Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Reduce the number of repairs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

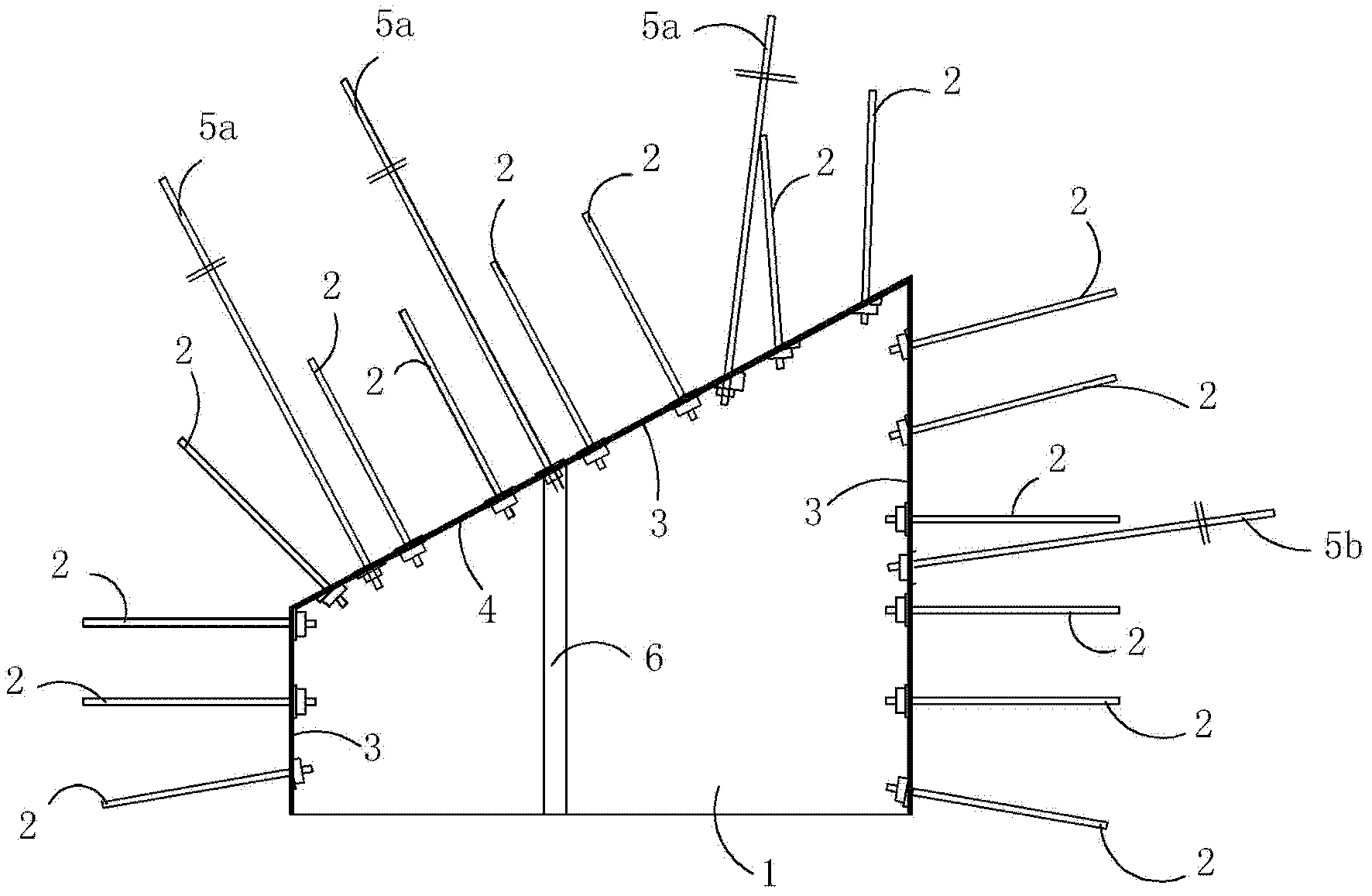

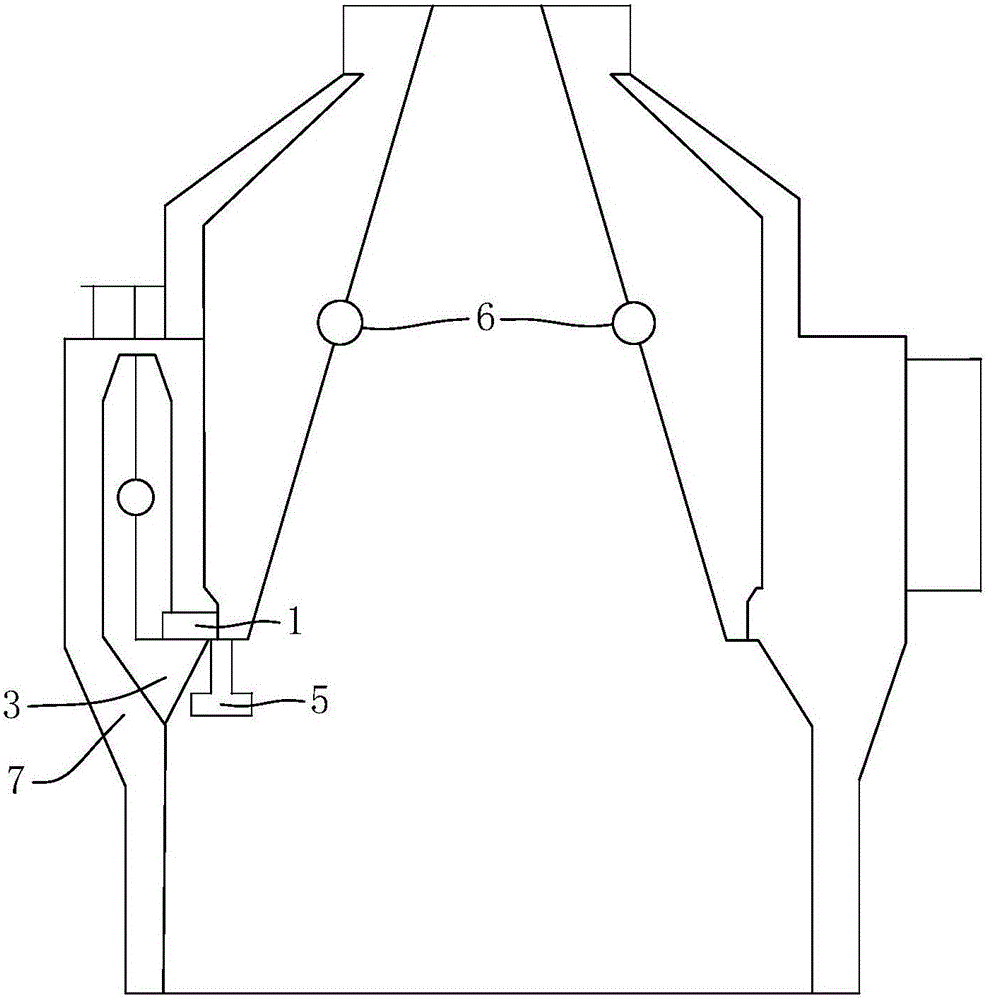

Asymmetric bolt-mesh-cable combination support method for special-shaped mining roadway in large dip angle coal seam

InactiveCN102296976ASolve the characteristicsSolve the drum gang strongAnchoring boltsPre stressCoal

The invention discloses an asymmetrical bolt-net-cable combined supporting method for a special-shaped recovery tunnel of a large inclination angle coal bed. The method is characterized by comprising the following steps of: digging the tunnel according to the shape of the tunnel section, and supporting tunnel top plates, tunnel high-cut surrounding rock and tunnel low-cut surrounding rock by using prestressed anchor rods, steel bar nets and steel strips; arranging top plate prestressed anchor cables on the tunnel top plates; for the solid coal recovery tunnel, arranging high-cut prestressed anchor cables on the tunnel high-cut surrounding rock when the tunnel is dug for 5 to 7 days, and arranging struts in the center of the tunnel towards one side of the low-cut surrounding rock; and for the small coal post reserved recovery tunnel, arranging low-cut prestressed anchor cables on the tunnel low-cut surrounding rock when the tunnel is dug for 5 to 7 days, and arranging struts in the center of the tunnel towards one side of the low-cut surrounding rock. The combined asymmetrical supporting method has good application effect of stability control of the special-shaped recovery tunnel of the large inclination angle coal bed, the repair frequency of the tunnel is greatly reduced, and the supporting cost of the tunnel is reduced.

Owner:ANHUI UNIV OF SCI & TECH

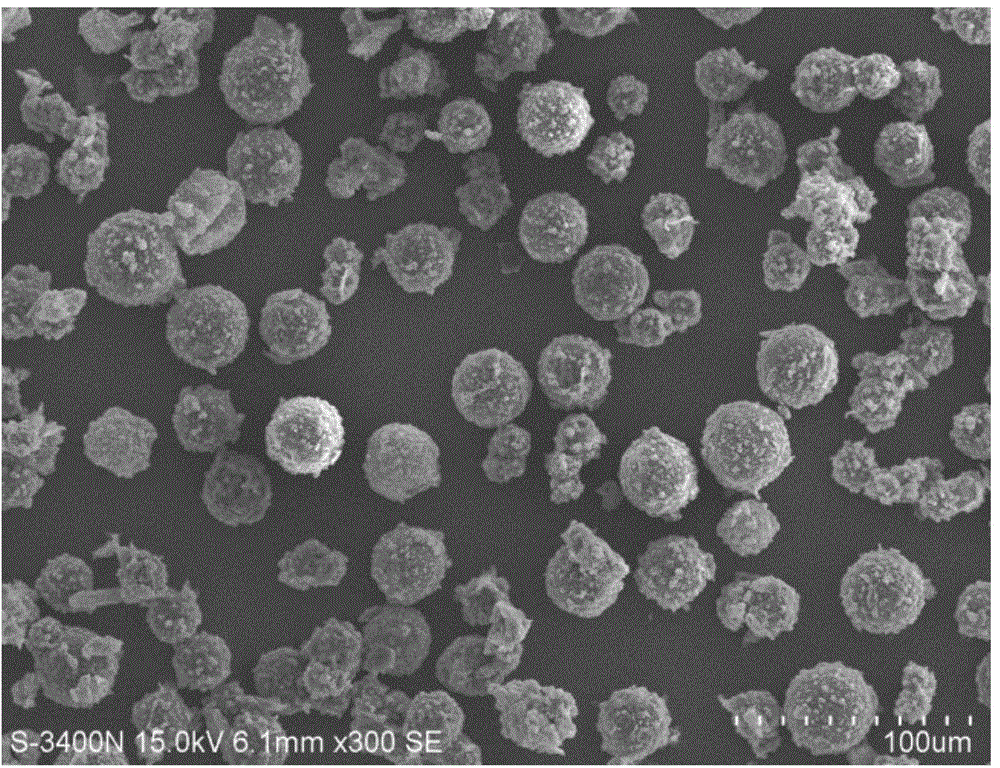

Microcapsule type additive for corrosion-resistant coating and preparation method thereof

ActiveCN104927468AImprove corrosion resistanceExtended service lifeAnti-corrosive paintsMicroballoon preparationMelamine formaldehyde resinRust converter

The invention discloses a microcapsule type additive for corrosion-resistant coating and a preparation method thereof. The microcapsule type additive is prepared by the following components by weight percent, 40wt-80wt% of water, 5wt%-35wt% of air-drying type film-forming substance, 0.01wt%-10wt% of anti-rusting agent, 5wt%-30wt% of capsule-wall resin and 0.05wt%-2wt% of emulsifying agent; the mixture of the air-drying film-forming substance and the anti-rusting agent is wrapped in the capsule-wall resin which is urea resin, melamine-formaldehyde resin or modified polymer of the urea resin and melamine-formaldehyde resin or mixture of two or more than two substances. The additive disclosed by the invention has the advantages that the additive is added into the corrosion-resistant coating, the corrosion resistance of the prepared coating can be further improved, especially when the paint film is damaged due to action of external force, the added additive can release a restoration agent and the anti-rusting agent to restore the damage and inhibit the corrosion expansion by self, so that the service life of the paint film is prolonged.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

