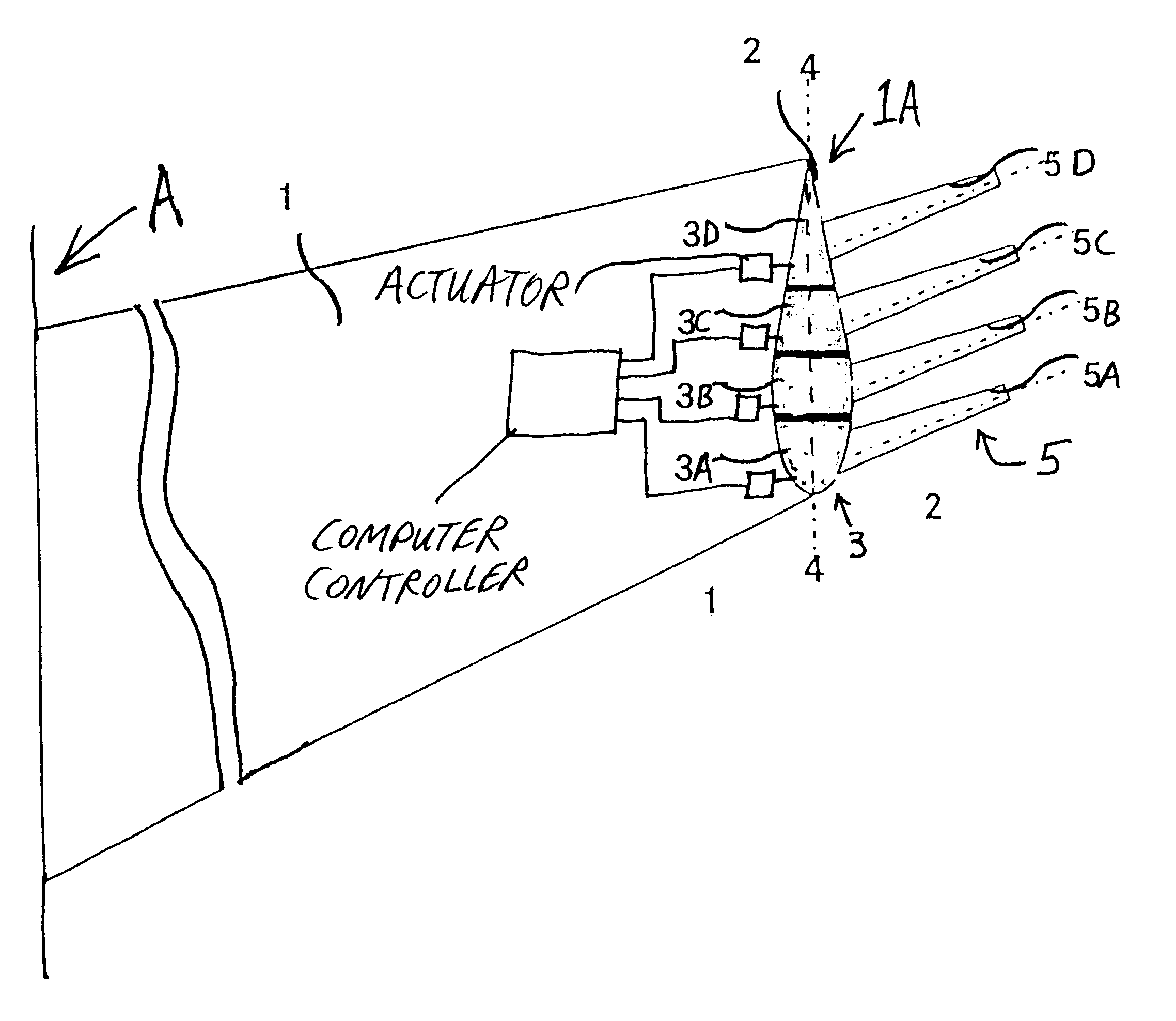

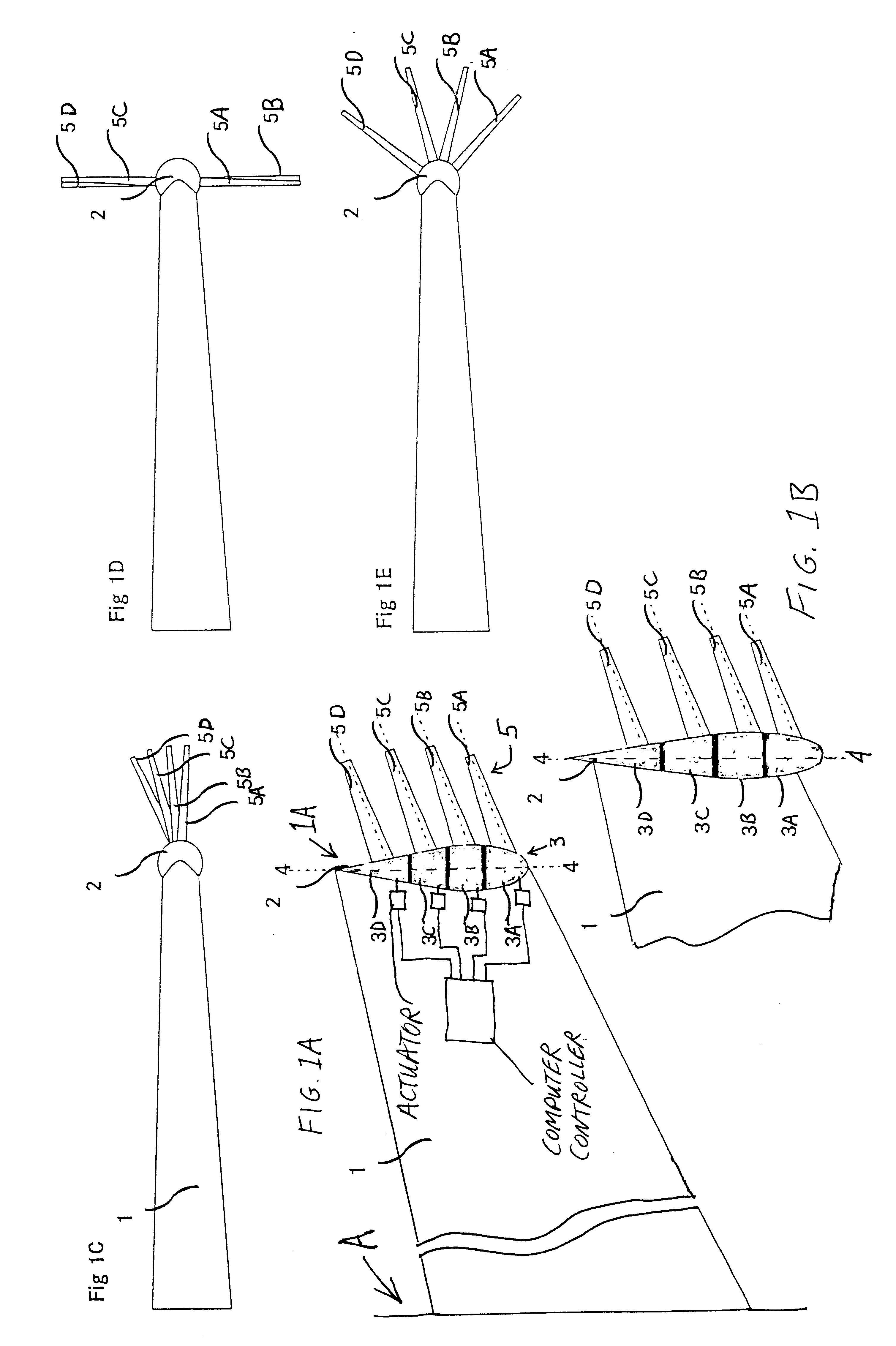

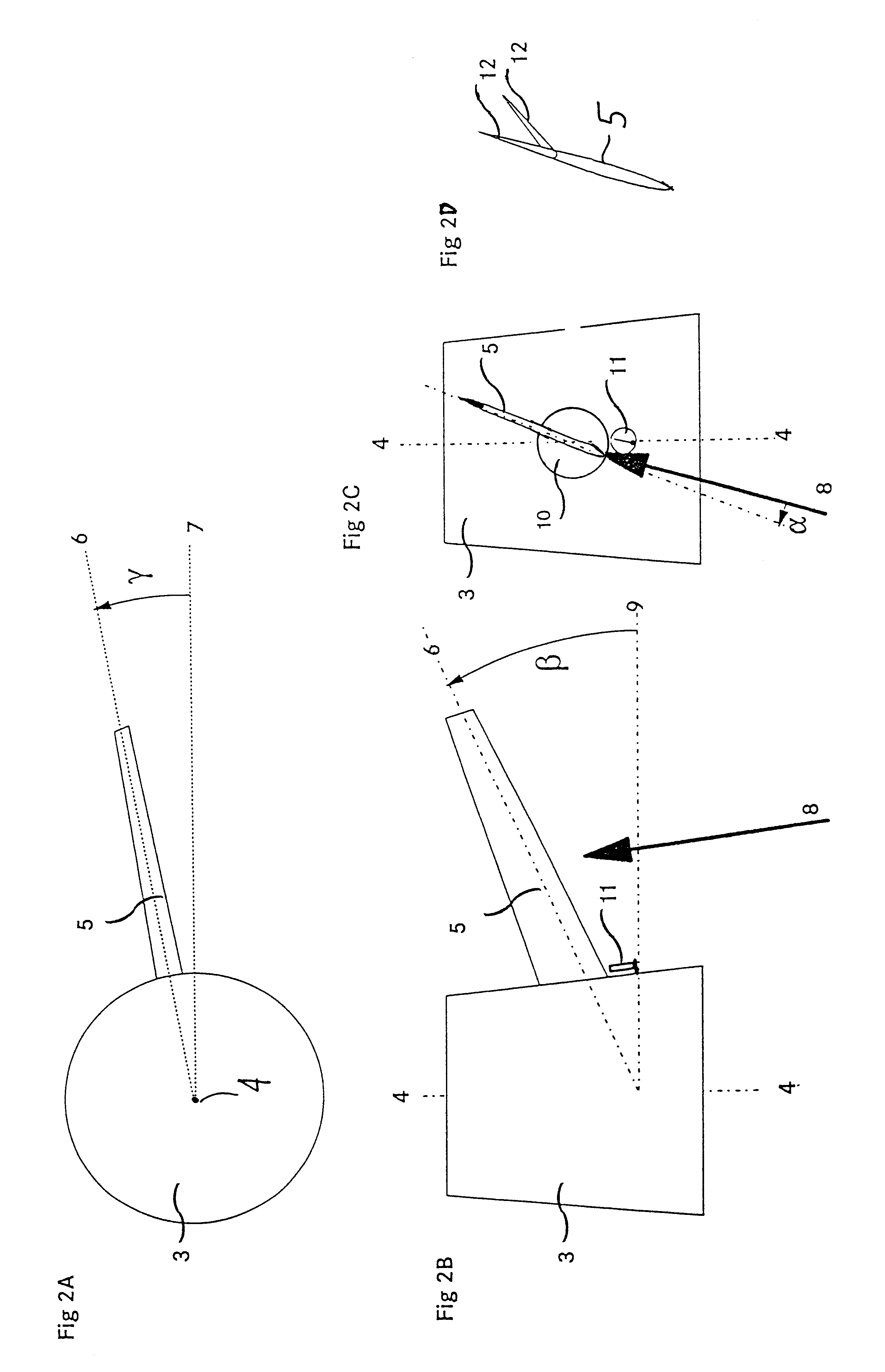

Subsonic aircraft with backswept wings and movable wing tip winglets

InactiveUS6345790B1Optimized aerodynamic streamline contourRaise the ratioInfluencers by generating vorticesAircraft stabilisationWingspanAirplane

A subsonic aircraft having backswept lifting wings is equipped with individually rotatable winglets at the wing tips thereof, in order to reduce drag during cruise flight, to minimize the dangers posed by wing tip vortices to following aircraft during take-off and landing, and to minimize the total wingspan during ground operations, with respective different positions of the winglets. A streamline-shaped rotation body made up of at least two individually rotatably supported rotation segments is mounted on the wing tip of each lifting wing. A respective winglet is mounted on each respective rotation segment. Each rotation segment with its associated winglet is individually rotatable about a rotation axis of the rotation body extending substantially parallel to the aircraft lengthwise axis. Thereby, each winglet is individually pivotable to any selected pivot angle relative to a horizontal plane extending through the rotation axis. Each winglet and its associated rotation segment is rotatable through an angular range between maximum end limits of at least +90° (vertically upward) and at least -90° (vertically downward) relative to the horizontal plane.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

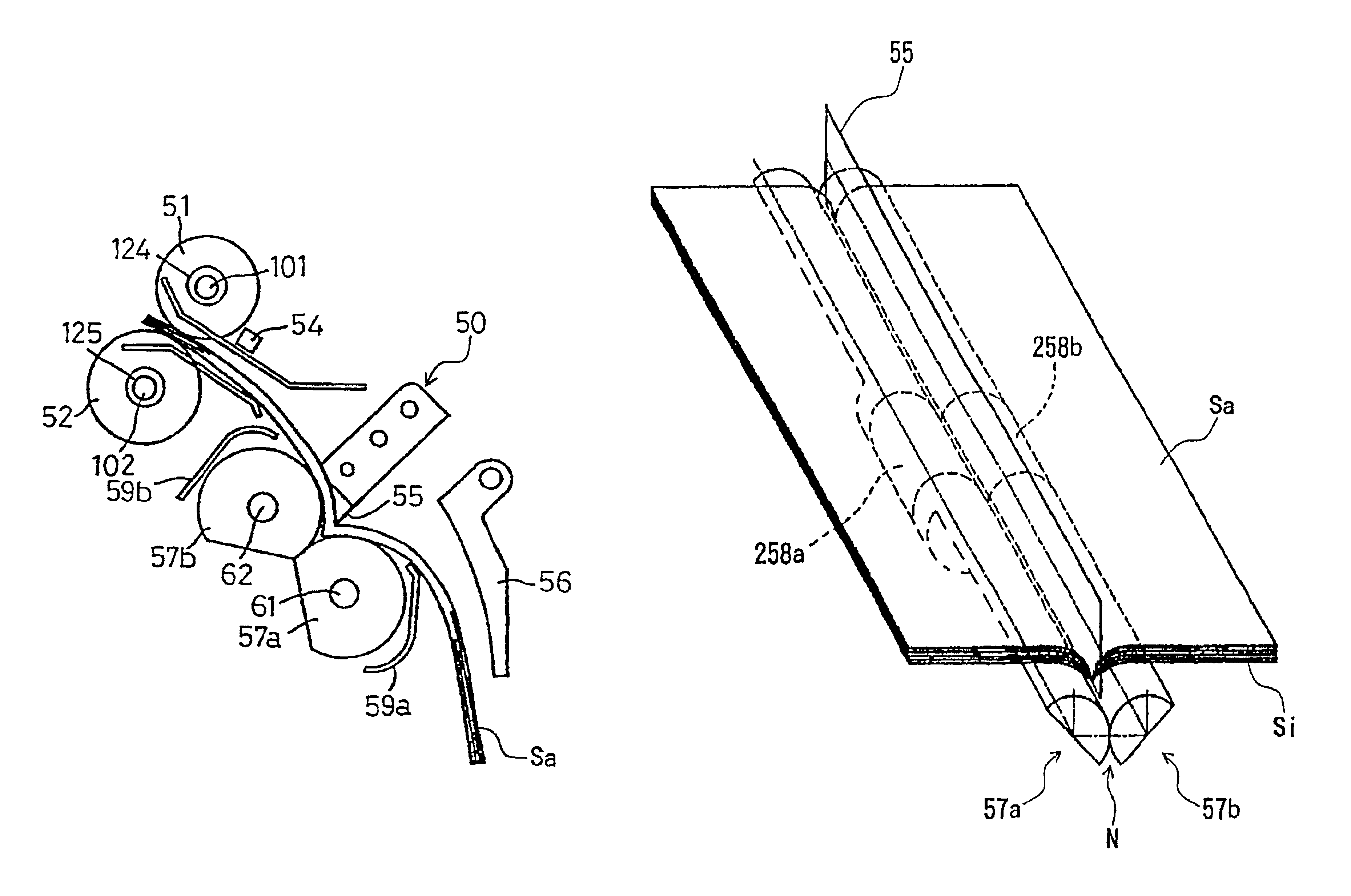

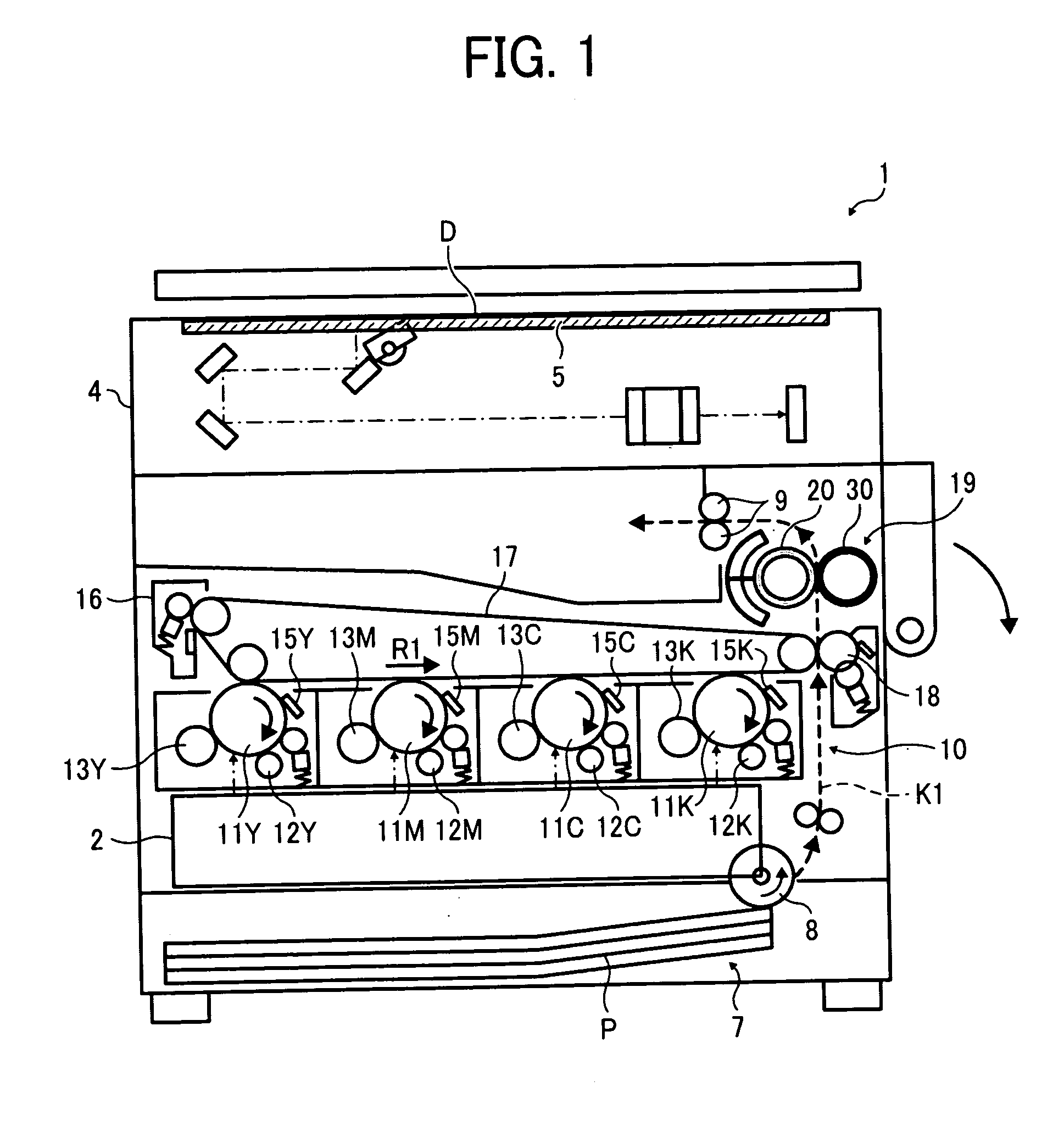

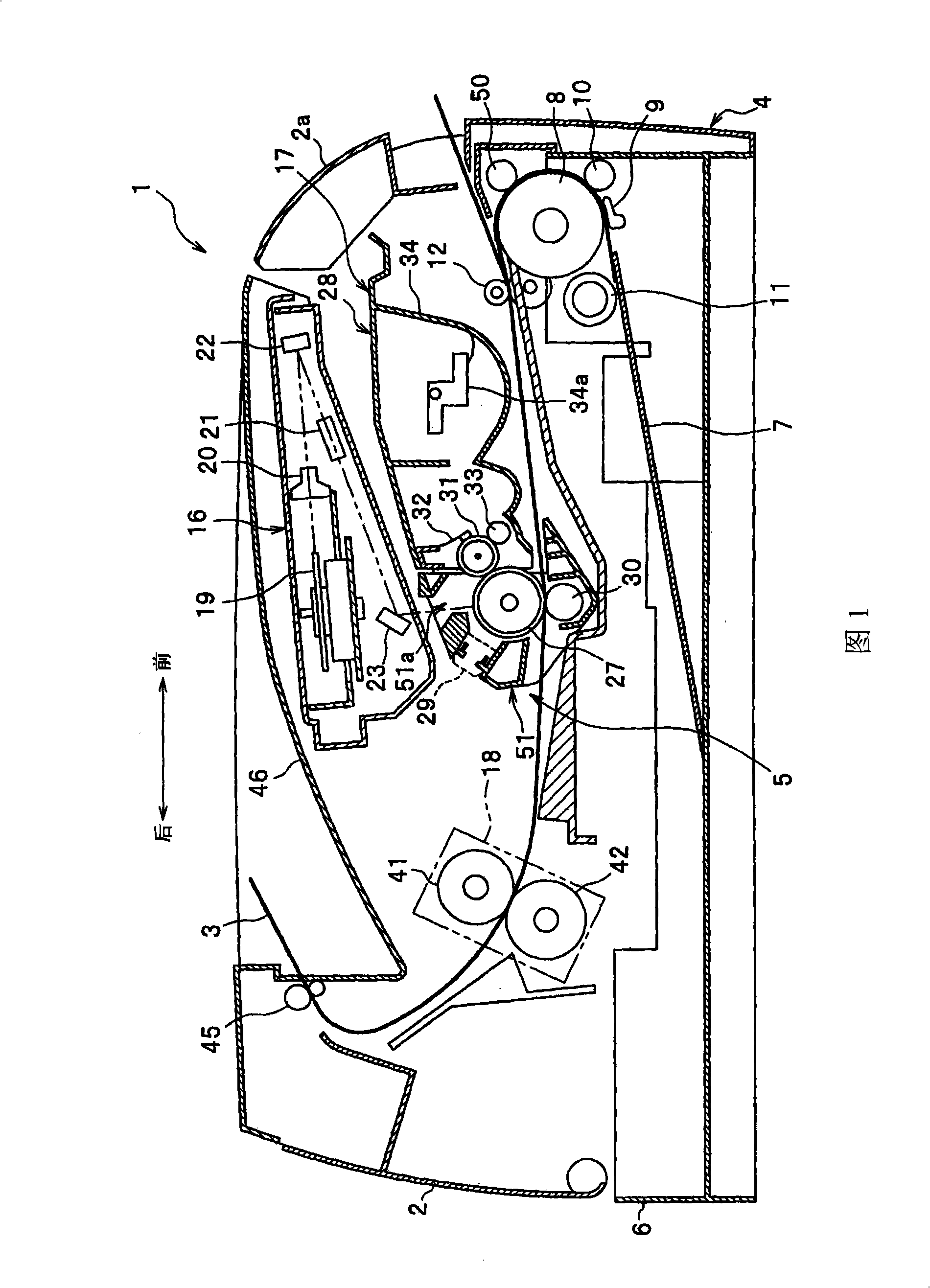

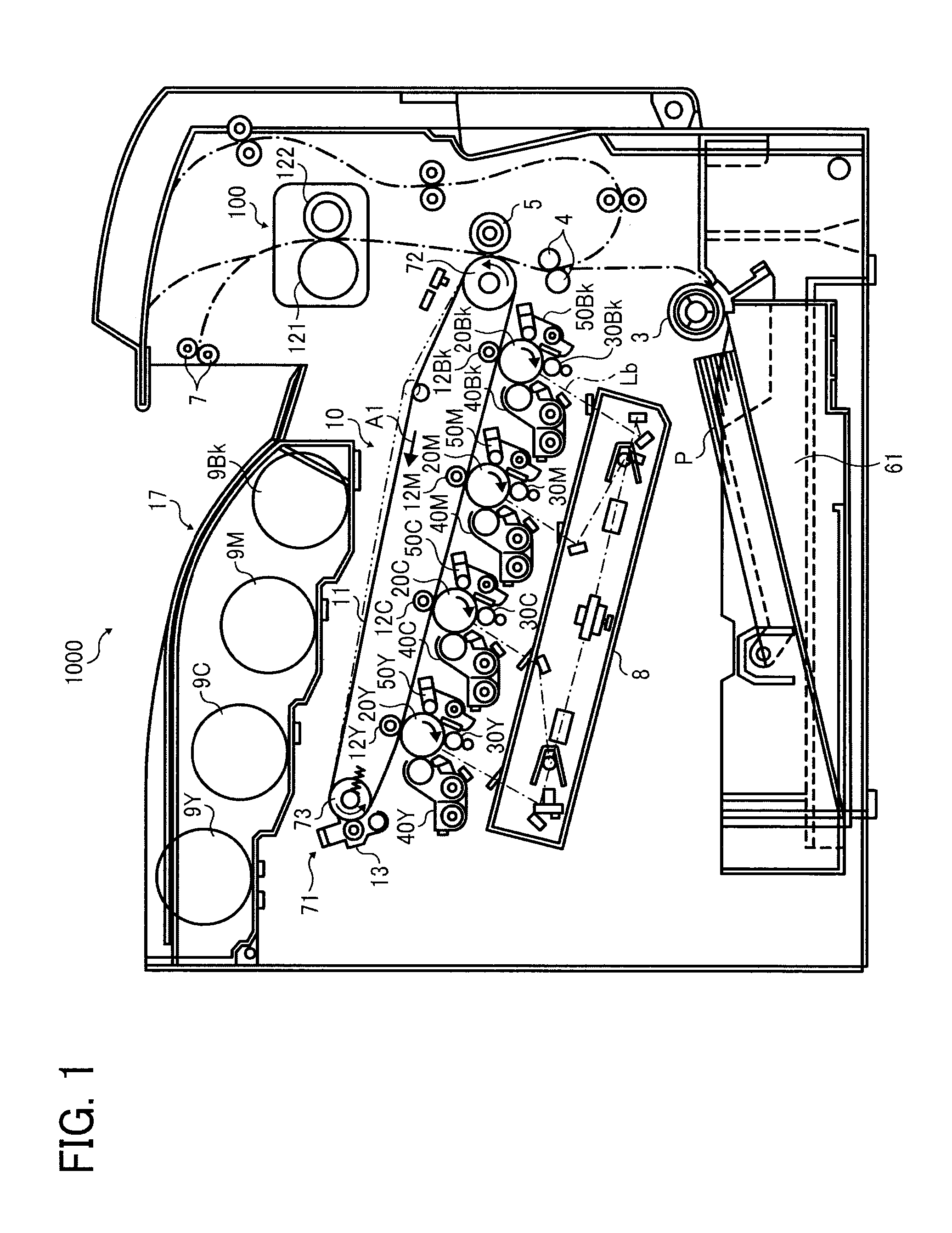

Sheet processing apparatus and image forming apparatus equipped with the same

InactiveUS6837840B2Increase coefficient of frictionReduce coefficient of frictionEnvelopes/bags making machineryMechanical working/deformationPull forceSolid of revolution

A sheet processing apparatus for folding a sheet bundle at a predetermined position includes paired rotating bodies for folding the sheet bundle having nip portions, a pressing device for pressing the predetermined position of the sheet bundle into the nip portions of the paired rotating bodies, and a device connected to the paired rotation bodies for providing rotation to the paired rotating bodies. A pulling force of the rotating bodies to pull the sheet bundle pressed into the nip portions of the rotating bodies has an amount which does not separate a sheet of the sheet bundle contacting the rotating bodies from the subsequent sheets in the sheet bundle when pulling the sheet bundle.

Owner:NISCA KK

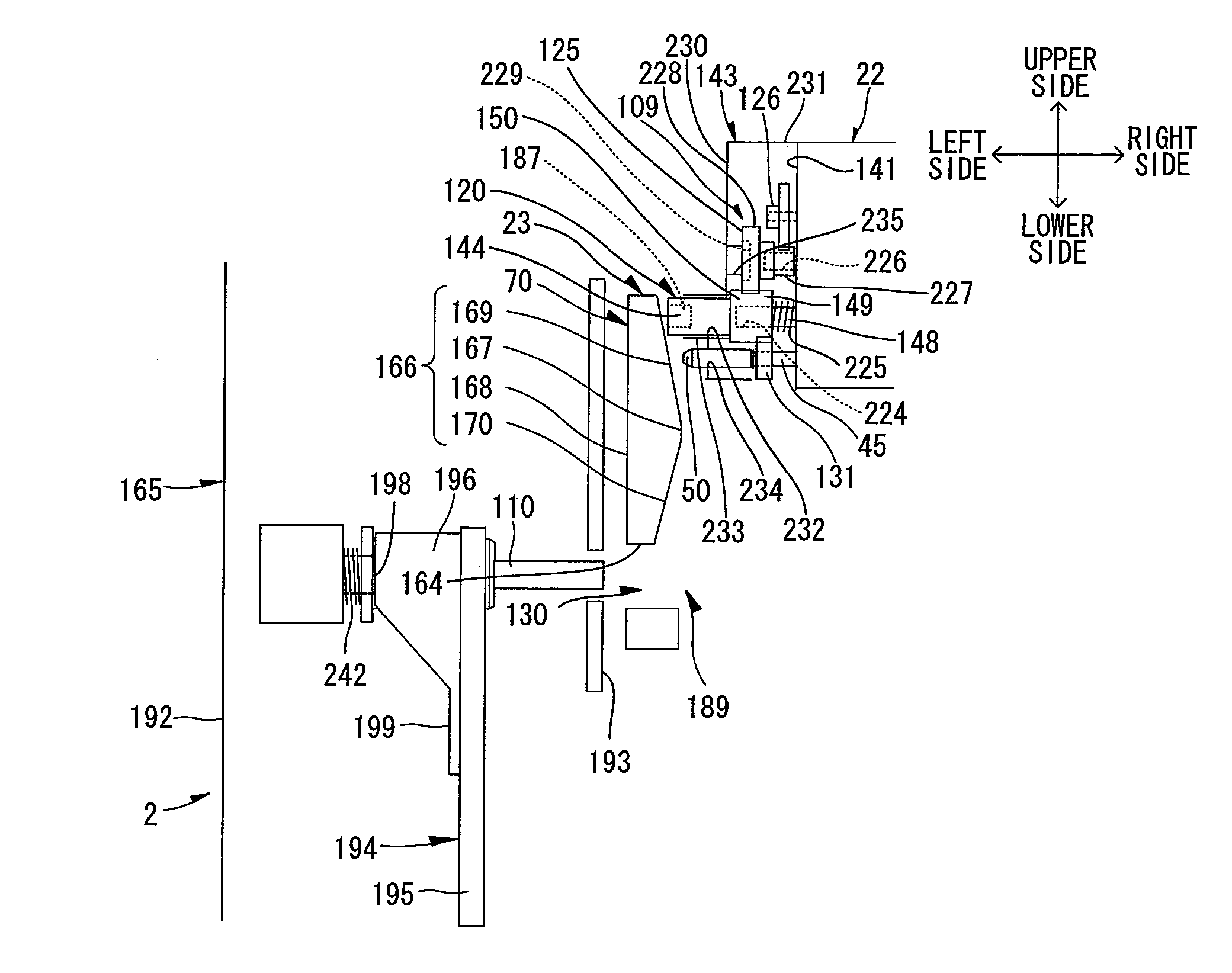

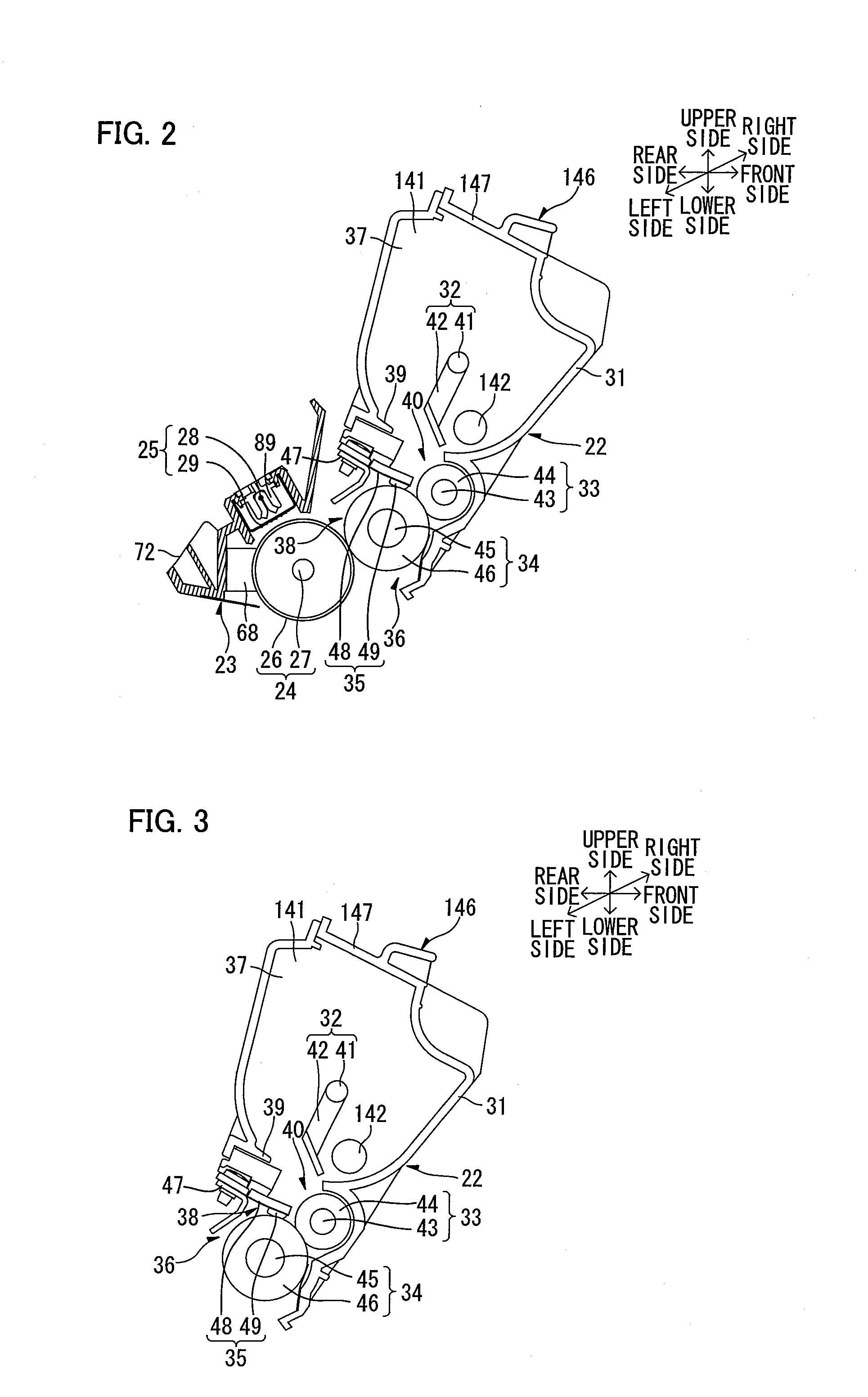

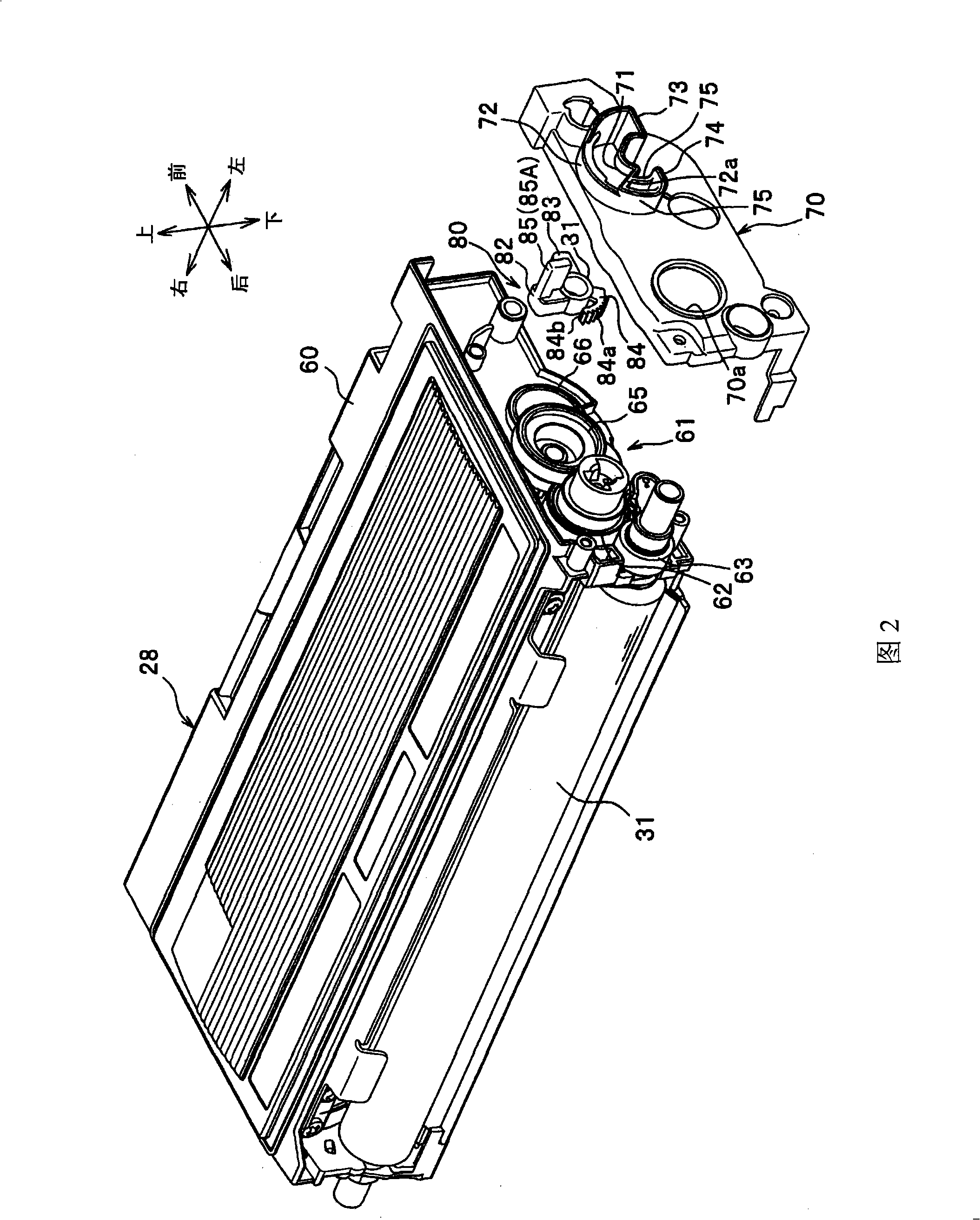

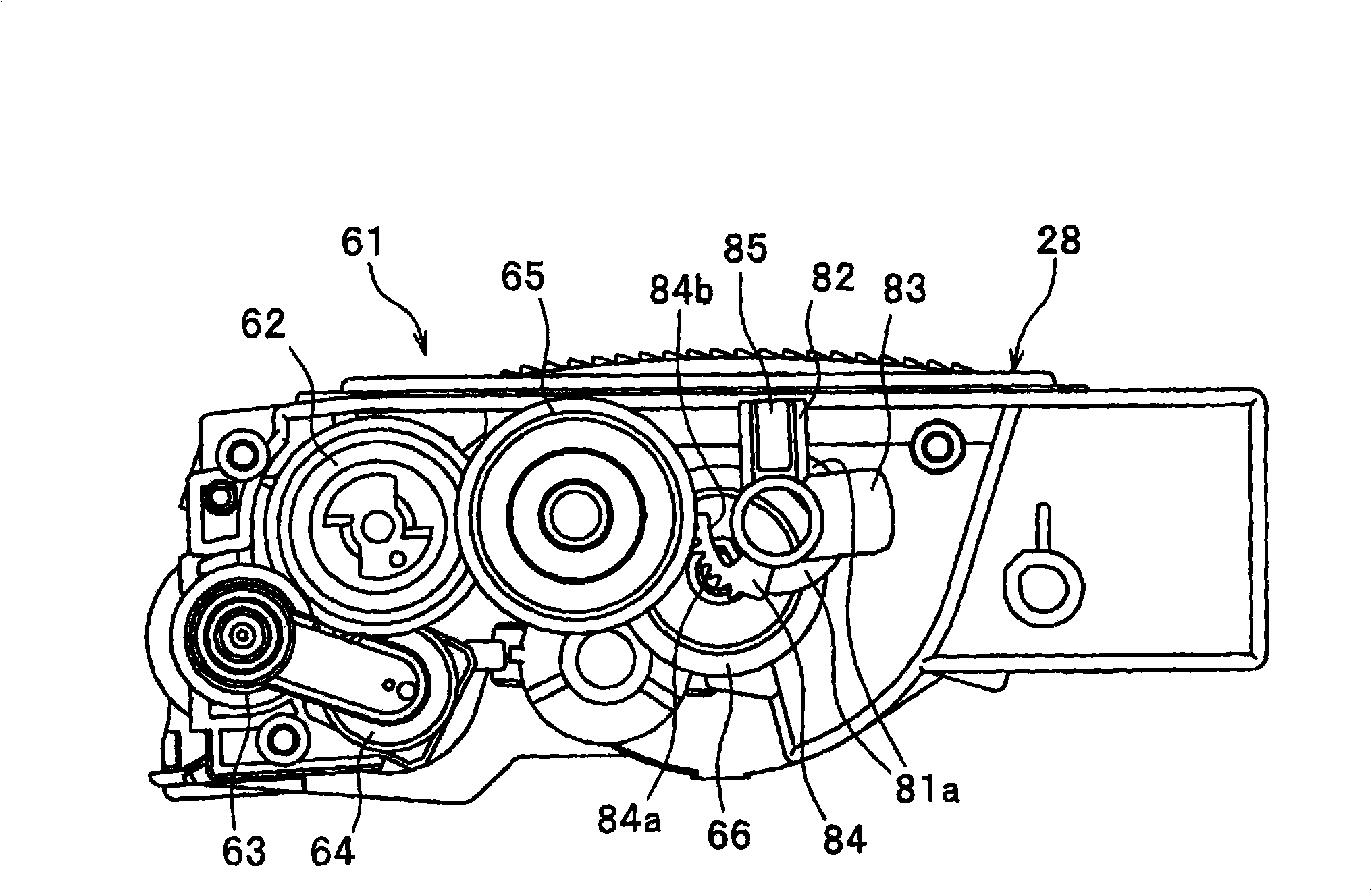

Developer cartridge, image carrier unit, and image forming apparatus

ActiveUS7526228B2Easily and securely retainedEasy constructionElectrographic process apparatusImage formationEngineering

The present invention provides a developer cartridge detachably attachable to a casing of an image carrier unit, includes a developing roller and a first rotation body that rotates the developing roller by coupling to a second rotation body provided in an image forming apparatus body with the developer cartridge attached in the casing. The first rotation body is configured to advance and retract with respect to a side wall of the casing which extends along an attachment / detachment direction of the developer cartridge, and is normally urged in an advance direction. A downstream end portion of the first rotation body in the advance direction is arranged downstream in the advance direction from an upstream end of the side wall in the advance direction with the developer cartridge attached in the casing.

