Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133results about "Transit-tube vessels/containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shell for packaging microwave assembly and laser sealing method of shell

InactiveCN102496552AControlled Thermal ShockReduce thermal shockTransit-tube vessels/containersVessels or leading-in conductors manufactureMicrowaveThermal impact

The invention relates to a shell for packaging a microwave assembly and a laser sealing method of the shell. The shell for packaging the microwave assembly comprises an aluminum silicon alloy shell and a 4047 aluminum alloy cover plate, wherein the aluminum silicon alloy shell is abutted with the 4047 aluminum alloy cover plate. The laser sealing method comprises the following steps of: cleaning the aluminum silicon alloy shell and the 4047 aluminum alloy cover plate by using acetone, then abutting the aluminum silicon alloy shell with the 4047 aluminum alloy cover plate by using a tool, then fixing the aluminum silicon alloy shell and the 4047 aluminum alloy cover plate by using an Nd:YAG laser, and continuously integrally welding the shell by using the Nd-YAG laser, welding from the bottom of the aluminum silicon alloy shell until reaching the surface of the 4047 aluminum alloy cover plate, wherein the two welding processes are carried out in a nitrogen protective gas. The invention is used for carrying out sealing by using the laser, is easy to realize, has good sealing property and controllable welding depth, can be used for repaired for two times, has little thermal impact to a substrate and a chip because local heating is adopted in the welding process, can realize automatic operation, and has no soldering flux pollution and high reliability.

Owner:WUXI HUACE ELECTRONICS SYST

Component having a multipactor-inhibiting carbon nanofilm thereon, apparatus including the component, and methods of manufacturing and using the component

ActiveUS20130033343A1Improve component reliabilityReduce transmissionTransit-tube vessels/containersMaterial nanotechnologySecondary electronsEnergy device

A high power RF energy device component is disclosed that is exposed to high power RF energy in a vacuum environment, and includes a multipactor-inhibiting carbon nanofilm covering at least one surface of the component. A secondary electron efficiency (SEE) coefficient of the multipactor inhibiting carbon nanofilm is desirably less than a SEE coefficient of the underlying surface of the component.

Owner:NOKOMIS

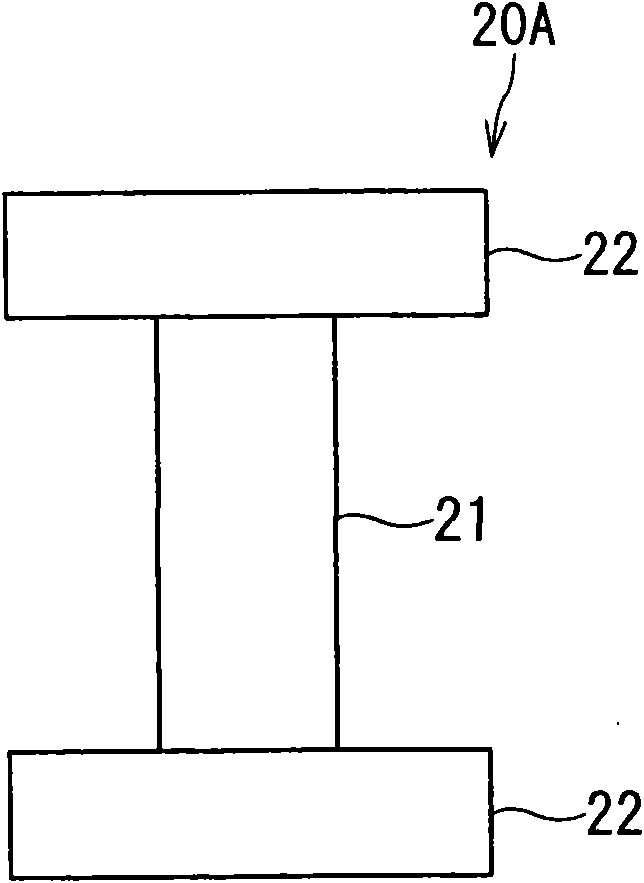

Tube amplifier assembly having a power tube and a capacitor assembly

Tube amplifier assembly including a power tube that is configured to be coupled to a grounding deck and positioned within an opening of the grounding deck. The tube amplifier assembly also includes a tube adapter that is configured to be coupled to the grounding deck. The tube adapter has a capacitive plate that extends parallel to the grounding deck and an adapter wall that is coupled to the capacitive plate. The tube adapter has an adapter opening that is aligned with the deck opening to form a tube passage. The tube adapter includes flexible conductive elements that are electrically coupled to the capacitive plate and surround the tube passage. The flexible conductive elements engage the power tube in the tube passage and electrically couple the power tube to the capacitive plate. The grounding deck and the capacitive plate form a capacitor assembly.

Owner:GENERAL ELECTRIC CO

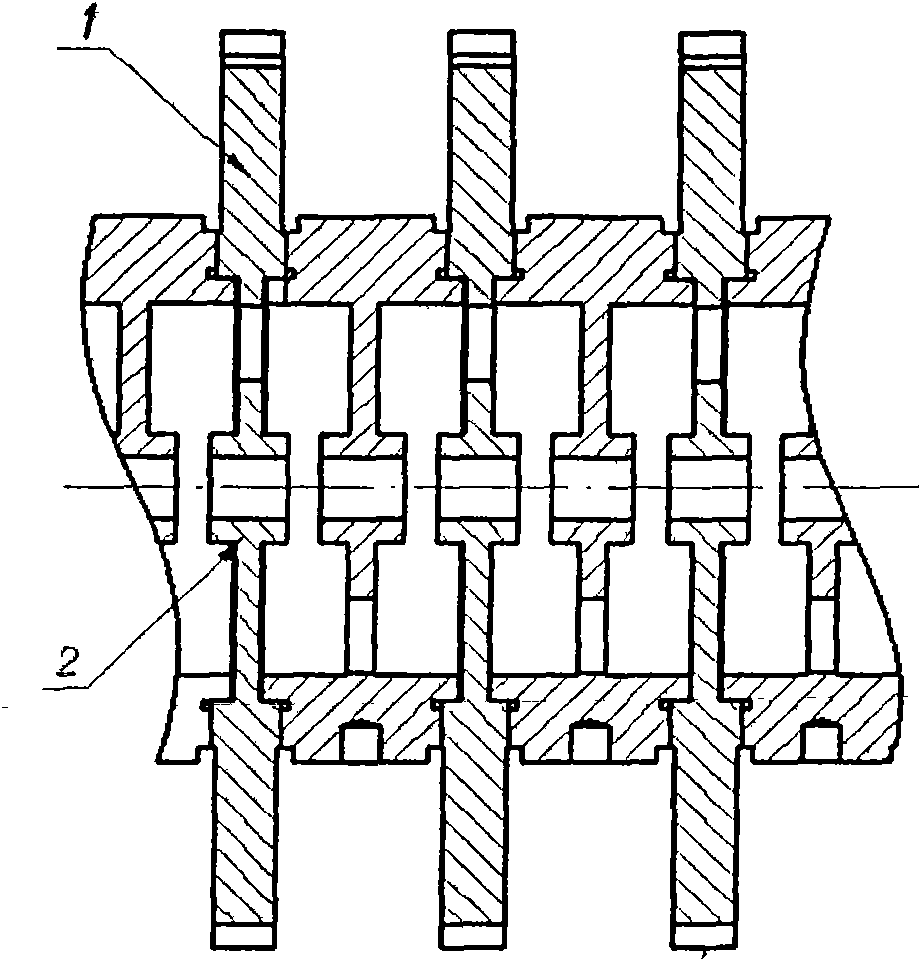

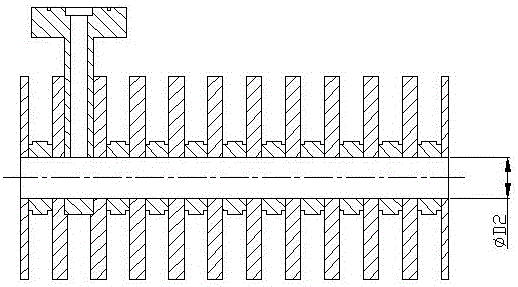

Millimeter wave traveling wave tube composite cellpacking and preparation method thereof

InactiveCN101673651AMeet the size parameter requirementsImprove thermal conductivityTransit-tube vessels/containersEngineeringNon magnetic

The invention relates to a millimeter wave traveling wave tube composite cellpacking and a preparation method thereof, belonging to the field of the vacuum electronic device. The composite cellpackingcomprises pole shoes of the focusing system used for the millimeter wave traveling wave tube. The composite cellpacking is characterized in that the pole shoes and nonmagnetic metal material rings are arranged axially at intervals and are welded and fixed together to form an integrated composite cellpacking. The length of the composite cellpacking and the lateral dimension of the pole shoes are both decided by the electrical parameter of the millimeter wave traveling wave tube. By using the composite cellpacking of the millimeter wave traveling wave tube, the lateral dimension of the whole tube and the inner diameter of the pole shoes are reduced to the minimum so as to meet the demand of the dimensions parameters of the whole tube, reduce the difficulty of the focusing control and benefit the heat conduction of the slow-wave system.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

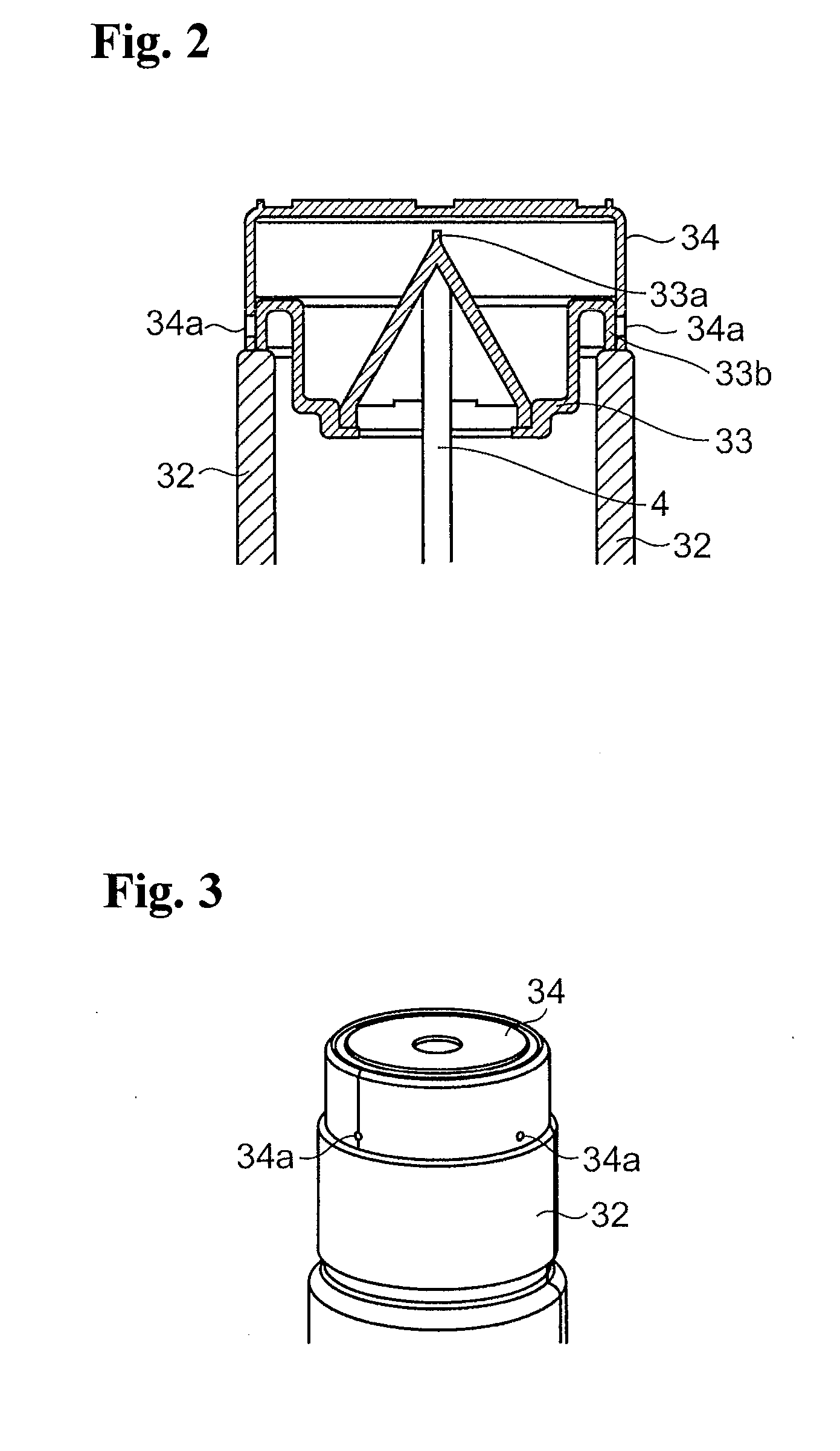

Ceramic part for magnetron, magnetron employing the same, and process for producing ceramic part for magnetron

ActiveCN101652829AImprove joint strengthImprove reliabilityTransit-tube vessels/containersTransit-tube leading-in arrangementsAdhesion strengthGrain boundary

A ceramic part for magnetrons which has a metallic layer having improved adhesion strength. The ceramic part for magnetrons comprises a ceramic main body part (1) comprising an alumina sinter and Mo-Mn metallic layers (9 and 10) disposed by metallization on the surface of part of the ceramic main body part, wherein the ceramic main body part is an alumina sinter having an Mn-containing grain boundary phase and has an Mn-rich phase at the interface between the ceramic main body part and the Mo-Mn metallic layers.

