Multi-station hoisting device for overhauling control rod driving mechanism of high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and hoisting device technology, applied in the field of reactor maintenance, can solve the problems of helium atmosphere damage, prolong the period of helium purification and dehumidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present disclosure, the present disclosure will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

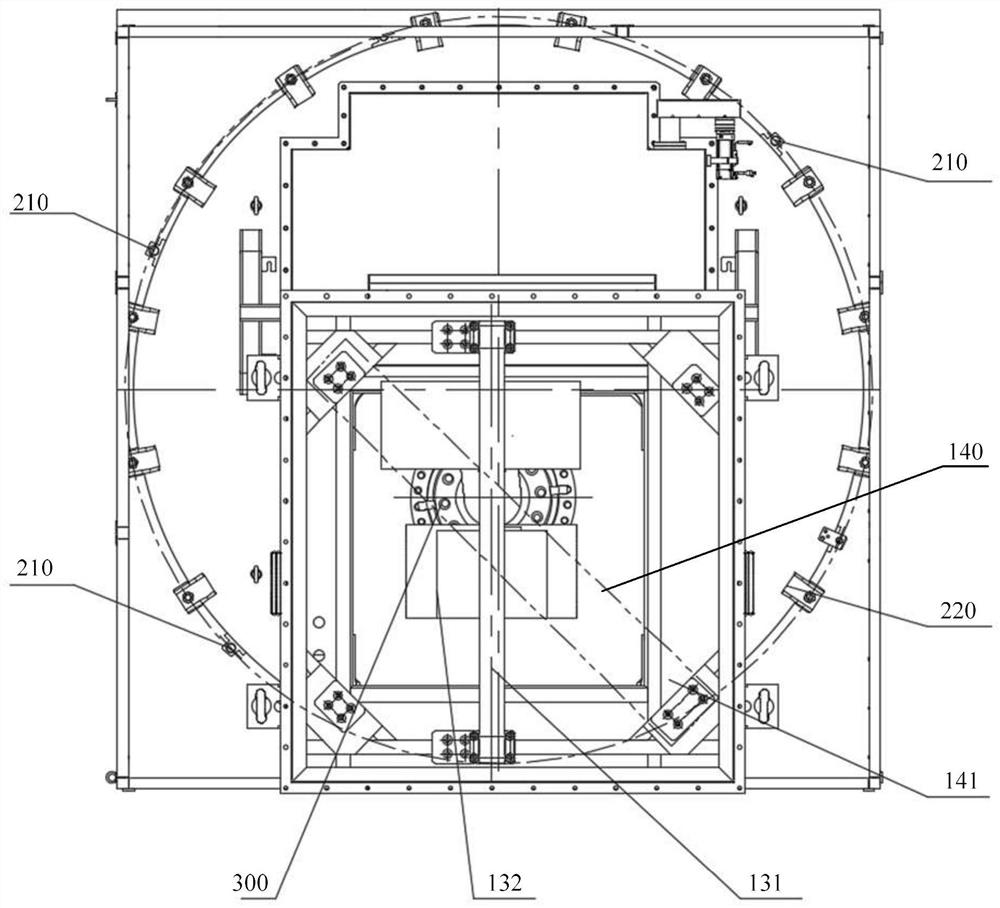

[0024] Such as Figure 1 to Figure 3 As shown, this embodiment relates to a multi-station hoisting device 100 for overhauling the control rod driving mechanism of a high-temperature gas-cooled reactor. The suspension assembly 140 and the rotatable mounting plate 150 .

[0025] Exemplary, such as Figure 1 to Figure 3 As shown, the skeleton 110 can be a three-dimensional (such as cuboid or cube, etc.) frame surrounded by a plurality of columns or steel pipes, and there is a hoisting space inside the frame, so that the first hoisting assembly 130 or the second hoisting assembly 140 can be used to hoist the atmosphere. The isolation device 200 is an atmosphere-isolated control rod drive mechanism 300 . The skeleton 110 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com