Owner:BROTHER KOGYO KK

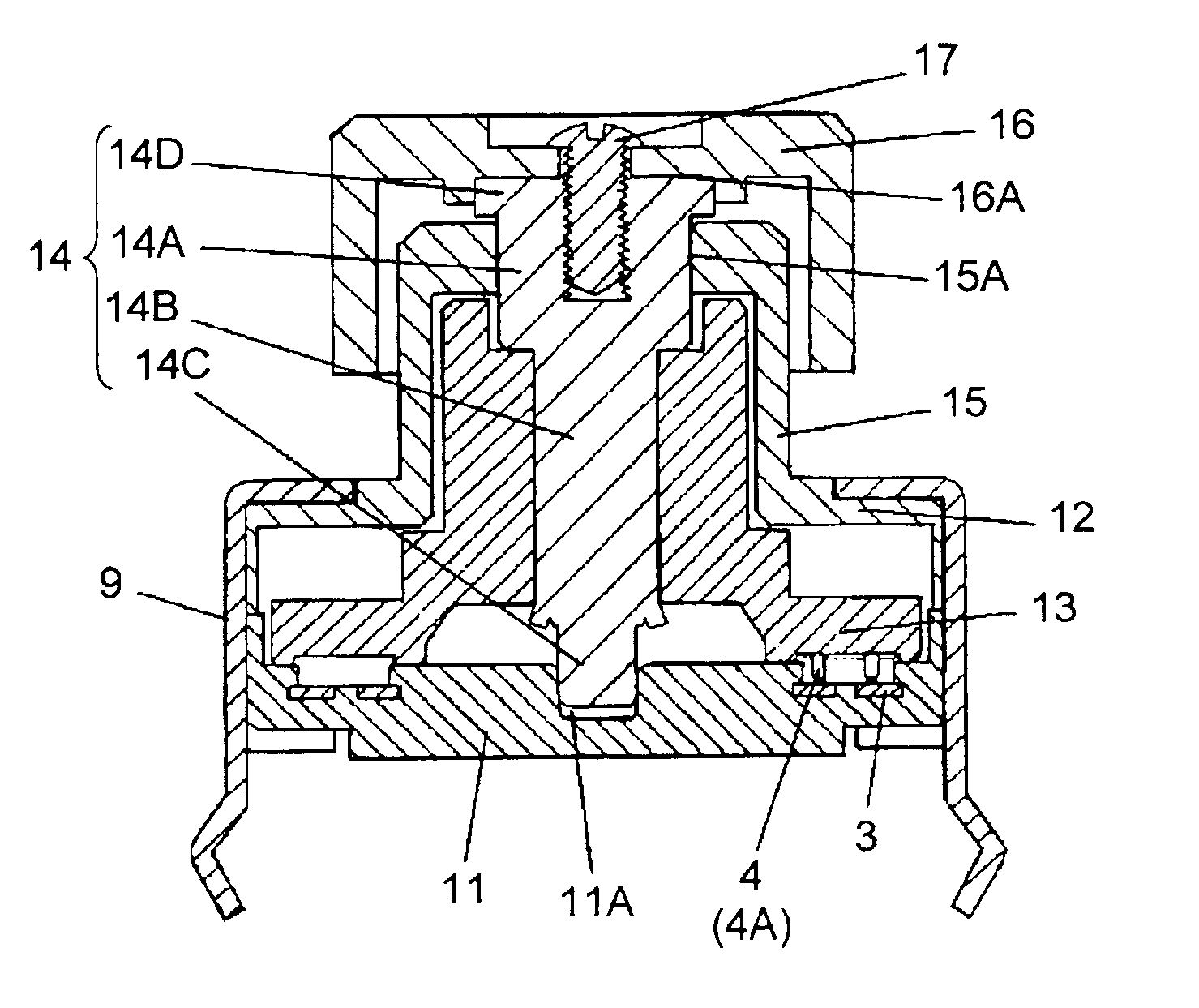

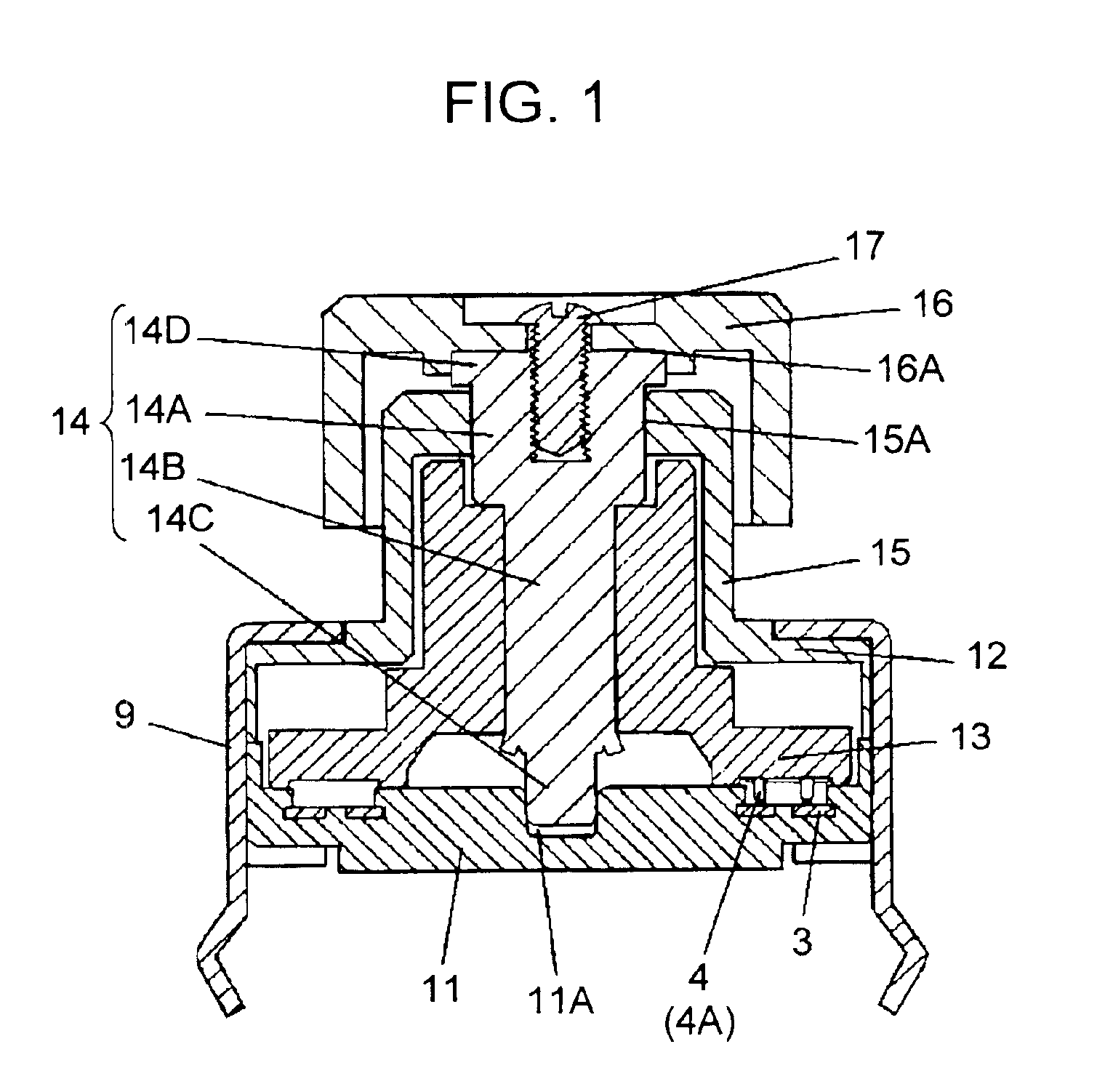

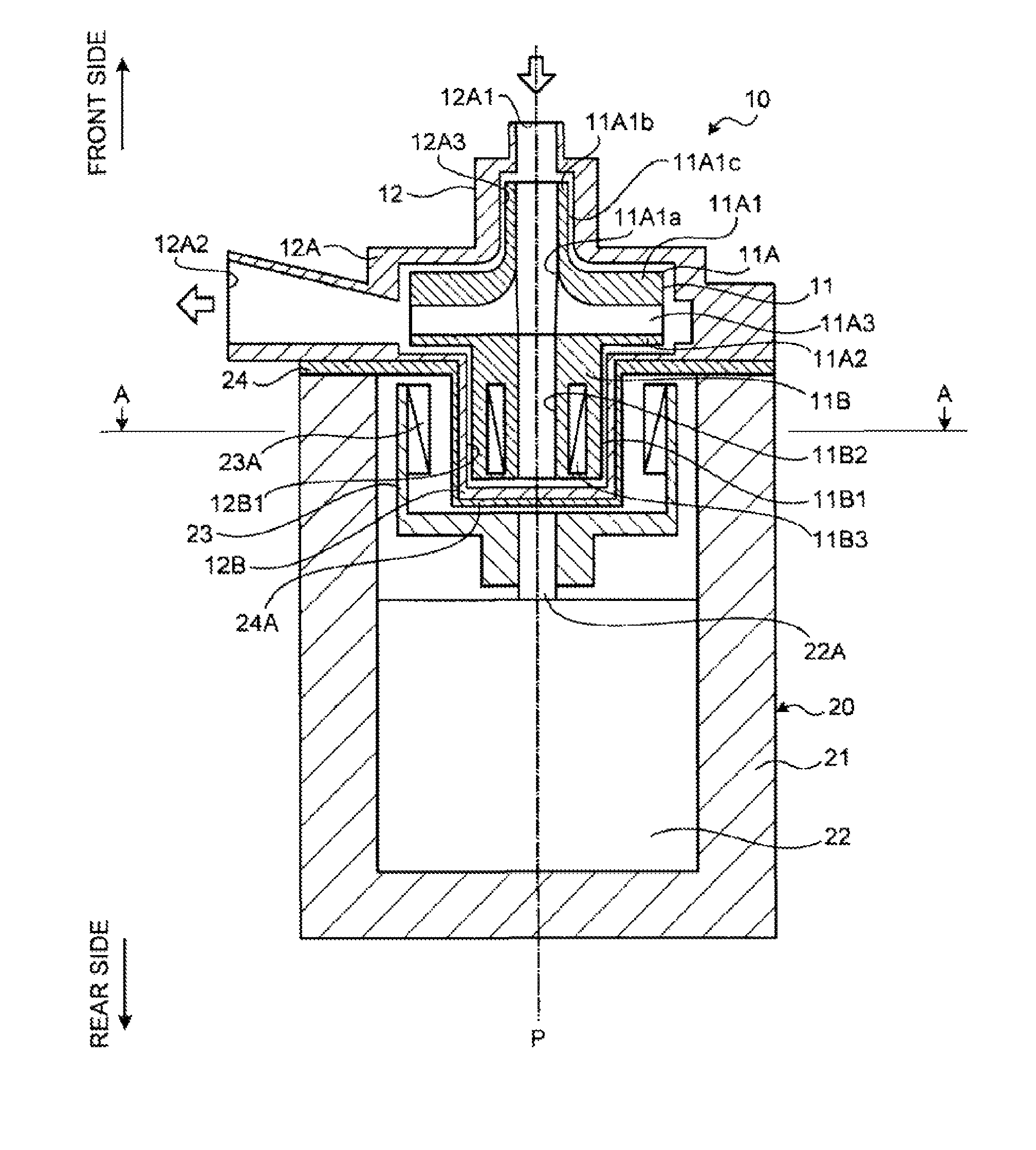

Rotary manipulation type electronic component

InactiveUS6998553B2Contact operating partsResisitors with sliding contactContact formationEngineering

A rotary manipulation type electronic component includes a space formed by a case. A base houses a rotating body holding a resilient contact as a movable element. A comb-like contact is formed as a fixed element. A first bushing in the case and a second bushing in the base rotatably support a rotating shaft that rotates together with the rotating body. An inner bottom face of a cap-shaped knob is secured onto an end of the rotating shaft so that the knob receives a barrel portion, which supports the rotating shaft as a portion of the case.

Owner:PANASONIC CORP

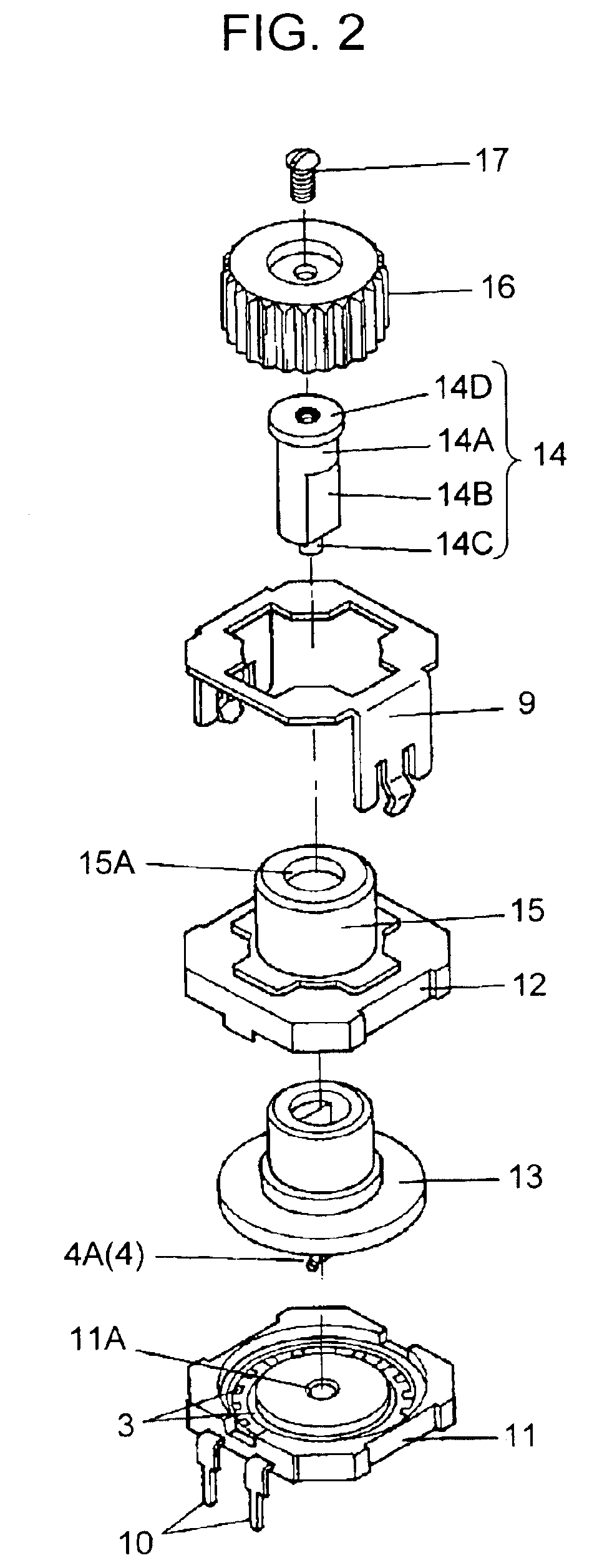

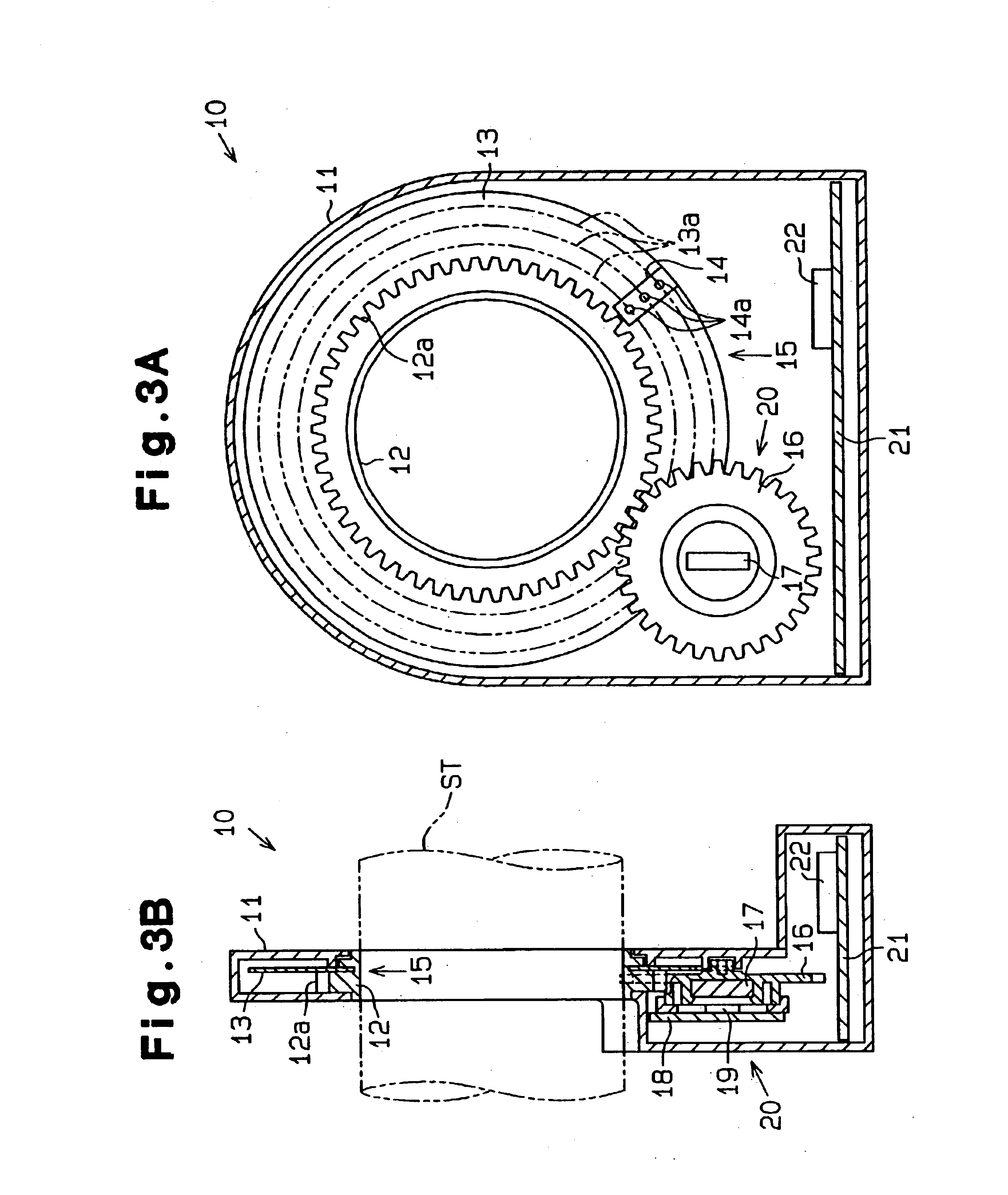

Blood pump and pump unit

ActiveUS8114008B2Reduce manufacturing costImprove reliabilityPump componentsBlood pumpsImpellerCoupling

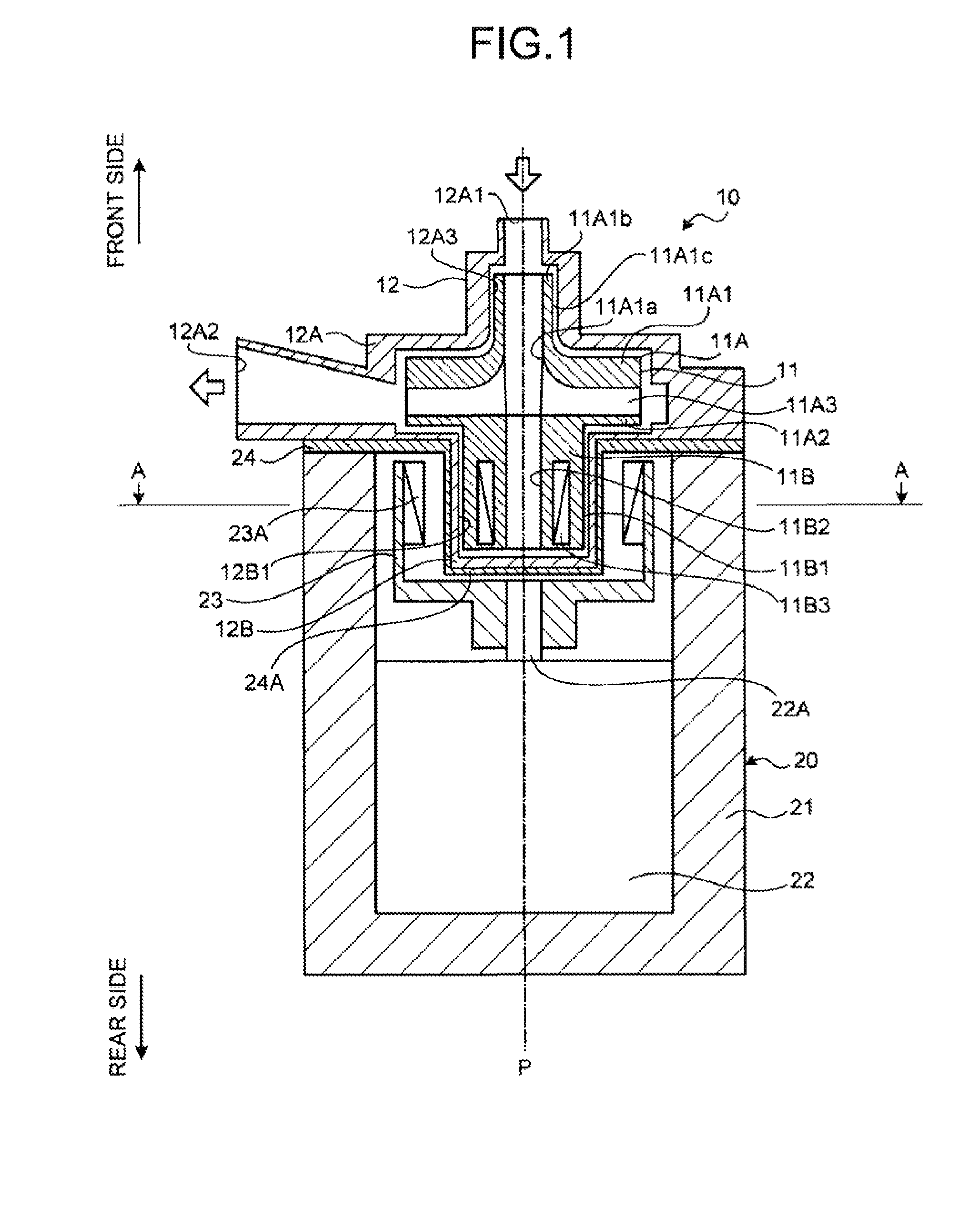

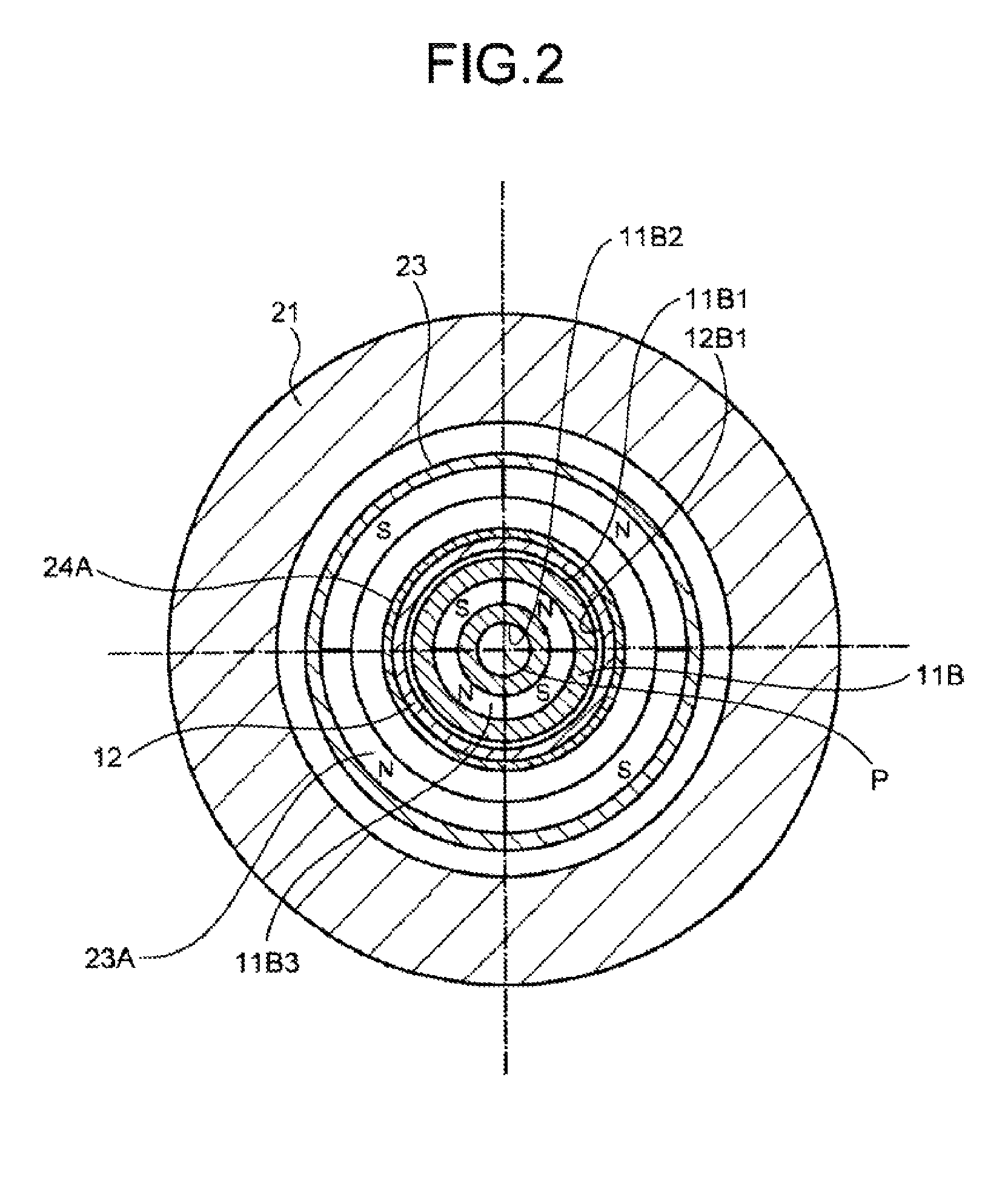

Provided are a magnetic coupling as an axial bearing including a driven magnet (11B3) that is a permanent magnet provided to a rotating body (11) inside a casing (12) and a drive magnet (23A) that is a permanent magnet placed face to face with the driven magnet in a radial direction of the rotating body outside the casing to be magnetically coupled with the driven magnet, a driving motor (22) that rotatably drives the drive magnet about an axis (P) of the rotating body, a radial bearing that is a dynamic bearing having annular bearing surfaces (12B1, 11B1) centering on the axis on an inner wall of the casing and the rotating body, each of the annular bearing surfaces being arranged with a gap between the drive magnet and the driven magnet in the radial direction of the rotating body, and a closed impeller (11A) including a front shroud (11A1) arranged on a front side in the axis direction in the rotating body, a rear shroud (11A2) arranged on a rear side in the axis direction of the front shroud, and a vane (11A3) arranged between the front shroud and the rear shroud.

Owner:NIPRO CORP

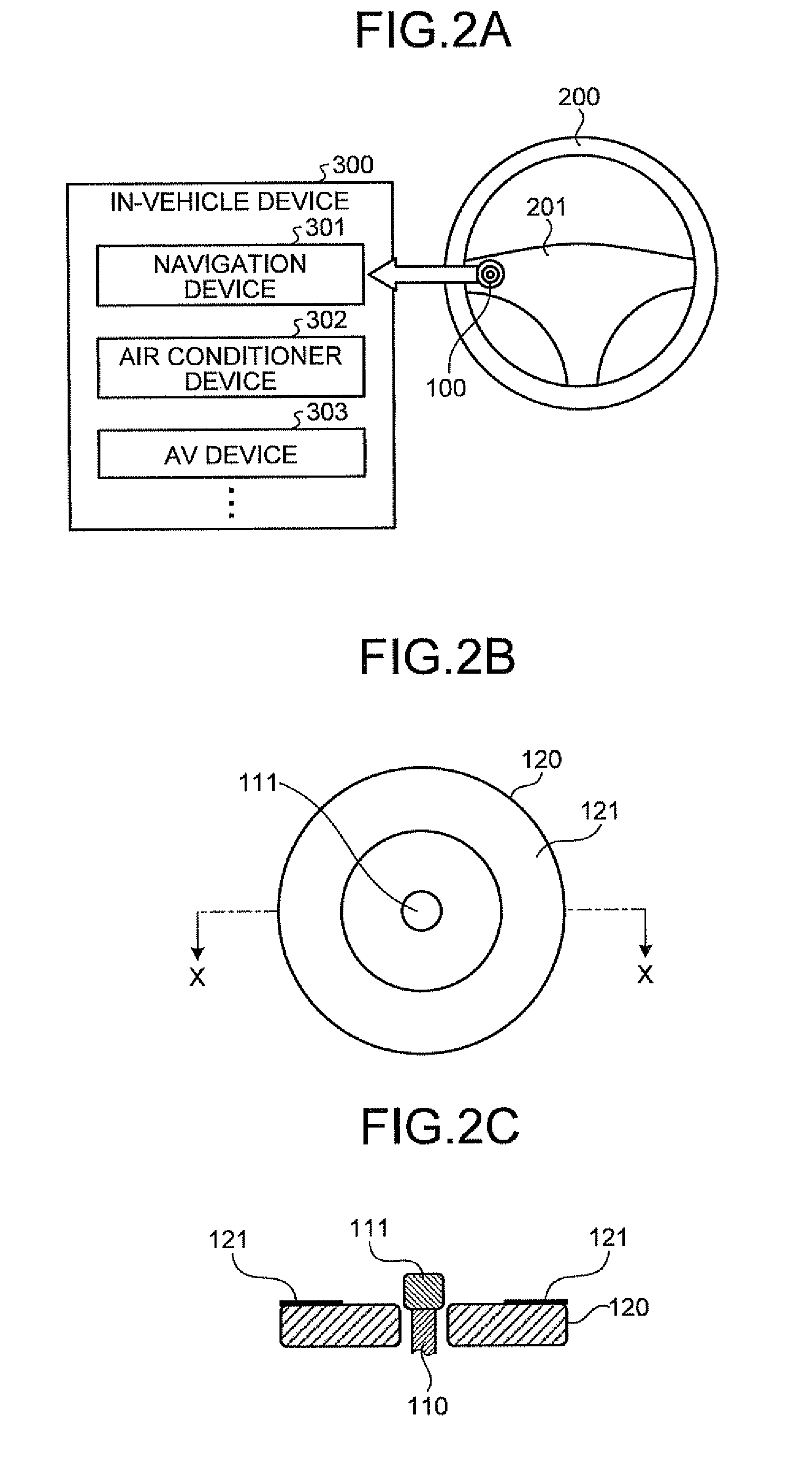

Operation unit

InactiveUS20110242064A1Solve problemsInstrument arrangements/adaptationsCathode-ray tube indicatorsEngineeringThumb

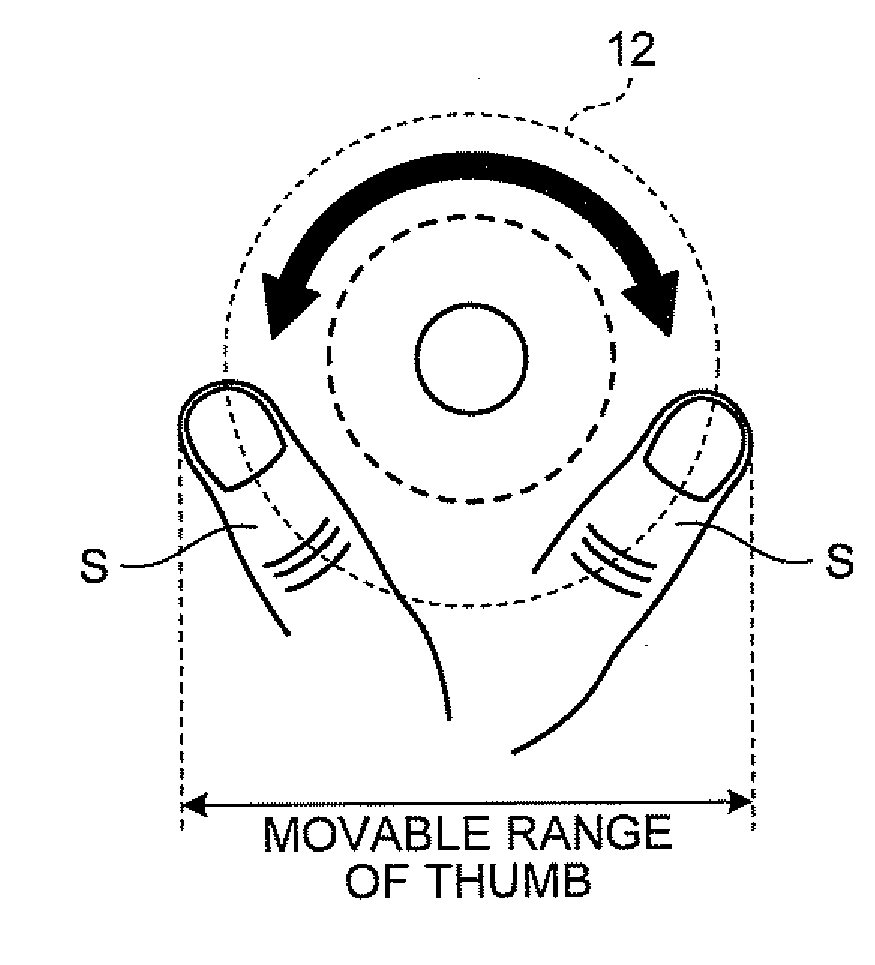

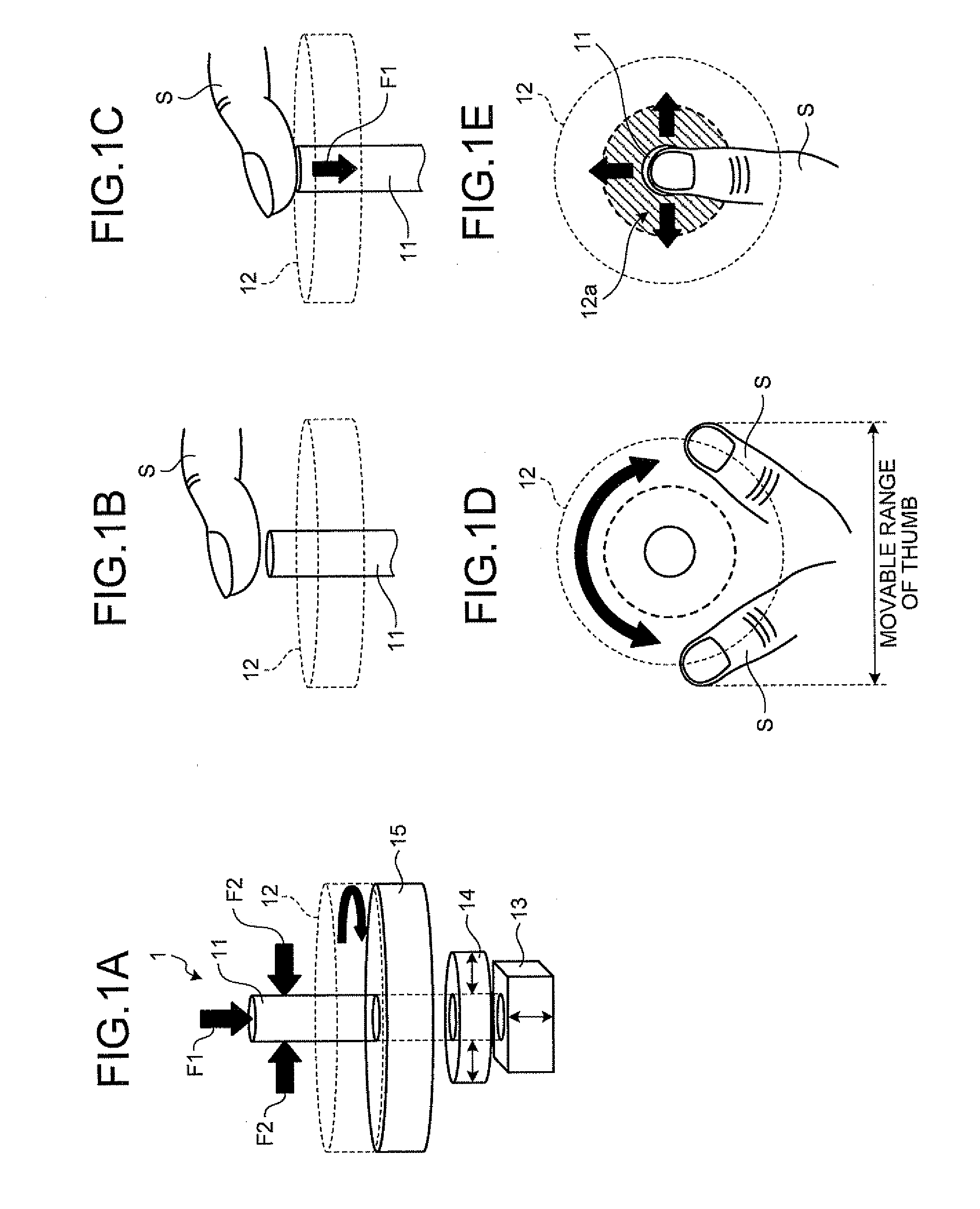

The operation unit includes a shaft that receives by its one end a pressing force applied through a pressing operation by a finger / thumb, a rotating body that rotates about the shaft according to an operation by the finger / thumb within a movable range of the finger / thumb, a first sensor that detects a pressing force applied to the shaft in an axial direction of the shaft, a second sensor that detects a pressing force applied to the shaft in a direction other than the axial direction of the shaft, and a third sensor that detects a rotating state of the rotating body.

