A method and device for controlling tension fluctuation of a galvanized wire weld seam finishing machine

A technology of skin pass mill and galvanizing line, which is applied in the direction of rolling mill control device, tension/pressure control, rolling force/roll gap control, etc. It can solve problems such as twill defect and tension fluctuation, so as to reduce cutting loss and ensure finished product rate, reducing the effect of tension fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

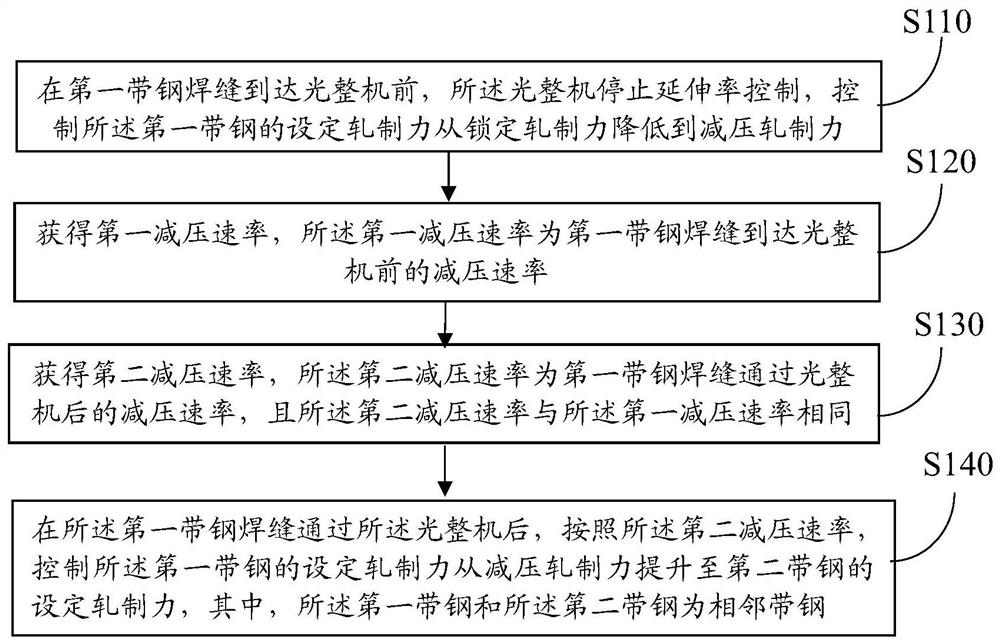

[0050] figure 1 It is a schematic flowchart of a method for controlling tension fluctuation of a galvanized wire weld pass through a skin pass machine in an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a method for controlling tension fluctuation of a galvanized wire weld passing through a skin pass machine, the method comprising:

[0051] Step 110: Before the weld seam of the first strip reaches the skin pass mill, the skin pass mill stops elongation control, and controls the set rolling force of the first strip to decrease from locked rolling force to reduced pressure rolling force;

[0052] Specifically, before the first strip weld arrives at the skin pass mill, lock the rolling force and stop the elongation control at the same time, start the decompression before the weld seam reaches the skin pass mill, and reduce the set rolling force to the decompression rolling force.

[0053] Step 120: Obtain a fi...

