Energy output structure of panel vacuum electron device

A vacuum electronic device and energy output technology, which is applied to the circuit components of transit time type electron tubes, traveling wave tubes, etc., can solve problems such as reducing device efficiency, affecting power amplification and energy output, and closing the collector entrance. The effect of easy processing, simple structure and high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

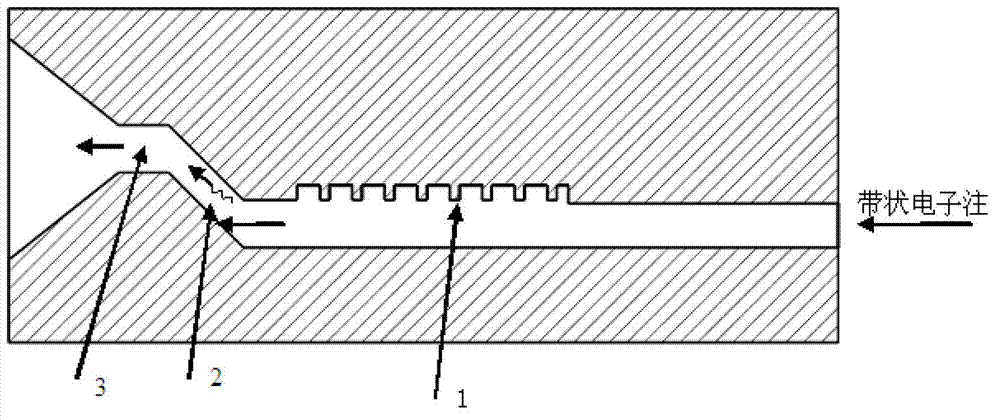

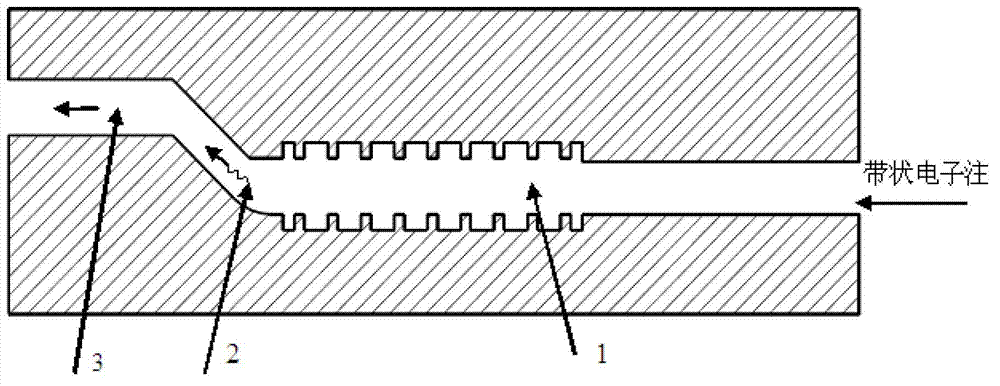

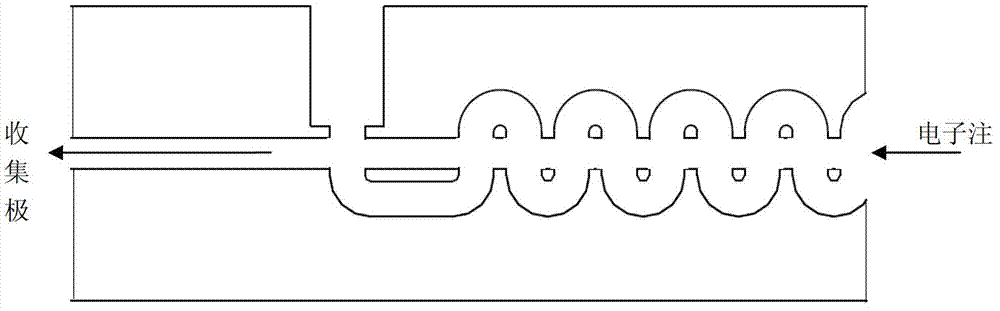

[0022] Embodiment 1: The planar slow-wave structure adopts a rectangular double-grid slow-wave structure. According to the parameters of the rectangular double-grid, the height of the energy output structure is 4mm and the width is 46mm. Through calculation, a circular arc transition (with a radius of 4 mm) is adopted, and the angle between the energy output structure and the slow wave structure is 45 degrees. The electron beam interacts with the rectangular double-gate structure to generate high-power millimeter wave oscillation, and then the TE wave is output from the energy output structure. The whole device generates high power oscillation output at 36GHz such as Figure 5 shown (measured at image 3 far left of the energy output structure shown).

Embodiment 2

[0023] Example 2: The slow-wave structure adopts a sinusoidal waveguide grating (single-grid or double-grid) slow-wave structure, and other structures remain unchanged. Through optimal design, the angle between the rectangular oblique waveguide 2 and the planar sinusoidal waveguide grating slow-wave structure 1 is 30 degrees, the output energy is output along the rectangular straight waveguide 3 .

Embodiment 3

[0024] Embodiment 3: The slow wave structure adopts the trapezoidal grid (single grid or double grid) slow wave structure, and other structures remain unchanged. Through optimized design, the angle between the rectangular inclined waveguide 2 and the flat trapezoidal grid slow wave structure is 60 degrees. The output energy is output along the rectangular straight waveguide 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com