Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139 results about "Graphite dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process and equipment for producing graphite dust

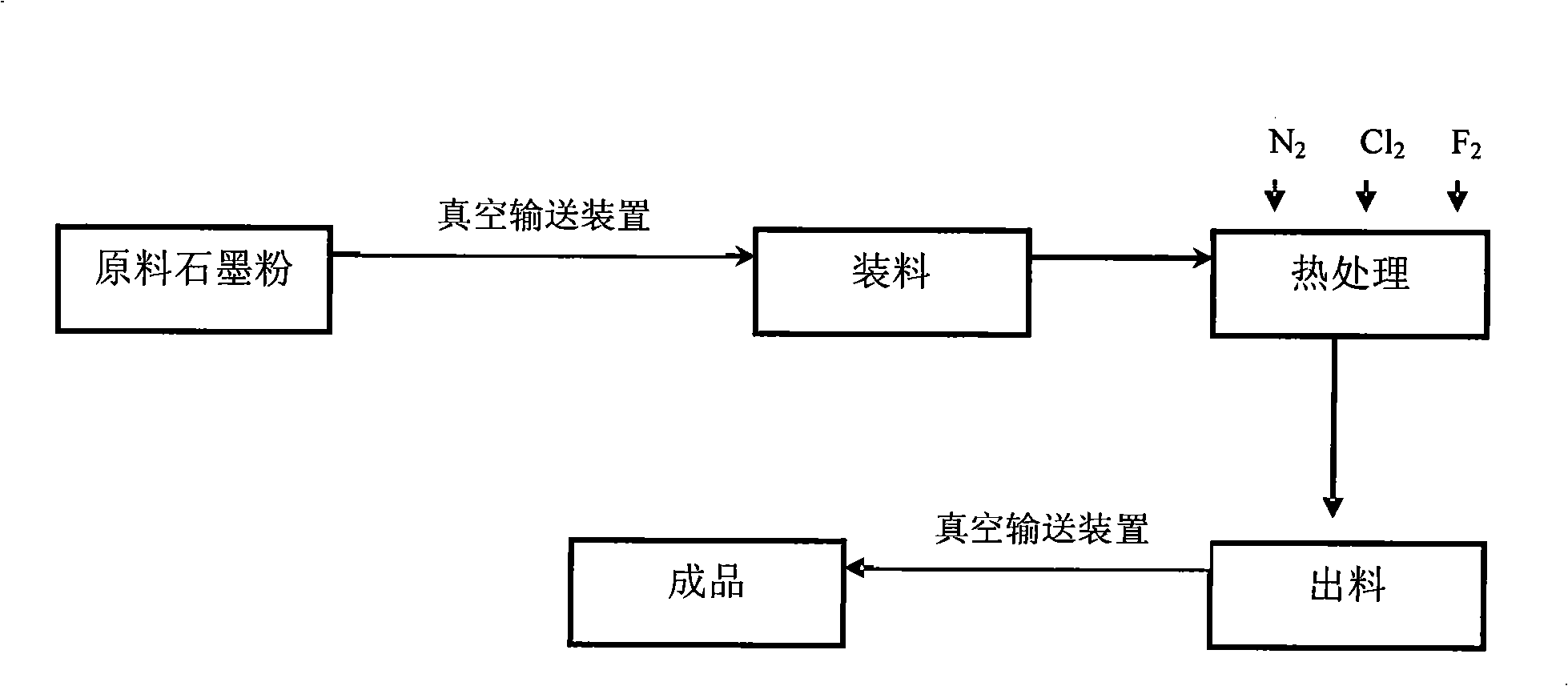

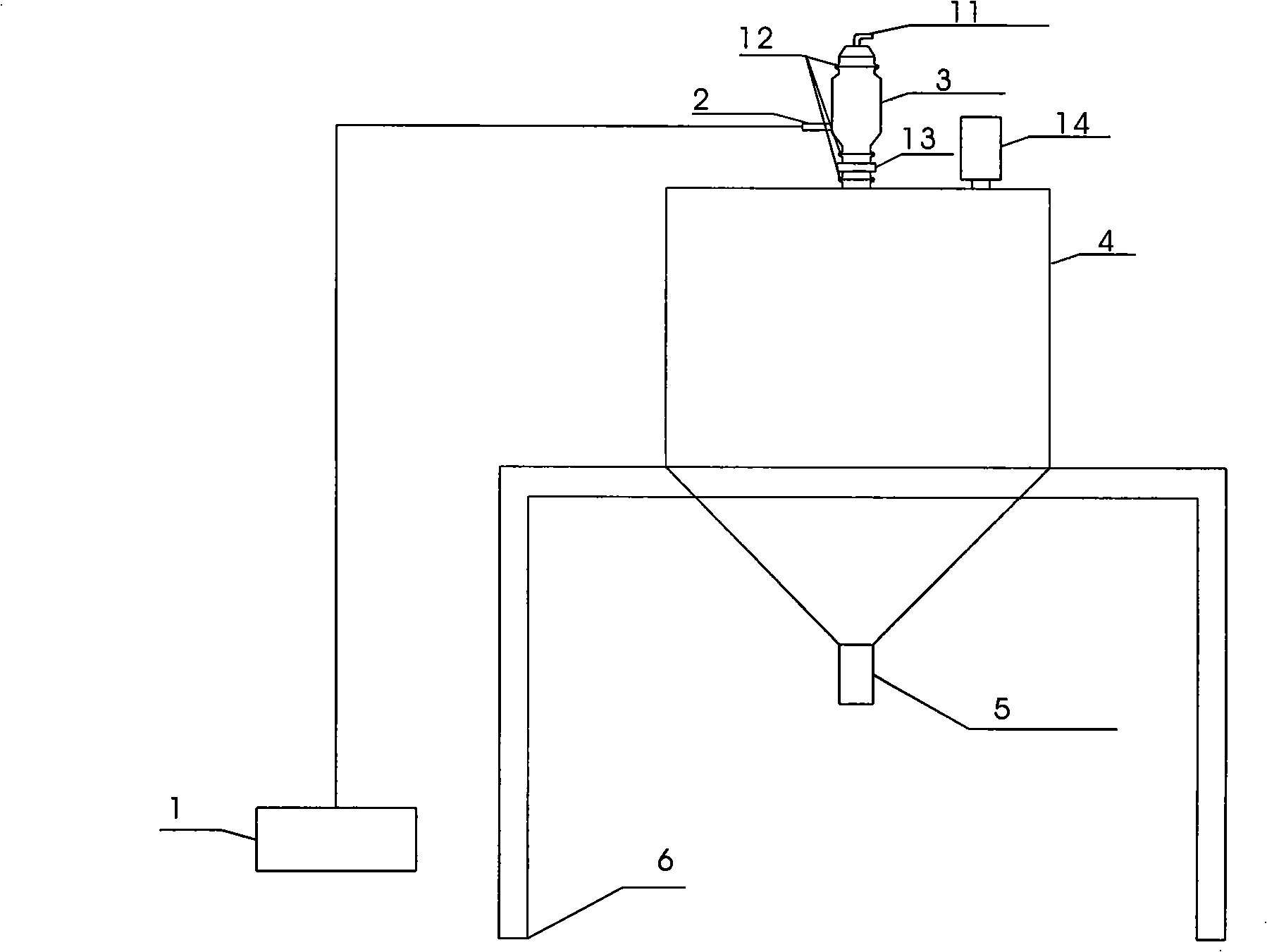

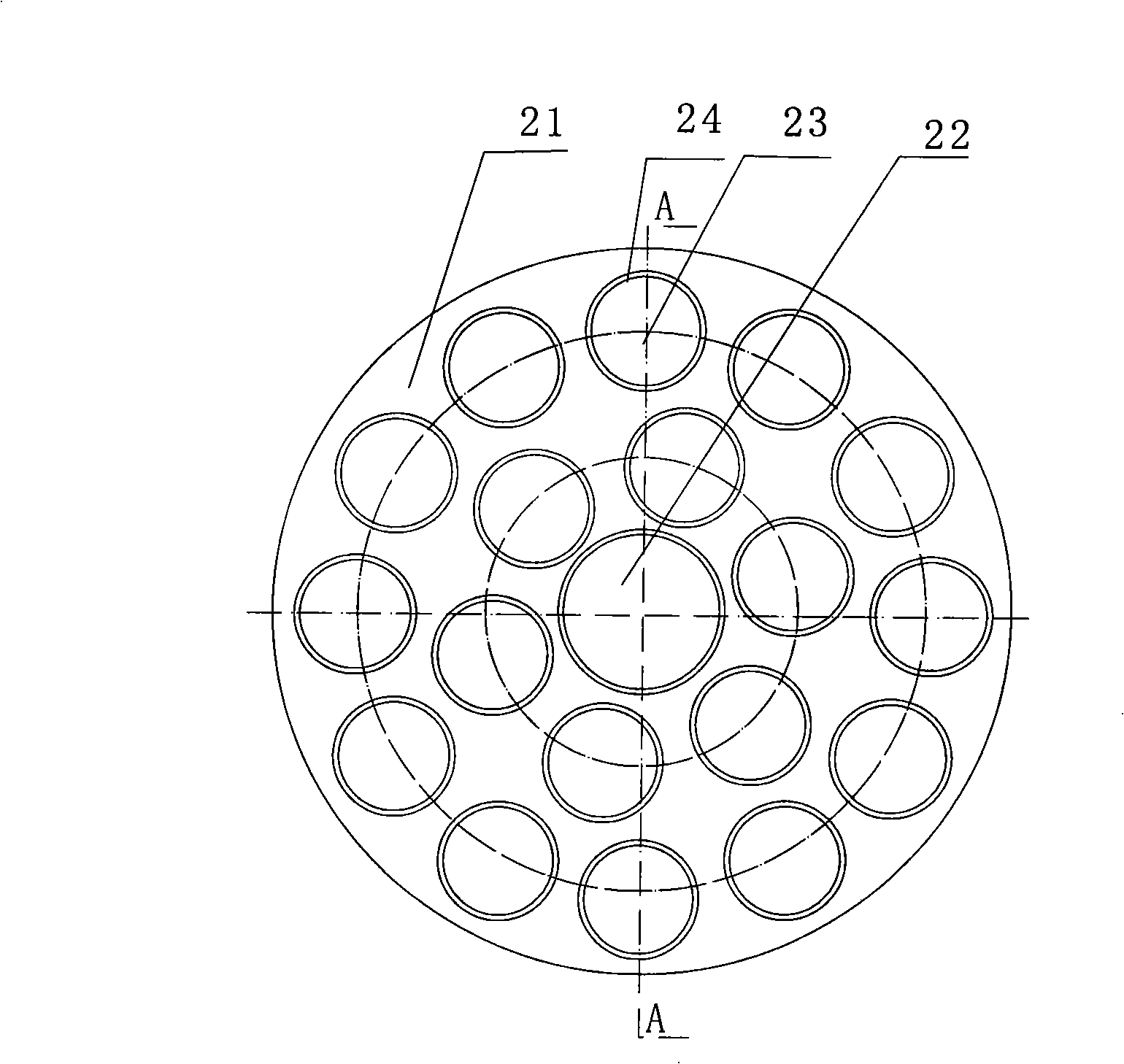

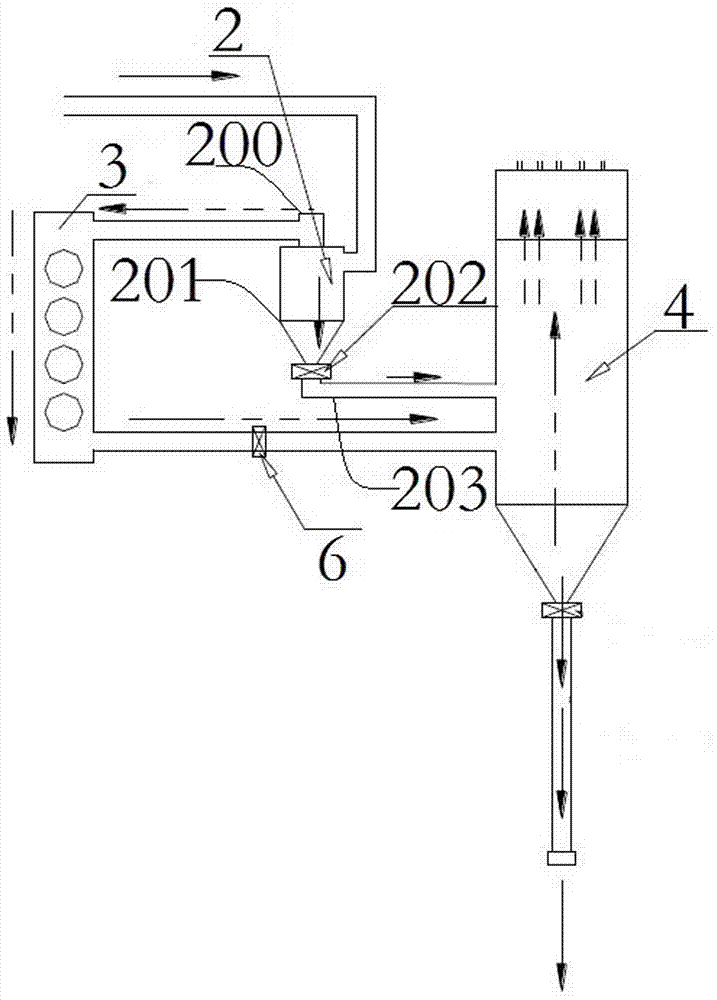

ActiveCN101318648AReduce entryImprove graphitization heat treatment efficiencyCell electrodesChemical industryState of artVacuum delivery

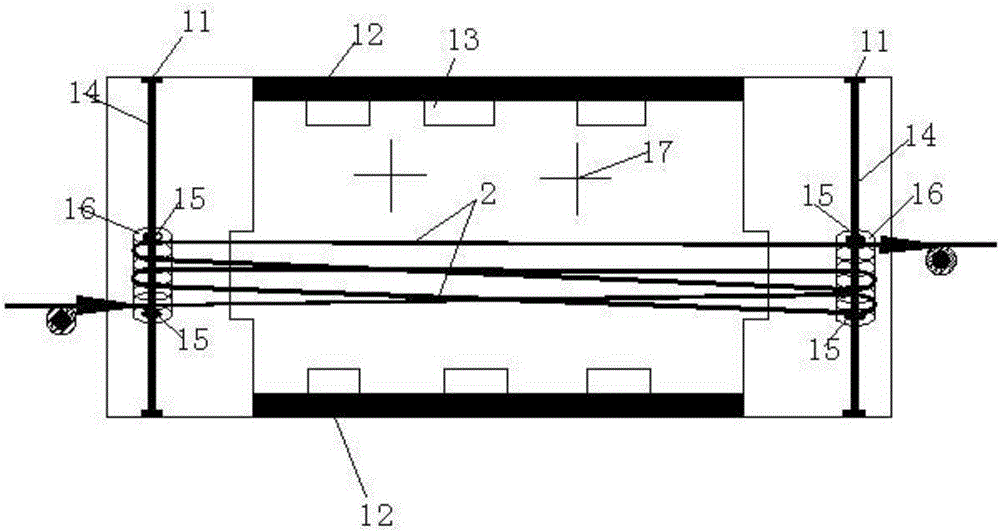

The invention discloses a method for preparing graphite powder and the equipment thereof and aims at solving the technical problems of improving the purity of graphite powder and reducing cost. The method of the invention comprises the following steps: the raw micro powder is delivered to a graphite crucible under vacuum state and put into a graphitizing furnace; and a graphite powder product is obtained after heat treatment and cooling. The preparation equipment of graphite powder is composed of a vacuum delivery device, a graphitizing furnace and a vacuum discharging device sequentially connected; the graphitizing furnace is equipped with a graphite crucible and connected with a gas filling system. Compared with the prior art, the method and the equipment of the invention are characterized in that the raw micro power is put into the graphite crucible after vacuum delivery, thus the entry of impurities is reduced in the treatment process, the product purity is greatly improved after heat treatment, graphitization is even, the consistency of the product is good, the graphitization and heat treatment efficiency of the powder material is improved, the technique is simple and the cost is low.