Owner:FUJITSU GENERAL LTD +1

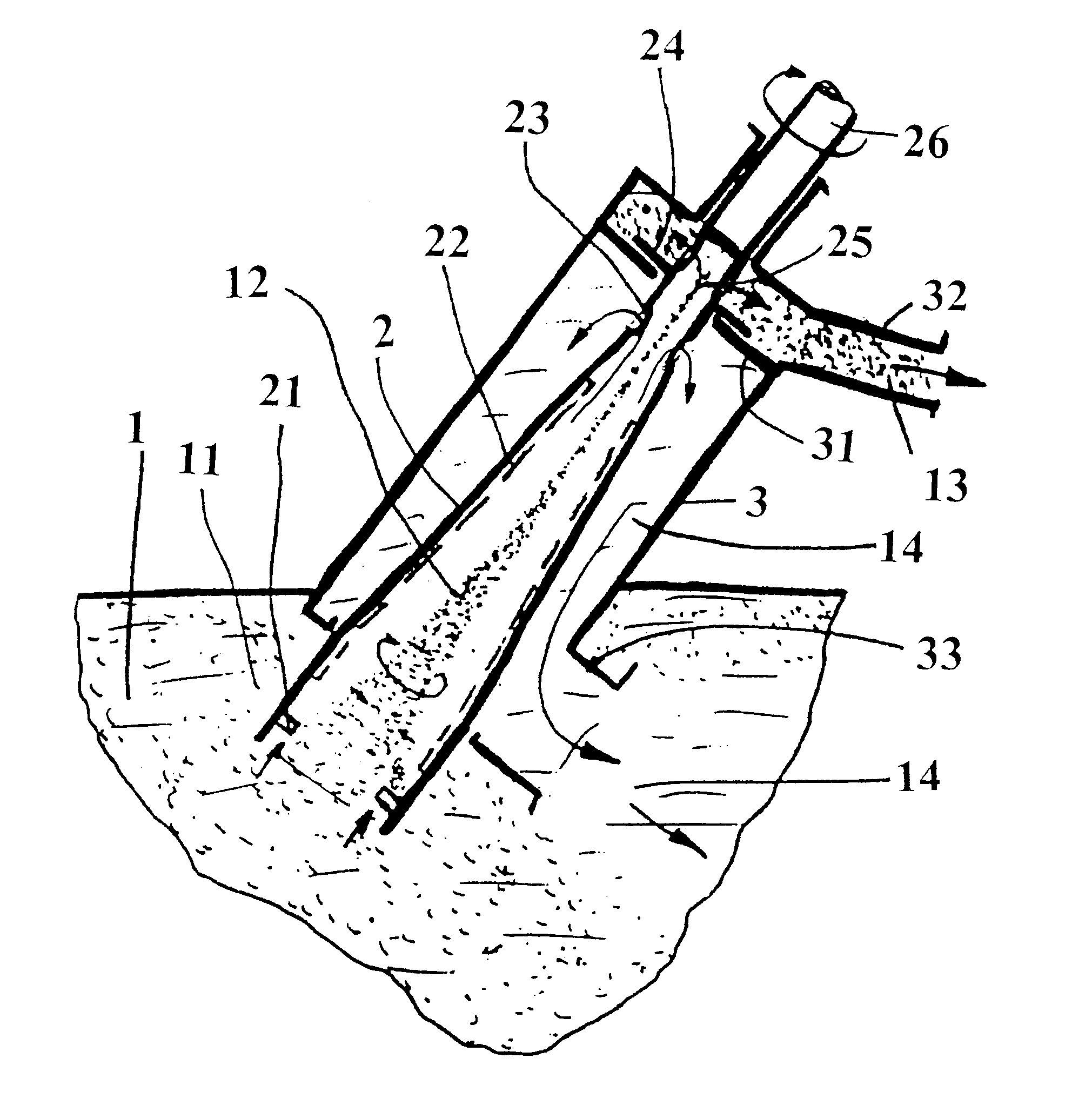

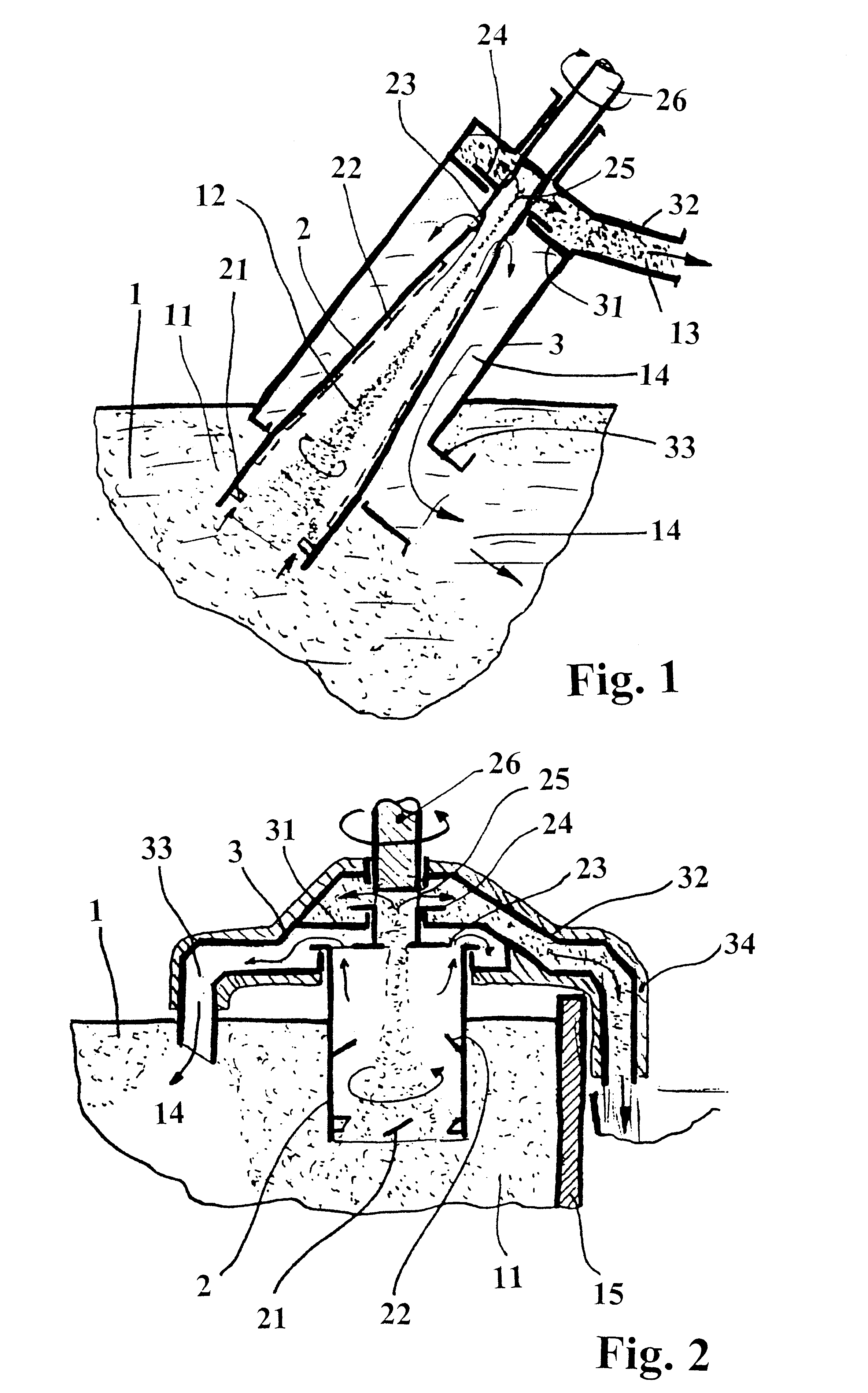

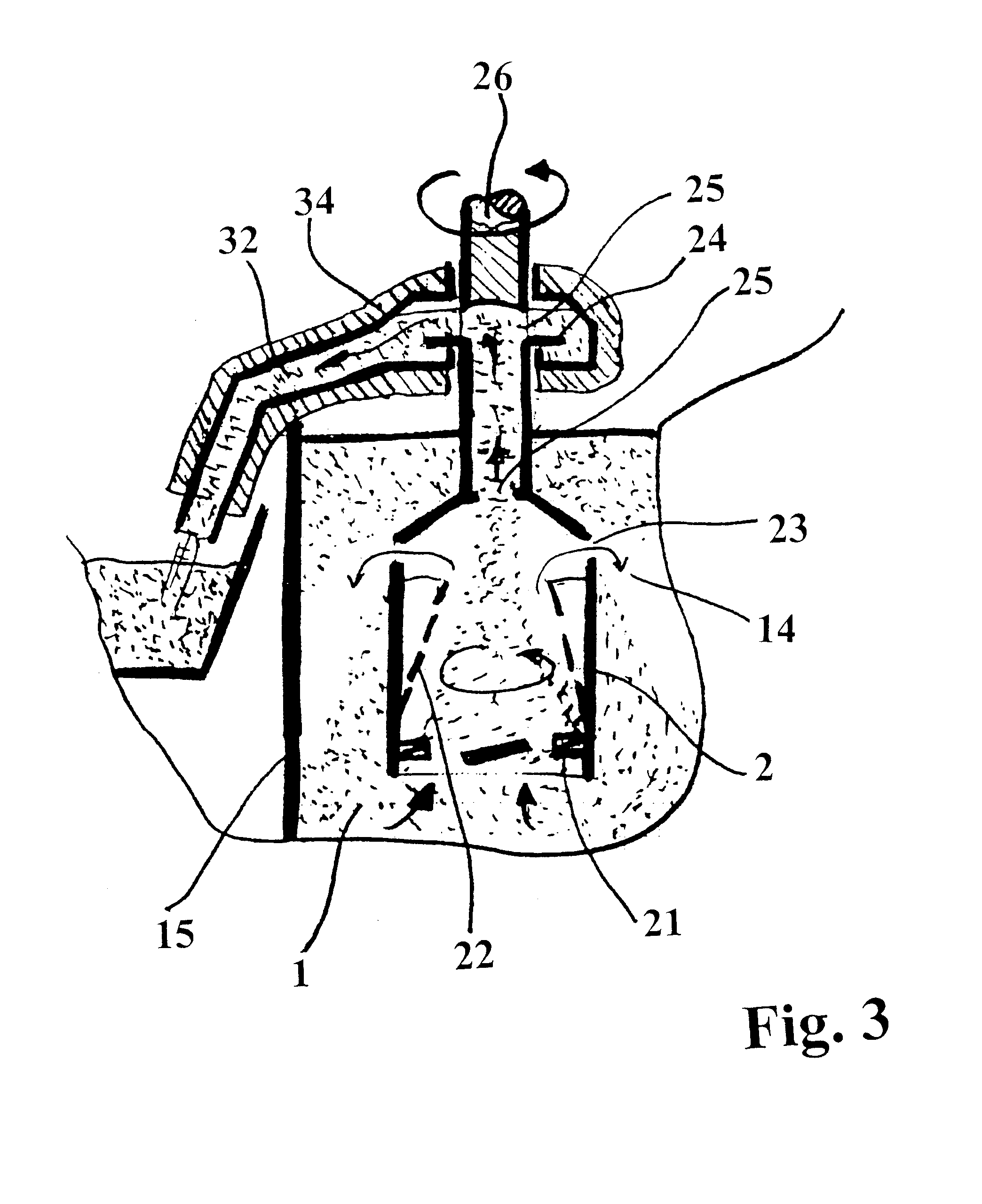

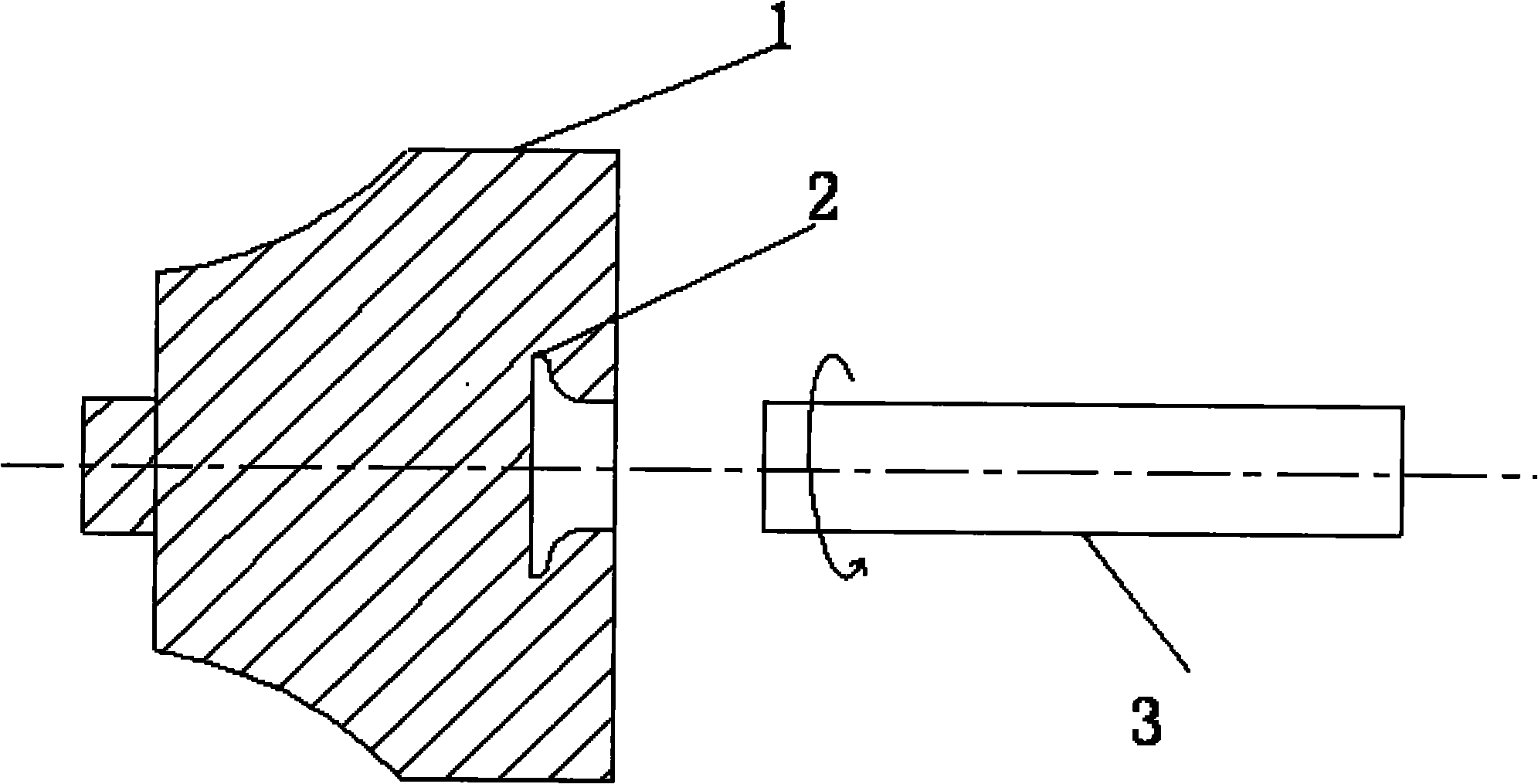

Process for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6364930B1High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsZinc metalLiquid metal

A process and device are disclosed for precipitating solid compounds from the liquid zinc or liquid zinc-based alloys of a metal bath. According to the disclosed process, partial amounts of the metal phase containing the compound(s) are exposed to an acceleration higher than the acceleration due to gravity and at least partially dissociated thereby into fractions containing heavier and / or lighter components. The molten mass depleted of solid compounds is returned to the metal bath and the part of the molten mass enriched with the desired compounds is discharged. The disclosed device is substantially characterized in that a hollow rotary body (2) is introduced into the molten mass (1). The hollow rotary body (2) can be driven about an axis and is fitted in the submerged or lower area with conveyor means (21) which project into the cavity. In its discharge or upper area, the hollow rotary body (2) is provided with at least one discharge opening (23) for the depleted molten mass (14) eccentrically arranged in its wall and with at least one further discharge opening (25) for the liquid metal enriched with the desired compounds centrally arranged and / or eccentrically arranged on the discharge side. At least one of the upper molten mass discharge openings (23, 24) in the rotary body (2) opens into a discharge area of a housing (3) which at least partially surrounds the rotary body (2).

Owner:ANDRITZ PATENTVERW GES

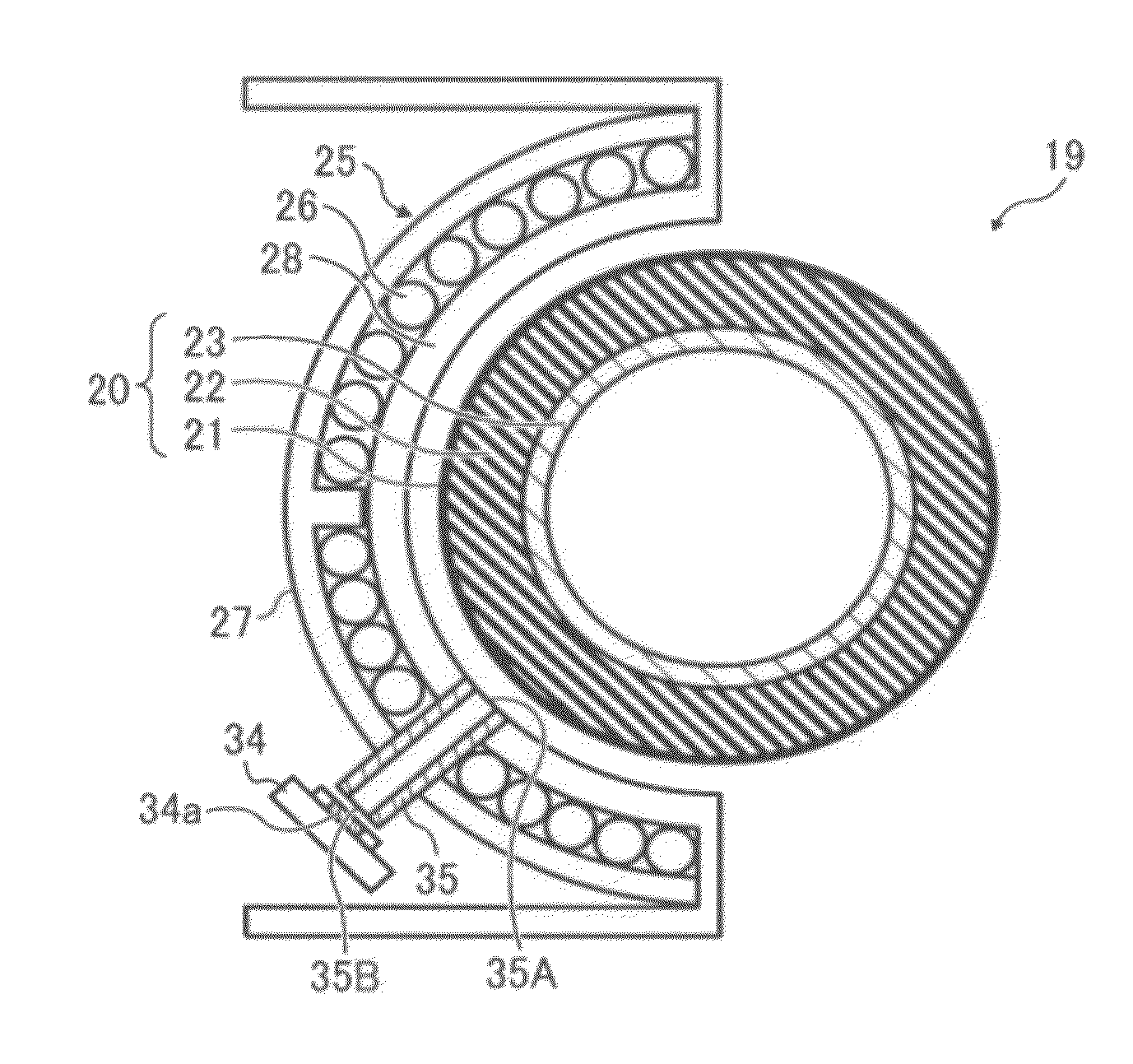

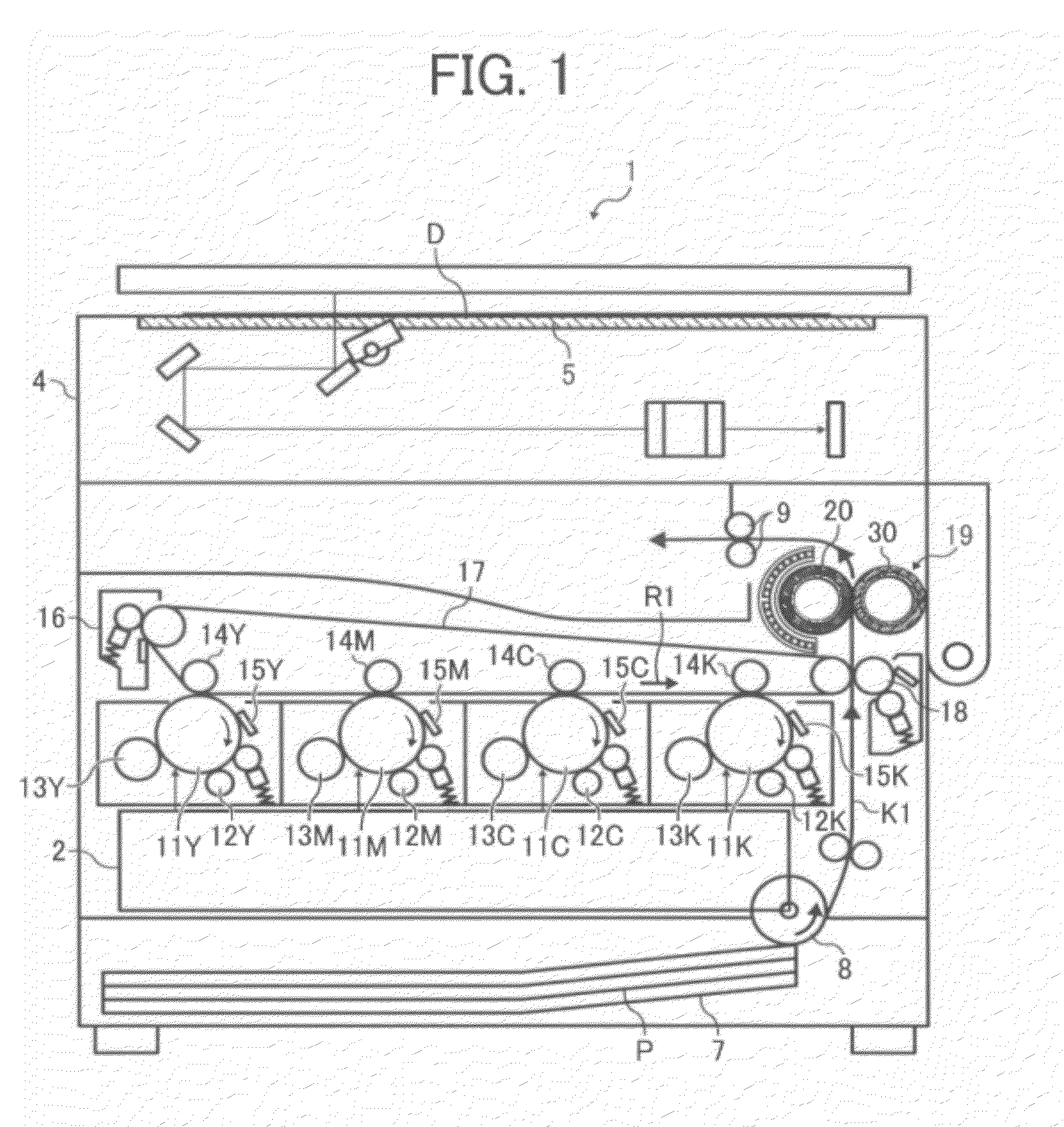

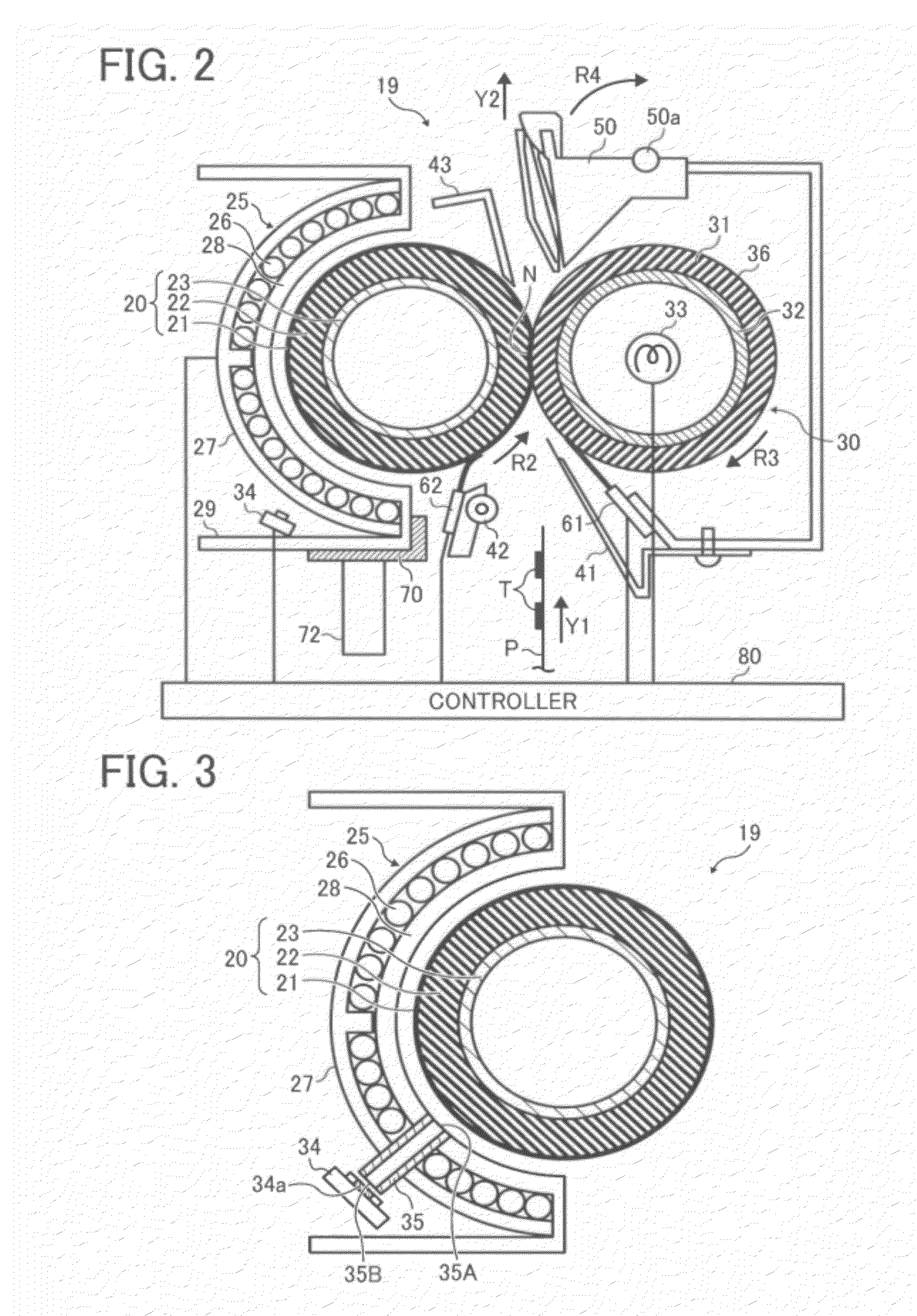

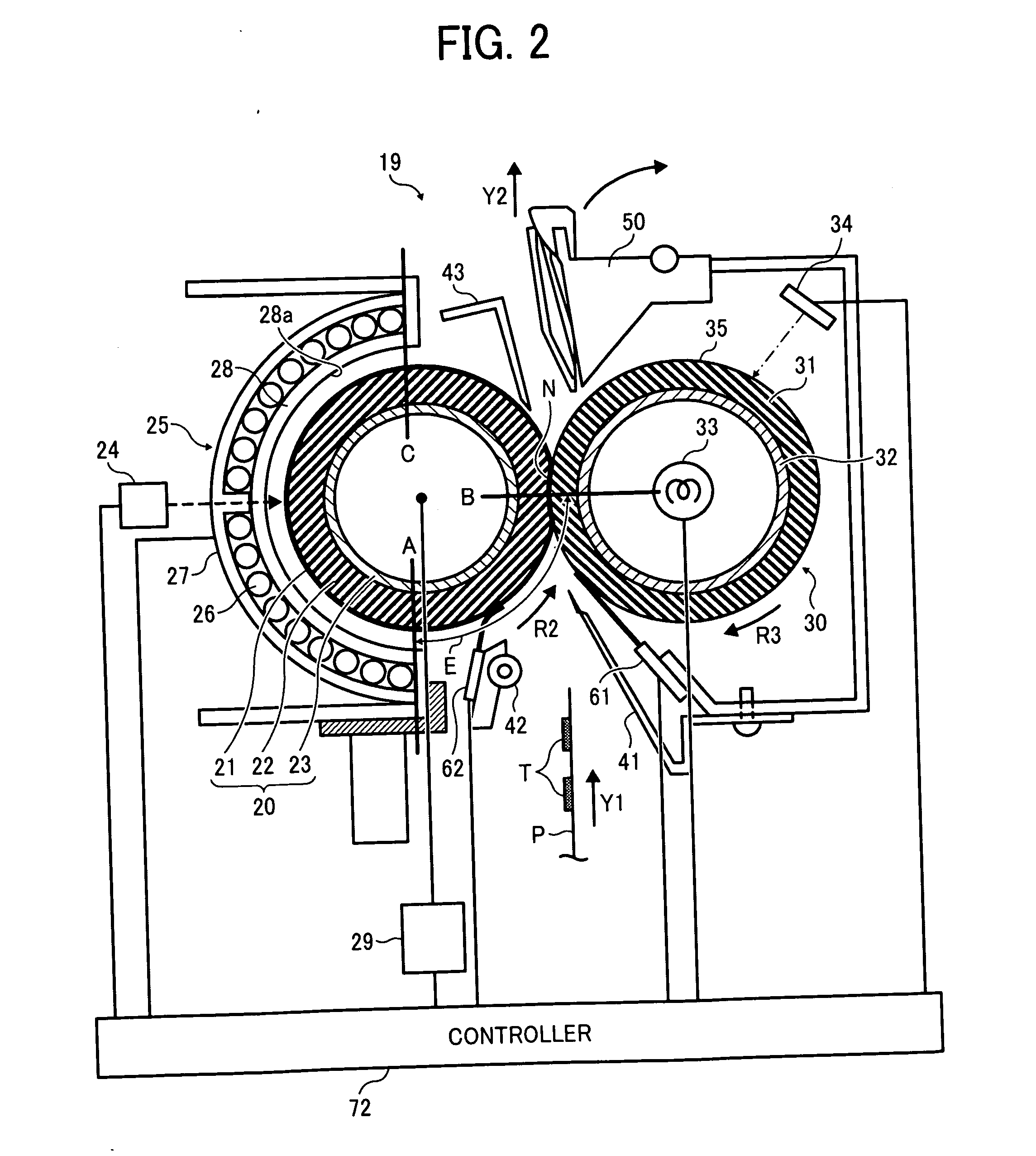

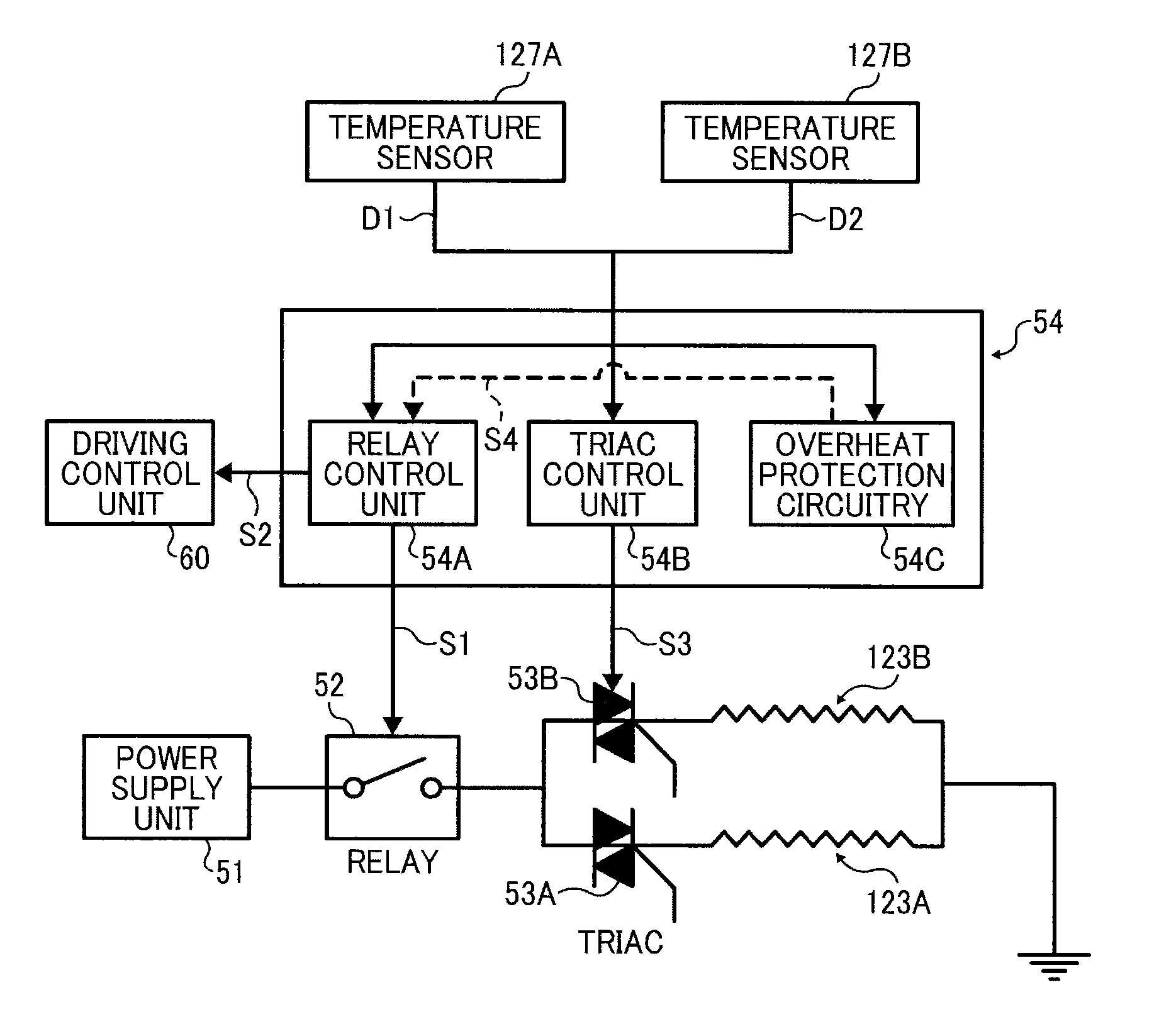

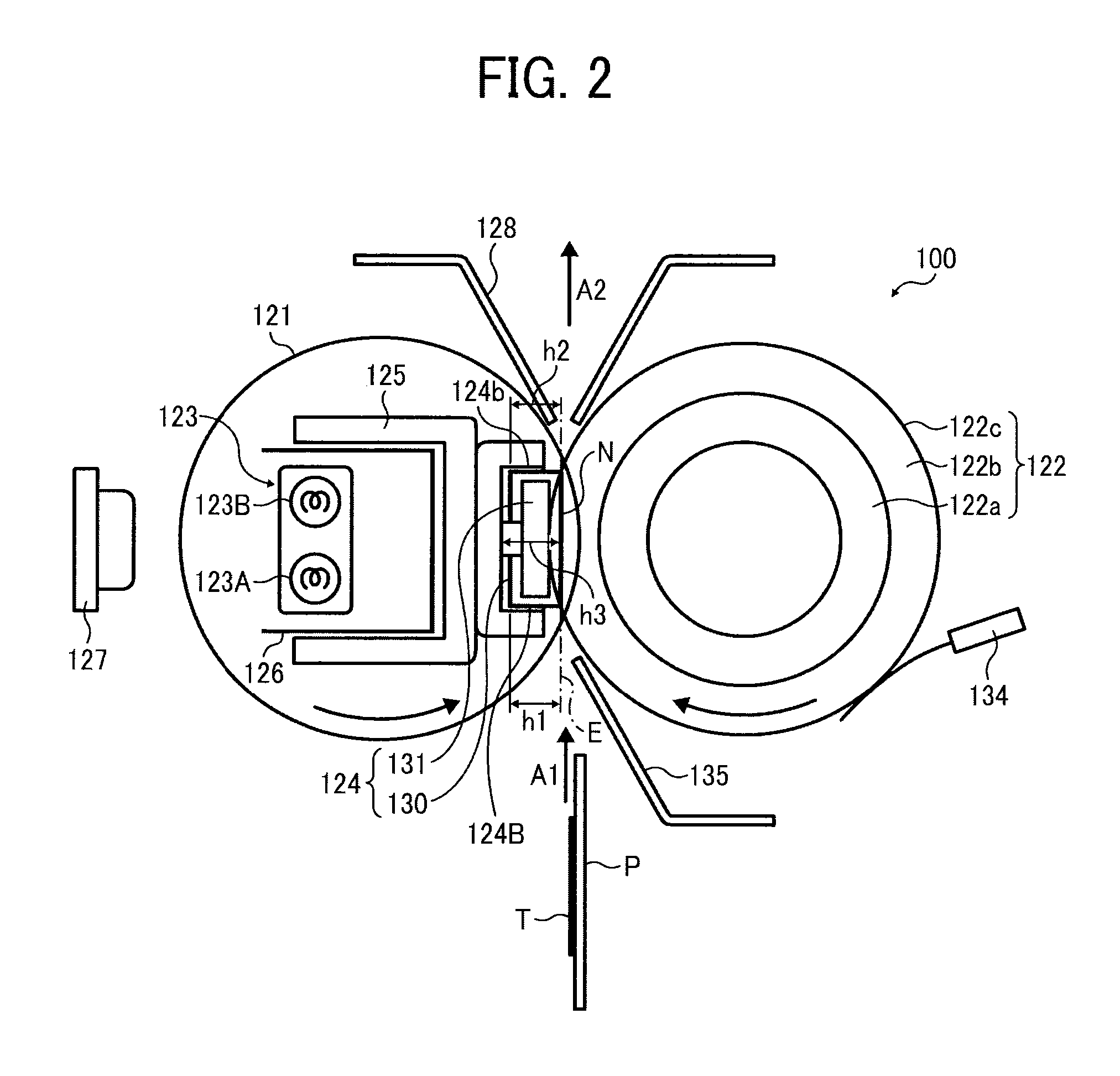

Fixing device and image forming apparatus incorporating same

A fixing device includes a fixing rotary body rotatable in a predetermined direction of rotation to radiate infrared rays; a pressing rotary body, rotatable in a direction counter to the direction of rotation of the fixing rotary body, pressed against the fixing rotary body to form a fixing nip therebetween through which a recording medium bearing a toner image is conveyed; a heater disposed opposite the fixing rotary body to heat the fixing rotary body; a temperature detector spaced apart from the fixing rotary body to detect a temperature of the fixing rotary body based on the infrared rays from the fixing rotary body and disposed below the fixing nip in a vertical direction; and a tube disposed between the fixing rotary body and the temperature detector, the tube through which the infrared rays from the fixing rotary body enter the temperature detector.

