Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

906 results about "Traveling-wave tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A traveling-wave tube (TWT, pronounced "twit") or traveling-wave tube amplifier (TWTA, pronounced "tweeta") is a specialized vacuum tube that is used in electronics to amplify radio frequency (RF) signals in the microwave range. The TWT belongs to a category of "linear beam" tubes, such as the klystron, in which the radio wave is amplified by absorbing power from a beam of electrons as it passes down the tube. Although there are various types of TWT, two major categories are...

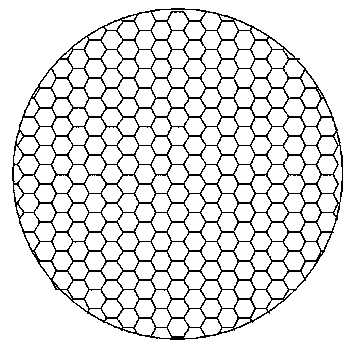

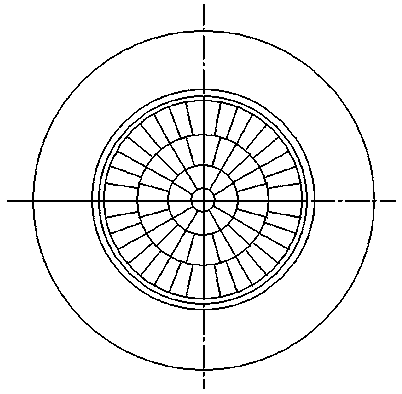

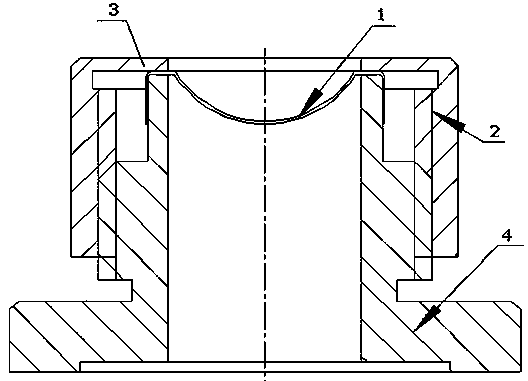

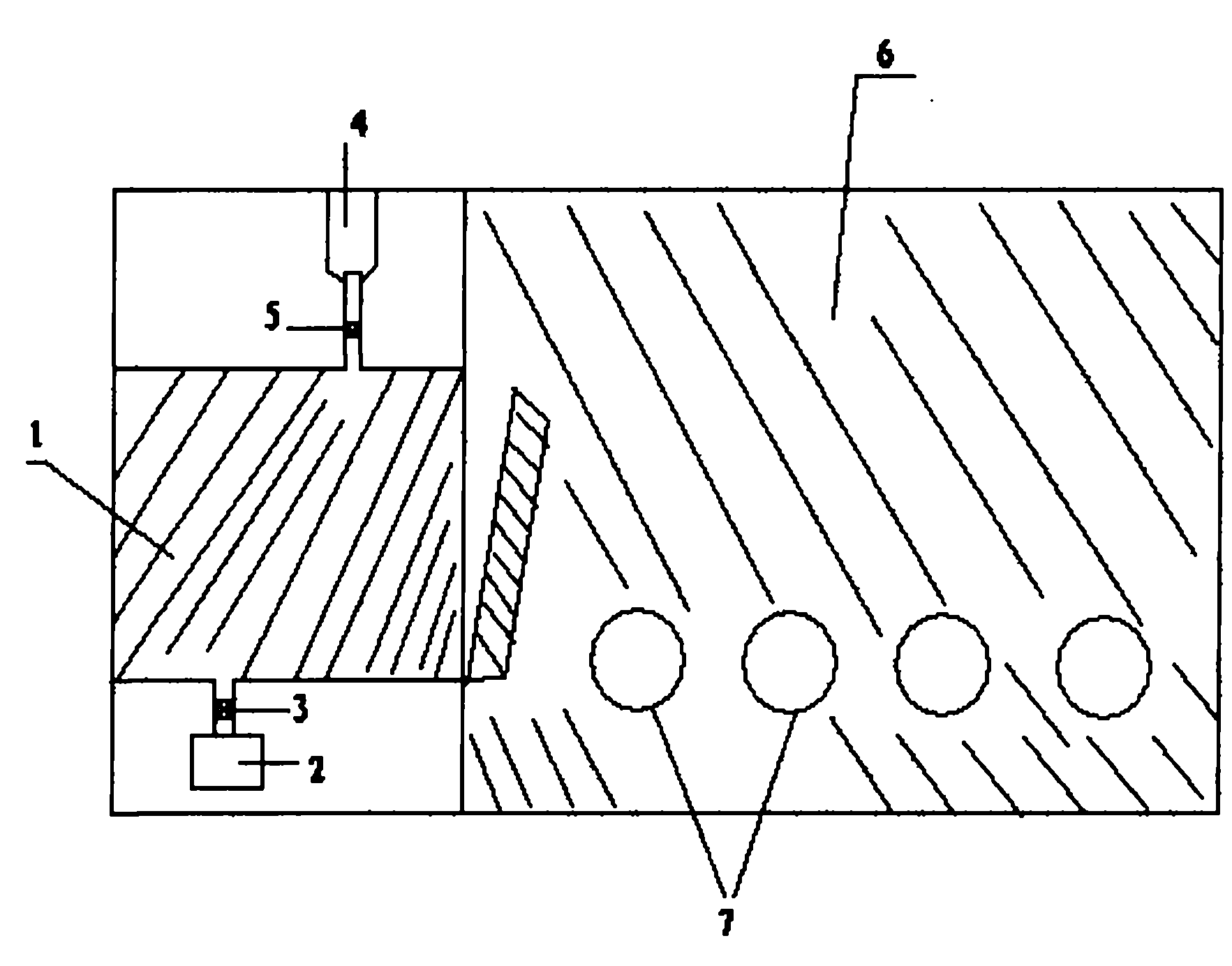

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

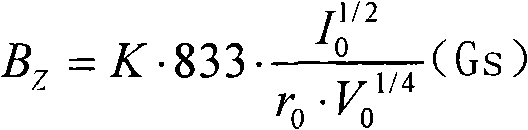

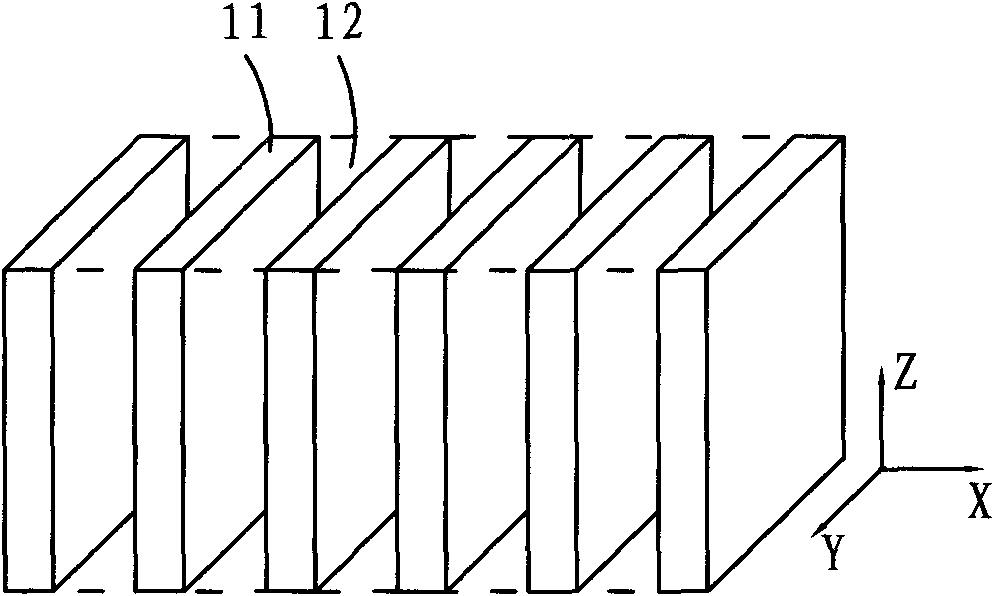

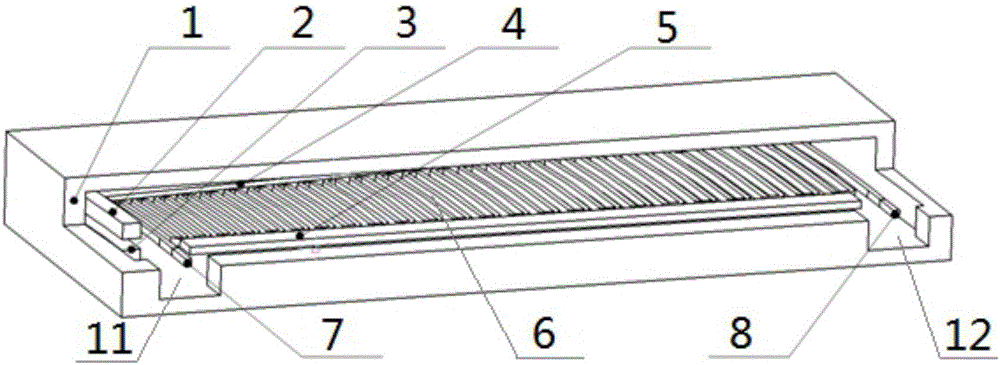

Traveling-Wave Tube 2D Slow Wave Circuit

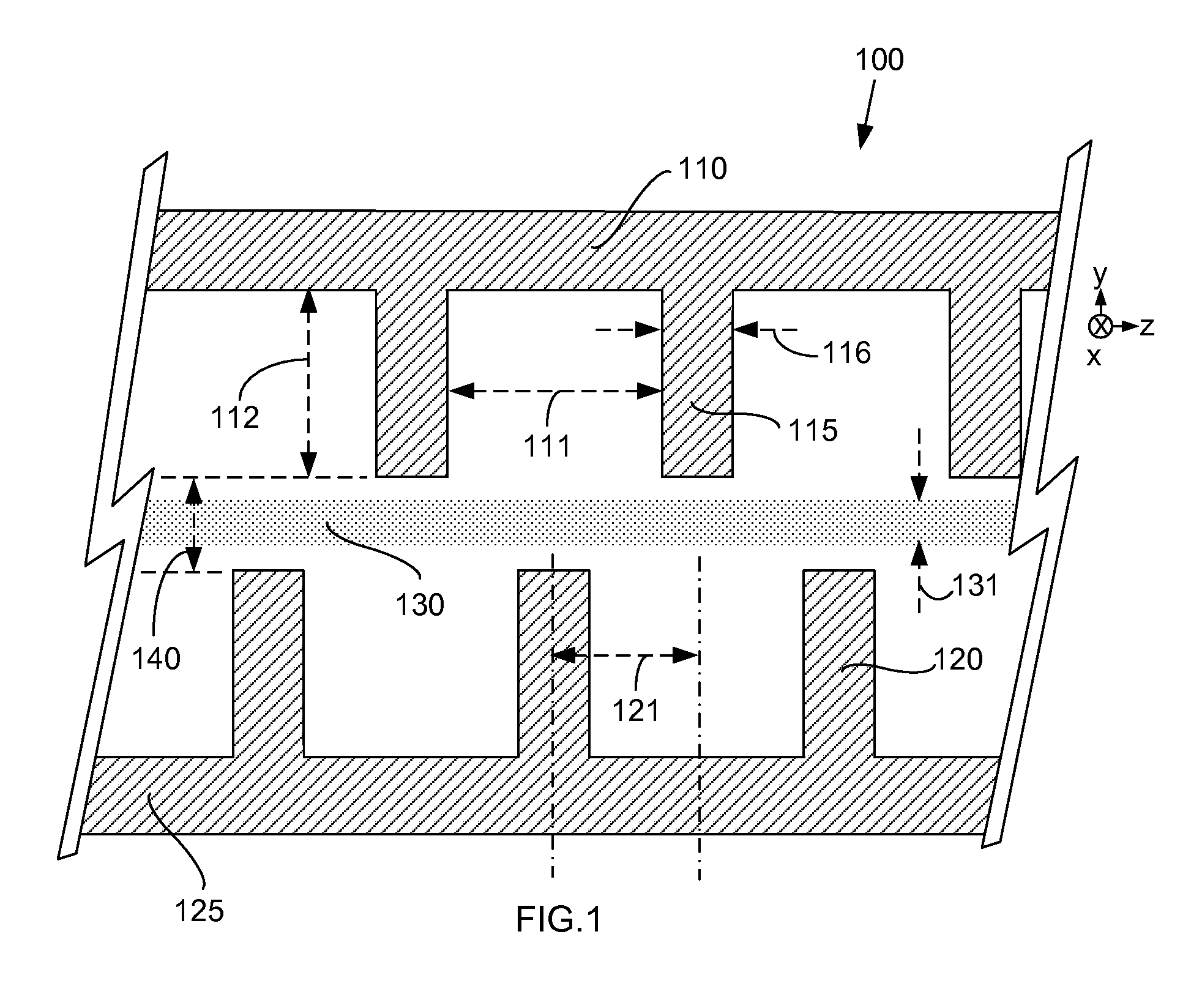

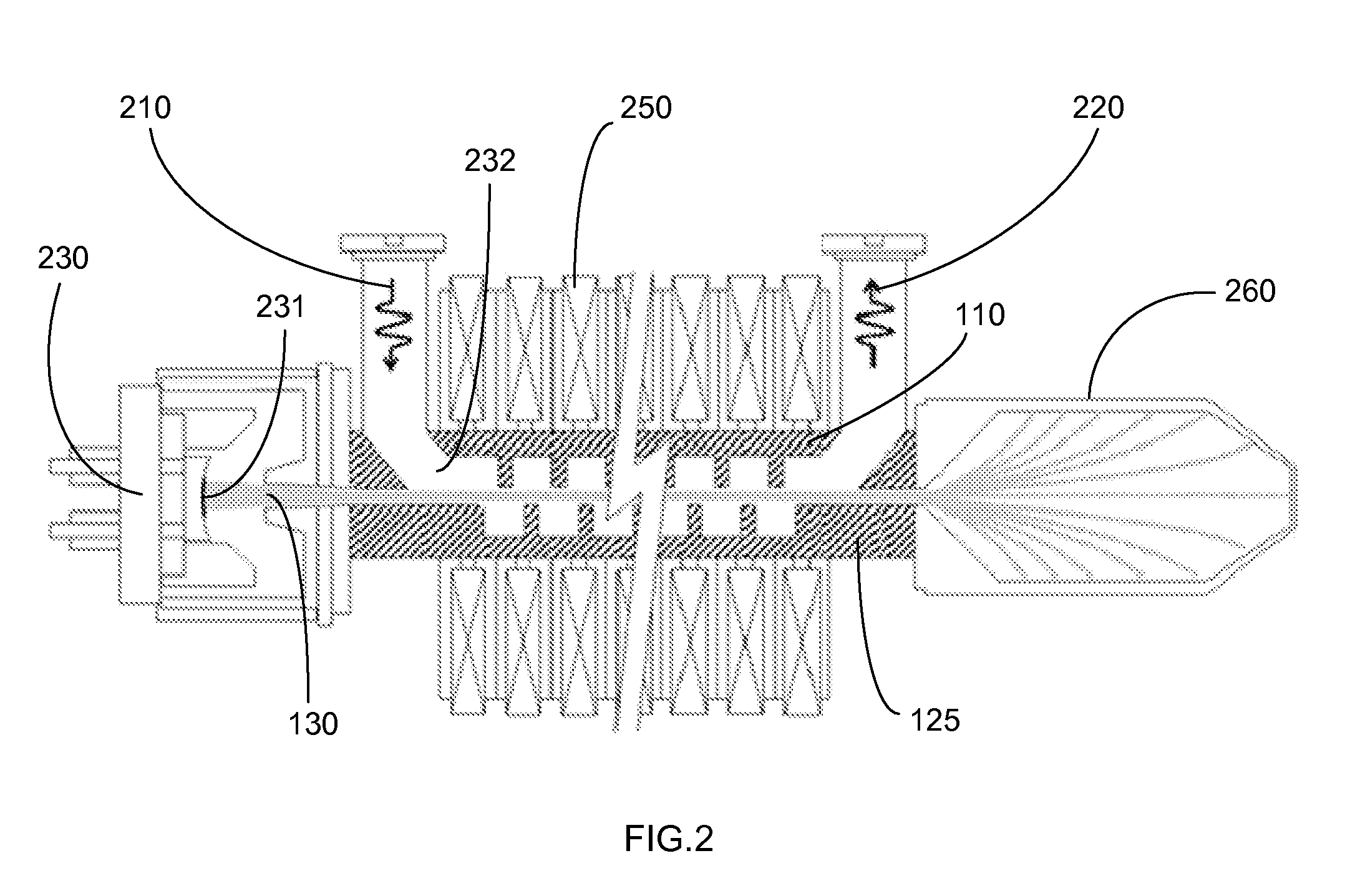

InactiveUS20090096378A1Wider instantaneous bandwidth capabilityEnhanced interactionTravelling-wave tubesTransit-tube circuit elementsAudio power amplifierSolid body

A two-dimensional circuit for a traveling-wave tube for millimeter and sub-millimeter electromagnetic waves synchronously interacts with an electron beam in a vacuum electronic microwave amplifier or oscillator. The circuit is a solid body having a length along the tube axis. The solid body has an electrically conductive top section and an electrically conductive bottom section. The top section is configured with a plurality of vertical vanes having a width and height and configured parallel to each other. The bottom section is similarly configured such that when the circuit is viewed in cross section along the length, the vanes on the bottom section are staggered with respect to the vanes on the top section. The top section and the bottom section are separated from each other to define a tunnel through the solid body along the length.

Owner:BARNETT LARRY R +1

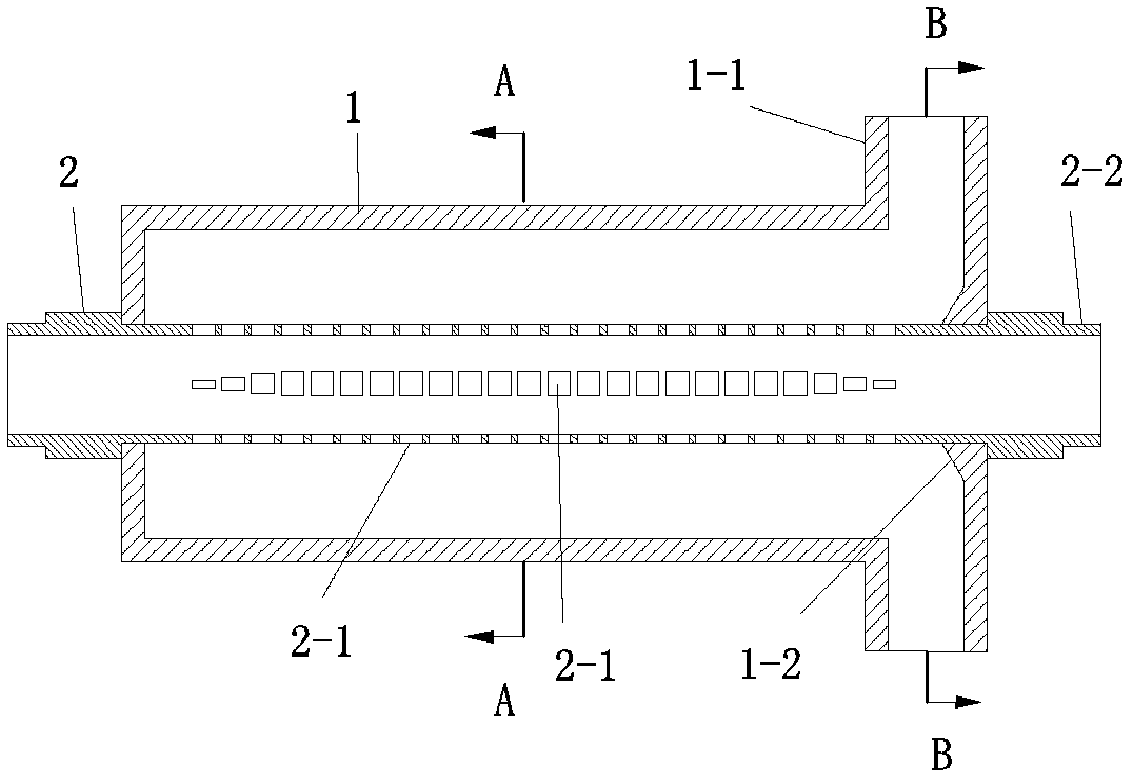

Secondary harmonic inhibition method for broadband helix travelling wave tube

ActiveCN105304438AImprove overall tube performanceGood harmonic suppressionTravelling-wave tubesTransit-tube circuit elementsHarmonic mitigationHarmonic