Owner:KK TOSHIBA +1

Magnetron For Microwave Oven

A magnetron for microwave oven has an anode cylinder, vanes (height: H (mm)), a cathode spirally extending along the central axis, a pair of end hats (outer diameter: DEH1 (mm), DEH2 (mm)) fixed to both ends of the cathode, and a pair of pole pieces. Vanes extend from an inner surface of the anode cylinder to the central axis. Free ends of the vanes form a vane inscribing circle (diameter: Da (mm)). Pole pieces expand like funnels from through-holes (inner diameter: DPP1 (mm), DPP2 (mm)) facing to the end hats and pinch the cathode. The shape of the magnetron satisfies, H≦8.5, H / Da≦0.95, DEH1 / DPP1≦0.8, DEH1 / DPP2≦0.8, DEH2 / DPP1≦0.8, DEH2 / DPP2≦0.8, 0.92≦Da / DPP1≦0.95, and 0.92≦Da / DPP2≦0.95.

Owner:TOSHIBA HOKUTO ELECTRONICS CORP

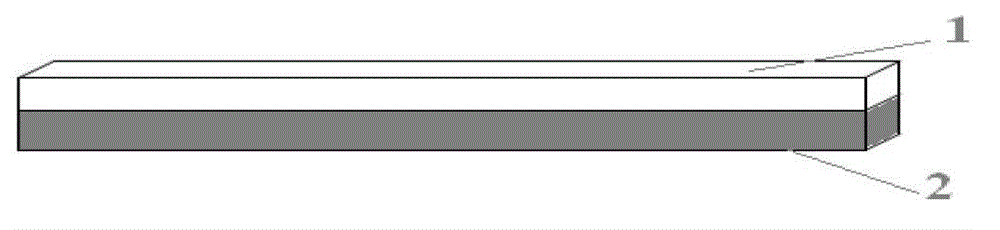

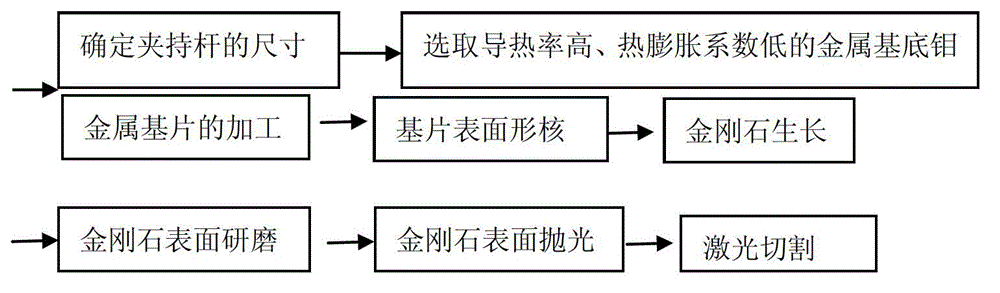

Diamond-metal compound type clamping rod for travelling wave tube and manufacture method of diamond-metal compound type clamping rod

InactiveCN102867716AHigh strengthIncrease output powerTransit-tube vessels/containersVessels or leading-in conductors manufactureGas phaseChemical vapor deposition

The invention discloses a diamond-metal compound type clamping rod for a travelling wave tube and a manufacture method of the diamond-metal compound type clamping rod, belonging to the technical field of vacuum electronics. The diamond-metal compound type clamping rod is used as one part in a travelling wave tube and high-frequency structure and comprises an artificially synthesized diamond and a metal substrate. The manufacture method of the diamond-metal compound type clamping rod comprises the following steps of: firstly forming a diamond crystal nucleus on the surface of the metal substrate, then artificially synthesizing a diamond layer by using a chemical vapor deposition method, then grinding and polishing the surface of the diamond, and cutting and processing into the diamond-metal compound type clamping rod by using laser. The diamond-metal compound type clamping rod has the advantages of greatly shortening the growing time of diamond, reducing the cost, improving the strength of the clamping rod, and remarkably improving the output power of the travelling wave tube compared with that when a beryllium oxide clamping rod is used.

Owner:NO 12 RES INST OF CETC

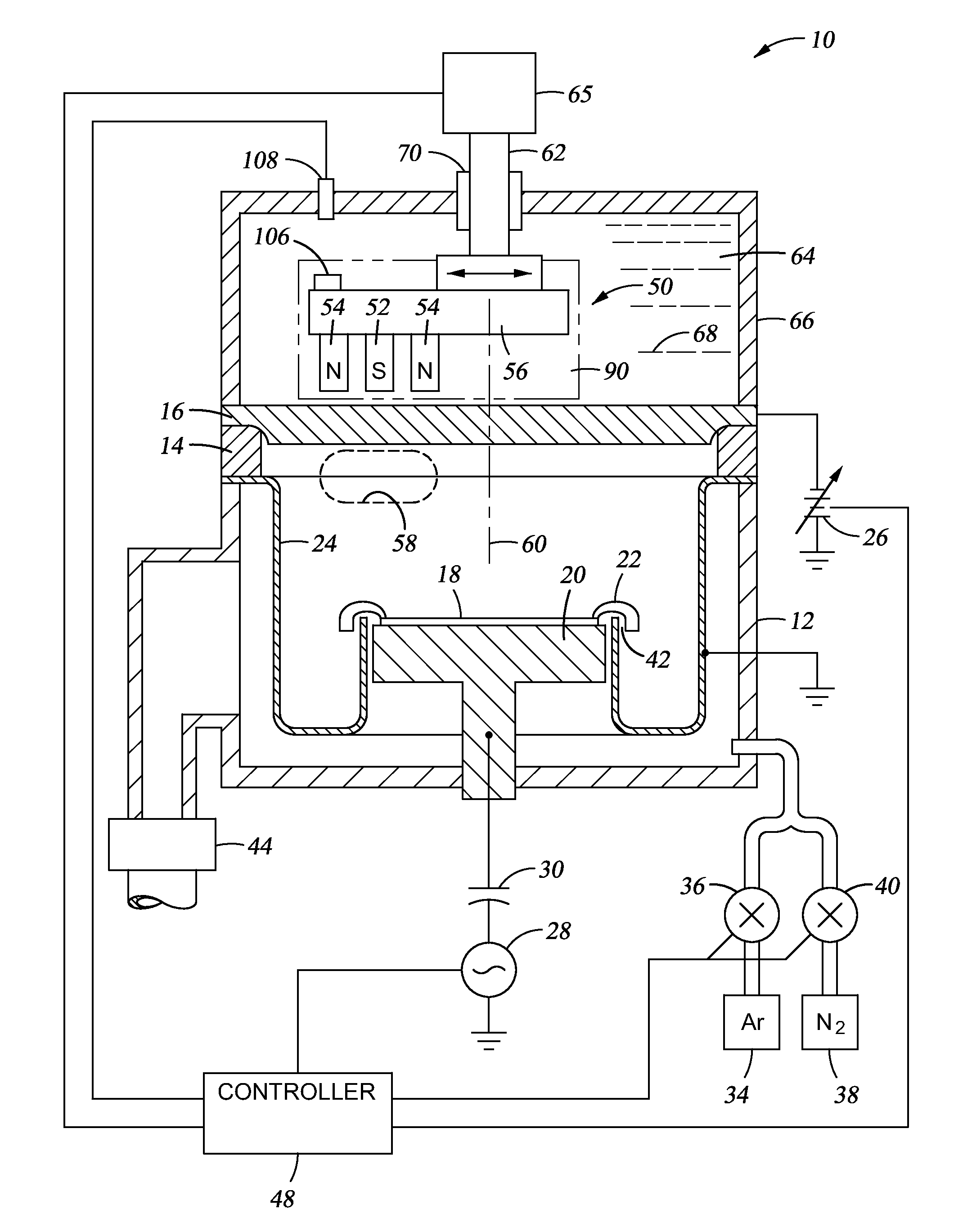

Encapsulated magnetron

ActiveUS20150048735A1Transit-tube vessels/containersAngle modulation by transit-time tubeMagnetic polesEngineering

Owner:APPLIED MATERIALS INC

Composite casing of travelling-wave tube

InactiveCN1681070ATransit-tube vessels/containersVessels or leading-in conductors manufactureCouplingEngineering

The invention consists of outer tube case and inner tube case, which all are shape tube and have same length. The inner diameter of outer tube case matches the outer diameter of inner tube case, and inner tuber case is housed in outer tube case. The inwall of outer tube case makes rigid coupling with out wall of inner tube case.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

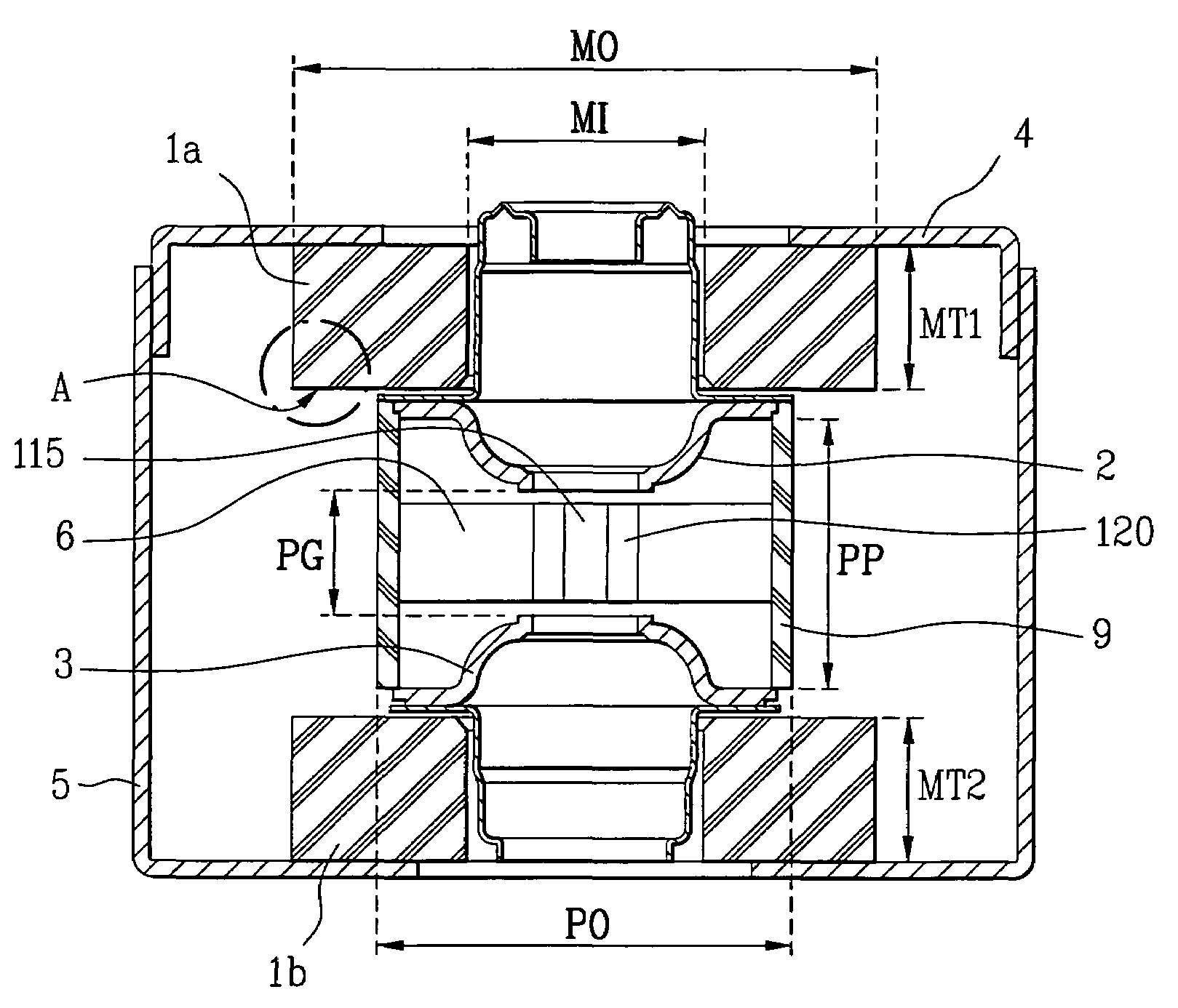

Magnetron

InactiveUS20060219548A1Small sizeReduce output capacityCellsTransit-tube vessels/containersMagnetic polesPhysics

Disclosed herein is a magnetron. The magnetron comprises an anode cylinder, upper and lower magnets provided to upper and lower portions of the anode cylinder, and upper and lower magnetic poles connected to the magnets, respectively. Each of the magnets has an inner diameter of 19˜21 mm, a thickness of 11.5˜12.5 mm, and an outer diameter of 50˜54 mm.