Owner:RICOH KK

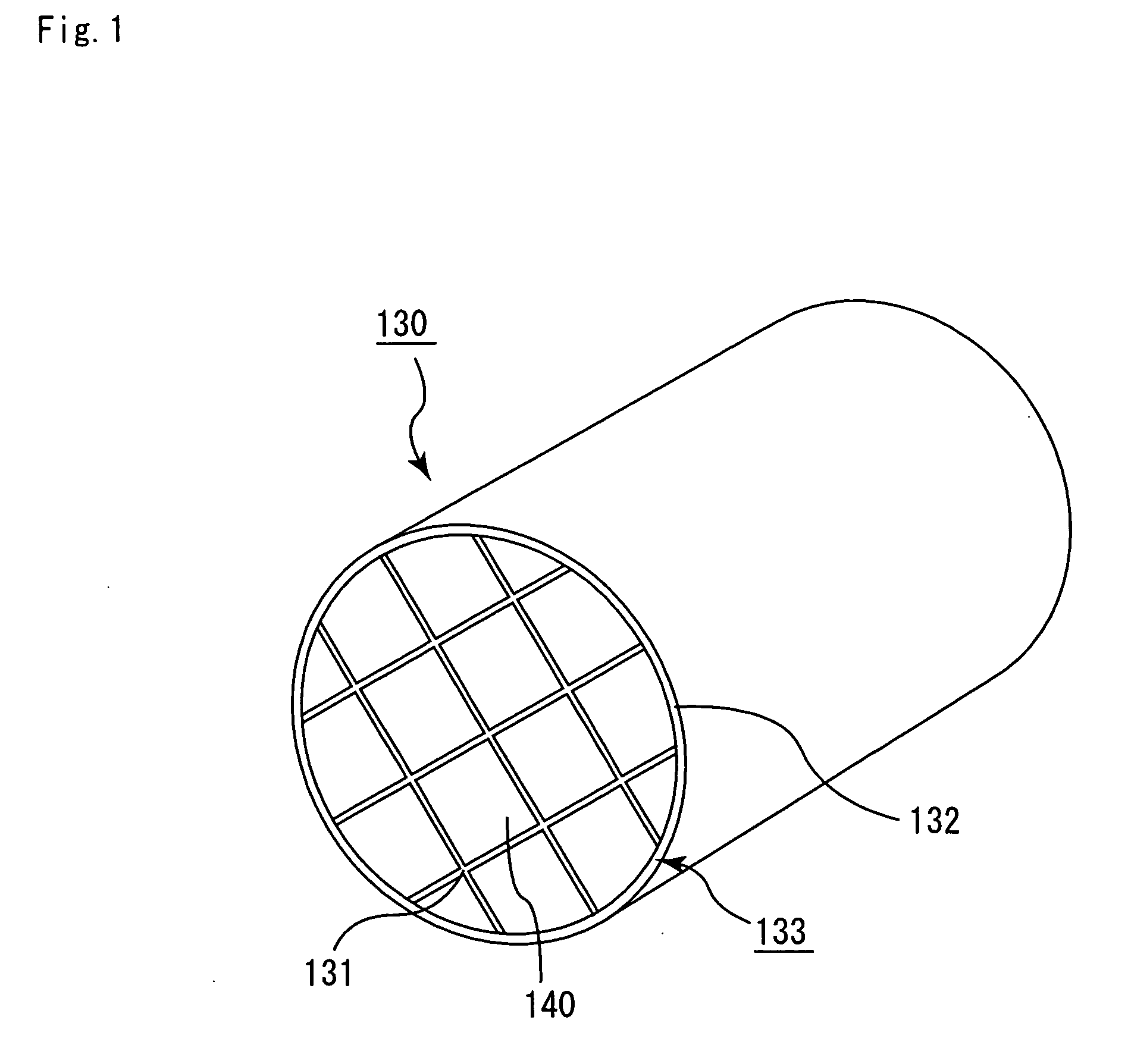

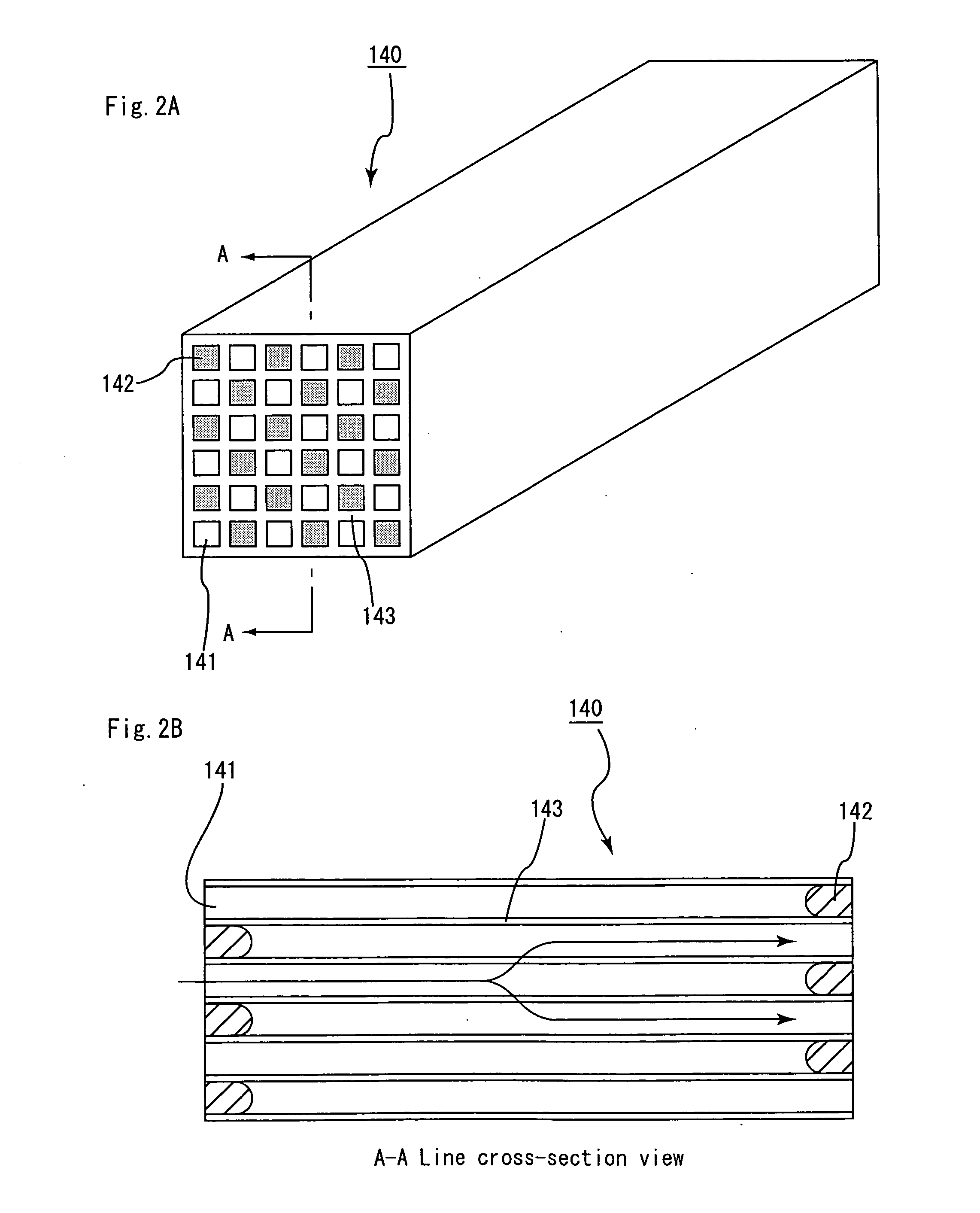

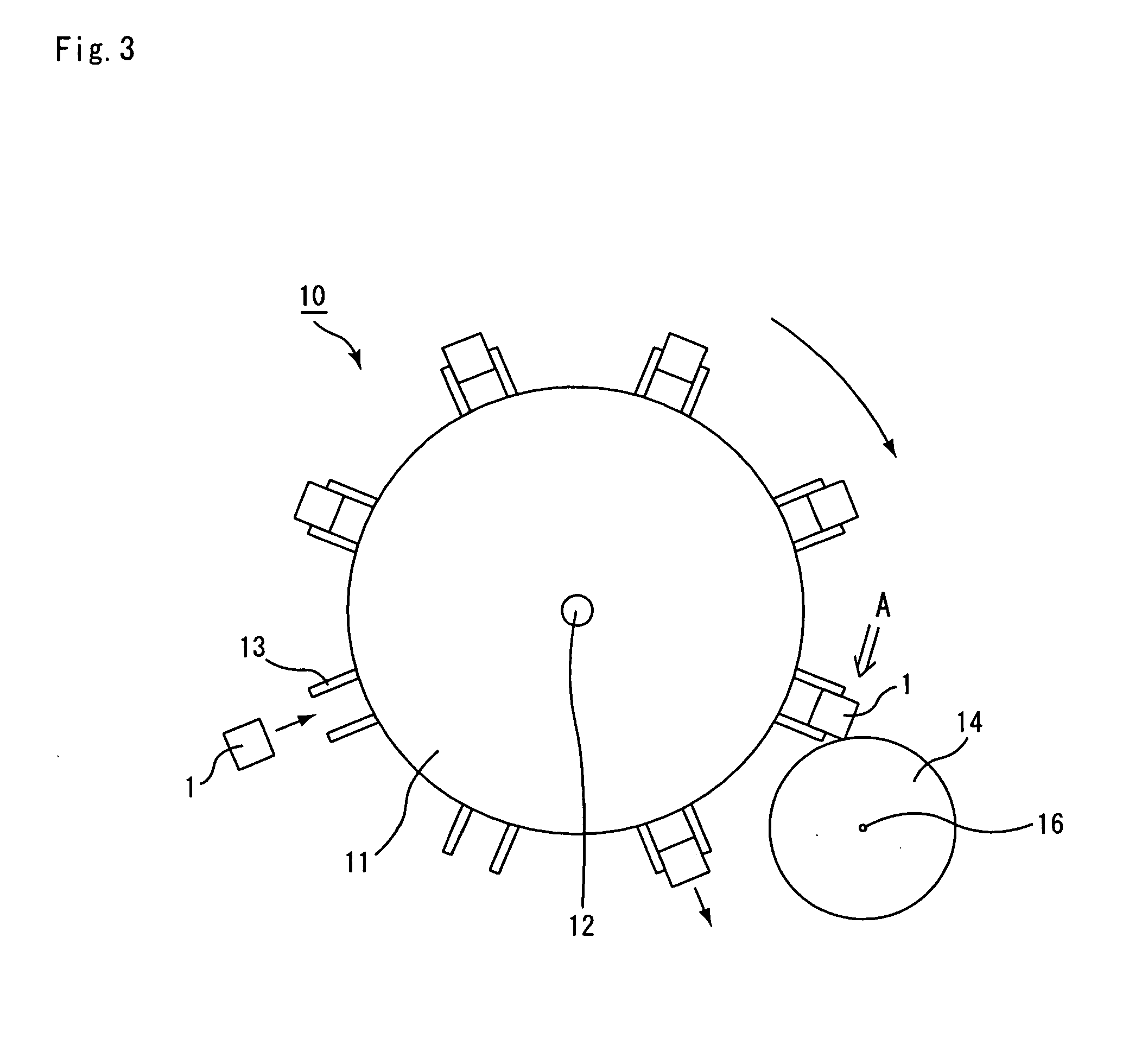

Cutting apparatus, honeycomb molded body cutting method, and honeycomb structure manufacturing method

InactiveUS20070277655A1Ceramic shaping apparatusMetal working apparatusEngineeringHoneycomb structure

The cutting apparatus of the present invention is a cutting apparatus to execute cutting the end portion of a pillar-shaped honeycomb molded body having multiple cells that are established in rows in the longitudinal direction and partitioned by cell walls, and is provided with a rotary body having a rotary shaft established horizontally, a molded body clamping member configured to clamp the honeycomb molded body established on the rim of the rotary body, and at least one cutting disk, and is configured in such a manner as to execute cutting of an end portion of the honeycomb molded body while the honeycomb molded body, which is clamped by the molded body clamping member, is in a state of being put in motion according to the rotary movement of the rotary body.

Owner:IBIDEN CO LTD

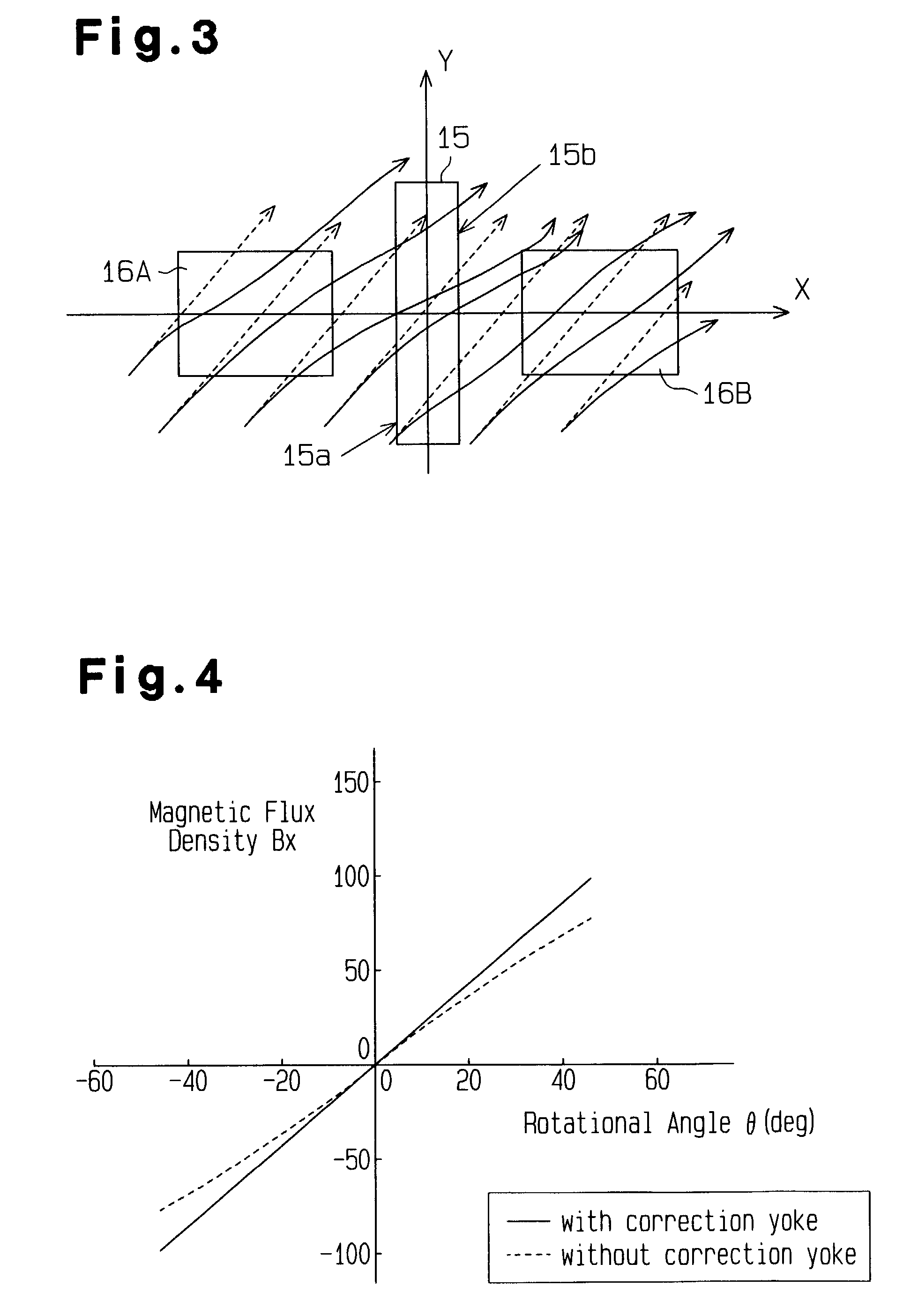

Angular sensor with a magneto-electric transducer and a magnetic deflection device

InactiveUS7030606B2Magnetic-field-controlled resistorsSolid-state devicesUltrasonic sensorTransducer

An angular sensor which enables to obtain an output signal proportional to a relative rotational angle with low manufacturing cost and with miniaturized size. An angular sensor which includes a first magnet and a second magnet fixed to a rotation body, magnetic flux sensing surface is fixed to the stator to be positioned in magnetic field between the first magnet and the second magnet and perpendicular to magnetic sensing direction for sensing a magnetic flux, a magneto-electric transducer element for outputting an electric signal corresponding to a magnetic sensing direction element of the magnetic density, deflection yokes. The deflection yokes are positioned facing the magnetic flux sensing surfaces. The deflection yokes are positioned within a range of three quarters of a distance between the first magnet and the second magnet in X-axis direction and one half of a distance between the first magnet and the second magnet in Y-axis direction.

Owner:AISIN SEIKI KK

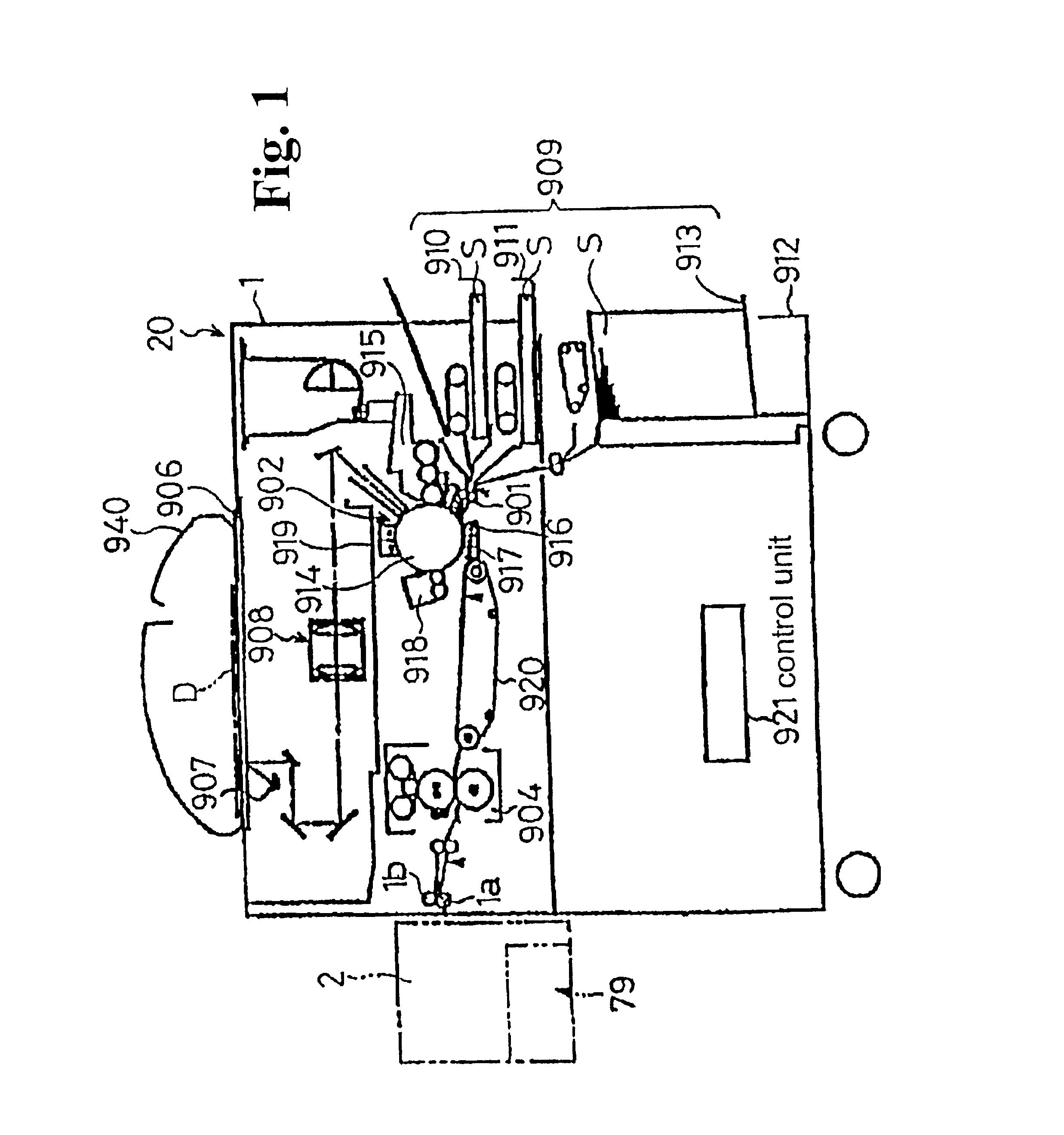

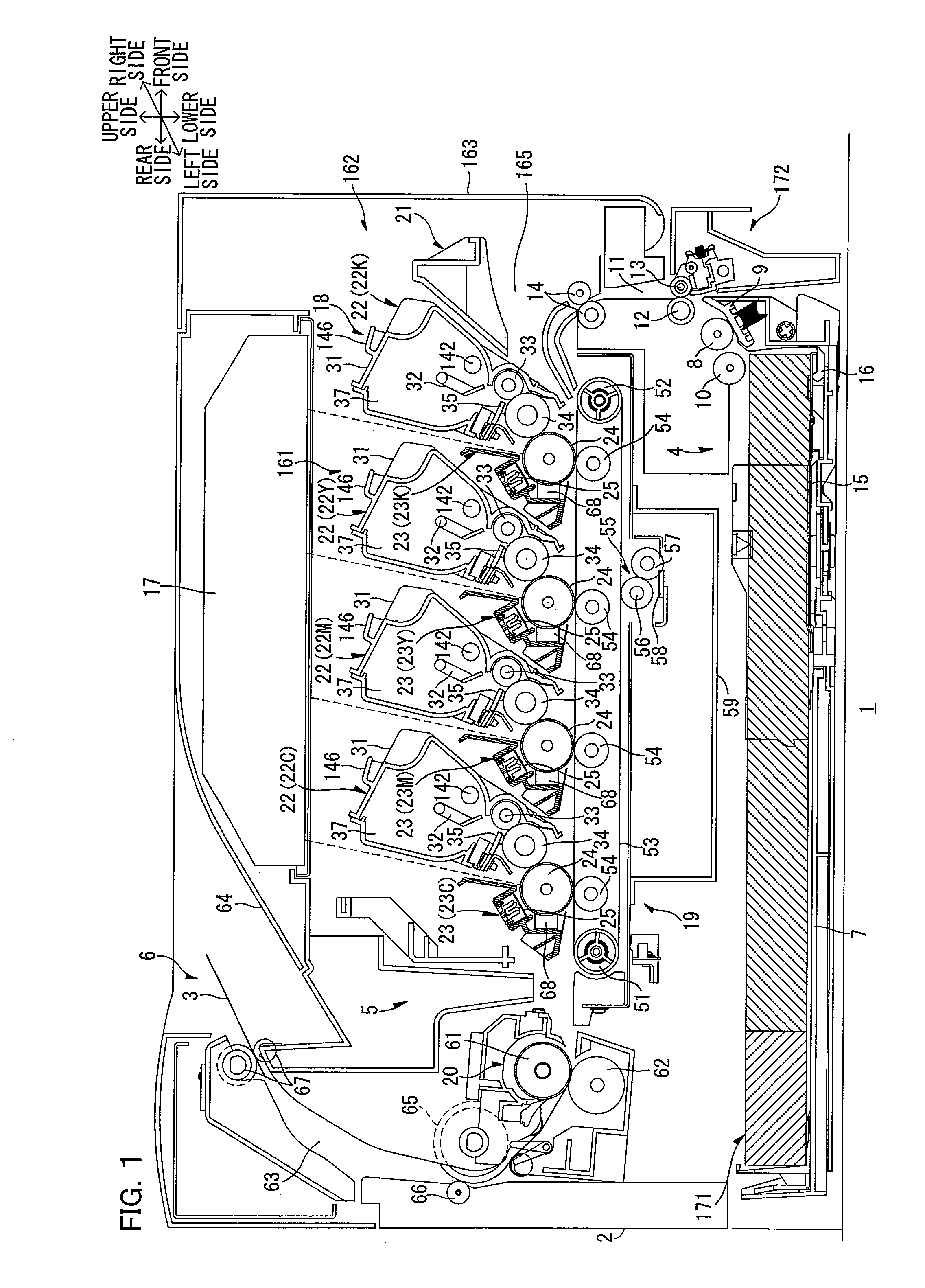

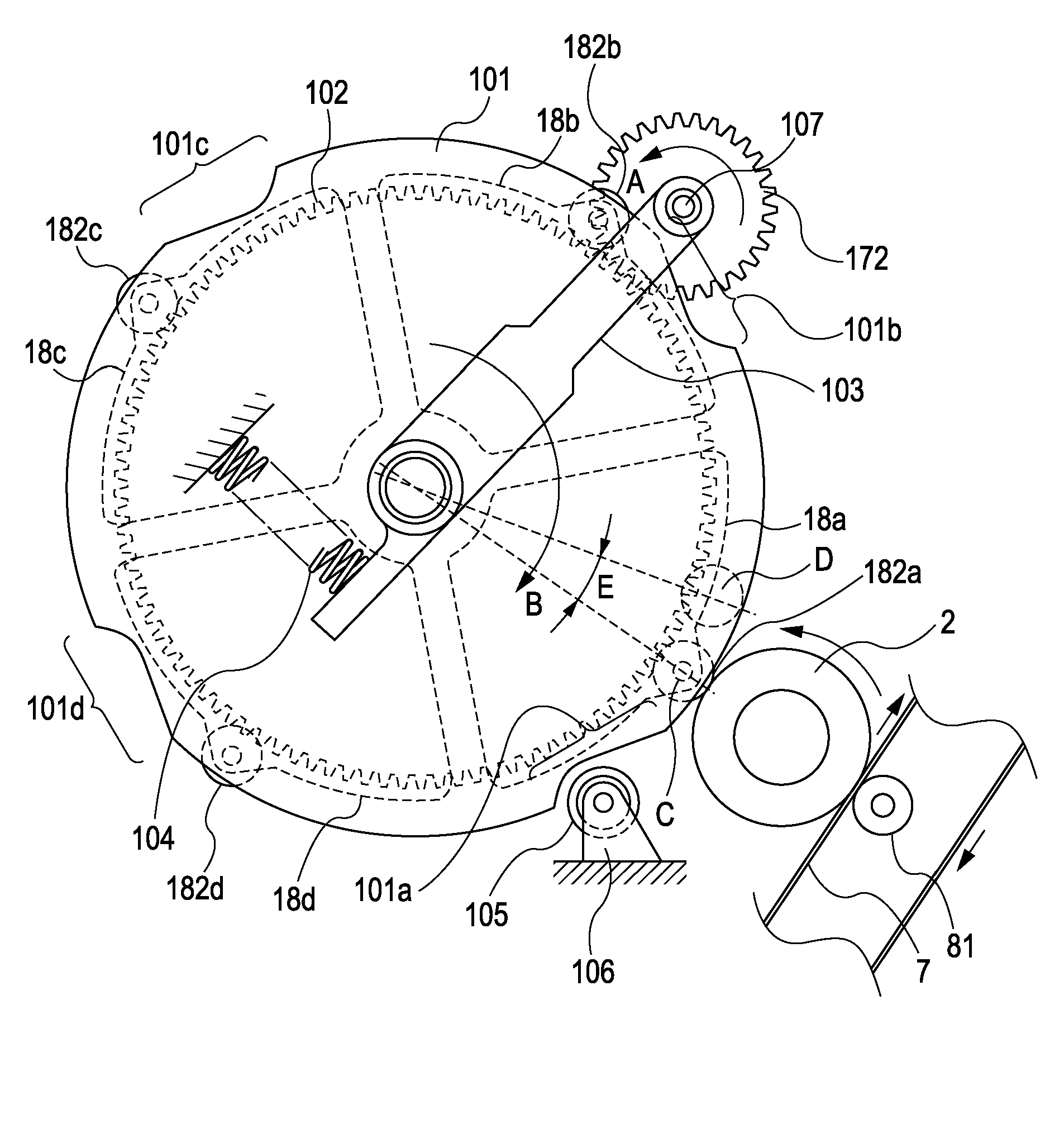

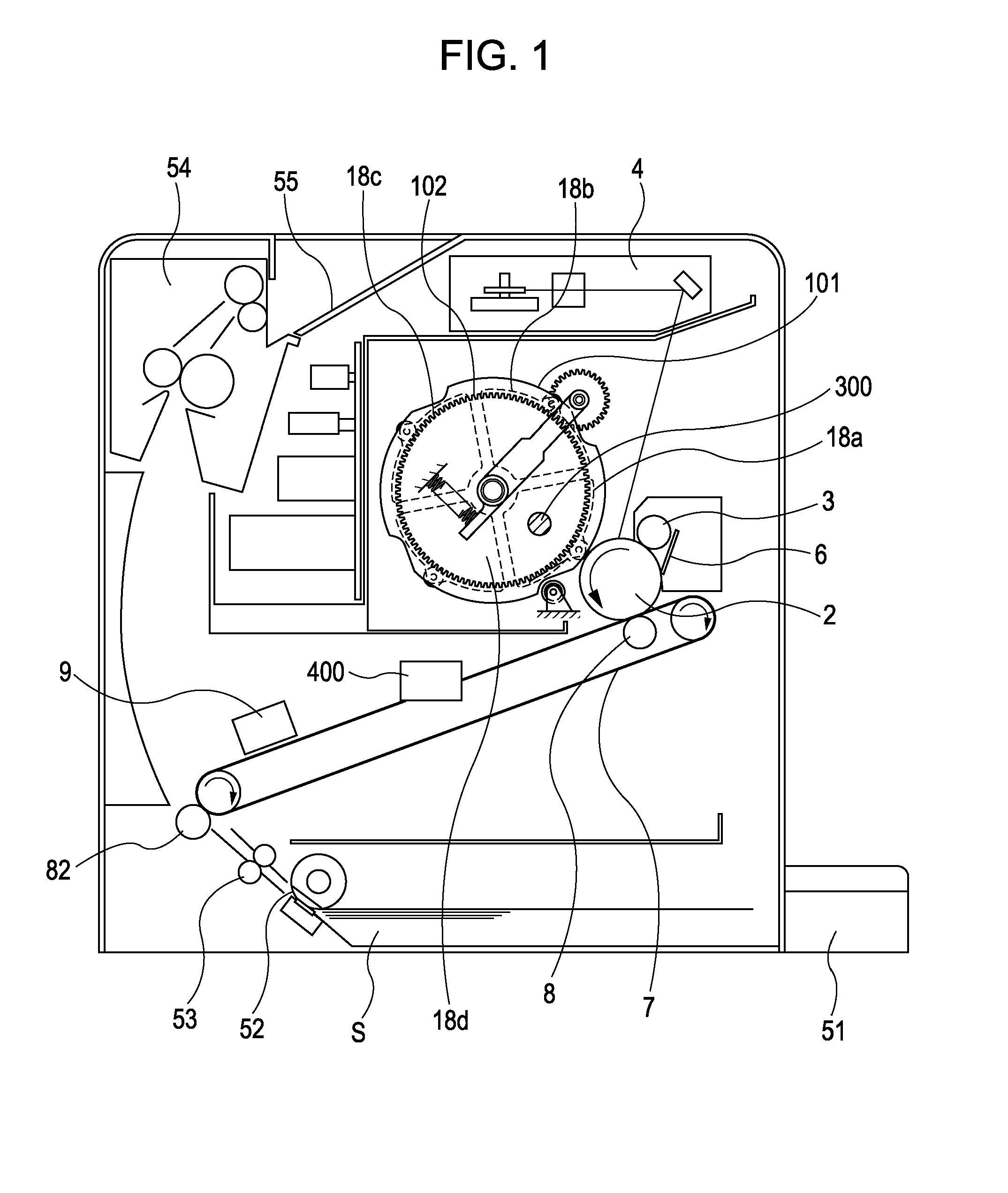

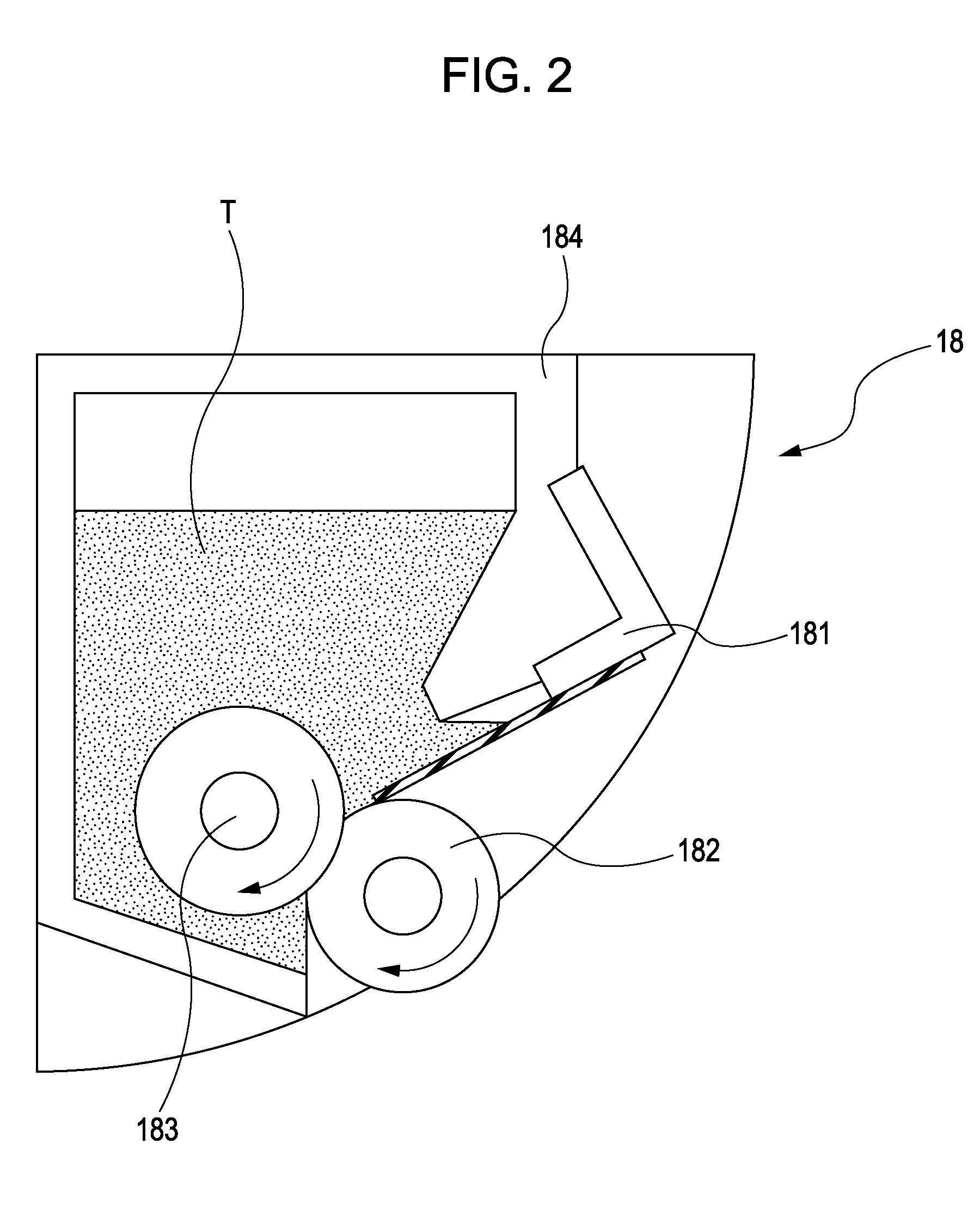

Image forming apparatus

ActiveUS20100054778A1Improve image qualitySmaller main apparatusElectrographic process apparatusImage formationEngineering

In a rotary-type image forming apparatus, rotation of a rotary is temporarily stopped at a position where a coupling member and a drive transmission member are engageable with each other, and a developing roller is set in a rotating state. Subsequently, the rotary is rotated so as to bring the developing roller into contact with a surface of a photosensitive drum.

Owner:CANON KK

Monitoring device for rotating body

InactiveUS20050253051A1Accurately detect defectAccurately breakdownCooking-vessel materialsRadiation pyrometryFiber Bragg gratingEngineering

A fiber Bragg grating (FBG) sensor is mounted to a rotating body, which is supported by a rotating shaft mounted rotatably with respect to a fixed element. The FBG sensor extends along the rotating shaft, one end of which is disposed at the center of the end of the rotating shaft. An optical fiber is mounted to the fixed element, one end of which is disposed opposite to the end of the FBG sensor, apart from the FBG sensor. Light emitted from a broadband light source passes through the optical fiber and is transmitted to the FBG sensor across a gap between the optical fiber and the FBG sensor. The FBG sensor reflects light with frequencies corresponding to deformation of the rotating body. A data processing unit receives the reflected light and calculates the deformation of the rotating body based thereupon.