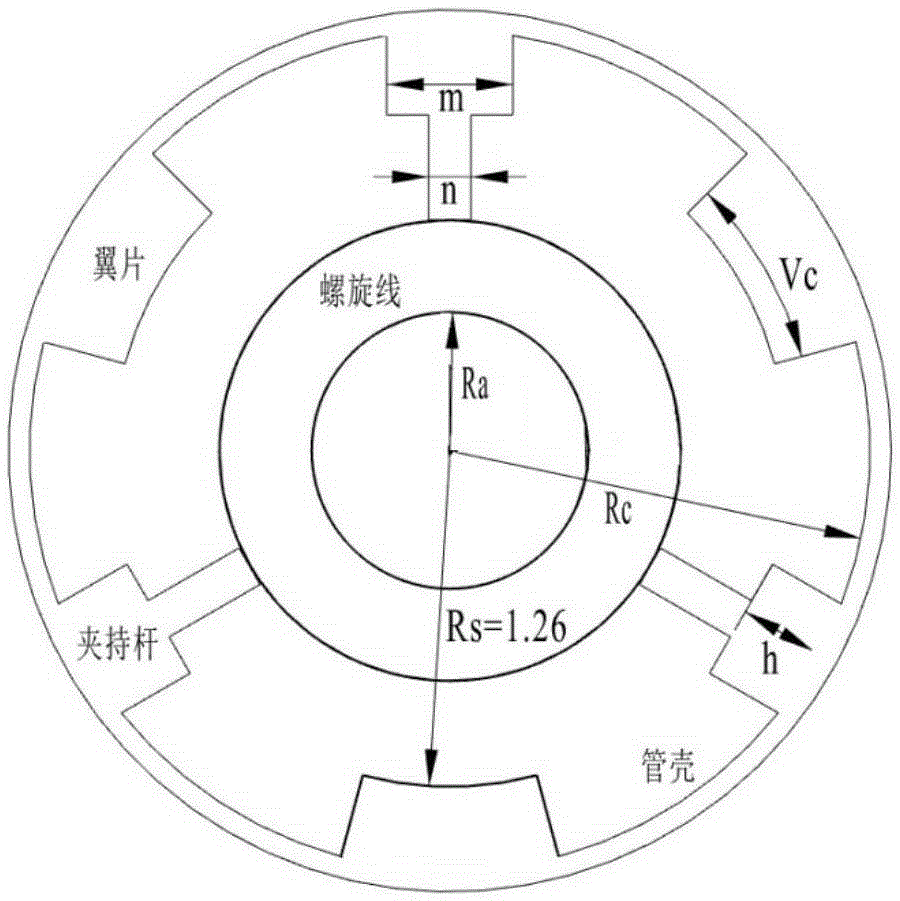

The invention discloses and especially relates to a secondary harmonic inhibition method for a broadband helix travelling wave tube, and belongs to the technical field of broadband helix travelling wave tubes. Within a certain range, a travelling wave tube harmonic inhibition situation becomes greater if a distance between a fin to a center is reduced, however, the reduced distance will make the fin closer to a helix and might cause engineering machining troubles and many other potential troubles. Therefore, two different fin structures are adopted by an input segment and an output segment respectively, and the distance from a fin on the input segment to the center is made to be greater. Through the even and symmetric fin structure, a better harmonic inhibition effect is exhibited, and other factors in terms of the design of a travelling wave tube can be better weighed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

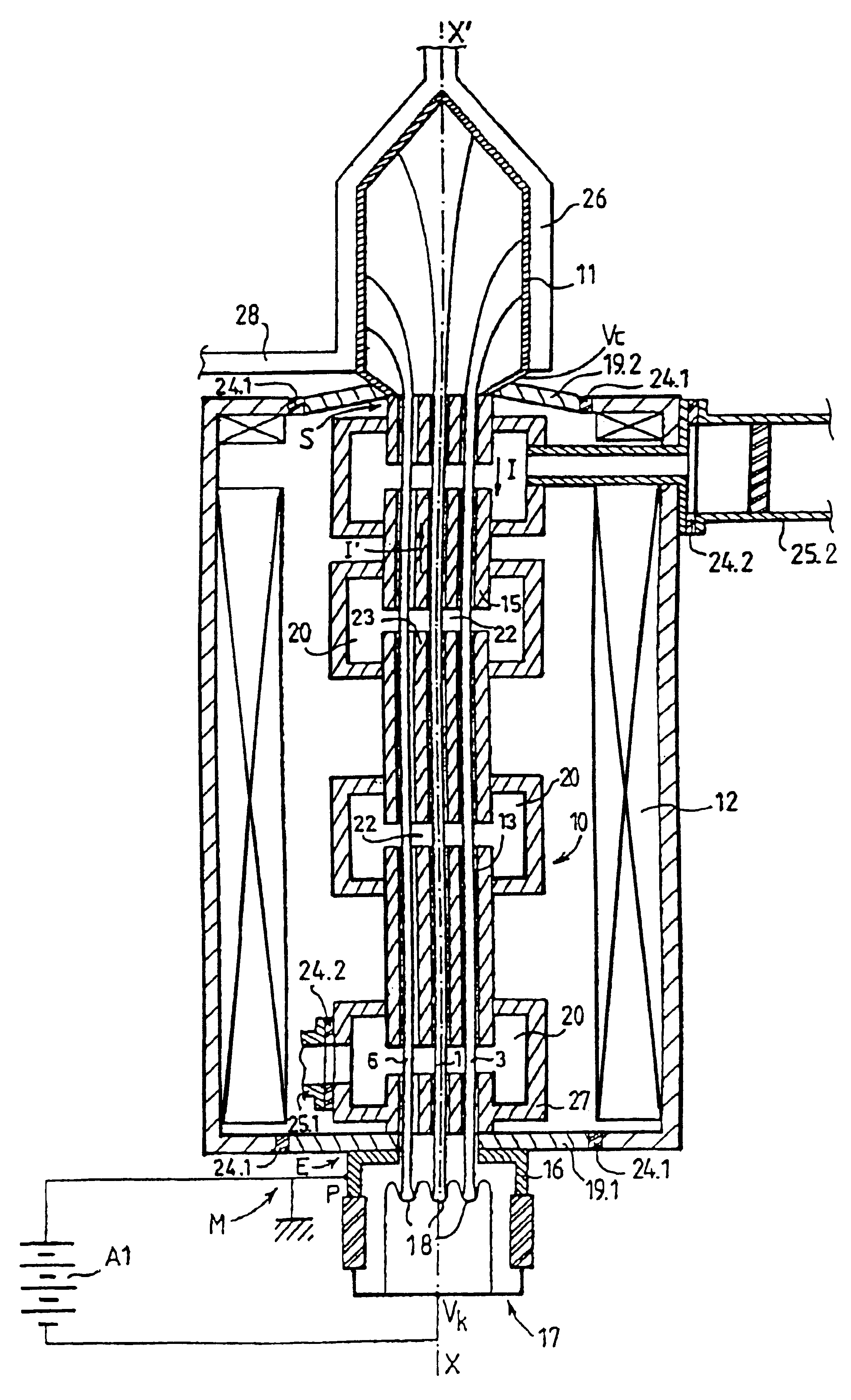

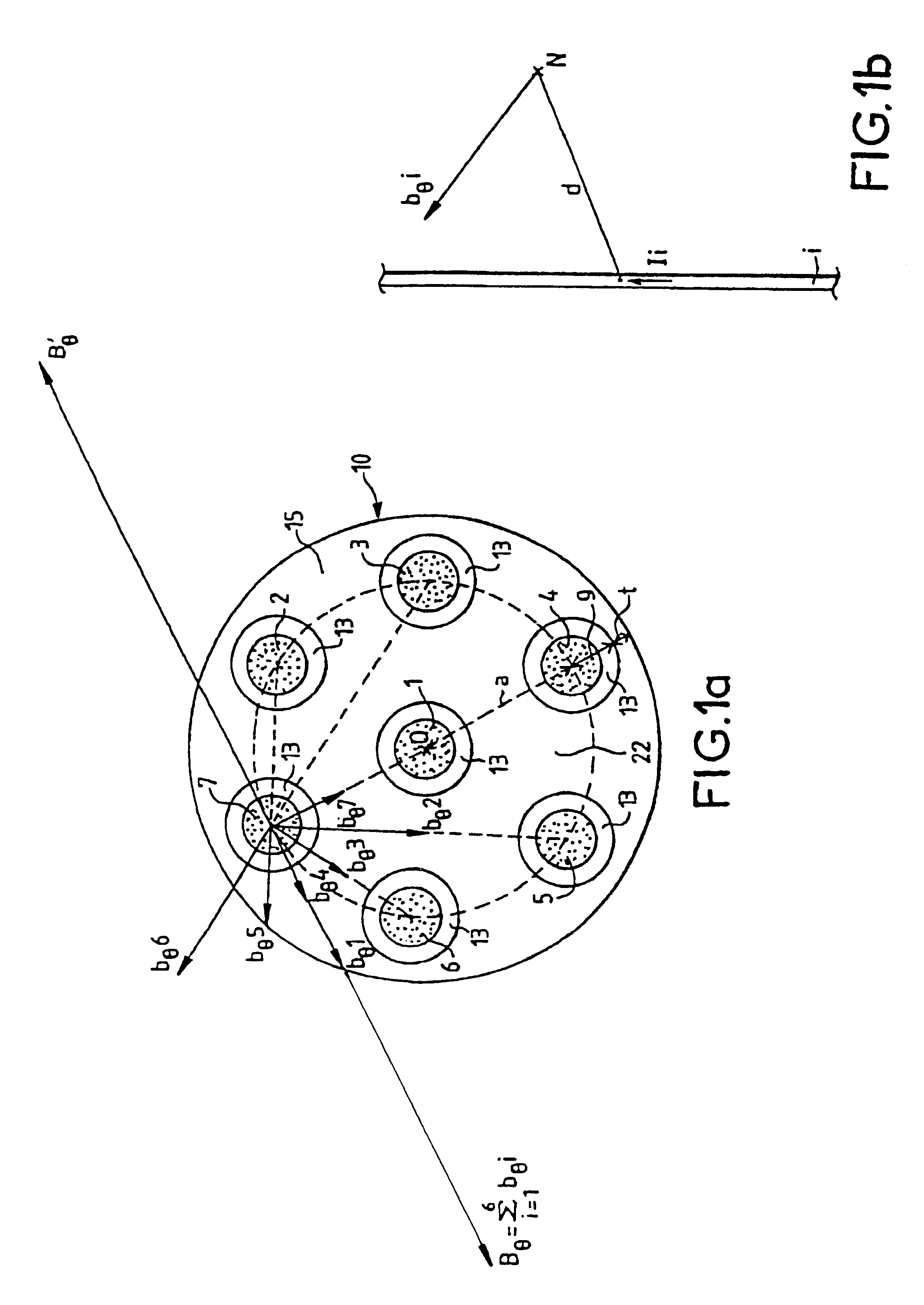

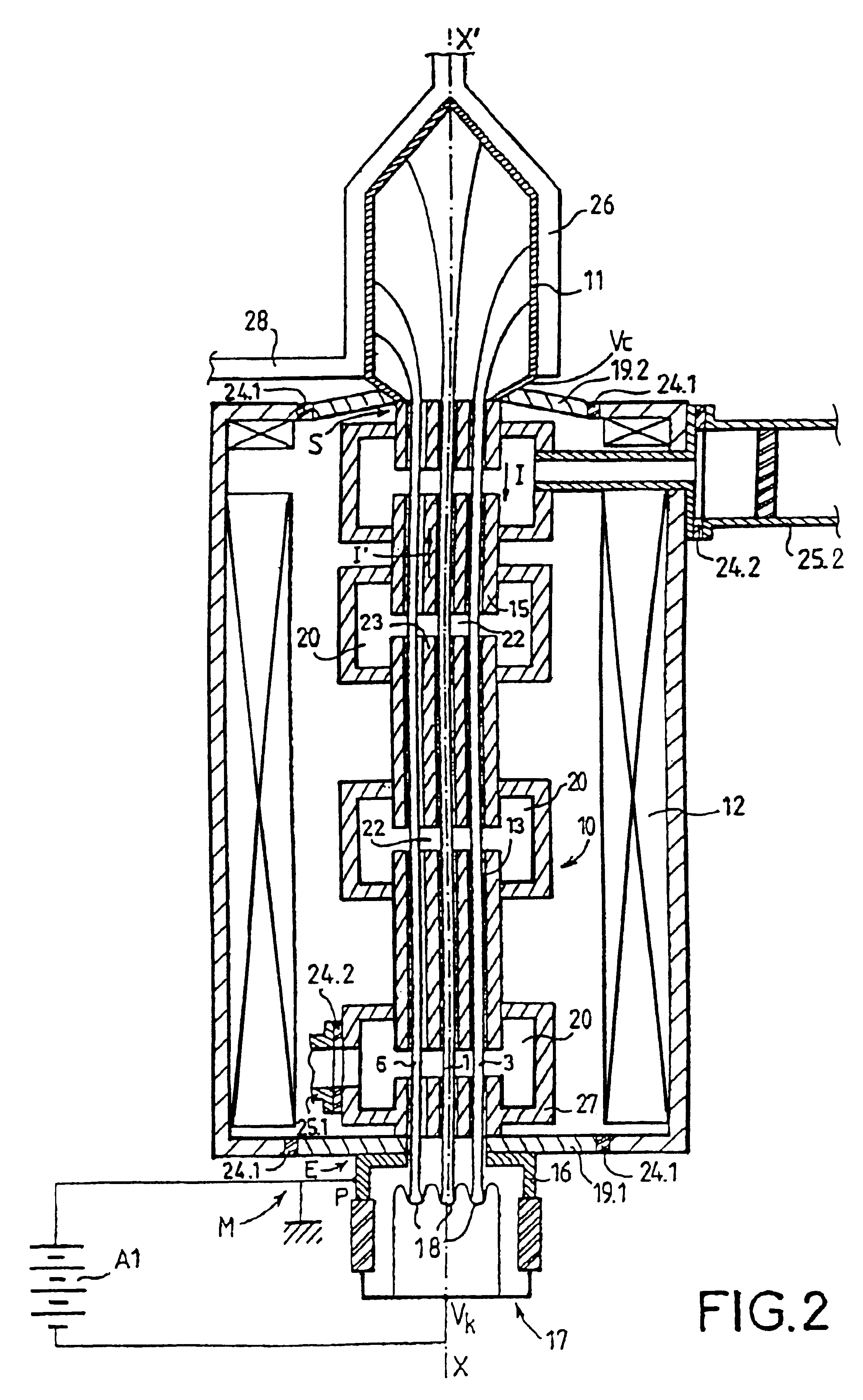

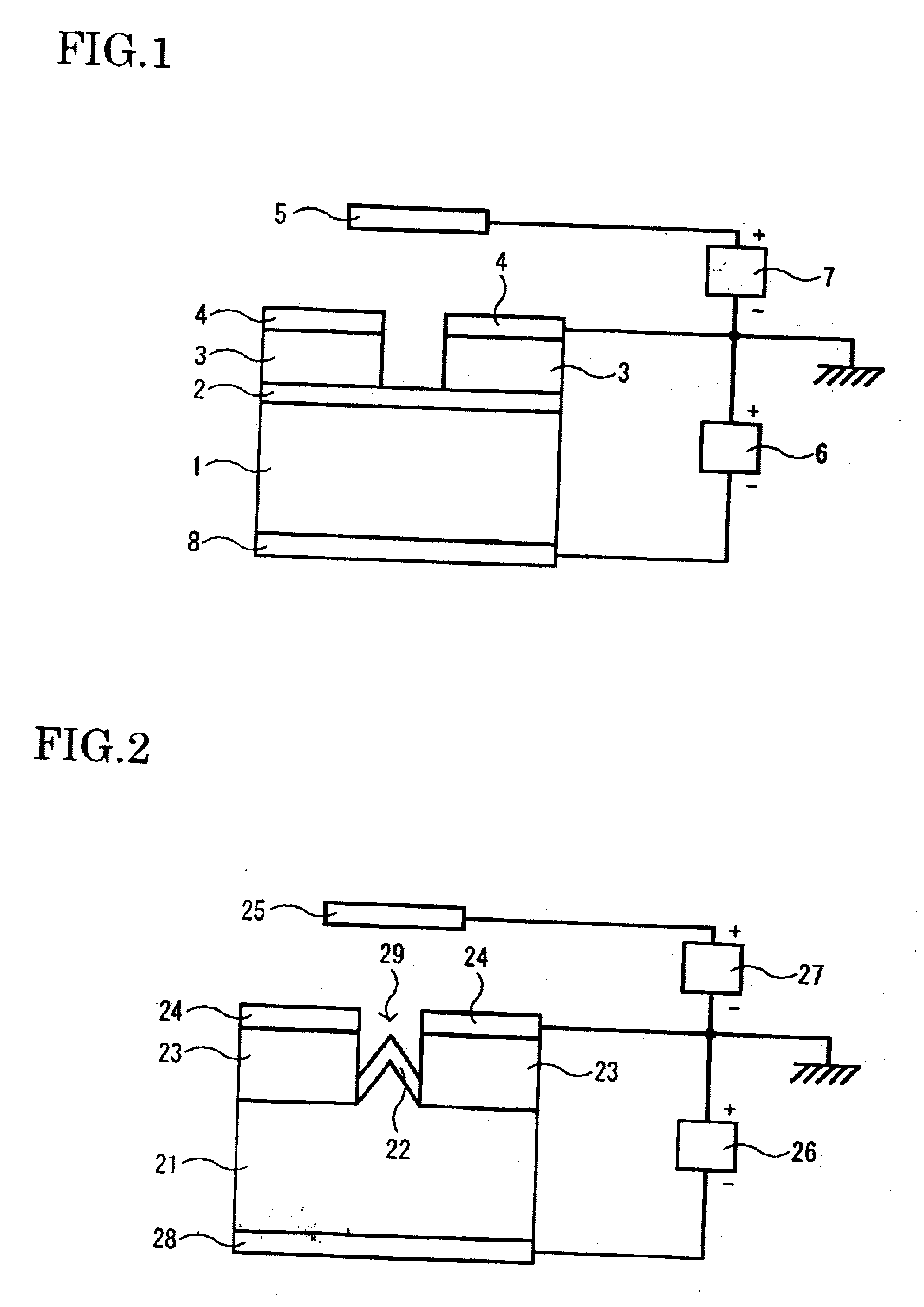

Multibeam electronic tube with magnetic field for correcting beam trajectory

InactiveUS6486605B1Degrading gainDegrading efficiency characteristicTravelling-wave tubesTransit-tube focussing arrangementsKlystronBeam trajectory

A multibeam electron tube with several approximately parallel electron beams passing through a body. Among the beams, at least some define an interbeam volume, each beam defining the interbeam volume being subjected to a perturbing azimuthal magnetic field induced by all the other beams. The tube includes an element allowing, in at least one conducting element located in the interbeam volume, flow of a reverse current in the opposite direction to that of the current of the beams, this reverse current generating, in the beams defining the interbeam space, a magnetic correction field whose purpose is to oppose the perturbing magnetic field. Exemplary embodiments of the present invention especially apply to the multibeam klystrons or traveling wave tubes.