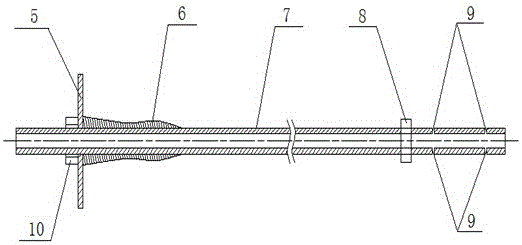

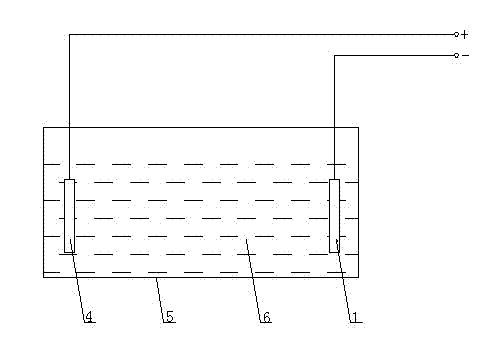

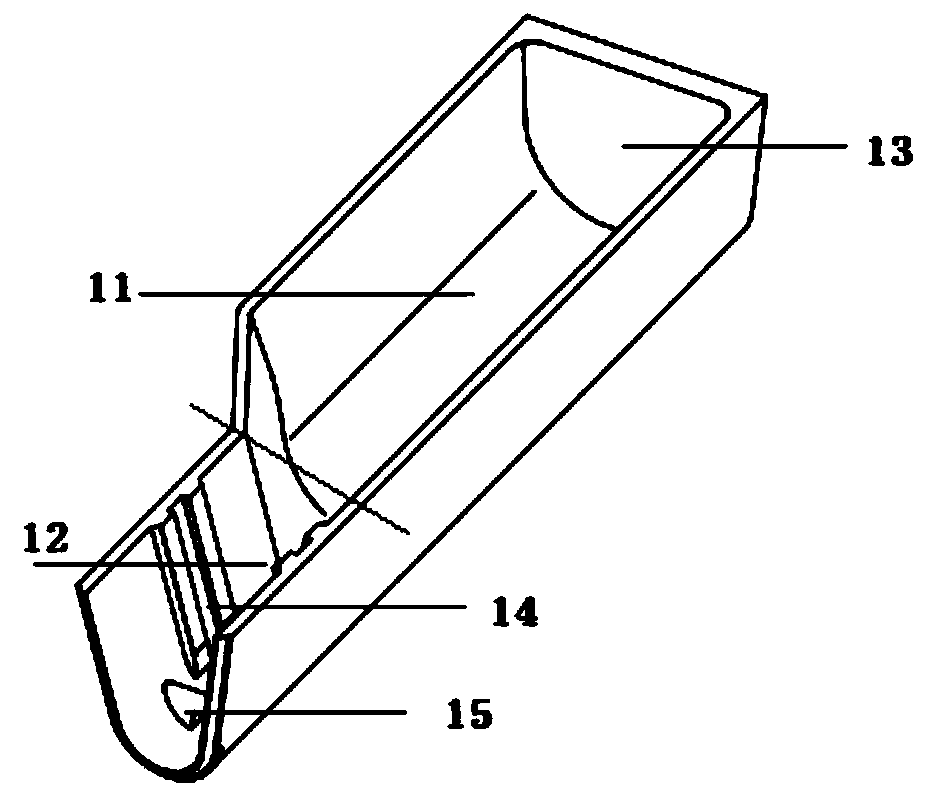

Ni-P alloy coating continuous casting crystallizer copper plate and preparation process thereof

ActiveCN102773432AImprove bindingReduced hot cracking tendencyMetal layered productsAlloy coatingCopper

The invention discloses a continuous casting crystallizer copper plate plating layer and a preparation process thereof. The Ni-P crystallizer copper plate plating layer comprises a crystallizer copper plate base body, wherein an Ni-P alloy layer is plated on the surface of the crystallizer copper plate base body, and contains nickel with the mass ratio being 95 percent to 99.7 percent, and phosphorus with the mass ratio being 0.3 percent to 5 percent. The preparation process of the continuous casting crystallizer copper plate plating layer comprises the following steps of: a, preplating the base body; b, preparing composite electroplate liquid containing Ni-P materials in a plating bath; and c, electroplating the Ni-P alloy layer. Due to the adoption of the scheme, the defects of low steel production, large abrasion, frequent repair of the continuous casting crystallizer copper plate can be overcome, and the continuous casting crystallizer copper plate plating layer with uniform densification, favorable binding force, low heat crack tendency, small internal stress, excellent wear-resisting property and long life cycle is obtained.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

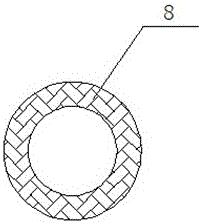

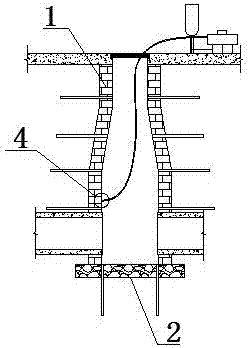

Method for controlling surrounding rock deformation of gateway subjected to repeated overhead mining by using hollow grouting anchor cable

InactiveCN103075170AImprove the support effectSolve the large amount of deformationAnchoring boltsMining engineeringPre stress

The invention relates to a method for controlling surrounding rock deformation of a gateway subjected to repeated overhead mining by using a hollow grouting anchor cable. The method comprises the following implementation steps of: performing repair brushing on the section of the gateway, reinforcing support in a bottom plate gateway to be mined in an advance face which is 280-320 meters in range by adopting high-performance pre-stressed anchor rods, and meanwhile, arranging a metal net on the entire section of the gateway; arranging a novel hollow grouting anchor cable between a top plate of the gateway and the high-performance pre-stressed anchor rods on both sides; grouting on the surface of the surrounding rock of the gateway for enclosing; and injecting a grouting material into the hollow grouting anchor cable. The method has the characteristics of high setting load, sudden increase in resistance and high bearing capability, the problems of high gateway deformation, strong heaving floors and difficulty in maintaining can be well solved, the gateway repair times are reduced, and the gateway support cost is reduced effectively; and the method is particularly suitable for solving the problems of rapid attenuation and loss of anchoring force caused by looseness, breakage and large deformation of surrounding rock due to repeated overhead mining on the gateway.

Owner:CHINA UNIV OF MINING & TECH +1

Surrounding rock supporting construction method and surrounding rock supporting structure of water-contained roadway of coal mine

ActiveCN105804767APrevent intrusionImprove stabilityUnderground chambersTunnel liningStructure of the EarthRock bolt

The invention discloses a surrounding rock supporting construction method of a water-contained roadway of a coal mine and belongs to the field of surrounding rock supporting of underground engineering. The surrounding rock supporting construction method comprises the following steps that (1) primary spraying is conducted after the roadway is excavated; (2) according to the geological conditions of the water-contained roadway, a controllable grouting anchor rod structure is designed, and controllable grouting anchor rod-anchor cable supporting parameters are designed; (3) through the combination of controllable grouting anchor rods, anchor cables, metal nets and sprayed grout supporting, so that a grouting reinforcement waterproof ring is formed, and grout is sprayed onto the surrounding rock on the surface of the roadway; (4) the key portion where supporting needs to be reinforced and water insulation is needed is determined through the field observation technical means such as numerical simulation; (5) the supporting parameters of the water-contained roadway are adjusted and optimized, and grouting reinforcement supporting is conducted on the key portion; and (6) a base plate of the roadway is reasonably supported. The invention further provides a surrounding rock supporting structure. The supporting method and structure are suitable for water-contained roadways with different depths, roadways with broken surrounding rocks, and soft rock roadways; and in addition, construction is easy and convenient, and the supporting method and structure can be popularized within a wide range.

Owner:内蒙古双欣矿业有限公司

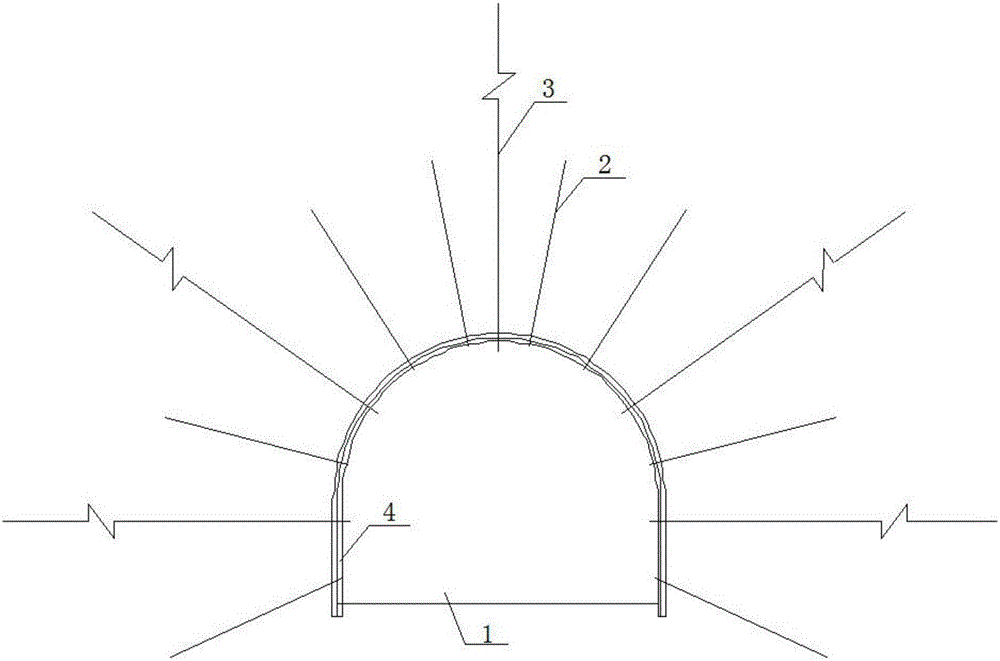

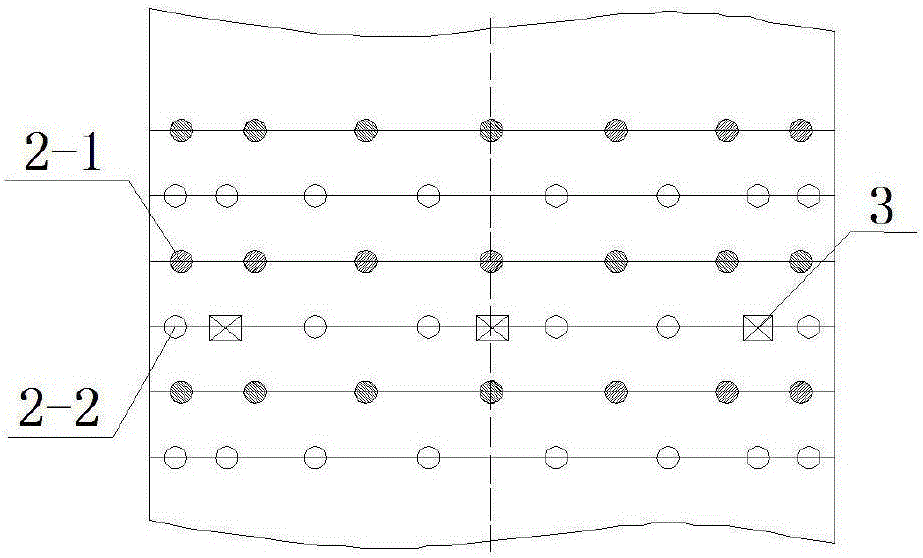

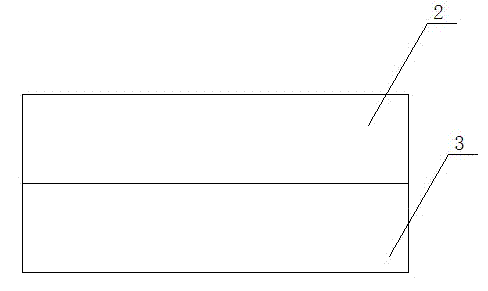

Double-layer anchor net cable supporting structure for controlling mining roadway surrounding rock deformation and method thereof

InactiveCN106321119AImprove support strengthImprove carrying capacityUnderground chambersTunnel liningEngineeringStructural engineering

The invention discloses a double-layer anchor net cable supporting structure for controlling mining roadway surrounding rock deformation. The double-layer anchor net cable supporting structure is characterized in that secondary anchor net supporting is performed on the basis of primary anchor net supporting, secondary supporting anchor rods (2-2) and primary supporting anchor rods (2-1) are arranged at intervals, the row spacing between the anchor rods is 700-900 mm, the specifications of the secondary supporting anchor rods (2-2) are the same as those of the primary supporting anchor rods (2-1), hollow grouting anchor cables (3) are arranged between the secondary supporting anchor rods (2-2), the interval between the hollow grouting anchor cables (3) is 1000-1500 mm, and the row spacing is 700-1800 mm. According to the supporting structure, the capability of a double-layer anchor net actively supporting shallow part surrounding rock can be brought into full play, the supporting capability of deep part surrounding rock can be improved through the anchor cables, the roadway supporting safety reliability is improved, severe deformation of a mining roadway can be controlled, it can be guaranteed that the supporting structure is continuously effective during the service life of the roadway, the roadway rework times are reduced, and the roadway maintenance cost is reduced.