Owner:LG ELECTRONICS INC

Non-introducing magnetic field compact high-power microwave device

InactiveCN105551916AIncrease powerIncrease beam intensityTransit-tube vessels/containersElectrical conductorElectron

The invention discloses a non-introducing magnetic field compact high-power microwave device, which comprises an anode, a cathode, a coaxial inner conductor, a coupling plate, and four annular metal grid meshes, wherein the anode is provided with an accommodating cavity; the cathode is connected with the anode via an insulator and is located in the accommodating cavity; the coaxial inner conductor is connected with the anode and is located in the accommodating cavity, and the coaxial inner conductor and the accommodating cavity form a coaxial structure; the coupling plate is connected onto the end surface of the coaxial inner conductor; the four annular metal grid meshes have the same circle center but different semidiameters; the metal grid meshes are fixedly connected onto a grid mesh supporting area and the coaxial inner conductor; and the four annular metal grid meshes, the coupling plate, and the coaxial inner conductor form a resonant cavity. An electron beam emission mode is changed into a radial direction, the metal grid meshes are used for separating the cavity; as the electron beam is radially emitted, the electron beam has a large cross section, and a higher beam current strength can be transmitted in a low current density condition; and due to the radial structure, the space charge effects are small, the current limit current is large, input of large beam current can be allowed, and virtual cathode effects are not generated.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

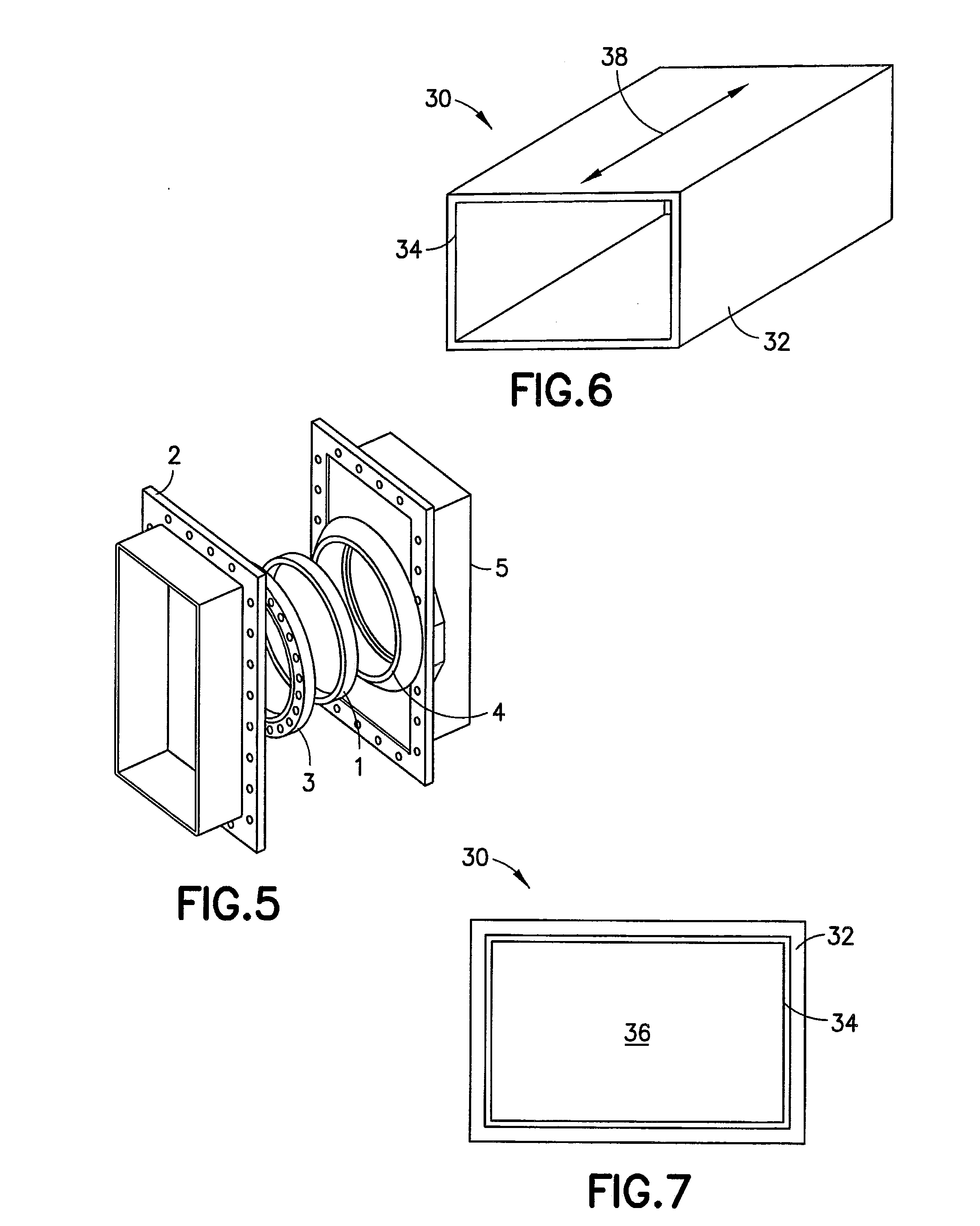

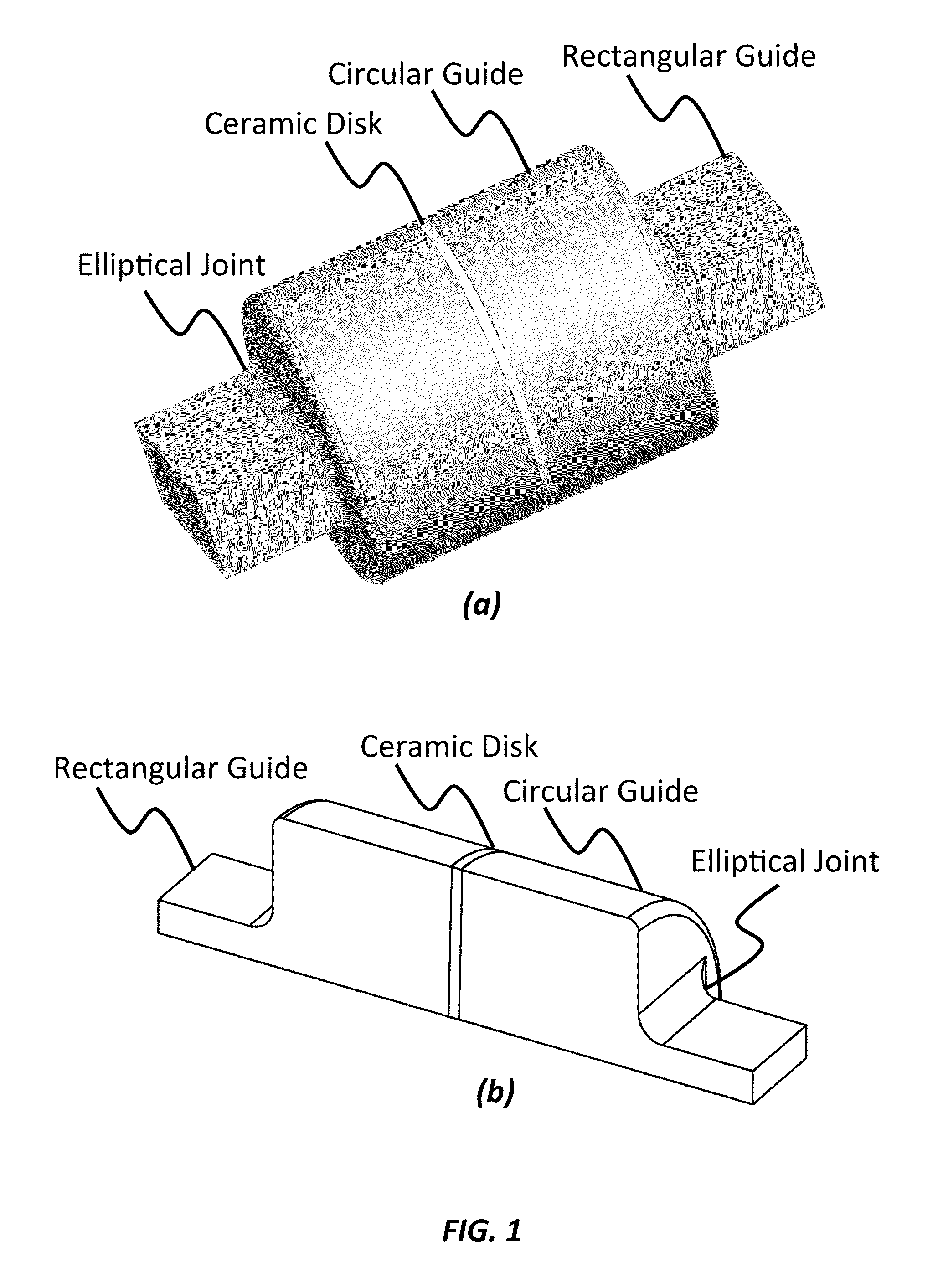

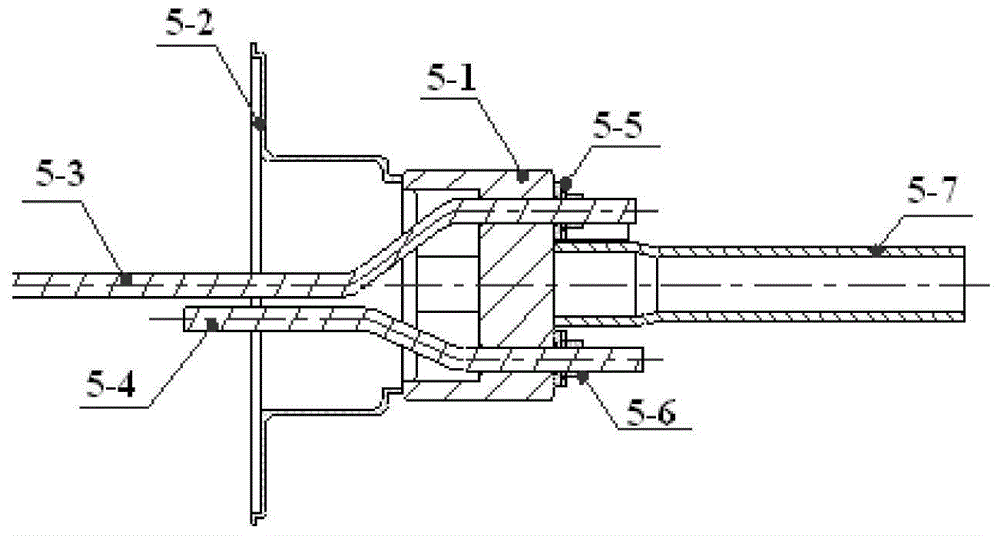

RF window to be used in high power microwave systems

ActiveUS20140333395A1Minimizing componentMinimizing a surface magnetic and electric fieldsTransit-tube vessels/containersKlystronsMicrowaveEngineering

A high-power microwave RF window is provided that includes a cylindrical waveguide, where the cylindrical waveguide includes a ceramic disk concentrically housed in a central region of the cylindrical waveguide, a first rectangular waveguide, where the first rectangular waveguide is connected by a first elliptical joint to a proximal end of the cylindrical waveguide, and a second rectangular waveguide, where the second rectangular waveguide is connected by a second elliptical joint to a distal end of the cylindrical waveguide.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Magnetron