Embodiment 2

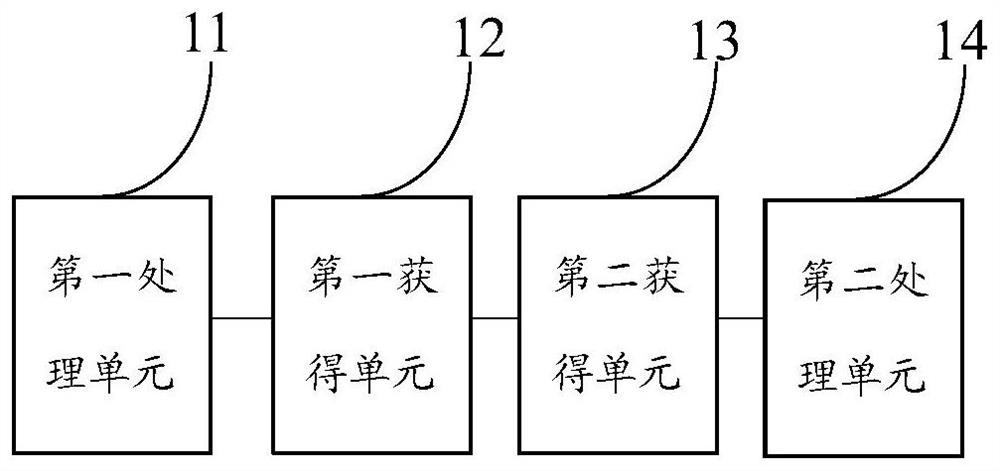

[0070] Based on the same inventive concept as the control method for the tension fluctuation of a galvanized wire weld pass through the skin pass machine in the foregoing embodiment, the present invention also provides a control device for the tension fluctuation of the galvanized line weld pass through the pass pass machine, such as figure 2 As shown, the device includes:

[0071] The first processing unit 11, before the weld seam of the first steel strip reaches the skin pass mill, the skin pass machine stops the elongation control, and the first processing unit 11 controls the set rolling force of the first strip steel from The locked rolling force is reduced to the reduced rolling force;

[0072] The first obtaining unit 12, the first obtaining unit 12 obtains a first decompression rate, and the first decompression rate is the decompression rate before the first strip weld reaches the skin pass mill;

[0073] The second obtaining unit 13, the second obtaining unit 13 obt...

Embodiment 3

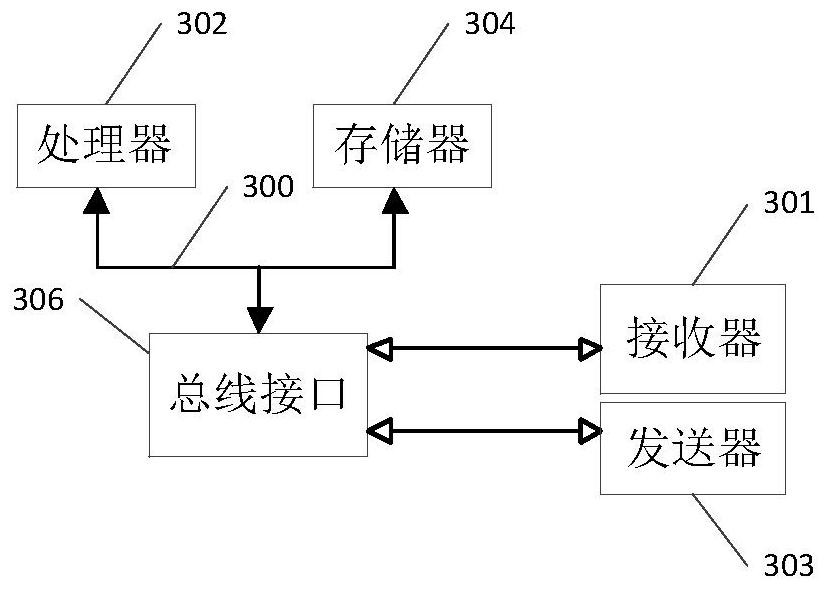

[0092] Based on the same inventive idea as the control method for the tension fluctuation of the galvanized wire weld passing through the skin pass machine in the foregoing embodiments, the present invention also provides a control device for the tension fluctuation of the galvanized wire weld passing through the skin pass machine, on which A computer program is stored, and when the program is executed by the processor, the steps of any one of the above-mentioned methods for controlling the tension fluctuation of the galvanized wire weld passing through the skin pass machine are realized.

[0093] Among them, in image 3 In, bus architecture (represented by bus 300), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits linked together. The bus 300 may also link together various other circuits, such as peripherals, voltage regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com