Owner:GUIZHOU UNIV

High-drawing speed continuous casting machine crystallizer copper plate electroplating process

The invention provides a high-drawing speed continuous casting machine crystallizer copper plate electroplating process. The process comprises the steps of a), performing electroplating pretreatment of a copper plate base body; b), bonding the lower portion of a copper plate firmly by using insulating tapes and placing the copper plate in a electrolyzer; c), placing a positive electrode in an electroplating tank, and injecting high-temperature coating resistant electroplate liquid into the tank; d), switching on the power supply and starting electroplating; e), bonding the upper portion of the copper plate firmly by using the insulating tapes, placing the lower portion of the copper plate to the electrolyzer after pretreatment; f), placing the positive electrode into the electroplating tank, and injecting wear-resistant coating electroplate liquid; g), switching on the power supply and starting electroplating; and h), after the electroplating, performing electroplating aftertreatment of the copper plate. According to the process, twice electroplating of the crystallizer copper plate is performed, the upper portion and the lower portion of the copper plate are electroplated with different coatings respectively, the upper surface is provided with a high temperature-resistant coating, and the lower surface is provided with an anti-wear coating. The service life of the copper plate is prolonged, the usage times of the crystallizer copper plate are increased, and the maintenance costs and the maintenance load are reduced.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

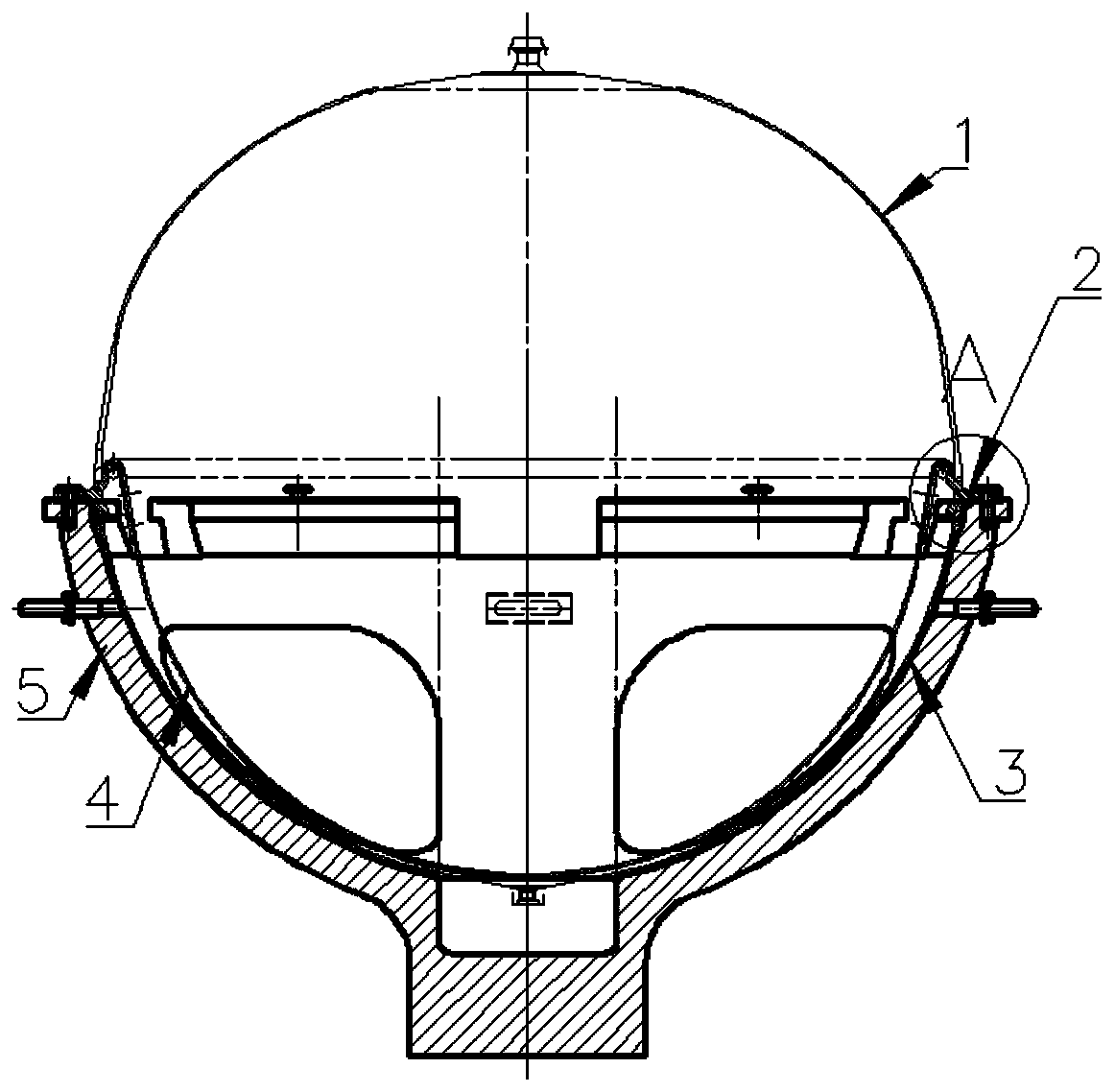

Vacuum electron beam welding method for aluminum alloy metal diaphragm storage tank

ActiveCN111037083AAchieve staggerImprove welding strengthWelding/cutting auxillary devicesPipeline systemsVacuum electronicsUltimate tensile strength

The invention discloses a vacuum electron beam welding method for an aluminum alloy metal diaphragm storage tank. The method comprises the following steps of (1) processing two hemispherical electronbeam welding tools, wherein six notches are uniformly distributed on the hemispherical electron beam welding tools; (2) clamping a support ring, a metal diaphragm and an air cavity shell by utilizinga first electron beam welding tool; (3) firstly, positioning and welding the support ring and the metal diaphragm in a segmented mode, secondly, positioning and welding the support ring and the air cavity shell through the gap of a tool, and finally, welding the support ring and the metal diaphragm through electron beams in the whole circumference; (4) removing the first electron beam welding tool, clamping all the components on the second electron beam welding tool, wherein a liquid cavity shell is located below the second electronic beam welding tool, firstly positioning and welding the support ring and the liquid cavity shell through the gap of the tool at first, and welding the support ring and the air cavity shell by the electron beams in the whole circumference; and (5) removing thesecond electron beam welding tool, clamping the product by using the first electron beam welding tool, and welding the support ring and the liquid cavity shell by using the electron beams in the wholecircumference. Through the method disclosed by the invention, the internal quality qualification rate and the welding line strength of the electron beam welding line of the aluminum alloy metal diaphragm storage tank are improved.

Owner:XIAN SPACE ENGINE CO LTD

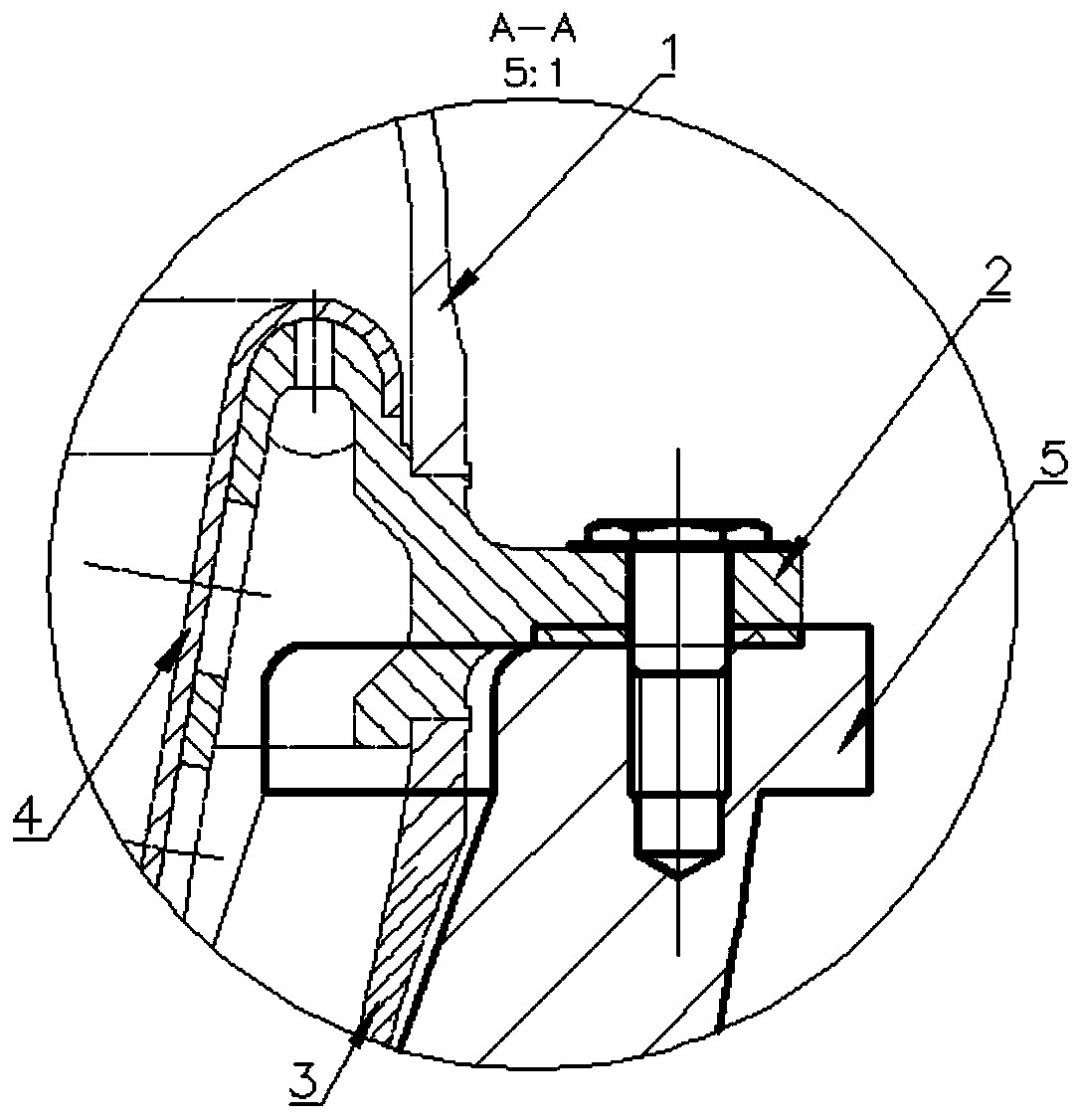

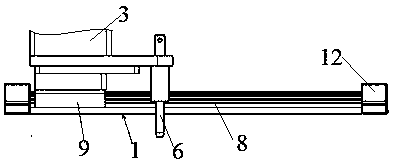

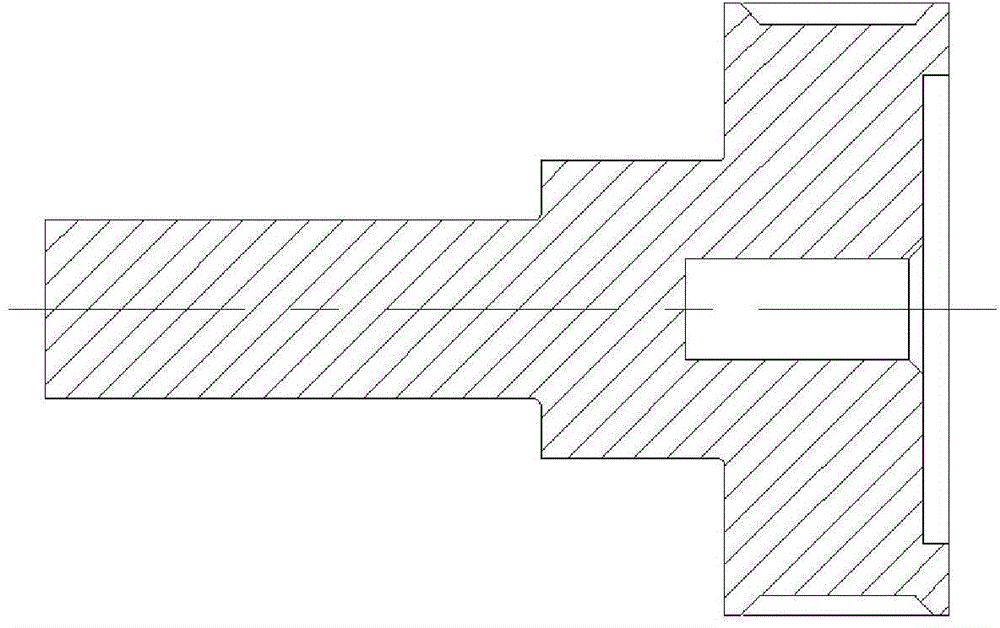

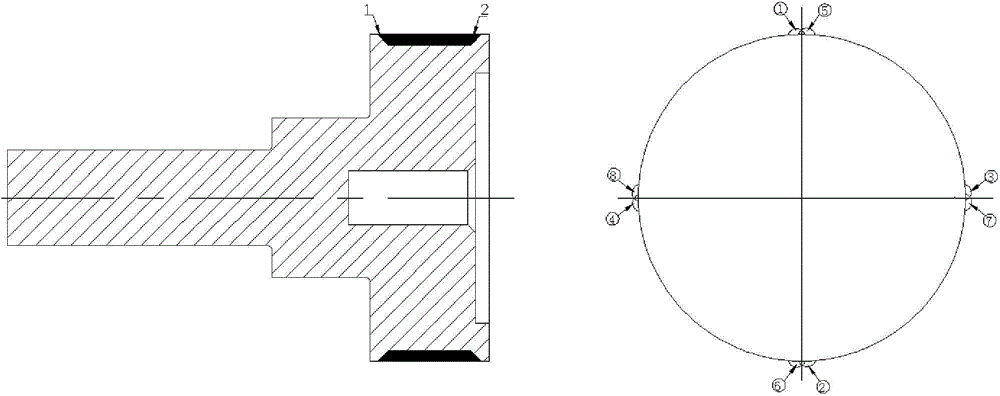

Surface grinder spindle grinding disc device

InactiveCN101947754AIncrease speedReduce centrifugal forceGrinding drivesToothed gearingsEngineeringCentrifugal force

The invention relates to a surface grinder spindle device and a planetary grinding disc device. The spindle device comprises an inner spindle and an outer spindle. The grinding disc device comprises a revolving disc, a solar grinding disc and a planetary grinding disc. The revolving disc moves at low speed while the solar grinding disc and the planetary grinding disc move at high speed, the inner and outer spindles and the planetary grinding disc are associated with an upper gear case and a lower gear case, and the inner and outer spindles can be driven by one or two variable frequency speed-adjusting motors. The device has the advantage that: by means of the modification of traditional technology, namely one large grinding disc is changed into a plurality of small grinding discs, centrifugal forces of the grinding discs is reduced, overall linear speed of grinding heads is enhanced, surface shape of grinding tools can be repaired effectively by utilizing workpieces to realize constant removal, and repair times of grinding tools is reduced. Therefore, the effect of increasing yield and efficiency and saving energy is obtained, and simultaneously, an outer planetary grinding disc can be further arranged on the grinder according to the requirement of processed products.