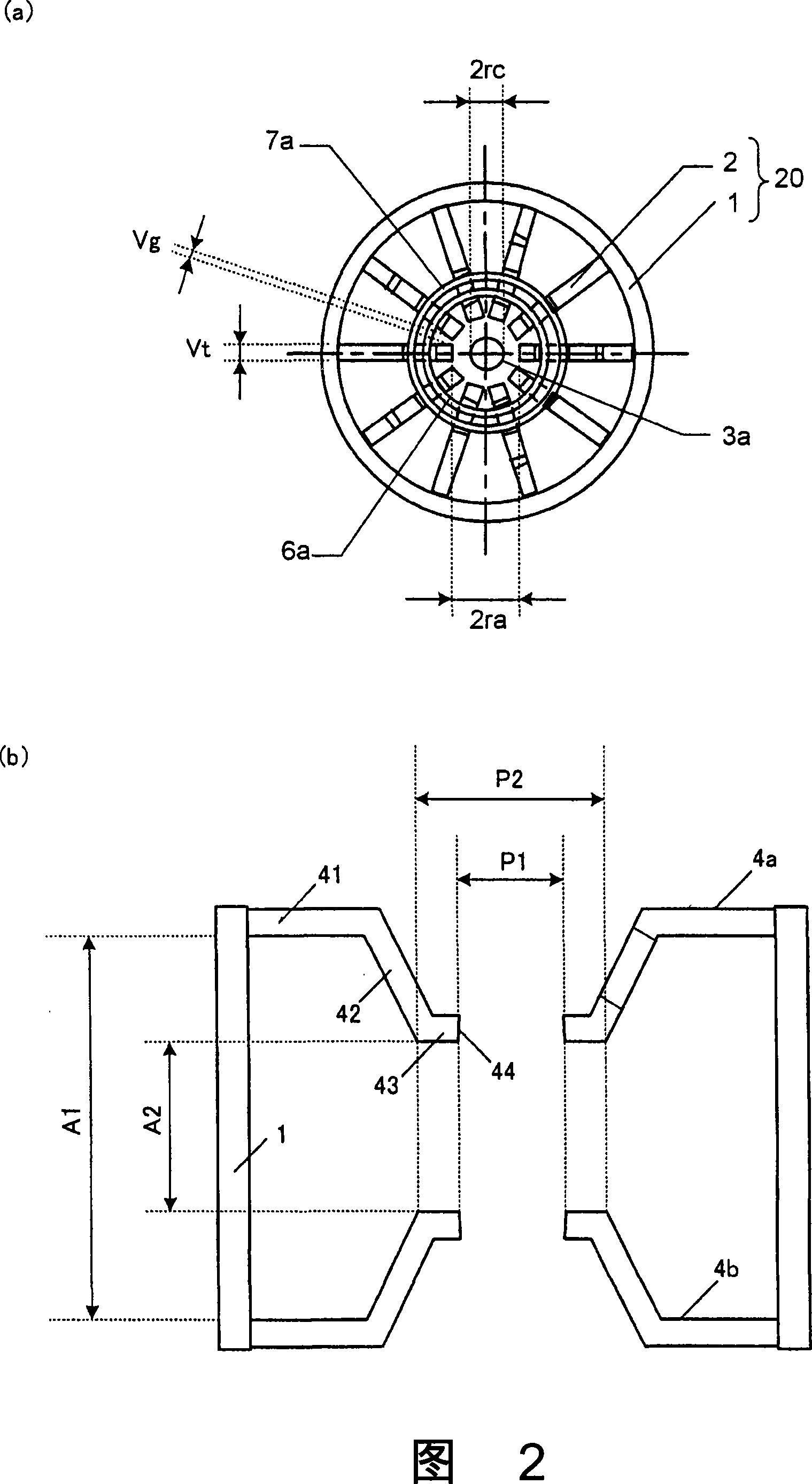

InactiveUS20070296515A1Enhanced oscillationTransit-tube vessels/containersAngle modulation by transit-time tubeElectrical and Electronics engineeringFunnel shape

At an oscillation frequency of 2450 MHz band, number of the vanes constituting the anode part of the magnetron being, the diameter 2ra of the circle inscribing tip portions of the vanes on the cathode side being 8.0 to 8.8 mm, the diameter 2rc of the outer periphery of the filament constituting the cathode part being 3.5 to 3.9 mm, the height A3 of the vane in the direction of the tube axis is 7.0 to 8.0 mm, the mutual distance A1 between the bases of the pair of funnel-shaped pole pieces fixed to both sides of the anode part being 21.5 to 23.5 mm, the mutual distance A2 between the bottom portions of the pair of pole pieces being 10.2 to 11.2 mm, the inner diameter P1 of the through-hole of the pole piece being 8.3 to 8.5 mm, and the outer diameter P2 of the bottom portion being 11.0 to 16.0 mm are set up.

Owner:TOSHIBA HOKUTO ELECTRONICS CORP

Magnetron

ActiveCN101093770AImprove oscillation output efficiencyMiniaturizationTransit-tube vessels/containersTransit-tube circuit elementsEngineeringFunnel shape

At an oscillation frequency of 2450 MHz band, number of the vanes constituting the anode part of the magnetron being, the diameter 2 ra of the circle inscribing tip portions of the vanes on the cathode side being 8.0 to 8.8 mm, the diameter 2 rc of the outer periphery of the filament constituting the cathode part being 3.5 to 3.9 mm, the height A 3 of the vane in the direction of the tube axis is 7.0 to 8.0 mm, the mutual distance A 1 between the bases of the pair of funnel-shaped pole pieces fixed to both sides of the anode part being 21.5 to 23.5 mm, the mutual distance A 2 between the bottom portions of the pair of pole pieces being 10.2 to 11.2 mm, the inner diameter P 1 of the through-hole of the pole piece being 8.3 to 8.5 mm, and the outer diameter P 2 of the bottom portion being 11.0 to 16.0 mm are set up.

Owner:TOSHIBA HOKUTO ELECTRONICS CORP

Magnetron

InactiveUS7375470B2Small sizeReduce output capacityCellsTransit-tube vessels/containersMagnetic polesPhysics

Disclosed herein is a magnetron. The magnetron comprises an anode cylinder, upper and lower magnets provided to upper and lower portions of the anode cylinder, and upper and lower magnetic poles connected to the magnets, respectively. Each of the magnets has an inner diameter of 19˜21 mm, a thickness of 11.5˜12.5 mm, and an outer diameter of 50˜54 mm.

Owner:LG ELECTRONICS INC

Multi-tube fluorescent discharge lamp

InactiveUS7164223B2Reduce the cross-sectional areaHigh densityTransit-tube vessels/containersElectrode assembly support/mounting/spacing/insulationPhosphorFluorescence

A multi-tube fluorescent discharge lamp, which is constructed of multiple glass tubes of different caliber in coaxial structure, the both sides of the inner most tube are connected to a cathode respectively, by isolating, perforating and blocking the discharge path, forming a successive discharge path, and coating phosphor on surface of the discharge tubes. The Invention can then have more fluorescent area than a conventional fluorescent lamp of the similar size and higher lumen as well as power transfer factor. Compared with the power consumption of a conventional fluorescent discharge lamp, the Invention therefore has higher luminous flux.