Owner:BTR NEW MATERIAL GRP CO LTD

Engraving and milling machine for graphite rod production

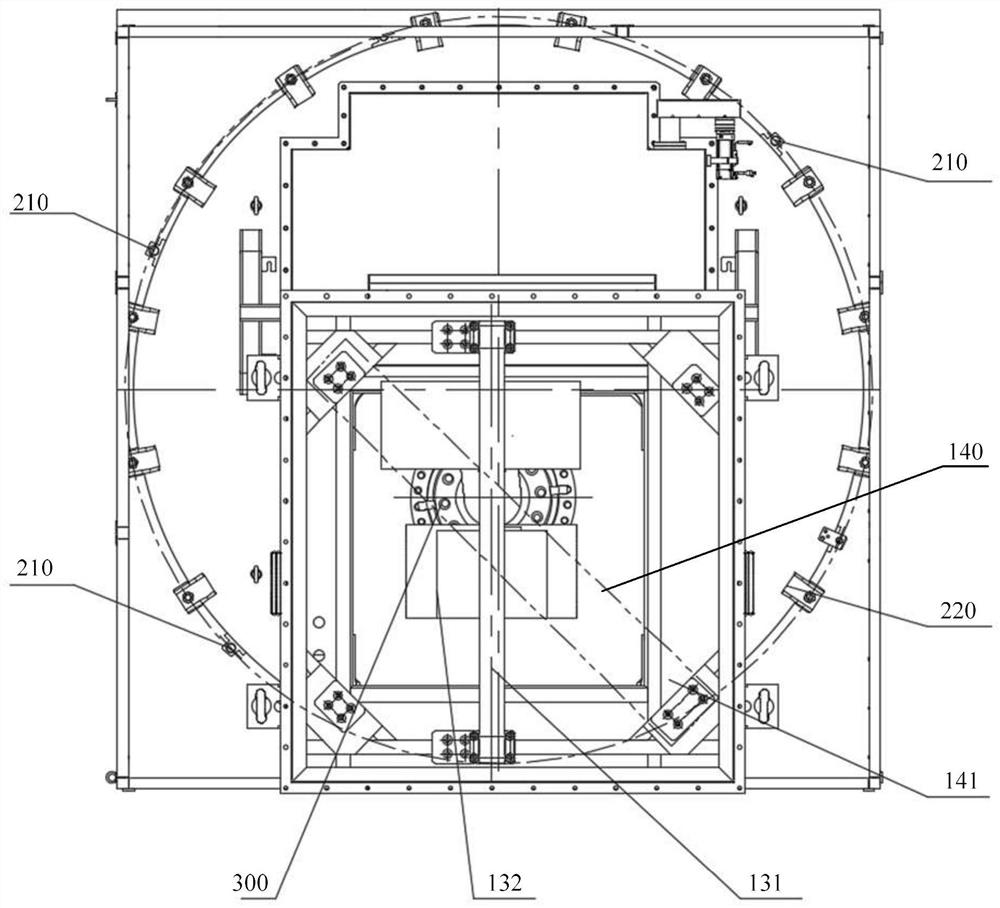

ActiveCN105397923AStable jobMove fastWorking accessoriesStone-like material working toolsEngineeringGraphite dust

The invention discloses an engraving and milling machine for graphite rod production. The engraving and milling machine comprises a machine base, a horizontal movement table, supporting plates, a movable device and an engraving and milling mechanism. The horizontal movement table is connected with the machine base through a drive mechanism. Locating supporting mechanisms are arranged on the top face of the horizontal movement table. The movable device comprises a locating frame and a movable mechanism. A first motor is arranged on one side of the locating frame, and a limiting block is arranged on the other side of the locating frame. The limiting block is connected with a second U-shaped supporting plate through a connecting block. A gas conveying pump is arranged in the second U-shaped supporting plate and connected with the engraving and milling mechanism through a gas conveying guide pipe. The engraving and milling machine is simple in structure in structure and high in practicality, the stability of a graphite plate on the horizontal movement table is improved, and the flexibility and practicality of the engraving and milling mechanism are improved; the engraving and milling mechanism and the horizontal movable table do relative movement together so that the engraving and milling machine can achieve machining of graphite rods of different sizes; and graphite dust generated during machining can be effectively recycled.

Owner:SHENGZHOU SIGMA TECH

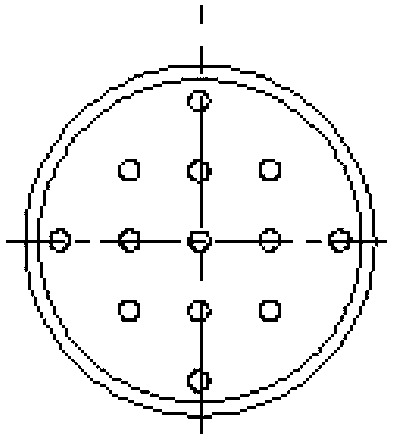

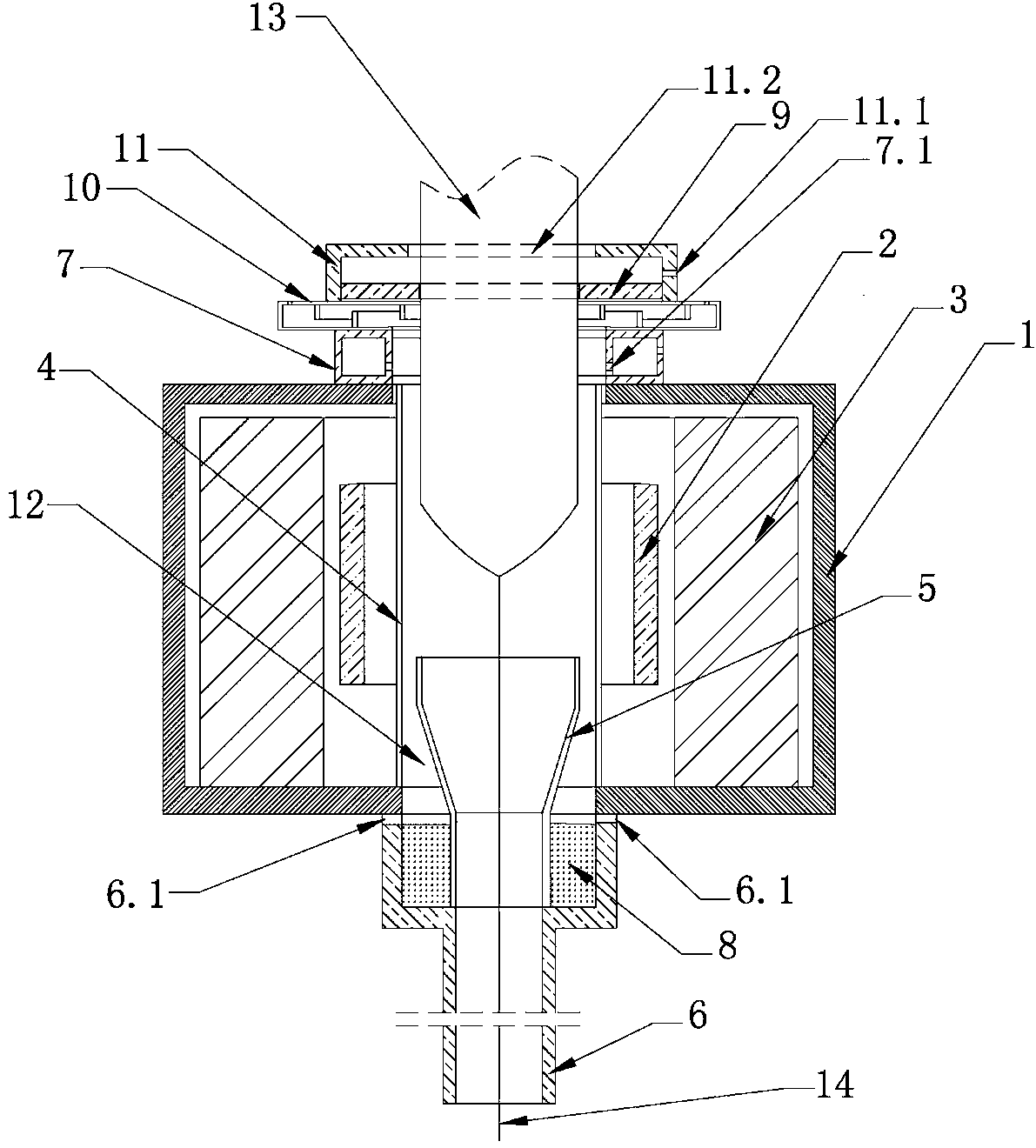

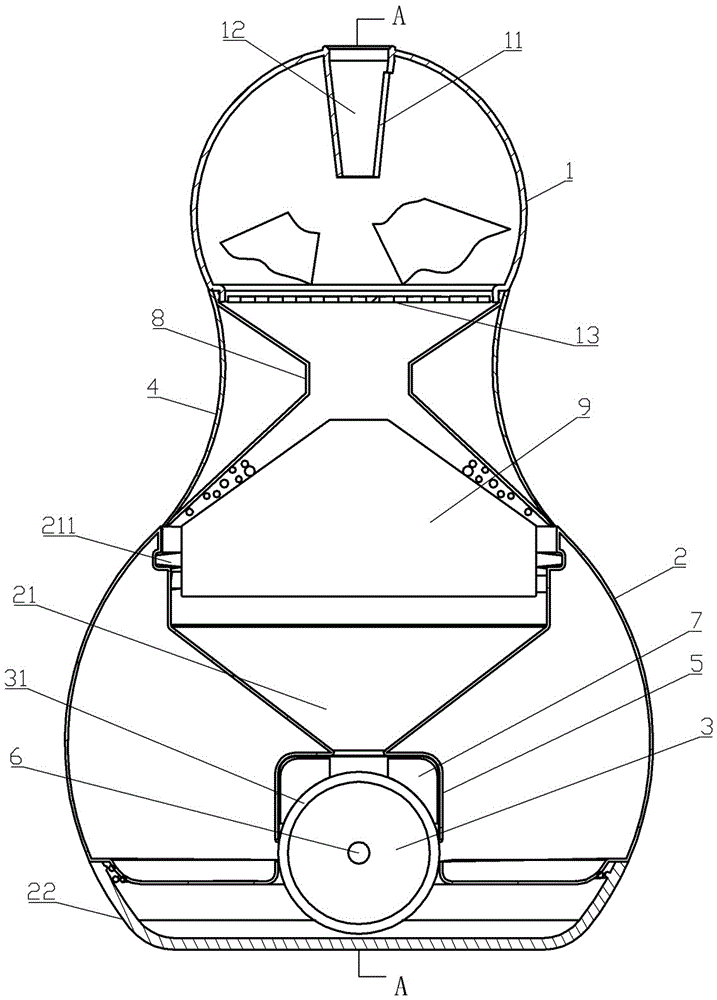

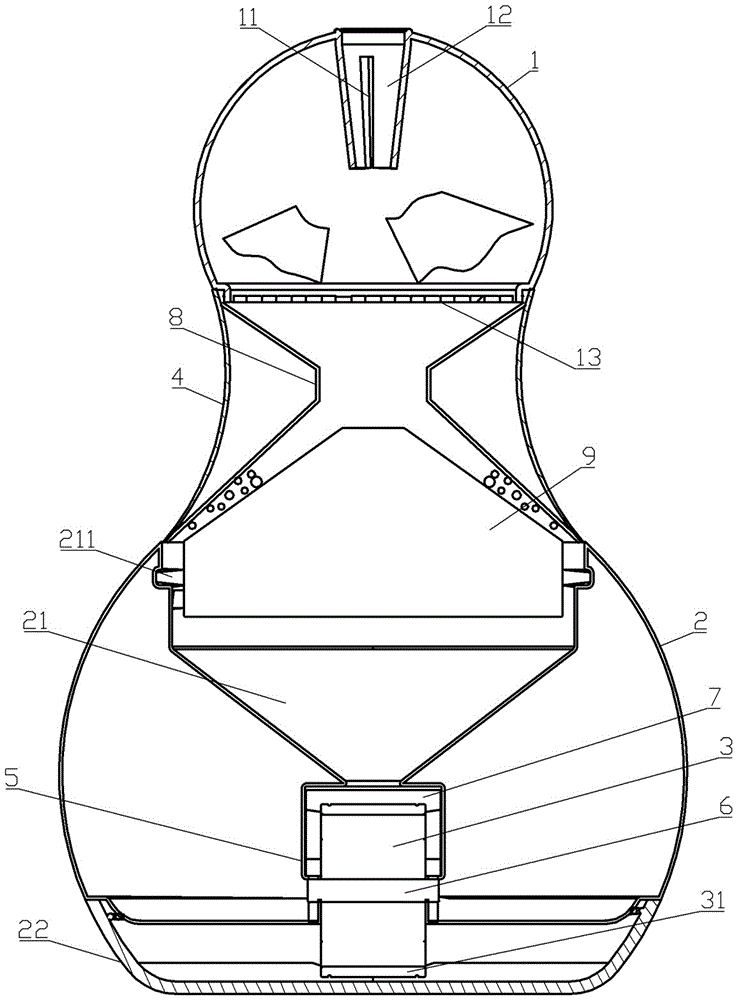

Reactor core fuel sphere position measurement device of pebble-bed-type high-temperature gas cooled reactor

