Cable surface graphite coating device

A coating device and cable technology, which is applied to the surface coating liquid device, cable/conductor manufacturing, circuit, etc., can solve the problems that endanger the health of workers, the normal operation of machines and equipment, the difficulty of completely eradicating graphite dust suspension, and graphite dust Suspension and other problems to achieve the effect of eliminating graphite dust pollution, ensuring health and preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0021] see Figure 1 to Figure 4 ,

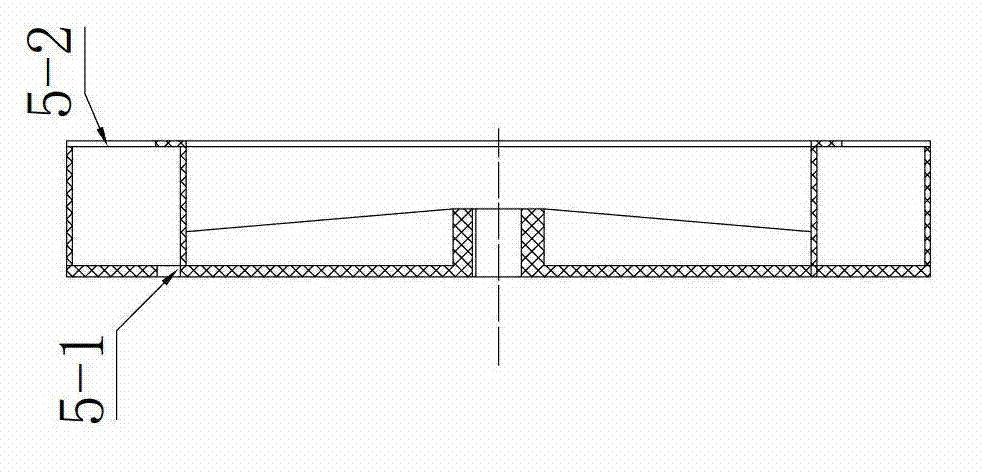

[0022] A cable surface graphite coating device, comprising a box body 1 and wire inlet holes 2 and outlet holes 3 on the left and right sides of the box body, a liquid graphite tank 4 is arranged in the box body, and the liquid graphite liquid level in the liquid graphite tank is low In the wire inlet and outlet holes, at least one actively driven pulp extraction wheel 5 is provided in the middle of the box body, and pulp extraction holes are provided on the pulp extraction wheel, and a liquid wiping device 6 is provided on the outlet side of the box body.

[0023] One end face of the pulping wheel is facing the cable, the side facing the cable is provided with a pulping hole 5-1, and the side away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com