Owner:LEE WEN TSAO

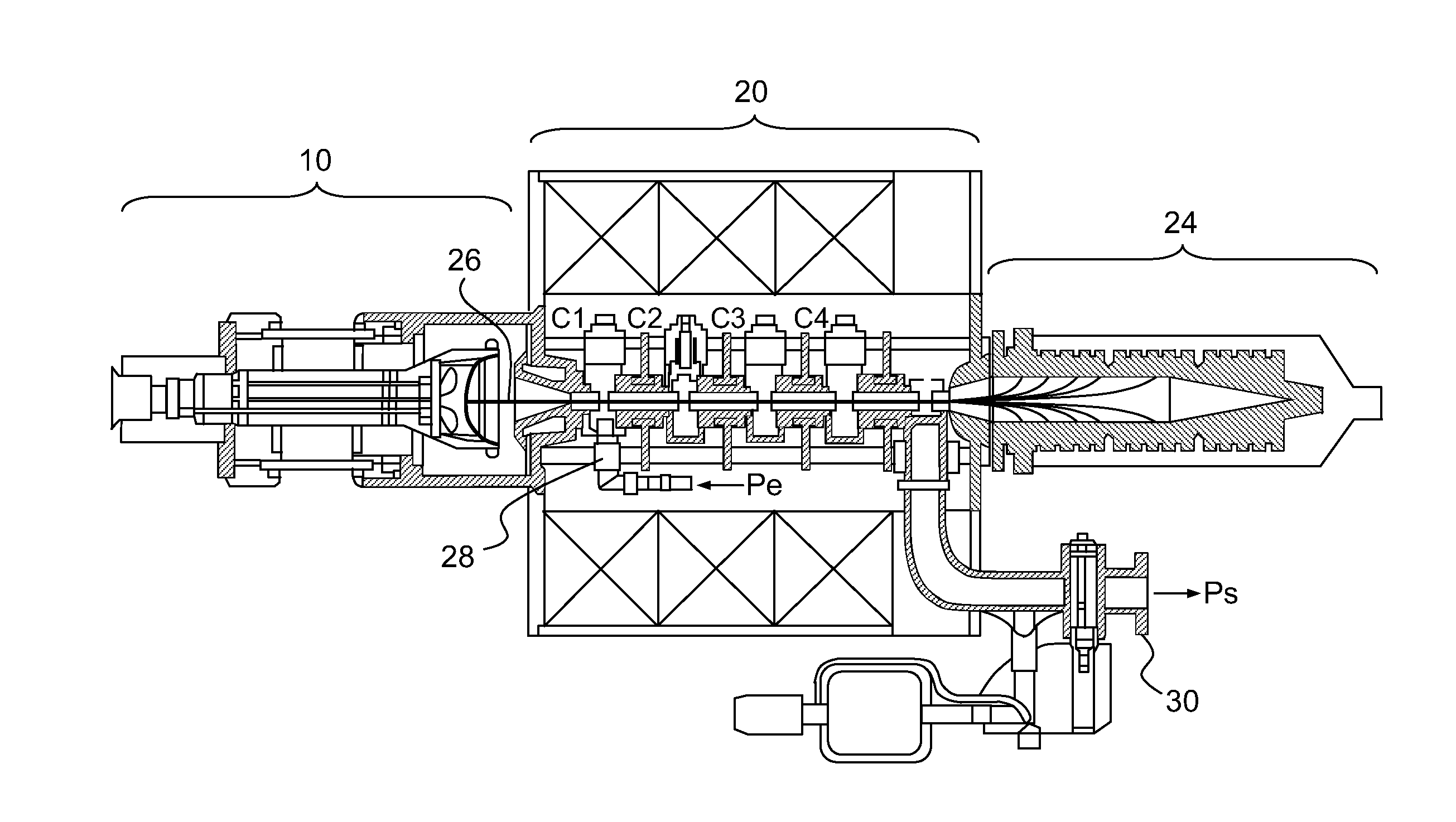

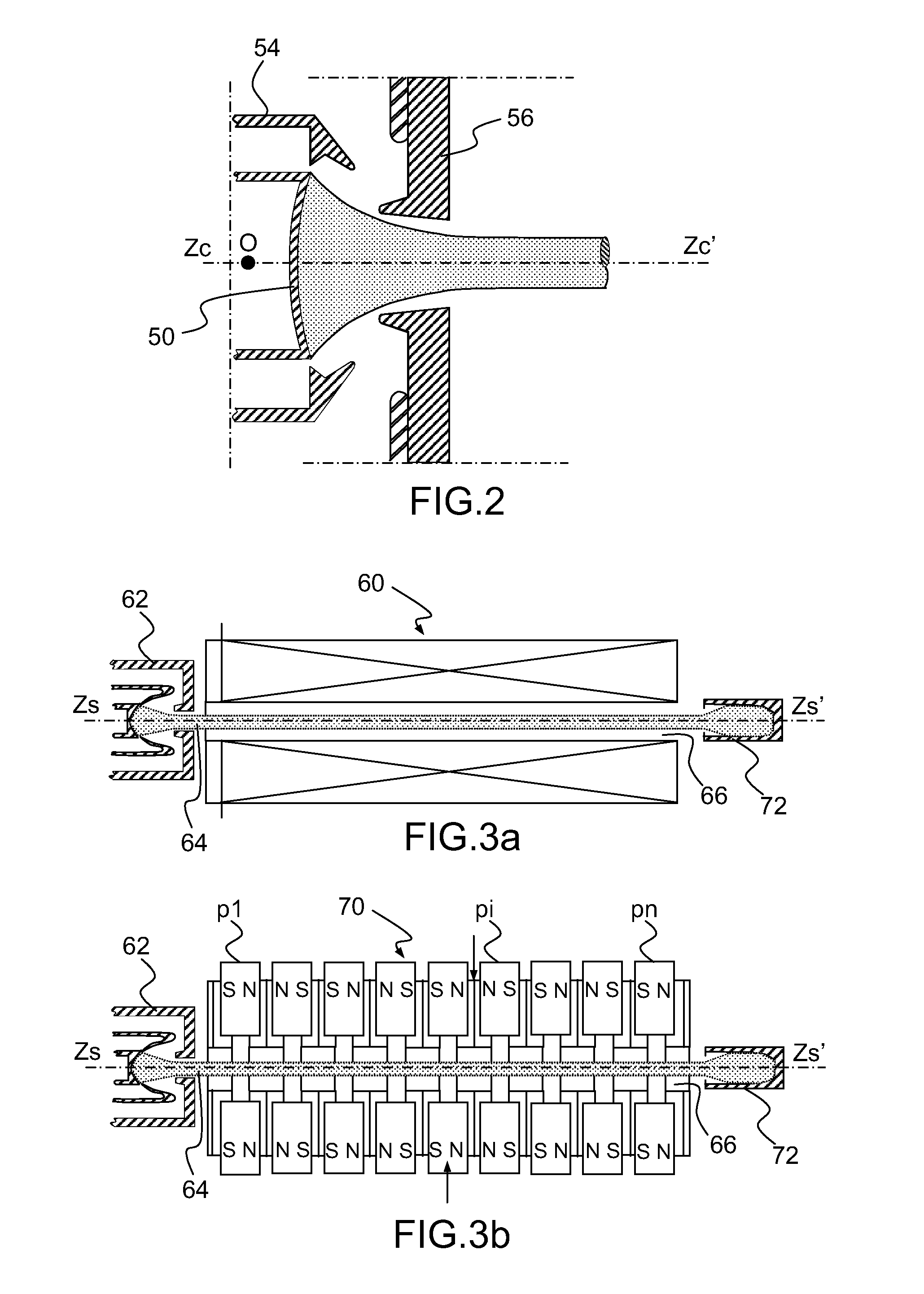

Electron tube with optimized injection of the electron beam into the tube

InactiveUS20110291545A1Transit-tube vessels/containersTransit-tube focussing arrangementsKlystronMicrowave

An electron tube includes a microwave structure, an electron gun having a cathode-wehnelt assembly, with axis for providing a linear electron beam along the same axis in a circular cylindrical passage with axis of the microwave structure, the cathode comprising a centre of rotation of the beam on the said axis of the cathode. The electron gun and the microwave structure each comprise portions of spherical surfaces in contact inscribed on one and the same sphere of radius centred on the centre of the cathode so as to form a swivel for angular adjustment of the axis of the cathode and to make the axis of the electron beam coincide with the axis of the circular cylindrical passage of the microwave structure. Applications include microwave electron tubes such as travelling wave tubes and klystrons.

Owner:THALES SA

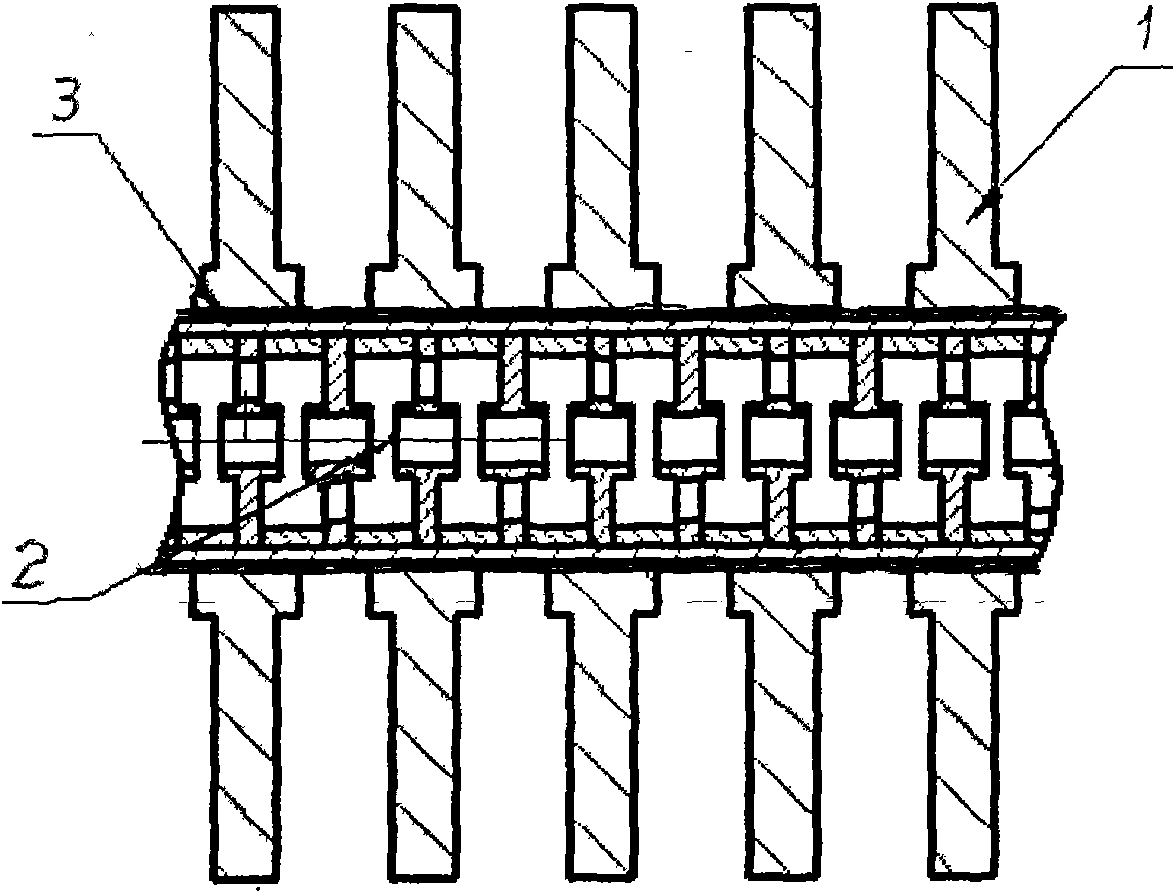

Processing method of composite slow-wave tube shell

ActiveCN106271428AImprove air tightnessReduce air leakage rateTransit-tube vessels/containersTransit-tube circuit elementsSurface finishWire cutting

The invention relates to a processing method of a composite slow-wave tube shell. The composite slow-wave tube shell comprises docking pole shoes, pole shoes, spaced rings, transfer pole shoes, an adapter and a positioning core rod. The processing method comprises the following steps: mounting and welding the docking pole shoes, the pole shoes, the spaced rings, the transfer pole shoes and the adapter, and then forming an inner hole processing channel of the tube shell; linearly cutting and processing the inner hole processing channel to the honing size of an inner hole channel, and forming an inner hole honing channel; honing the inner hole honing channel to reach a design size of the inner hole channel; testing; carrying out oil removal cleaning; performing an air-tightness test. According to the method, an advanced slow-wire cutting processing technology and an inner circle honing process are used for processing the inner hole channel of the composite slow-wave tube shell for a helix traveling-wave tube. The method disclosed by the invention has the advantages of high inner-diameter precision of the processed tube shell, good inner surface smoothness, high concentricity, low air leak rate of the processed composite tube shell, and the like.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

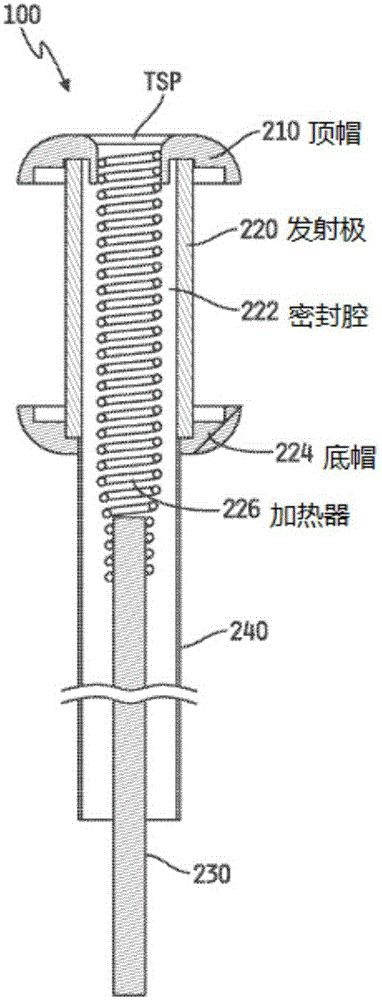

Multi-ring electron beam radiation source based on cold cathode

ActiveCN114023617AHigh degree of integrationImprove power efficiencyTransit-tube vessels/containersTravelling-wave tubesMicrowaveCold cathode

The invention belongs to the field of microwave, millimeter wave and terahertz wave band electric vacuum, and provides a multi-ring electron beam radiation source based on a cold cathode. The multi-ring electron beam radiation source comprises a high-frequency beam-wave interaction unit, a cathode substrate with one sealed and fixed end, an anode substrate with the other sealed and fixed end, and an output system device, wherein the high-frequency beam-wave interaction unit is designed in a way that a beam-wave interaction space is divided into Q + 1 electron beam channels by Q cylindrical metal partition plates which are distributed in a nested manner; and the nested cold cathode circular ring emitter on the surface of the cathode substrate simultaneously emits electrons to the corresponding nested annular sleeve high-frequency beam-wave interaction unit, so that the generation and stable transmission of multiple annular electron beams are ensured. The beam-wave interaction unit not only can work in a high-order mode, but also can inhibit the generation of a competition mode, thereby enlarging the beam-wave interaction space, and enabling the output power and efficiency of a radiation source to be greatly improved; and the integration degree of the electric vacuum device is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

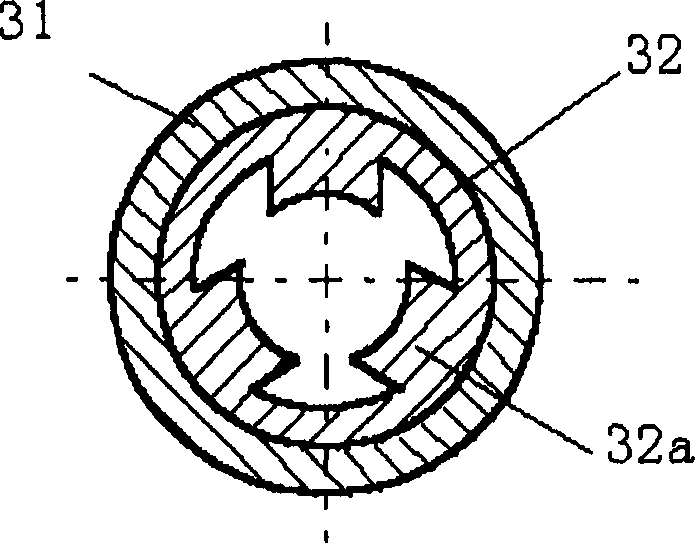

Method for manufacturing tube shell of traveling wave tube

InactiveCN101615545ASmall sizeControl precisionTransit-tube vessels/containersVessels or leading-in conductors manufactureMicrowaveEngineering

The invention discloses a method for manufacturing a tube shell of a traveling wave tube, and belongs to the manufacturing field of microwave vacuum devices. The method comprises the following operation steps: sleeving an annealed tube on a core rod, and coating lubricating oil between the core rod and the tube; assembling a clamp component with shrinkable inside diameter; and putting the tube with the core rod into the clamp component with the shrinkable inside diameter, and shrinking the inside diameter of the clamp by using an extruding method. The manufactured tube shell can ensure that the precision of the inside diameter is within 0.005 millimeter and the concentricity is within 0.008 millimeter on long size, and can ensure vacuum air tightness; and the manufacturing process has simple operation and low cost.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