Owner:周伟宏

High-heat conductivity and wear-resistant composite material

A high-heat conductivity and wear-resistant composite material comprises a main material and an auxiliary material, wherein the main material comprises zirconium corundum fine powder, nanometer aluminum nitride, pure calcium aluminate cement, carbon fiber, magnesium zirconium sand, silica micropowder, aluminum oxide micropowder, sodium tripolyphosphate, silicon carbide, graphene and the like; and the auxiliary material comprises phosphoric acid, ink-grade aluminum hydroxide, aluminum oxide, graphene, a sintering agent and the like. The high-heat conductivity and wear-resistant composite material provided by the invention has high compressive strength, high compactness, very high wear resistance, corrosion resistance and scouring resistance, heat shock stability and high heat conductivity. The high-heat conductivity and wear-resistant composite material is applied to wear-resistant and flame-isolating parts of a circulating fluidized bed boiler and chemical and industrial kilns, and can prolong the service life of wear-resistant layers of the wear-resistant and flame-isolating parts, so that the complex repair times, the maintenance cycle and the maintenance cost are reduced, and thus a requirement on long-cycle safe operation of the high-temperature wear-resistant layer of the circulating fluidized bed boiler is met.

Owner:YIXING GUOQIANG FURNACE IND

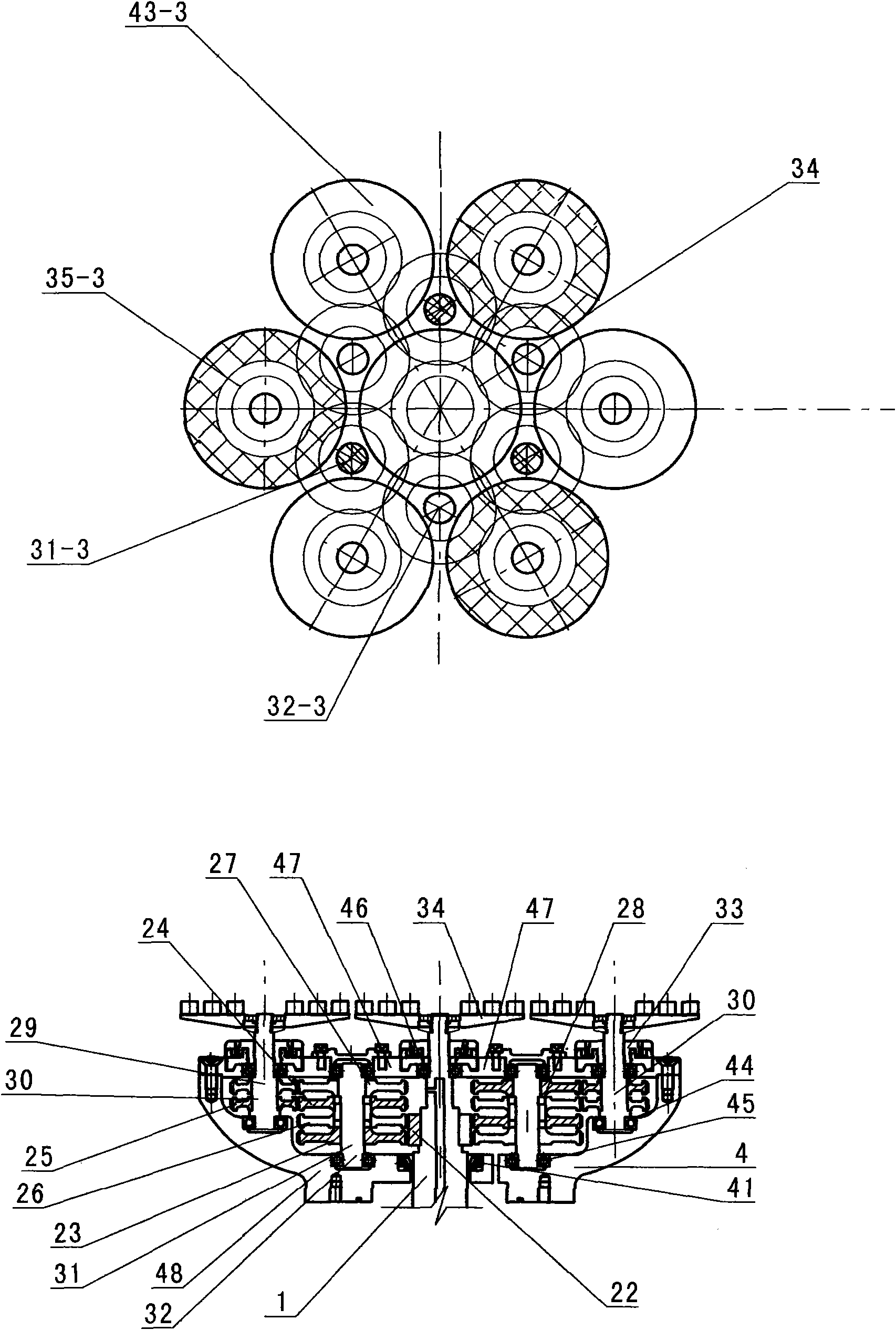

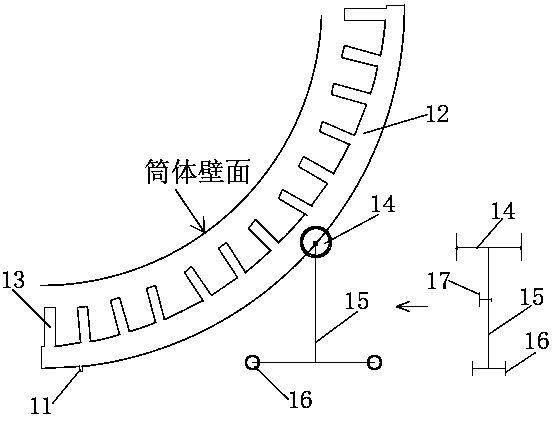

Large-curvature aircraft fuselage assembly double-track positioner unit

ActiveCN107628267AIncrease telescopic distanceSmall sizeWork holdersAircraft assemblyEngineeringCantilever

The invention discloses a large-curvature aircraft fuselage double-track positioner unit, which comprises a first mounting base mounted on a tooling platform, a vertical column mounted on a free end of the first mounting base, a second mounting base arranged on the top of the vertical column, and a cantilever arranged on the second mounting seat. The vertical column is slidably connected with thefirst mounting seat through a first sliding mechanism. A positioning pin is fixedly arranged on the vertical column. The cantilever is mounted on the second mounting seat. The cantilever is slidably connected with the second mounting seat through a second sliding mechanism. Symmetrical cantilever positioning quick locking pins are arranged on the second mounting seat and on both sides of the cantilever. The cantilever is provided with a product positioning pin bolt at a working end. According to the invention, the retractable distance and the reachable size of the positioner are improved, thetooling space is enlarged, meanwhile, the post-maintenance cost of the positioned is reduced, and the service life of the positioned is prolonged.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Technique for preventing defects of surfacing wear-resistant layer of part

InactiveCN104308327AImprove the passing rate of one-time inspectionAvoid scratchesArc welding apparatusIsosceles trapezoidWear resistant

The invention discloses a technique for preventing defects of a surfacing wear-resistant layer of a part. By the technique, the surfacing quality of parts such as pistons is improved, the number of rework is reduced, the one-step delivery-check qualified rate of the parts is improved, and the production cost is reduced. According to the technical scheme, the technique comprises the following steps of (1) roughly turning outlines of a piston part to obtain a part with a cylindrical boss structure and forming an annular groove with the inverted-isosceles-trapezoid-shaped section in a cambered surface of a large end of the part; (2) surfacing a nickel-base superalloy auxiliary layer in the annular groove, performing crossing symmetrical welding, transversely welding the annular groove along the axial direction, sequentially welding the annular groove until surfacing on the whole annular groove of the part is finished and machining the auxiliary layer; (3) surfacing an aluminum bronze layer on the auxiliary layer and performing crossing symmetric welding; and (4) sequentially performing destressing treatment and finish machining on the piston part after the piston part is subjected to surfacing so as to obtain a finished product of a piston.

Owner:AECC AVIATION POWER CO LTD

Chromium corundum-silicon carbide-carbon castable for iron troughs

The invention relates to a chromium corundum-silicon carbide-carbon castable for iron troughs. The castable comprises, by mass, 45-75 % of chrome corundum, 10-30 % of silicon carbide, 1-6% of spherical asphalt, 1-10% of alpha-Al2O3 powder, 1-5% of silicon micro-powder, 1-7% of a binder, 0.1-2% of a composite antioxidant and 2-6% of a composite additive. The prepared castable for iron troughs has the characteristics of good erosion resistance, good wear resistance, good thermal shock stability, high erosion resistance and long service life, and can increase the iron influx of blast furnace iron troughs in order to reduce consumption of a refractory material.

Owner:上海新泰山高温工程材料有限公司

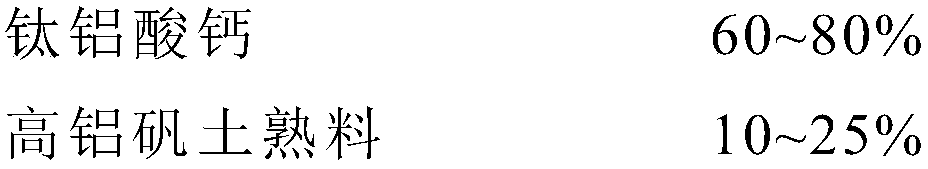

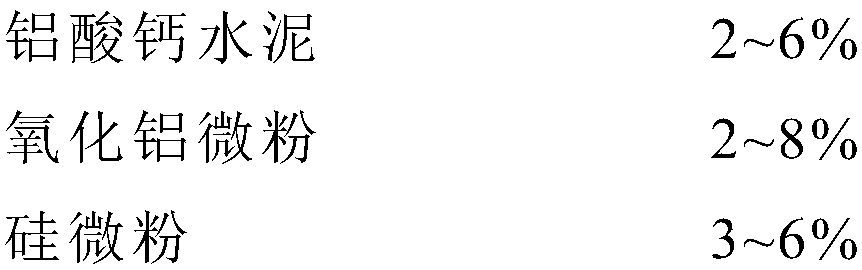

Titanium calcium aluminate castable for ladle or foundry ladle and preparation method thereof

The invention discloses a titanium calcium aluminate castable for ladle or foundry ladle. The titanium calcium aluminate castable for ladle or foundry ladle comprises (by weight): 60-80% of titanium calcium aluminate, 10-25% of high alumina bauxite clinker, 2-6% of calcium aluminate cement, 2-8% of alumina micro-powder and 3-6% of silica micropowder. In the preparation, polypropylene fiber and a water reducer are added, wherein the polypropylene fiber accounts for 0.01-0.04% of total weight of the raw materials; and the water reducer accounts for 0.1-0.5% of weight of the raw materials. by adding the alumina micro-powder and silica micropowder, volume stability of the ladle or foundry ladle can be maintained at the use temperature, and damage degree and potential safety hazard of the product are effectively reduced. By using calcium aluminate cement and silica micropowder as a compound binder, the product has good workability and medium and high temperature strength, service life is long, repair frequency is reduced, and smooth production of ladle is guaranteed. By using titanium calcium aluminate in quantity, volume stability of the titanium calcium aluminate castable at medium and high temperature is good, and the strength is high.