Owner:KOREA INST OF SCI & TECH

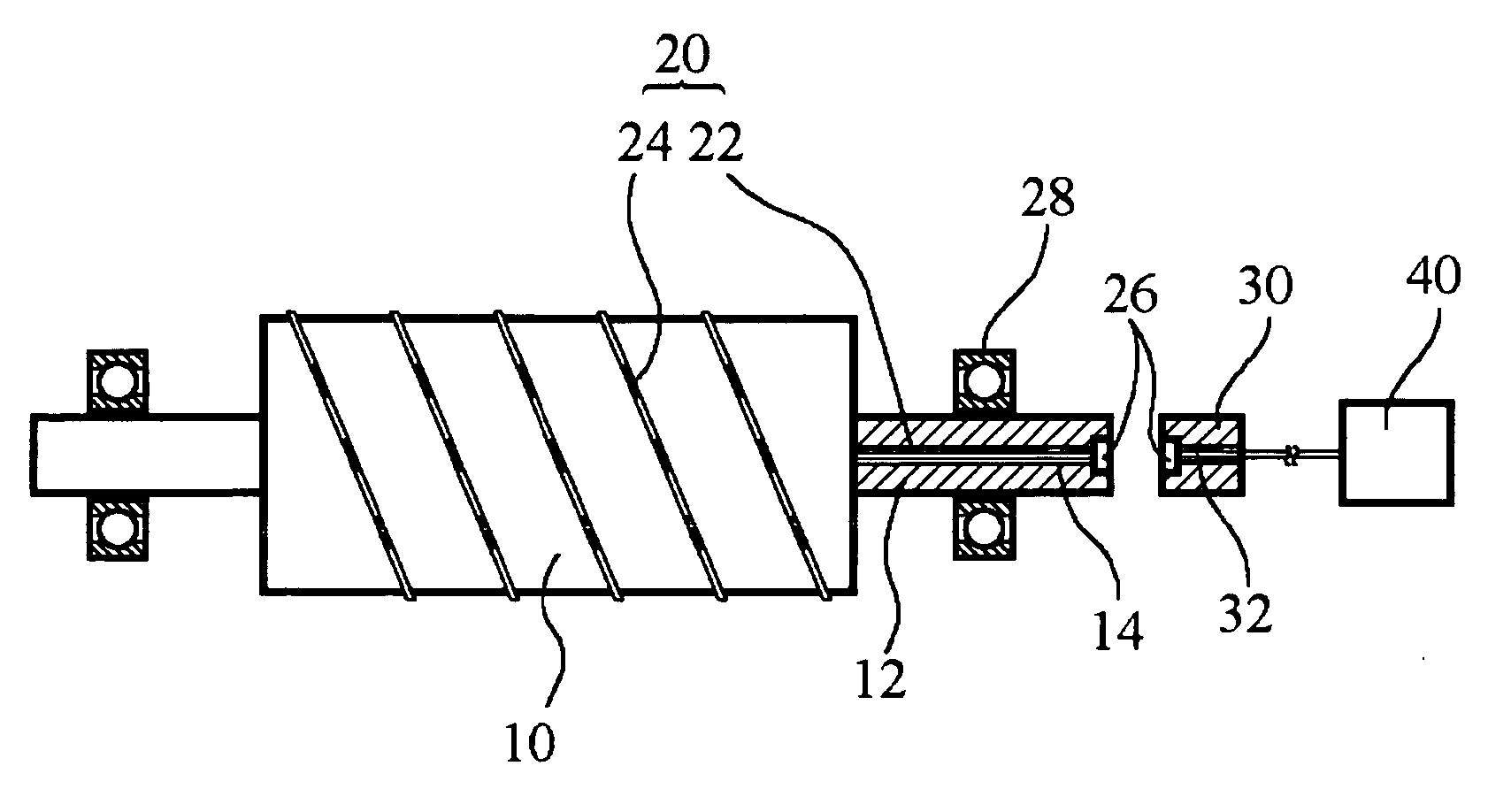

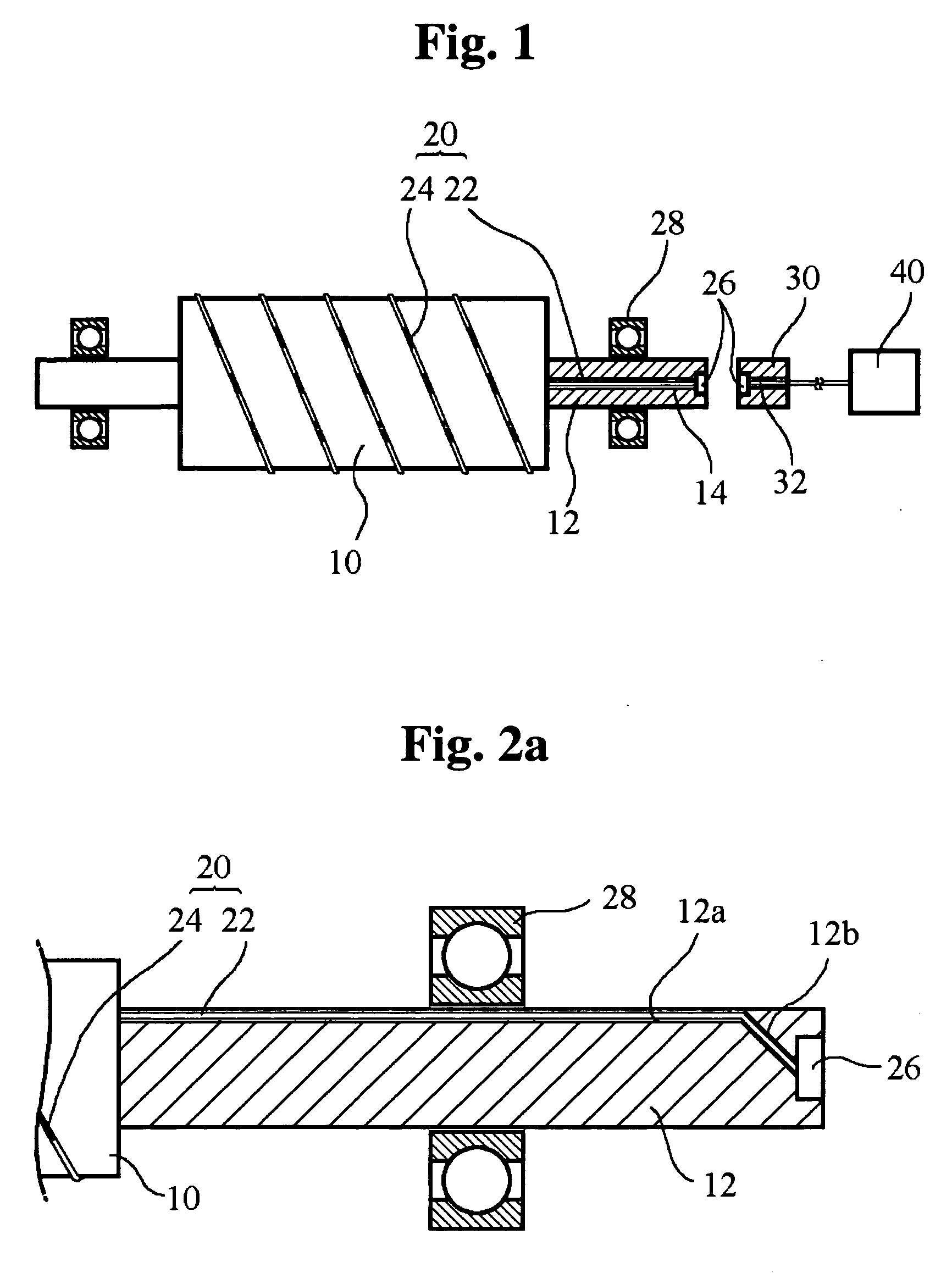

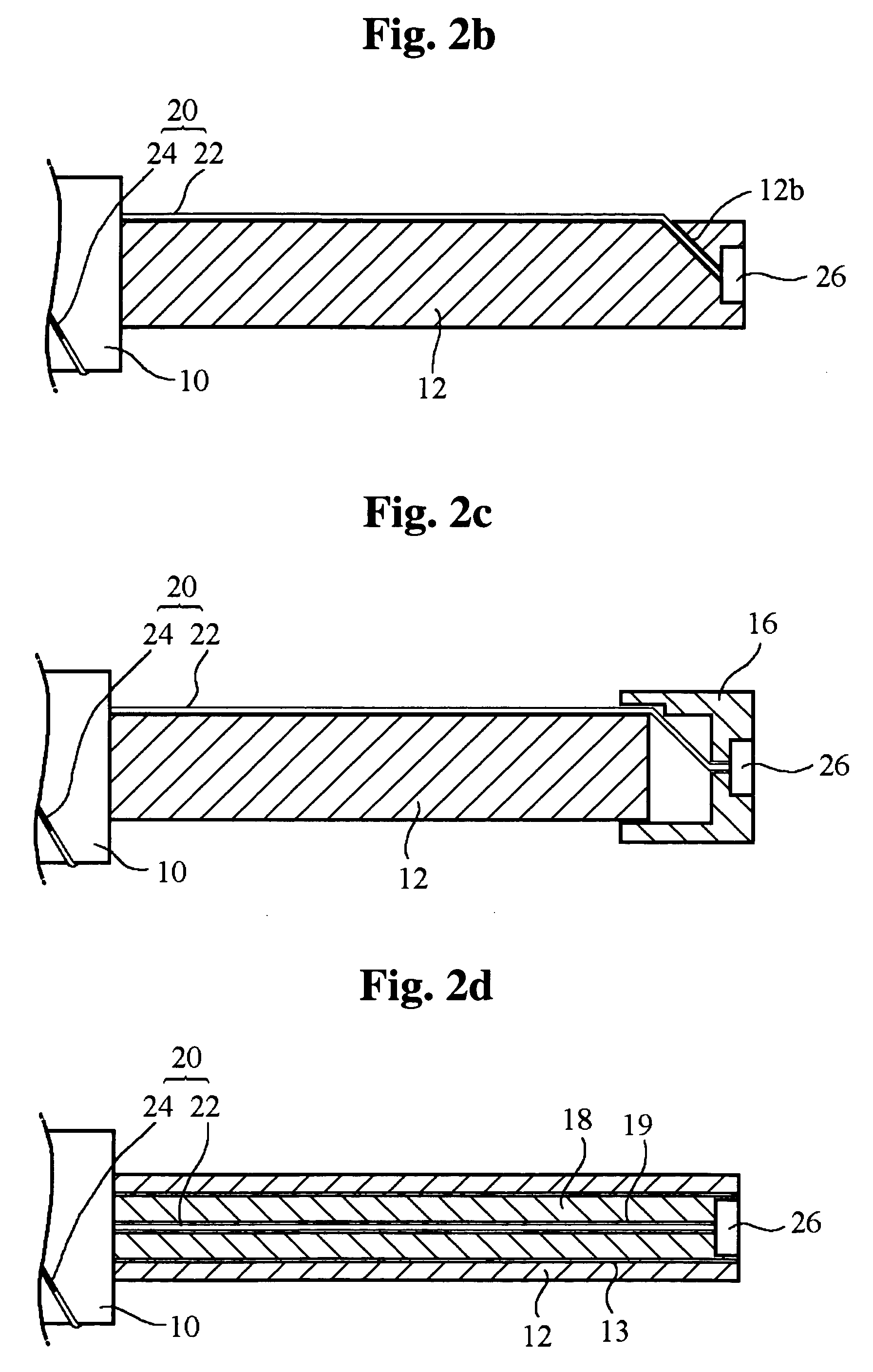

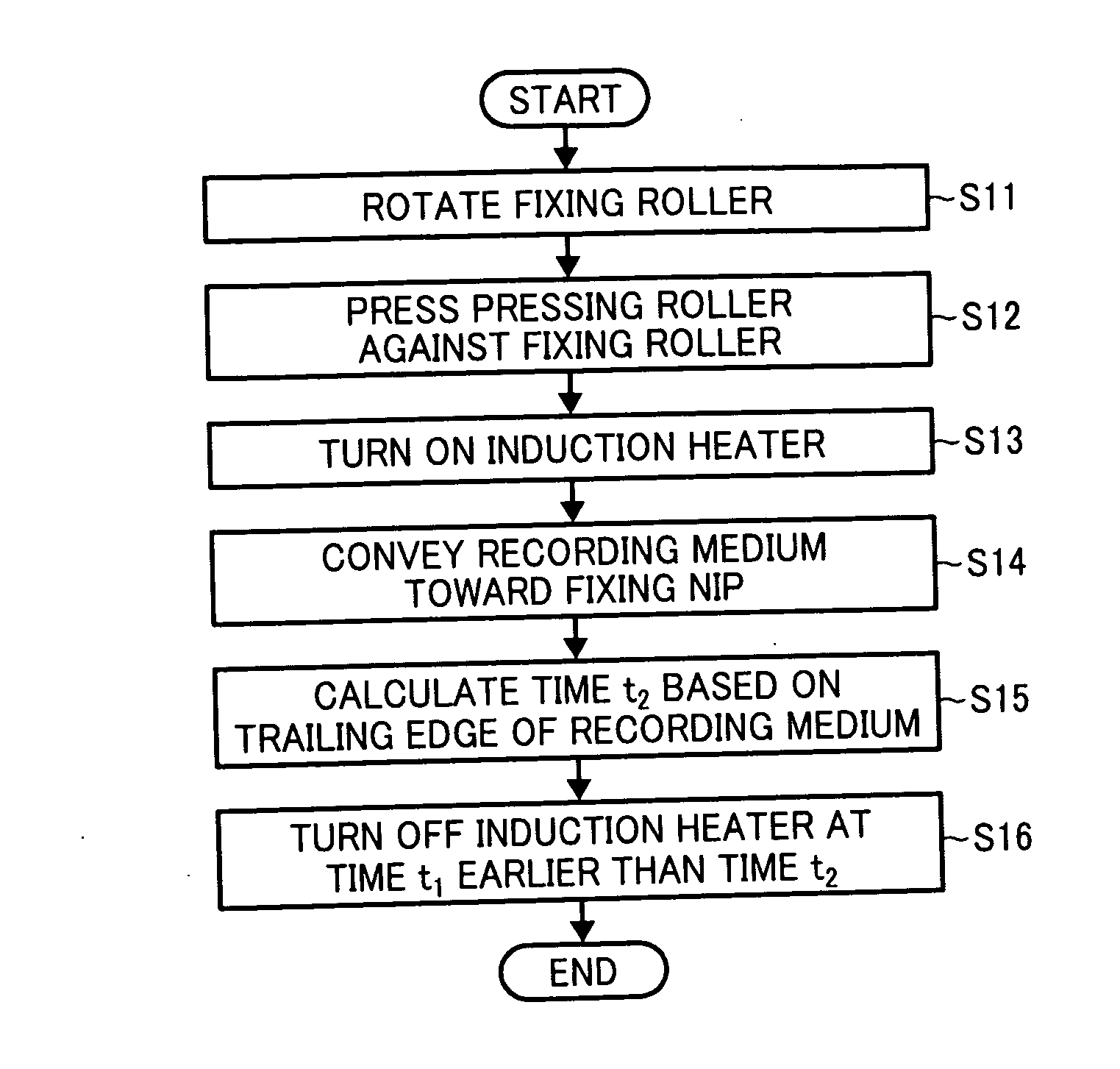

Fixing Device, Image Forming Apparatus Incorporating Same, And Method For Fixing Toner Image On Recording Medium

A fixing device includes a pressing rotary body pressed against a fixing rotary body to form a fixing nip therebetween through which a recording medium bearing a toner image is conveyed; a heater to heat the fixing rotary body, disposed opposite a circumferential surface of the fixing rotary body and upstream from the fixing nip a predetermined circumferential distance along the circumferential surface of the fixing rotary body in a direction of rotation of the fixing rotary body; a heater driver to turn on and off the heater; a timing calculator to calculate a reference time at which a trailing end portion of the recording medium in a conveyance direction of the recording medium reaches the fixing nip; and a heater driver controller to cause the heater driver to turn off the heater at a turn-off time earlier than the reference time.

Owner:RICOH KK

Omnidirectionally Moving Wheel, Moving Device, Carrying Device, and Massage Device

An omnidirectionally moving wheel includes multiple rotating bodies and a wheel, wherein each rotating body has a flexibility to be able to bend a rotational axis, is bent to encircle an outer circumference of the wheel in a ring-like shape, and is compressed in a direction of the rotational axis of each rotating body to be disposed on the wheel in a manner to allow rotation centered around each rotating body's secured rotational axis extending along a plane perpendicular to the rotational axis of the wheel.

Owner:FUJI SHINICHIRO

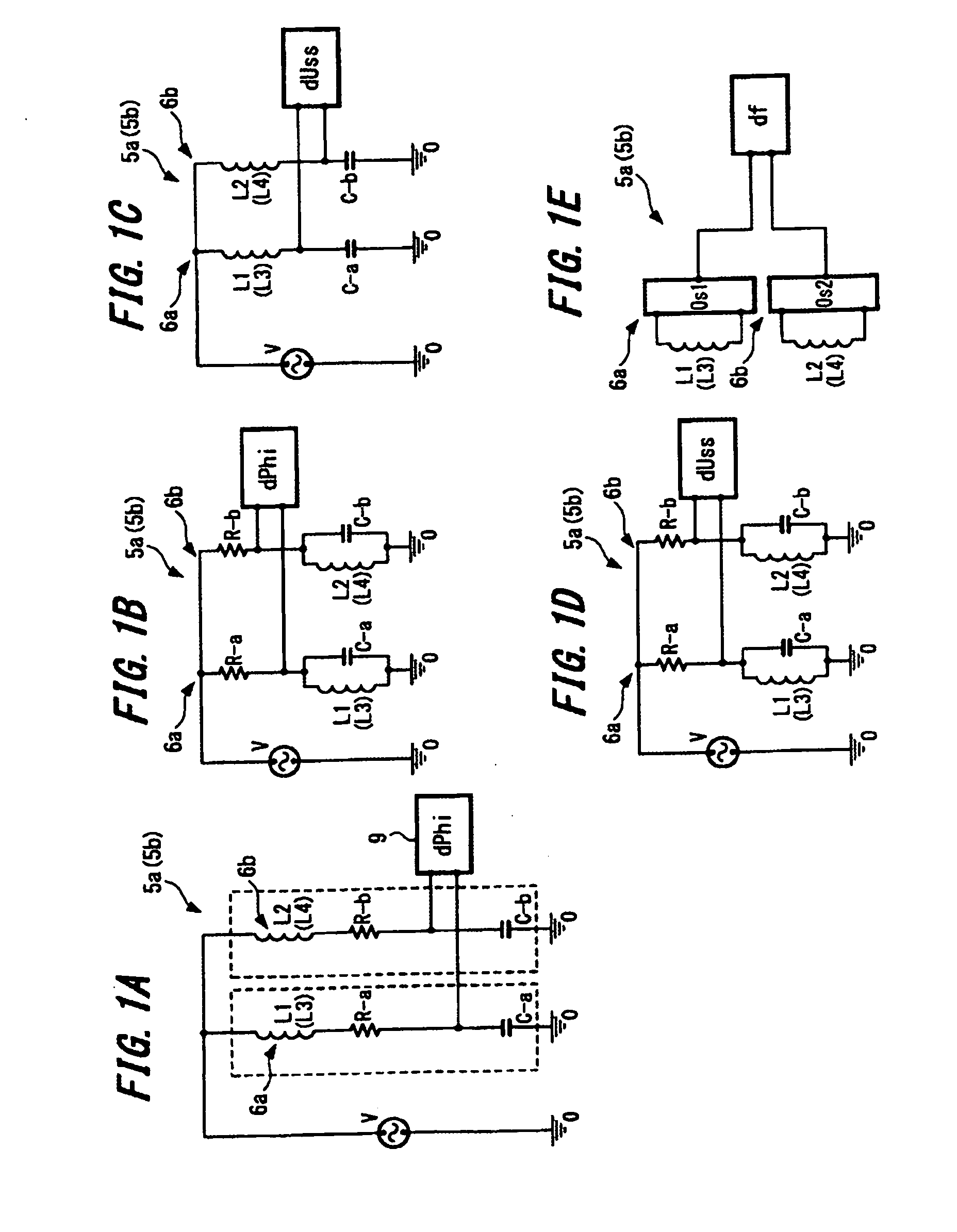

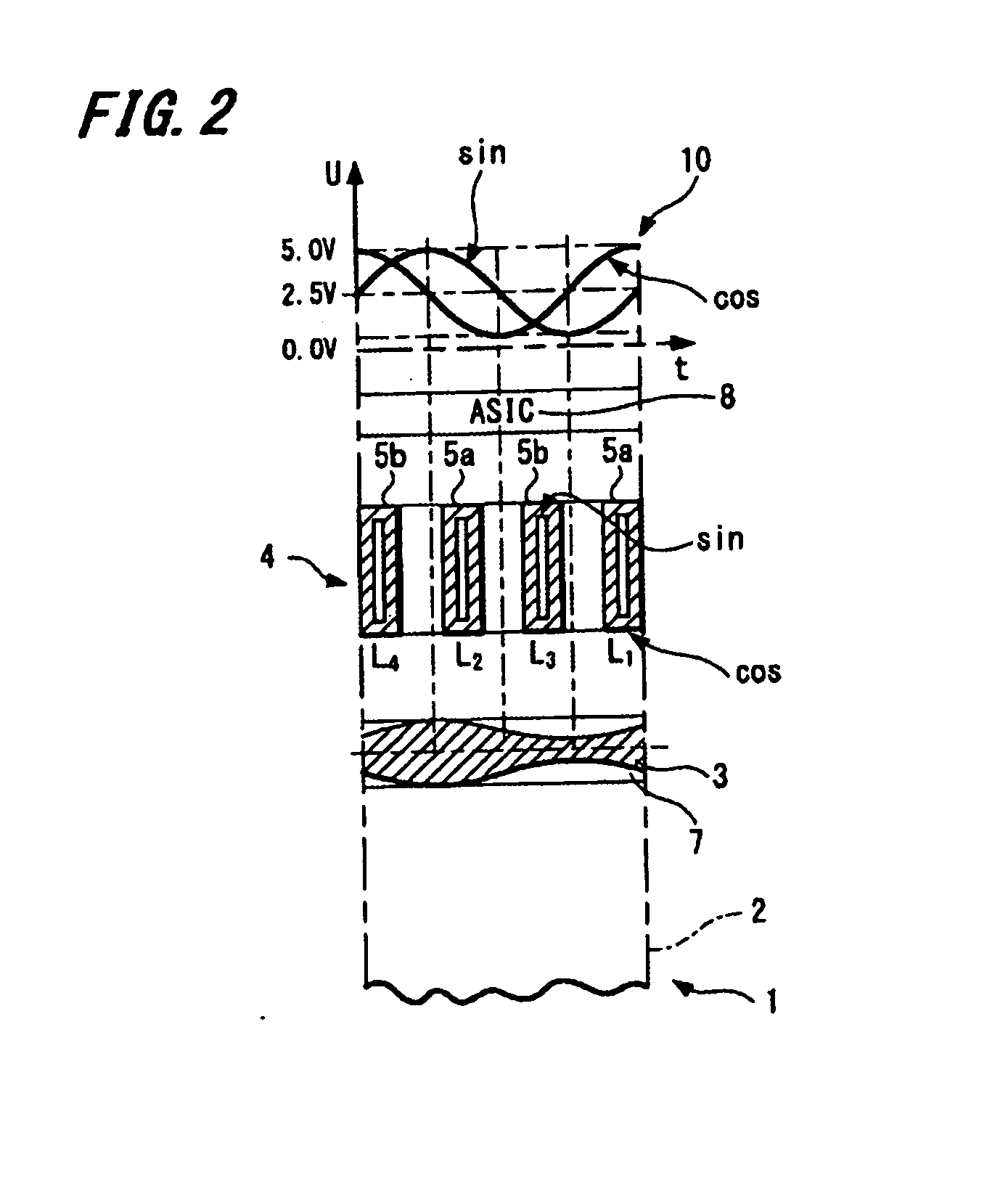

Position encoder and a method for detecting the position of a movable part of a machine

ActiveUS20100156402A1Increase flexibilityEffective positioningUsing electrical meansConverting sensor output electrically/magneticallyInductorEngineering

A rotation angle detection sensor system for a rotational body is provided, which has a reduced sensitivity against an interfering magnetic field and an interfering electric field. The rotation angle detection sensor system comprises an encoder structure that is attached to the rotational body of a machine and is movable along with this rotational body. A stationary sensor assembly is positioned opposite to this encoder structure and supplies at least one sensor signal for determining the angle position. The sensor assembly includes a first inductive element, the inductance of which is dependent on the angle position of the encoder structure.

Owner:VOGT ELECTRONICS COMPONENTS

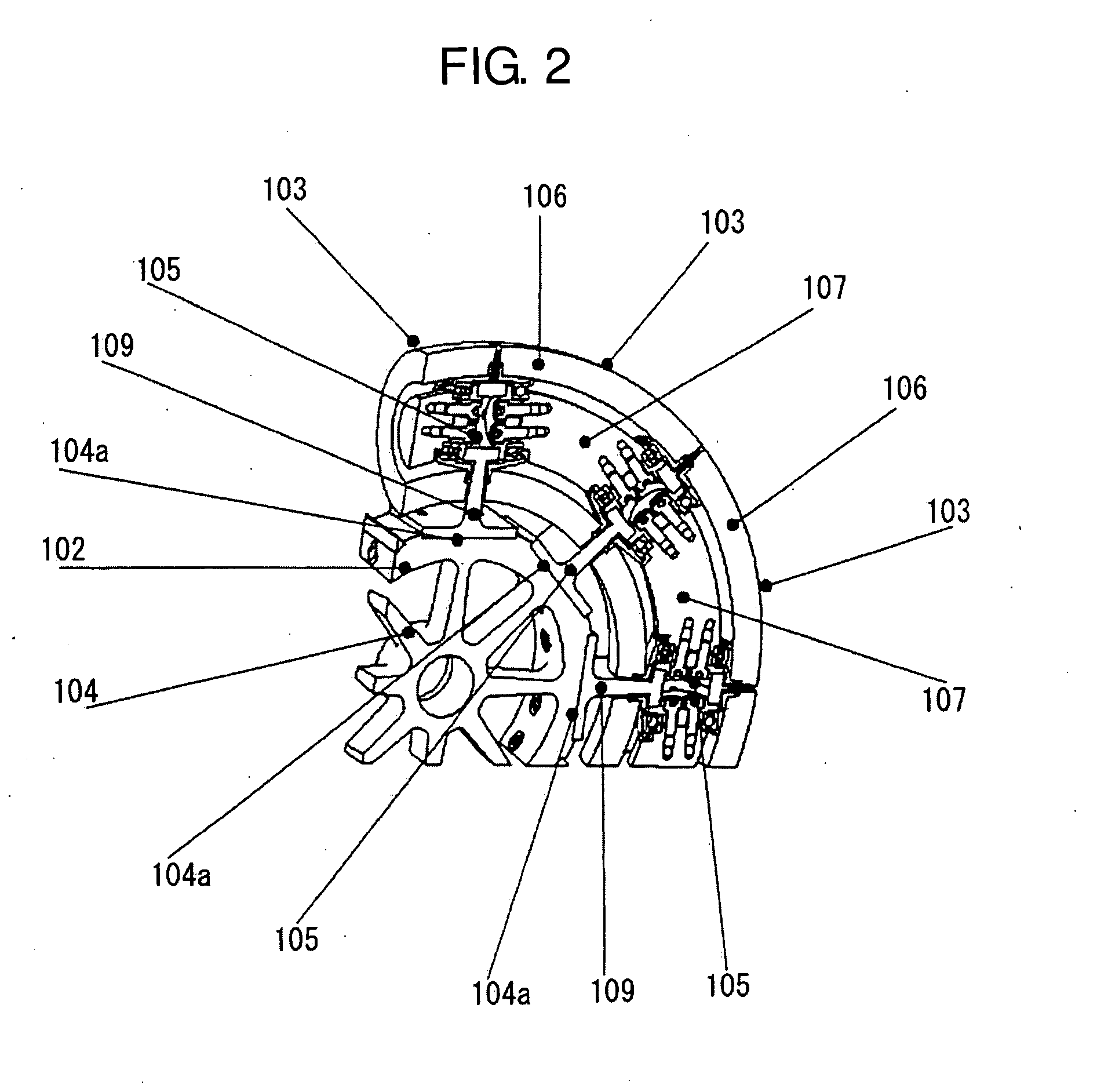

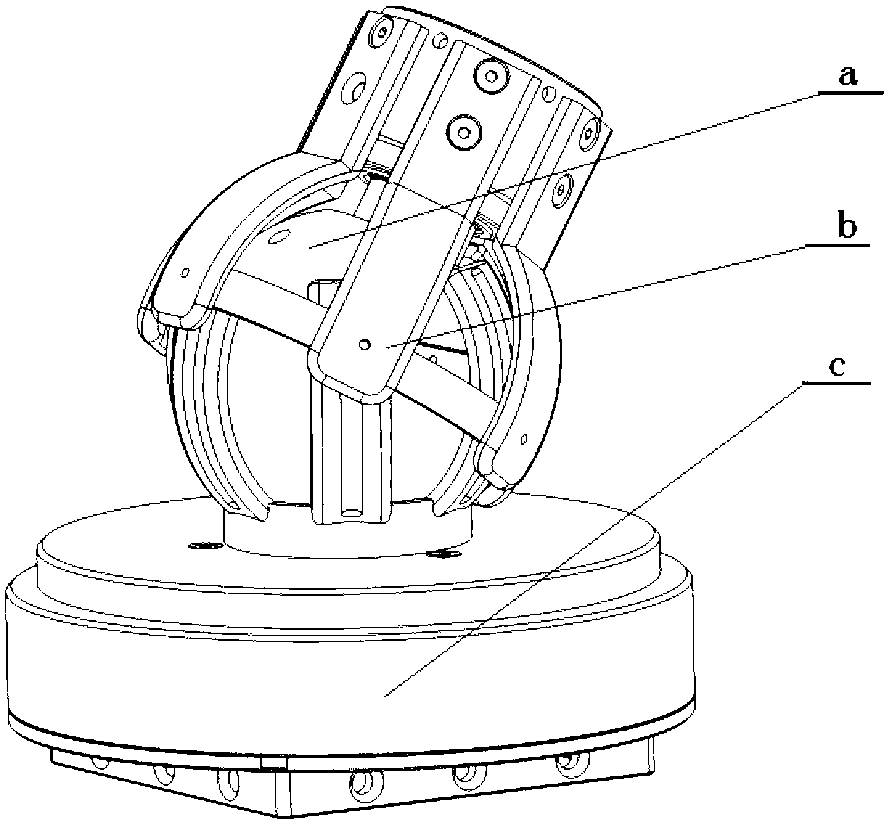

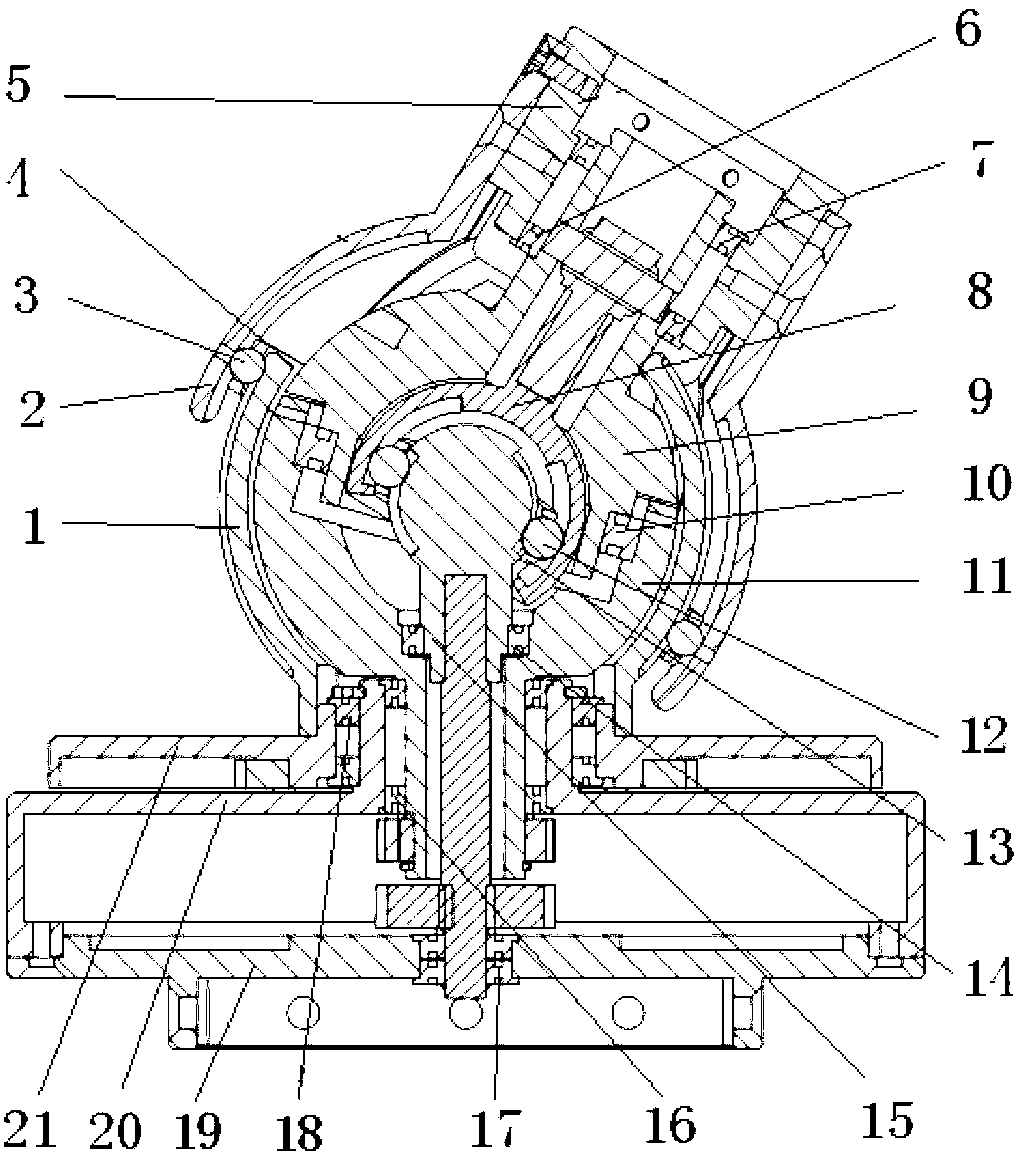

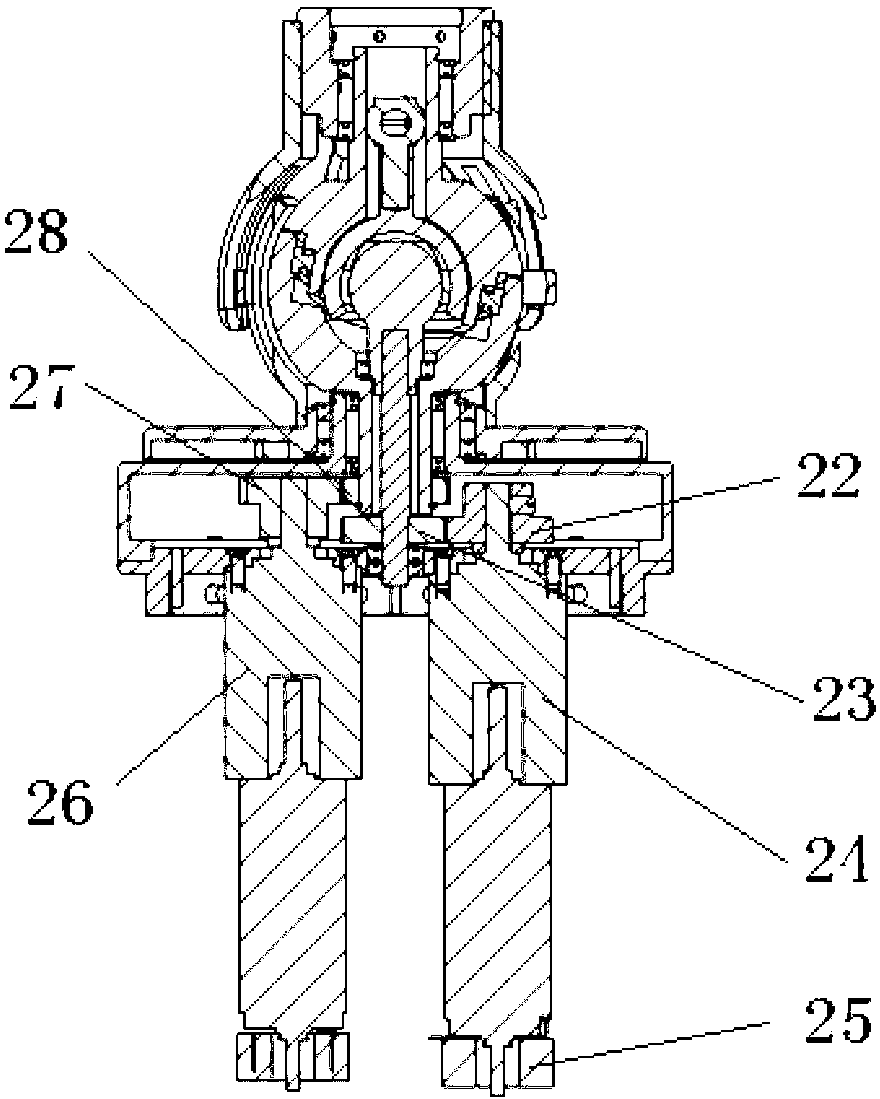

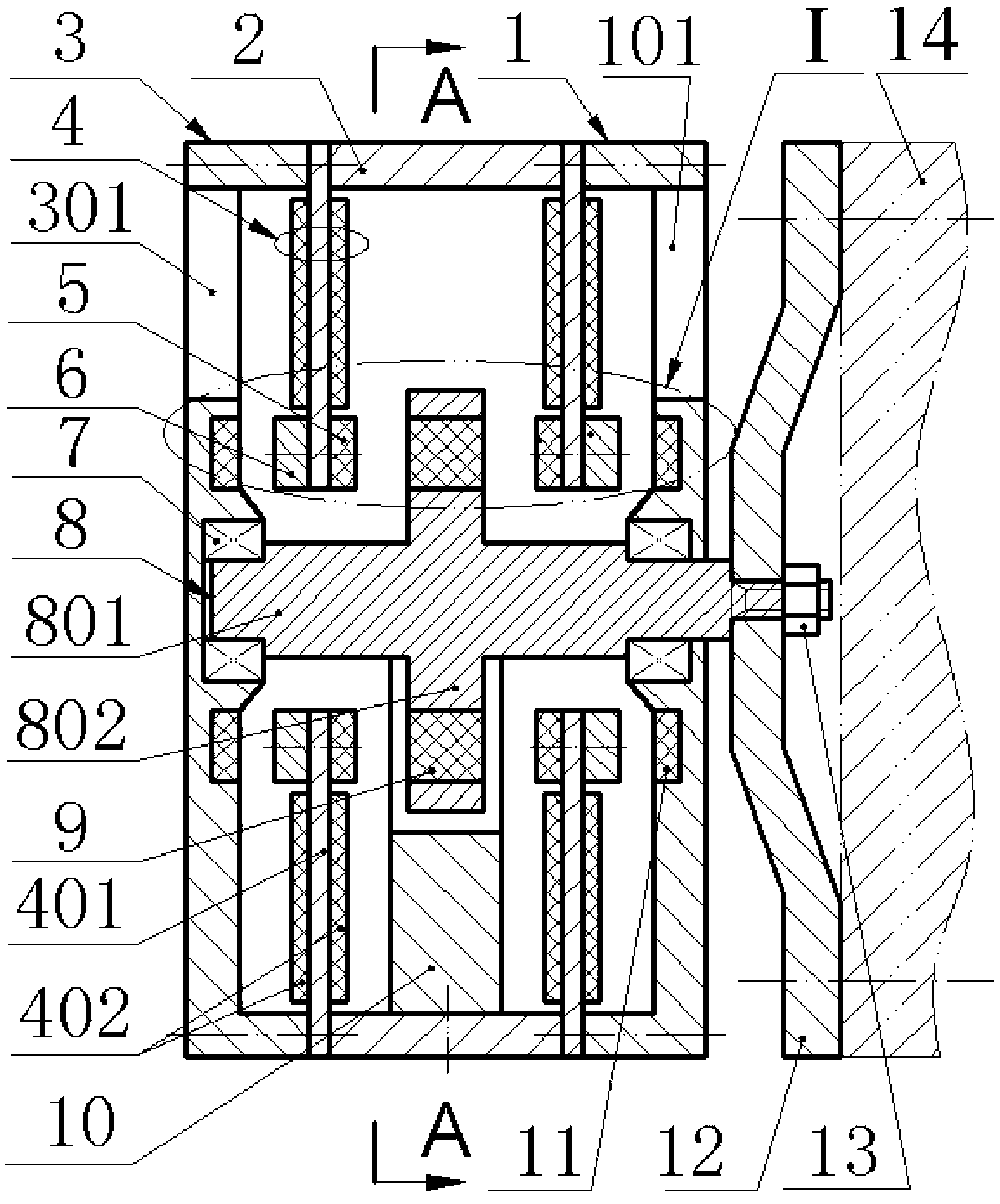

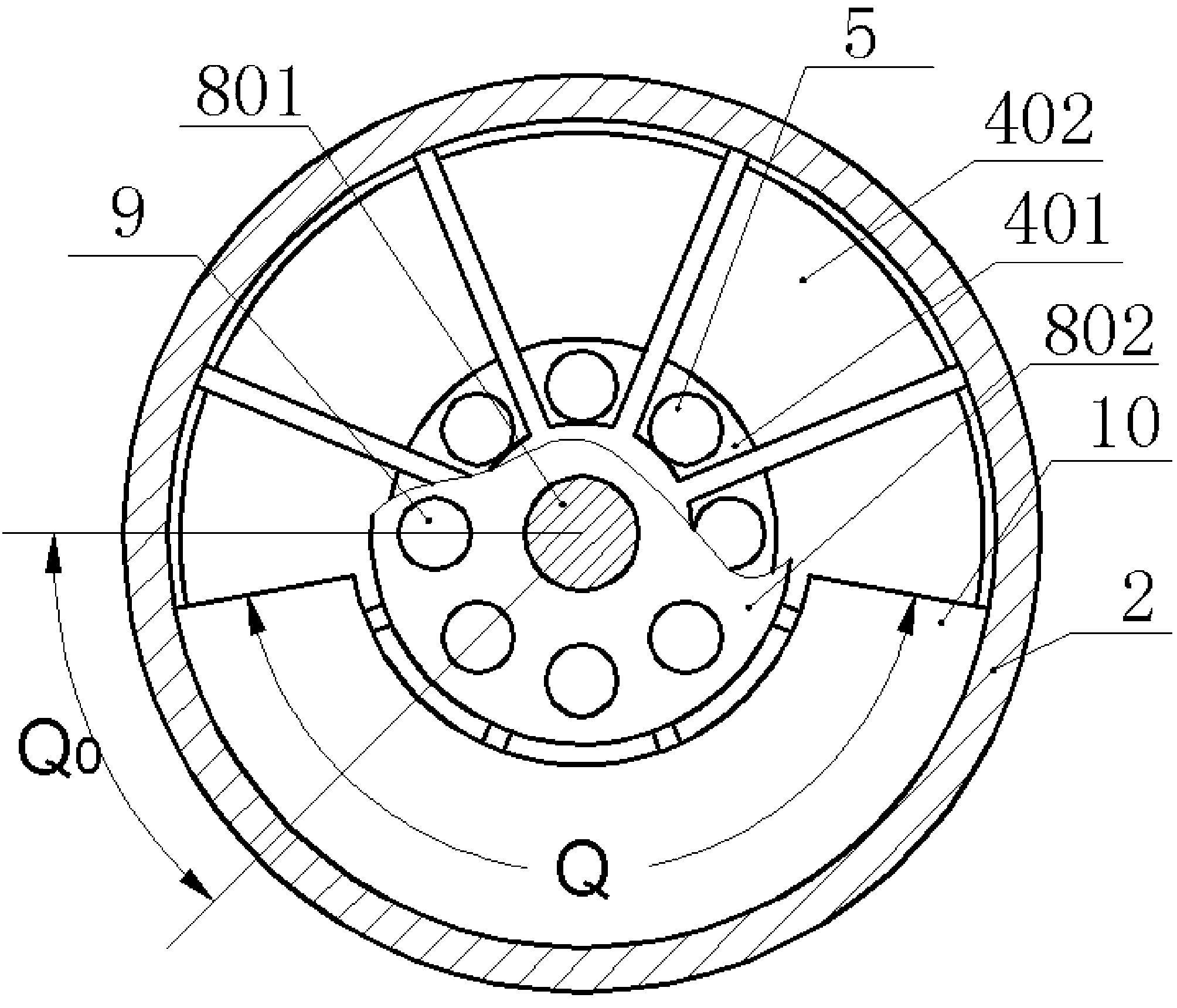

Three-freedom-degree constant speed decoupling space robot active spherical wrist and universal compliant control method

ActiveCN103341865AImprove stabilityIncreased range of angle adjustmentJointsKinematic couplingUniversal joint

The invention relates to a three-freedom-degree constant speed decoupling space robot active spherical wrist and a universal compliant control method. The offset mode that the included angles are formed among rotation plane normal and rotating shafts is adopted for both an upper hemisphere rotating body and a lower hemisphere rotating body. The intersection point of the two rotating shafts of the upper rotating body and the lower rotating body is the sphere center of hemispheres of the upper rotating body and the lower rotating body, the intersection point of the two rotating shafts coincides with the rotating center of an inner ball cage universal joint and the rotating center of an outer ball cage universal joint respectively, and then constant speed decoupling of three input movements is achieved; the output end of the outer ball cage universal joint is connected with a shaft neck of the upper rotating body through a bearing in a suspension mode, three absolute corner coded discs are connected with the upper rotating body, the lower rotating body, a motor conducting spinning motion, and the output end of a speed reducing system respectively, a six-dimensional ATI sensor is installed at the output tail end of the wrist, and a wrist universal compliant follow-up control mode is achieved by a rotating joint of an upper hemisphere, a rotating joint of a lower hemisphere and a joint conducting spinning motion through a system friction force compensation technology. The three-freedom-degree constant speed decoupling space robot active spherical wrist and the universal compliant control method are accurate in locating, stable in movement, and capable of avoiding oscillation phenomena of movement coupling and mechanical arms and effectively relieving mechanical interference in a spherical wrist full compliant mode.