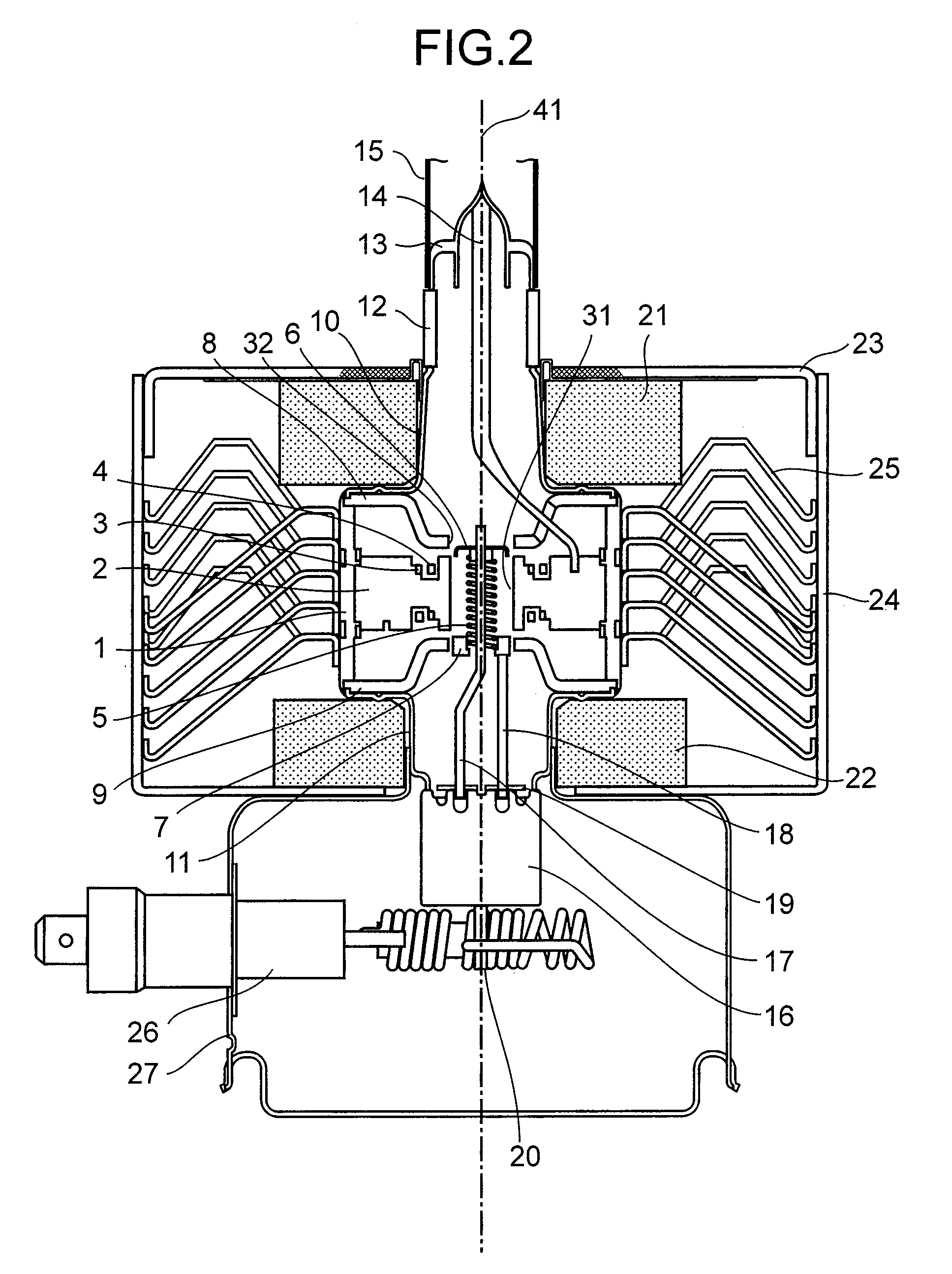

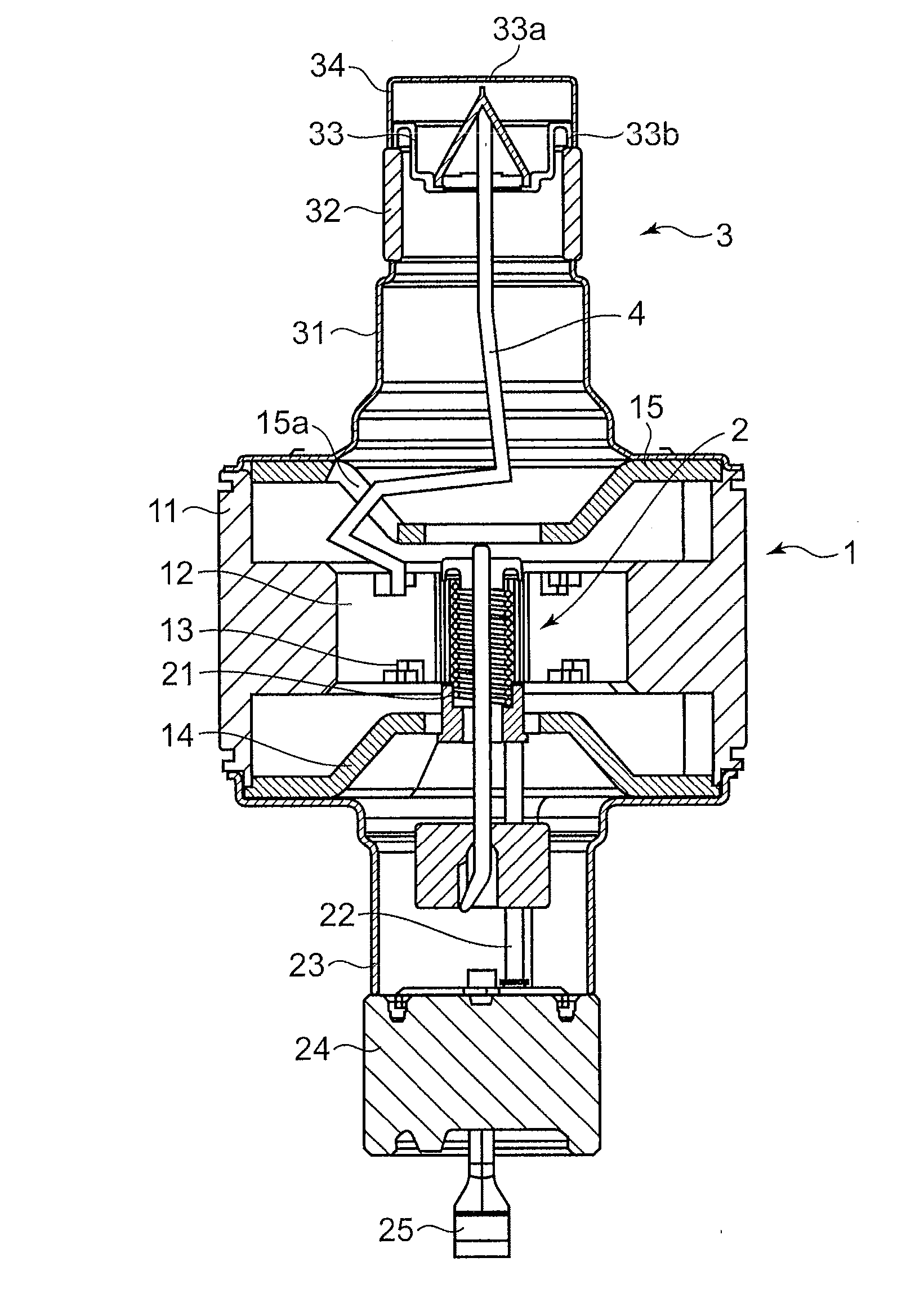

Magnetron with relatively fixed yoke and cooling block by means of a cushioning material and fixing member

InactiveUS7855495B2Increase resistanceImprove vibrationTransit-tube vessels/containersMagnetronsCushioningEngineering

A gap is provided between a cooling block 22 and a magnetic yoke 20. A cushioning material 25 is interposed in the gap to fix the cooling block 22 relatively to the magnetic yoke 20 by screws. Thus, even when metals having a large difference in tendency of ionization are used in the cooling block 22 and the magnetic yoke 20, the corrosion of the metals hardly arises. Further, the cushioning material 25 is provided in the gap between the cooling block 22 and the magnetic yoke 20, so that an impact or vibration to an anode tubular member 10 can be mitigated and the disconnection and deficiency of the filament of a cathode structural member can be reduced. Further, since a dimensional unevenness of the cooling block 22 or the magnetic yoke 20 can be absorbed by the cushioning material 25, the dimensional accuracy of parts does not need to be improved to make an assembly easy.

Owner:PANASONIC CORP

Magnetron and device using microwaves related applications

InactiveUS20140191656A1Reliably suppress removalSuppress removalTransit-tube vessels/containersAntenna supports/mountingsMicrowaveEngineering

The magnetron according to the present invention includes an anode portion, a cathode portion arranged in a central portion of the anode portion, an output antenna connected to the anode portion, an exhaust pipe arranged around the output antenna to serve as a part of a vacuum tube, and an antenna cap covering a chip-off portion included in the exhaust pipe. The antenna cap and the exhaust pipe are welded to each other.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

