Vacuum electron beam welding method for aluminum alloy metal diaphragm storage tank

A vacuum electron beam, electron beam technology, applied in electron beam welding equipment, welding equipment, metal processing and other directions, can solve the problems of post-welding weld strength reduction, weld strength reduction, poor fusion and other problems, to avoid weld cracking , Weld strength assurance, the effect of improving production efficiency and quality reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

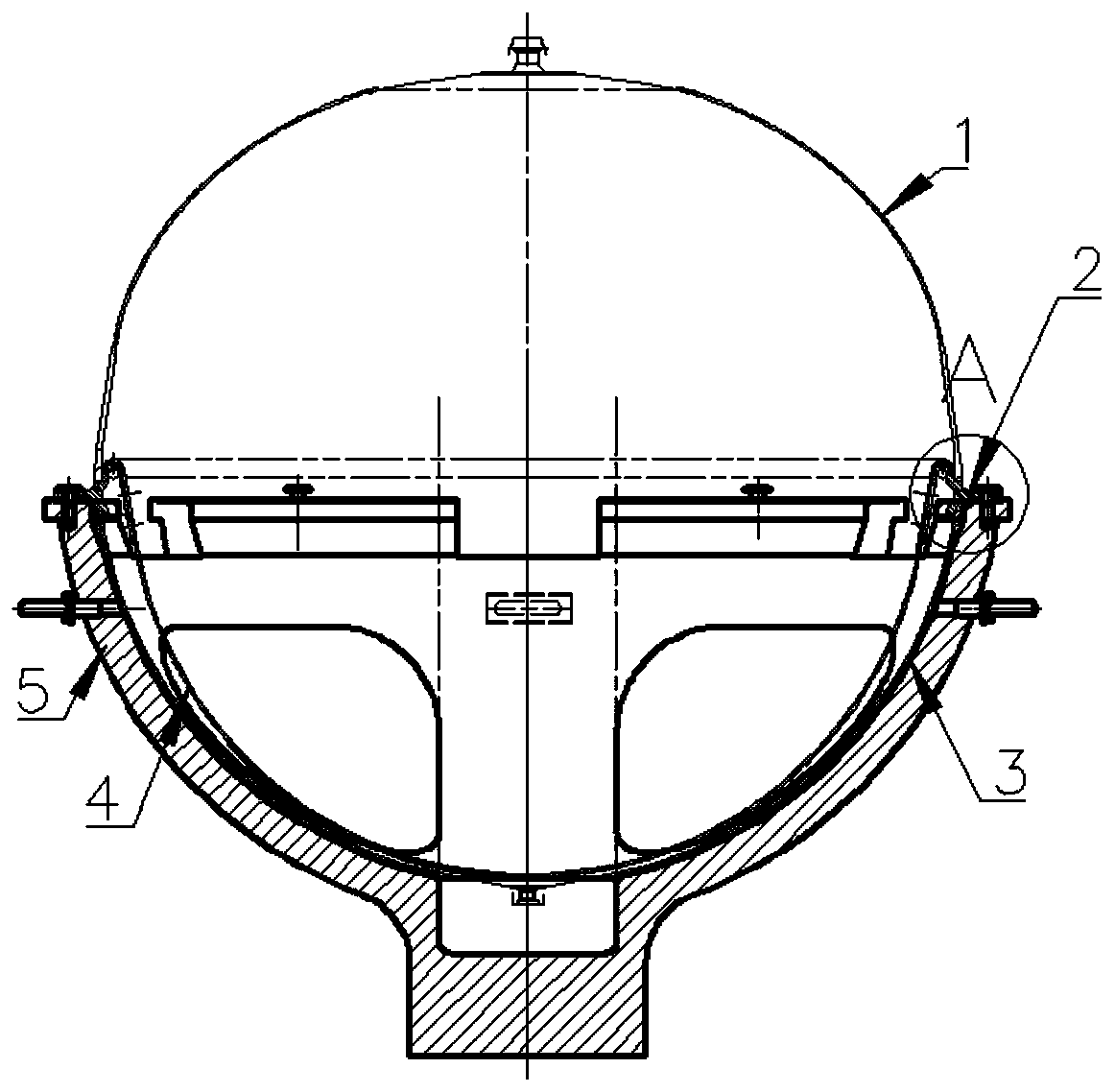

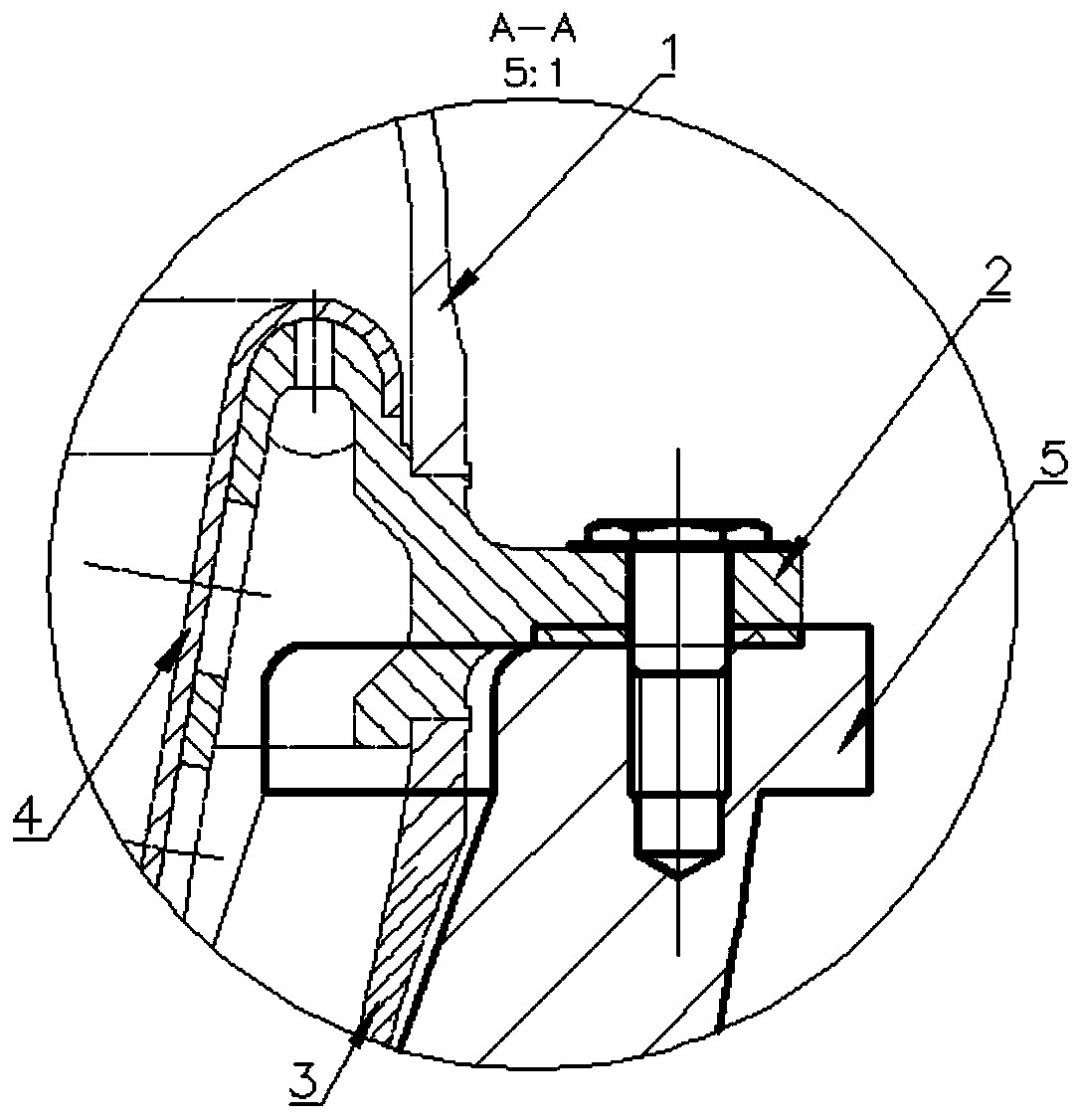

[0037] (1) Process the support ring, metal diaphragm, liquid chamber shell and air chamber shell to ensure the butt joint size of the electron beam weld. The butt joint gap between the support ring and the metal diaphragm electron beam weld is 0.2mm, and the lap gap of the lock bottom is 0.2mm ;The butt joint gap between the support ring and the gas chamber shell electron beam weld is 0.1mm, and the lap gap of the lock bottom is 0.2mm; mm.

[0038](2) Use the first electron beam welder to clamp the metal diaphragm, the support ring and the air cavity shell, and make the air cavity shell be located below. Adjust the electron gun to the horizontal position to prepare for horizontal welding. Firstly, the support ring and the metal diaphragm are segmented and segmented by the electron beam tack welding method. The number of tack welding segments is 18; the length of each segment is 50mm; secondly, the electron beam segmental tack welding is used The support ring and the air cavit...

Embodiment 2