Owner:WUGANG REFRACTORY CO LTD

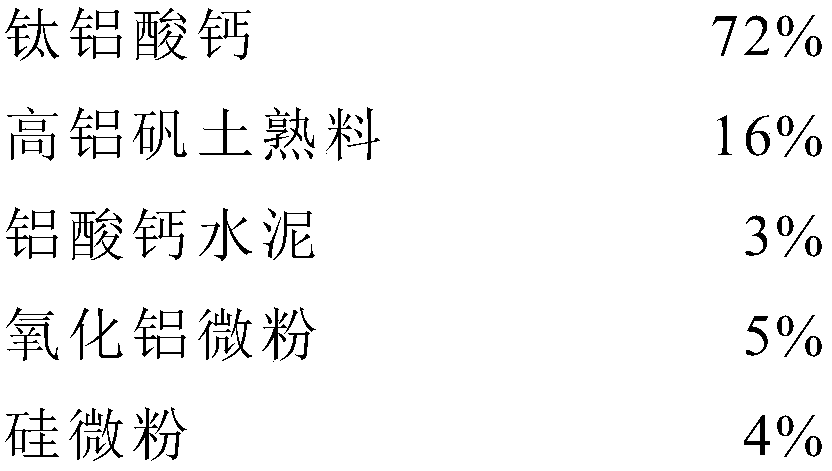

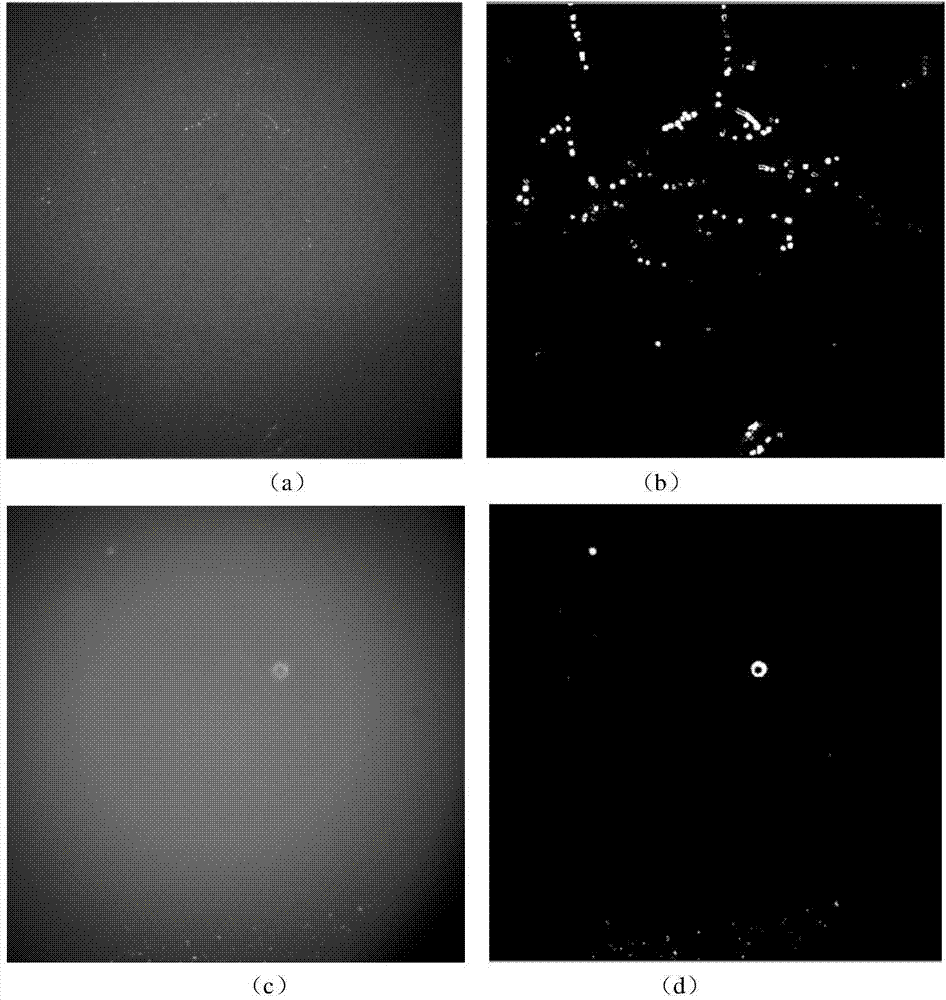

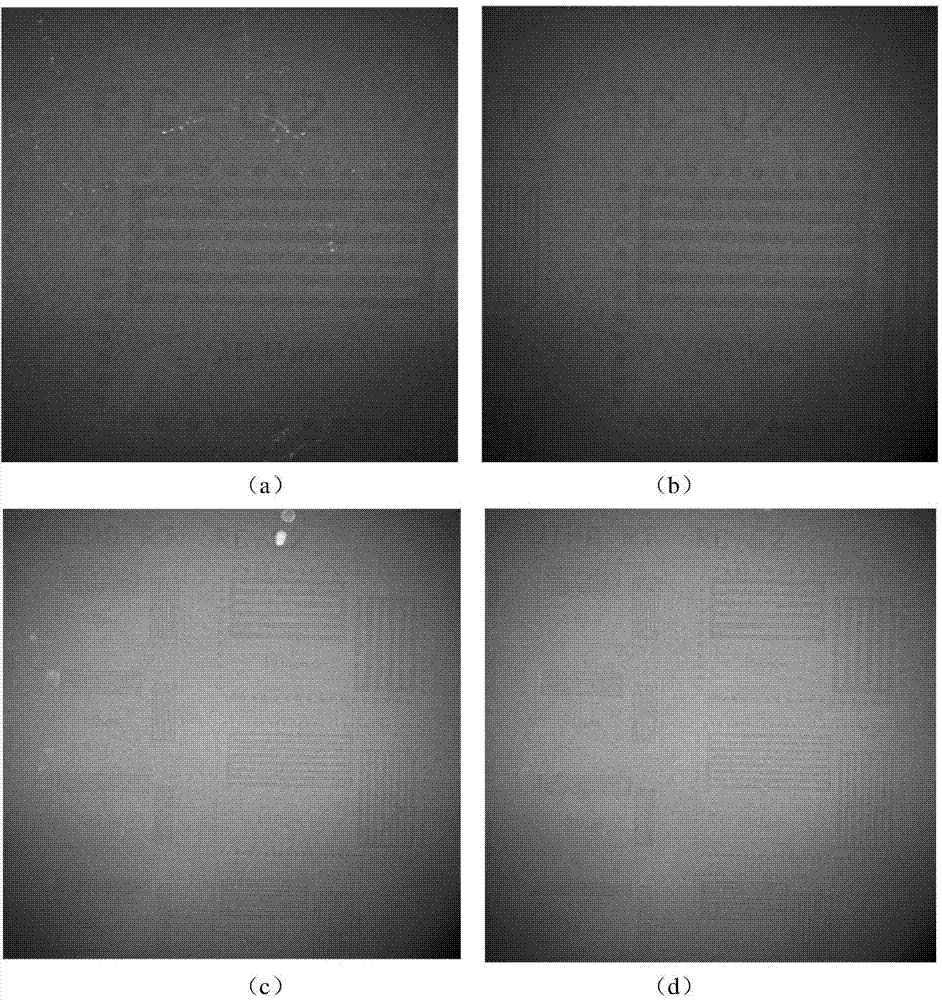

Repair algorithm for image artifact caused by scintillator defects in micro-CT

ActiveCN103778603AReduce the impact of noiseShorten the timeImage enhancementImaging qualityMarking out

The invention relates to a micro-CT (Computed Tomography) and aims to improve the image quality by repairing an image artifact caused by scintillator defects in the micro-CT. Therefore, the technical scheme adopted in the invention is that a repair algorithm for an image artifact caused by scintillator defects in micro-CT comprises the following steps: (1) acquiring a background projection image, namely, a blank scanning image; (2) obtaining a mask image of which an artifact region is marked out; (3) using micro-CT imaging equipment to acquire a sample image; (4) carrying out non-uniform illumination correction; (5) repairing a corresponding region of the sample image; (6) diffusing a corresponding region of the sample image acquired in step (4); and (7) alternately performing the repairing process in step (5) and the diffusion process in step (6), and repeating the process until a set number of times reaches. The repair algorithm of the invention is mainly used for micro-CT image processing.

Owner:TIANJIN UNIV

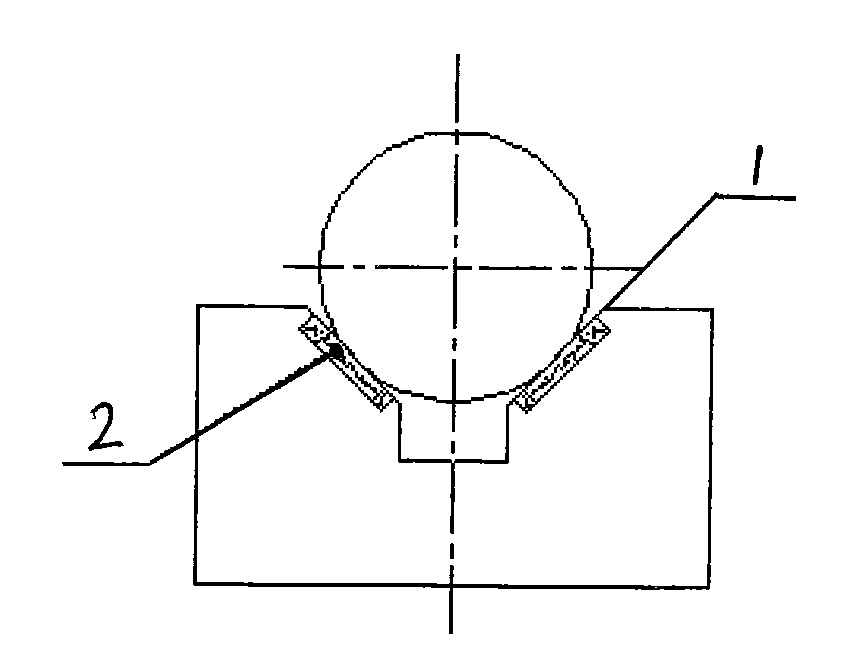

V-shaped block and manufacturing method thereof

InactiveCN101664885AReduce wearExtended service lifePositioning apparatusPress ramAlloyMaterials science

The invention relates to a V-shaped block which is technically characterized in that grooves are arranged on a V-shaped surface, and hard alloys matching with the grooves in size are fixed in the grooves. A manufacturing method comprises the following steps: firstly, processing the grooves on the V-shaped surface of the V-shaped block; secondly, placing the hard alloys in the processed grooves, and fixing the alloys; and finally, grinding the V-shaped surface on which the hard alloys are fixed. By mounting the extremely wearable hard alloys fixedly on the V-shaped block, the invention can reduce abrasion of the V-shaped surface, thereby prolonging the service life of the V-shaped block.

Owner:ZHONGBEI UNIV

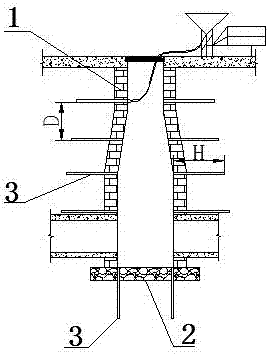

Support method for deep soft rock roadway

ActiveCN109184747AImprove support strengthReduce the number of repairsUnderground chambersTunnel liningGeomorphologyShotcrete

The invention discloses a support method for a deep soft rock roadway, which includes the following steps: (1) measuring the thickness of the broken rock zone of the surrounding rock of a roadway; (2)determining the relationship between the deformation of the roadway and the creep time; (3) carrying out primary shotcrete support; (4) installing an anchor rod net; (5) carrying out secondary shotcrete support; (6) installing a circular steel bracket; and (7) backfilling the bottom of the roadway. A support method based on concrete-anchor rod net-concrete-shed pipe-steel support is adopted, andthe support structure is rigid-flexible, which can improve the support strength and reduce the number of repairs. The same support structure is also adopted at the bottom of the roadway, and the bottom is backfilled with gravel, which can improve the support strength at the bottom of the roadway and solve the problem of bottom heave. A structure of shed pipe-steel support is adopted, and the shedpipe can withstand a certain amount of deformation, so that the influence of long-term creep deformation of the roadway on the steel support structure can be avoided, and the number of support repairscan be reduced.

Owner:CENT SOUTH UNIV

Regenerated type road cold-repairing material

The invention relates to a regenerated road cold feeding material, which comprises 56-87% milling material, 0.08-0.34% cold feeding additive, 0.87-1.6% diesel, and stones. The invention adds stone, feeding liquid, diesel, and macromolecule activate modified additive into the milling waste of highway, to be heated and mixed, to save material and reduce the pollution, while the added macromolecule activate modified additive can resolve the aging problem of pitch. And the invention uses the milling waste as material to avoid damaging the continuity of road, while the regenerated cold feeding material has high strength.

Owner:河南交投交通建设集团有限公司 +4

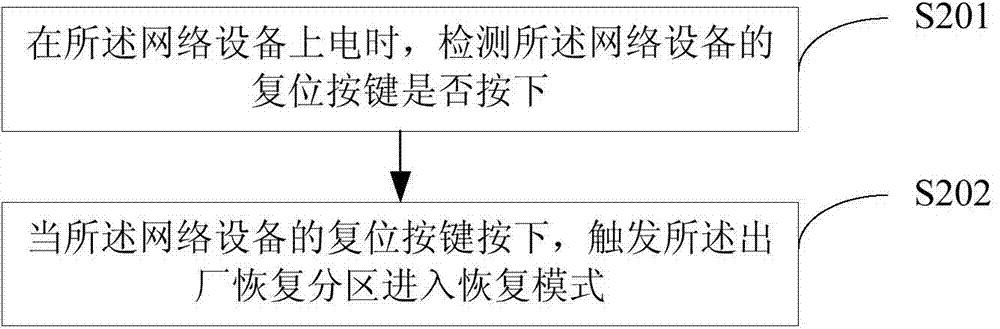

Firmware recovery method and device of network equipment

ActiveCN104750574AAvoid situations where you can't start successfullyReduce the number of repairsProgram loading/initiatingRedundant operation error correctionElectricityRecovery method

The invention belongs to the technical field of networks, and provides a firmware recovery method and device of network equipment. The method includes the steps that a factory leaving recovery partition is set in a flash memory of the network equipment, and the factory leaving recovery partition only supports read operation; after the network equipment is powered up, a CPU of the network equipment starts running from the factory leaving recovery partition; the factory leaving recovery partition is triggered to enter in a recovery state; firmware uploaded through a web page is recovered into the flash memory partition corresponding to the firmware in the recovery mode. When the firmware of the network equipment is damaged, the firmware recovery method can avoid the phenomenon that the network equipment cannot be started successfully, firmware repair of the network equipment can be guided to be achieved by users in the recovery mode, the number of rework and the abandoned phenomenon of the network equipment are reduced, the repair speed of the network equipment is decreased, and the production efficiency is improved.

