Graphite dust disposing device

A technology of graphite dust and treatment device, which is applied in the direction of power supply technology, electrostatic effect separation, cleaning method and utensils, etc., to achieve the effect of effective collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

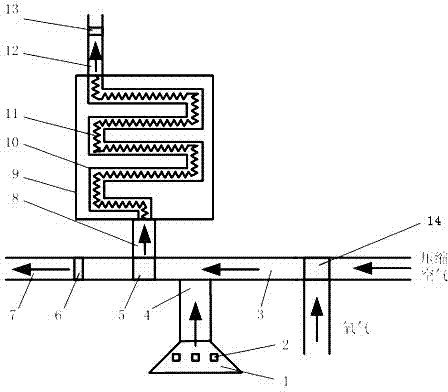

[0040] A graphite dust processing device, including a dust suction mechanism and a dust removal mechanism.

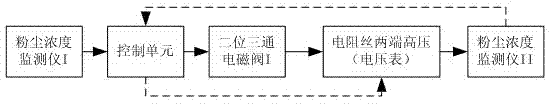

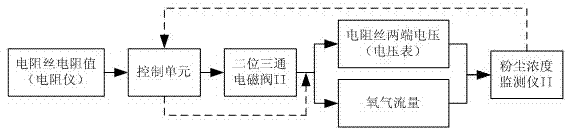

[0041]The dust removal mechanism includes: a curved pipe 10; a guide pipe 8 connected to the entrance of the curved pipe 10; an exhaust pipe 12 connected to the outlet of the curved pipe 8; a resistance wire 11 located in the curved pipe; used to detect dust at the exit of the dust removal channel Concentration dust concentration monitor II13; power supply device, wherein, the positive pole of the power supply device is connected to the resistance wire 11, and the negative pole is connected to the curve tube 10; a resistance meter.

[0042] The dust collection mechanism includes: compressed air source; dust collection cover 1 as the dust suction inlet, dust collection cover 1, external fixed magnet block 2; dust collection cover 1 is connected with suction hose 4, dust collection hose 4 and input air pipe 3 Connected, two-position three-way valve I6 and two-position thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com