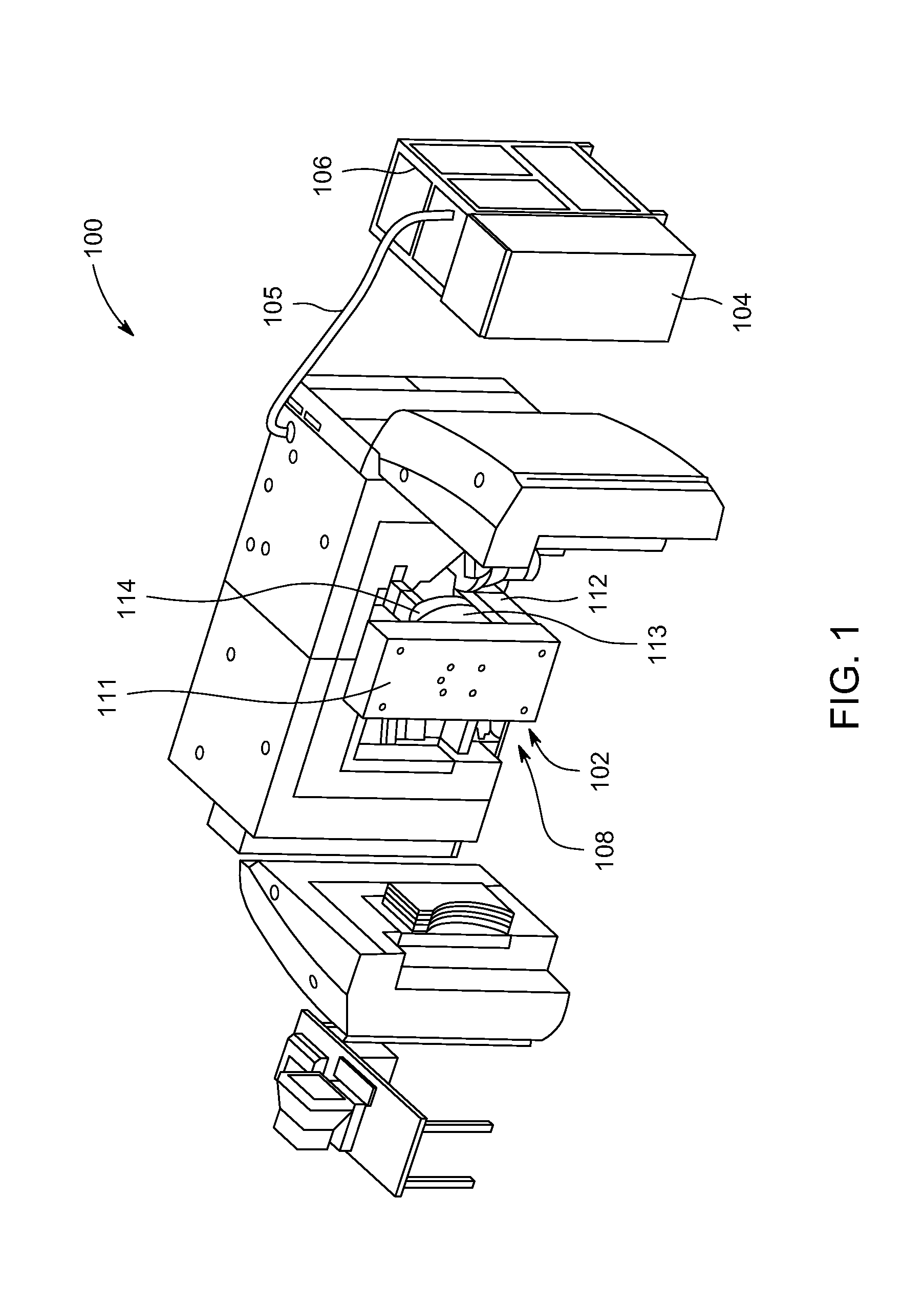

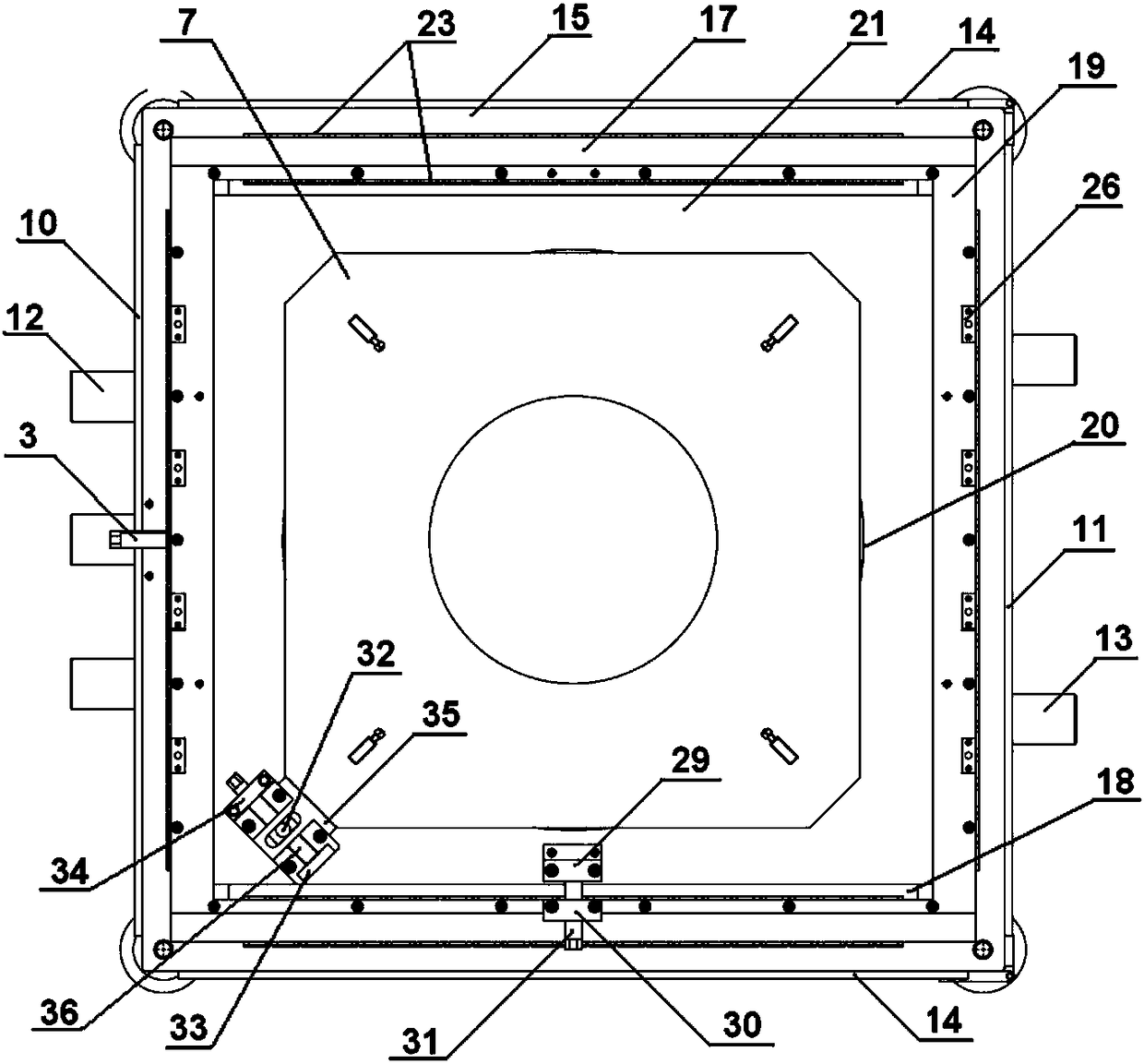

Four-dimensional adjustable large-power gyrotron base

ActiveCN108269723AEasy to adjustMeet precise docking requirementsTransit-tube vessels/containersNuclear energy generationLayout planningElectron cyclotron resonance

The invention belongs to the technical field of an electron cyclotron resonance heating system and concretely relates to a four-dimensional adjustable large-power gyrotron base. The four-dimensional adjustable large-power gyrotron base includes a base pedestal, a two-dimensional horizontal moving assembly, a first horizontal driving mechanism, a second horizontal driving mechanism, a rotation assembly, a rotation driving mechanism, and a base rotary table. The invention solves the problems that a conventional gyrotron base is difficult to mount and adjust, so there are great deviations betweena microwave transmission path axis output from a gyrotron and a transmission system axis, the transmission efficiency is affected and even an ignition system may not function normally. Through the reasonable and ingenious design of an adjusting mechanism structure and layout planning of an adjusting mechanism, flexible, smooth and accurate adjustment of the base in the limited space of the tablein four dimensions including up and down directions, left and right directions, front and back directions and the rotary direction is realized, and accurate butt joint requirements needed for an electron cyclotron system in terms of a super-heavy large-power gyrotron and a transmission system are completely satisfied.

Owner:SOUTHWESTERN INST OF PHYSICS

Ultra-wideband planar dual-beam slow wave structure

ActiveCN108682606AWeak dispersionHigh coupling impedanceTransit-tube vessels/containersTransit-tube circuit elementsWave structureUltra-wideband

The invention discloses an ultra-wideband planar dual-beam slow wave structure. The ultra-wideband planar dual-beam slow wave structure comprises a planar metal slow wave wire, a metal shell and two dielectric support rods; the planar metal slow wave wire comprises straight metal lines and curved metal lines alternatively connecting the straight metal lines; extension sections are disposed on twoopposite side surfaces of the inner layer of the metal shell, and an opening is disposed between every two adjacent extension sections; the two dielectric support rods are fixed between the inner andouter layers on both sides of the metal shell; parts of the side surfaces of the dielectric support rods are exposed from the openings between the extension sections, are in surface contact with the curved metal lines of the planar metal slow wave wire, and clamp the planar metal slow wave wire to make the planar metal slow wave wire suspend within the inner cavity of the metal shell; each of theextension sections of each side surface of the inner layer extends into the corresponding opening facing the side surface, of the planar metal slow wave wire. The invention can reduce the dispersion characteristics and improve the coupling impedance under the premise of ensuring a large bandwidth.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

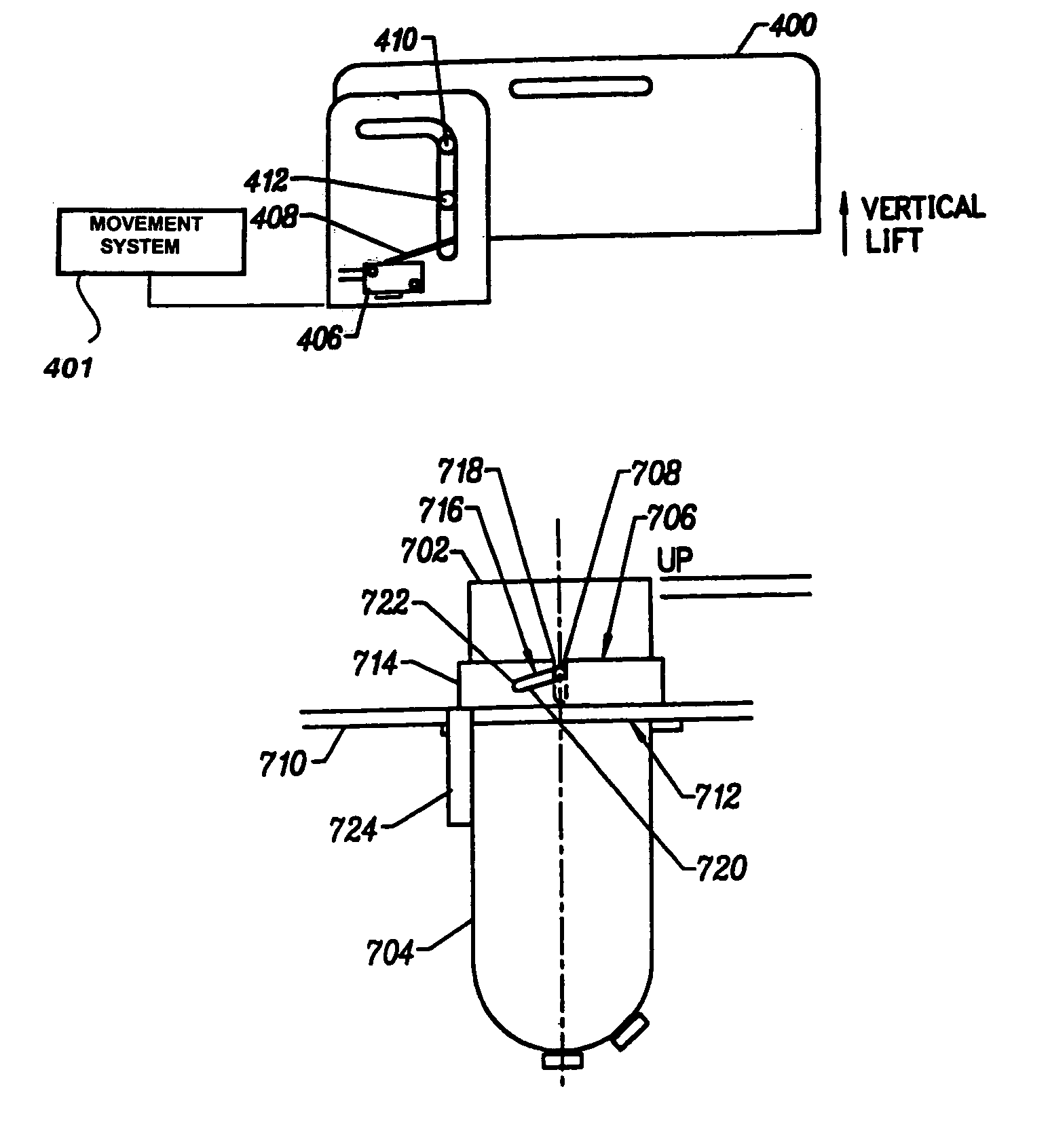

Cover assembly for vacuum electron device

InactiveUS7029296B1Good seat alignmentPrevent RF leakageTransit-tube vessels/containersTransit-tube leading-in arrangementsLocking mechanismEngineering

A self guiding cover assembly for a vacuum electron device (VED) enclosure has a cover, a pair of guide plates, and a pair of guide elements. The cover has a top, a sidewall, an inside and an outside, and at least one electrical connector disposed on the inside of the cover for mating with an electrical connector on a VED. The pair of guide plates is disposed on opposite sides of the outside of the sidewall of the cover. The guide plates each have a track. The guide elements are mounted on the enclosure on opposite sides of the cover. The pair of guide elements each mates with the track to guide the cover as it is lifted from the enclosure. The cover further comprises a breach lock mechanism for seating the VED into the VED enclosure having the cover and a base. The breach lock mechanism has guide elements mounted on the cover. A sleeve is mounted on the base and removably receives the cover with the VED. The sleeve rotates about the cover. The sleeve has tracks for mating with the guide elements. A rotation of the sleeve pulls the top into the base for seating the VED.

Owner:COMM & POWER IND

Component Having a Multipactor-Inhibiting Carbon Nanofilm Thereon, Apparatus Including the Component, and Methods of Manufacturing and Using the Component

ActiveUS20150170867A1Improve component reliabilityReduce transmissionTransit-tube vessels/containersMaterial nanotechnologySecondary electronsEnergy device

A high power RF energy device component is disclosed that is exposed to high power RF energy in a vacuum environment, and includes a multipactor-inhibiting carbon nanofilm covering at least one surface of the component. A secondary electron emission (SEE) coefficient of the multipactor inhibiting carbon nanofilm is desirably less than a SEE coefficient of the underlying surface of the component.

Owner:NOKOMIS

Virtual cathode inverted relativistic magnetron

ActiveCN111933501AImplement pre-clusteringFavorable pre-clusteringTransit-tube vessels/containersTransit-tube cathodesParticle physicsRadio frequency

The invention discloses a virtual cathode inverted relativistic magnetron, and belongs to the technical field of microwaves. The magnetron comprises a cathode, an anode, a reflection cavity, a radio frequency excitation structure, a circular waveguide output structure and a shell transition section. By exchanging the positions of the anode and the cathode, a fan-shaped cathode unit for generatingelectrons is arranged between the end part of the cathode and the anode blade. According to the fan-shaped cathode unit, the problems of pulse shortening, frequency drift, efficiency reduction and thelike caused by plasmas generated by explosive emission in an interaction region are effectively solved; and meanwhile, pre-clustering of favorable electrons can be realized, so that the energy conversion efficiency and the purity of an excitation mode are improved, and the overall efficiency of the device is remarkably improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Magnetron

InactiveCN105190822AImprove performanceTransit-tube vessels/containersTransit-tube cathodesResonant cavityEngineering

A 4G magnetron is disclosed. The magnetron may include an anode comprising a cylindrical member and anode vanes disposed within the cylindrical member which define resonant cavities therebetween, and a dispenser cathode, suitable for heating and located coaxially within said anode. The magnetron may operate in a temperature range of about 850-1050 DEG C. The magnetron may include conductive cooling. The magnetron may comprise inventive anode and cathode structures. A method for preparing a plurality of magnetron tubes substantially simultaneously is further provided.