Owner:深圳市美科星通信技术有限公司

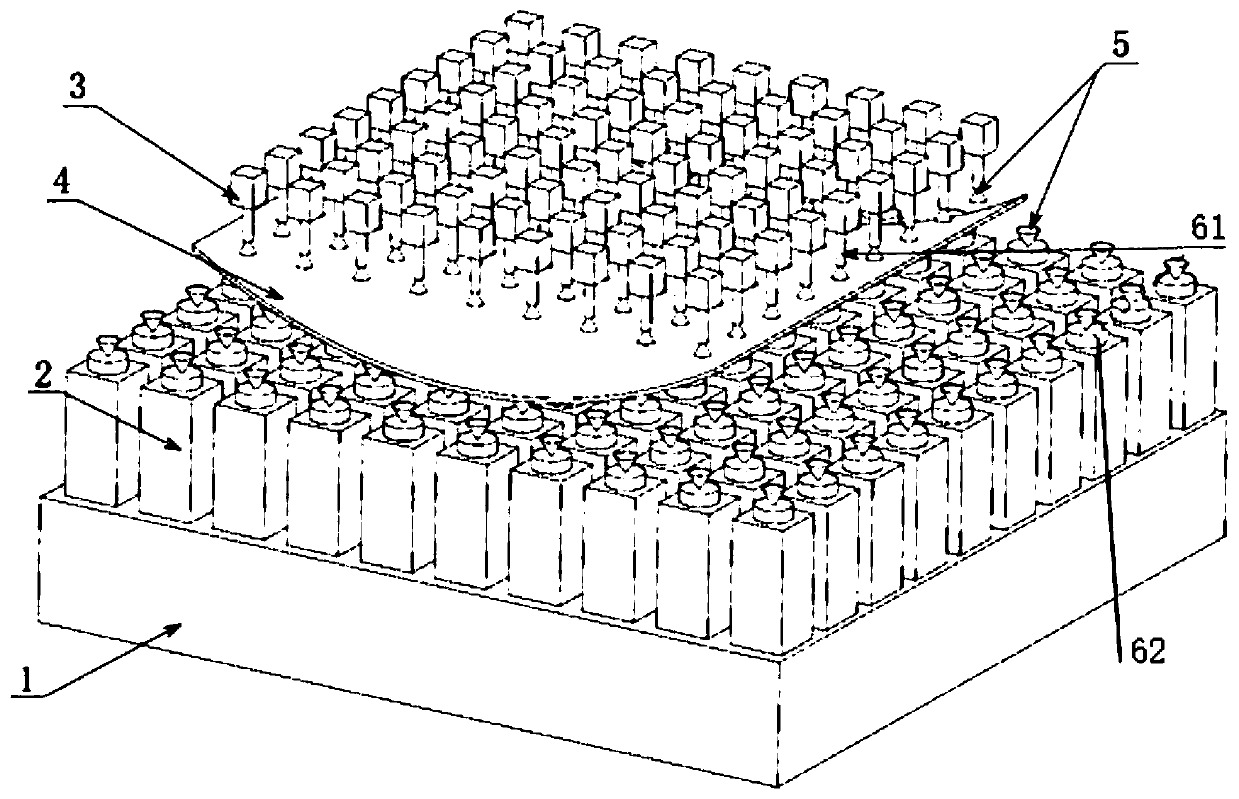

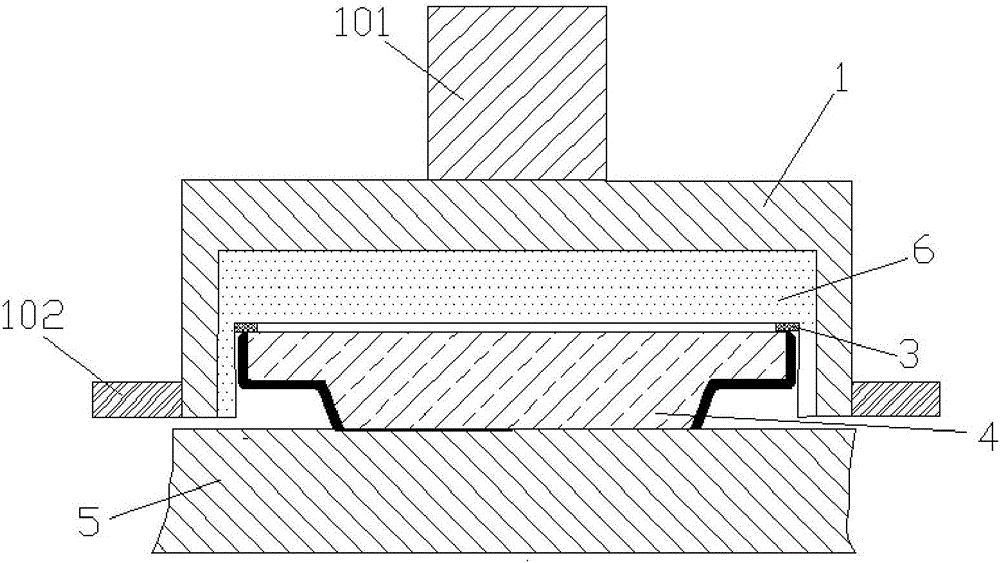

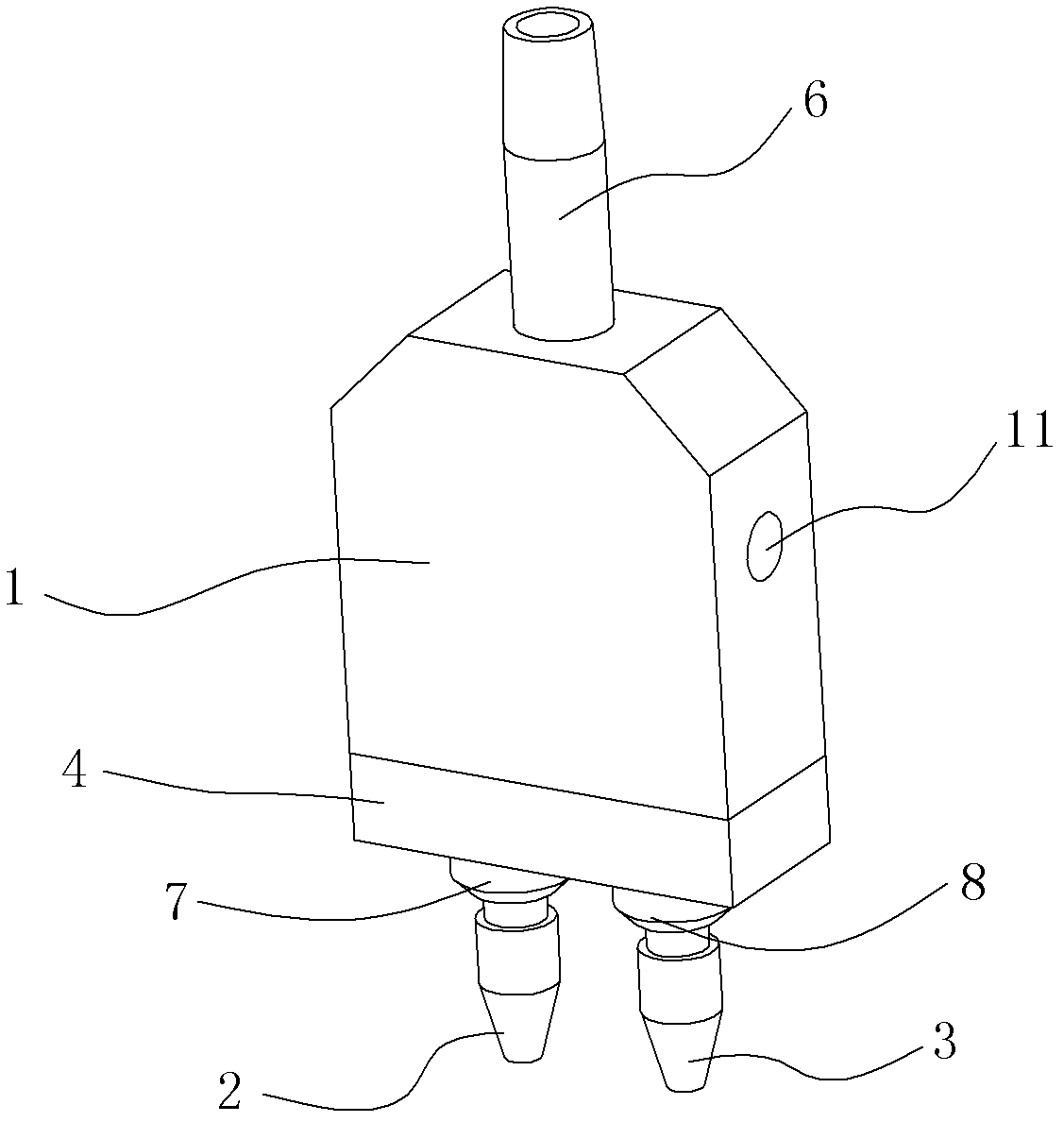

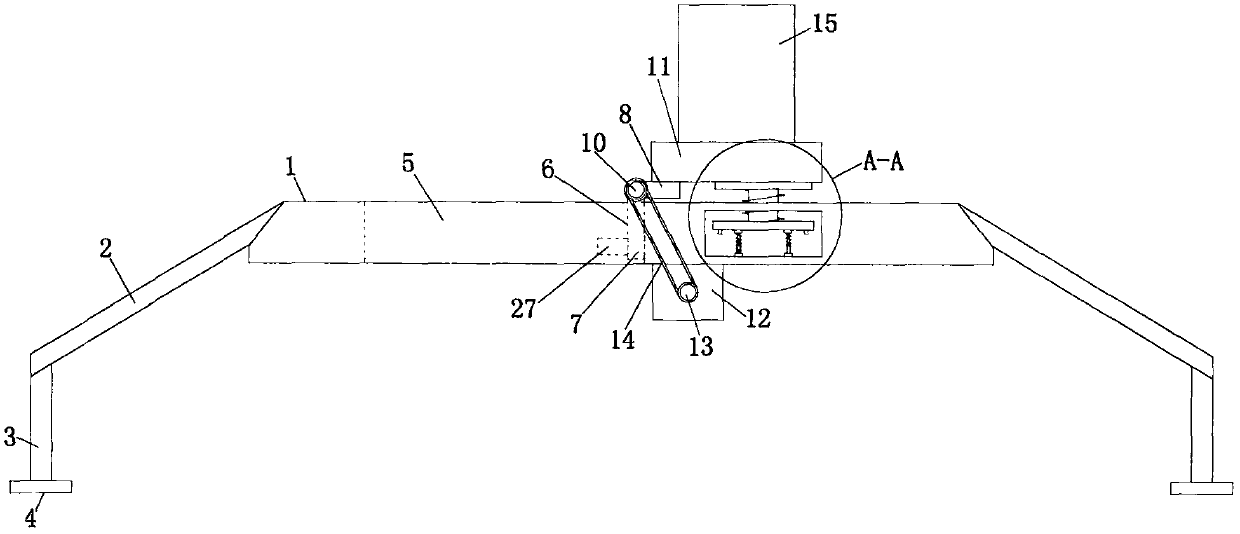

Flexible welding tool and fixing method for curved-profile structural workpiece

ActiveCN110480173AImprove fitReduce the amount of processingLaser beam welding apparatusSupporting systemControl system

The invention provides a flexible welding tool and control method for a curved-profile structural workpiece, belongs to the technical field of laser welding tools, and solves the problems of long product update cycle, high accumulated cost, low reaction speed, relatively low efficiency and the like caused by repair, adjustment and even remanufacturing of existing special tools. The tool comprisesa lattice supporting system, a lattice pressing system, a control system, a base and a substrate; the lattice supporting system comprises multiple lattice supporting units; the lattice pressing systemcomprises multiple lattice pressing units; each lattice pressing unit and each lattice supporting unit are connected with the control system separately; and each of the lattice pressing units and thelattice supporting units comprises a casing, a servo motor, a tail-end tray and a sliding screw. The flexible welding tool is used for fixing the curved-profile structural workpiece.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