Owner:THOMSON TUBES ELECTRONIQUES

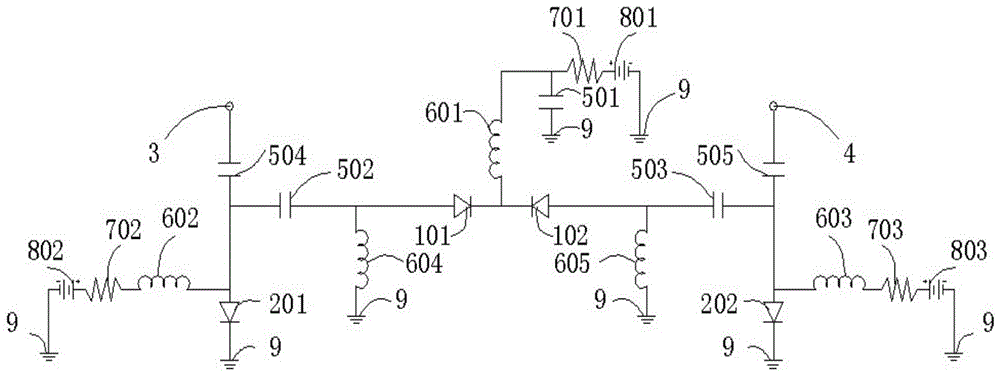

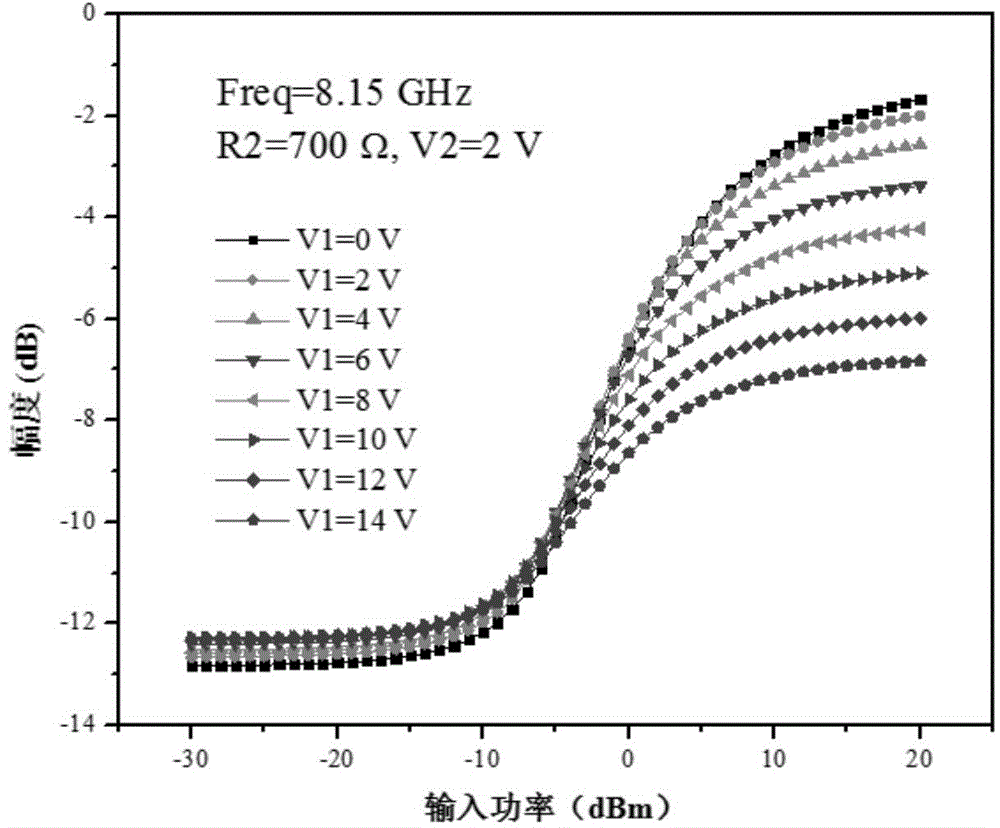

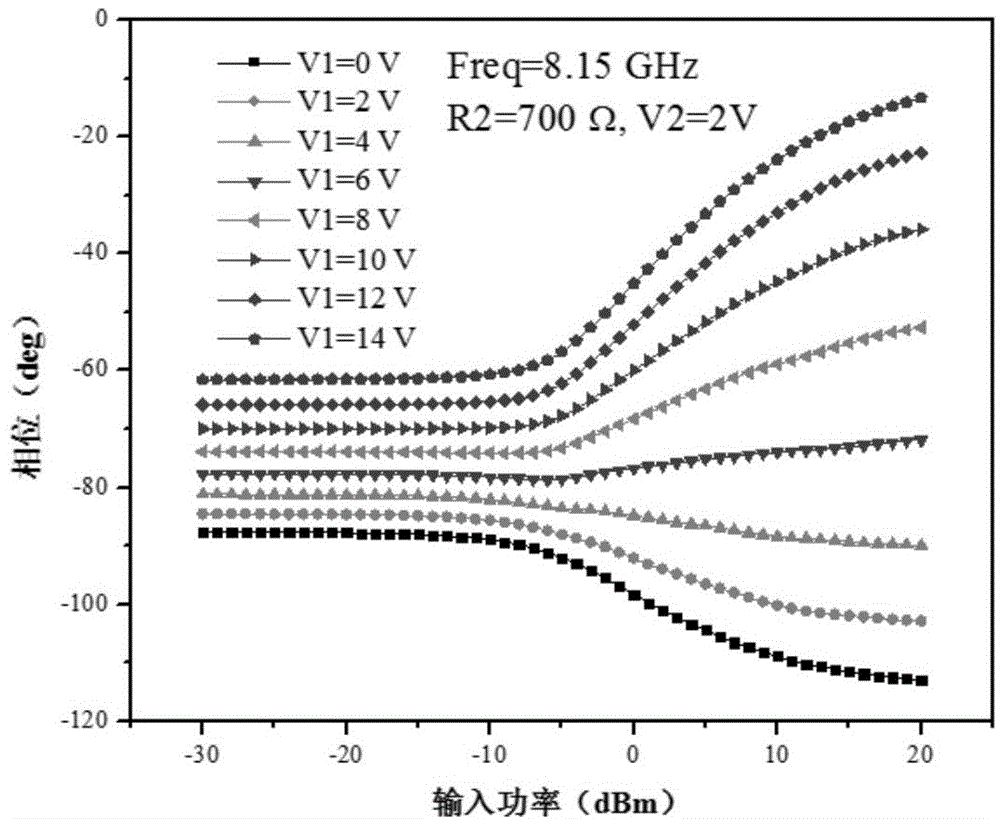

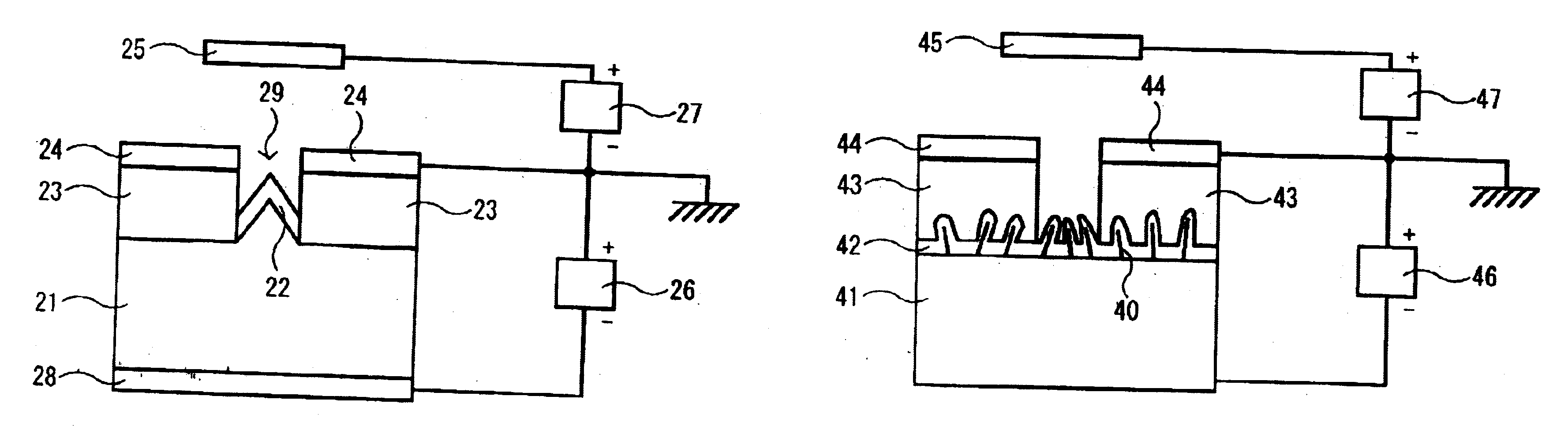

Amplitude and phase tunable type pre-distortion linearizer

InactiveCN104167994AAchieving nonlinear predistortion linearizationEnhancement rangeAmplifier modifications to reduce non-linear distortionMicrowavePhase change

The invention belongs to the technical field of microwave linearization, and particularly relates to an amplitude and phase tunable type pre-distortion linearizer. According to the pre-distortion linearizer, based on the diode pre-distortion linearization working mechanism, by means of the vector superposition principle, pre-distortion nonlinear compensation with different amplitude and phase requirements is obtained through phase change, and the defect of traditional series-connection and parallel-connection transmission type simulation pre-distortion circuits that only pre-distortion signals suitable for solid-state power amplifiers can be generated and the defect of reflection type pre-distortion circuits that only pre-distortion signals suitable for microwave traveling-wave tube power amplifiers can be generated mostly are overcome; meanwhile, the capacity of control, over the amplitude expansion and phase expansion degrees of generated non-linear signals, of a microwave pre-distortion circuit is improved, and accurate strong-nonlinearity amplitude and phase compensation can be achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