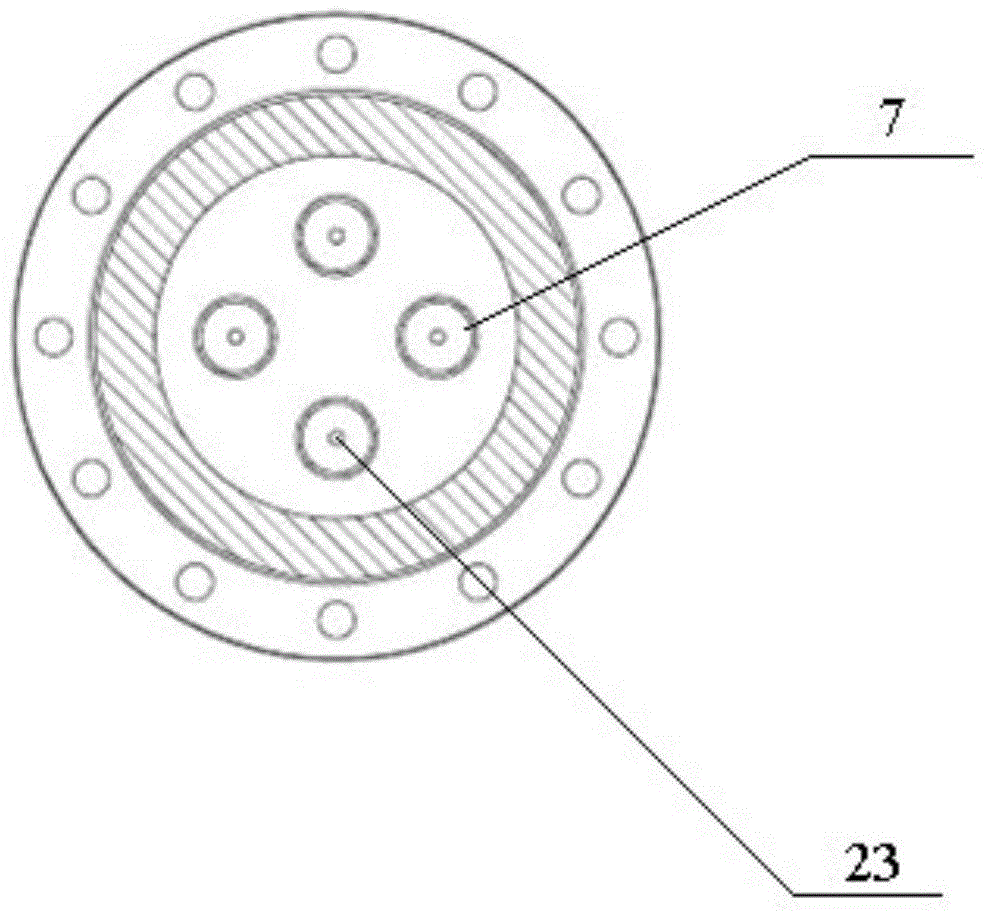

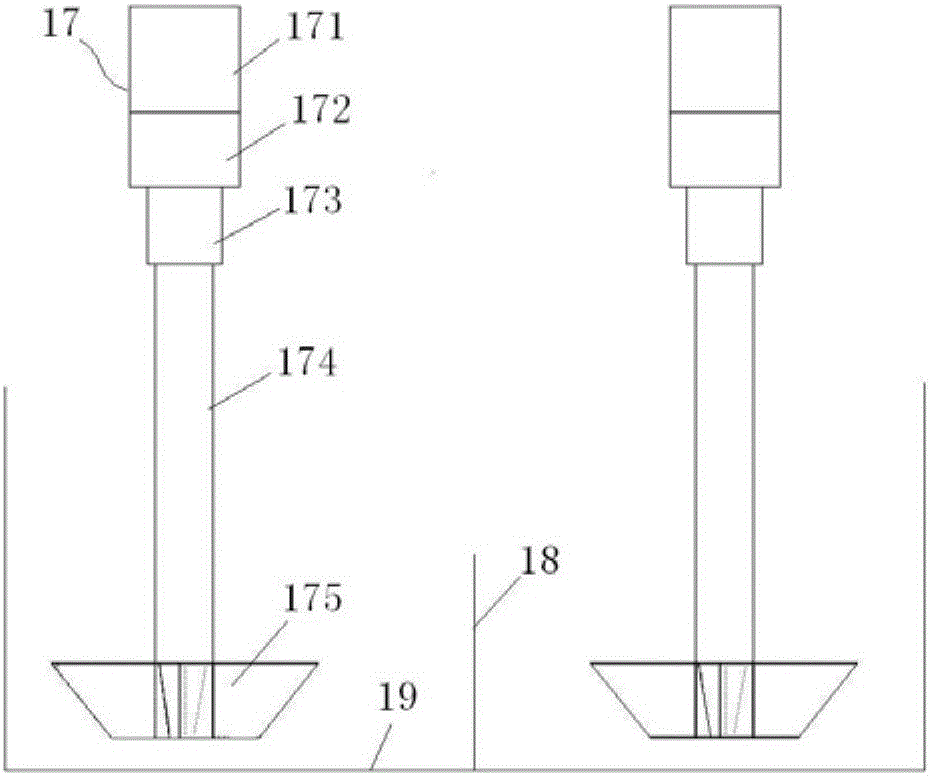

ActiveCN103137226ASimple structureAvoid accumulationNuclear energy generationNuclear monitoringMeasurement deviceImage resolution

The invention discloses a reactor core fuel sphere position measurement device of a pebble-bed-type high-temperature gas cooled reactor. A reactor core is a cylindrical cavity with a cone-shaped bottom, the cylindrical cavity is formed by graphite blocks in a stacking mode, the graphite blocks form side reflection layers, and fuel is a spherical body with a graphite substrate. The measurement device comprises a plurality of sphere position probes arranged on the side reflection layers at intervals, each sphere position probe is connected with an electrode lead, and the electrode leads are connected with a secondary indication instrument to display fuel sphere position information detected by the sphere position probes. The measurement device is simple in structure, stable, reliable, and capable of providing precise sphere position information in the gas cooled reactor; currently a high-temperature gas cooled experiment reactor cannot achieve the functions; electrode contact-type measurement adapts to various measurement ranges and meets requirements of the resolution ratio, the sphere position information can be directly displayed through the indication instrument, measurement circuits are obviously simplified, and stability is improved; and annular air nozzles and gas guide channels in the sphere position probes can achieve helium washing, avoid accumulation of graphite dust, and guarantee long-term operation of a measurement system.

Owner:TSINGHUA UNIV

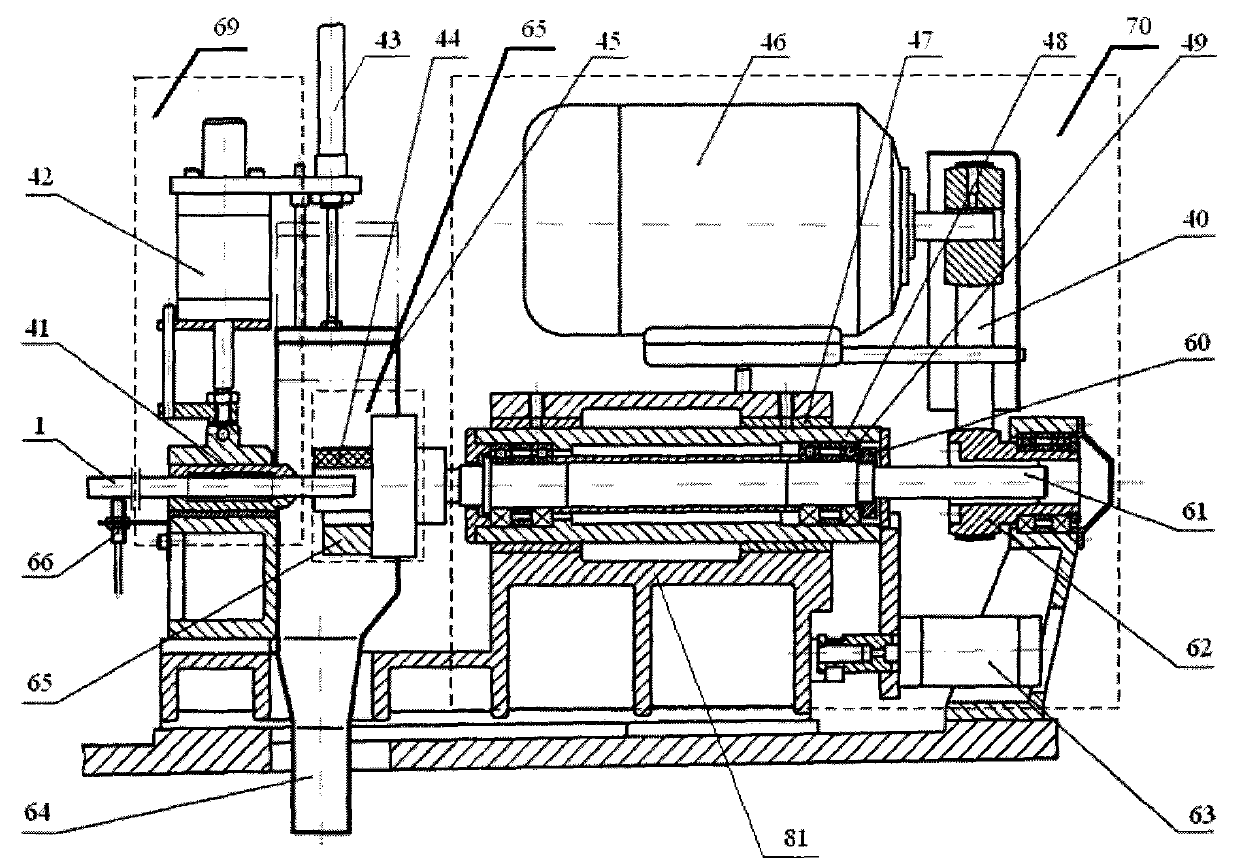

Numerical control engraving and milling lathe for processing graphite electrode

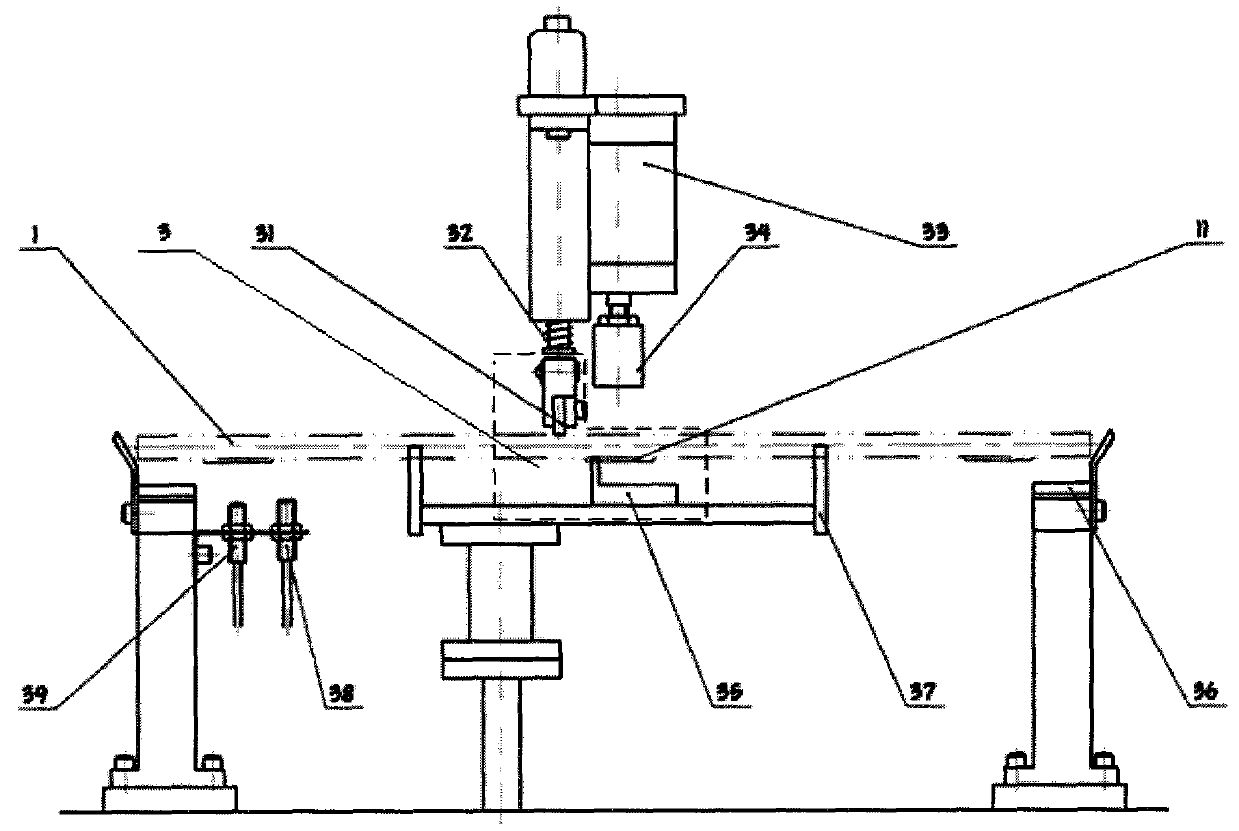

InactiveCN102151884AAvoid pollutionAvoid efficiencyMilling equipment detailsNumerical controlGraphite electrode

The invention discloses a numerical control engraving and milling lathe for processing a graphite electrode. The numerical control engraving and milling lathe comprises a lathe body (1), a working table (01), an X-axis system (02), a Y-axis system (03) and a Z-axis system (04). The lathe body below two sides of the working table of the numerical control engraving and milling lathe is formed into funnel slope shaped dust collection openings; an air draft channel communicated with the dust collection openings is formed in the center inside the lathe body; the outlet of the air draft channel is formed on the rear side face of the lathe body; a dust absorption fan is arranged on the rear side face of the lathe body; and the absorption end of the dust absorption fan is connected with the outlet of the air draft channel. During working, the dust absorption fan gathers and absorbs graphite dust produced by milling through the dust collection openings and the air draft channel, and sends the graphite dust into a water-filtering dust-removal pot through a hose for wetting, precipitation and integrated processing. By the technical scheme, the shortcomings that the dirt pollutes the environment, the dust removal efficiency is low, and the cooling liquid consumption and the production cost are high are avoided; and by the dry-type dust absorption mode and the water-filtering dust removal mode, the processing of the graphite electrode fulfills the aims of low cost and high efficiency in dust removal.