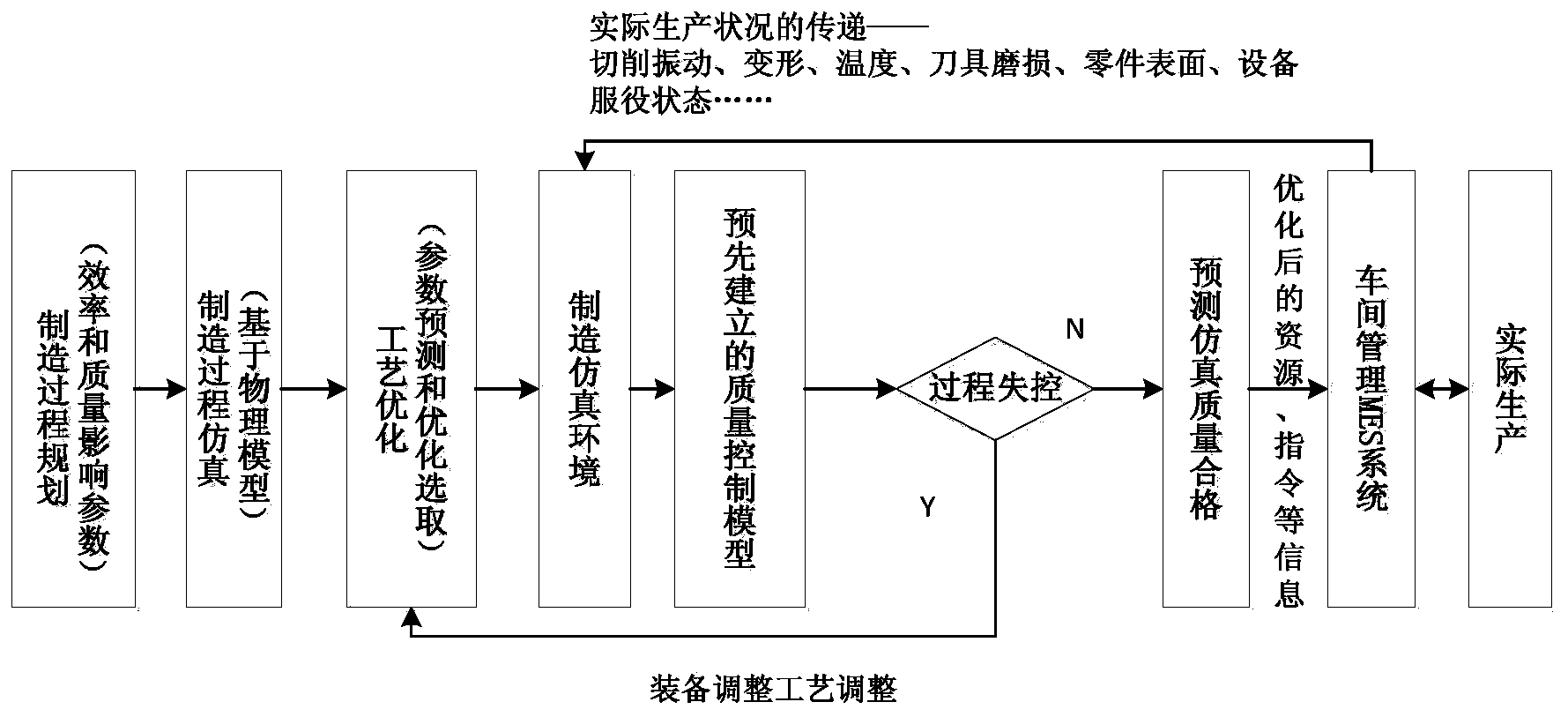

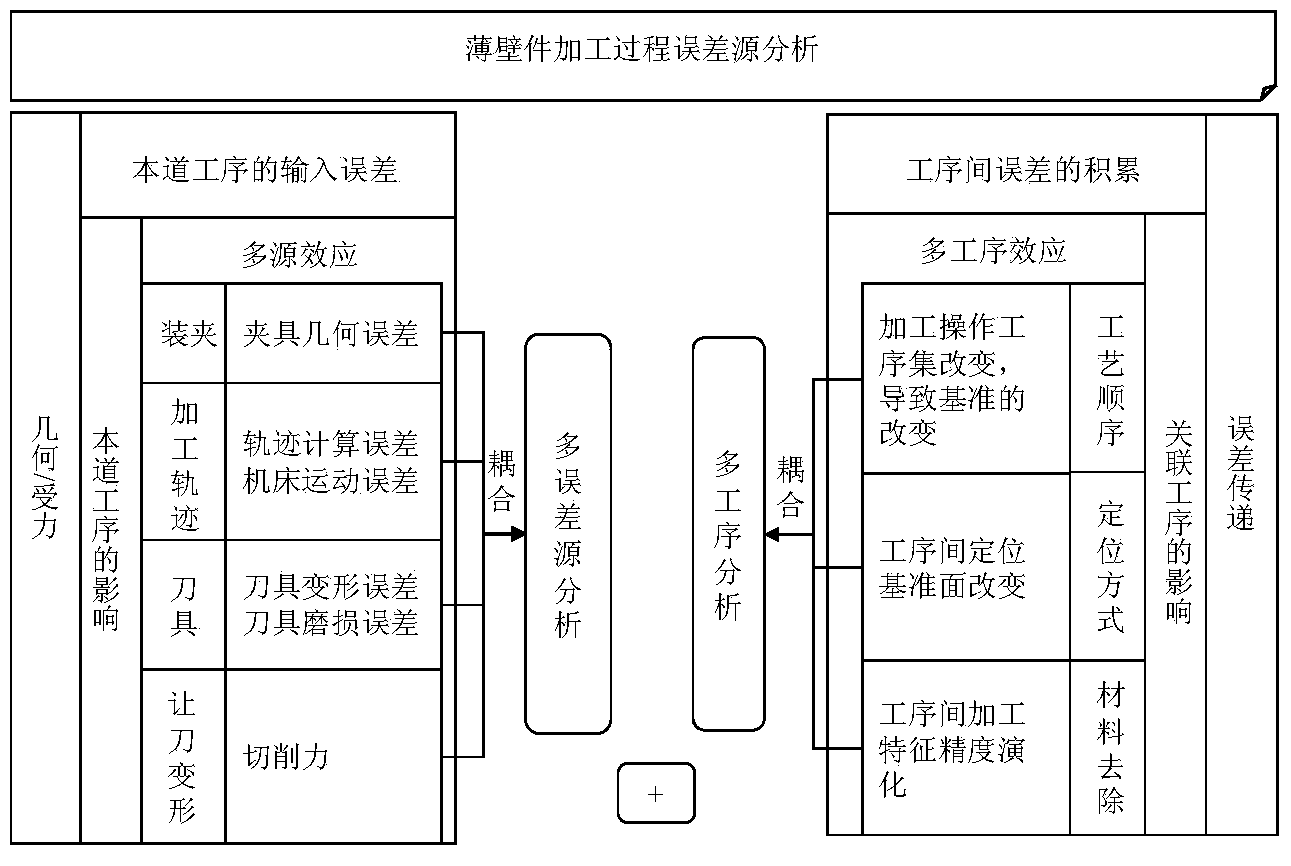

Closed-loop quality control simulation method with simulation prediction and actual production integrated

InactiveCN104268350AAvoid quality problemsReduce scrap rateSpecial data processing applicationsCouplingClosed loop

The invention belongs to the field of error control during part machining process, and relates to a closed-loop quality control simulation method with simulation prediction and actual production integrated. The method includes the steps of 1), performing multi-operation multi-error source analysis and description of the part machining process; 2), designing a data integration real-time collecting method and device of on-side multi-operation multi-error sources; 3), performing simulation prediction on comprehensive error on the basis of a dynamic error source coupling model; 4), predicting a quality pre-control method on the basis of dynamic error simulation prediction; 5), adjusting the out-of-control process according to quality monitoring situations and realizing closed-loop quality control. Thinking bandage of an existing method is broken through during control over the multi-operation machining process of the parts, prediction of the errors during the machining process is performed firstly, and then quality pre-control and process adjustment is performed on the basis of error prediction. Conventional afterwards quality control is converted into prior pre-control of quality by the method which is ideal in quality control.

Owner:CHINA XD ELECTRIC CO LTD

Polishing method for glass input window element and clamp

ActiveCN105710740AGuaranteed anti-halation effectReduce scrap rateGrinding work supportsPlane surface grinding machinesEngineeringMachining

The invention discloses a polishing method for a glass input window element and a clamp and belongs to the field of glass machining. According to the polishing method, initial polishing and final polishing are conducted on the two surfaces of the glass input window element. The polishing method includes the following steps that initial polishing is conducted, wherein the glass input window element to be polished is pressed on a polishing disc to be subjected to initial polishing till the number of apertures of the surface of the element ranges from 1 to 5; and final polishing is conducted, wherein the element obtained after initial polishing is pressed on the polishing disc to be subjected to final polishing till the defect of the surface of the element reaches the zero level standard. The polishing method has the beneficial effect of being low in rejection rate.

Owner:CHINA BUILDING MATERIALS ACAD

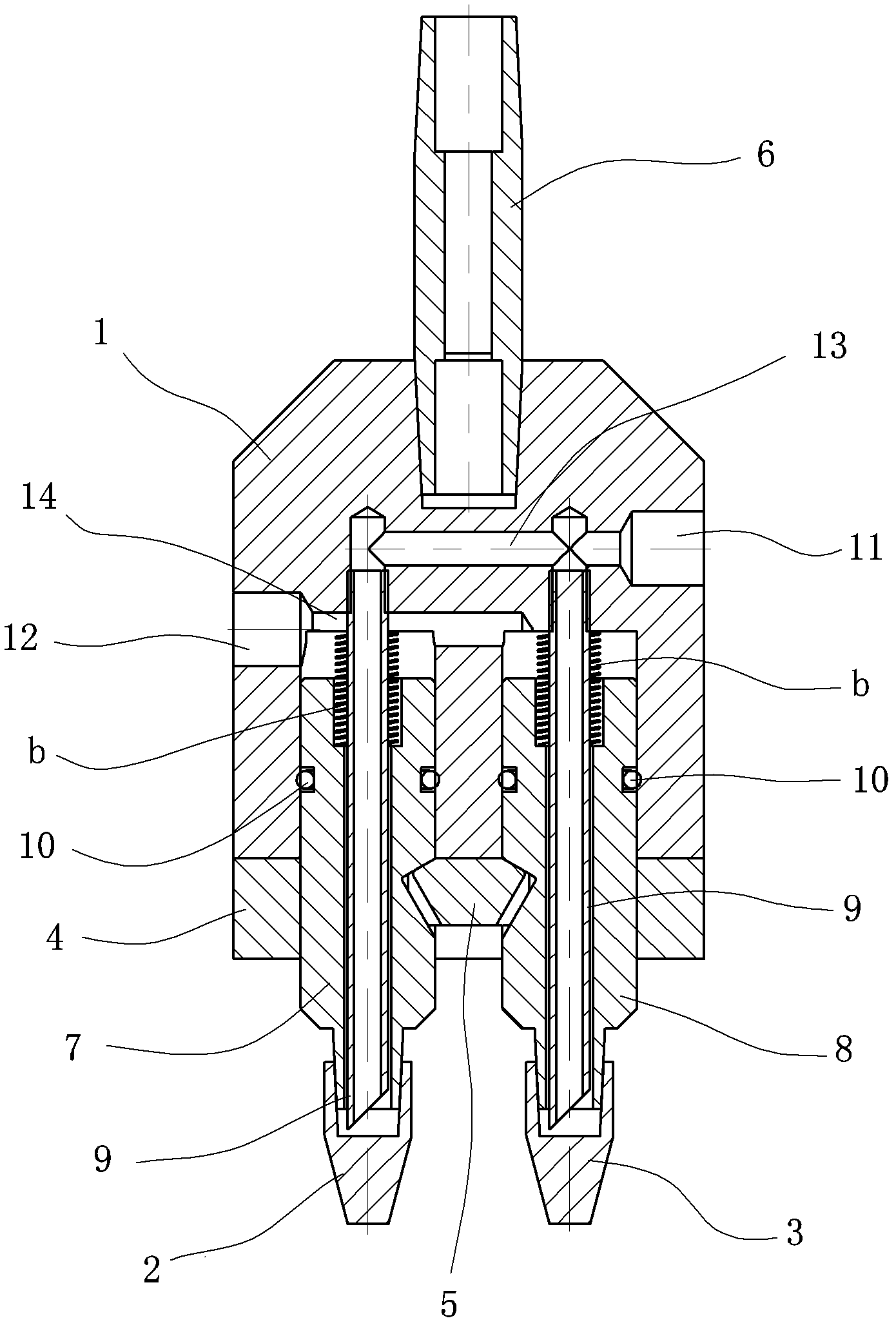

Duplex spot welding electrode

ActiveCN102581463AReduce the number of repairsAvoid Welding PhenomenonElectrode featuresNatural stateEngineering

The invention relates to a duplex spot welding electrode. Improvements are made on the basis of an electrode holder, a first electrode, a second electrode, a first guide pillar and a second guide pillar, namely an auxiliary block is fixed on the bottom surface of the electrode holder; two through holes are arranged in the auxiliary block; a sunken groove is arranged on the upper part of the auxiliary block, and is communicated with the two through holes; a sliding block is positioned in the sunken groove; each of the two lateral surfaces of the sliding block is provided with a downwardly inclined surface; a groove matched with the corresponding downwardly inclined surface of the sliding block is arranged on the lateral surface of each of the first and second guide pillars; a spring is arranged in each of mounting holes, and makes each of the first and second electrodes always tend to be exposed out of the electrode holder; and each spring is in a natural state, the sliding block is pressed against the grooves on the first and second guide pillars, and a gap is formed between the downwardly inclined surface on each of the two sides of the sliding block and each groove. The two electrodes can float and be automatically leveled, so that the two electrodes contact a workpiece with the same force, a pseudo soldering phenomenon is avoided, the number of overhauling times of the abraded electrode is decreased, the use cost is decreased, and the welding efficiency is improved.

Owner:北京敏实汽车零部件有限公司

Cu-Cr-Ag alloy crystallizer copper plate and preparation process thereof

The invention discloses a Cu-Cr-Ag alloy crystallizer copper plate comprising the following components in percentage by mass: 0.1-0.3% of metal chromium, 0.03-0.05% of a deoxidizing agent namely metal magnesium, 0.08-0.2% of metal silver and 99.56-99.79% of metal copper. The invention also discloses a preparation process of the Cu-Cr-Ag alloy crystallizer copper plate. The Cu-Cr-Ag alloy crystallizer copper plate disclosed by the invention has very good heat-conducting property and relatively high tensile strength, and simultaneously has very high softening temperature, high thermal cracking resistance and good creep resistance, so that the service life of the crystallizer copper plate is prolonged, the pulling rate of a plate blank casting machine is improved, the production efficiency of plate blanks is greatly improved, and thus the Cu-Cr-Ag alloy crystallizer copper plate is a novel high-thermal-cracking-resistance crystallizer copper plate which is suitable for multi-steel-type continuous casting operation for high-pulling-rate high-efficiency production of ultra-low-carbon steel, silicon steel, SPHC and the like.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Method for welding martensite heat-resistant steel

ActiveCN109794668APrevent oxidationLow costArc welding apparatusWorkpiece edge portionsThick wallMartensite

The invention relates to a method for welding martensite heat-resistant steel, and belongs to the field of high-parameter container manufacturing. For solving the problems that the closed seam weldingconstruction of the high-parameter container martensite heat-resistant steel used in a secondary reheating unit is prone to occur the conditions of crack defect, post-welding low hardness and the like, the method comprises the following steps that 1, a welding groove is machined; 2, pre-welding predation is performed; 3, pre-welding is preheated; 4, argon is filled; and 5, welding is performed; if a barrel body is too large, a weld joint is too long, an interlayer temperature is difficult to control, and then a flame heating temperature compensator is adopted to heated in a following mode soas to compensate for temperature loss, if the volume of the barrel body is too large, root oxidation cannot be prevented by establishing a large-scale closed gas protection chamber, and then a specialargon gas protection device is adopted for protection; and in the welding process of the high-alloy steel thick-wall container barrel body, the welding joint is heated in a flame preheating mode, thechange condition of the temperature is difficult to continuously measure, and a temperature monitoring device is arranged at the front end of the to-be-welded weld joint of the container barrel body.According to the method, the number of rework times and the probability can be reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Laser radar for driverless car with high safety performance

InactiveCN109581413AImprove safety performanceReduce the number of inspections and repairsElectromagnetic wave reradiationHinge angleEngineering

The invention provides a laser radar for a driverless car with high safety performance, and relates to the field of parts for the driverless car. The laser radar for the driverless car with high safety performance comprises a transverse plate. A through hole is formed in the transverse plate; a hinge is fixedly connected to the right side of the inner wall of the through hole, and the hinge comprises a upper hinge piece and a lower hinge piece; two rotating bases are fixedly connected to one side, close to the upper hinge piece, of the lower hinge piece; one side, close to the lower hinge piece, of the upper hinge piece is fixedly connected to the surface of a rotating rod; the two ends of the rotating rod are penetrating the two rotating bases and extend to the outside of the two rotatingbases respectively; the upper hinge piece is located between the two rotating bases, and the lower hinge piece is fixedly connected to the right side of the inner wall of the through hole; an iron plate is provided at the top of the transverse plate. The laser radar for the driverless car with high safety performance is high in the safety performance, reduces the number of times of performing inspection and repair on the laser radar by a car owner, and saves time and labor.

