Dissimilar metal lamination composite complete blank assembly equipment and blank assembly method

A dissimilar metal layer and blank assembly technology, which is applied in the fields of dissimilar metal lamination and composite blank assembly equipment and combined blanks, can solve problems such as poor product quality stability, high safety and environmental risks, and difficulty in mass production, and achieve weld quality Excellent, improved efficiency, reduced metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

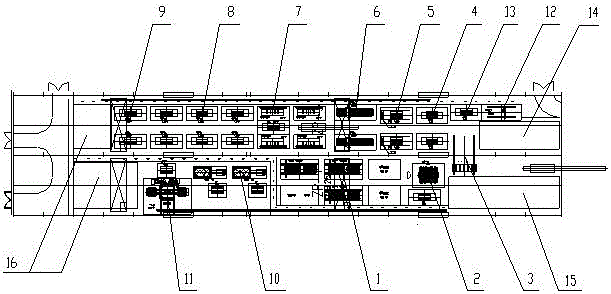

[0045] A complete set of blank assembly equipment for lamination of dissimilar metals. The No. 1 workshop is equipped with double board turnover warehouse 14, plasma welding splicing equipment 12, weld seam grinding table 13, surface grinding table 4, coating table 5, and pressure group. Billet recording unit 6, narrow gap automatic gas shielded welding long side edge banding unit 7, gas shielded welding short side edge banding unit 8, flaw detection unit 9, and finished welding billet turnover warehouse 16;

[0046] Workshop No. 2 is equipped with a slab turnover warehouse 15, a cross-span trolley 3, a flap alignment device 2, a CNC gantry surface milling device 1, a spacer drying device 10, a vacuum electronic welding unit 11, and a turnover warehouse 16 for finished welded blanks. The side of the isolating agent drying device 10 is provided with a gas-shielded welding short side edge sealing unit 8, and a flaw detection inspection unit 9 is provided next to the vacuum electr...

Embodiment 2

[0057] A complete set of blank assembly equipment for lamination of dissimilar metals. The No. 1 workshop is equipped with double board turnover warehouse 14, plasma welding splicing equipment 12, weld seam grinding table 13, surface grinding table 4, coating table 5, and pressure group. Billet recording unit 6, narrow gap automatic gas shielded welding long side edge banding unit 7, gas shielded welding short side edge banding unit 8, flaw detection unit 9, and finished welding billet turnover warehouse 16;

[0058] Workshop No. 2 is equipped with a slab turnover warehouse 15, a cross-span trolley 3, a flap alignment device 2, a CNC gantry surface milling device 1, a spacer drying device 10, a vacuum electronic welding unit 11, and a turnover warehouse 16 for finished welded blanks. The side of the isolating agent drying device 10 is provided with a gas-shielded welding short side edge sealing unit 8, and a flaw detection inspection unit 9 is provided next to the vacuum electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com