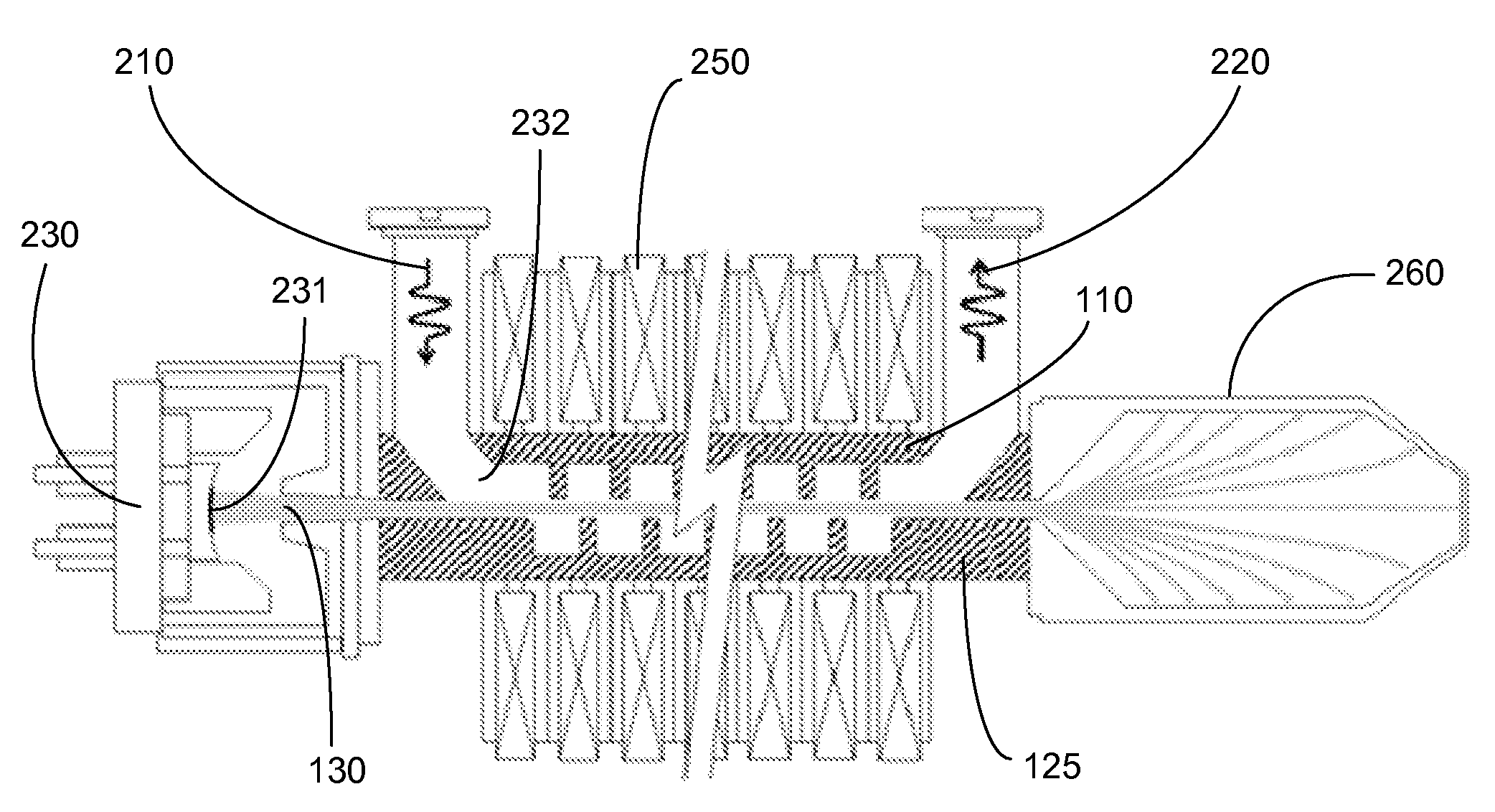

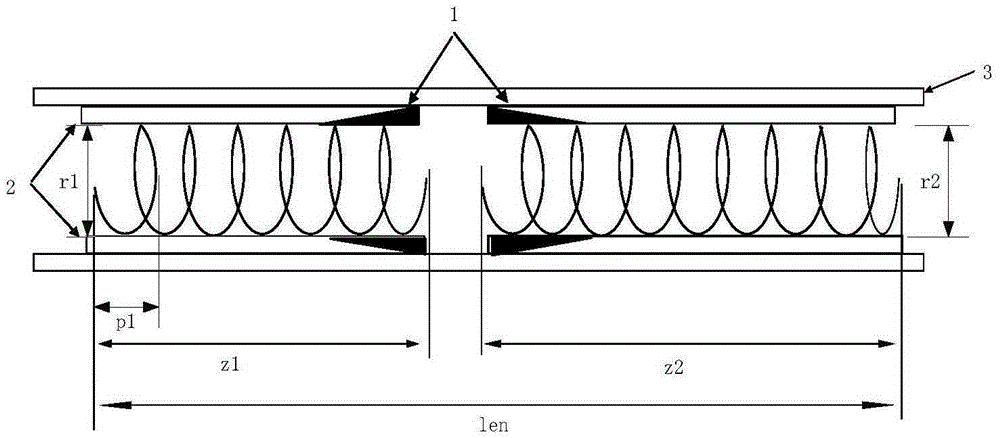

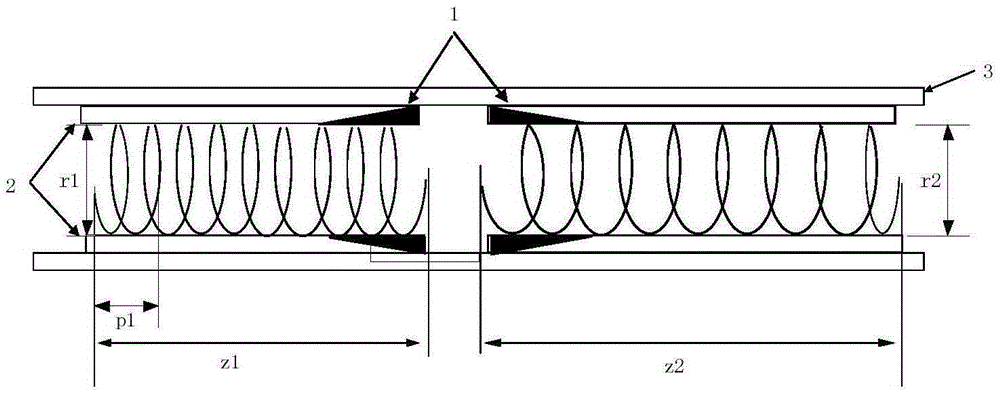

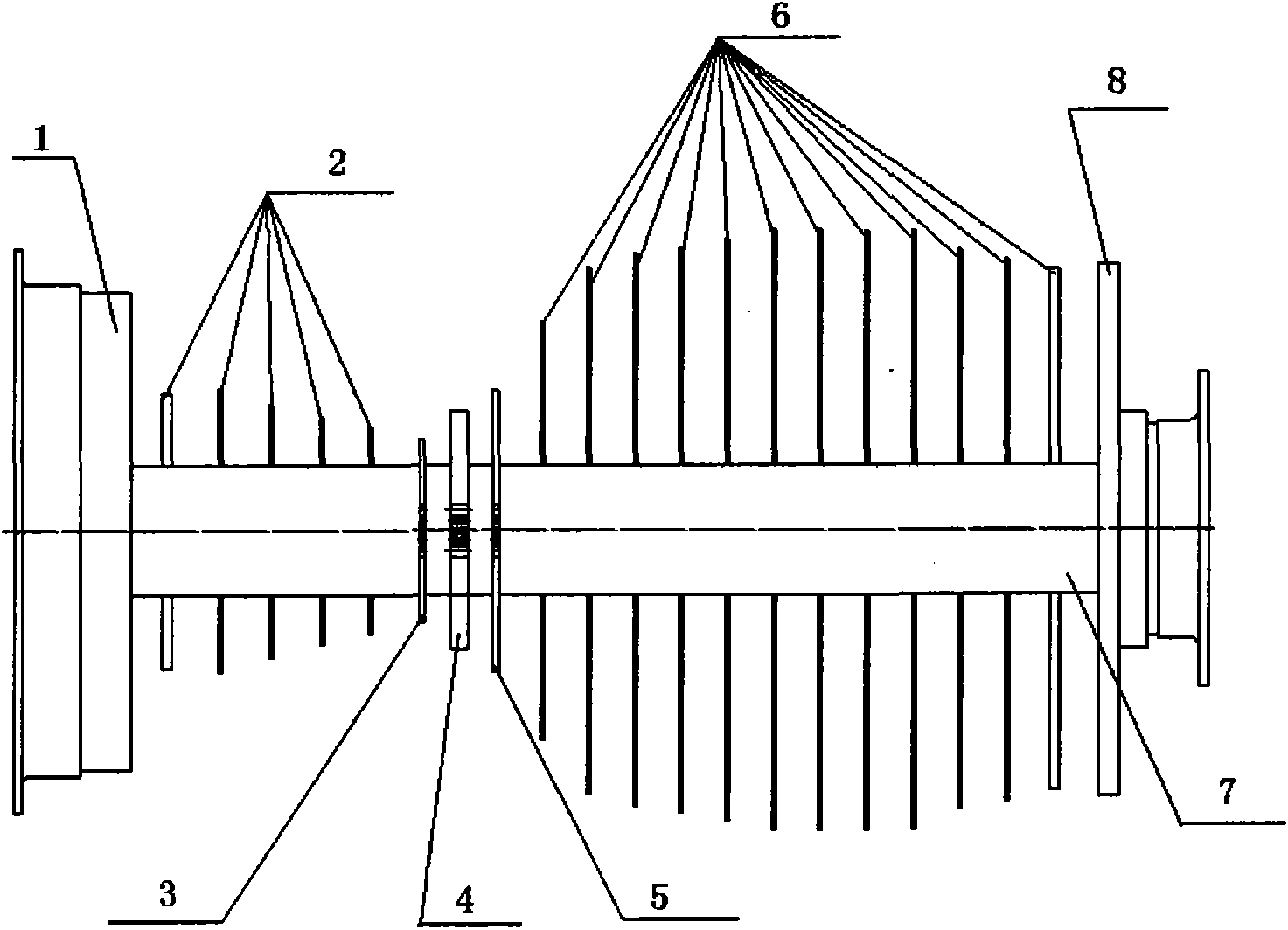

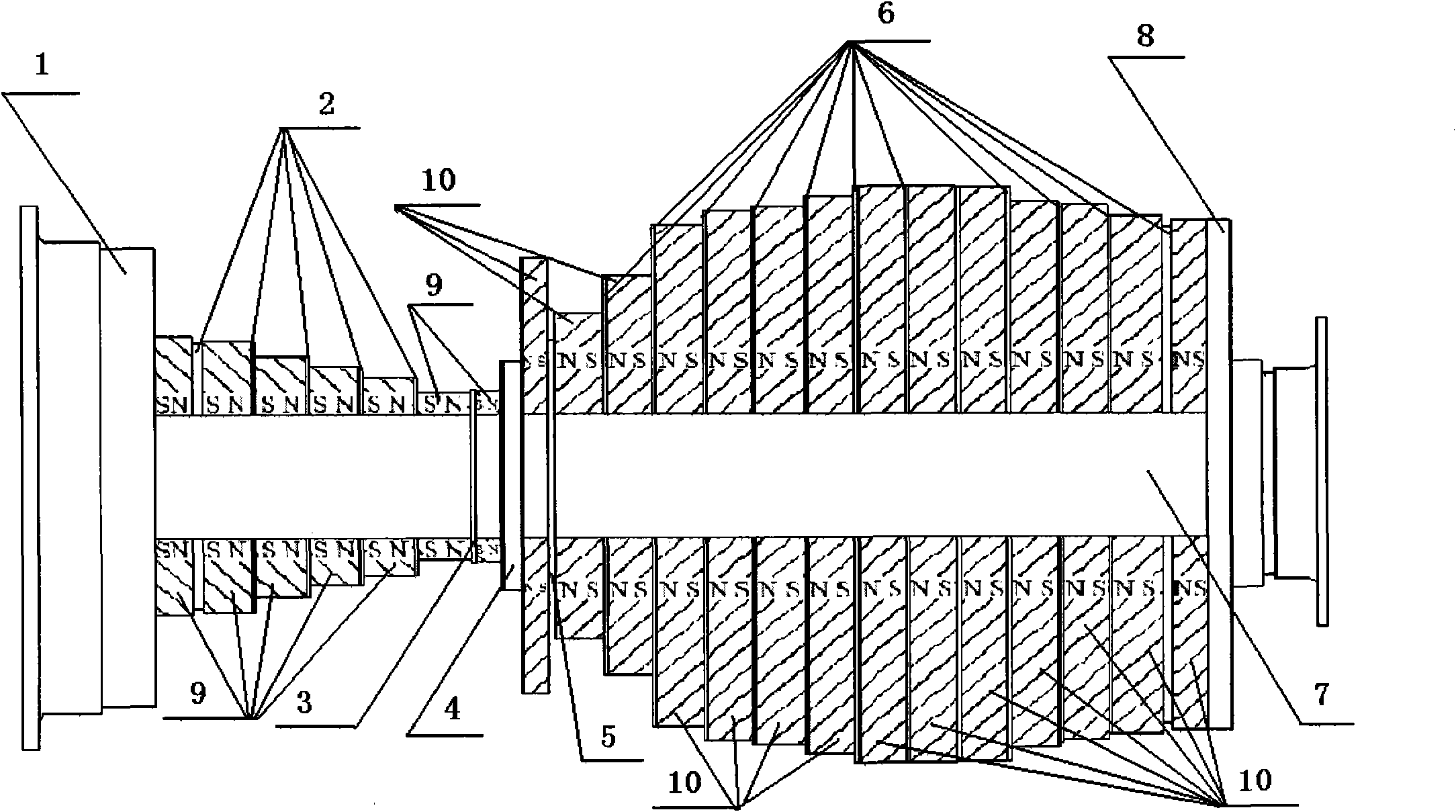

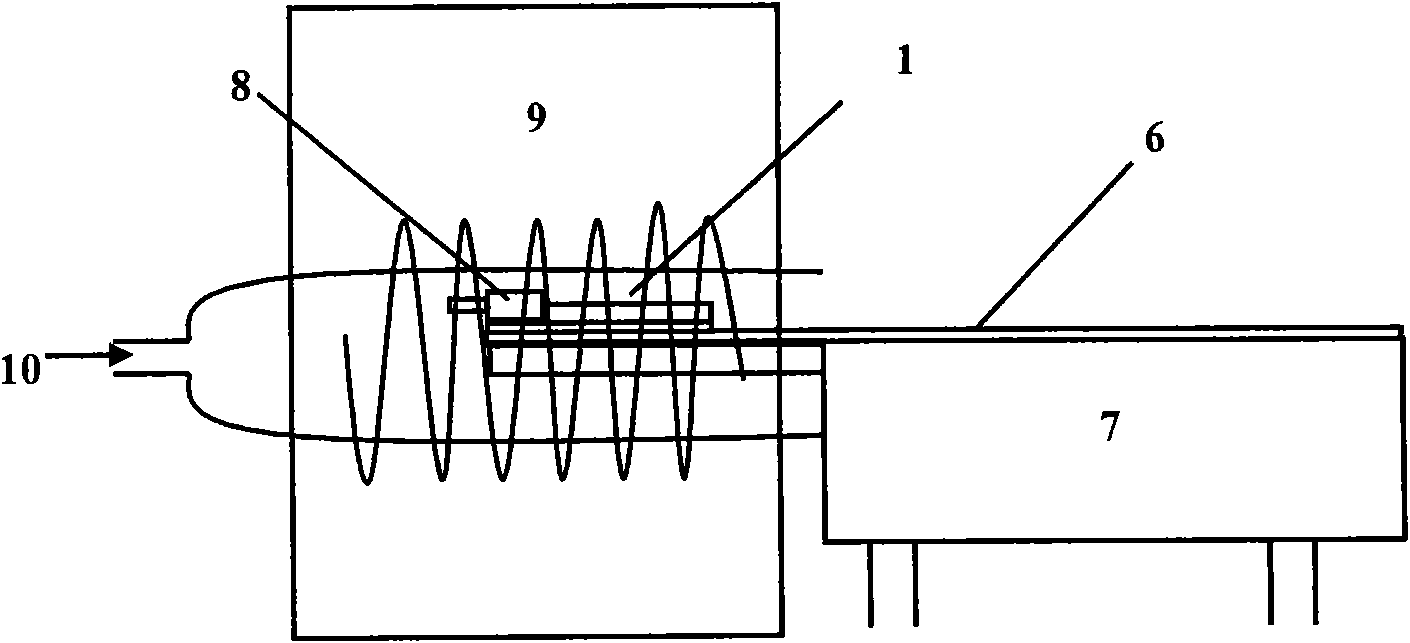

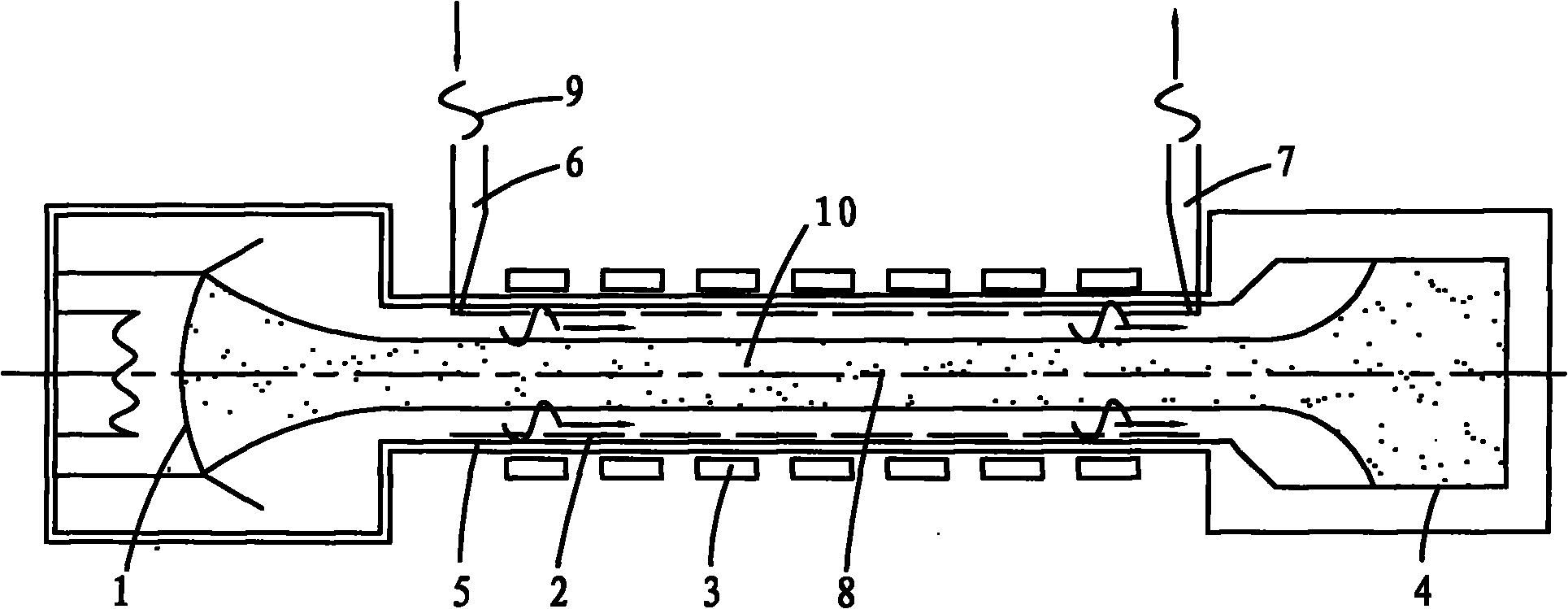

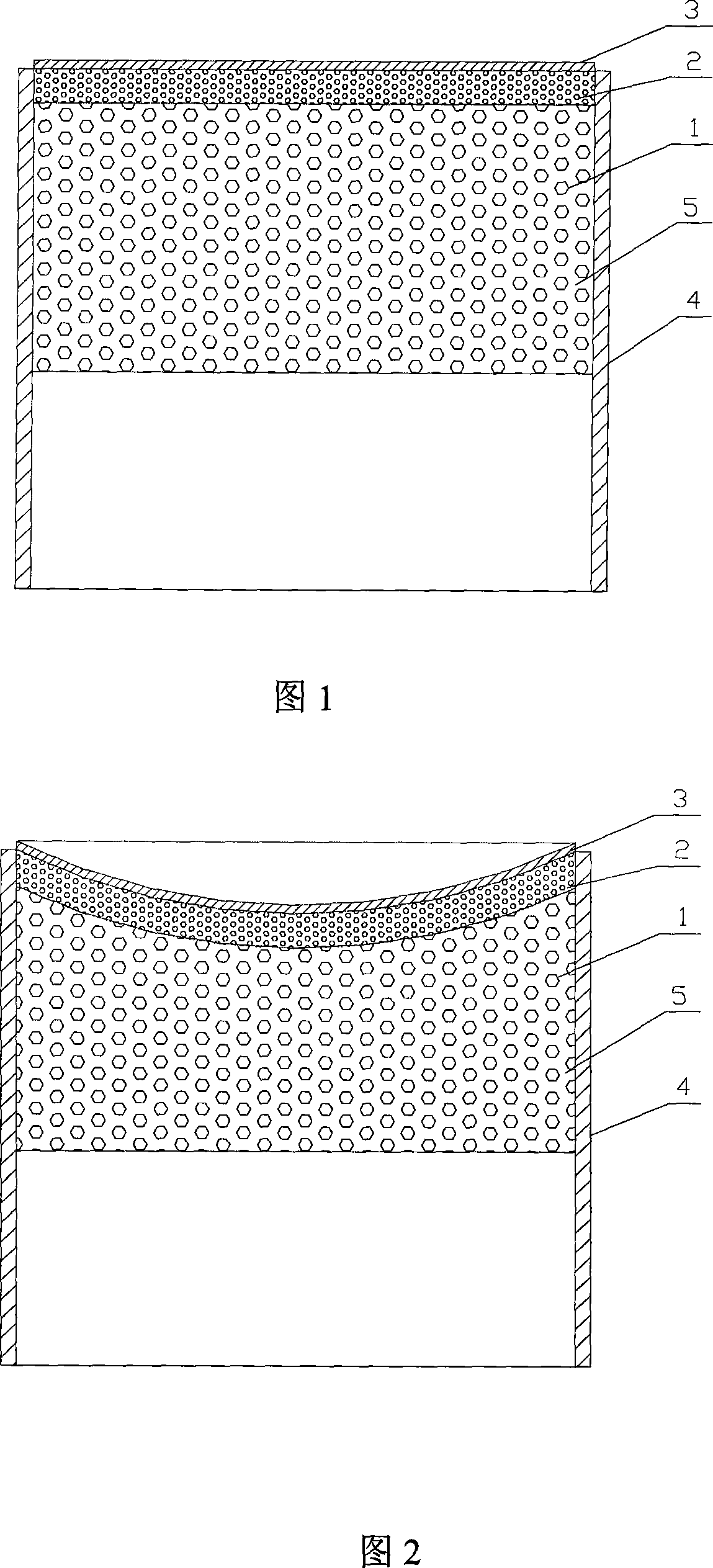

Reversed-field permanent-magnet focusing system for multi-beam millimeter wave traveling-wave tubes and manufacturing method thereof

InactiveCN101944469ADoes not affect circulationSolve the problem of large permanent magnet volume when the gain is largeTransit-time tubesNon-emitting electrodes manufactureUniform fieldTransverse magnetic field

The invention discloses a reversed-field permanent-magnet focusing system for multi-beam millimeter wave traveling-wave tubes, which consists of an electron gun end face (1), first magnetic field rectifiers (2), a first peak generation pole shoe (3), a magnetic field reversal pole shoe (4), a second peak generation pole shoe (5), second magnetic field rectifiers (6), a vacuum sealed case (7), a collector end face (8), first permanent magnets (9) and second permanent magnets (10). The reversed-field permanent-magnet focusing system for the multi-beam millimeter wave traveling-wave tubes rectifies magnetic fields on the left and right sides of a magnetic system by the first and second magnetic field rectifiers (2 and 6) so as to reduce a transverse magnetic field without influencing flux rates of electron beams, and simultaneously solves the problem of large volumes of the permanent magnets of a uniform-field permanent-magnet focusing system with large gain due to the applicability of the plurality of first and second permanent magnets (9 and 10) with small volumes to the focusing system.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Internal-feedback-type terahertz traveling wave tube oscillator

InactiveCN103021770AReduce volumeIncrease powerTransit-tube circuit elementsTransit-tube coupling devicesWave structurePhase shifted

The invention discloses an internal-feedback-type terahertz traveling wave tube oscillator, and relates to a terahertz electromagnetic wave source technique. Based on a traveling wave tube, a feedback mechanism is introduced so as to form an oscillator. Compared with the existing traveling wave tube, the structure is characterized in that 1. a tuning device is added at an input port of the oscillator, and is a variable short circuit device; and 2. an output port is designed with a special method, so that the oscillator has certain reflection in a working frequency band, and the reflection coefficient is about 0.2. According to the oscillator provided by the invention, a feedback loop of an electromagnetic wave is introduced into the structure, the phase shift of the electromagnetic wave through the feedback loop is integral multiples of 2*pi, and under the condition that a slow wave structure provides sufficient gain, the device is oscillated, and one or a plurality of electromagnetic waves with specific frequency is / are output. Because the tuning device can introduce phase shift variations through methods of mechanical tuning and the like in the feedback loop, the frequency of a start oscillation electromagnetic wave also varies to meet the condition that the total phase shift of the feedback loop is integral multiples of 2*pi, so that the tunable characteristic is realized.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

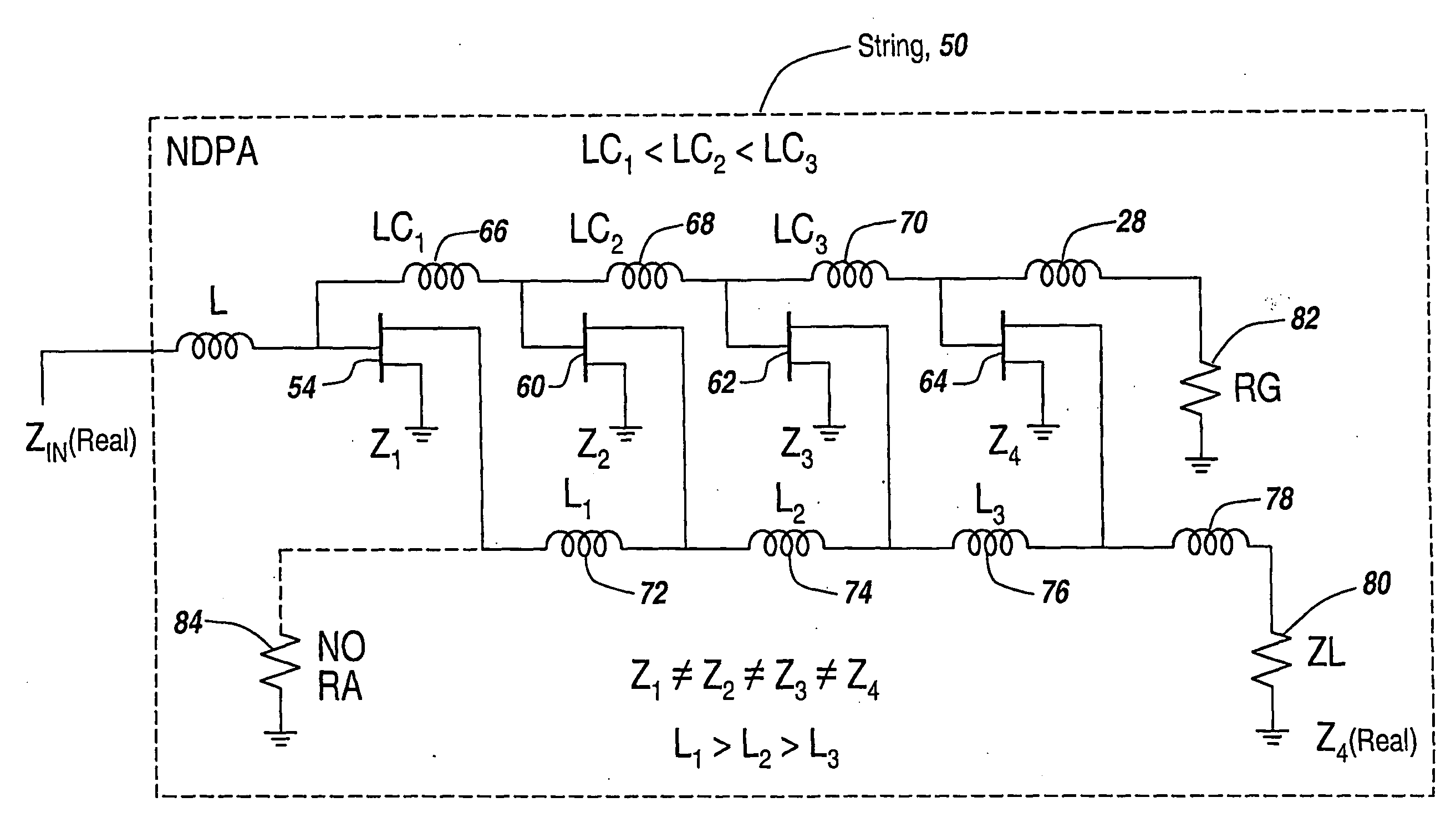

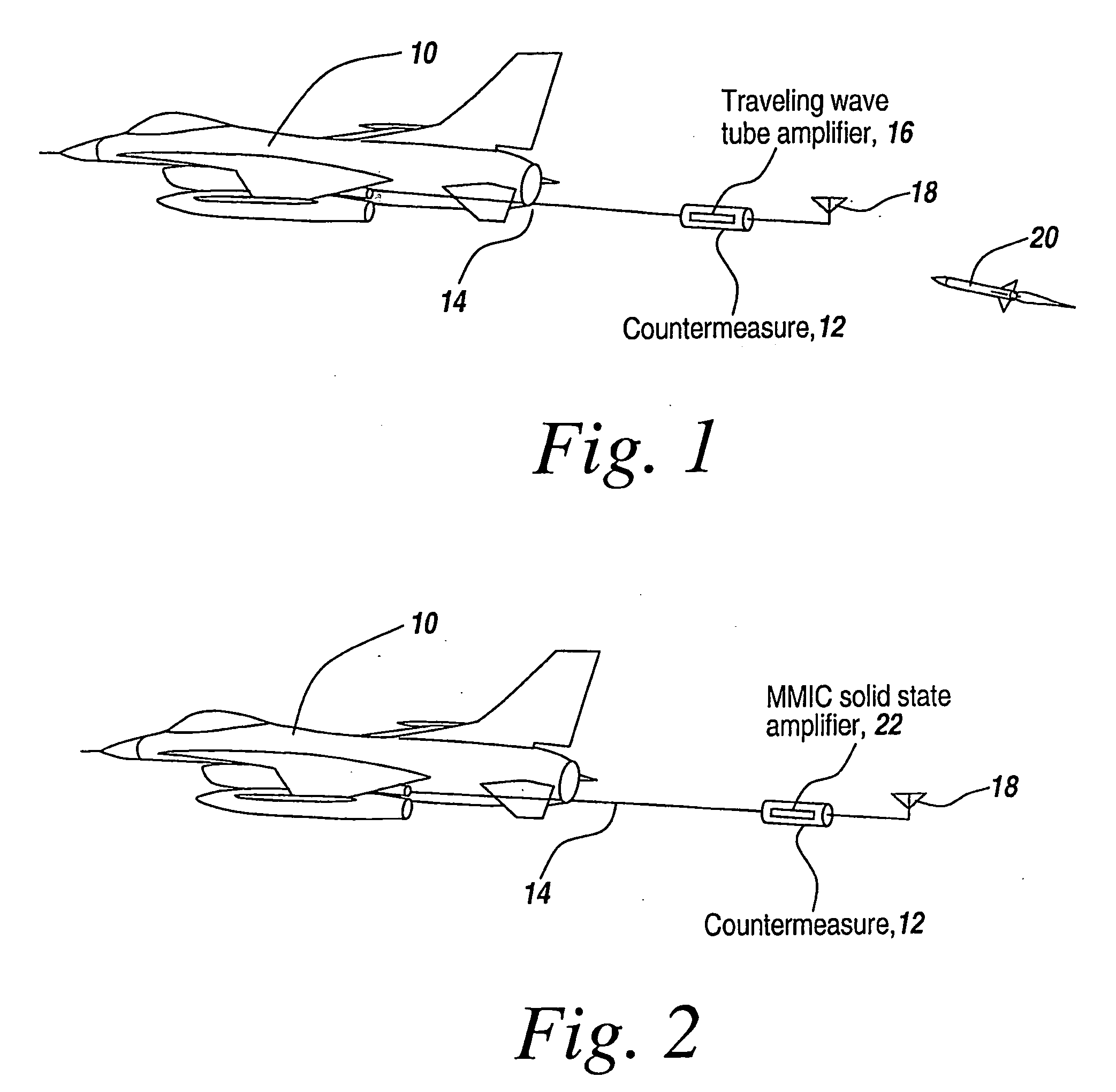

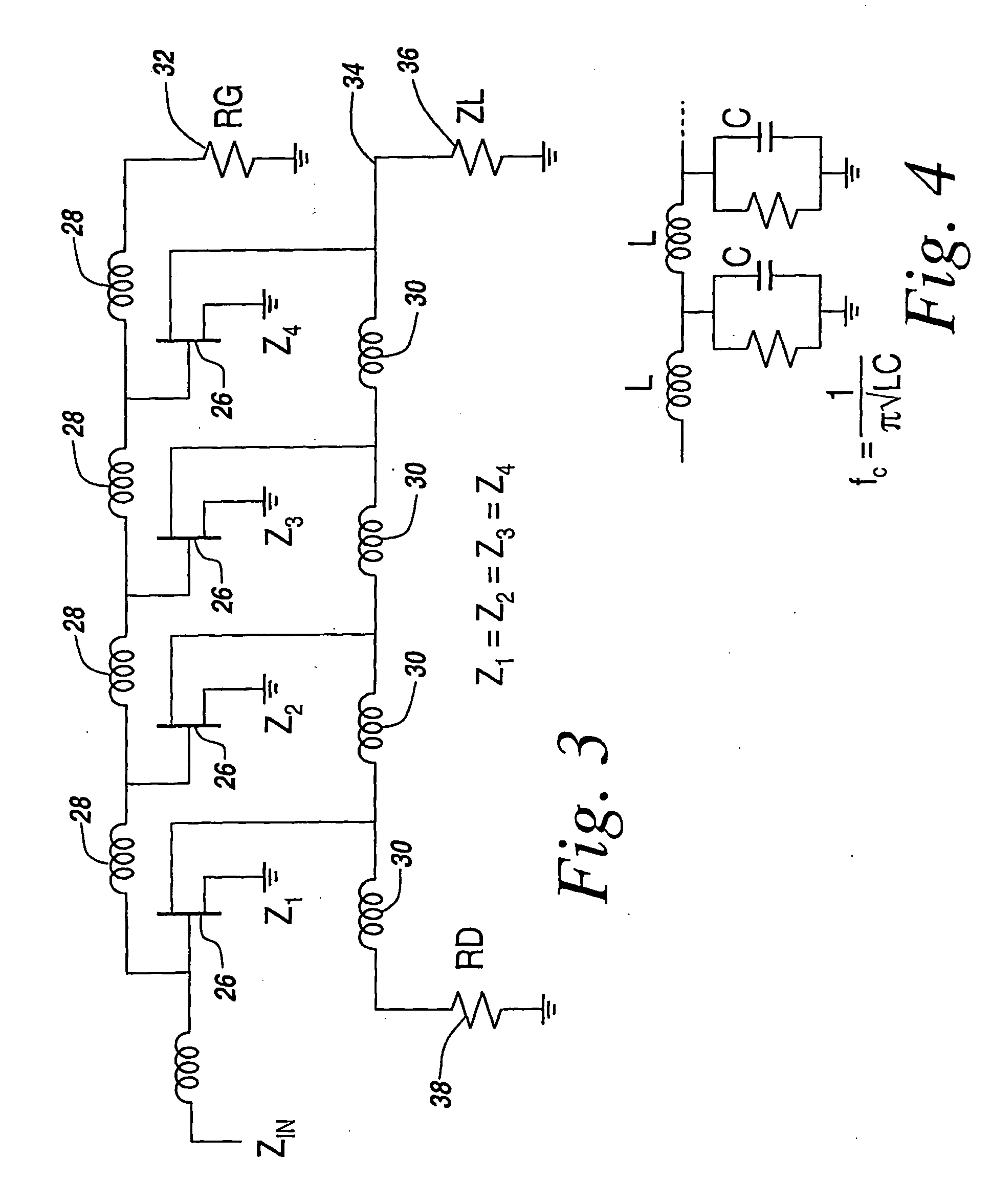

Solid-state ultra-wideband microwave power amplifier employing modular non-uniform distributed amplifier elements

ActiveUS20090309659A1Increase power levelHigh bandwidthHigh frequency amplifiersAmplifiers wit coupling networksUltra-widebandDistributed amplifier

A number of identical non-uniformly distributed ultra-wideband power amplifier string building blocks are coupled together to form an ultra-wide bandwidth high-power amplifier. The non-uniform distribution results in an amplifier utilizing modular string building blocks that have input and output impedances with only real values. This permits the strings to be replicated and connected together with simple impedance matching. The internal impedance matching associated with the non-linear distribution also absorbs parasitic capacitance to permit the ultra-broadband operation. In one embodiment identical transistors are used for each cell so that the strings may be identically replicated. This permits modular re-use without reconfiguration. In one embodiment a non-uniform distributed power amplifier built using the subject building blocks provides an ultra-wideband multi-octave device suitable for electronic warfare and communications applications, especially to replace traveling wave tubes.