Owner:李晓洋

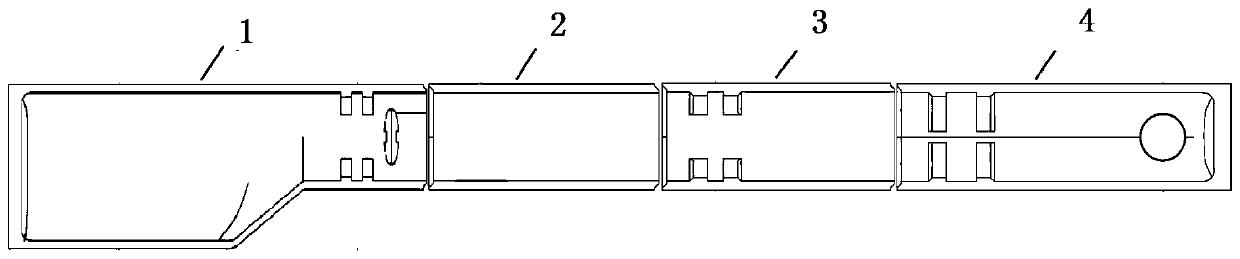

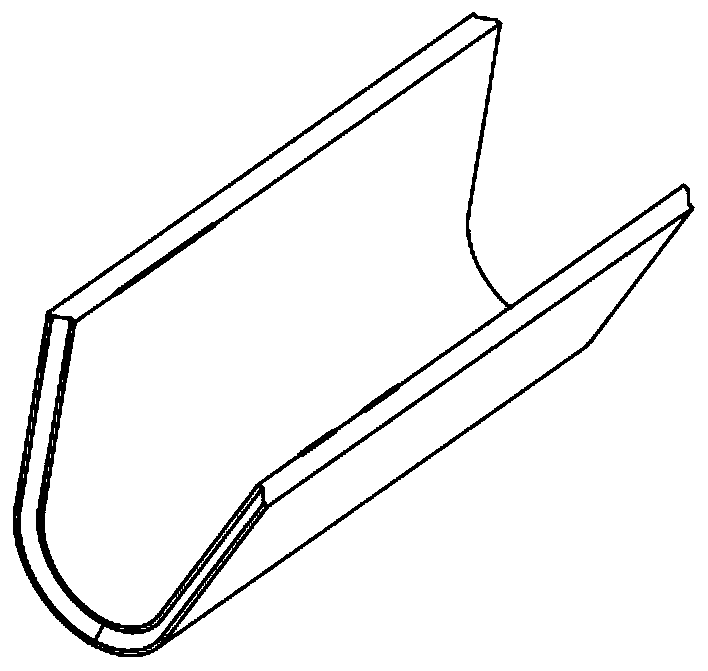

Ultrathin aluminum-based steel flowing tank

ActiveCN110479971AAvoid crackingReduce thicknessFoundry mouldsCasting cleaning apparatusRepair materialAlloy

The invention relates to the field of alloy smelting facilities and provides an ultrathin aluminum-based steel flowing tank. The wall thickness of a tank body of the steel flowing tank is 12-25 mm, and the tank body of the steel flowing tank is of a segmental structure and comprises a steel receiving tank, a first steel flowing tank, a second steel flowing tank and a tapping tank connected successively. The tank body of the steel flowing tank is lighter and thinner. As the wall thickness and the weight are reduced greatly, the production and application costs are lowered. A connecting mode between the tank body assemblies is also changed, so that the tank body assemblies are more easily replaced. Therefore, the risk that a repair material pollutes an alloy solution is reduced fundamentally.

Owner:SHENYANG HENGTAI XINYUAN PRECISION CASTING REFRACTORY MATERIAL CO LTD

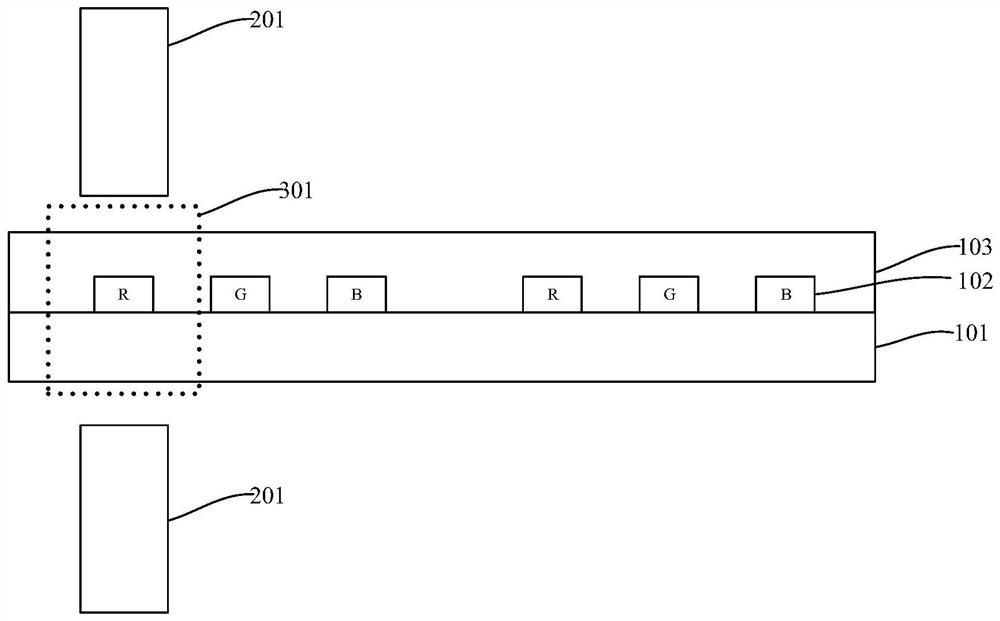

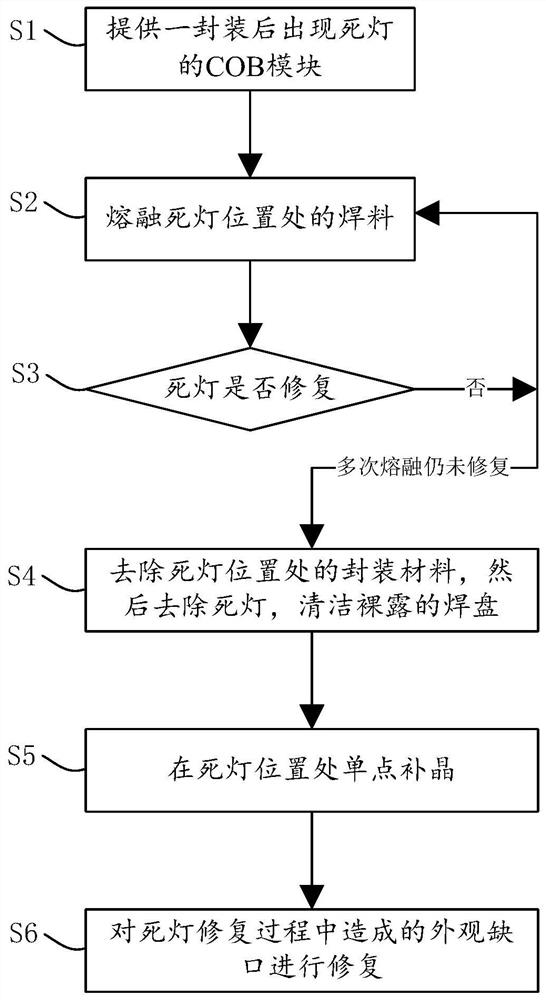

COB module repairing method

ActiveCN112951972AImprove repair efficiencyReduce the number of repairsSemiconductor devicesStructural engineeringMechanical engineering

The invention discloses a COB module repairing method. The method comprises the following steps of providing a COB module with an LED damage after packaging; melting the solder at the LED damage position; and if the LED damage is still not repaired, melting the welding flux at the dead lamp position repeatedly. According to the COB module repairing method provided by the invention, chip-level repairing can be realized through a fixed-point heating mode, the times of glue digging, crystal fixing and film pressing repairing are greatly reduced, and then single-point crystal supplementing repairing is carried out on the remaining LED damage positions which cannot be repaired through the fixed-point heating mode. According to the COB module repairing method, the dead lamp repairing efficiency can be greatly improved.

Owner:HCP TECH CO LTD

Dry quenching furnace bracket repairing method

The invention discloses a dry quenching furnace bracket repairing method capable of prolonging service life of a repaired bracket. The method comprises following steps: a, damaged bracket bricks in a to-be-repaired bracket are dismantled after an inner ring brick ring beam of a dry quenching furnace is supported; b, at least two holes are drilled in a joint surface constructed by the bracket bricks and exposed after the damaged bracket bricks are dismantled, a heat resistant steel nail is drilled into each hole, and the length of the heat resistant steel nail exposed out of the joint surface is 80-120 mm; c, the joint surface is cleaned up and is coated once with an adhesion agent; d, a formwork is supported on the outer surface of the bracket according to the outline size of the original bracket, and a bracket brick mold is jointly defined by the formwork, the joint surface and the other complete bracket bricks; e, castable and the adhesion agent are mixed in a specific ratio and are poured into the bracket brick mold for tamping; f, maintenance is performed for a period of time, so that the castable is completely condensed; the formwork is dismantled after the maintenance is finished. The bracket repaired with the method is firmer in structure, is free of mortar joints and has longer service life.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

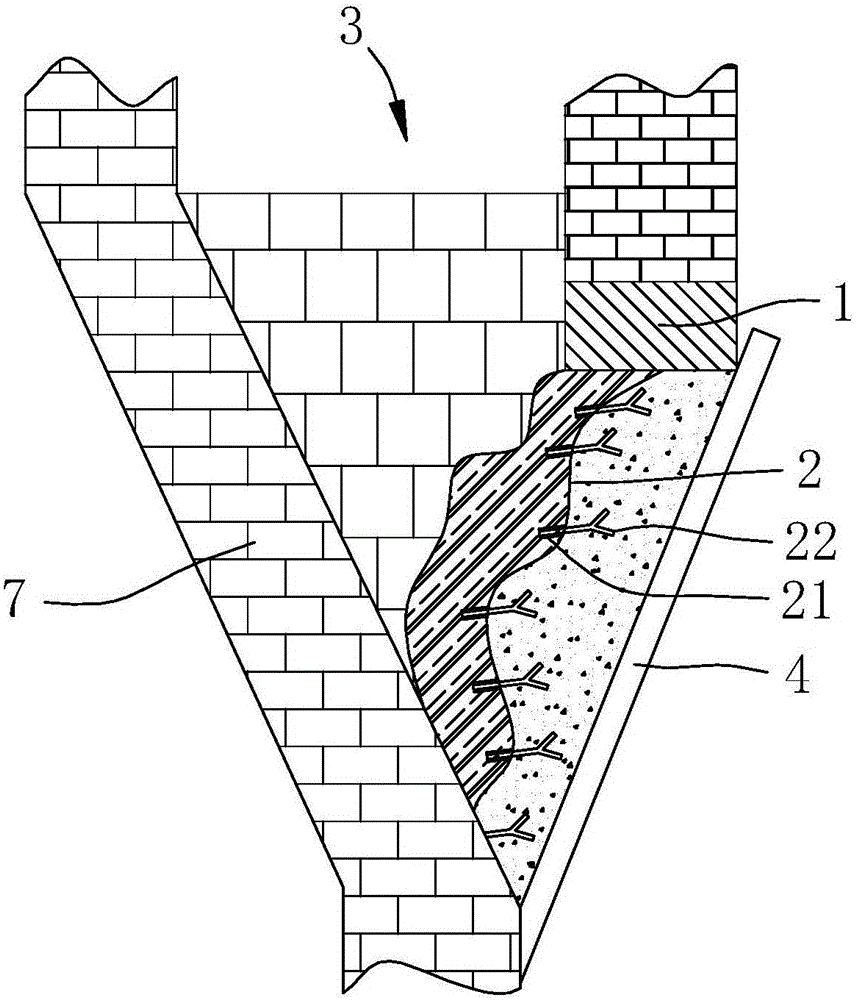

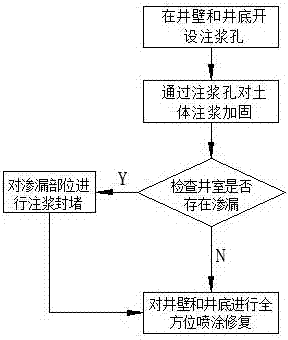

Non-excavation inspection wheel comprehensive repairing method

ActiveCN108005121AStable structureImprove restoration qualityArtificial islandsUnderwater structuresEngineering

The invention relates to the field of municipal engineering, and particularly discloses a non-excavation inspection wheel comprehensive repairing method. The non-excavation inspection wheel comprehensive repairing method comprises the steps of grouting reinforcement for a soil body, local leakage checking and stoppage, comprehensive surface spray repairing, and the like. According to the non-excavation inspection wheel comprehensive repairing method, an inspection wheel is comprehensively reinforced and repaired, the repairing effect is good, and the service life of the inspection well and corresponding pipe networks is effectively prolonged.

Owner:浙江华仕管道科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com