Hollow oxygen-free copper bar vacuum electron beam welding method, current lead and nuclear fusion device

A technology of vacuum electron beam welding and oxygen-free copper rods, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., which can solve the problem of poor sealing of welded joints, difficulty in meeting design requirements, and poor weld surface shape and other problems, to achieve the effect of good sealing of welded joints, long service life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

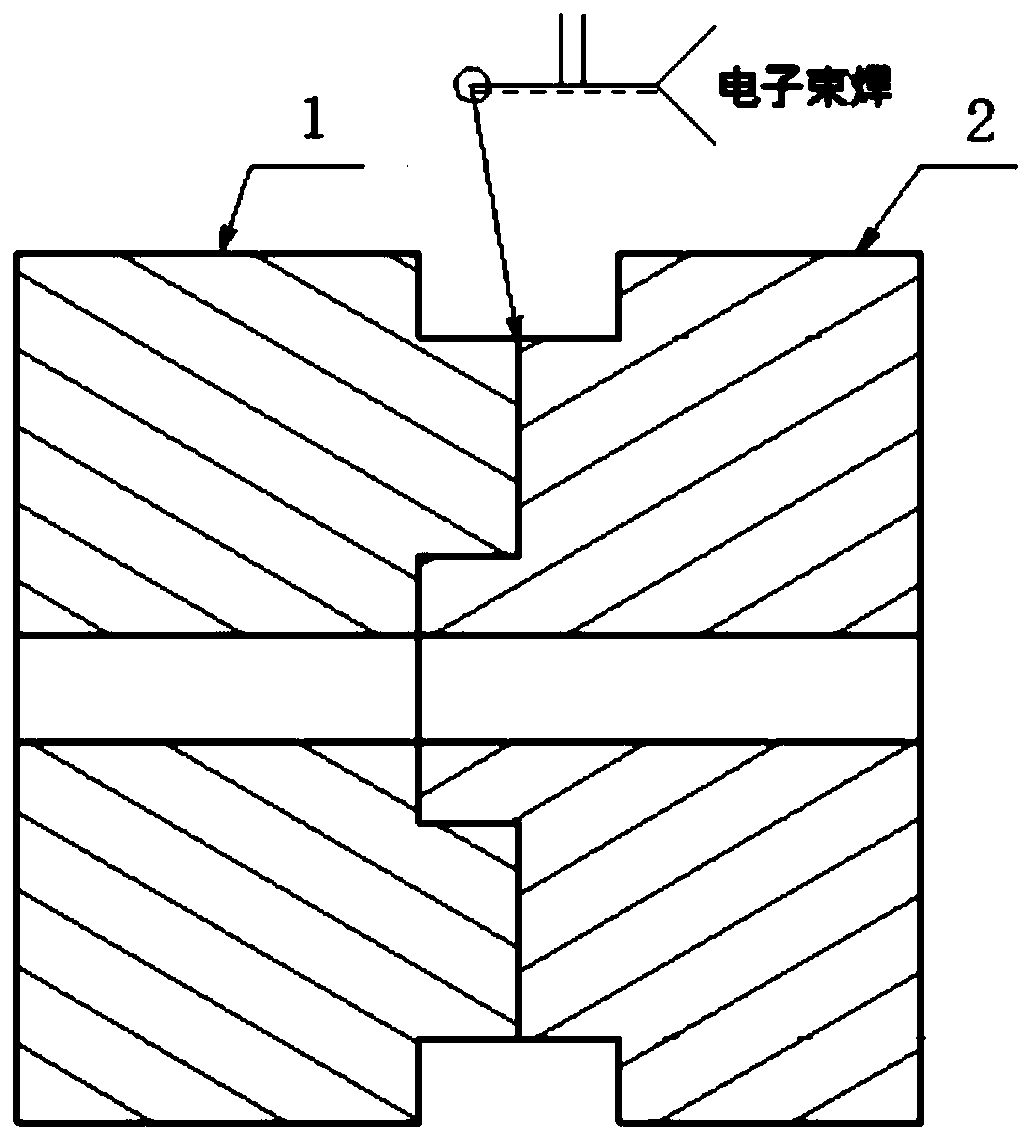

[0025] This embodiment takes two C10200 hollow oxygen-free copper rods with an outer diameter of φ105mm, an inner hole diameter of φ16mm, and a copper rod length of 80mm as an example, which are hereinafter referred to as the first hollow oxygen-free copper rod 1 and the second hollow oxygen-free copper rod 2 ( Such as figure 1 shown).

[0026] A vacuum electron beam welding method for a hollow oxygen-free copper rod provided by the invention comprises the following steps:

[0027] (1) Use fine sandpaper dipped in alcohol to polish the first and second hollow oxygen-free copper rods to be welded and the metal surface within 40mm of the surroundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com