Owner:GULA CONSULTING LLC

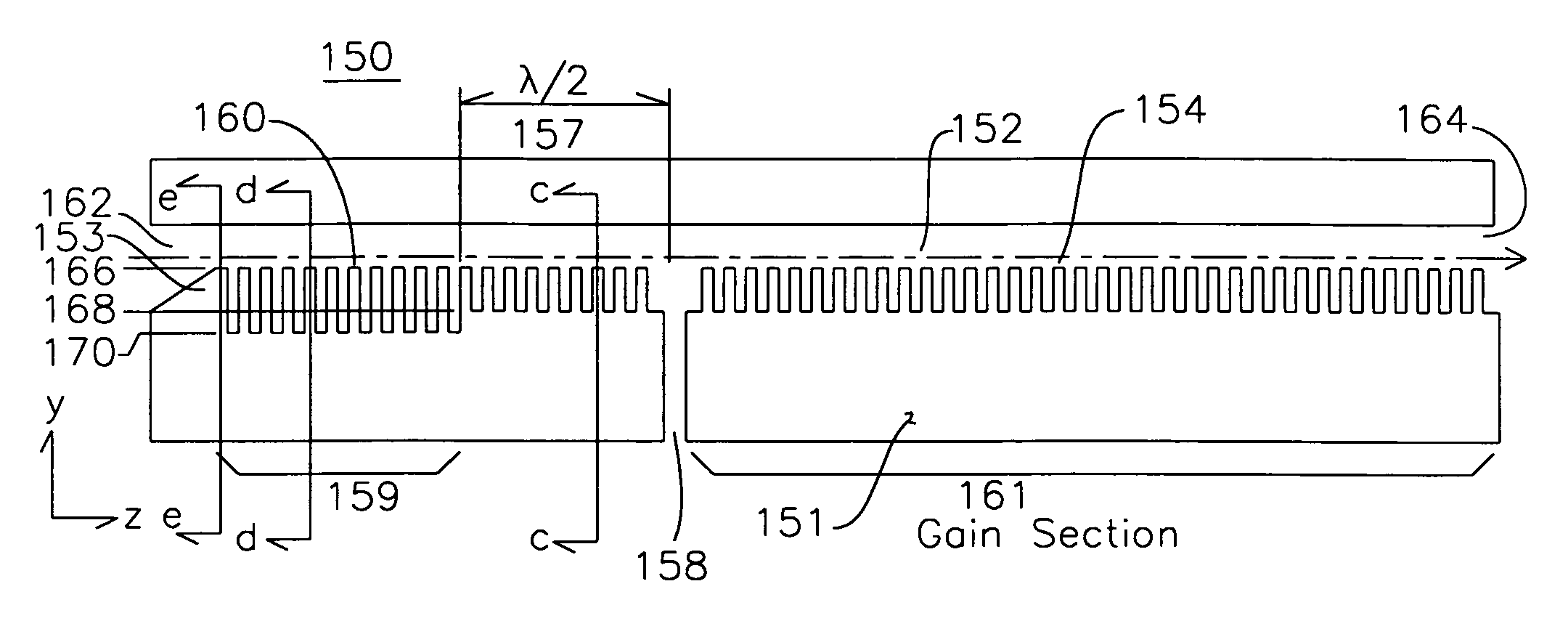

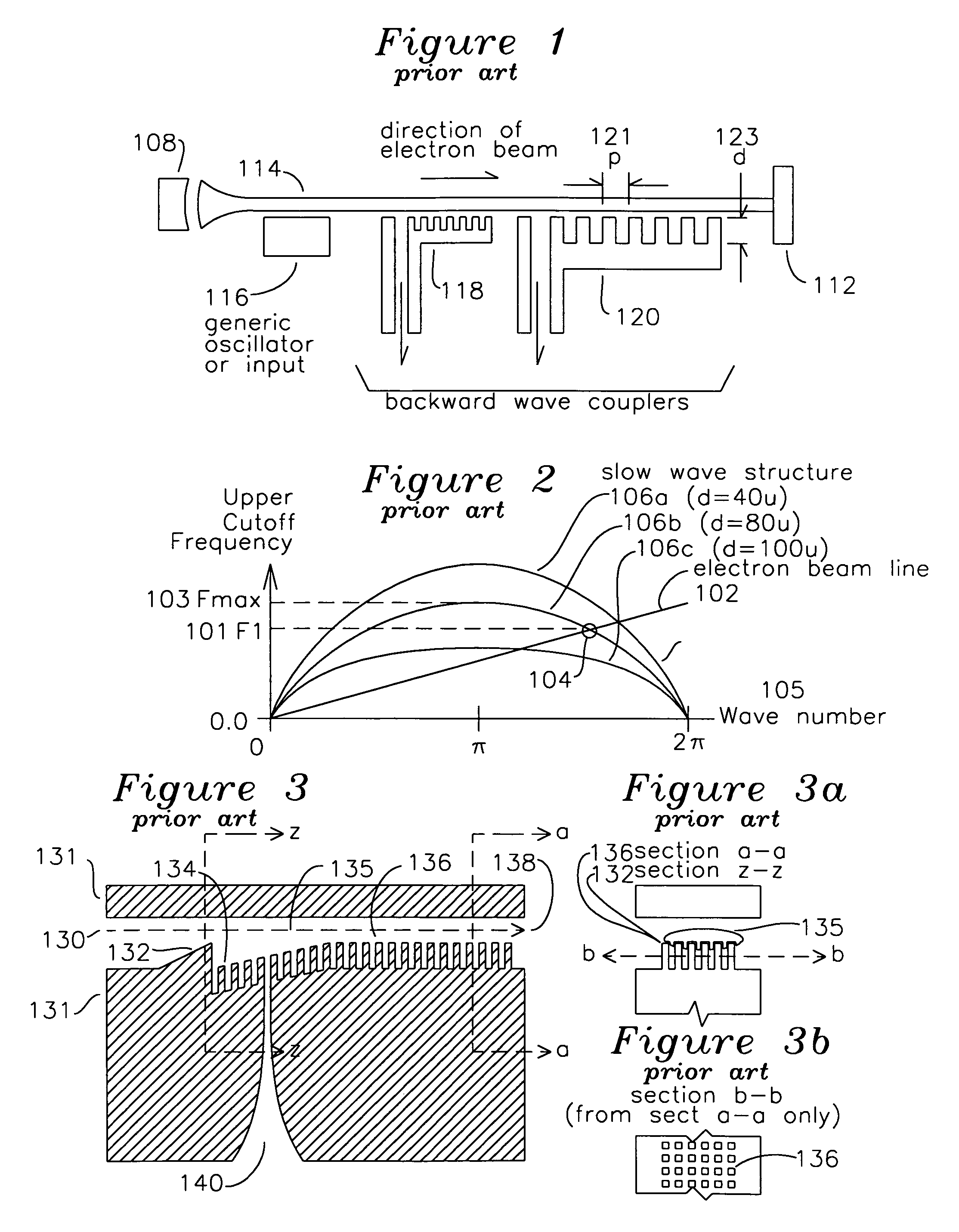

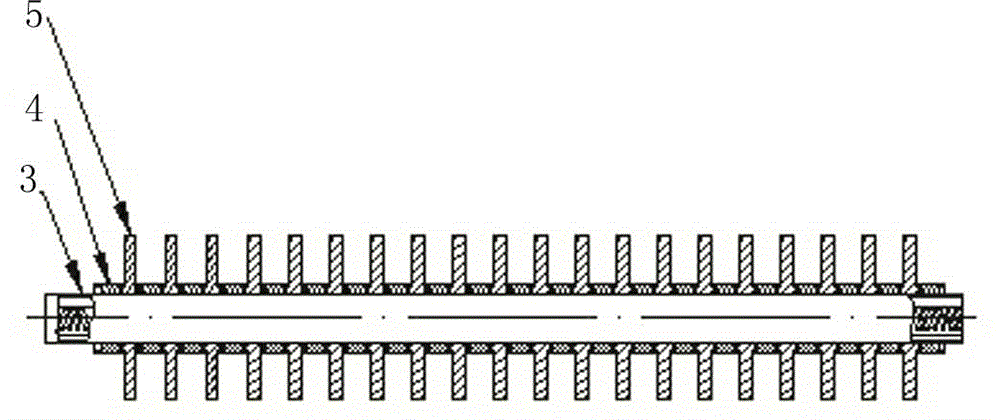

Backward wave coupler for sub-millimeter waves in a traveling wave tube

A slow wave structure for coupling RF energy with an electron beam comprises a co-propagating RF section including a plurality of pins having a uniform separation from the plane of an electron beam axis. An output aperture is positioned a half wavelength from a reflection section comprising a change in depth of the pintles, such that RF energy reflected by the change in pintle depth is added to the RF energy traveling with the electron beam. One or more rows of pintles are removed in the region of the output aperture to enhance coupling to the output aperture. The device may include a beam shaper for shaping the electron beam to surround the pintles, and the beam shaper and pintles may share common channels which are longitudinal to the electron beam axis. The slow wave structure may operate in forward and backward wave modes, and may be used in conjunction with other structures to form amplifiers and oscillators.

Owner:CALABAZAS CREEK RES

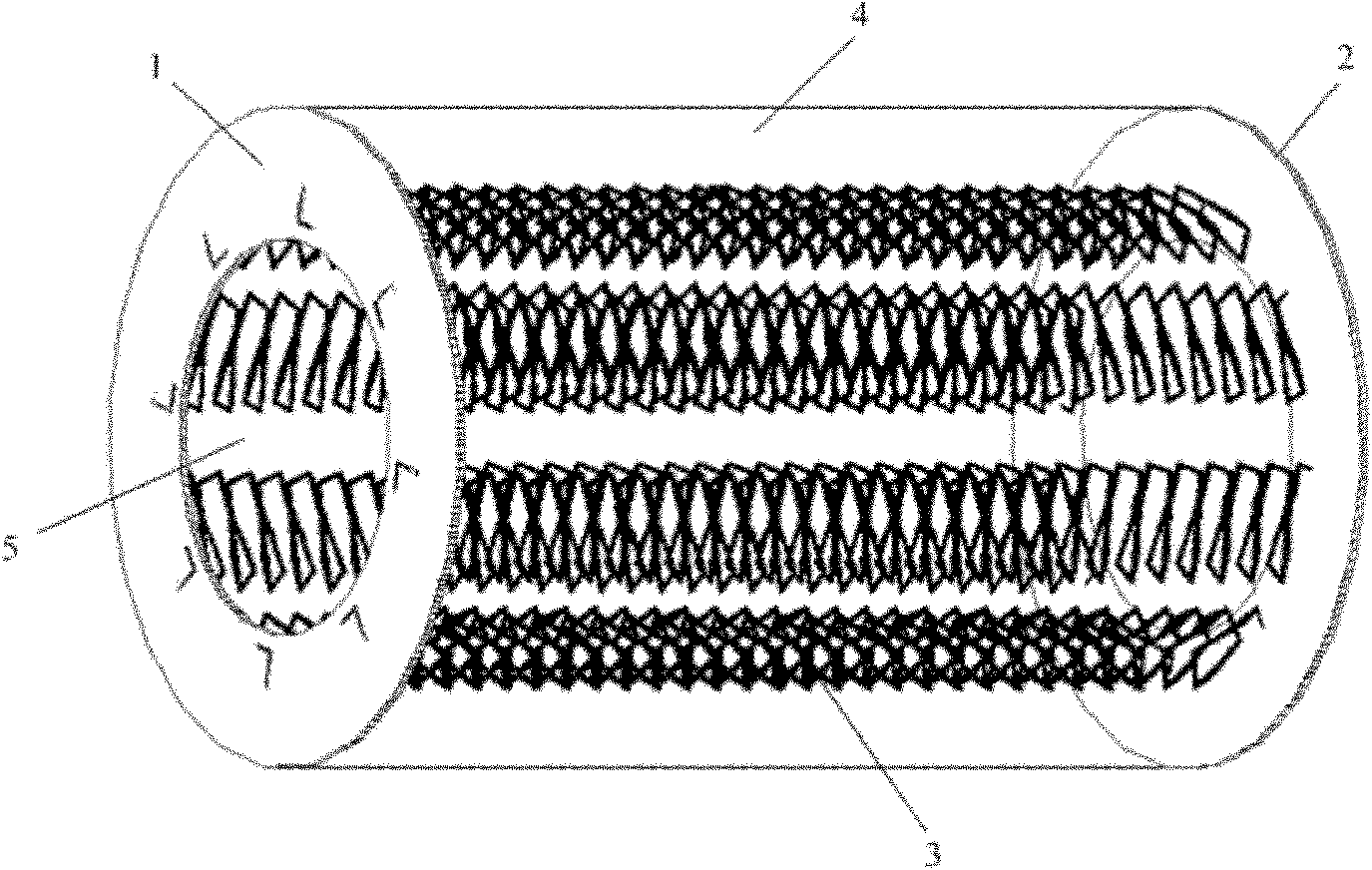

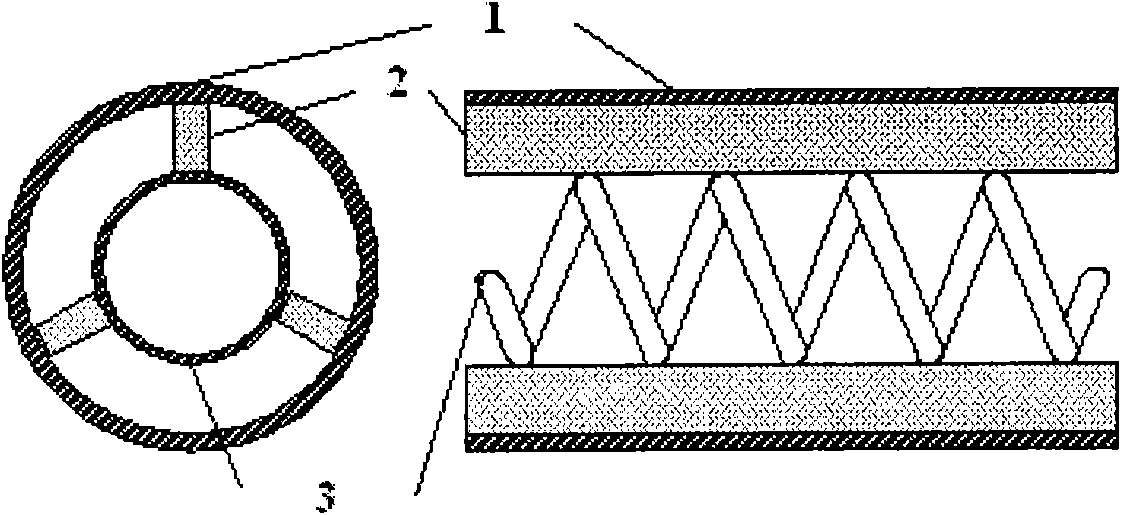

Helix TWT slow wave component and production method

InactiveCN101271803AImprove cooling effectEasy to processTransit-tube circuit elementsCold cathode manufactureHelical lineWave tube

The invention discloses a helical line traveling wave tube slow-wave component and a preparation method thereof. The method comprises the steps as follows: a cleaned medium holding rod and the helical line are arranged in a diamond deposition chamber; the diamond is deposited on the surface of the medium holding rod and the helical line to form a diamond film; the medium holding rod and the helical line with the diamond film and a metal pipe shell are fixed on a loading die and extruded into the metal pipe shell. The component comprises the medium holding rod, the helical line, a pipe shell, a first diamond film and a second diamond film. The diamond is deposited on the surfaces of medium holding rod and the helical line, therefore, the defect of low heat conductivity of other mediums is compensated, the heat dissipation capability of the slow-wave component is improved, and the problems of difficult processing and expensive price of the diamond holding rod are solved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Electrode and device using the same

InactiveUS20040041508A1High resolutionImprove throughputGas discharge electrodesGas discharge vessels/containersFiberDisplay device

A high-efficiency electron-emitting device that can emit electron with higher luminance at a voltage lower than conventional electron-emitting devices, as a key device of a flat panel display, image pickup device, electron beam device, microwave traveling-wave tube is provided to improve the carrier injection efficiency and enhance luminance of an organic light-emitting device. A film having space charge with a thickness of 50 nm or less is formed on a surface of a conductive material on which irregularities, amorphous or fibrous materials are formed. The film includes compounds of group 3 atoms such as aluminum nitride, boron nitride, aluminum nitride boron, aluminum nitride gallium, boron nitride gallium and nitrogen atoms, and nitride, carbon, silicon, oxygen and boron such as oxides including nitrogen boron carbon, boron carbide, carbon nitride, boron.