Owner:宁波市凯博数控机械有限公司

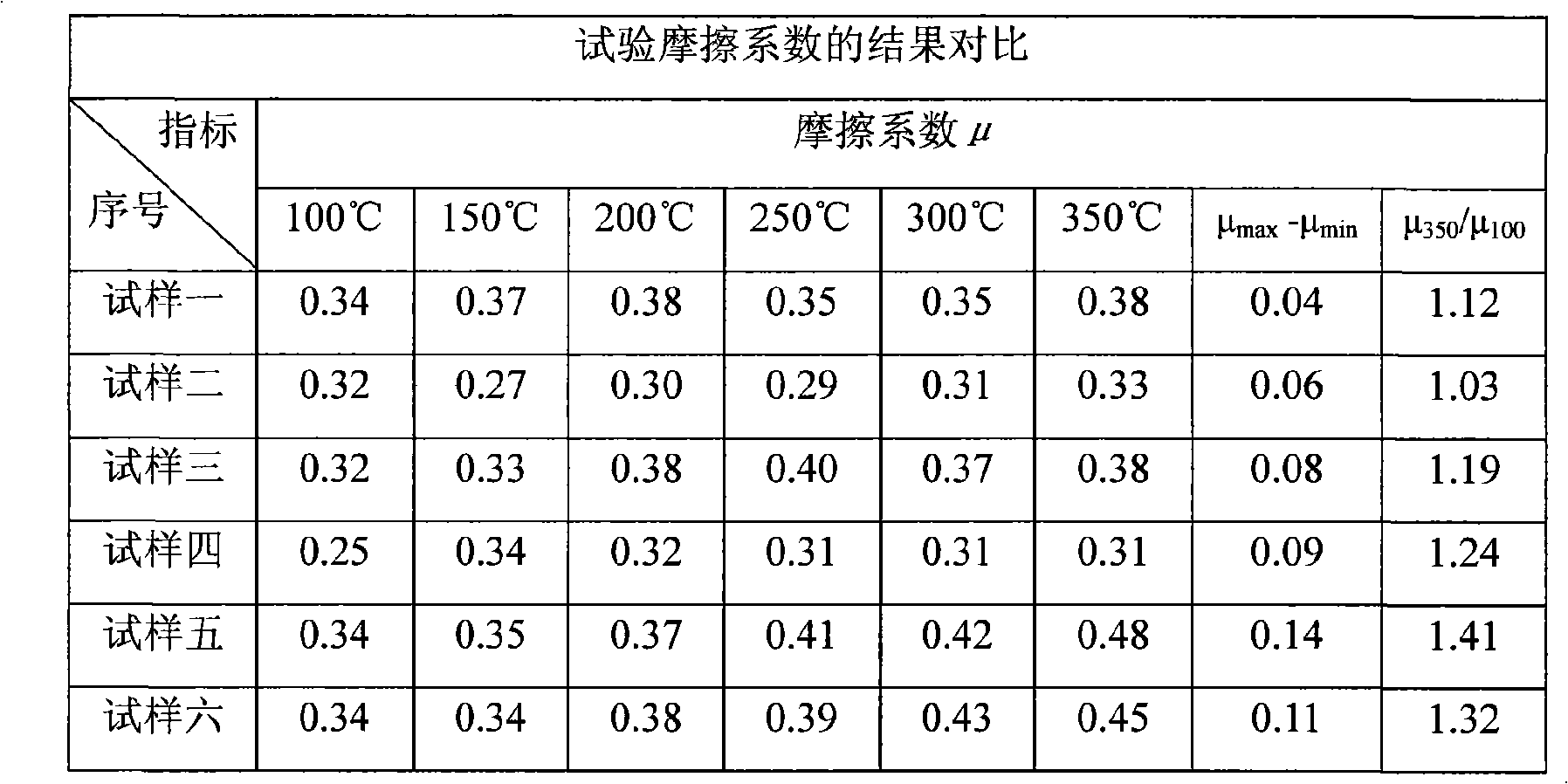

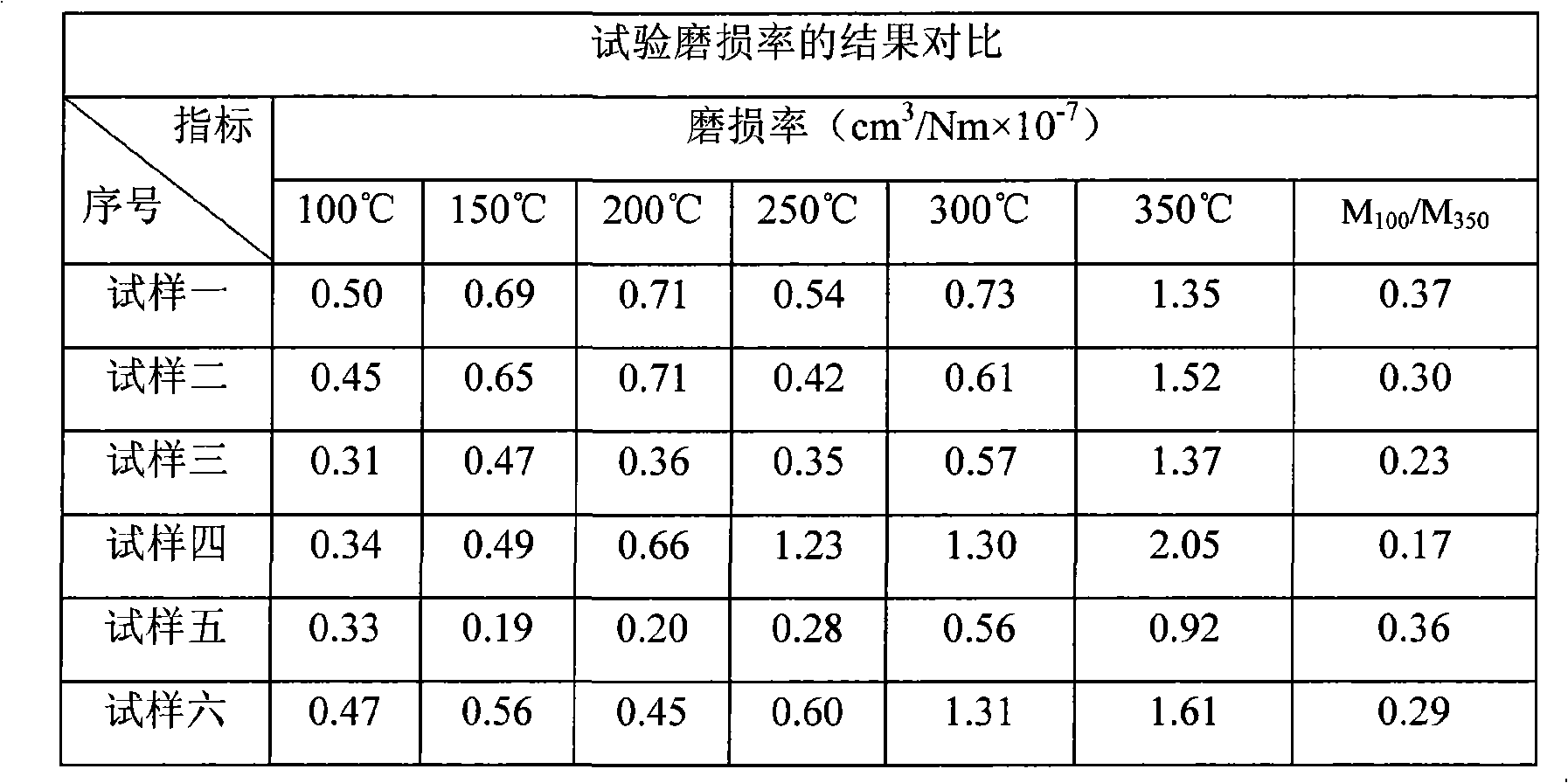

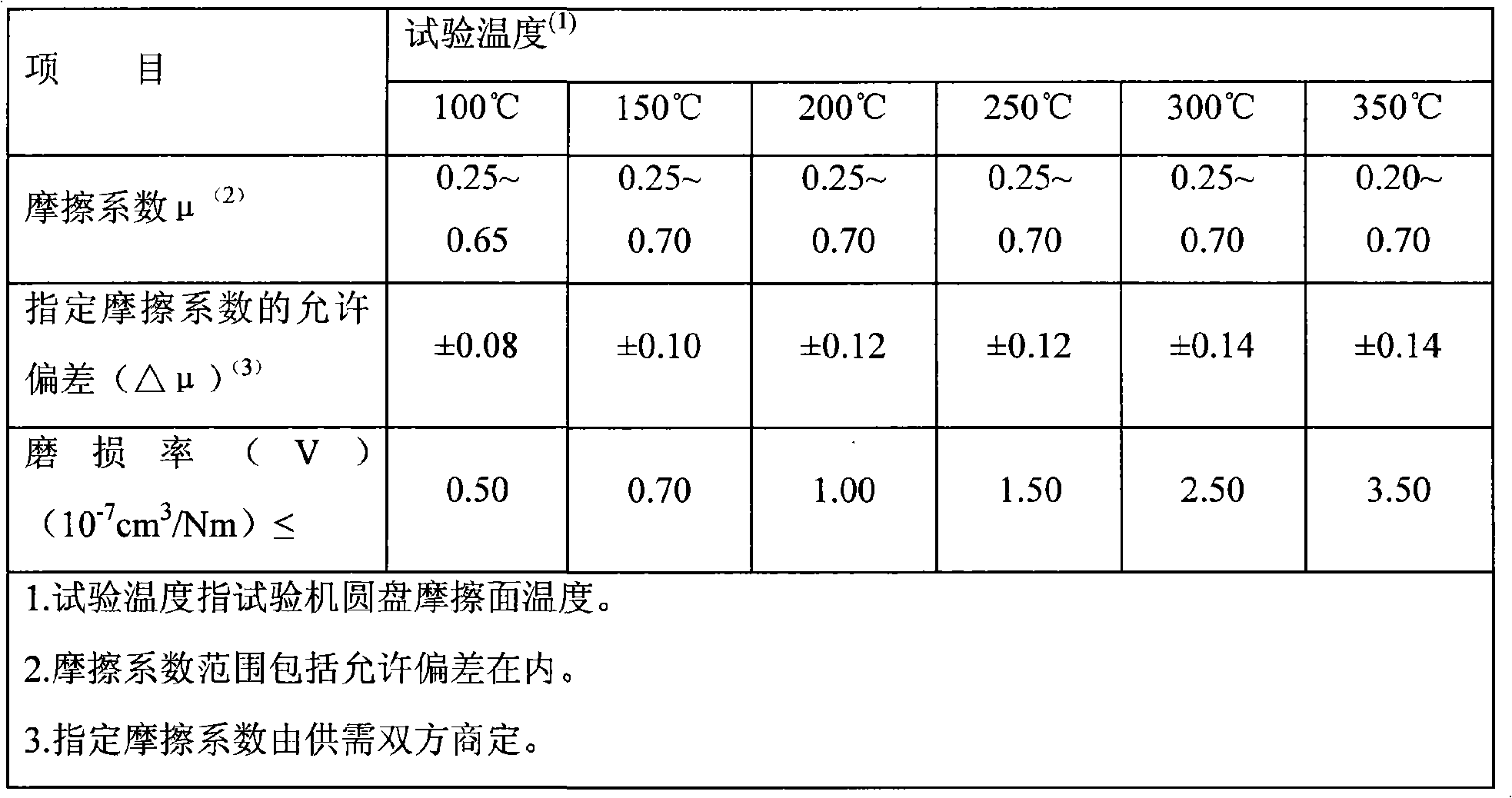

Vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof

InactiveCN101514251AStable coefficient of frictionReduce wear rateFriction liningPyrophylliteConfusion

The present invention provides a vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof. The raw materials of composite friction material is composed of bamboo fiber, phenolic resin, magnesium sulfate crystal whisker, steel fiber, copper powder, graphite dust, pyrophyllite powder, aluminum oxide, iron oxide, barium sulfate and zinc stearate. The preparing method comprises the following steps: preprocessing the raw materials, mixing the raw materials, hot pressing shaping and heat processing. The invention uses the bamboo fiber with low cost for reinforcing the phenolic resin. The proper amount of wear-increasing agent, anti-wear agent and filling agent for exerting the cooperative coupling function among the substrate, the fiber / crystal whisker and filling agent, thereby obtaining the novel vehicle braking composite material which has the advantages of stable friction coefficient under different temperatures, low wear rate, high heat fading resistance, excellent braking effect, shock absorbing, noise reduction and low cost.

Owner:FUZHOU UNIV

Method for baking scorched particles in aluminum electrolytic cell

This invention relates to a method for torrefying coke granules in aluminum electrolytic cell. The content of graphite granules in the mixed materials paved under the corner anode is 15-40 wt.% higher than that of graphite granules or graphited coke in the mixed materials paved under the non-corner anode. The mixed materials paved under the non-corner anode include: graphite granules or graphited coke 0-20 wt.%, and calcined coke 80-100 wt.%. The mixed materials paved under the corner anode include: graphite granules or graphited coke 15-60 wt.%, and calcined coke 45-80 wt.%. The method has uniform distribution of calcining temperature, and the temperature in the electrolytic cell is uniformly and stably increased. The method has such advantages as low cost, little graphite dust generation at start, appropriate resistance between electrodes, and high torrefaction performance.

Owner:SHANDONG NANSHAN ALUMINUM

Cable surface graphite coating device

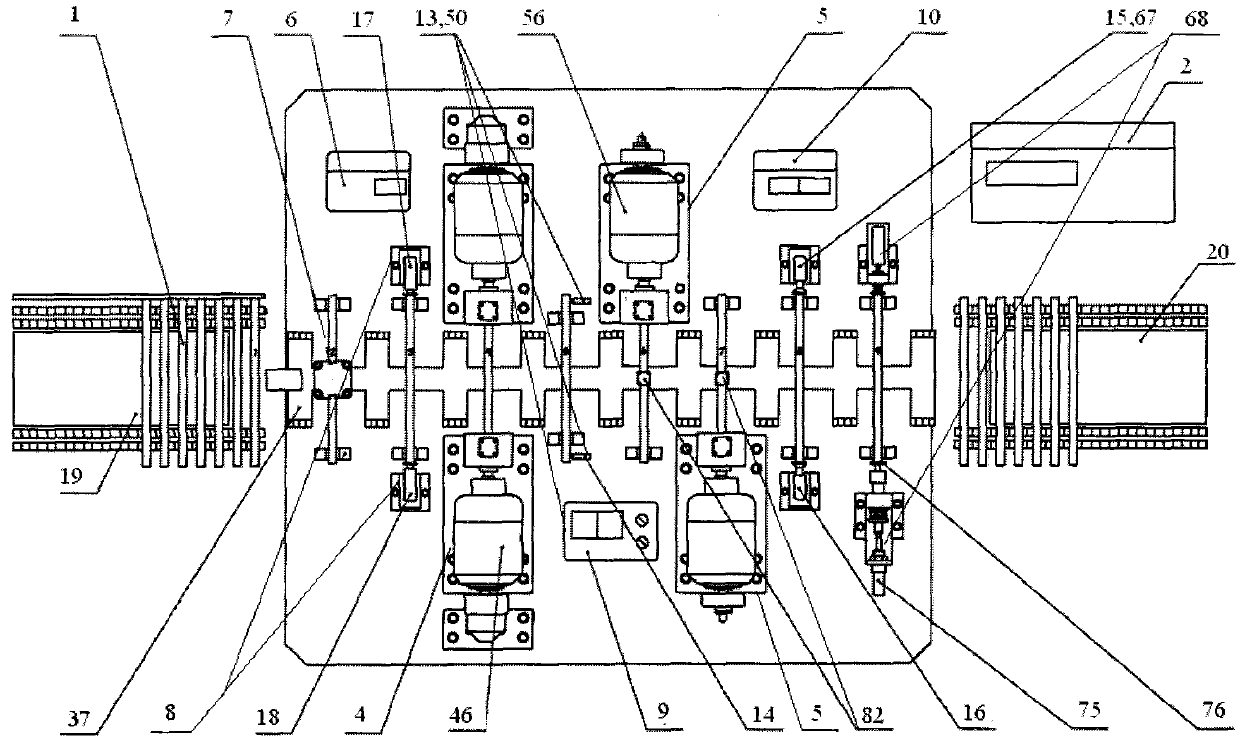

ActiveCN102856007AUniform coverageAdjustable thicknessLiquid surface applicatorsCoatingsLiquid waterEngineering

The invention relates to a cable surface graphite coating device. The cable surface graphite coating device comprises a box body, a wire inlet hole and a wire outlet hole, wherein the wire inlet hole and the wire outlet hole are arranged on the left side surface and the right side surface of the box body. The cable surface graphite coating device is characterized in that a liquid graphite groove is arranged in the box body, and the liquid level of the liquid graphite in the liquid graphite groove is lower than the wire inlet hole and the wire outlet hole; at least one size lifting wheel under active drive is arranged at the middle of the box body, and a size lifting hole is arranged on the size lifting wheel; and a liquid wiping device is arranged on the outlet side of the box body. With the adoption of the cable surface graphite coating device provided by the invention has the advantages that the liquid water-soluble graphite can be uniformly coated on the surface of a cable and has no dust pollution; the surface of the cable can be coated with the graphite in form of graphite size, therefore, the air pollution due to lots of suspended graphite dust in the air can be prevented, and the operating condition is obviously improved, and moreover, the health of operators on site can be guaranteed, and the normal operation of machines and equipment on site can be guaranteed.