Owner:DALIAN UNIV OF TECH

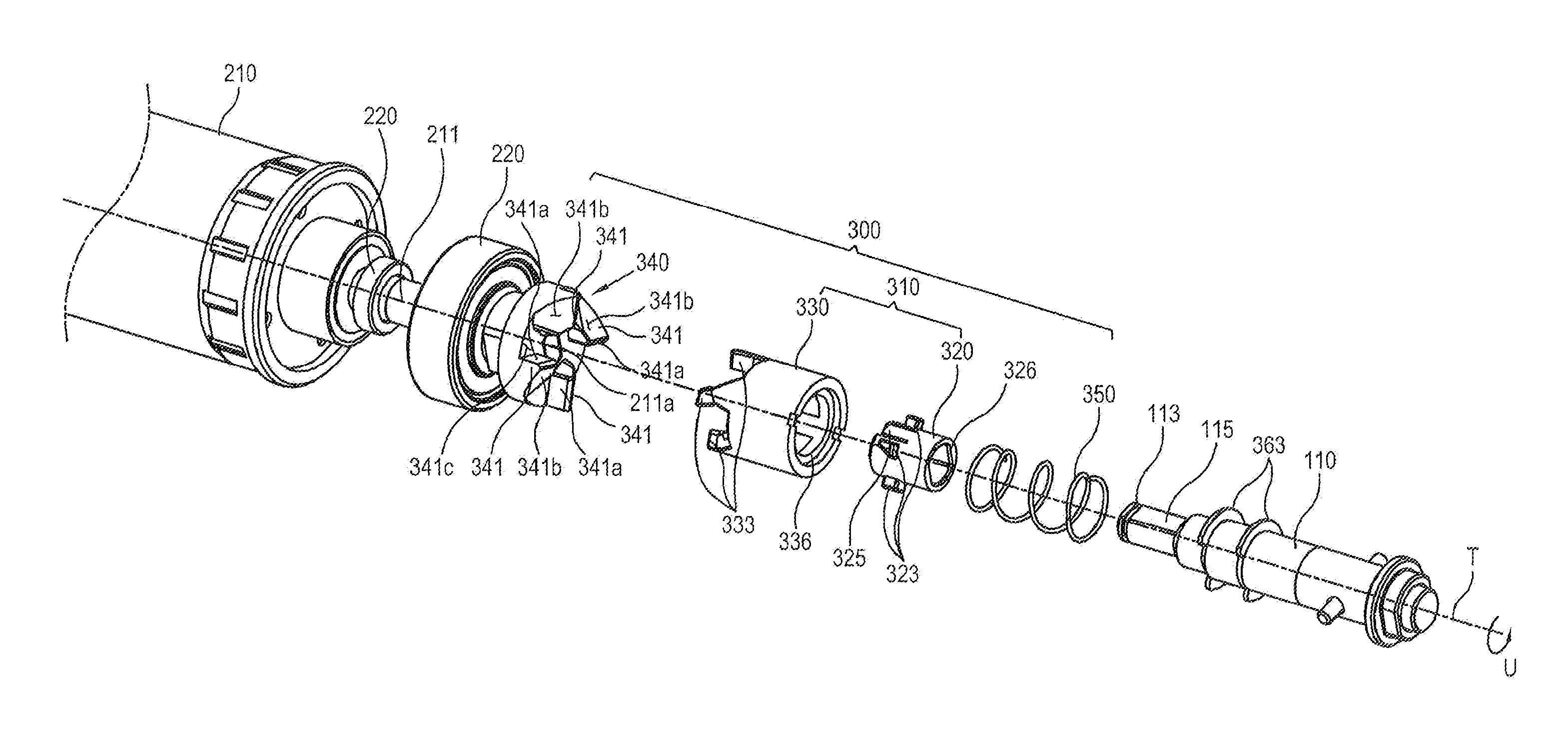

Image forming apparatus and developing cartridge thereof

ActiveUS20100303503A1Couplings for rigid shaftsElectrographic process apparatusRotational axisDrive shaft

Disclosed are an image forming apparatus of improved power transmission structure and a developing cartridge thereof. The image forming apparatus may include a main body; a driving unit which includes a driving shaft mounted to the main body and a driving coupler connected to the driving shaft. The driving coupler may be provided with a plurality of driving tips. The image forming apparatus may further include a consumable unit that may be detachably received in the main body. The consumable unit may include a driven shaft, a rotating body rotating with the driven shaft and a passive coupler rotating with the driven shaft. The passive coupler may be provided with a plurality of passive tips. The plurality of driving tips and the plurality of passive tips may come into engaging contact with each other when the consumable unit is operably received in the main body, and may remain in the engaging contact even when the respective rotational axes of the driving shaft and the driven shaft intersect with each other.

Owner:HEWLETT PACKARD DEV CO LP

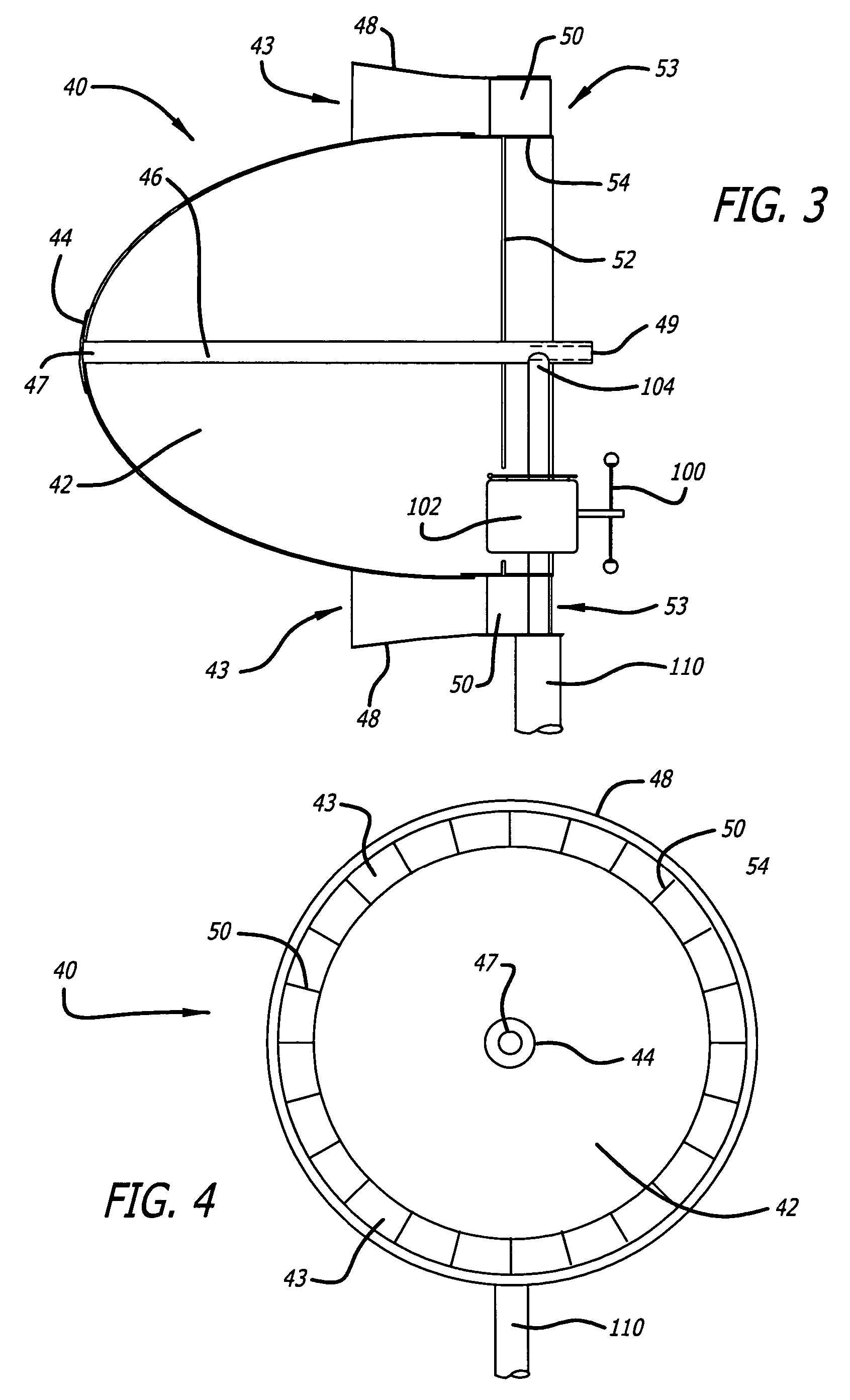

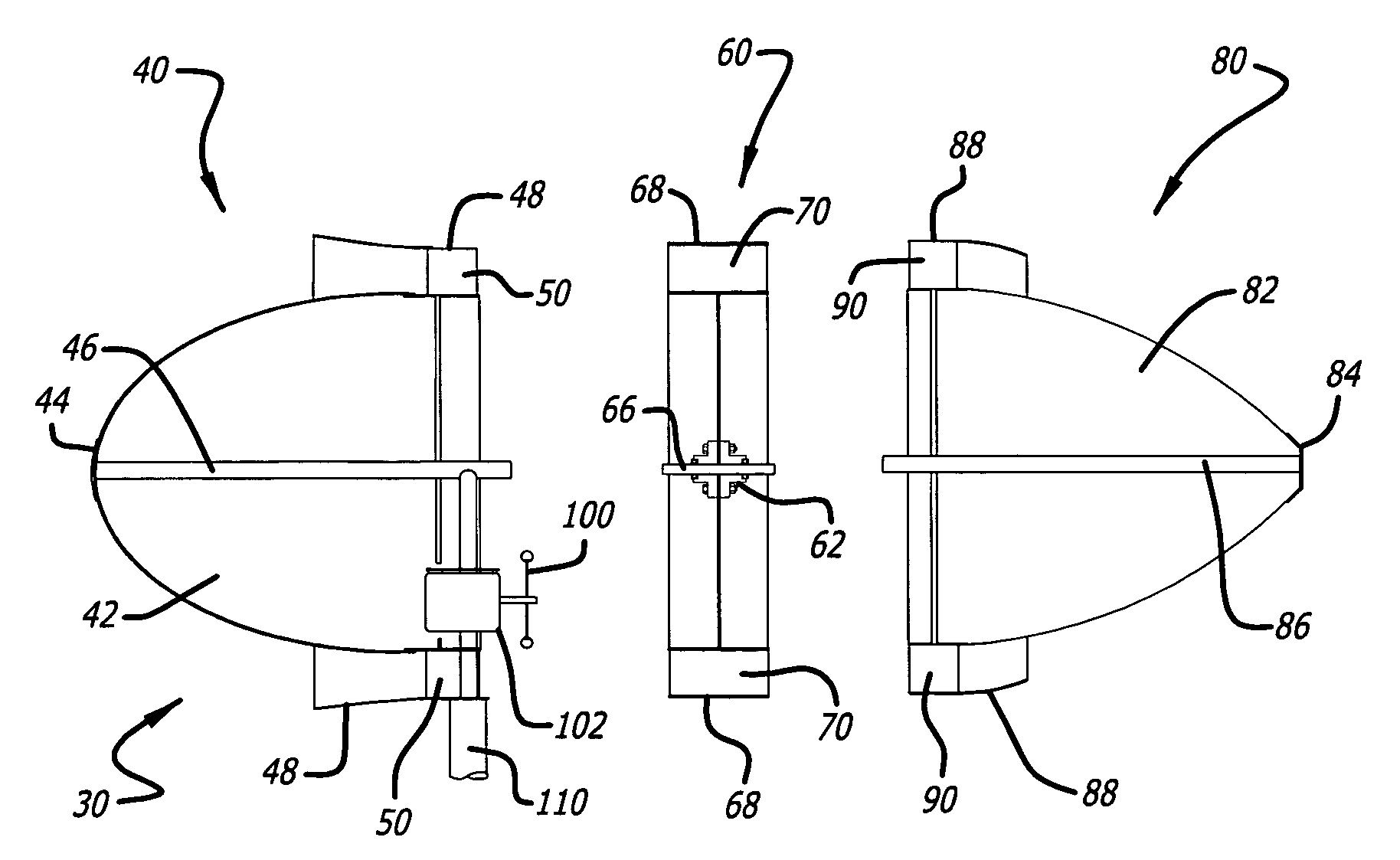

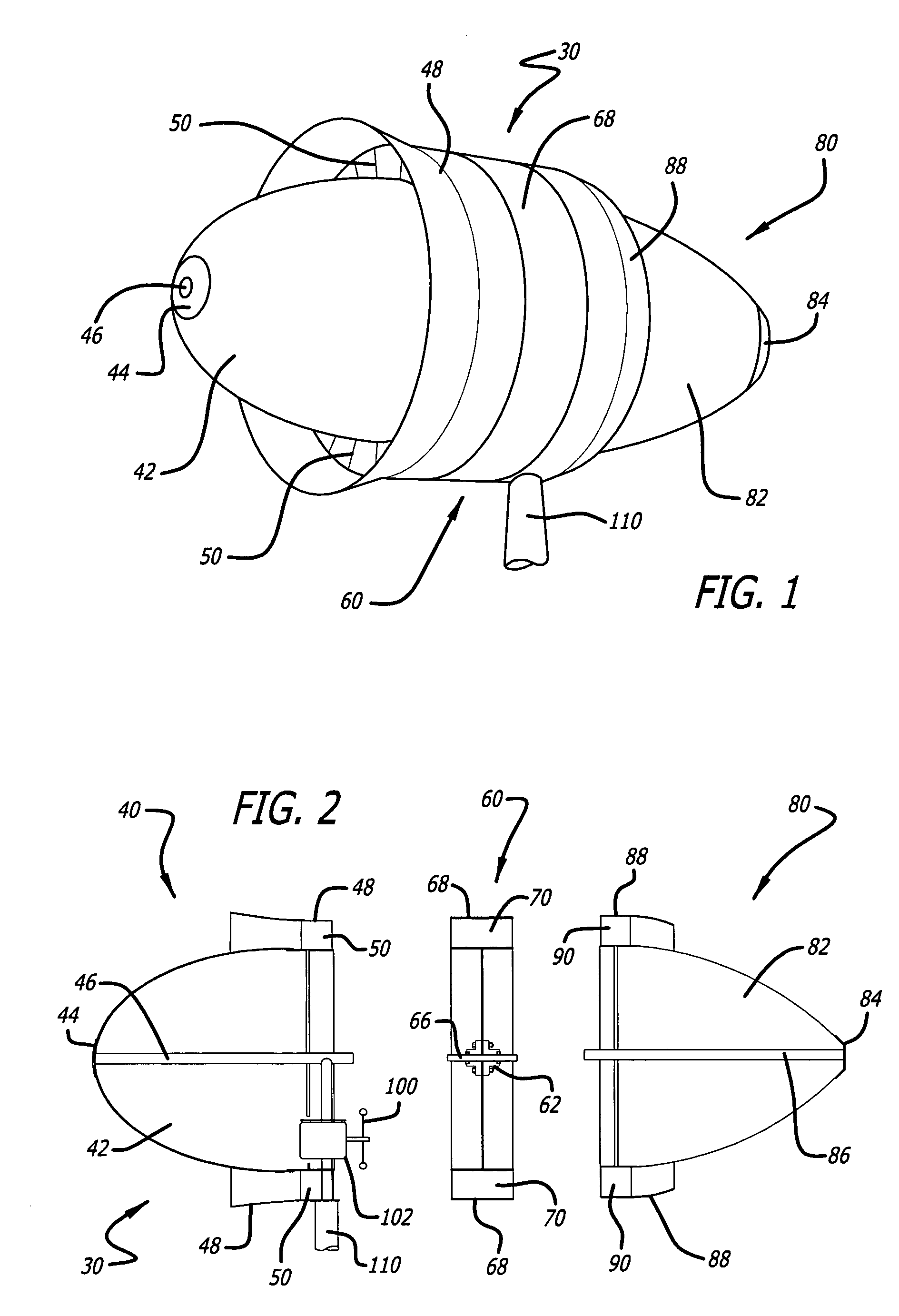

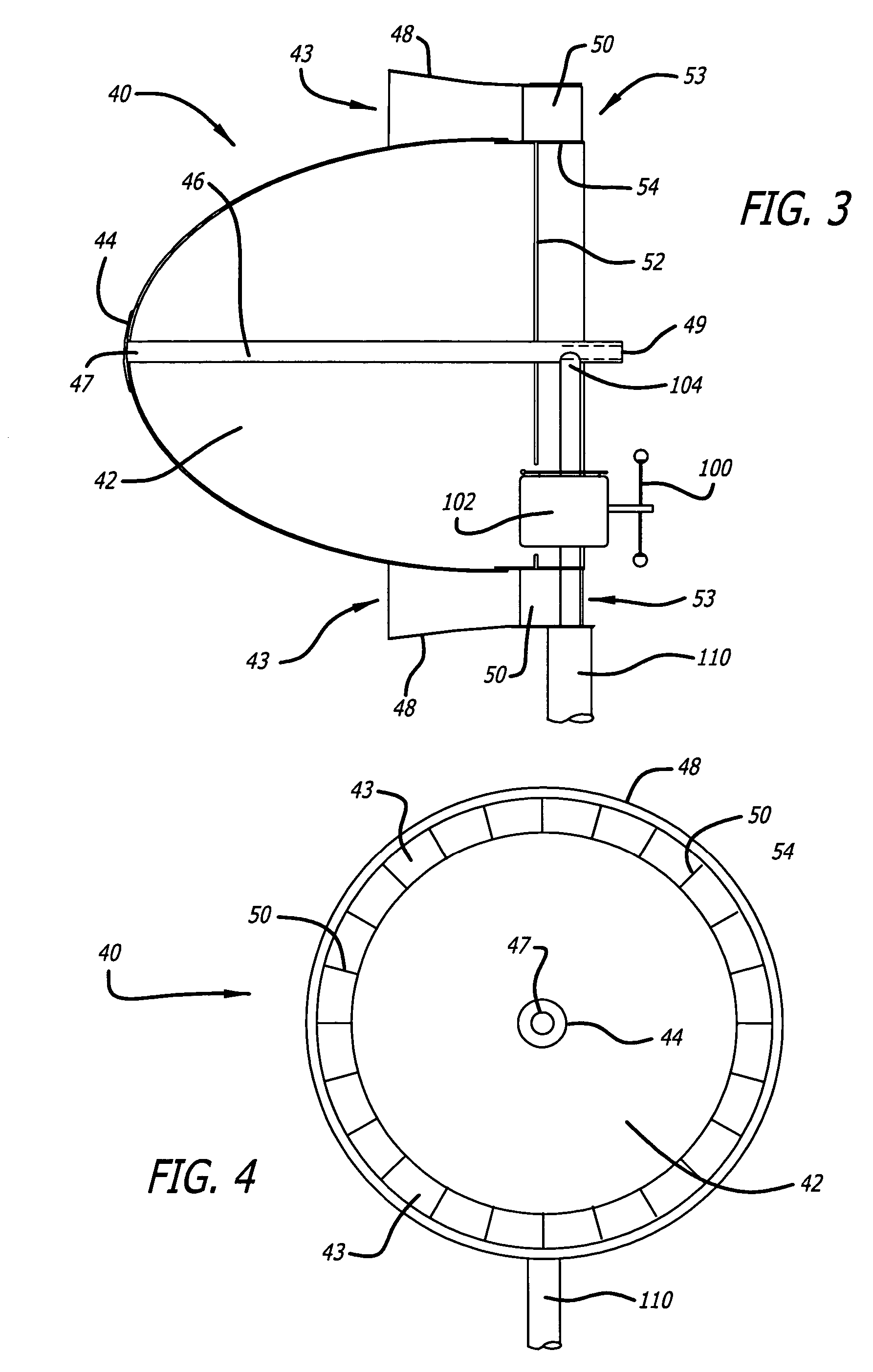

Laminar air turbine

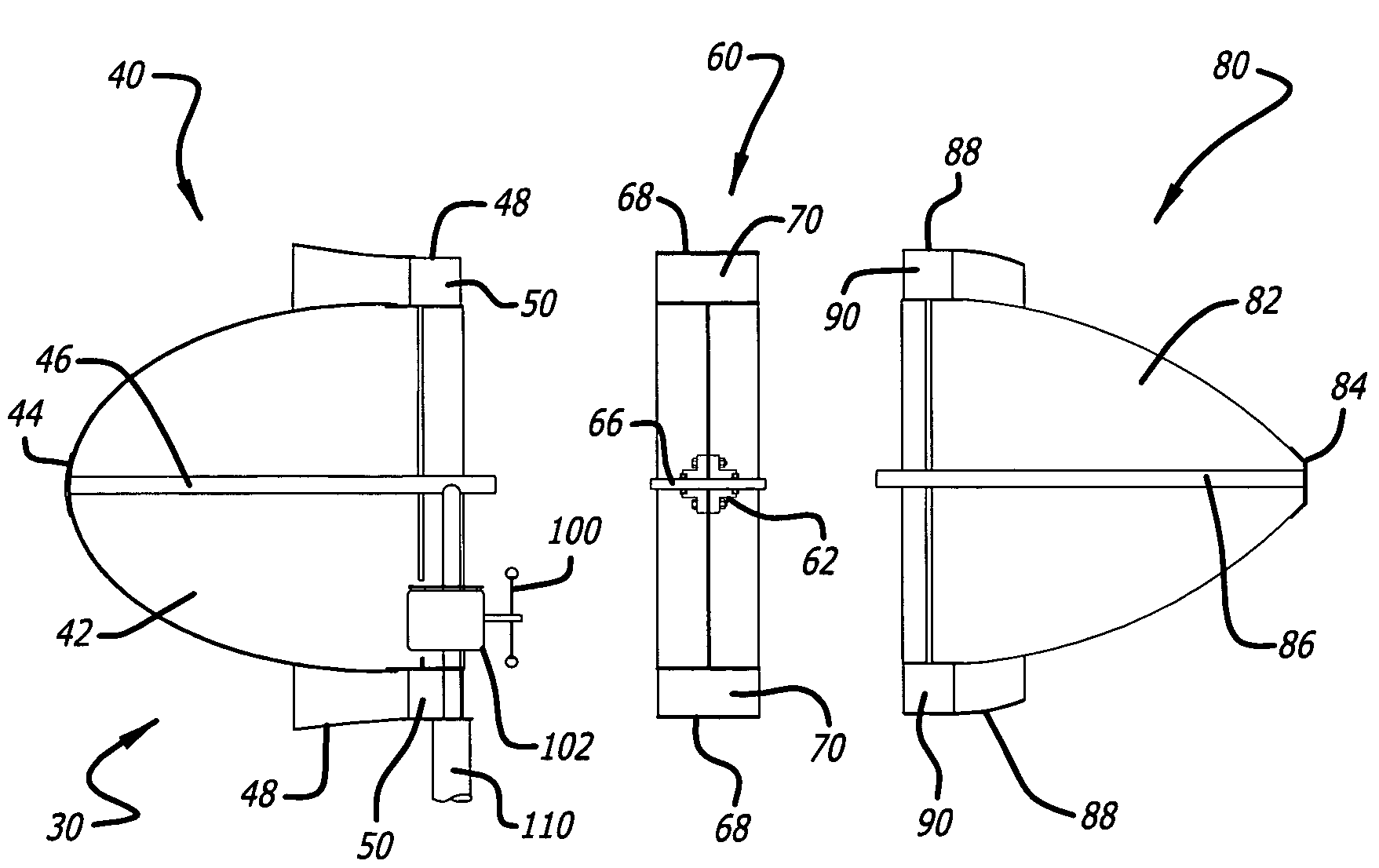

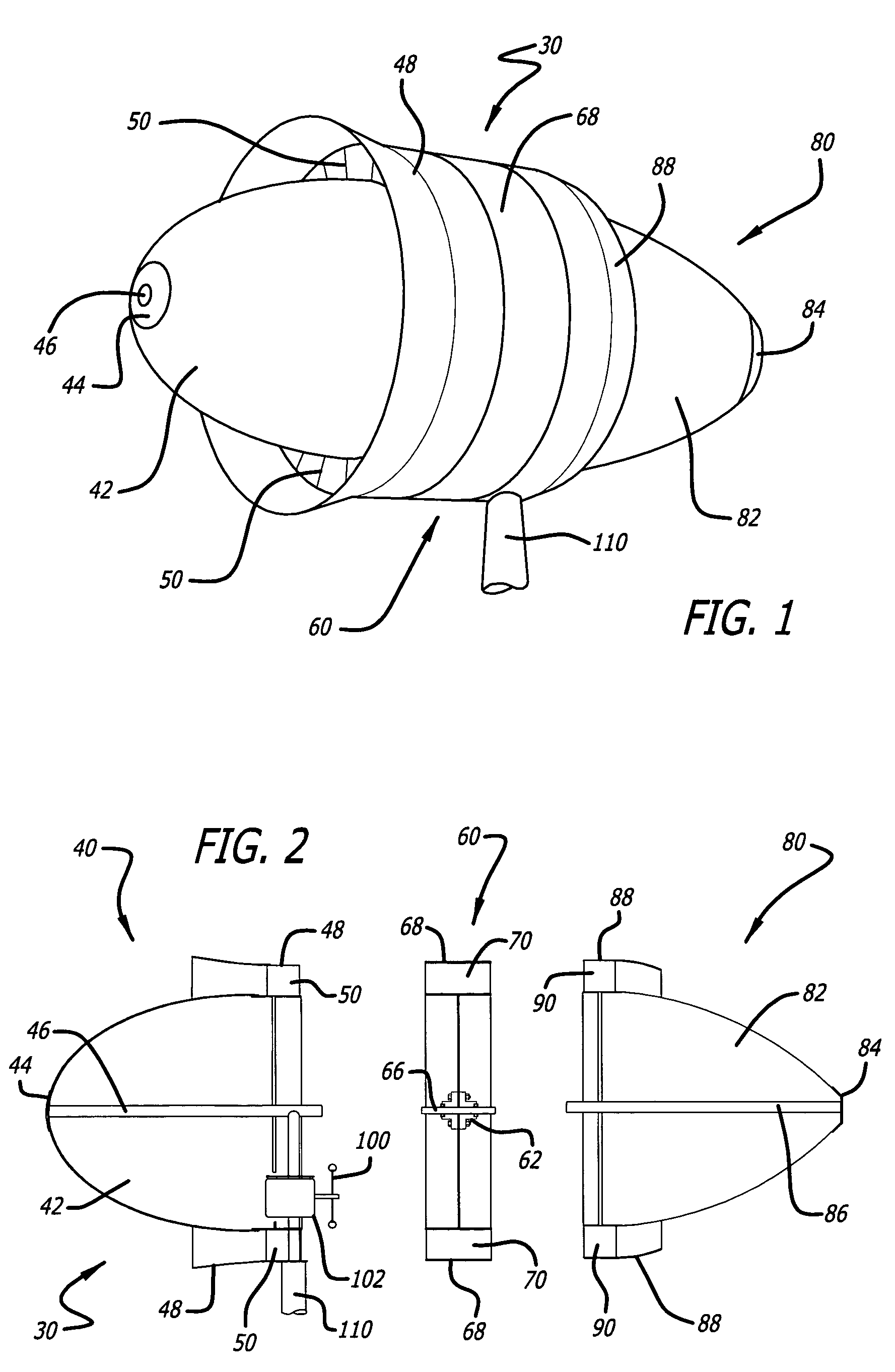

InactiveUS7214029B2Low costMaximize rotational forcePump componentsWind motor controlWind drivenTurbine wheel

The windmill assembly is a low drag, streamlined body of revolution that captures the kinetic energy content of the accelerated laminar air surrounding the body. The assembly includes a power-generating, wind-driven turbine that is compact, lightweight and capable of producing a substantially greater output than a conventional windmill with a comparable size rotor. The turbine includes a protruding aerodynamic nose and outer cowling that provide a streamlined, wind-collecting inlet section that constricts the incoming air stream and increases its velocity through the turbine blades. The turbine further includes an exit section designed to exhaust the air stream with a minimum of turbulence. One or more generators are coupled to a turbine wheel, and are electrically switched on and off to maximize the energy capture over the full range of ambient winds. The wind turbine assembly may be configured around a blimp-type body having counter-rotating turbine assemblies.