Owner:SUGINO TAKASHI +1

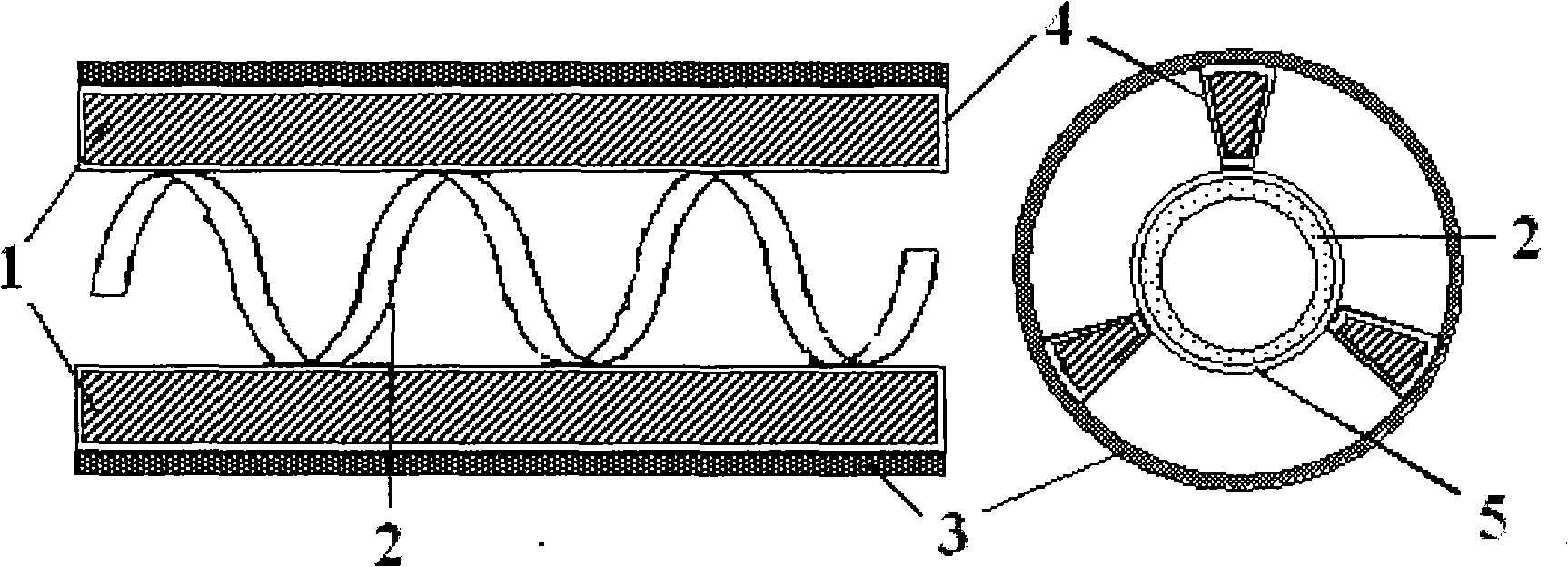

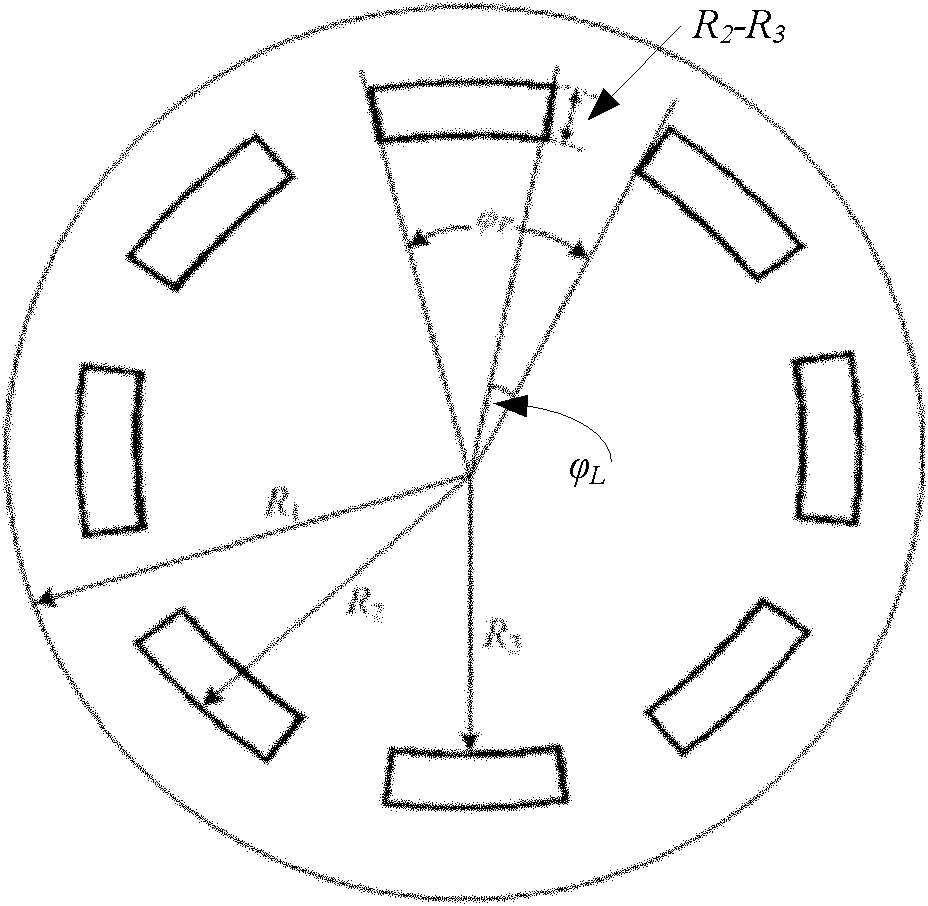

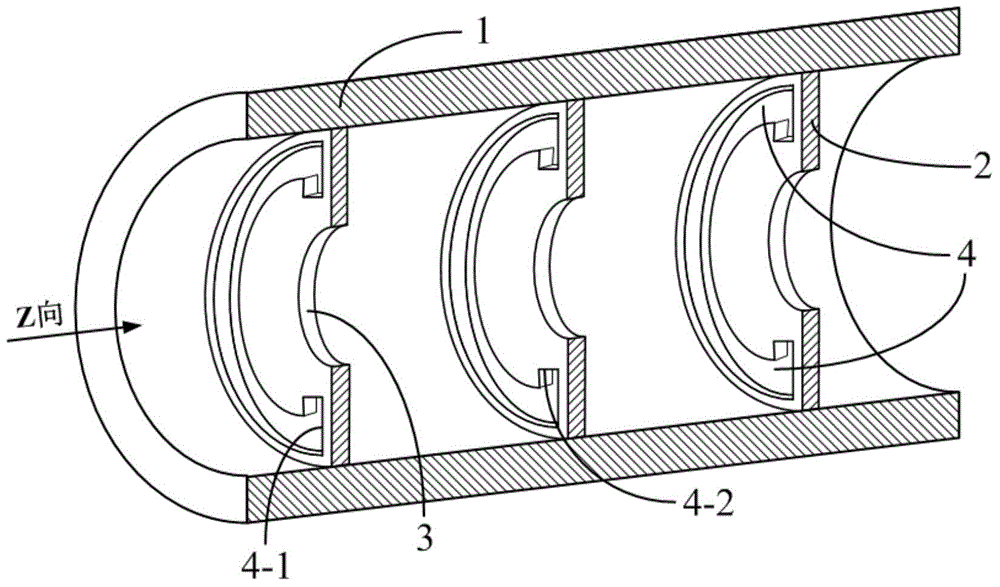

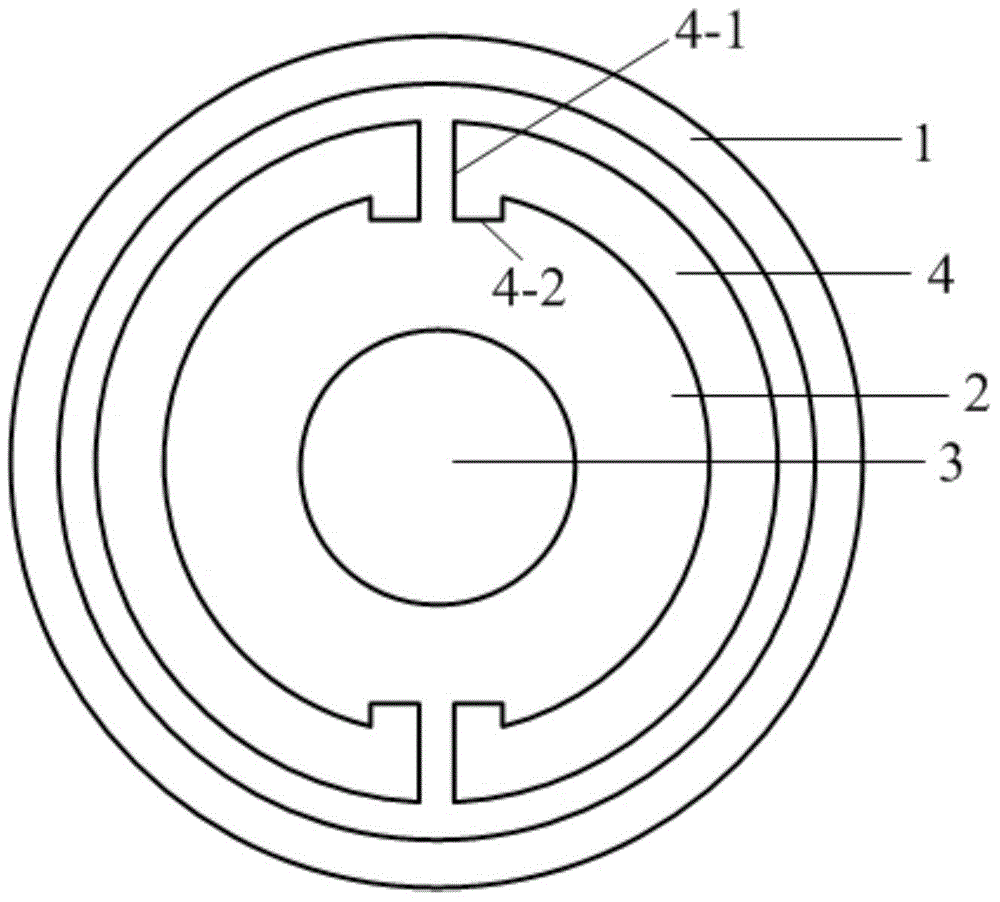

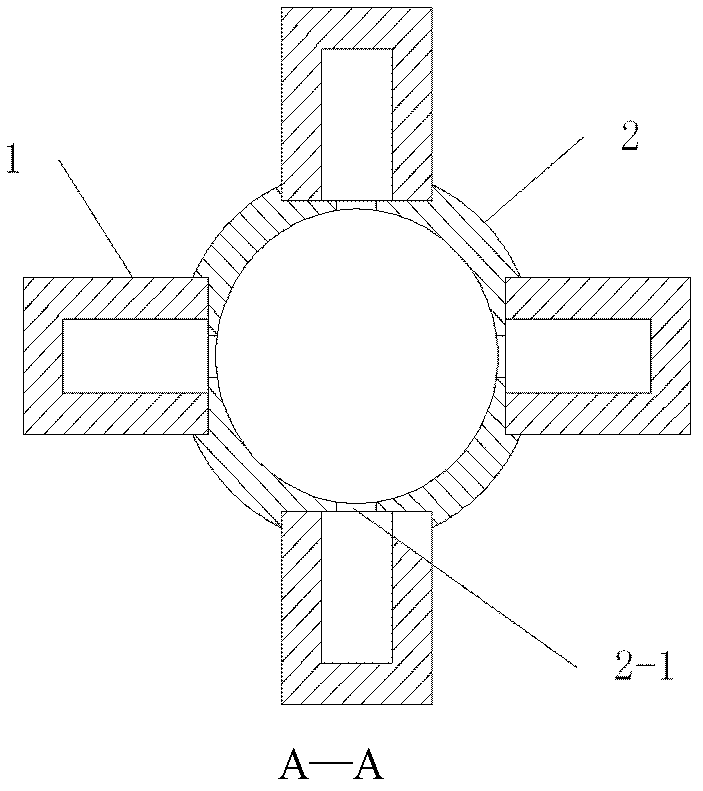

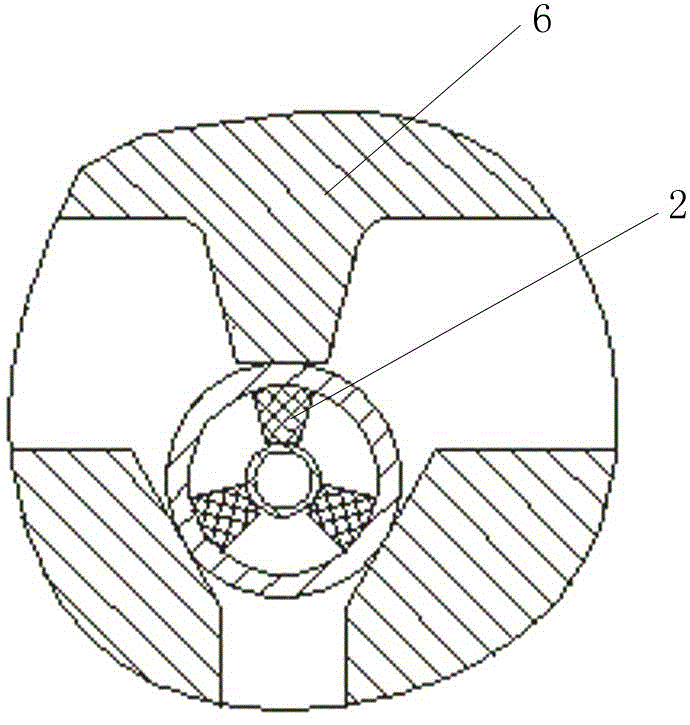

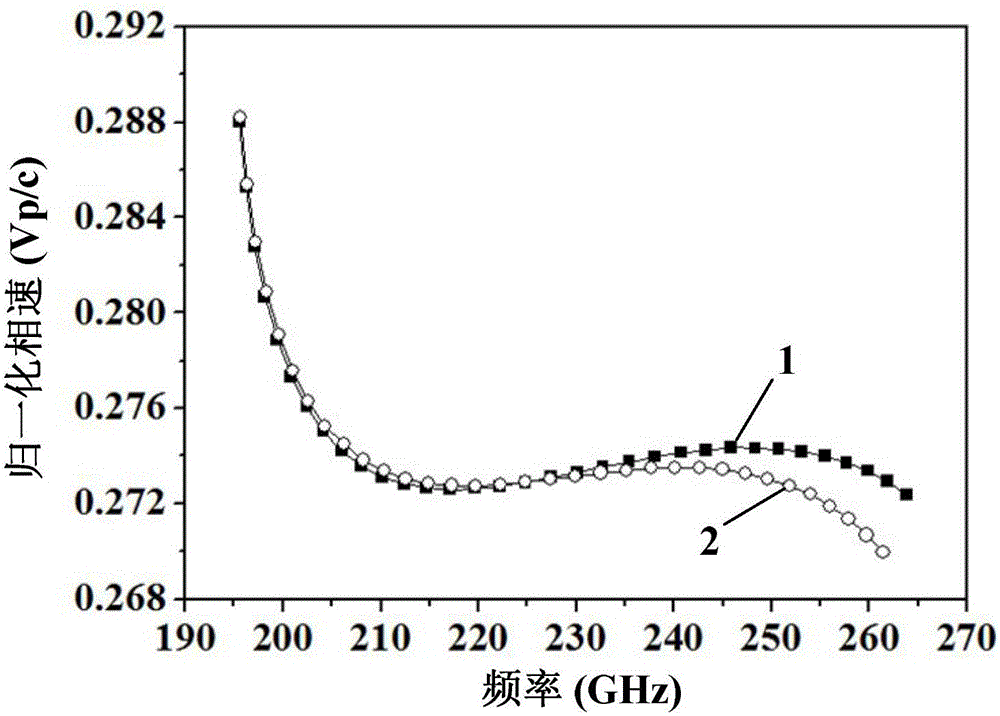

Circular-waveguide slow-wave structure for angularly loading spiral line

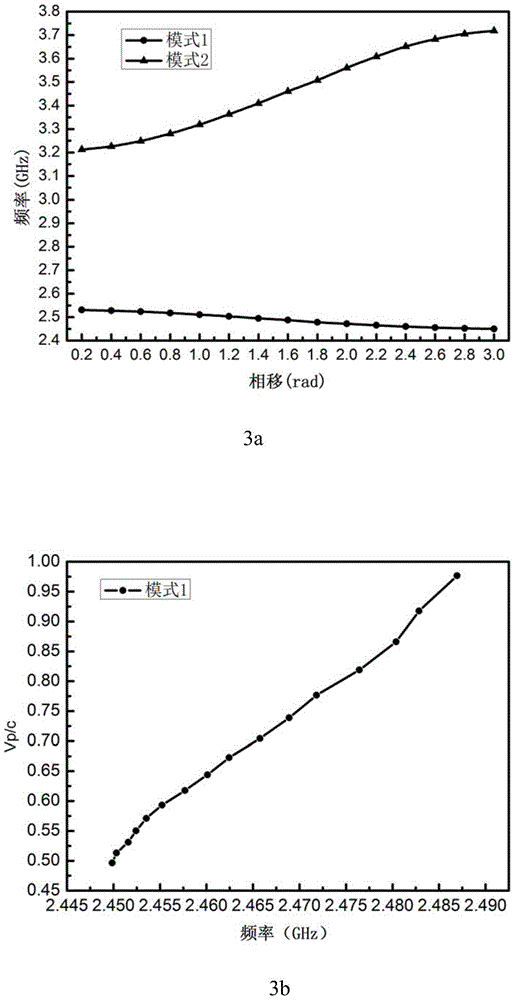

InactiveCN102074439AHigh gainImprove efficiencyTransit-tube circuit elementsWave structureDispersion curve

The invention relates to a circular-waveguide slow-wave structure for angularly loading spiral lines, which belongs to the technical field of vacuum electrons and comprises a circular waveguide, N identical spiral lines and two circular-ring medium sheets, wherein the radius of the circular waveguide is R1, the outer radii of the two circular-ring medium sheets are R1, and the inner radii of the two circular-ring medium sheets are R5; the two circular-ring medium sheets are respectively fixed on the two end surfaces of the circular waveguide, and the N identical spiral lines are all connected between the two circular-ring medium sheets, so that the N identical spiral lines are angularly and uniformly distributed inside the circular waveguide; and the hollow parts of the two circular-ring medium sheets and a space part surrounded by all the spiral lines together form an electron-beam passage. The circular-waveguide slow-wave structure can work at short millimeter-wave and terahertz-wave bands, the coupling impedance can be effectively improved, and a dispersion curve is more flat, so that a traveling-wave tube adopting the novel slow-wave structure has higher gain and interaction efficiency, and the larger output power is obtained; and in addition, the phase velocity can be greatly decreased in the invention, accordingly a lower working voltage can be adopted, and the circular-waveguide slow-wave structure is favorable to the miniaturization of devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Deformation-free thermal extrusion method for helix slow-wave component preparation

InactiveCN101642865AInfluence of high frequency characteristicsWill not deformMetal working apparatusCold cathode manufactureMicrowaveRoom temperature

The invention discloses a deformation-free thermal extrusion method for helix slow-wave component preparation, which relates to the microwave device technology and is used for preparing a helix travelling wave tube component. The method comprises the following steps: placing and fixing a metal tube shell on an extrusion platform, feeding a helix and a medium clamping rod into an extrusion die, heating the tube shell firstly to increase the inside diameter of the tube shell, pushing the helix and the clamping rod of which positions are well fixed to the tube shell by using a push rod, then stopping heating, taking down the extrusion die, recovering the temperature of the whole component to the room temperature, and generating a great contraction force at the moment due to the contraction ofthe inside diameter of the tube shell to be applied to the helix and the clamping rod component to firmly extrude the both inside the tube shell so as to finish the preparation of the slow-wave component. Various dies required by the method can be prepared by machining of a linear cutting electro-discharge machine tool. The method not only can well improve the heat dissipation performance of theslow-wave component, but also can avoid the component structure deformation, dielectric performance reduction and high-frequency loss increment caused by the conventional assembly method.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

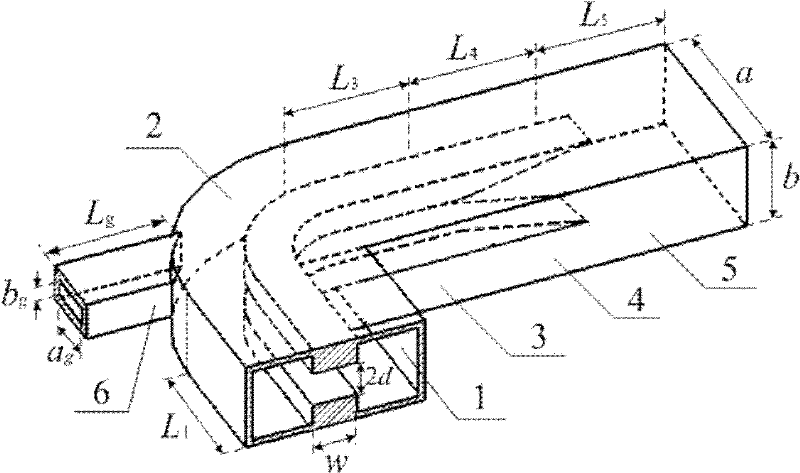

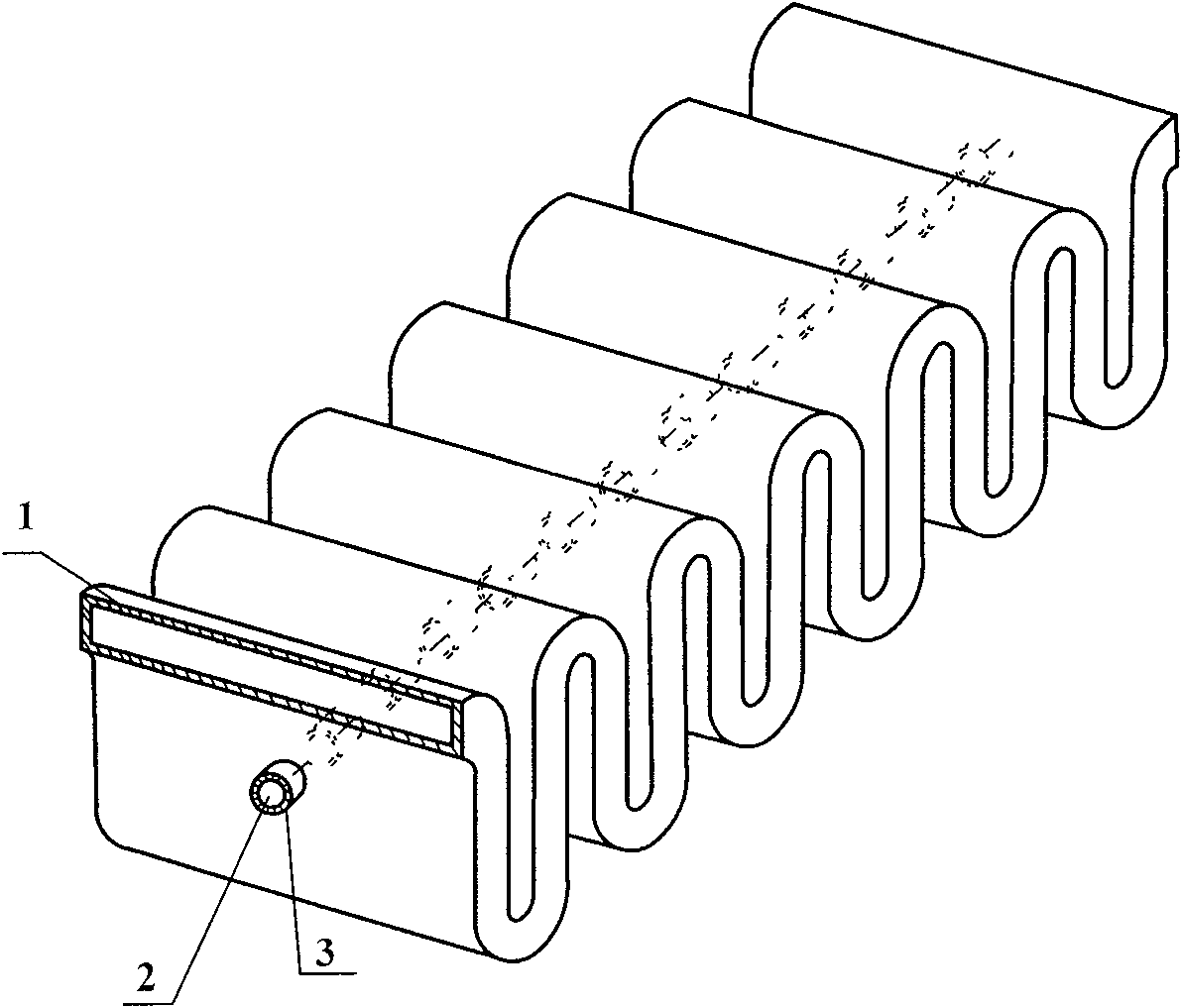

Input/output structure of broadband phase shift travelling wave tube

InactiveCN102315063ASimple structureEasy to processTransit-tube coupling devicesPhase shiftedBand shape