Owner:天津塑力集团超高压电缆有限公司

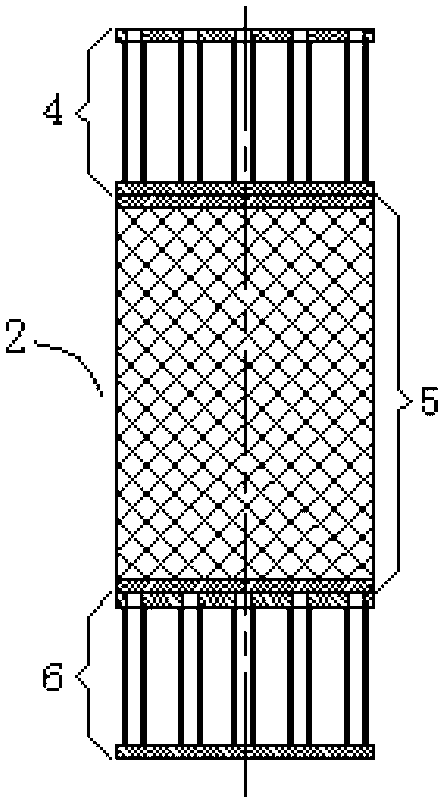

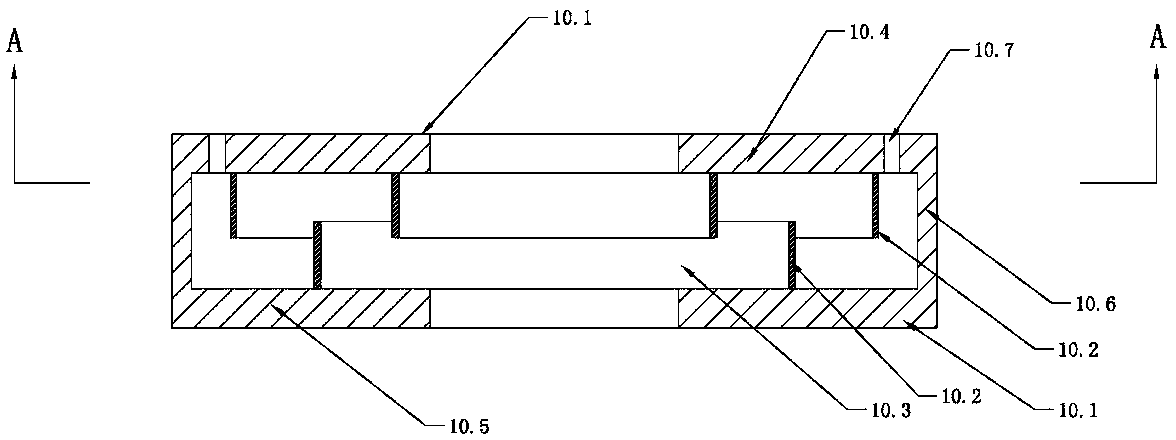

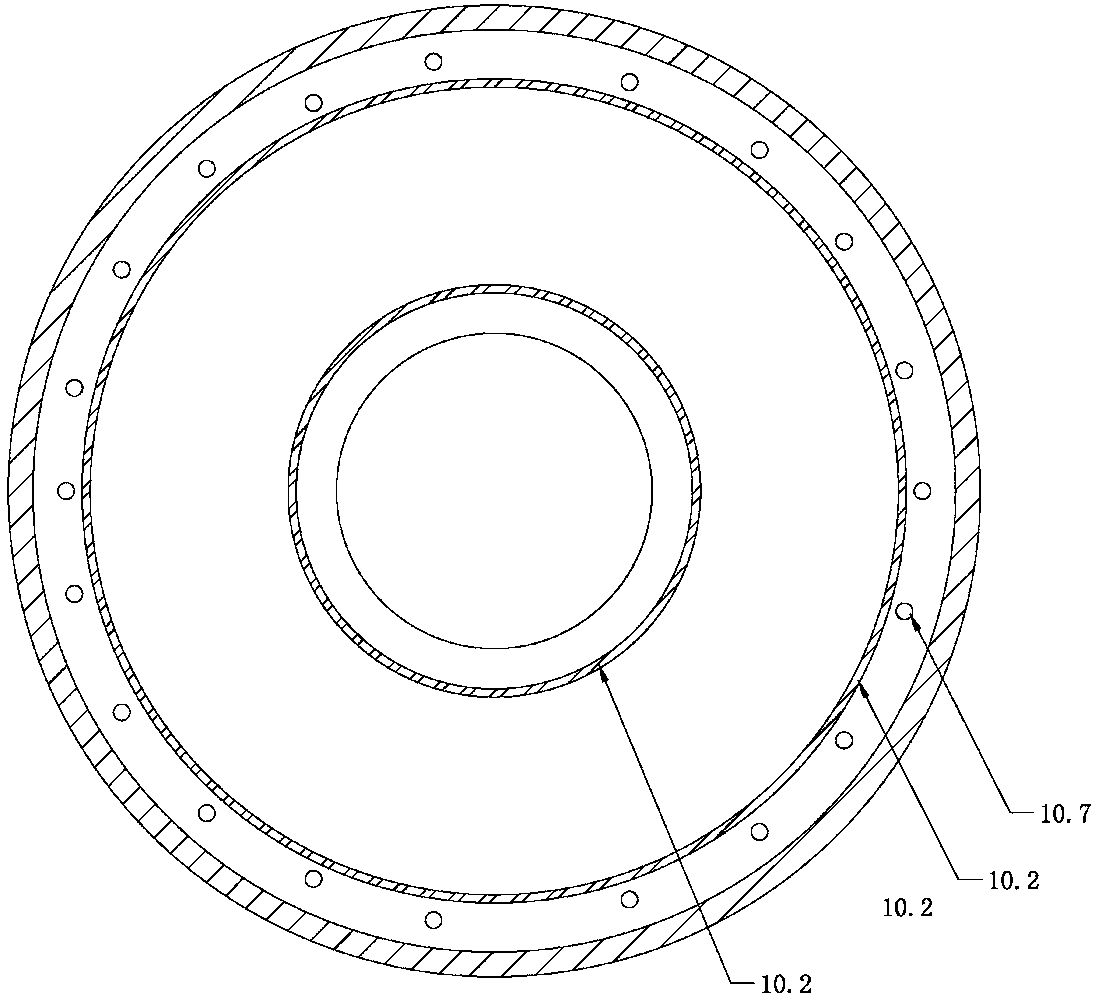

Combined type helium gas filtering sampling device for gas cooled reactor and installation method of device

ActiveCN103212250AFully depositedLarge filter areaDispersed particle filtrationNuclear energy generationMolecular sieveHelium

The invention relates to a combined type helium gas filtering sampling device for a gas cooled reactor and an installation method of the device. The combined type helium gas filtering sampling device is characterized by comprising a sleeve, at least two filter assemblies which are spaced along the axial direction and are fixed on the inner wall of the sleeve, and at least one molecular sieve assembly fixed between the two adjacent filter assemblies. The filtering sampling device provided by the invention adopts a sandwich combined type structure with the filter assemblies-the molecular sieve-the filter assembly, can fully filter fission product particles and graphite dust with different types and sizes carried by helium from a vapor generator, and can fulfill the purposes of multistage filtering, full deposition and adsorption of the fission product particles and graphite dust.

Owner:CHINERGY CO LTD

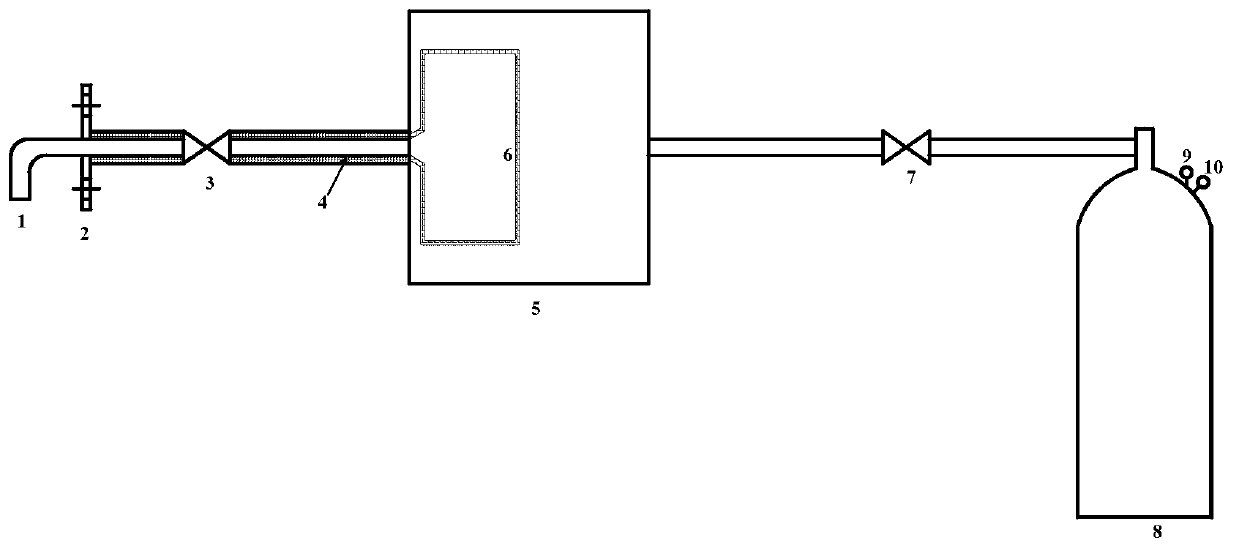

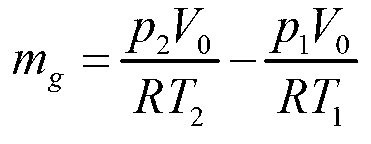

Device and method for measuring concentration of graphite dust in primary loop pipeline of high temperature gas cooled reactor

ActiveCN103278434ARealize measurementGuaranteed accuracyWithdrawing sample devicesParticle suspension analysisDifferential pressureProcess engineering

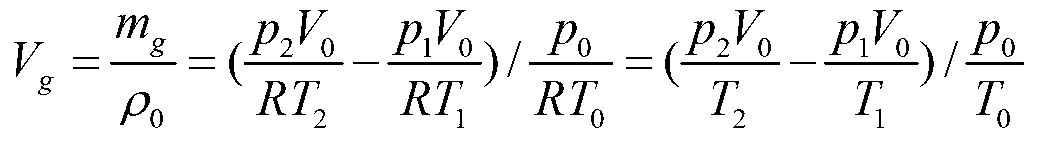

The invention provides a device and a method for measuring the concentration of graphite dust in a primary loop pipeline of a high temperature gas cooled reactor. The device comprises a sampling tube, a dust collecting chamber and a gas storage tank, wherein a gas inlet of the sampling tube is formed in the primary loop pipeline, a gas outlet of the sampling tube is connected with the dust collecting chamber, and the dust collecting chamber is connected with the gas storage tank through a pipeline. The whole device overcomes the thermal gradient sedimentation, does not use a differential pressure sensor or a flow meter, and is simple in structure, stable in performance and convenient to maintain. In the collecting process, high pressure gas flow containing the graphite dust in the high temperature gas cooled reactor can flow through the sampling tube and the dust collecting chamber, wherein the graphite dust can be intercepted by a dust collecting net in the dust collecting chamber, and the high pressure gas flow can be stored in the gas storage tank. By measuring the mass of the graphite dust intercepted in the dust collecting chamber and the amount of the gas collected in the gas storage tank, the concentration of the graphite dust in the primary loop pipeline of the high temperature gas cooled reactor can be calculated.

Owner:TSINGHUA UNIV

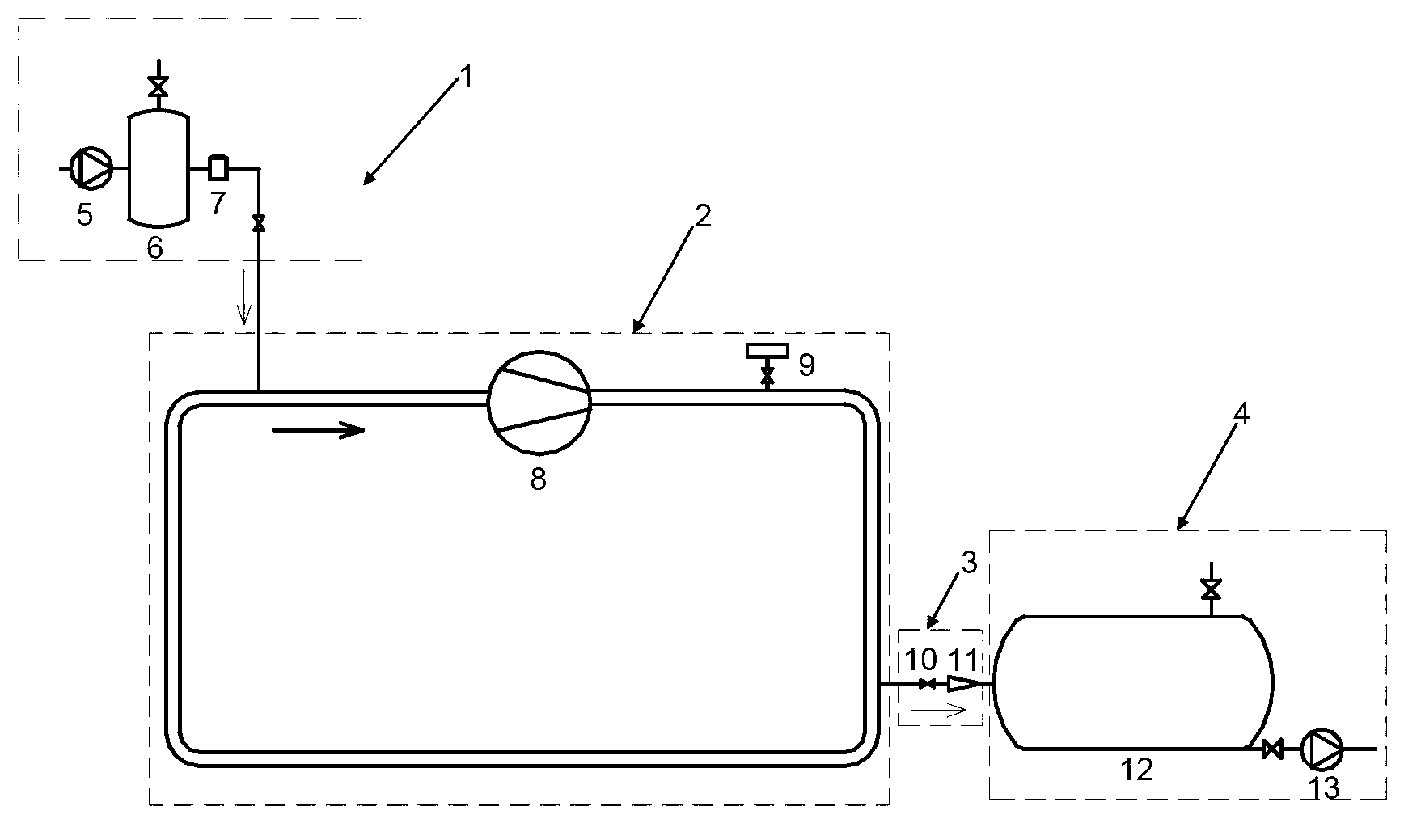

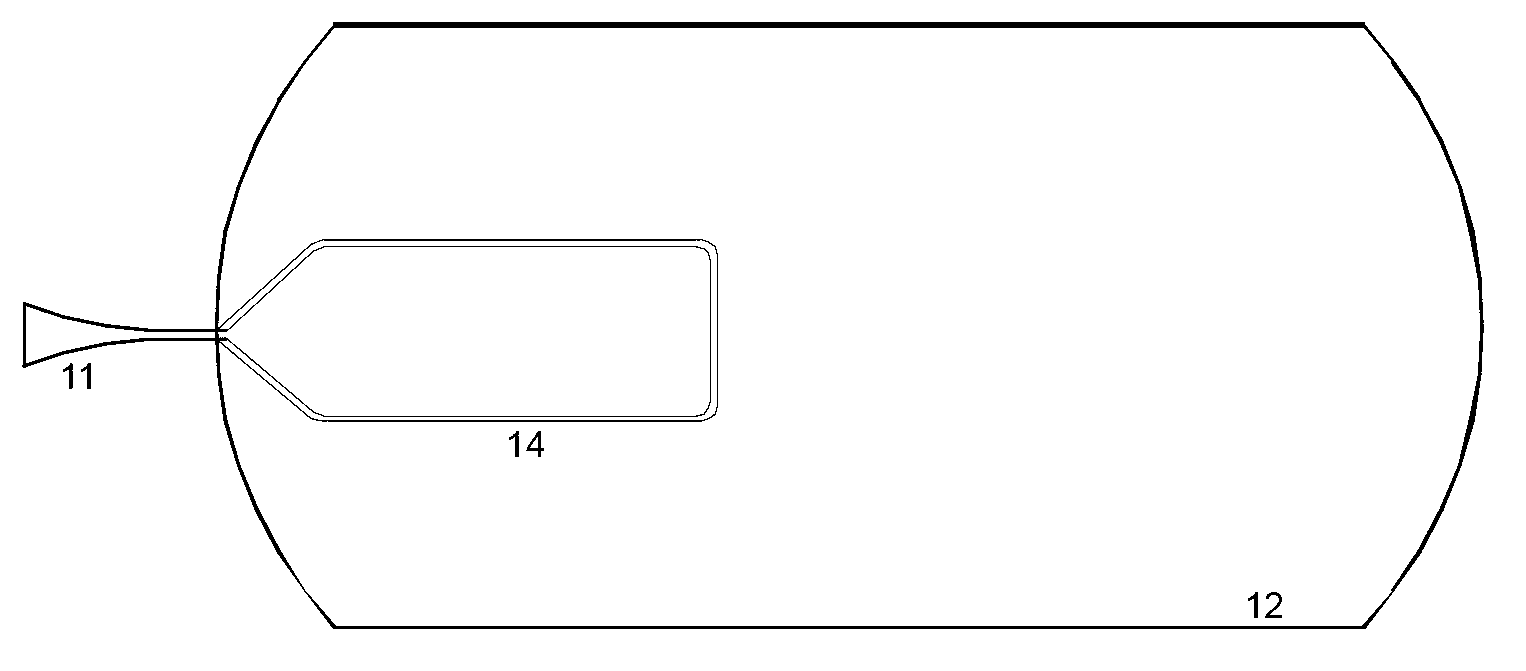

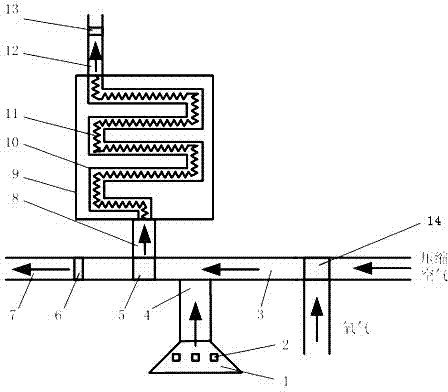

Device for simulating graphite dust emission during break accident of high-temperature reactor and discharge testing method