Owner:RICHTER DONALD L

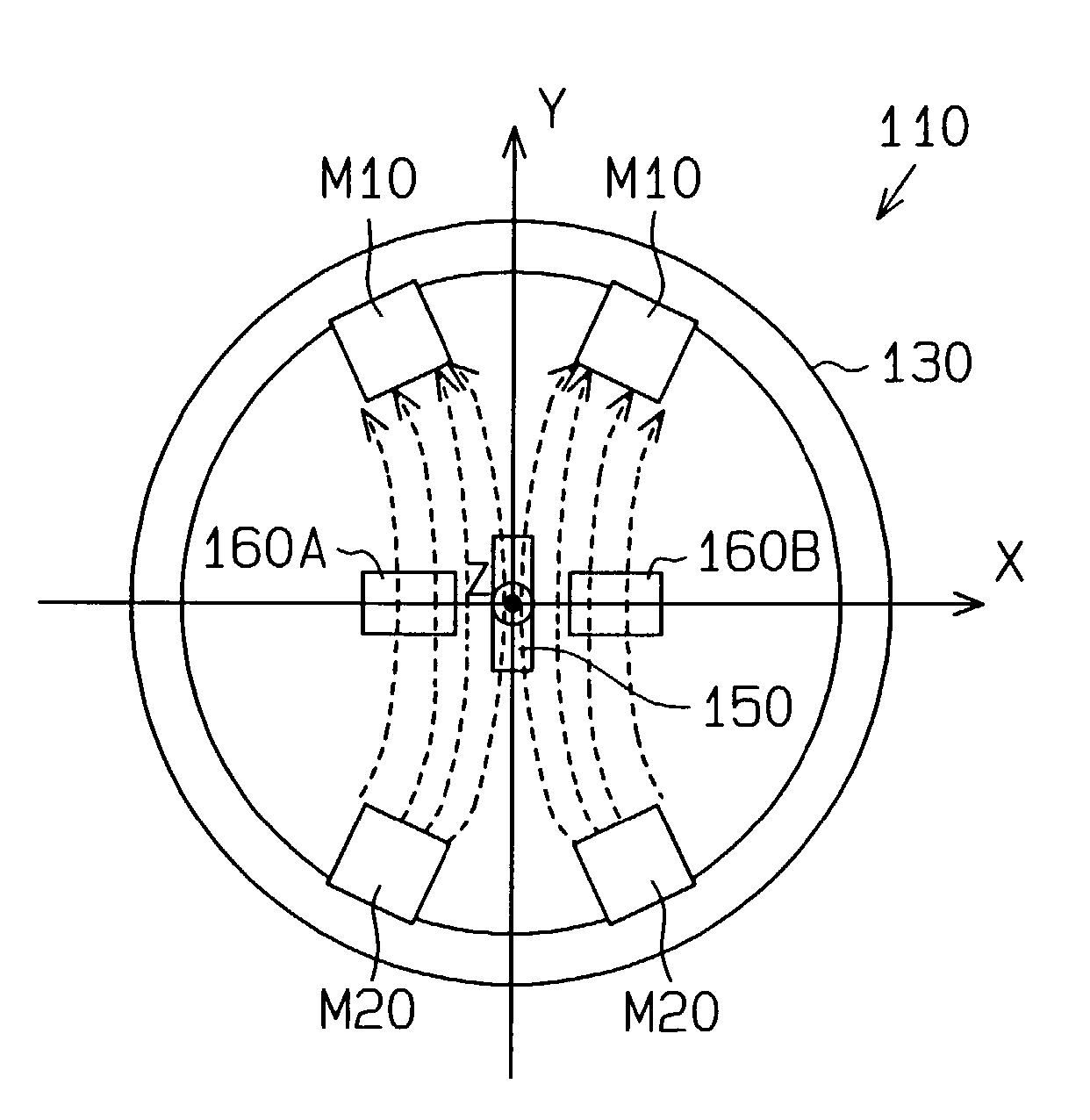

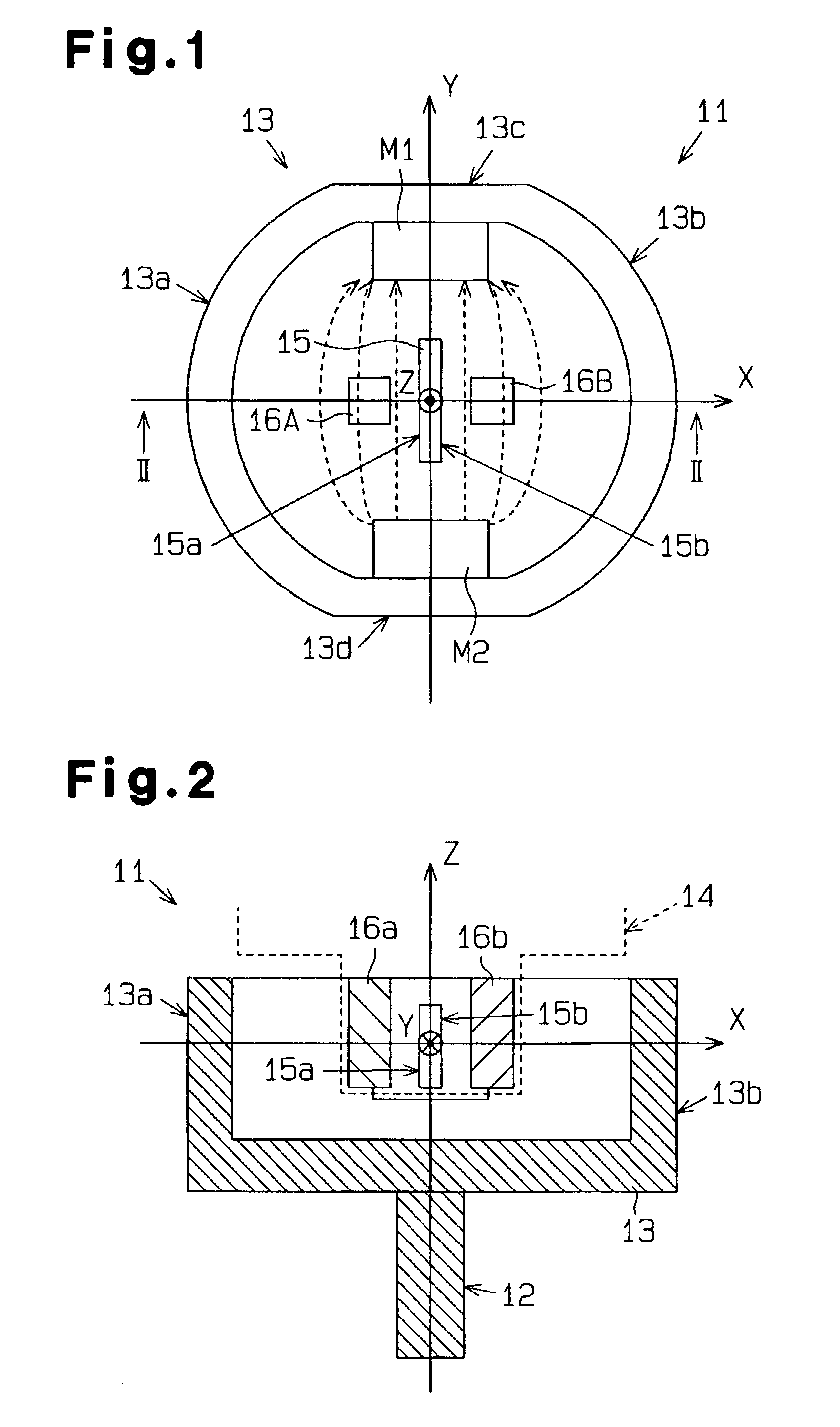

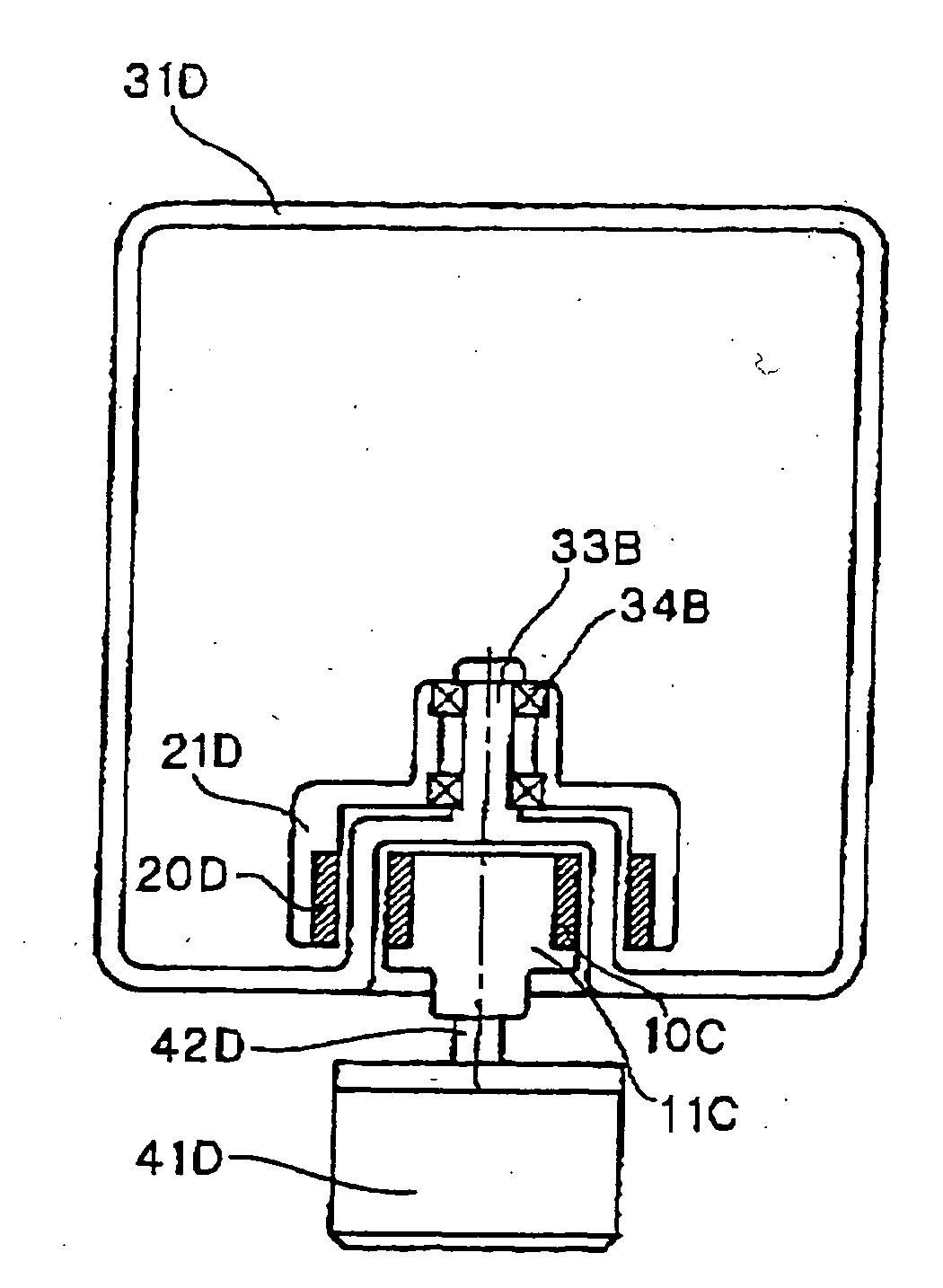

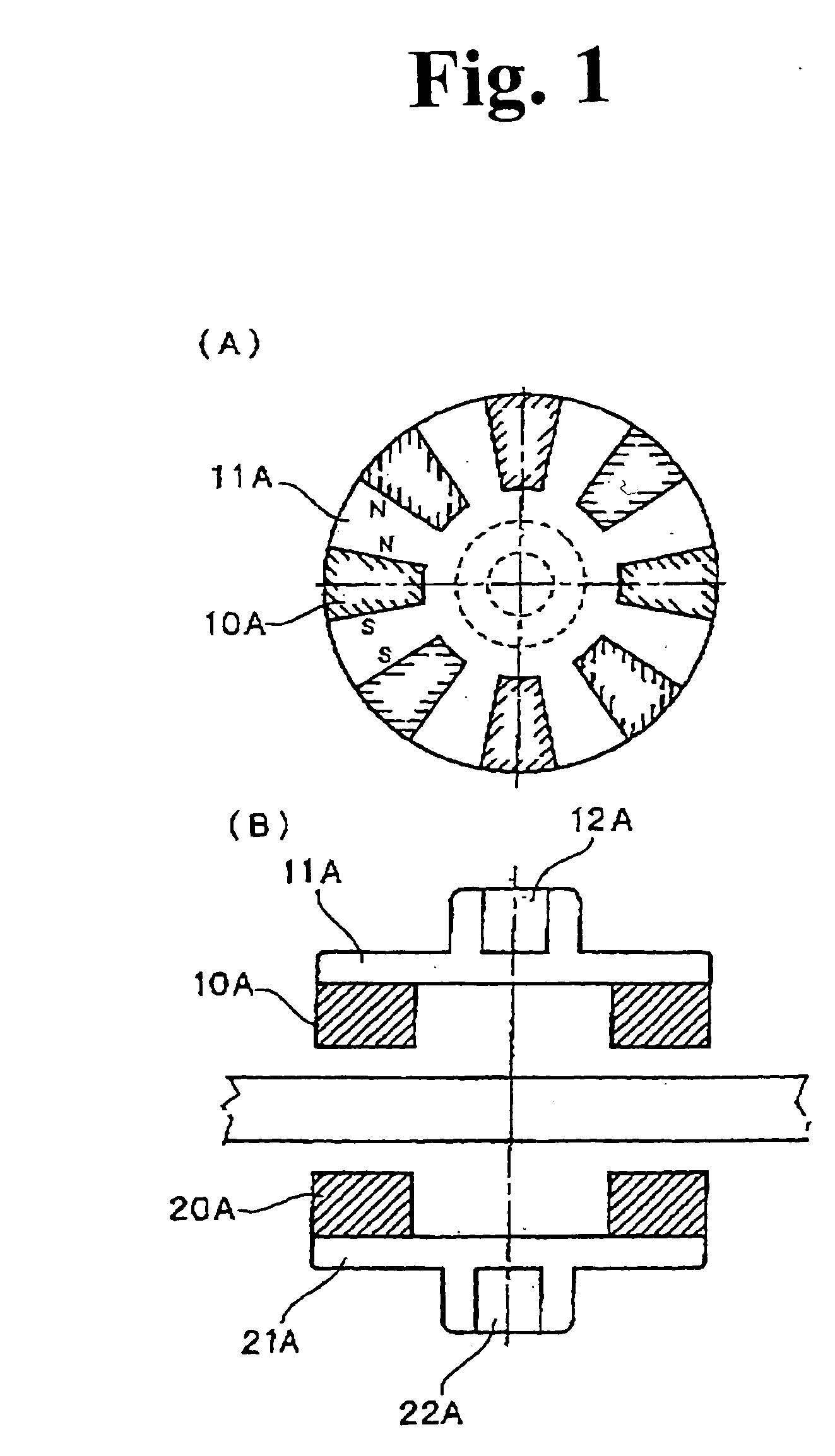

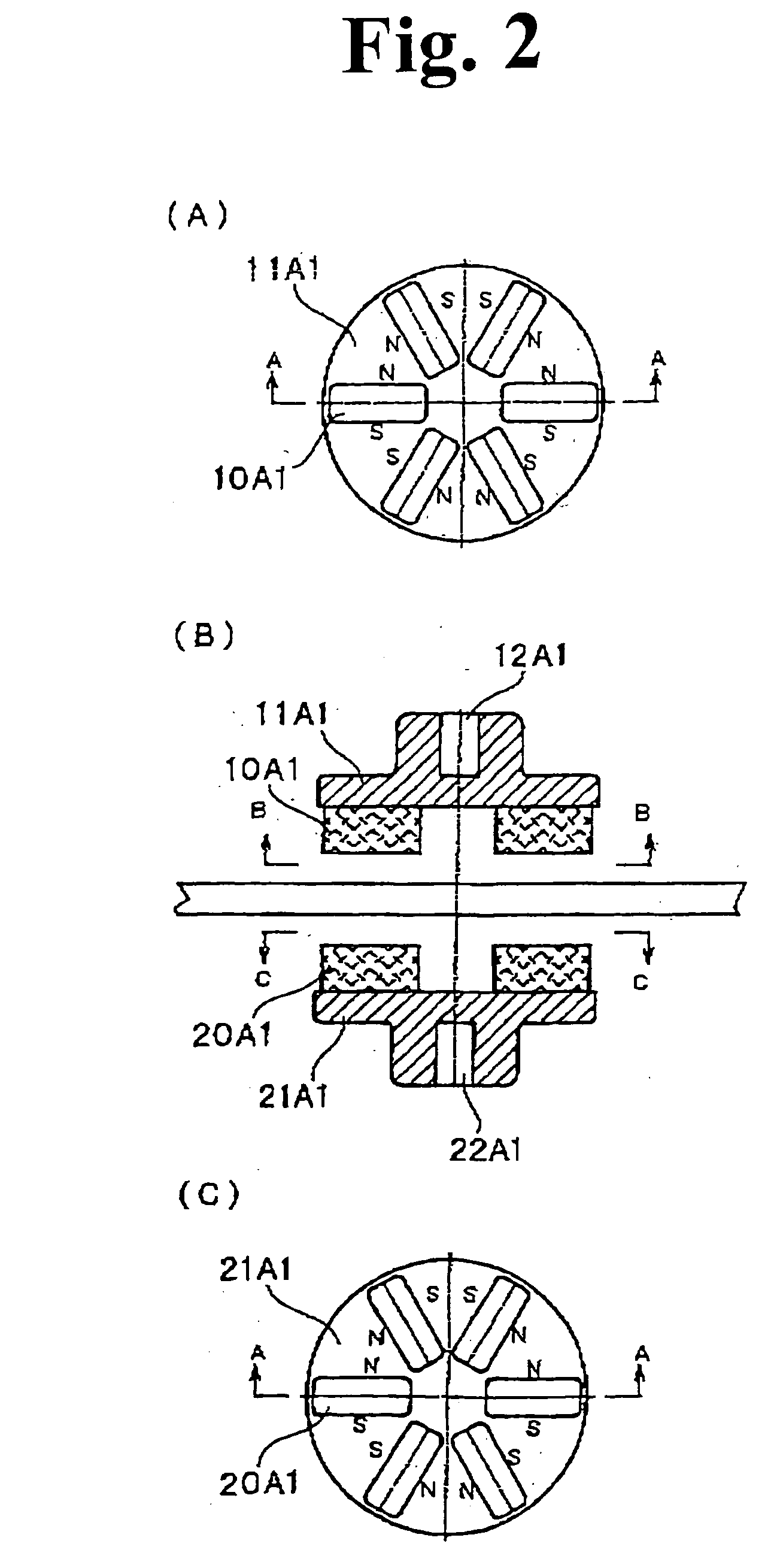

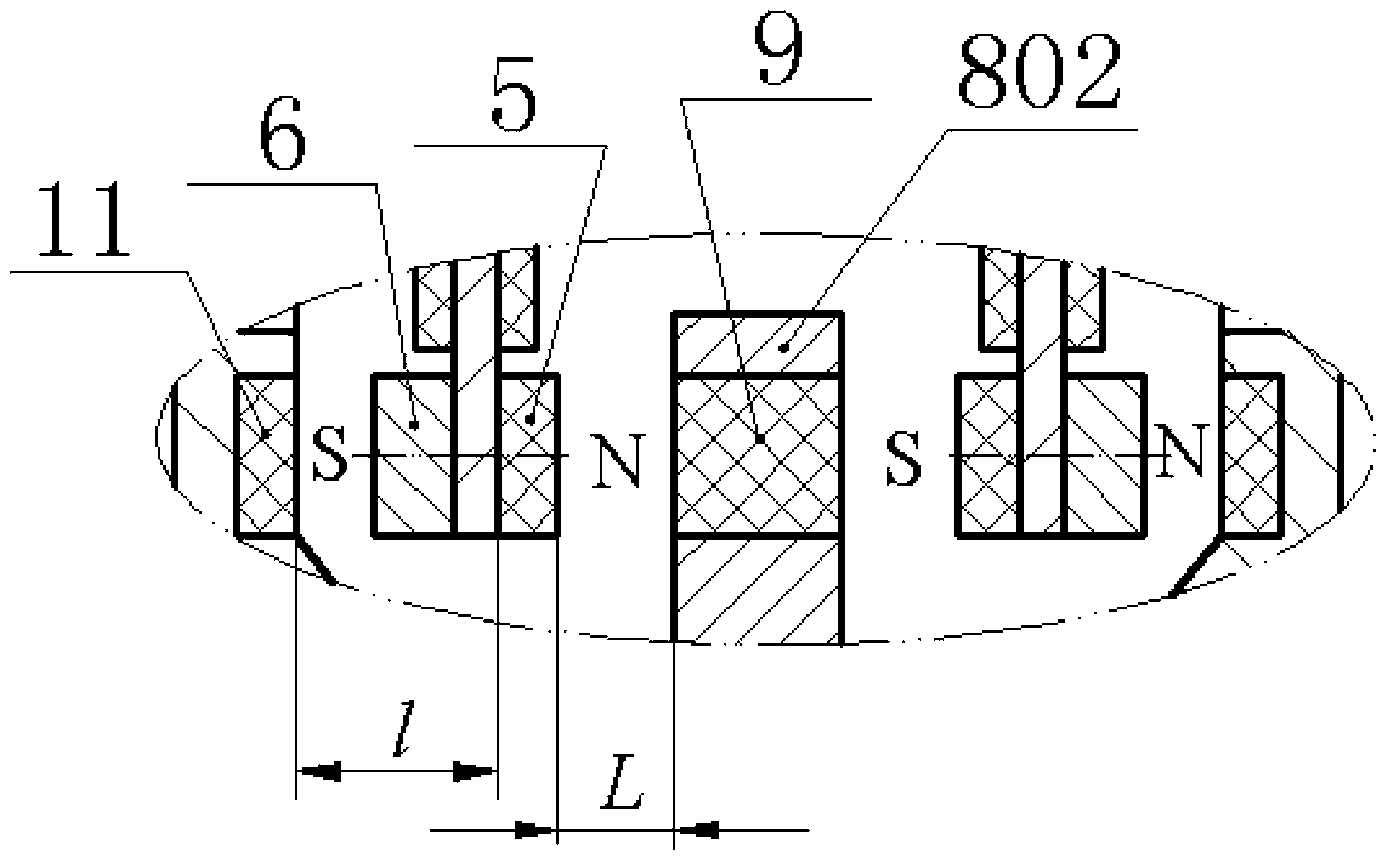

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS20050206260A1Dynamo-electric brakes/clutchesRotary stirring mixersElectric arc furnaceMagnetic rotation

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

Image forming apparatus

An image forming apparatus comprises: a main unit; and a developer cartridge detachably attached to the main unit. The developer cartridge comprises: a rotational body having a rotational axis and rotatable in a rotation direction; and an extended portion formed on the rotational body to extend along the rotational axis, the extended portion rotatable around the rotational axis. The main unit comprises: a driving unit configured to rotate the rotational body in the rotation direction; a detecting unit configured to detect a movement of the extended portion and an extending amount of the extended portion; and a determining unit configured to: determine whether the developer cartridge is a new product according to a presence of a movement of the extended portion detected by the detecting unit; and determine type of the developer cartridge based on the extending amount of the extended portion detected by the detecting unit.

Owner:BROTHER KOGYO KK

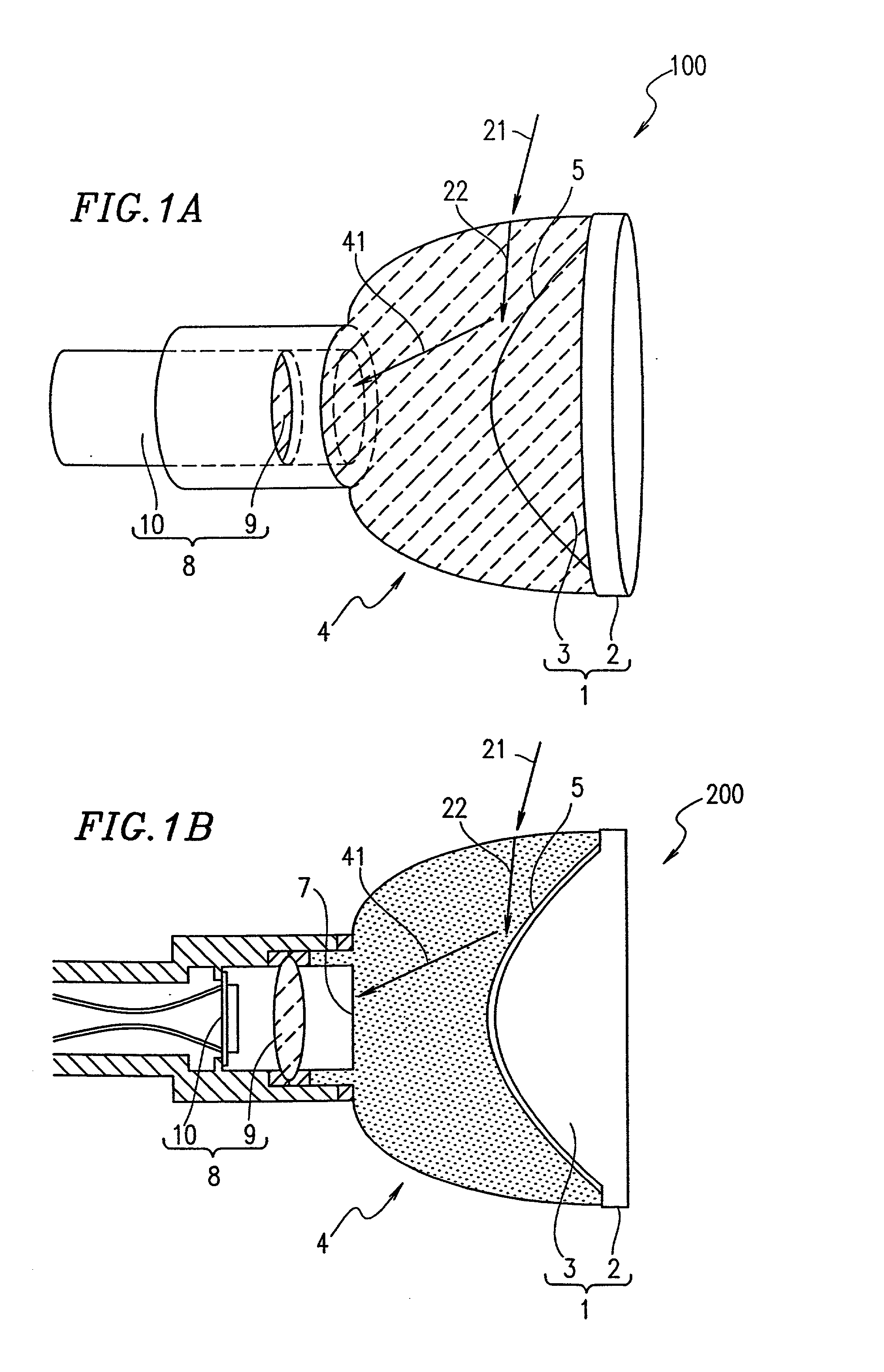

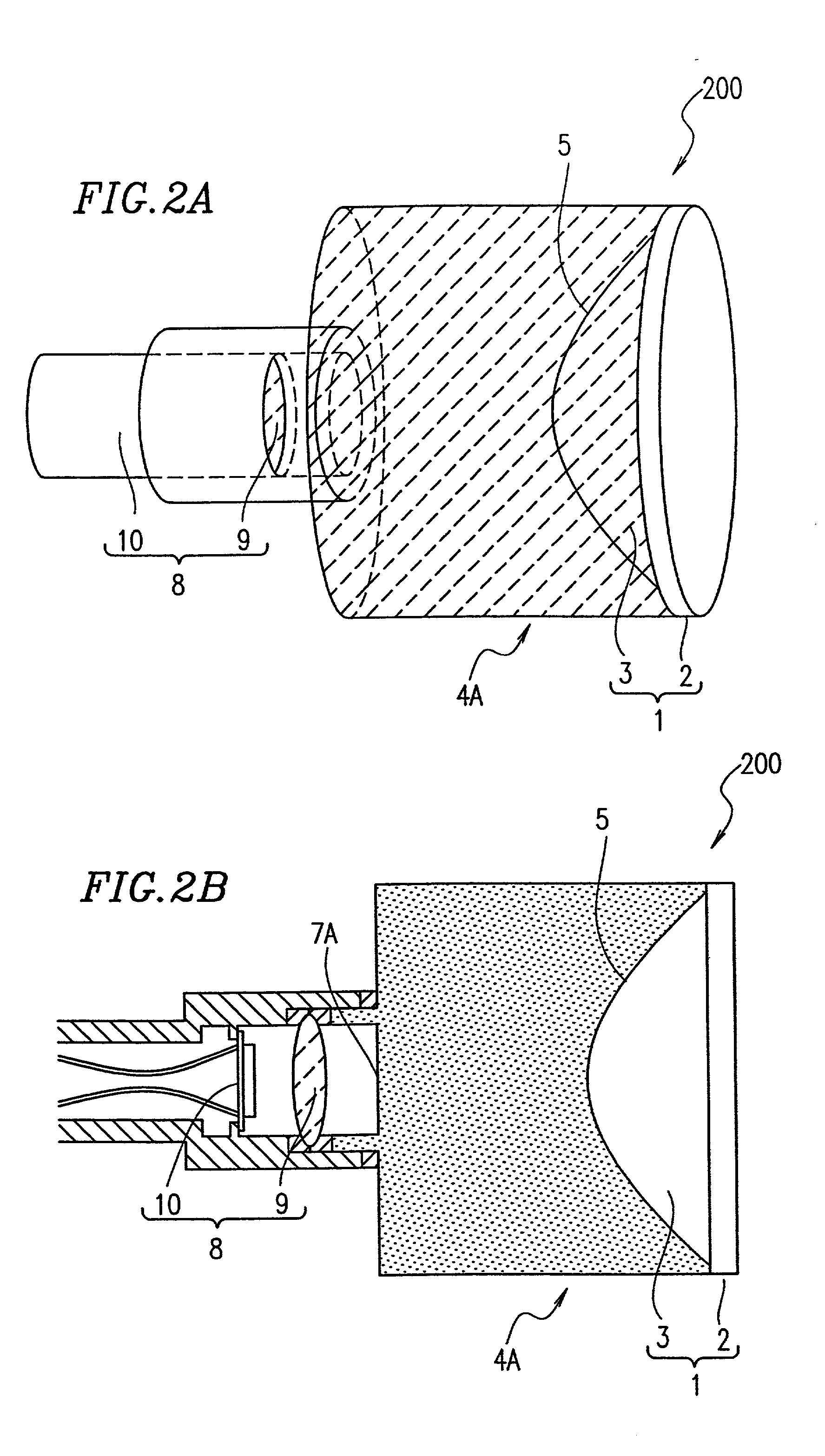

Imaging device and method for producing the same

InactiveUS20020109772A1Reduce component countReduce in quantityTelevision system detailsMirrorsClose contactOptics

An imaging device includes a convex mirror for reflecting incident light representing an object, the convex mirror having a shape of solid of revolution; an imaging mechanism for taking an image represented by reflected light from the convex mirror; and an optical member for guiding the incident light toward the convex mirror and guiding the reflected light toward the imaging mechanism, the optical member being in close-contact with the convex mirror.

Owner:SHARP KK

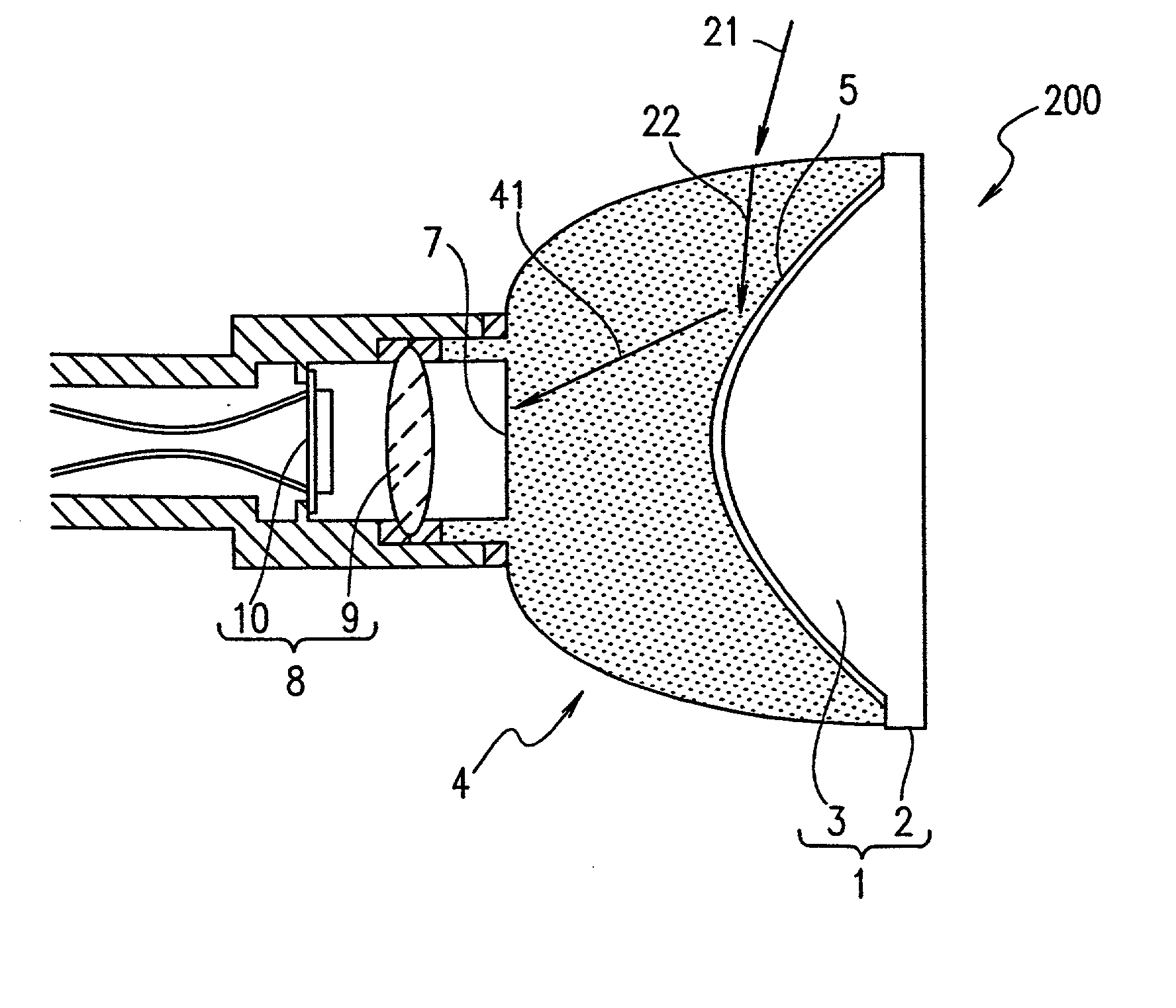

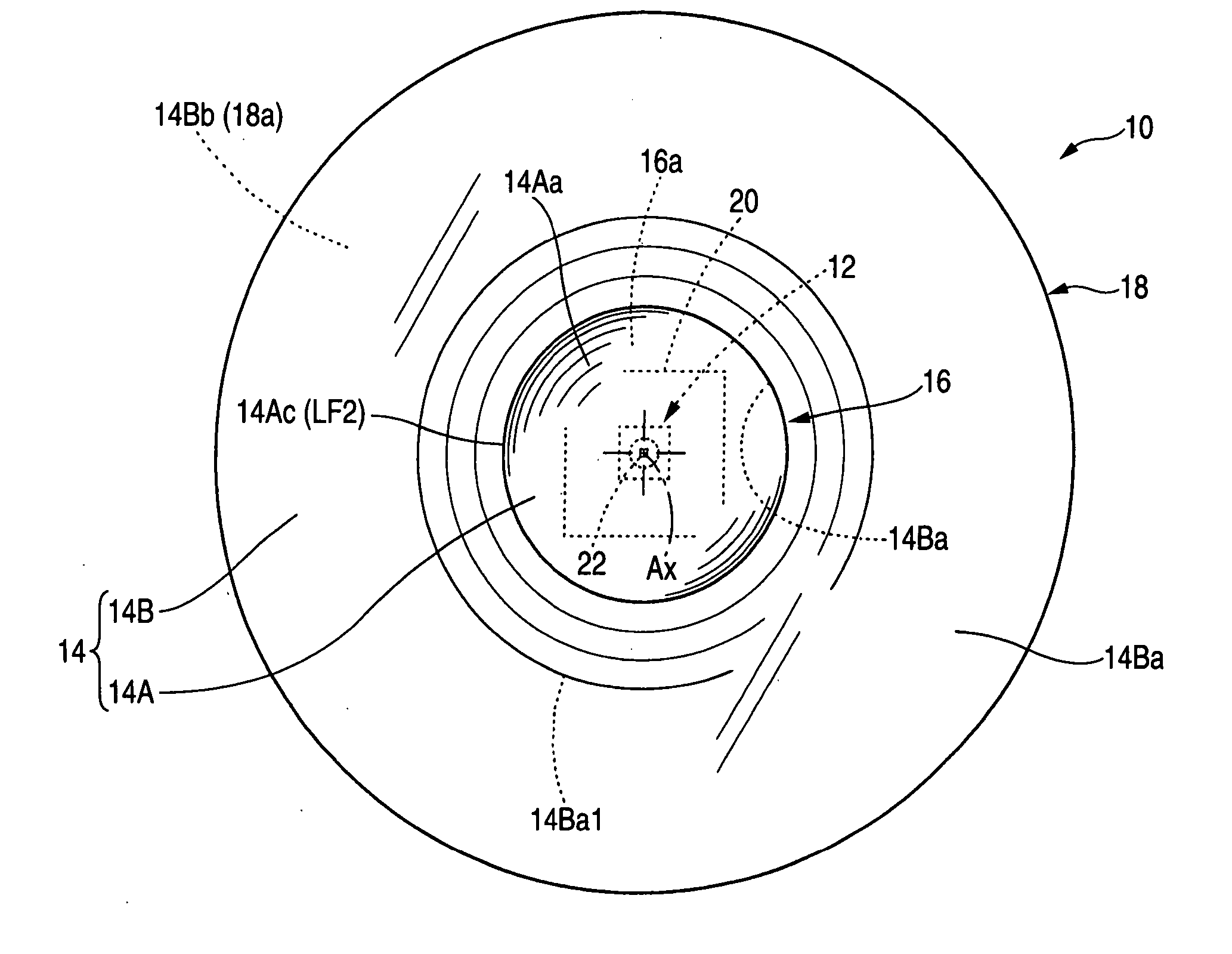

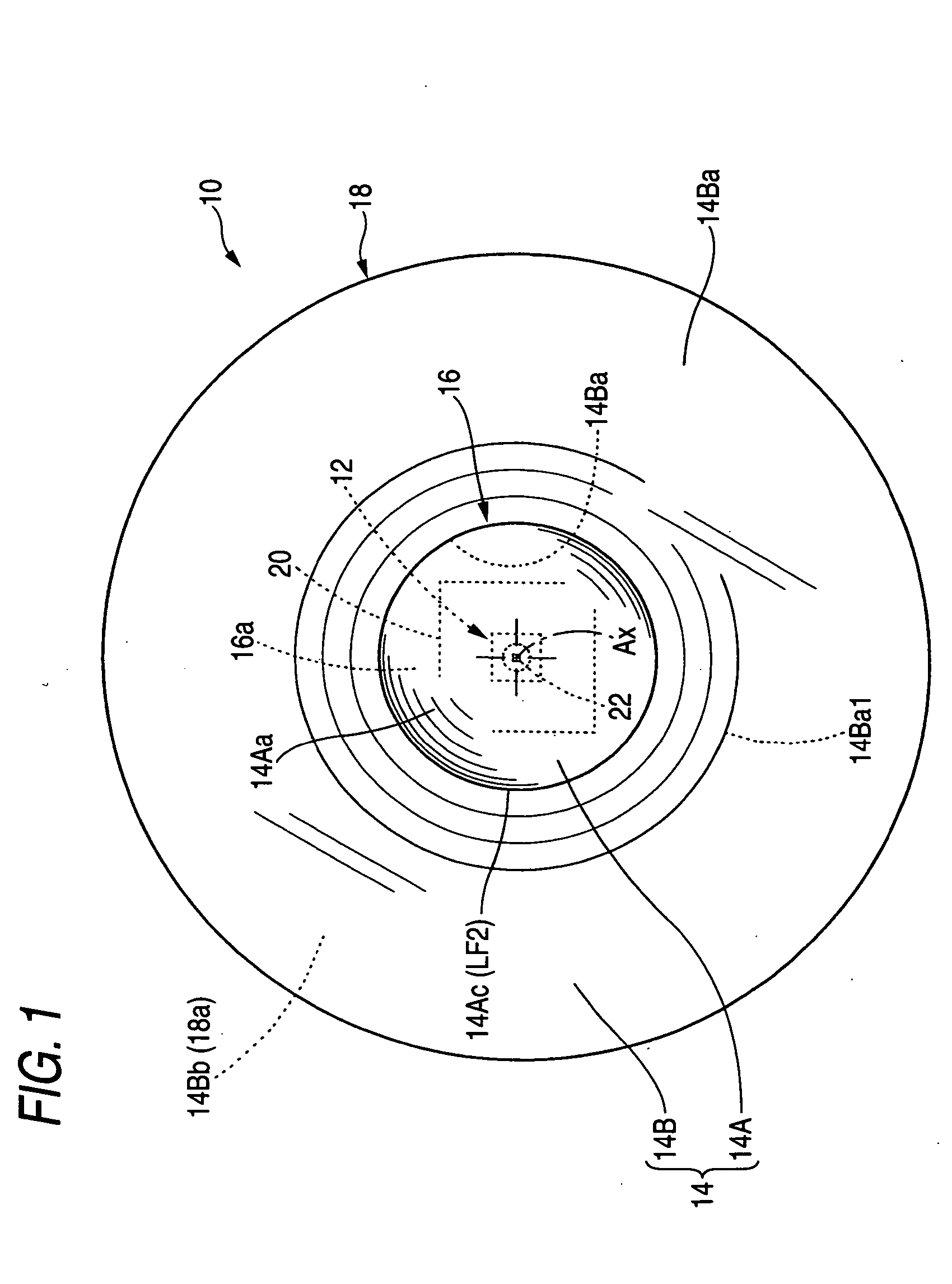

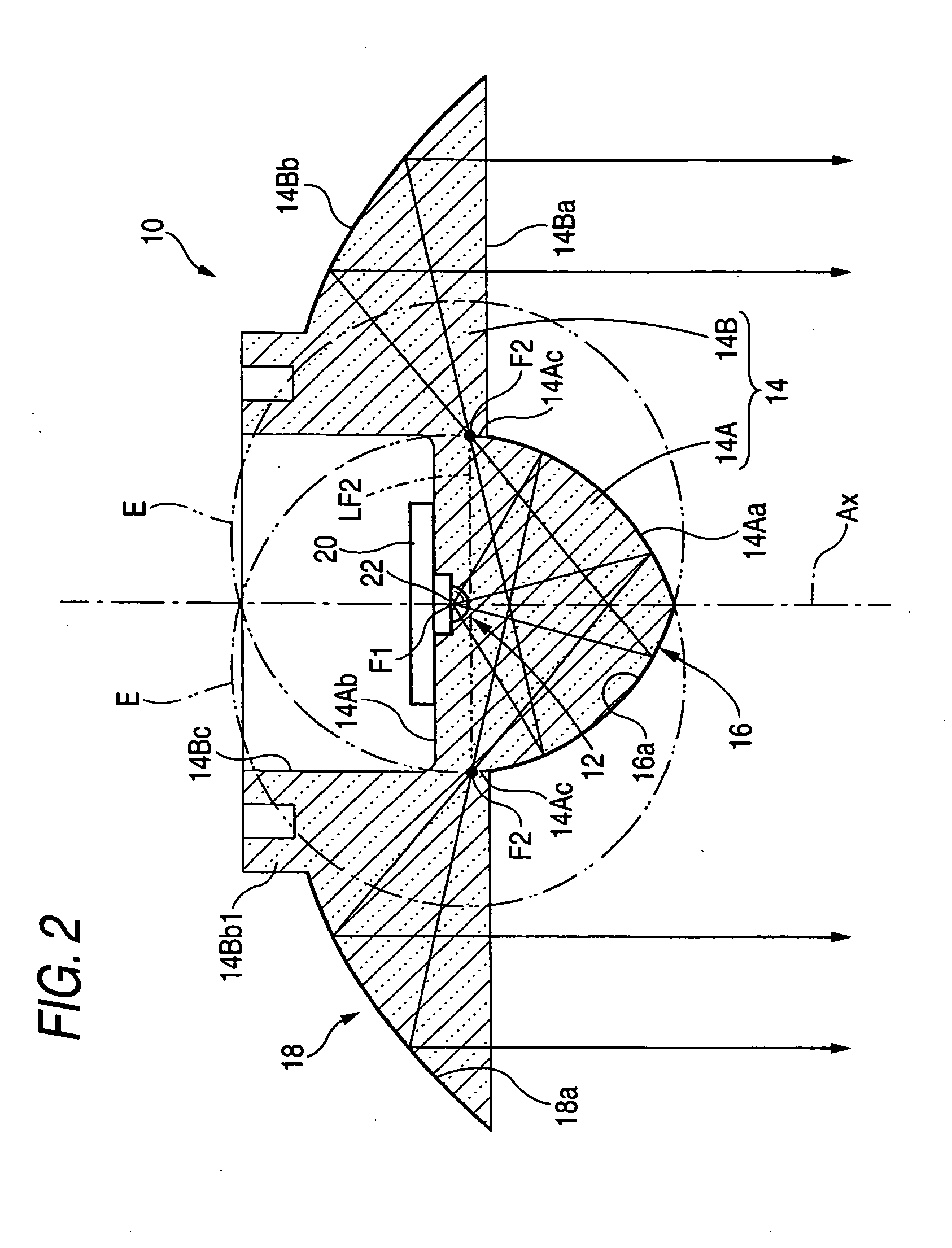

Vehicle lighting device

A vehicle light emitting device including a light emitting element, a primary reflector, and a secondary reflector. A reflecting surface of the primary reflector has a shape of a substantially dome-shaped body of revolution formed by rotating about the optical axis Ax an ellipse E which has a primary focal point F1 which is a point near the light emitting element and a secondary focal point F2 which is a point near the reflecting surface. The primary reflector includes a belt-shaped region, which straddles a ring-shaped locus of the secondary focal point F2 and is configured as a light translucent portion, whereby reflected light from the primary reflector is caused to temporarily converge on the secondary focal point F2 in each cross-section of the body of revolution including the optical axis Ax and is thereafter caused to be incident on the secondary reflector as a diffused light.