[0041] (1) Process the support ring, metal diaphragm, liquid chamber shell and air chamber shell to ensure the butt joint size of the electron beam weld. The butt joint gap between the support ring and the metal diaphragm electron beam weld is 0.4mm, and the lap gap of the lock bottom is 0.4mm ;The butt joint gap between the support ring and the gas chamber shell electron beam weld is 0.3mm, and the lap gap of the lock bottom is 0.3mm; mm.

[0042] (2) Use the first electron beam welder to clamp the metal diaphragm, the support ring and the air cavity shell, and make the air cavity shell be located below. Adjust the electron gun to the horizontal position to prepare for horizontal welding. Firstly, the support ring and the metal diaphragm are segmented by the electron beam segmental tack welding. The number of tacking welding segments is 12; the length of each segment is 30mm; secondly, the electron beam segmental tacking welding is used The support ring and the air chamber s...

Embodiment 3

[0045] (1) Process the support ring, metal diaphragm, liquid chamber shell and air chamber shell to ensure the butt joint size of the electron beam weld. The butt joint gap between the support ring and the metal diaphragm electron beam weld is 0.5mm, and the lap gap of the lock bottom is 0.5mm The butt gap between the support ring and the electron beam welding seam of the air chamber shell is 0.5mm, and the lap gap of the lock bottom is 0.5mm; mm.

[0046] (2) Use the first electron beam welder to clamp the metal diaphragm, the support ring and the air cavity shell, and make the air cavity shell be located below. Adjust the electron gun to the horizontal position to prepare for horizontal welding. Firstly, the support ring and the metal diaphragm are segmented by electron beam segmental tack welding. The number of tacking welding segments is 15; the length of each segment is 30mm; secondly, the electron beam segmental tacking welding is used The support ring and the air cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com