The invention, which belongs to the vacuum electronic technology field, relates to an input / output structure of a broadband phase shift travelling wave tube. The structure comprises six parts of waveguide type elements: a first double-ridge loading rectangular wave guide; a double-ridge loading rectangular wave guide, which is in a bending state of 90 degrees; a second double-ridge loading rectangular wave guide; a double-ridge gradient double-ridge loading rectangular wave guide; a first rectangular wave guide and a second rectangular wave guide. The first double-ridge loading rectangular wave guide and the second double-ridge loading rectangular wave guide are respectively connected with two ends of the double-ridge loading rectangular wave guide that is in a 90 degree bending; the double-ridge gradient double-ridge loading rectangular wave guide is connected between the second double-ridge loading rectangular wave guide and the first rectangular wave guide; and the second rectangular wave guide is connected with an outboard curved surface window of the double-ridge loading rectangular wave guide that is in a 90 degree bending, wherein a central axis of the double-ridge loading rectangular wave guide that is in a 90 degree bending is superposed with a central axis of the first rectangular wave guide. According to the invention, broadband microwave signal energy and a band shape electronic beam can be well introduced and a sine wave guide structure can be lead out; besides, the input / output structure is simple and is easy to process and realize.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

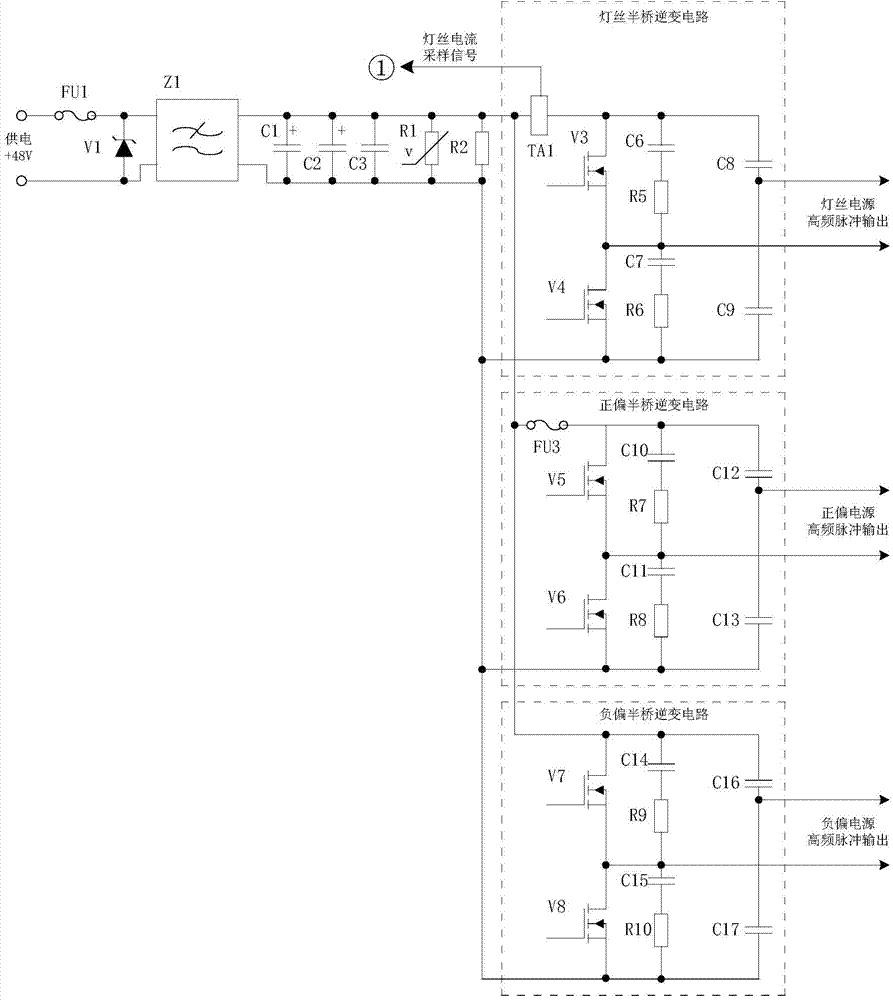

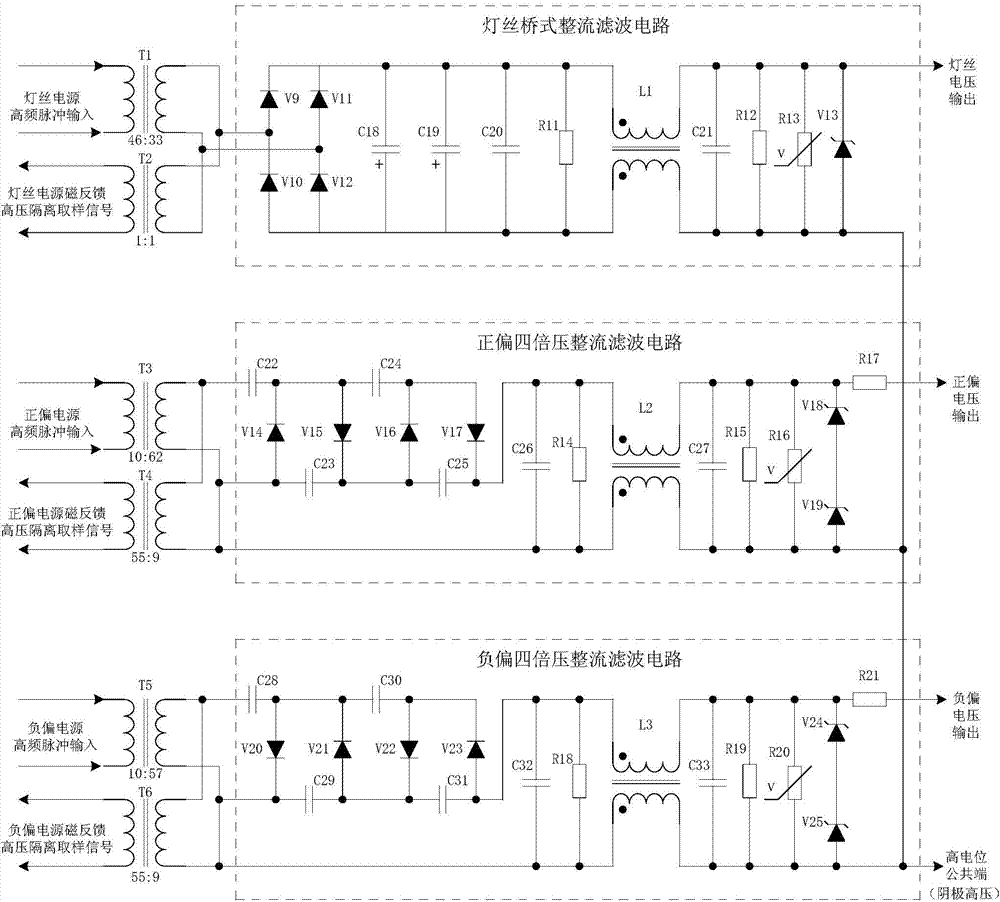

Adjustable integrated high-voltage grid electrode pulse modulator

ActiveCN103929847AMeet the requirements of working conditionsPerfect protection circuitElectric light circuit arrangementPower conversion systemsLow voltageEngineering

The invention relates to an adjustable integrated high-voltage grid electrode pulse modulator. An improved design is conducted on a filament high potential power supply circuit, a positive biased high potential power supply circuit, a negative biased high potential power supply circuit and a grid electrode pulse modulator circuit, and the high dense integration of the three high potential power supply circuits and the grid electrode pulse modulator circuit is achieved; a feedback circuit of a high potential power supply is improved, a magnetism feedback high voltage isolation sampling technology is adopted, and respectively independent adjustment to the high potential power supply output voltage values is achieved at the low voltage side; a high potential integrated failure detecting circuit is added, and the high potential power supply multi-circuit failures are integrated into one circuit signal; a pulse driving circuit is improved, and a dual-level denoising circuit is added; a grid electrode floating plate modulating circuit is improved, and an fire-making resistance protection circuit protection modulator and a traveling wave tube are added; a high-voltage transformer structure used for the modulator is improved, the size is reduced, and high-voltage isolation is achieved.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

Trapezoidal slow wave lines of coupling slot for traveling wave tube

InactiveCN101840834ASolve job instabilityHigh bandwidthTransit-tube circuit elementsPhotonic crystalCoupling

The invention relates to trapezoidal slow wave lines of a coupling slot for a traveling wave tube. Multiple groups of rectangular metal plates are periodically arranged along the axial direction of an electron beam passage of the traveling wave tube; the rectangular metal plates are vertical to the axial direction; the centers of the rectangular metal plates are provided with round holes, and the two ends of narrow sides of the rectangular metal plates are provided with rectangular coupling slots; the rectangular metal plates are coated by axially extending metal shielding shells of which the insides have rectangular shapes matched with the sizes of the rectangular metal plates. The trapezoidal slow wave lines are characterized in that: at least one photonic crystal bar which extends along the axial direction of the electronic beam passage is arranged in the rectangular coupling slots. The trapezoidal slow wave lines have the advantage of overcoming the defects of narrow bandwidth and unstable higher-mode work existing in the conventional trapezoidal slow wave lines of the coupling slot.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Ridge loading zigzag waveguide slow wave line

InactiveCN101651074ALow coupling impedanceHigh coupling impedanceTransit-tube circuit elementsWave structureMicrowave

The invention relates to a ridge loading zigzag waveguide slow wave line which belongs to the technical field of microwave vacuum electrons and relates to a traveling wave tube amplification device. The device is formed by connecting a series of arc bending waveguides (or right-angle bending waveguides) and straight waveguides end to end, i.e. bending rectangular waveguides into a U-shaped zigzagline (or a right-angle zigzag line) periodically along the electric field surface, so as to form a zigzag waveguide structure. A metal ridge sheet with a certain thickness is loaded on the inner wallsof the straight waveguides of each zigzag unit, and the waveguide walls and the metal ridge sheets are provided with round through holes along the position of a middle axle symmetric line of a slow wave structure, wherein the round through holes of the straight waveguides of two adjacent zigzag units are connected through a metal pipe with an aperture size the same as the aperture size of the round through hole so as to form an electron bunch passage. The invention can improve the coupling impedance of a zigzag waveguide slow wave system, thereby ensuring that a zigzag waveguide traveling wave tube has higher gain and efficiency.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Small all-metal slow wave device

ActiveCN104064422AIncrease output powerImprove output efficiencyTransit-tube circuit elementsElectrical conductorVacuum electronics

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

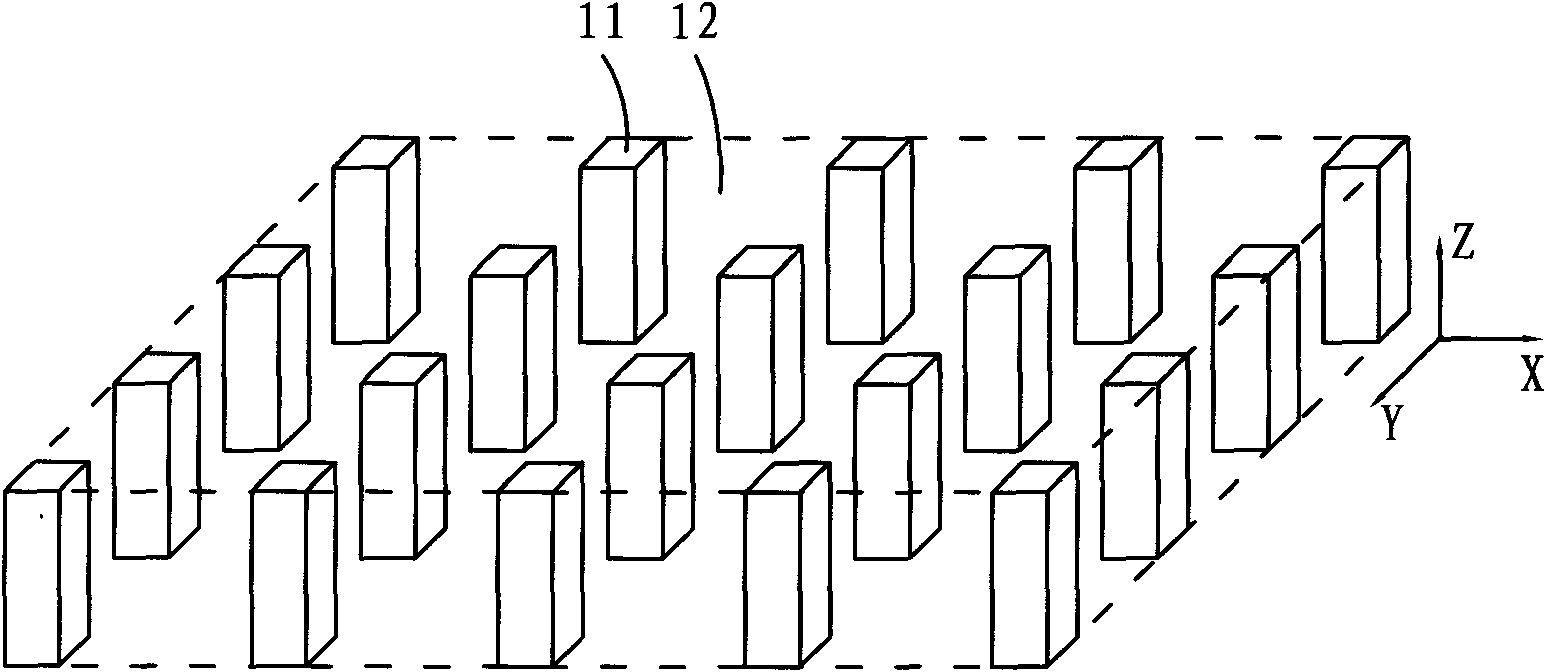

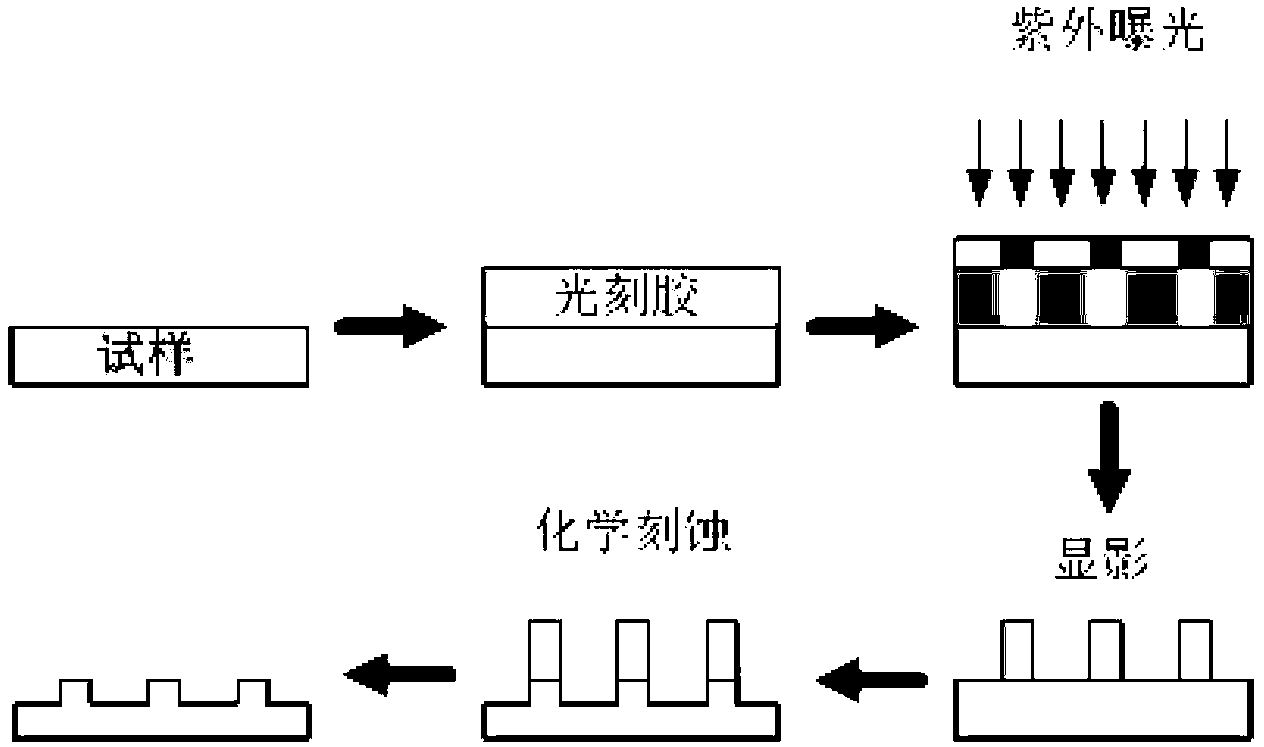

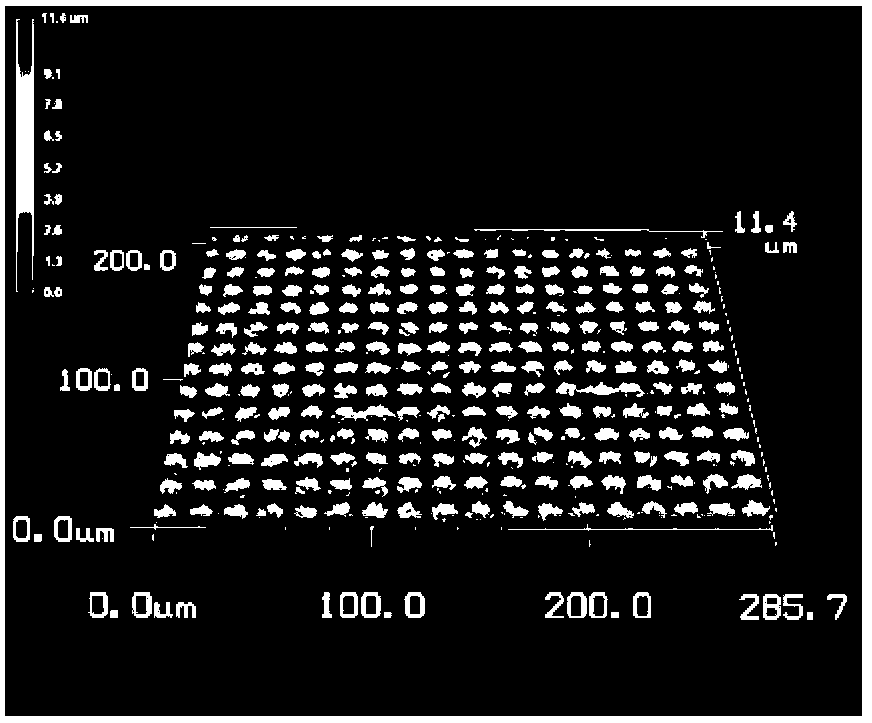

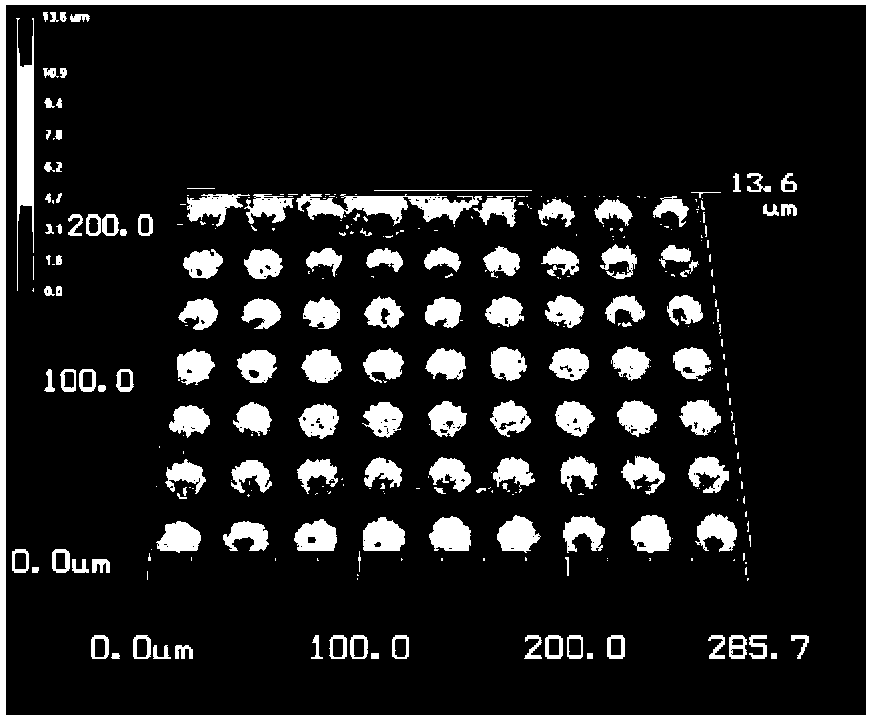

Method for reducing metal secondary electron yield by utilizing regular array structure

InactiveCN102795591AImprove work performanceLower secondary electron emission coefficientDecorative surface effectsChemical vapor deposition coatingPorositySecondary electrons

The invention provides a method for inhibiting a metal surface SEY (Secondary Electron Yield) by utilizing a regular array structure. The regular array structure is realized by utilizing an image photolithography process of a semiconductor device field. A typical array structure can adopt a circular hole or a rectangular groove structure; and the size of the structure ranges from several microns to dozens of microns. The shape of the regular array structure is determined by a designed mask, and the depth / width ratio of a regular trap is determined by etching time. Under the condition of the same depth / width ratio and porosity, the inhibiting effect of a circular hole trap surface SEY is better than that of a rectangular groove trap surface; with the regard to the same array structure, the porosity is greater when the depth / width ratio is greater, and the SEY inhibiting effect is better. The technology disclosed by the invention has the potential application value on inhibiting a micro-discharging effect of a metal microwave part in a satellite load and a particle accelerator, namely the surface SEY is reduced through a surface imaged photolithography under the precondition of not changing a surface metal material of the part, so that the micro-discharging effect can be inhibited in a greater extent. Meanwhile, the technology is also applicable to various special application fields needing to carry out metal surface SEY inhibition, such as a traveling wave tube collection electrode and the like; and the method has certain universality.