ActiveCN103308275AMeet static pressure injection requirementsHydrodynamic testingCollection systemProcess engineering

The invention provides a device for simulating graphite dust emission during a break accident of a high-temperature reactor and a discharge testing method. The device comprises a pressure injection system, a main loop pipeline system, a spray pipe discharge system and a vacuum can collection system. Based on analysis a similar principle, external air enters the main loop pipeline system through the pressure injection system to achieve a design rated value, and fine graphite dust is added into a pipeline by a dust addition system to form uniform gas dust two-phase flow under the driving of a circulating fan. By designing a spray pipe discharge pipe system vertically connected with a main loop pipeline, graphite dust is sprayed into a vacuum tank through a transonic spray pipe under the action of static pressure of main loop gas, the graphite dust in the main loop is discharged into the vacuum tank along with the air flow, and the graphite dust which is discharged into the vacuum tank is collected, so that the emission of the graphite dust of the high-temperature gas cooled reactor under accident conditions can be predicted.

Owner:TSINGHUA UNIV

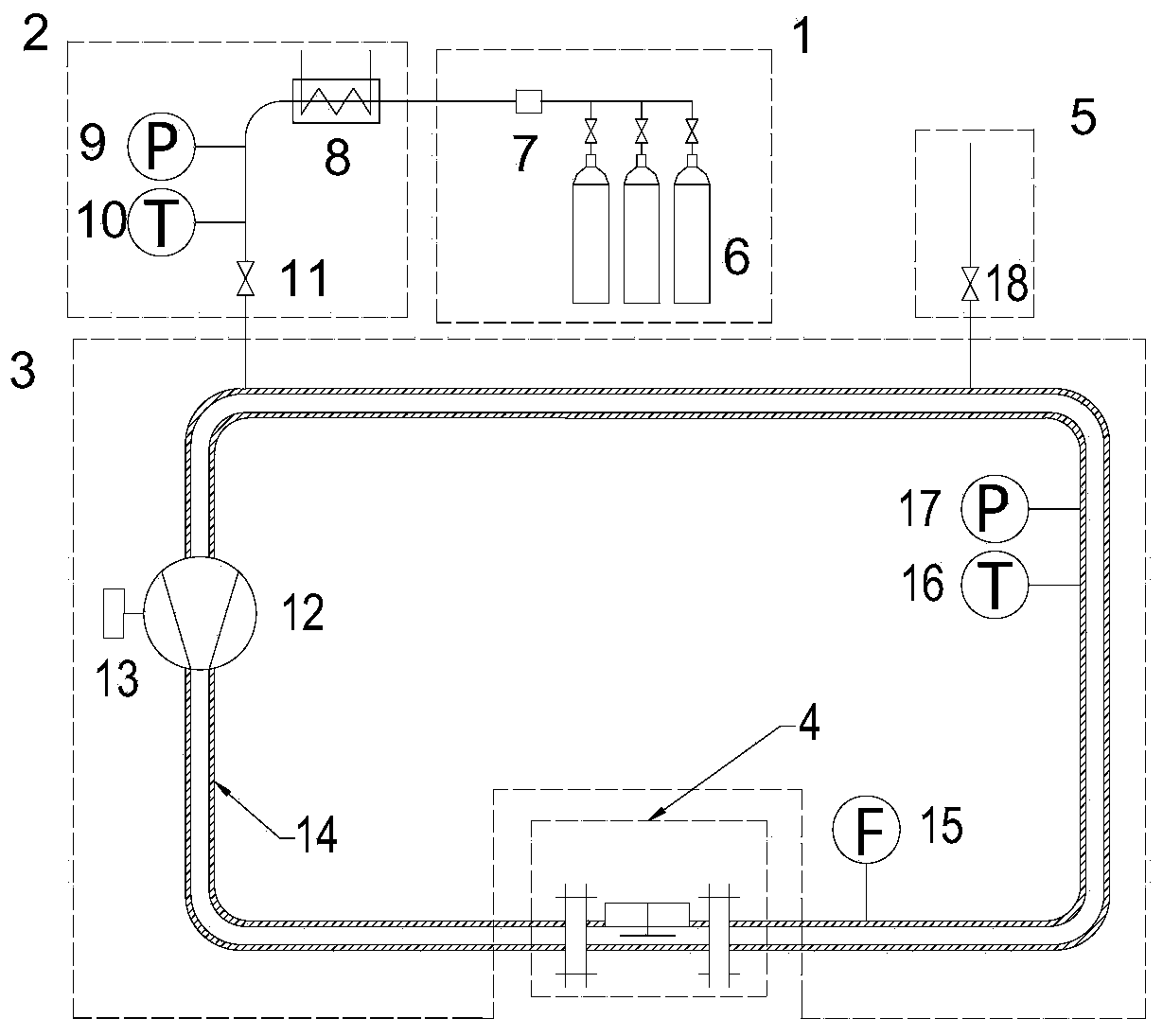

Device and method for analyzing heavy suspension rules of graphite dust in high-temperature heap breach accident

The invention provides a device and a method for analyzing heavy suspension rules of graphite dust in a high-temperature heap breach accident. The device comprises a high-pressure gas cylinder, a high-pressure air storage system, an electromagnetic valve, a flow meter, a discharge pipeline, a dust deposition wall surface, a stop valve, a sonic nozzle, a vacuum tank, and a vacuum pump. The device simulates the sound emission of a high-temperature heap breach through the sonic nozzle; the wall surface on which the graphite dust is deposited is arranged inside the discharge pipeline; high-pressure gas flow in the high-pressure air storage system is discharged into the vacuum tank via the sonic nozzle through the discharge pipeline under the differential pressure effects of the high-pressure air storage system and the vacuum tank in measurement; the deposited graphite dust in the discharge pipeline generates heavy suspension in the process. Thus, the heavy suspension rules of the graphite dust in the discharge process can be detected.

Owner:TSINGHUA UNIV

Device and method for measuring dust emission of graphite dust particles

The invention provides a device and a method for measuring the dust emission of graphite dust particles. The device comprises a high-pressure gas injection system, a pipeline electrical heating system, a main loop system, a dust emission testing section and a pressure relieving system. The device can be used for researching the dust emission characteristics of graphite dust at the high temperature under the high pressure and the change of particle size before and after dust emission. Before being injected into a main loop by the high-pressure gas injection system, an air source is heated by a pipeline heating device, and a high-temperature and high-pressure environment is formed in the main loop. The flow speed of the airflow can be continuously adjusted by a frequency modulation fan. The graphite dust particles are deposited on a detachable flat plate suspending in the center of a pipeline. The dust emission amount of the particles can be obtained by measuring the mass change of the flat plate before and after dust emission. The particle samples on the flat plate are collected before and after dust emission, and particle size analysis is carried out on the samples, so that the particle size characteristics of the particles with dust emission can be further obtained under the different working conditions.

Owner:TSINGHUA UNIV

Graphite dust collector

InactiveCN103239963AEfficient captureImprove the lubrication effectCombination devicesWater bathsFiltration

The invention provides a graphite dust collector which comprises an atomizer, a chip liquid pump, a chip liquid filtering screen, a dust absorption cover and a water-bath-type filter, wherein the atomizer is connected with the chip liquid pump; the chip liquid pump is connected with the chip liquid filtering screen through a chip liquid pipe; the chip liquid filtering screen intrudes into a chip liquid box; the dust absorption cover is internally provided with a common filtering screen and a magnetized filtering screen respectively, and is connected with the air intake end of an axial-flow-type fan; the water-bath-type filter is connected with the air exhaust end of the axial-flow-type fan, and intrudes into the chip liquid box; the atomizer atomizes and sprays out a high-pressure chip liquid, and the atomized chip liquid captures graphite dust in air; the dust absorption cover absorbs the captured atomized chip liquid and filters twice; the atomized chip liquid is filtered by the water-bath-type filter, and clean air is exhausted; and the chip liquid by the filtering screen arranged in the chip liquid box is subjected to secondary filtering, and then enters the chip liquid pump so as to form circulation. Visibly, the device captures the graphite dust generated during a ball graphite cast iron machining process through the atomized chip liquid, and achieves a dust collection effect through water bath filtration.

Owner:ANHUI UNIV OF SCI & TECH

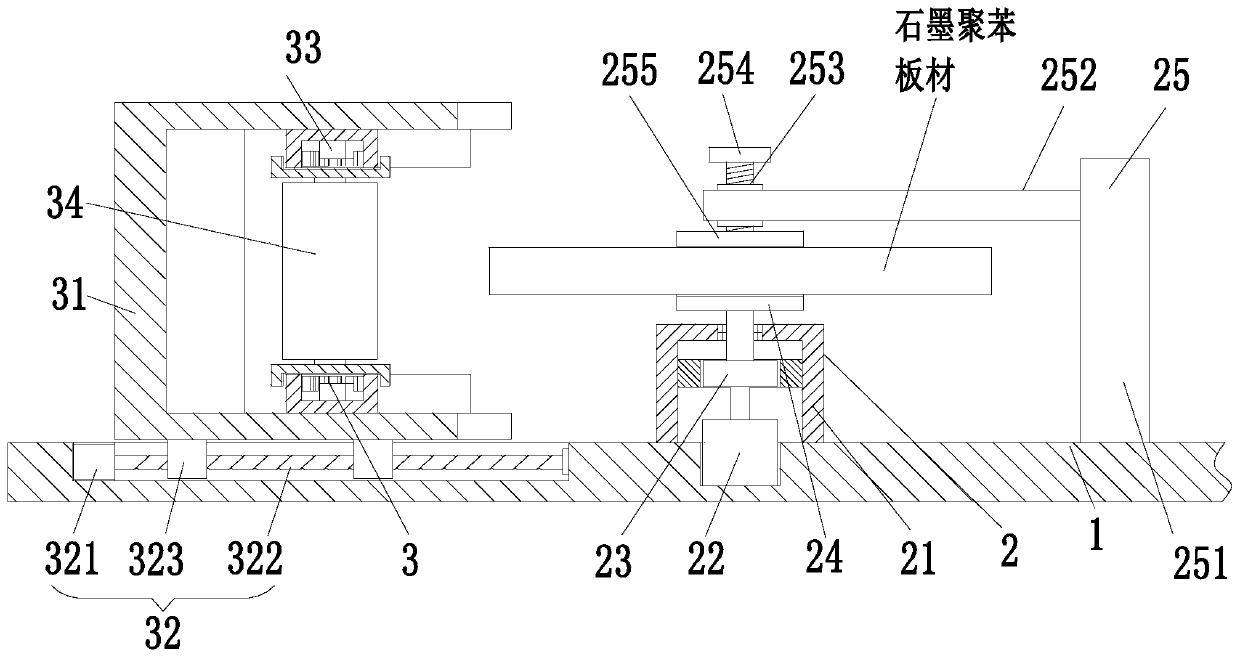

Secondary molding processing device and secondary processing method of graphite polyphenyl board

ActiveCN110802460ARealize the function of continuous grindingGuaranteed accuracyEdge grinding machinesGrinding drivesWorking environmentProcess engineering

The invention relates to a secondary molding processing device and a secondary processing method of a graphite polyphenyl board. The secondary molding processing device comprises a bottom plate, a clamping device and a grinding device, wherein the clamping device is mounted in the middle of the upper end of the bottom plate, and the grinding device is mounted on the rear side of the upper end of the bottom plate. The secondary molding processing device and the secondary processing method can solve the problems that when existing equipment performs circular arc grinding on corners of the graphite polyphenyl board, a grinding wheel, sandpaper and the like are commonly adopted to carry out manual grinding on the corners of the graphite polyphenyl board, so that the polishing effect is poor, the efficiency is low, the surface of the polished board is not uniform, more burrs are easily generated, the subsequent processing use is influenced, the graphite dust generated by processing cannot be cleaned in time when the existing equipment performs grinding and processing on the graphite polyphenyl board, the dust is prone to adhere to the surface of the board, the cleanliness of the board is affected, meanwhile, the dust is easy to cause environmental pollution, and the working environment of the workshop is influenced.

Owner:日照盛恒环保科技有限公司

Graphite processing center with dust suction device

InactiveCN105415739AImprove stabilityAvoid jitterUsing liquid separation agentDirt cleaningWater storage tankBackflow prevention device

The invention discloses a graphite processing center with a dust suction device. The graphite processing center comprises a box body, wherein the box body is internally provided with a graphite processing chamber; the graphite processing chamber is internally provided with a processing platform and processing equipment; a gear transmission box is arranged at the bottom of the processing platform; a graphite powder treatment box is arranged at the right side of the gear transmission box, and is internally provided with two sliding rails that are mutually parallel; the sliding rails are slidingly connected with an extrusion forming mechanism; the dust suction device is arranged at the top of the graphite processing chamber, and is communicated with the graphite powder treatment box through an air supply pipeline; the air supply pipeline is internally provided with a backflow prevention device; a water storage tank and a drying box are arranged at the left side of the graphite powder treatment box; and a cleaning mechanism is arranged at the right side of the graphite powder treatment box. The graphite processing center is simple in structure and high in practicability; dust suction treatment can be carried out on graphite dust generated during graphite processing; the graphite dust can be recycled; a utilization ratio of the graphite dust is increased; and the phenomenon of air backflow is avoided effectively.