Owner:朴秀用

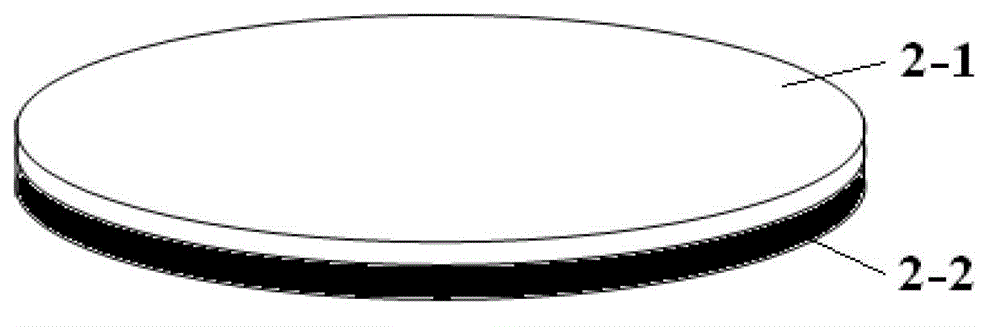

RF window assembly comprising a ceramic disk disposed within a cylindrical waveguide which is connected to rectangular waveguides through elliptical joints

ActiveUS9287598B2Minimizing componentMinimizing a surface magnetic and electric fieldsTransit-tube vessels/containersKlystronsMicrowaveEngineering

A high-power microwave RF window is provided that includes a cylindrical waveguide, where the cylindrical waveguide includes a ceramic disk concentrically housed in a central region of the cylindrical waveguide, a first rectangular waveguide, where the first rectangular waveguide is connected by a first elliptical joint to a proximal end of the cylindrical waveguide, and a second rectangular waveguide, where the second rectangular waveguide is connected by a second elliptical joint to a distal end of the cylindrical waveguide.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

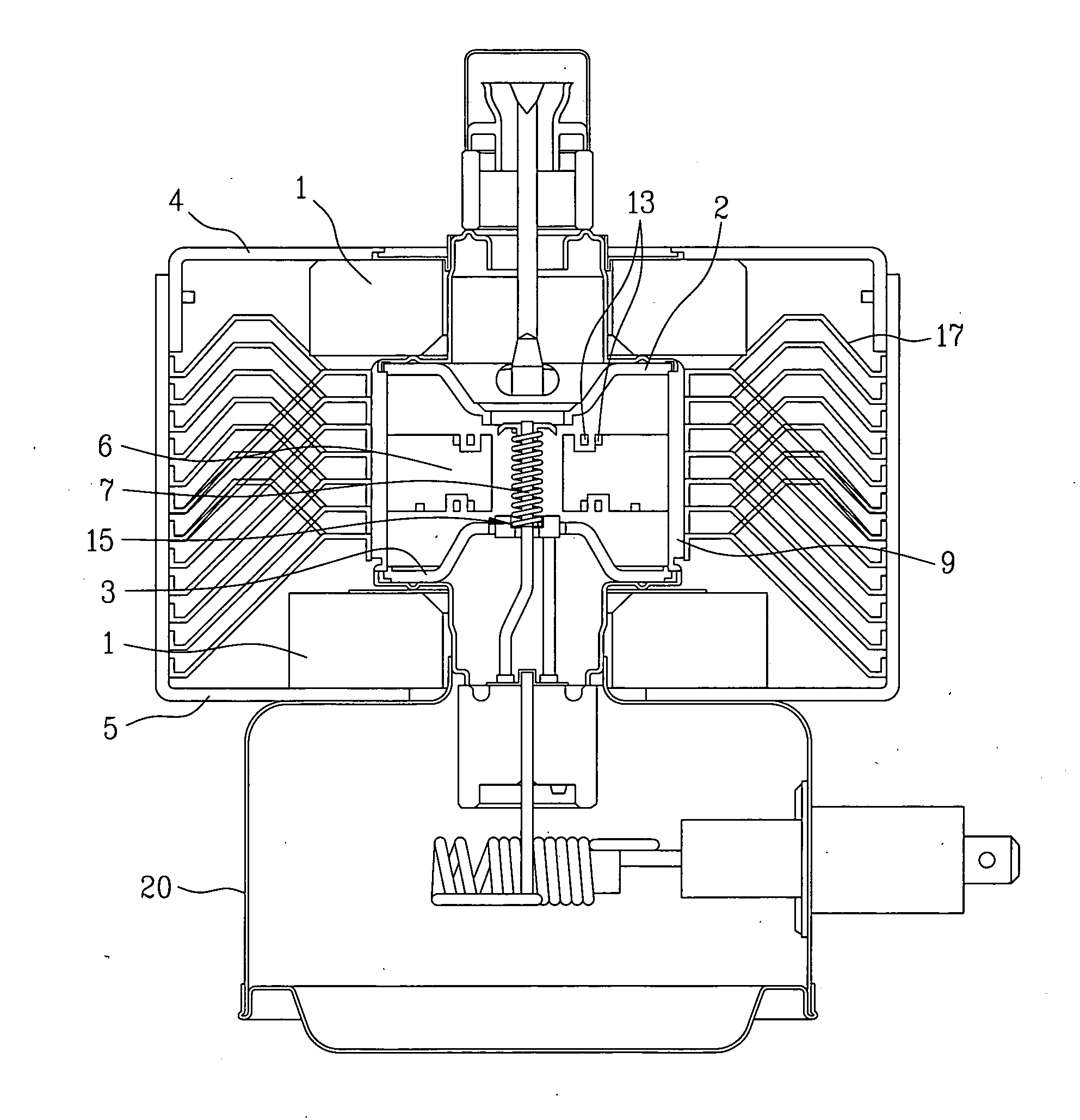

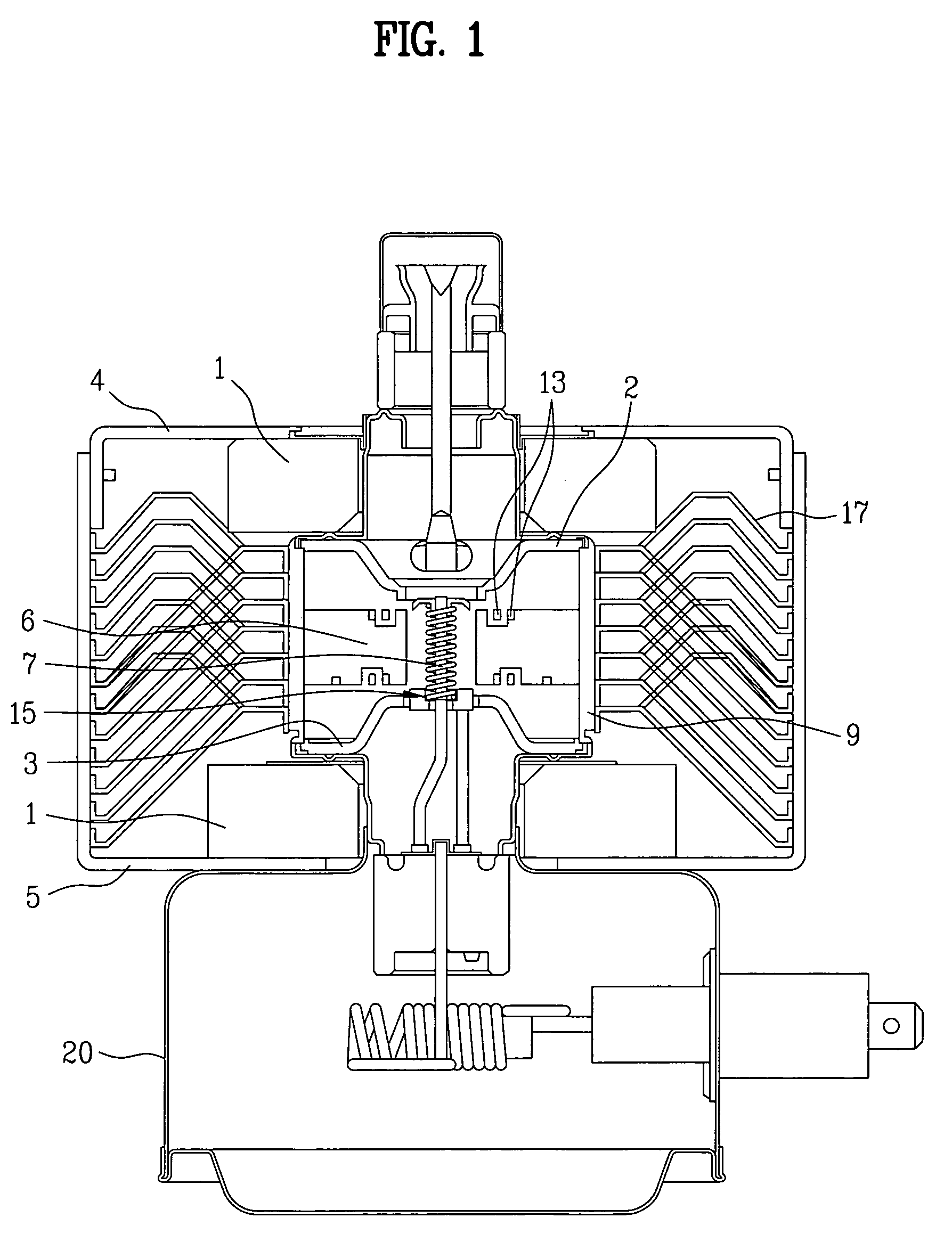

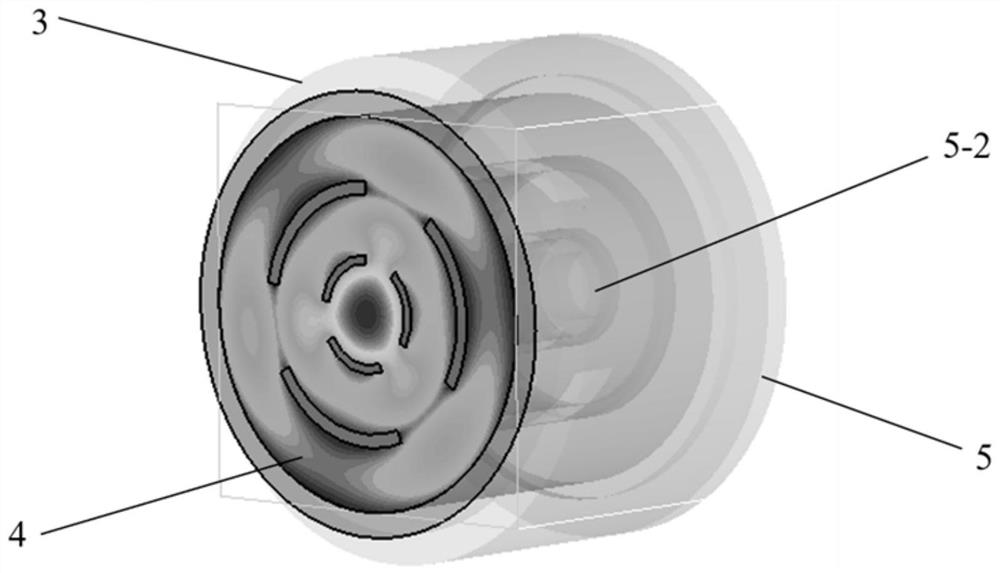

10kw/2450mhz package type continuous wave magnetron and preparation method

ActiveCN104966654AImprove the finishReduce glitchesTransit-tube vessels/containersTransit-tube leading-in arrangementsState of artMicrowave

The invention discloses a 10kW / 2450MHZ package type continuous wave magnetron and a preparation method. The 10kW / 2450MHZ package type continuous wave magnetron comprises a magnetron core (1), a magnetic circuit structure (2), a shielding box (3) and a cold water sleeve (4). The continuous wave magnetron disclosed by the invention is novel in the structure, small in volume and big in output power reaching 10KW. The continuous wave magnetron disclosed by the invention has more than 4000 hours of service life, is small in microwave leakage, and high in safety. The preparation method disclosed by the invention has gone through multitude screening tests, has a reasonable technology and is strong in operability. The obtained magnetron is high in sealing, vacuum degree and pressure resistance, and stable in performance, reduces the rate of fire striking, and overcomes the defects of the prior art.

Owner:NANJING SANLE MICROWAVE TECH DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com