Owner:KOITO MFG CO LTD

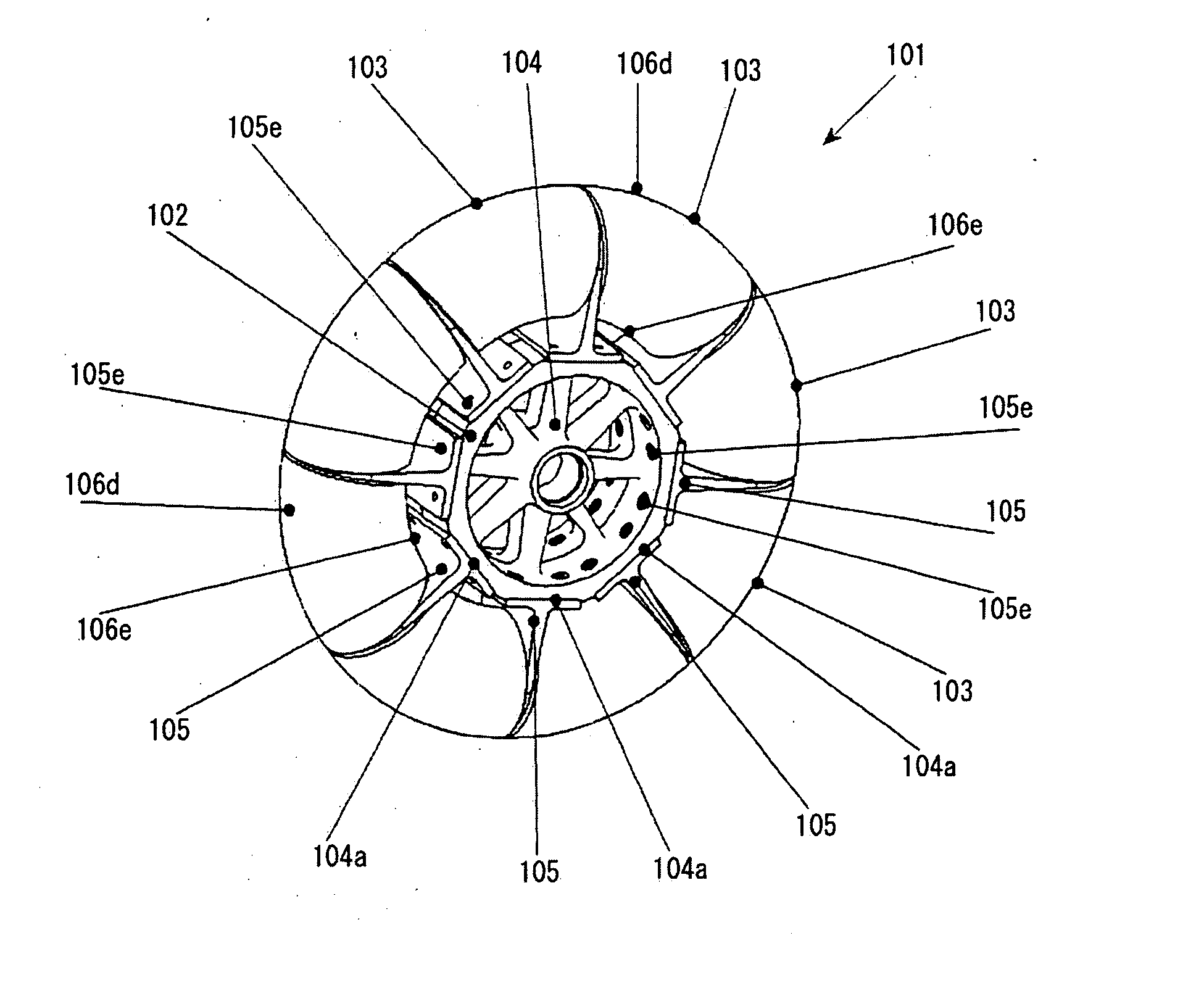

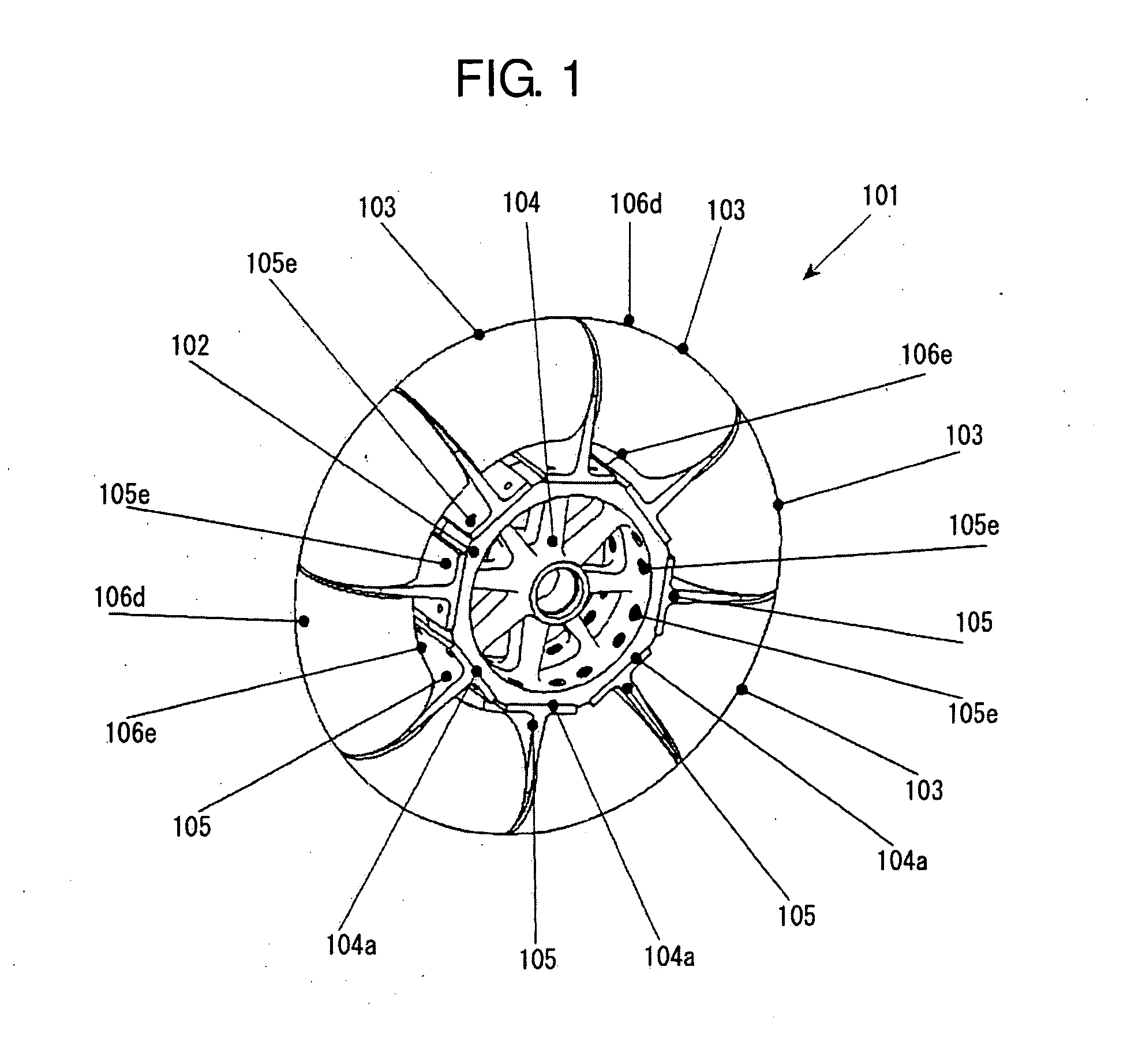

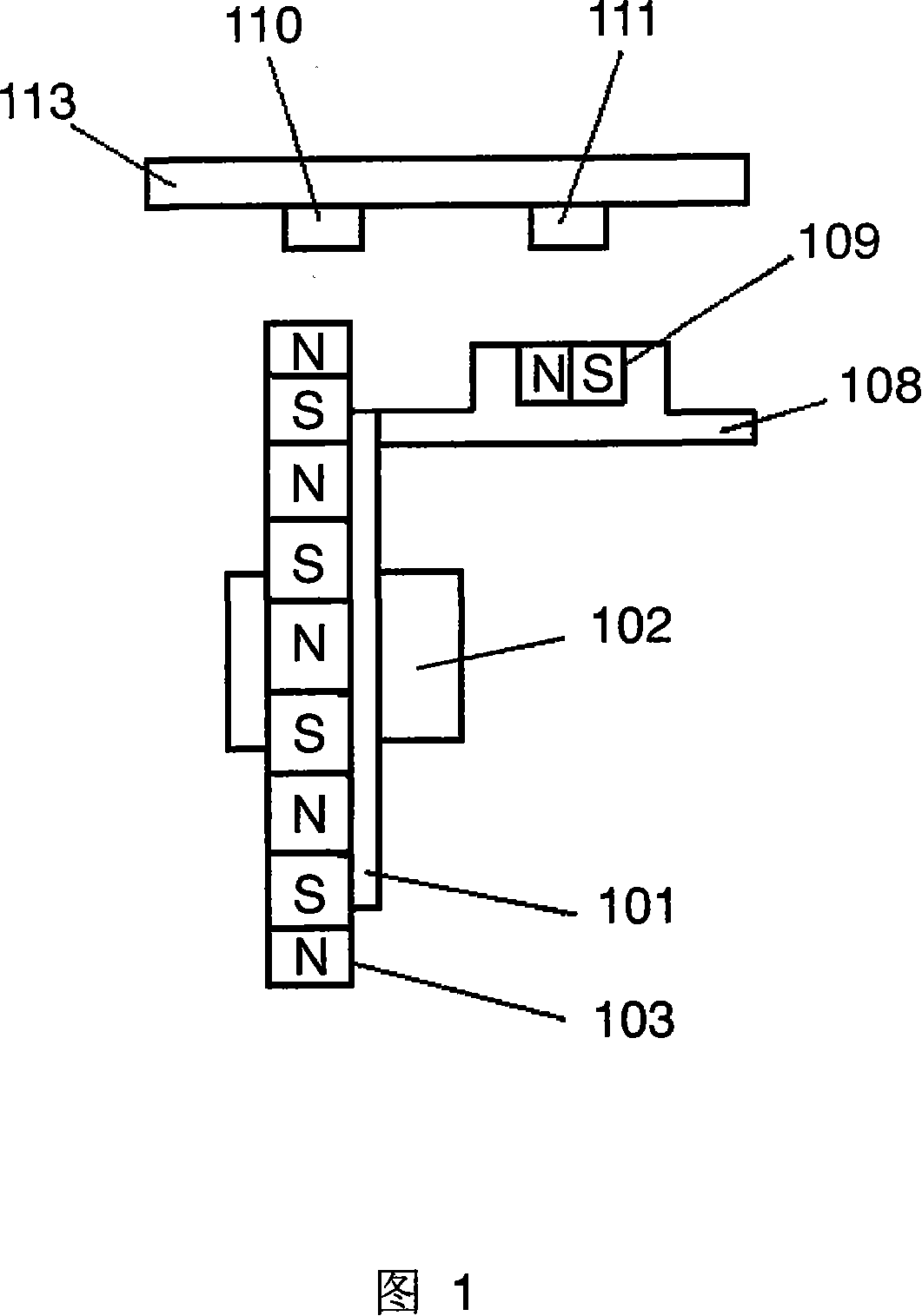

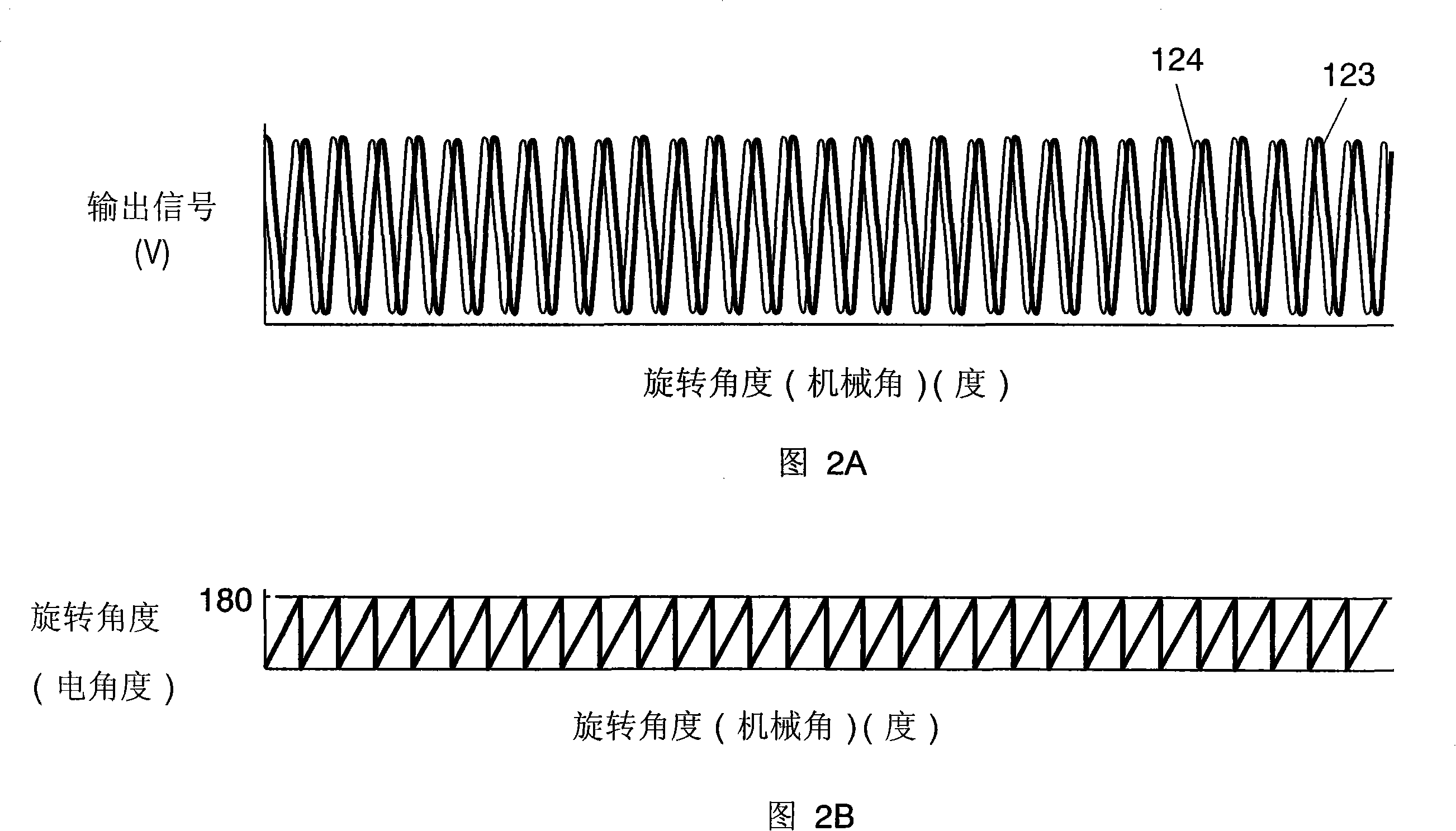

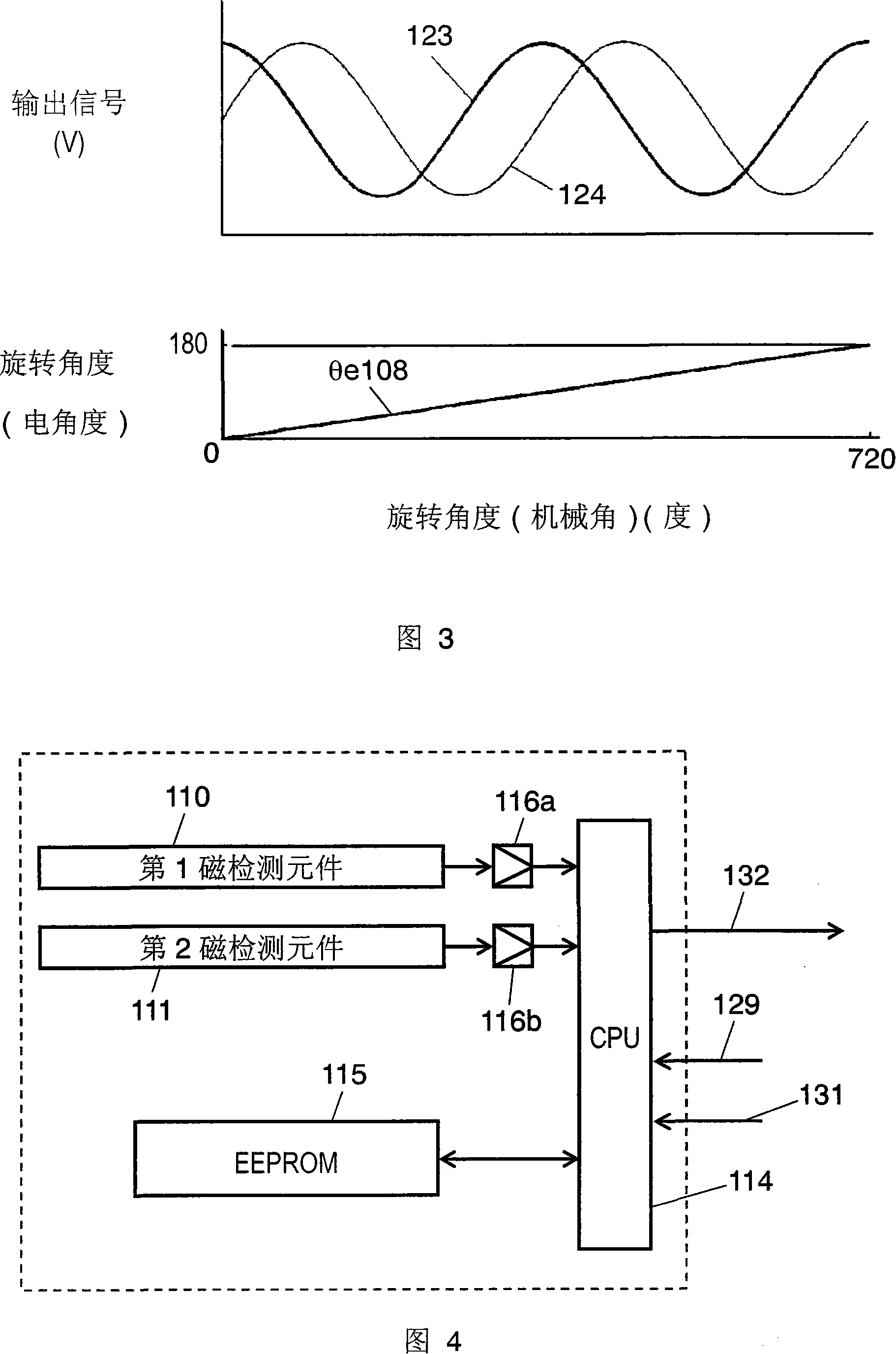

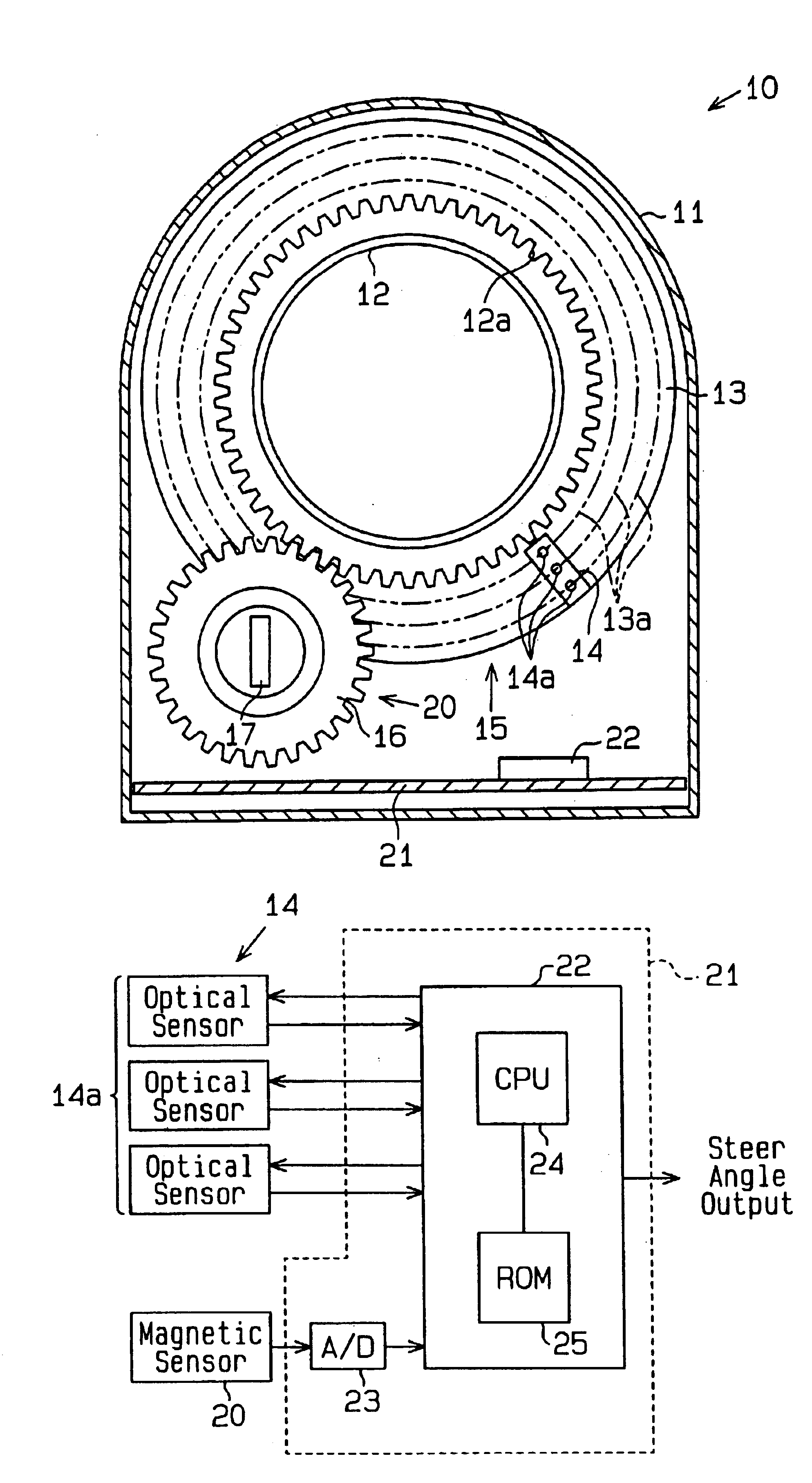

Rotation angle detection device and rotation angle correction method

InactiveCN101115968AHigh resolutionHigh precisionUsing electrical meansElectrical steeringRotational axisLow speed

There is provided a device for detecting an absolute rotation angle of multi-rotation with high accuracy and high resolution by using a target connected to the rotation angle and having an outer circumference to which magnetic poles of alternate polarities are magnetized. The device includes: a first rotor (101) holding the target (103) connected to an input axis (102) and having an outer circumference to which magnetic poles of alternate polarities are magnetized at an identical interval and having multi-rotatable gear; a second rotor (108) connected tot he gear of the first rotor (101), rotated at a low speed by the first rotor (101), and having a magnet (109) at the center portion; a first detection unit (110) and a second detection unit (111) for detecting the rotation angles of them. With a simple configuration, it is possible to detect an absolution rotation angle with a high accuracy and a high resolution.

Owner:PANASONIC CORP

Laminar air turbine

InactiveUS20060002786A1Low costMaximize rotational forceWind motor controlPump componentsWind drivenTurbine wheel

The windmill assembly is a low drag, streamlined body of revolution that captures the kinetic energy content of the accelerated laminar air surrounding the body. The assembly includes a power-generating, wind-driven turbine that is compact, lightweight and capable of producing a substantially greater output than a conventional windmill with a comparable size rotor. The turbine includes a protruding aerodynamic nose and outer cowling that provide a streamlined, wind-collecting inlet section that constricts the incoming air stream and increases its velocity through the turbine blades. The turbine further includes an exit section designed to exhaust the air stream with a minimum of turbulence. One or more generators are coupled to a turbine wheel, and are electrically switched on and off to maximize the energy capture over the full range of ambient winds. The wind turbine assembly may be configured around a blimp-type body having counter-rotating turbine assemblies.

Owner:RICHTER DONALD L

Fixing device and image forming apparatus incorporating same

A fixing device includes a heating device to heat an endless rotary body with radiant heat, a power source to supply power to the heating device, a first heat source to heat a region on the endless rotary body corresponding to a width of the small size sheet, and a second heat source to heat regions on the endless rotary body corresponding to both widthwise ends of the large size sheet outside the width of the small size sheet. The power source supplies power only to the first heat source when the small size sheet is printed and to both the first and second heat sources when the large size sheet is printed. The power source supplies more power to the first heat source when the small size sheet is printed than when the large size sheet is printed within a maximum power available to the fixing device.

Owner:RICOH KK

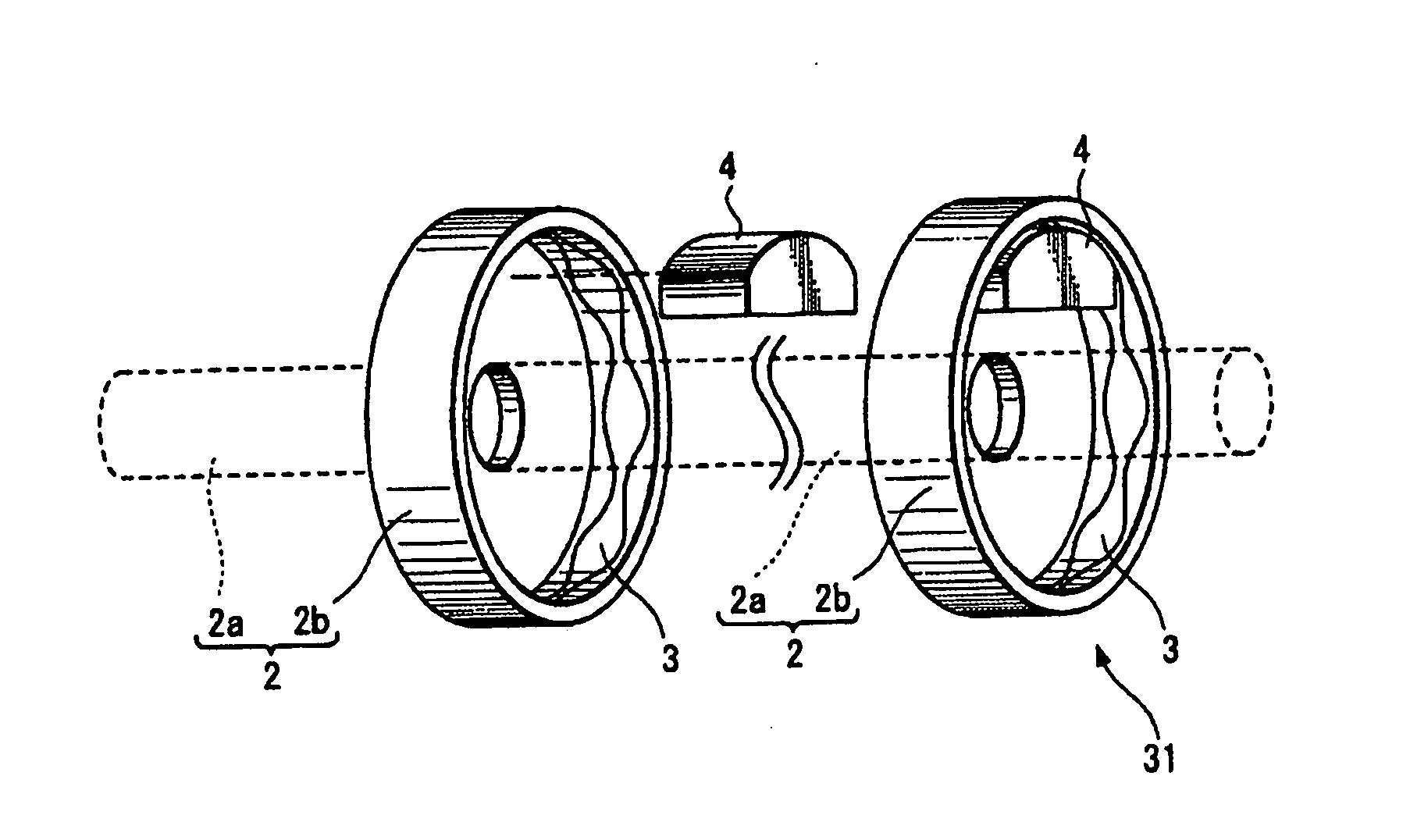

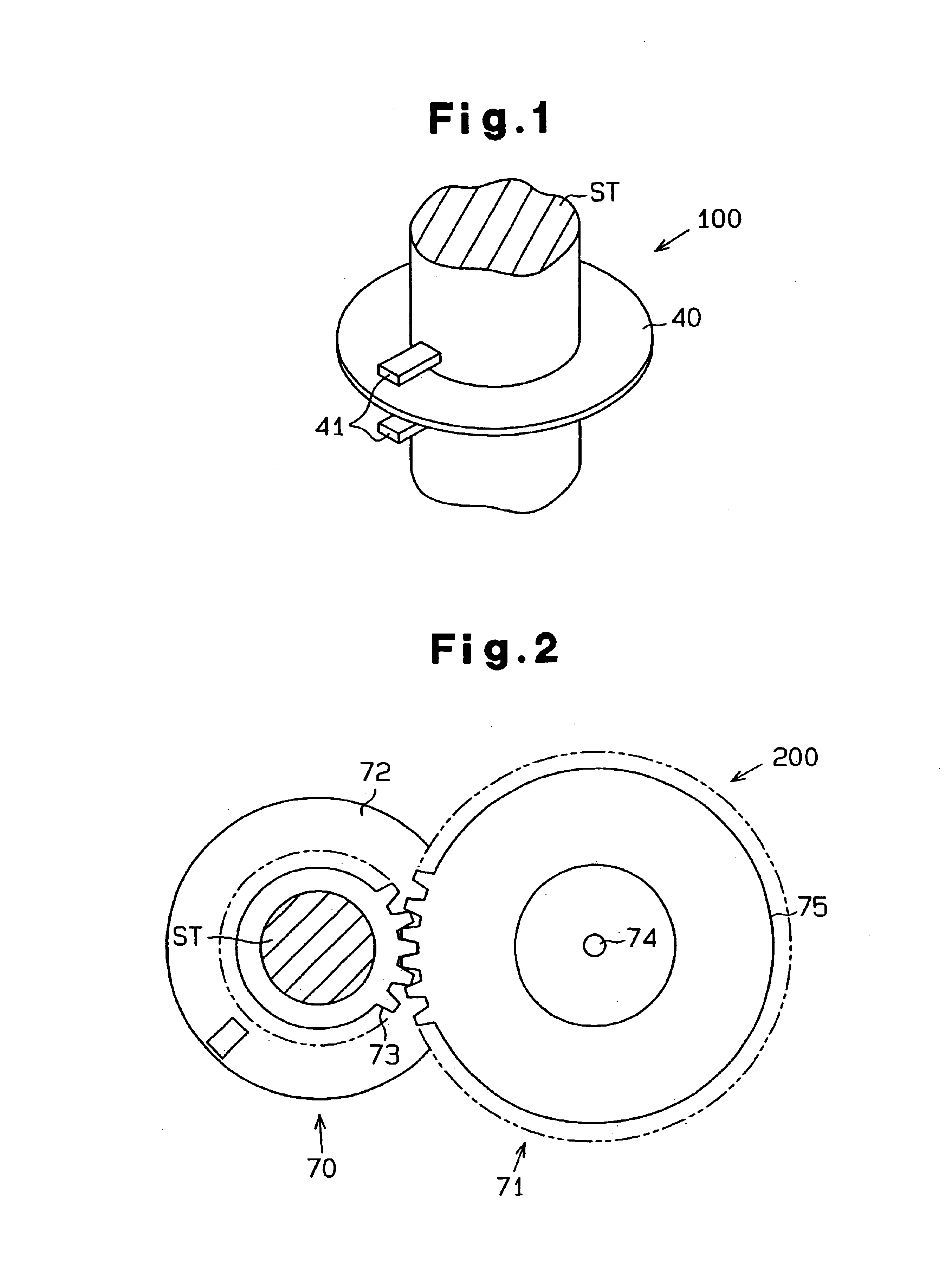

Rotation angle detector

InactiveUS6848187B2Reduced space required for installationImprove accuracyConverting sensor output electrically/magneticallyIncline measurementAbsolute rotationSolid of revolution

A rotation angle detector that is able to detect an absolute rotation angle of a detection body accurately and is able to reduce the installation space required. The rotation angle detector includes a first rotation angle detector connected to the detection body for generating a first detection signal having a cycle corresponding to the rotation of the detection body. The first rotation angle detector includes a first rotating body which is connected to the detection body and rotates together with the detection body. The detector includes a second rotation angle detector connected to the first rotation angle detector. The second rotation angle detector includes a second rotating body that rotates together with the first rotating body at a rate greater than that of the first rotating body, and generates a second detection signal having a cycle corresponding to the rotation of the second rotation body. The control device detects an absolute rotation angle of the detection body in accordance with the first detection signal and the second detection signal.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

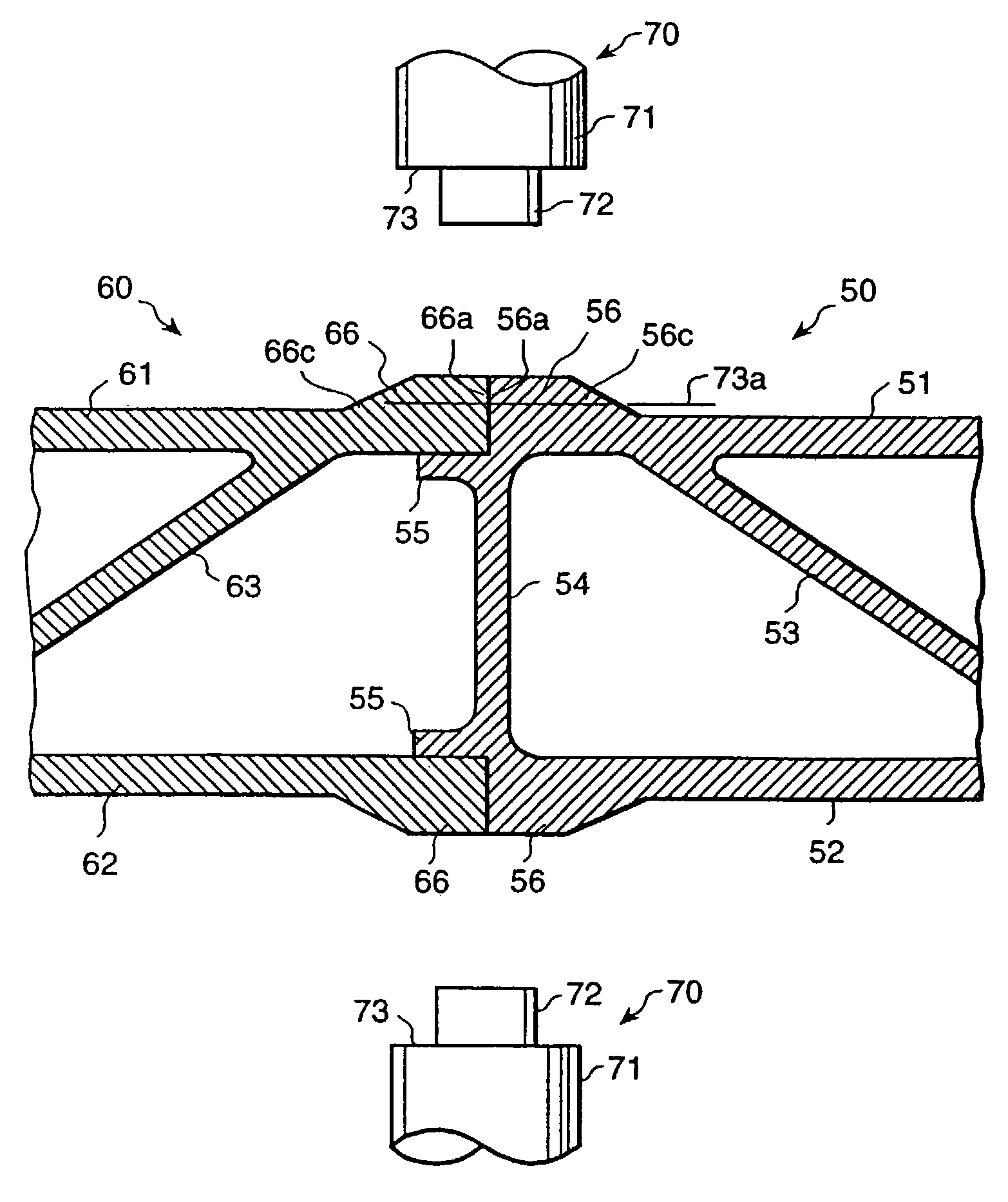

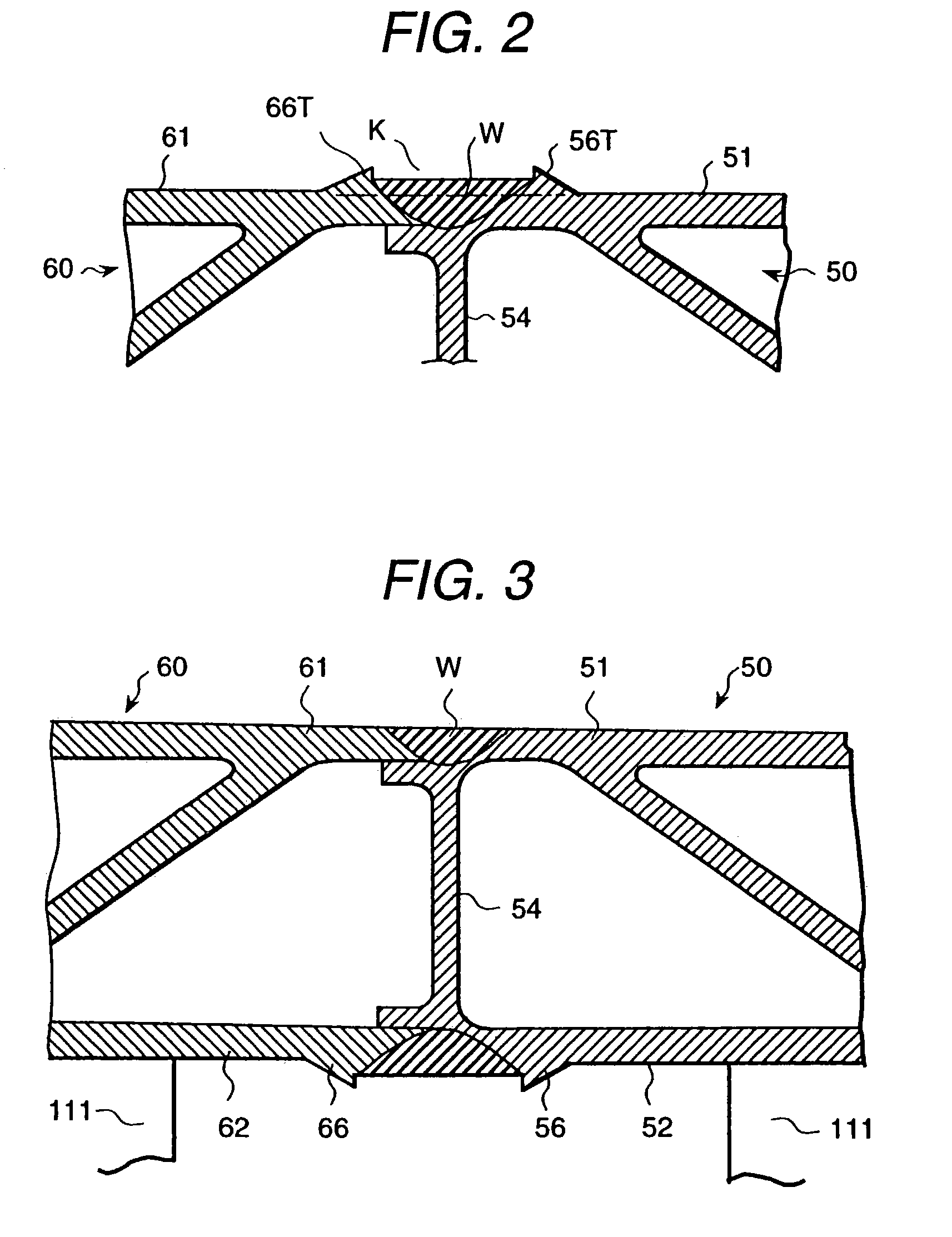

Friction stir welding method, frame members used therein, and product formed thereby

InactiveUS7036707B2High resultEasy to deleteWelding/cutting auxillary devicesStructural elementsEngineeringFriction stir welding

Disclosed is a friction stir welding technique which avoids occurrence of a dent, in a joining region, extending to a level beneath the joined surfaces. At end portions of the frame members to be joined, at the joining region, thickened parts which project toward the rotary body joining tool are provided. Two adjoining thickened parts, of adjacent members to be joined, can form a trapezoid shape. The rotary body joining tool has a small-diameter tip portion and a larger diameter portion. The rotary body joining tool is inserted in the thickened parts. In a state where the rotary body joining tool has been inserted small-diameter tip end first, to a level where the larger diameter portion of the rotary body joining tool overlaps the thickened part but does not extend below the upper surface of the non-thickened surfaces of the members joined, the rotary body is rotated and moved along the joining region. Even when a gap exists between two thickened parts, a desirable joining can be carried out. After the joining, the remaining parts of the thickened parts can be machined so as to form a smooth surface.

Owner:HITACHI LTD

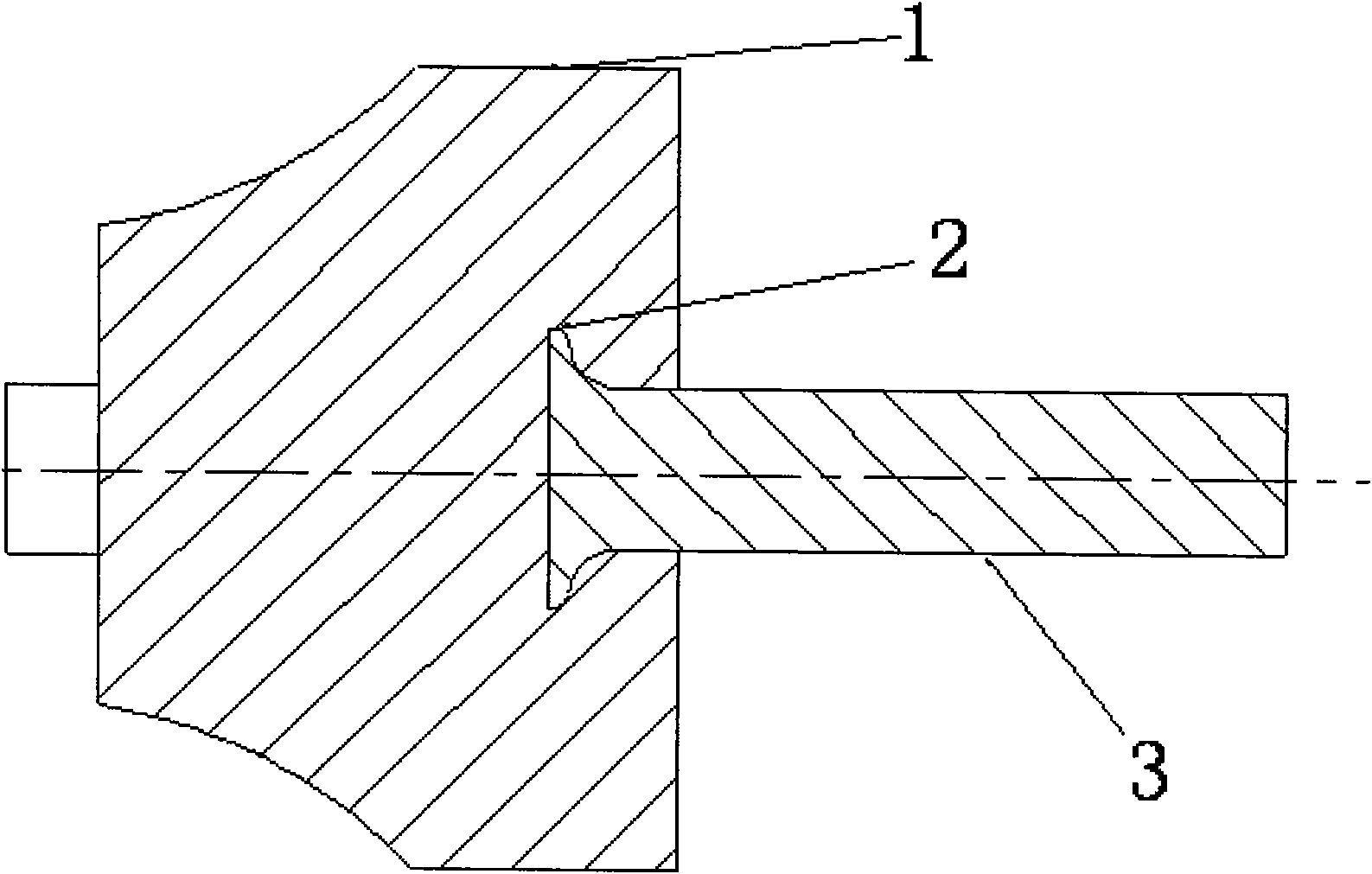

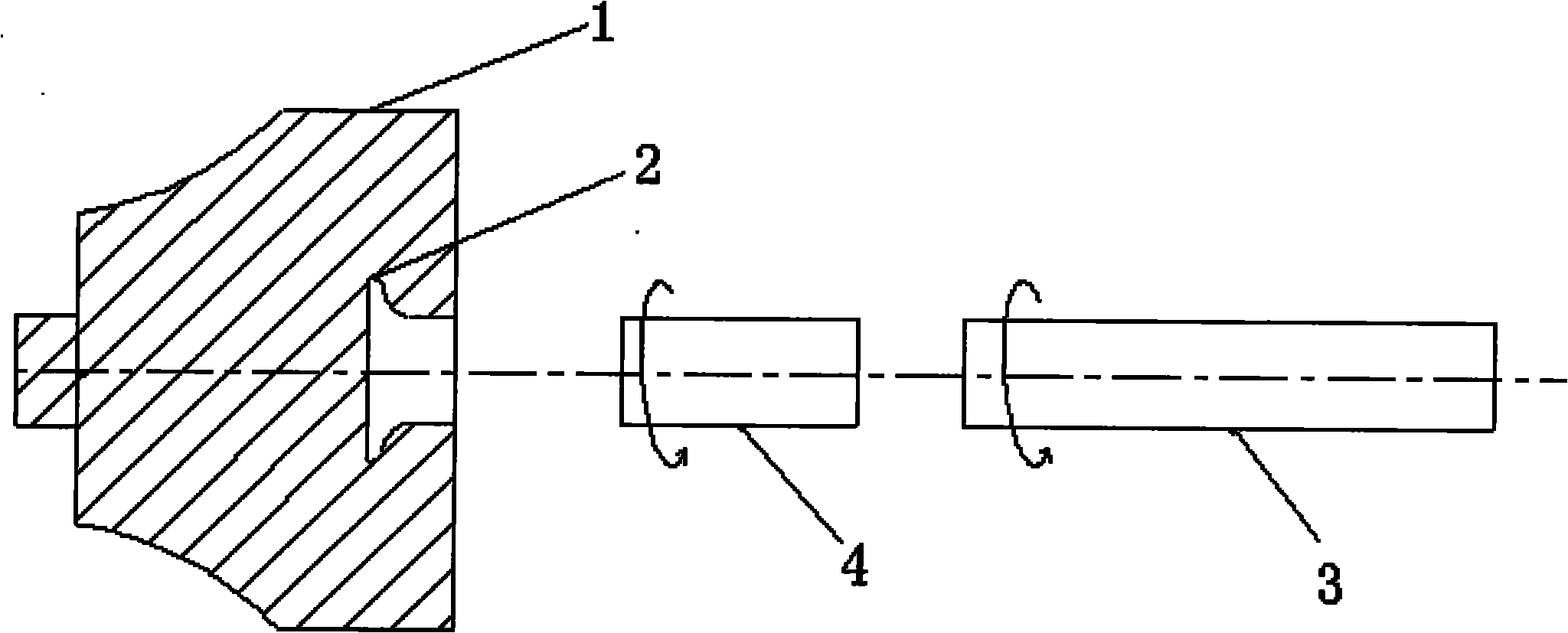

Friction welding method of titanium-aluminum alloy turbine and 42CrMo quenched and tempered steel shaft

InactiveCN101844271AHigh tensile strength at room temperatureAchieve associativityNon-electric welding apparatusFriction weldingDual effect

The invention discloses a friction welding method of a titanium-aluminum alloy turbine and a 42CrMo quenched and tempered steel shaft, which aims to solve the technical problem that when the titanium-aluminum alloy turbine rotor and the quenched and tempered steel shaft are connected by the current method, the tensile strength of a joint is low. The invention has the technical scheme that an embedded groove in a shape of a solid of revolution is processed at one side of the titanium-aluminum alloy turbine; in the welding process, the welding end surface of the turbine shaft has friction with the welding surface of the embedded groove of the titanium-aluminum alloy turbine; and by controlling the friction shortening amount, the casting fins formed at the turbine shaft side are fully filled into the embedded groove. Thus dual effects of metallurgical bonding and mechanical connection of the welding surface are achieved, and the tensile strength of the joint of connecting pieces at room temperature is increased from 390MPa in the background art to 480-537MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Shaft-end overhung piezoelectric cantilever beam electric generator

InactiveCN103259452AEffect of small axial bending deformationImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesNew energyEngineering

The invention relates to a shaft-end overhung piezoelectric cantilever beam electric generator, and belongs to the technical field of new energy resources and power generation. A left end cover and a right end cover are respectively installed at two ends of a shell body through screws. A semi-annular balancing weight is installed on the lower side of the interior of the shell body through a screw. The upper portion of the left end cover and the upper portion of the right end cover are respectively provided with a lightening hole. A magnet I and a bearing are embedded in the inner side of the bottom wall of the left end cover. A magnet I and a bearing are embedded in the inner side of bottom wall of the right end cover. A piezoelectric vibrator is arranged between the left end cover and the shell body in a compression joint mode. A piezoelectric vibrator is arranged between the right end cover and the shell body in a compression joint mode. A magnet II and a frequency-modulation mass block are installed at the free end of each piezoelectric vibrator. A rotating shaft of a rotor is installed on the left end cover and the right end cover through bearings. A connecting disc is installed at one end of the rotating shaft through a nut. A magnet III is embedded in a rotating disc of the rotor. The shaft-end overhung piezoelectric cantilever beam electric generator has the advantages that the piezoelectric vibrators are motivated for electric generation and external fixing and supporting are not needed; the shaft-end overhung piezoelectric cantilever beam electric generator is an integrated type individual component, so that the structure of a rotating body does not need to be changed, and the shaft-end overhung piezoelectric cantilever beam electric generator is convenient to install and maintain; the shaft-end overhung piezoelectric cantilever beam electric generator is high in reliability, strong in power generation capacity, and wide in velocity zone.

Owner:ZHEJIANG NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com