Owner:河南红旗渠新材料有限公司

Optical fiber drawing furnace

ActiveCN103342463APlay a collection roleNot easy to stickGlass making apparatusOptical fiber cableGraphite dust

The invention relates to an optical fiber drawing furnace comprising a furnace body, a heating element, a heat preservation element, a middle casing pipe, a flow guide pipe, an extension pipe and a furnace top gaseous disc. The optical fiber drawing furnace is characterized by further comprising a lantern ring, an elastic graphite ring and a gas guide disc. The gas guide disc is mounted on the furnace top gaseous disc. The elastic graphite ring is mounted on a hollow ring plate. The lantern ring is arranged between the flow guide pipe and the extension pipe. A plurality of first air inlet holes can be formed in the side wall of the extension tube at the upper end of the lantern ring. The optical fiber drawing furnace has the advantages of being applicable to drawing prefabricated bars in large diameter and optical fiber prefabricated bars with large diameter fluctuation, meanwhile ensuring that graphite dust has less possibility of being adhered to the prefabricated bars, and effectively controlling the air flow state in the drawing furnace.

Owner:JIANGSU FASTEN PHOTONICS

Dust filter

ActiveCN104001386AReduce flow rateEffective filteringDispersed particle filtrationEngineeringHigh pressure

The invention discloses a dust filter and relates to the technical field of reactor engineering. The filter comprises an inlet connection pipe, an upper head, a filter pipe, a cylinder body, a lower head and an outlet connection pipe; the inlet connection pipe is connected with the upper head; the upper head is connected with the upper end face of the cylinder body, and the lower end face of the cylinder body is connected with the lower head; the lower head is connected with the outlet connection pipe; and the filter pipe is arranged in the cylinder body and used to filter dust carried by helium flowing in through the inlet connection pipe. The provided dust filter is convenient to mount and dismount, and is capable of effectively filtering and purifying radioactive graphite dust in loop helium of a high-temperature gas-cooled reactor according to determined particle size without generating helium leakage.

Owner:CHINERGY CO LTD

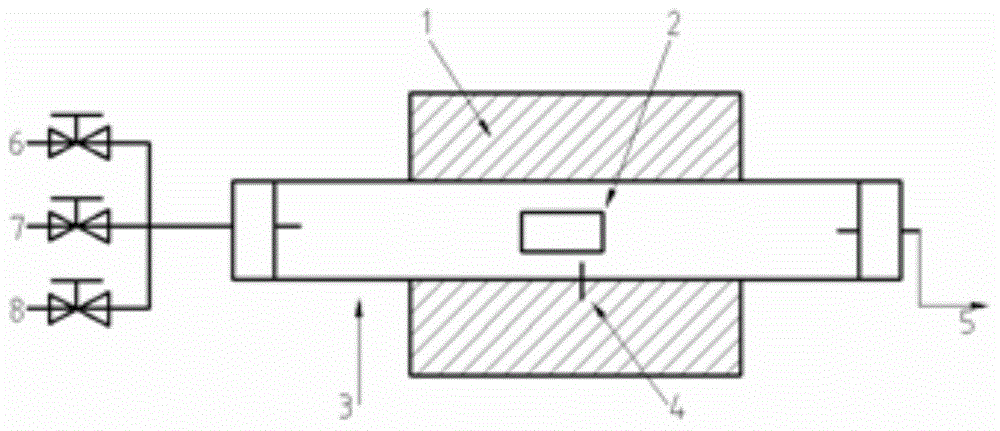

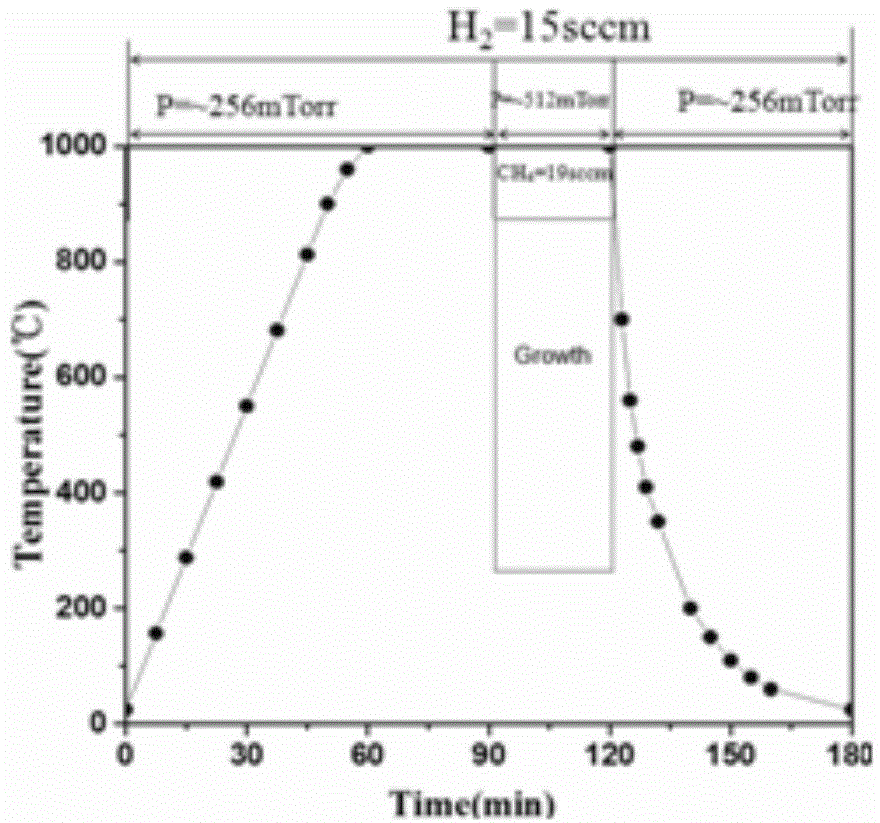

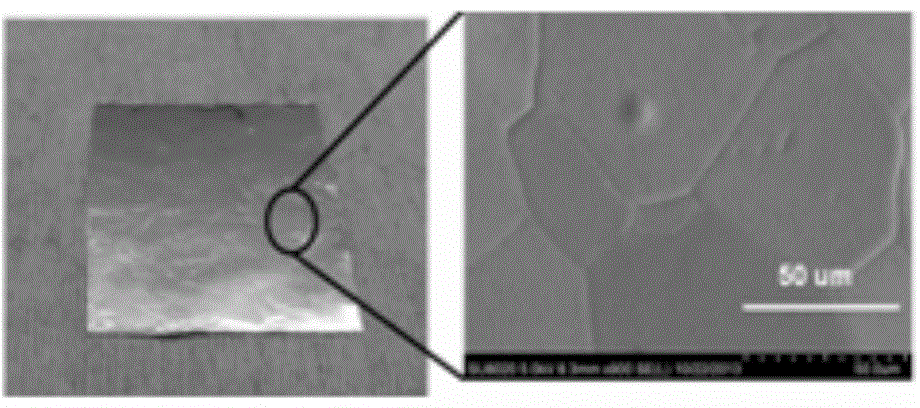

Method for processing surface of Cu electrode of multistage depressed collector through graphene

ActiveCN104465267ASolve the challenges of successful preparationOvercome the three-dimensional structureTransit-tube collectorsCold cathode manufactureSecondary electronsVacuum electronics

The invention discloses a method for processing the surface of a Cu electrode of a multistage depressed collector through graphene, relates to the technology of vacuum electronics, and provides a novel collector processing technology applicable to a high-efficiency travelling-wave tube. According to the method, a grapheme coating is adopted and can be directly used for processing the oxygen-free copper electrode, secondary electron emission is restrained, the recovery efficiency of the multistage depressed collector is improved, and the overall efficiency of the travelling-wave tube is improved. The method is simple in process, controllable in technology and low in cost, and the processed multistage depressed collector can achieve the same secondary electron emission restraining effect as a collector made of graphite. The processed multistage depressed collector has the advantages of a traditional graphite collector, has higher mechanical performance, electric conduction performance and heat conduction performance, and solves the problems that the structure is loose, strength is low and the graphite collector is prone to generating graphite dust under a long-term bombardment of electron beams, thereby effectively improving the efficiency and reliability of the travelling-wave tube.

Owner:HEFEI UNIV OF TECH

Graphite flake for diamond synthesis and its preparation method

The graphite leaf for diamond synthesis belongs to corresponding technical field. Wherein, the preparation method comprises: (1) as weight share, select boiled rock tar 60-70, boiled asphalt tar 20-30, native crystalline flake graphite 1-10 and molten asphalt 8-10 as raw material; (2) to boiled rock tar and boiled asphalt tar, coarse break, calcine, squash and mill to powder; (3) add graphite dust and molten asphalt to mix, roll and mill to powder; (4) use two-way equal-pressure compact method to make powder material into pressed shape; (5) bake the pressed shape for 5-7 days at 1100-1150Deg to form carbon rod with diameter 2mm larger than synthesis diamond cavity; (6) treat the carbon rod by dipping into tar; (7) then heat the rod to 2200-2800Deg for graphitizing 15-17days; bevel out circular, and cut pieces. The product has graphitizing degree 90í‚2%, volume density 2.0í‚0.2g / cm3ú¼ash degree less than 0.01%, and thickness 0.5-1.0mm, for diamond synthesis, which has high conversion rate, concentrated peak particle size, and high yield.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

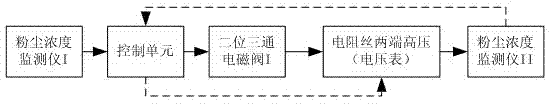

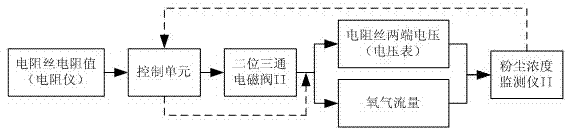

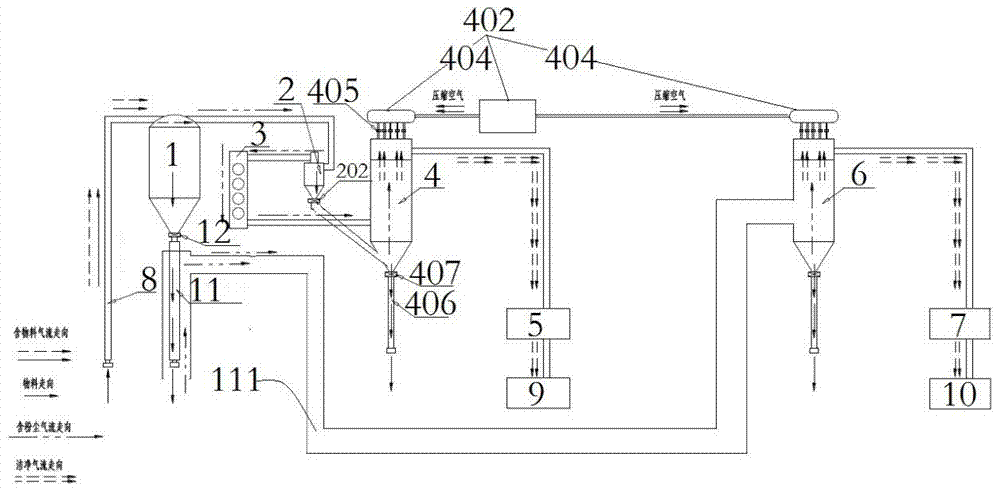

Graphite dust disposing device

ActiveCN104492756AAvoid harmAvoid secondary pollutionCleaning using gasesElectric supply techniquesDust controlEnvironmental engineering

The invention discloses a graphite dust collecting and nuisanceless disposing device. A graphite dust disposing device comprises a dust-collecting mechanism and a dust-removing mechanism, wherein the dust-removing mechanism comprises a dust-removing passage, at least one electrode positioned inside the dust-removing passage, at least one gas inlet passage, a detection device and at least one power supply device; the electrode is made of a resistance wire; the gas inlet passage is used for making graphite dust-containing gas, auxiliary combustion gas or a mixture of both enter into the dust-removing passage; the detection device is used for detecting the dust concentration at an outlet of the dust-removing passage. By virtue of an electrostatic adsorption principle, the graphite dust disposing device collects graphite dust in compressed air, enables the graphite dust to be adhered to the resistance wire, and burns the graphite dust, so that adsorption, collection and nuisanceless disposal of the graphite dust are implemented.

Owner:SHENYANG AEROSPACE UNIVERSITY

Graphite dust electrostatic dust collection system and method

InactiveCN107961635AReasonable process designClean emissionsCombination devicesBaghouseHigh pressure

The invention discloses a graphite dust electrostatic dust collection system and method. The system comprises a telescopic material suction pipe, a storage tank, a cyclone dust collector, an air cooler, a first bag-type dust collector, a first roots fan and a first electrostatic dust collection device which are sequentially communicated through a pipeline. The system further comprises a second bag-type dust collector, a second roots fan and a second electrostatic dust collection device, wherein the second bag-type dust collector is communicated with the second roots fan through a pipeline. Thestorage tank comprises a telescopic discharging pipe arranged at the bottom, a dust-proof cover is arranged outside the telescopic discharge pipe, and an opening is formed in the dust-proof cover andcommunicated with the lower portion of the second bag-type dust collector through a pipeline. The double roots fan and the double bag-type dust collectors are switched to finish dust collection in the feeding and discharging process, the advanced dust collection system integrates dust pretreatment, cooling and purification, is reasonable in process design, scientific in structure, compact in arrangement, convenient to operate and maintain, high in dust collection efficiency and sufficiently meets purification and discharge requirements of high-pressure, high-temperature and high-concentrationdust.

Owner:HUNAN UNIV OF TECH

Graphite machining center dust removal device

InactiveCN104324807AEasy to collectGuaranteed cleanlinessExternal electric electrostatic seperatorEngineeringHuman health

The invention relates to a graphite machining center dust removal device, which includes a pedestal, a stand, and a material base and a shell arranged on the pedestal. The shell is provided with at least one air inlet, which is provided with a sealing door. A collection box is arranged below the pedestal, the collection the box is equipped with at least one exhaust port, which is provided with an exhaust fan. The collection box bottom is provided with an electrostatic field generation instrument, and a shielding layer is disposed between the pedestal and the collection box. Compared with the prior art, the device provided by the invention can utilize the electrostatic field dust collection principle to clear away graphite dust generated in a graphite machining process, keep the inside of the machining center clean, prevent graphite dust from harming human health, and is also convenient to collect the eliminated graphite dust.

Owner:宁波聚益工具有限公司

Production technique for high-grade fine-particle diamond with high grade of transparency

The invention relates to an excellent transparent man made diamond sand manufacturing, using alloy powder and graphite dust compressed under super high pressure and temperature to synthesize diamond. The synthesized pressure is 96-98MPa, temperature rising pressure being 650-750MPa, synthesized temperature increased 2-10% than usual, temporary stopping pressure being 80-92% of the synthesized pressure, with a gap of 0. 10-0. 15MPa and time interval 120-180s and pressure maintaining time being 5-20s. Using the growing mechanism of intermiscibility, core formation, growing, and counter growing, it improves the product transparency when it starts extracts slag under high temperature, realizing fine and highly transparent diamond.

Owner:彭国强 +1

Multi-station hoisting device for overhauling control rod driving mechanism of high-temperature gas cooled reactor

PendingCN112850447APrevent leakagePrevent proliferationNuclear energy generationRunwaysThermodynamicsNuclear engineering

The invention provides a multi-station hoisting device for overhauling a control rod driving mechanism of a high-temperature gas cooled reactor. The multi-station hoisting device for overhauling the control rod driving mechanism of the high-temperature gas cooled reactor comprises a framework, a shell, a first hoisting assembly, a second hoisting assembly and a rotatable mounting plate, wherein the shell sleeves the outer side of the framework; the framework is provided with a first mounting position and a second mounting position; the first mounting position is selectively provided with the first hoisting assembly; the second mounting position is selectively provided with the second hoisting assembly; the first end of the rotatable mounting plate is connected with the framework; the second end of the rotatable mounting plate is used for being rotatably connected with an atmosphere isolation device; and the rotatable mounting plate is further provided with a hollowed-out position to allow the first hoisting assembly and the second hoisting assembly to be hoisted on control rod driving mechanisms below the atmosphere isolation device through the hollowed-out position. After the atmosphere isolation device is installed at a time, the multiple control rod driving mechanisms of any unit under the atmosphere isolation device can be hoisted and transferred, and leakage of helium in a loop and diffusion of radioactive graphite dust and other substances can be effectively prevented in the hoisting process.