Owner:XI AN JIAOTONG UNIV +1

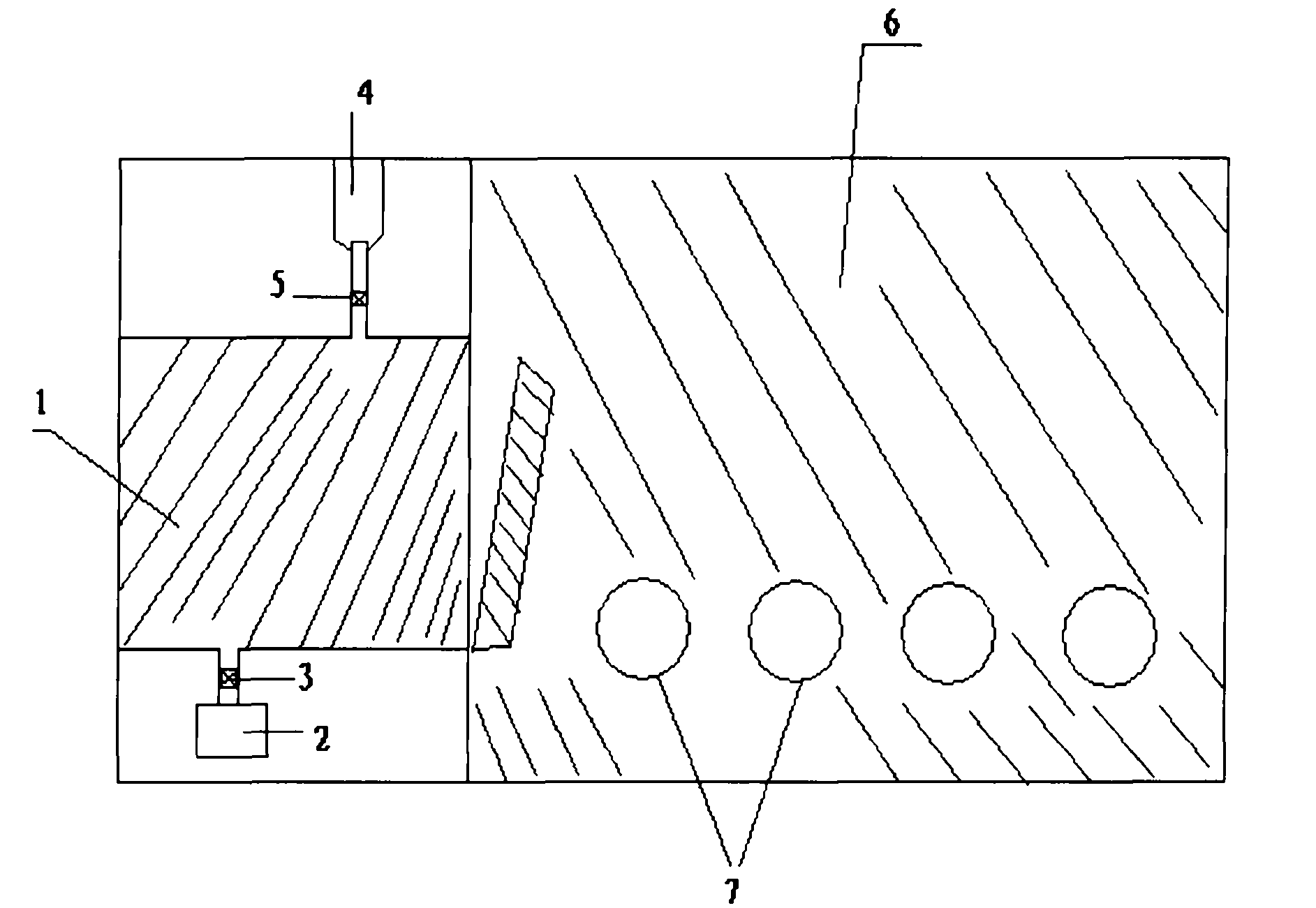

Glove box protective argon arc welding method

InactiveCN101844266ALower oxygen levelsImprove work efficiencyArc welding apparatusVacuum pumpingShielding gas

The invention discloses a glove box protective argon arc welding method. In the method, the oxygen concentration in a transition cabin and a glove box of the glove box protective argon arc welding equipment is lowered to minimum through the method of rapid vacuum pumping, aerating, rapid vacuum pumping and secondary aerating by the glove box protective argon arc welding equipment, and the factors, such as protective gas, protective gas flow, welding current, arc length and welding speed and the like in the welding process are screened to determine best welding process. Experimental results indicate that the glove box protective argon arc welding method provided by the invention can further improve anti-oxidation effect, has high welding efficiency and good-quality welded products, and can be used on high-power products; if the method is used for high-power travelling wave tubes, the quality of the travelling wave tubes is improved, the service life is prolonged and the economic benefit is better.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

Four-stage depressed collector for space traveling-wave tube

InactiveCN102110564AImprove recycling efficiencyImprove cooling effectTravelling-wave tubesTransit-tube collectorsCeramicElectrical and Electronics engineering

The invention relates to a four-stage depressed collector for a space traveling-wave tube. A first collector component, a second collector component, a third collector component and a fourth collector component are parallelly arranged inside a circular pipe-shaped collector outer cylinder in sequence in the axial direction, a certain insulating gap is formed between every two collector components, and the electrode lead of each collector passes through an insulating ceramic hole; each collector component comprises a collector electrode, electrode insulating ceramic and an electrode lead; the collector electrode is welded together with the collector outer cylinder through the insulating ceramic; the collector electrode is welded on the inner wall of the electrode insulating ceramic, the outer wall of the electrode insulating ceramic is welded together with the collector outer cylinder, and the electrode lead is directly welded together with the collector electrode and is insulated with other electrode through the insulating ceramic; and the collector outer cylinder is welded and fixed with a collector end cover to form the four-stage depressed collector.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

TWT impregnated Ba-W cathode and its preparation method

InactiveCN101145490AExtended service lifeLarge average pore sizeTransit-tube cathodesCold cathode manufactureRheniumPorosity

The invention discloses a dip-coated barium-tungsten cathode for traveling-wave tubes and a preparation method thereof. The dip-coated barium-tungsten cathode comprises a cathode drum, a cathode spongy body positioned inside the cathode drum. The invention is characterized in that the cathode spongy body is laminated by a tungsten spongy body and a tungsten-rhenium spongy body, wherein the tungsten-rhenium spongy body is coated with a noble metal film on the surface. With the above structure and preparation method, compared with the prior art, the cathode spongy body is a two-layered cathode spongy body laminated by the tungsten spongy body and the tungsten-rhenium spongy body, to replace the single-layer alloy substrate with uniform porosity in the prior art; the consumption of the noble metal Re is reduced; the porosity of the tungsten spongy body is increased; the storage level of cathode salts is increased; and the preferable proportion of the cathode salts allows both the emission behavior and the stability of salts better. With the noble metal Re coating, the cost of target materials is reduced. The consumption of noble metal is greatly reduced while ensuring the maximal emission and long service life of alloy substrate film-coated cathodes. The storage quantity of cathode salts is increased and the service life of cathode is prolonged.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Broadband multi-waveguide output device for rotary traveling wave tube

ActiveCN102509686AImprove conversion efficiencyCompact structureTransit-tube coupling devicesOutput deviceBand width

The invention belongs to a broadband multi-waveguide output device for a rotary traveling wave tube. The broadband multi-waveguide output device comprises a circular waveguide, long stripped rectangular waveguides and rectangular coupling holes, wherein the circular waveguide is provided with an input opening and an output opening, the long stripped rectangular waveguides are arranged on a circular waveguide casing at intervals in the axial direction and are provided with microwave output openings, the rectangular coupling holes are arranged between the circular waveguide and the rectangular waveguides, the axial lengths of all holes are identical, the center distances among all holes are identical, the widths of four front holes at two ends of each group of rectangular holes are in step-type arrangement from narrow to wide, the width of each hole in the middle is the same as the width of the fourth hole at the two ends, and in addition, an inclined coupling surface is also arranged at the junction part of each rectangular waveguide inner cavity front end surface and the circular waveguide. The multi-waveguide output device has the characteristics that the requirements of the millimeter band of high power, high gain and high frequency band for being matched with the rotary traveling wave tube to be used can be sufficiently met, the base parameters are provided for the optimization design of voltage reduction collection electrodes, and the like. The defects of narrow band width, matching use difficulty with the broadband rotary traveling wave tube, and the like in the prior art are overcome.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Structure of coaxial-to-waveguide transition and traveling wave tube

ActiveUS20080246553A1Easy to adjustAvoid arcingMultiple-port networksTravelling-wave tubesElectrical conductorCoaxial waveguides

The present invention includes a waveguide for outputting radio frequency wave, a vacuum envelope provided with a slow-wave circuit, a coaxial connection part connecting the waveguide and the vacuum envelope, an insulating window member which is provided in the coaxial connection part and which hermetically seals a said of vacuum envelope and a said of waveguide, a coaxial center conductor of exterior portion with one end supported by the waveguide, and a coaxial center conductor of an interior portion with one end abutting on the slow-wave circuit and the other end connected to the coaxial center conductor of the exterior portion. The waveguide is provided with a screw part supporting the coaxial center conductor of the exterior portion movably in an axial direction of the coaxial center conductor of the exterior portion. An end portion of the coaxial center conductor of the exterior portion is connected to the end portion of the coaxial center conductor of the interior portion movably in the axial direction of the coaxial center conductor of the exterior portion.

Owner:NEC NETWORK & SENSOR SYST

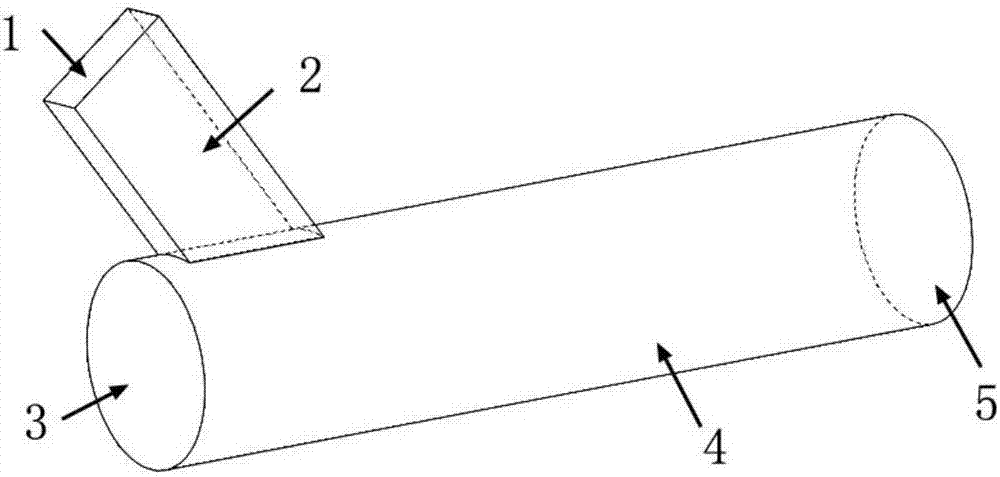

Mode exciter from rectangular waveguide TE<10> mode to round waveguide TE<21> mode and design method

ActiveCN107425237AImprove mode conversion efficiencySimple structureWaveguide type devicesRoad surfaceLength wave

The invention relates to a mode exciter from a rectangular waveguide TE<10> mode to a round waveguide TE<21> mode and a design method. The work wavelength of the mode exciter is Lambda, and comprises rectangular waveguide and round waveguide; the rectangular waveguide comprises an input port and an output port; the round waveguide comprises a short circuit surface and an output port; the output port end of the rectangular waveguide is tipsily embedded into the round waveguide in a position with the distance being 1 / 4 work wavelength away from the short circuit surface, so that electromagnetic waves are transmitted to the output port of the round waveguide from the input port of the rectangular waveguide; the mode excitation on the round waveguide can be realized; the narrow edge of the rectangular waveguide is vertical to the axial line of the round waveguide; the center line of the rectangular waveguide and the axial line of the round waveguide form an included angle being theta; the length of the rectangular waveguide is 1 to 2 times of the work wavelength; and the length of the round waveguide is 5 to 7 times of the work wavelength. The mode exciter provided by the invention has the advantages that the structure is simple; and the work frequency band and the mode conversion efficiency can meet the requirement of the propagation characteristic measurement of the TE<21> mode in a gyro traveling wave tube high-frequency system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Angular-clamping biradial electron beam angle logarithmic plane zigzag slow-wave line slow-wave structure

InactiveCN107180734AAchieve improvementImprove electronic efficiencyTransit-tube circuit elementsBeam angleWave structure

The invention discloses an angular-clamping biradial electron beam angle logarithmic plane zigzag slow-wave line slow-wave structure, and relates to the field of radial beam traveling-wave tube systems. The structure comprises a metal cavity, an angle logarithmic metal plane zigzag slow-wave line, an upper ideal cathode, a lower ideal cathode, a first medium supporting rod, and a second medium supporting rod. The structure solves a problem of an ineffective angle logarithmic micro-strip slow-wave structure in a working process of a radial beam traveling-wave tube, which is caused by a condition that a defocused electron beam is liable to bombard a logarithmic micro-strip and causes the fusion of the logarithmic micro-strip.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

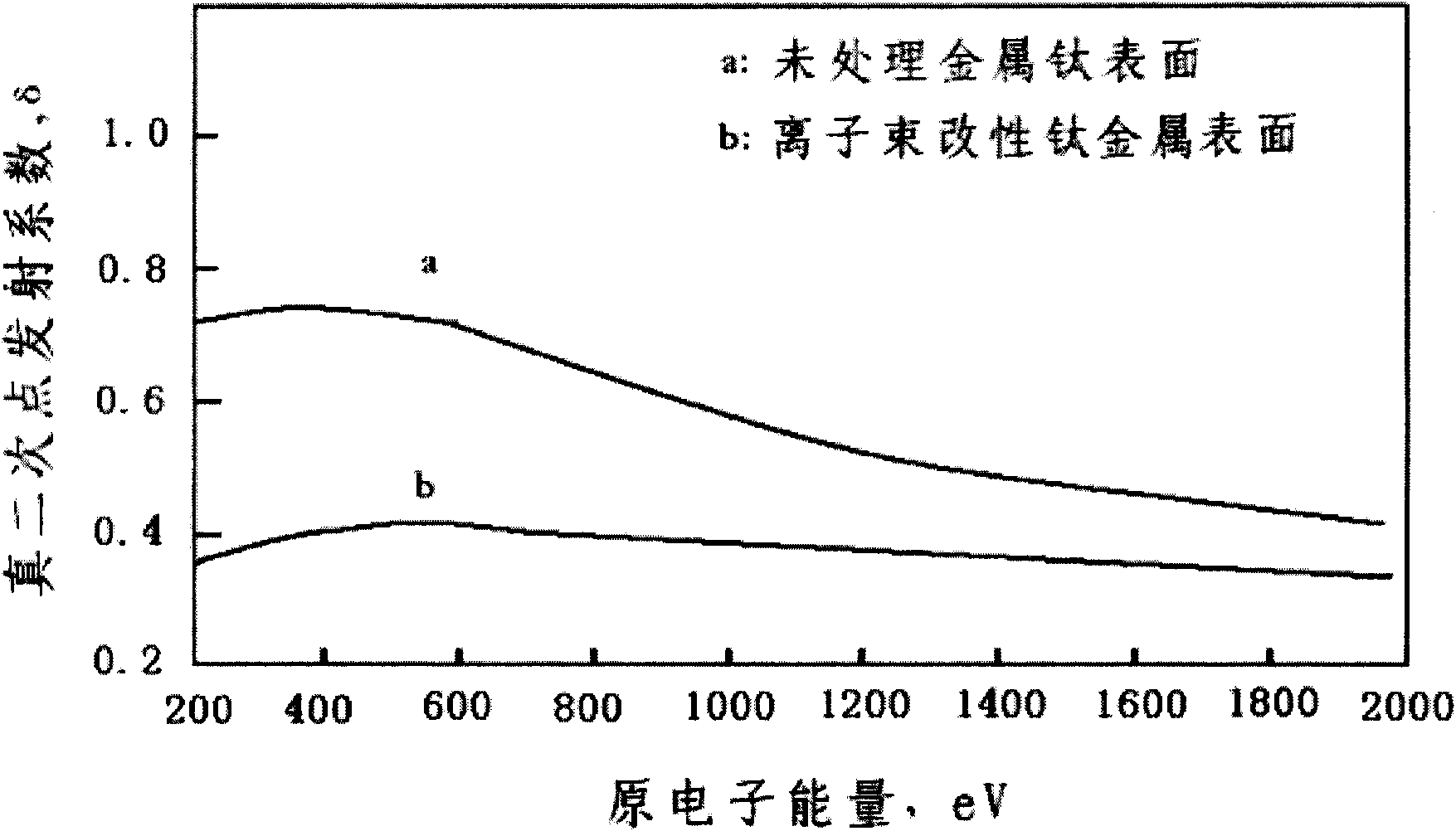

Multi-stage depressed collector material and preparation and surface treatment method thereof

InactiveCN101964290AImprove efficiencyTravelling-wave tubesTransit-tube collectorsIon beamSecondary electrons

The invention discloses a multi-stage depressed collector material and preparation and a surface treatment method thereof, which relates to a vacuum electronic technology and is a novel microporous electrode material which can be used for a multi-stage depressed collector of a satellite traveling-wave tube and a treatment process thereof. The electrode material has a micron / submicron-level microporous structure and is beneficial to inhibiting secondary electron emission and improving the recovery efficiency of the multi-stage depressed collector, thereby improving the overall efficiency of the traveling-wave tube. The method has the advantages of simple and controllable process and low cost. Compared with the surface modified by ion beams, the electrode surface of the prepared multi-stage depressed collector has the same effect on inhibiting secondary electron emission.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Manufacturing process of slow wave system for helix travelling wave tube

InactiveCN104485270ASimple structureImprove cooling effectCold cathode manufactureHelical lineEngineering

The invention relates to a manufacturing process of a slow wave system for a helix travelling wave tube. The manufacturing process comprises steps that, (1), a helix and a clamping rod are put in a tube casing to form a slow wave before extrusion; (2), the slow wave before extrusion is put in an extrusion tool, the position corresponding to the clamping rod is aligned with a pressing head of the extrusion tool, pressing force is exerted through the extrusion tool to make the tube casing, the clamping rod and the helix to realize tight contact; (3), a white copper ring and a pure iron pole shoe are sleeved outside the tube casing, an AgCu welding material is filled, and the parts are sent to a hydrogen furnace; (4), the temperature curve of a hydrogen furnace is set as follows, the temperature increasing / decreasing speed is 15DEG C / min, the soldering temperature is 780 DEG C, the insulation time is 2 minutes, and the parts are taken out after soldering; and (5), whether the clamping rod and the helix of the slow wave system generate displacement and whether the welding material is fully melted are detected through a microscope. According to the manufacturing process, structure soundness and thermal diffusivity of the slow wave system are greatly improved through the hot compression effect, and bearable power of the whole tube can be improved correspondingly.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

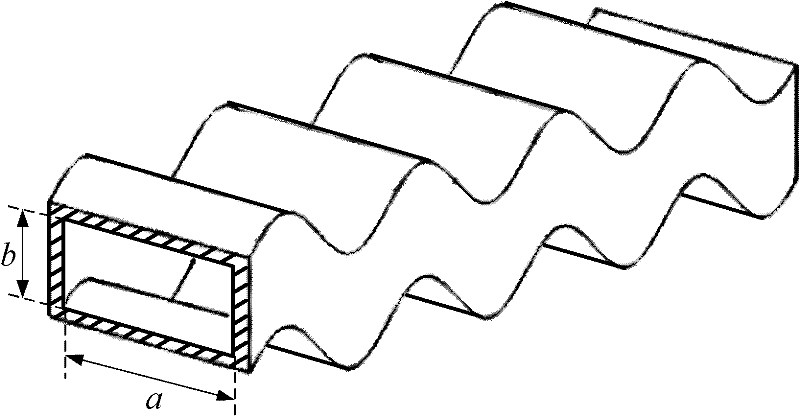

Flap-topped sine waveguide slow wave structure

InactiveCN105869971AHigh coupling impedance valueImprove dispersion characteristicsTransit-tube circuit elementsWave structureClassical mechanics

The invention discloses a flat-topped sine waveguide slow wave structure. The size b of a narrow side is compressed appropriately on the basis of a sine waveguide slow wave structure, and the compression size is equal to the height of periodical strip fluctuation cut-tops of upper and low sine lines, so that the size parameter meets the condition that b is smaller than the sum of hb and 2h, wherein hb is the height of a sheet electron beam channel and h is the height of periodical strip fluctuations of the sine lines. Tests show that the flat-topped sine waveguide slow wave structure has a higher coupling impedance value, the dispersion characteristic is improved, increase of traditional coupled impedance is prevented, the defect that the dispersion characteristic is reduced is overcome, the interactive capacity between electron beams and electromagnetic waves is improved, and the output power, the gain and the interaction efficiency of traveling-wave tubes are improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com