Owner:HUANENG SHANDONG SHIDAOBAY NUCLEAR POWER CO LTD +2

Device for measuring dust deposition characteristics of wall of component in high-temperature and high-pressure dust-containing gas flow

The invention provides a device for measuring the dust deposition characteristics of the wall of a component in high-temperature and high-pressure dust-containing gas flow. The device comprises a high-pressure gas source system, a heating system, a main pipeline system, a dust injection system, a test section system and a dust removal discharge system, and is of an open system structure as a whole. Gas is heated through the heating system before being injected into a main pipeline through the high-pressure gas source system, a high-temperature and high-pressure environment is formed in the main pipeline, graphite dust is injected into the main pipeline system through the dust injection system, the graphite dust and gas flow in the main pipeline form the dust-containing gas flow of a certain concentration, and the pressure and flow rate of the gas in the main pipeline can be regulated through a constant pressure regulating valve and a constant flow regulating valve. The device can measure the dust deposition condition of the wall of the test component in the high-temperature and high-pressure dust-containing gas flow.

Owner:TSINGHUA UNIV

Multifunctional pencil sharpener

The invention discloses a multifunctional pencil sharpener. The multifunctional pencil sharpener comprises a pencil rotating assembly and a printing assembly. The pencil rotating assembly comprises a pencil sharpener shell and a blade. A pencil rotating groove is formed in the surface of the pencil sharpener shell. The blade is arranged in the pencil rotating groove. The printing assembly comprises a seal shell and an idler wheel type seal mounted in the seal shell. A pattern layer is arranged on the surface of the idler wheel type seal. The seal shell is connected to an opening in the lower end of the pencil sharpener shell through an intermediate connecting body. An inner cavity of the seal shell, an inner cavity of the intermediate connecting body and an inner cavity of the pencil sharpener shell are communicated. A filter screen used for separating wood chips from graphite particles is arranged in the inner cavity of the intermediate connecting body or the inner cavity of the pencil sharpener shell. The multifunctional pencil sharpener has the advantages that when a pencil is sharpened, graphite dust enters the inner cavity of the intermediate shell by penetrating through the filter screen, the wood chips are left in the pencil sharpener shell, the wood chips can be poured out independently by unscrewing the pencil sharpener shell from the intermediate shell, and environment pollution caused by raising of the graphite dust is avoided.

Owner:NANHUA UNIV

Cable surface graphite coating device

ActiveCN102856007BUniform coverageAdjustable thicknessLiquid surface applicatorsCoatingsLiquid waterSlurry

Owner:天津塑力集团超高压电缆有限公司

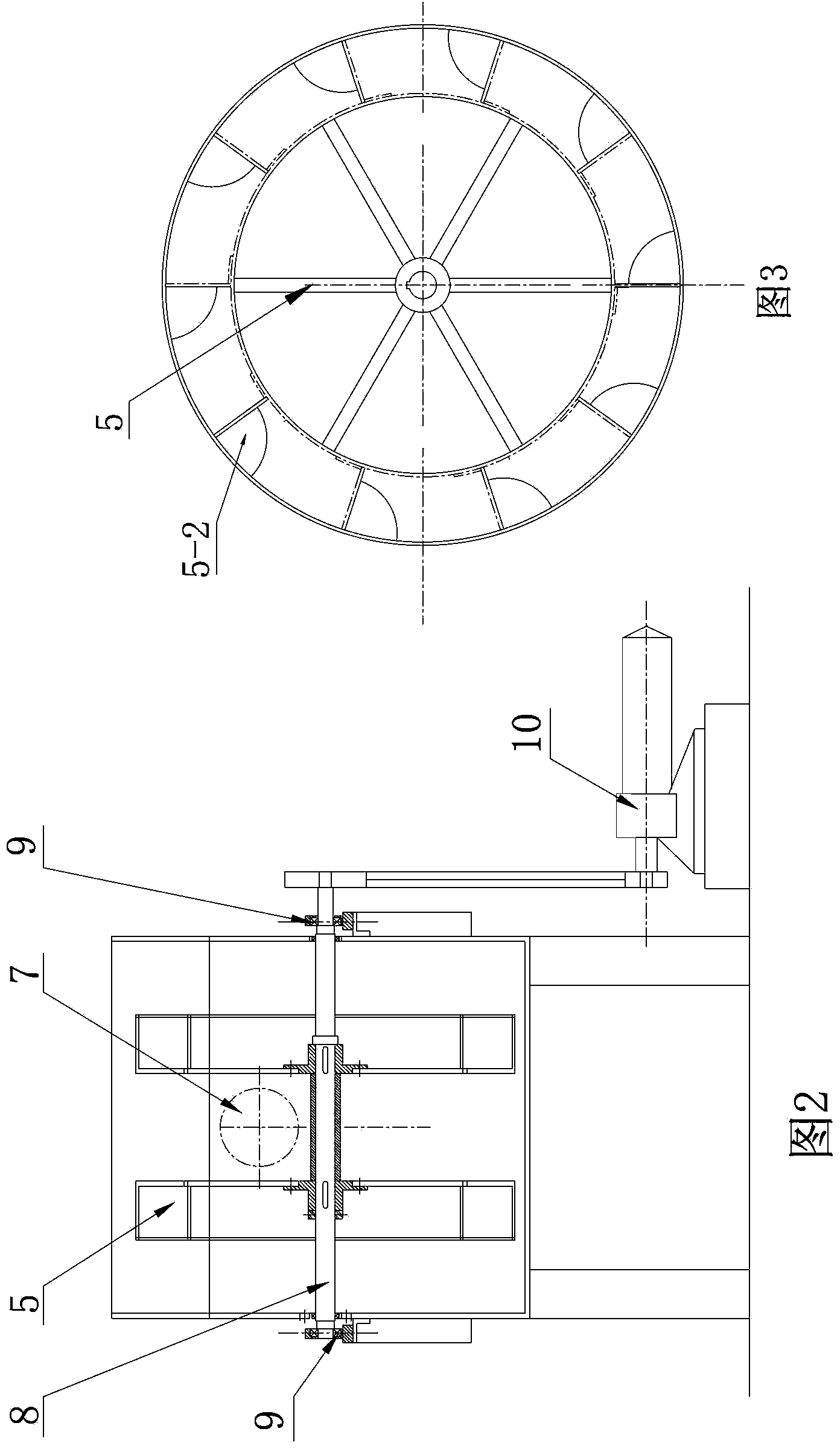

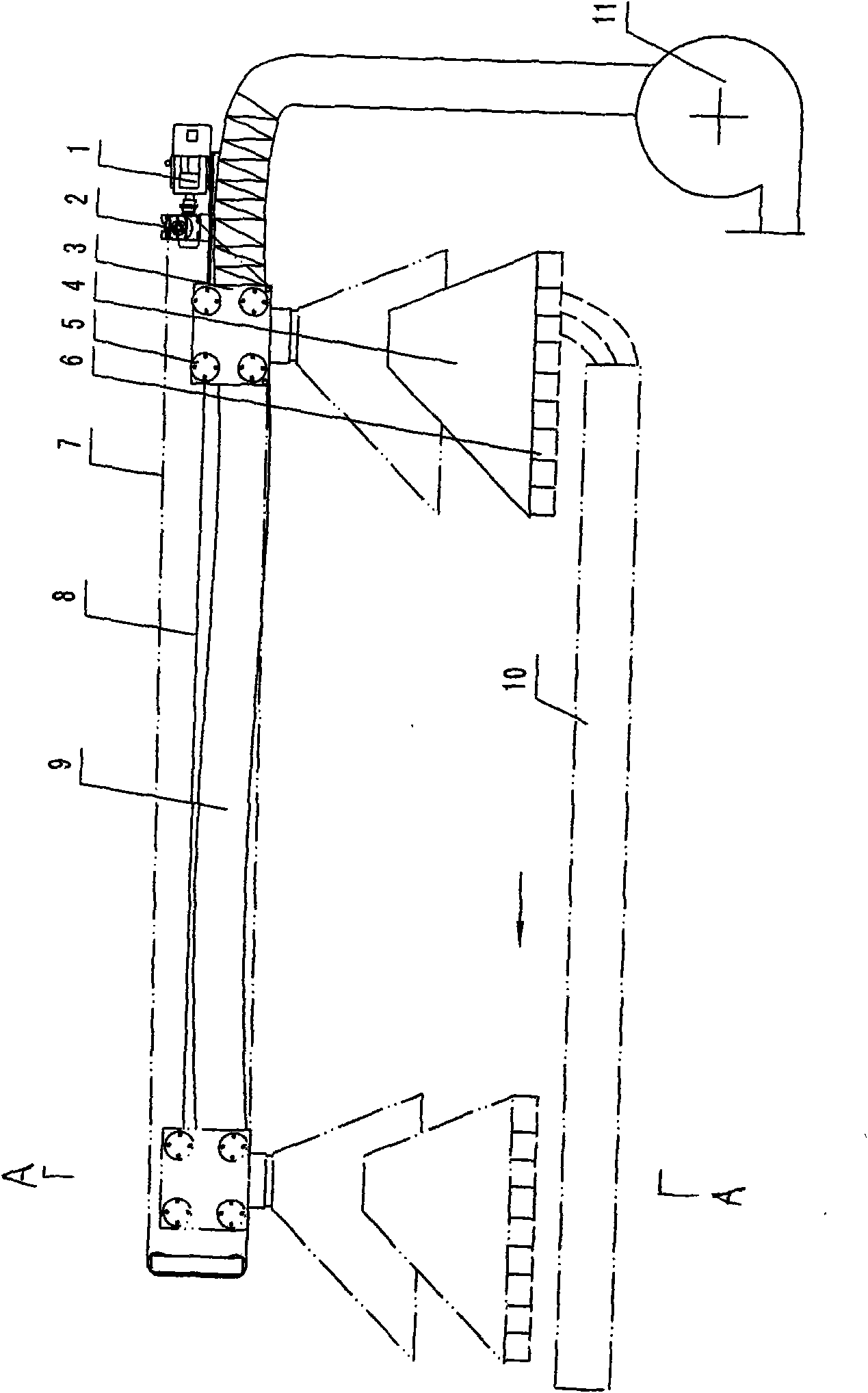

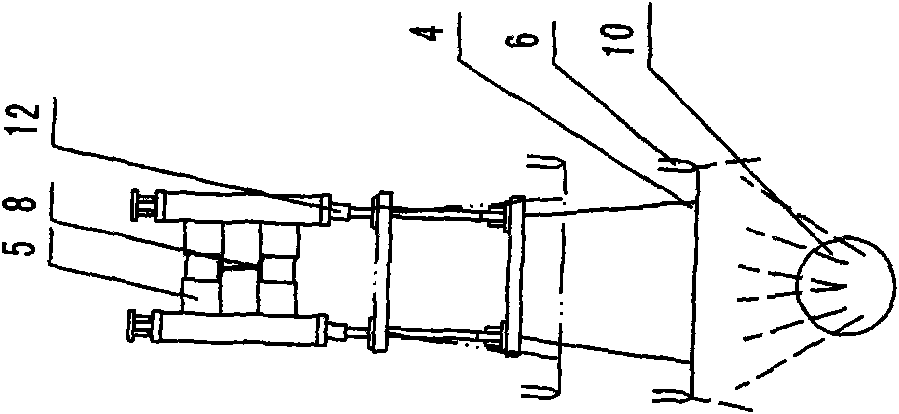

Device for absorbing graphite dust

The invention discloses a device for absorbing graphite dust, comprising a bracket. The bracket is provided with a motor (1), a speed reducer (2) and an I-beam (8). The motor (1) drives the speed reducer (2). The device is characterized in that the I-beam (8) is positioned right above a steel tube (10) made of an expanding pipe, the speed reducer (2) drives a pulley (5) to move along the I-beam (8) through a steel wire (7), the pulley (5) is fixedly connected with a dust absorbing hood (4) arranged below the pulley (5) and the dust absorbing hood (4) is connected with a draught fan (11) through a hose (9). The device ensures that the dust absorbing hood is positioned above the tail of the steel tube at any time by adopting a moving mode and effectively absorbs graphite diffused from a steel tube cavity to the outdoor at any time.

Owner:烟台鲁宝钢管有限责任公司

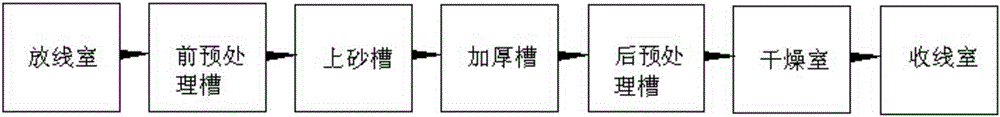

Device for manufacturing electroplated diamond wire saw

The invention discloses a device for manufacturing an electroplated diamond wire saw. The device comprises a wire unwinding chamber, a pretreatment tank, a sand feeding tank, a thickening tank, a drying chamber and a wire winding chamber; a cathode of the sand feeding tank is connected with a negative electrode of a power supply through a conductive shaft; a conductive cathode wheel is connected to the conductive shaft through a metal bearing; a base wire is wound on the conductive cathode wheel; the cathode of the thickening tank is also connected with the negative electrode of the power supply through the conductive shaft; the conductive cathode wheel is connected to the conductive shaft through the metal bearing; the base wire is wound on the conductive cathode wheel. According to the device disclosed by the invention, in the sand feeding tank and the thickening tank, each base wire is wound on the cathode wheel of the corresponding cathode so that the base wire becomes a negative electrode; each metal bearing mounted between the corresponding cathode wheel and the corresponding conductive shaft is capable of guaranteeing good electric conductivity and is also capable of making the corresponding cathode wheel rotate freely, so breakage of each base wire is prevented. In comparison with the previous conduction ways such as electric brush, the conduction way of the device disclosed by the invention is capable of enhancing the electric conductivity, free of loss, free of generation of graphite dust, and conductive to uniformity and wire diameter consistency of electroplated diamond particles on each base wire.

Owner:SHANGHAI FENGXUN PRECISION MACHINERY PARTS

Device for clearing and cutting fixed length of clad tube

InactiveCN101513740AGuaranteed coaxialityGuaranteed cleanlinessMetal working apparatusTube drawingWorking environment

The invention belongs to automatic turning device design field, in particular discloses a device for clearing and cutting fixed length of clad tube. Two fixed length cutting means are sequentially installed along both ends of a cradle so as to cut fixed length of the two ends of the clad tube along two stations but not cut simultaneously, thereby, the axiality of the clad tube and a molding cutter can be ensured, the adjustment of the axiality during the producing can be achieved, the yield is improved. A detecting device is installed after tube drawing, cleaning, and fixed length cutting stations, thus increasing the production accuracy and the yield. The cleaning device and the fixed length cutting device are respectively provided with a protective cover to prevent the sprinkling of chips, in addition, a chip collector is arranged for centralizedly recovery processing the cutting chips and graphite dust, accordingly, the clean of the workpiece is ensured, the work environment is improved. A pneumatic damper is adopted by the cutting feeding for achieving the change from the rapid advance phase to the feeding, thereby, the invention has advantages of stable performance , high control accuracy, easy maintenance, convenient adjustment, no pollution, and convenient replacement and purchase.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com