Flexible welding tool and fixing method for curved-profile structural workpiece

A welding tooling and fixing method technology, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of long product update cycle, slow response speed, and high cumulative cost, so as to improve flexibility, reduce processing cycle, reduce Effect of Processing Quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

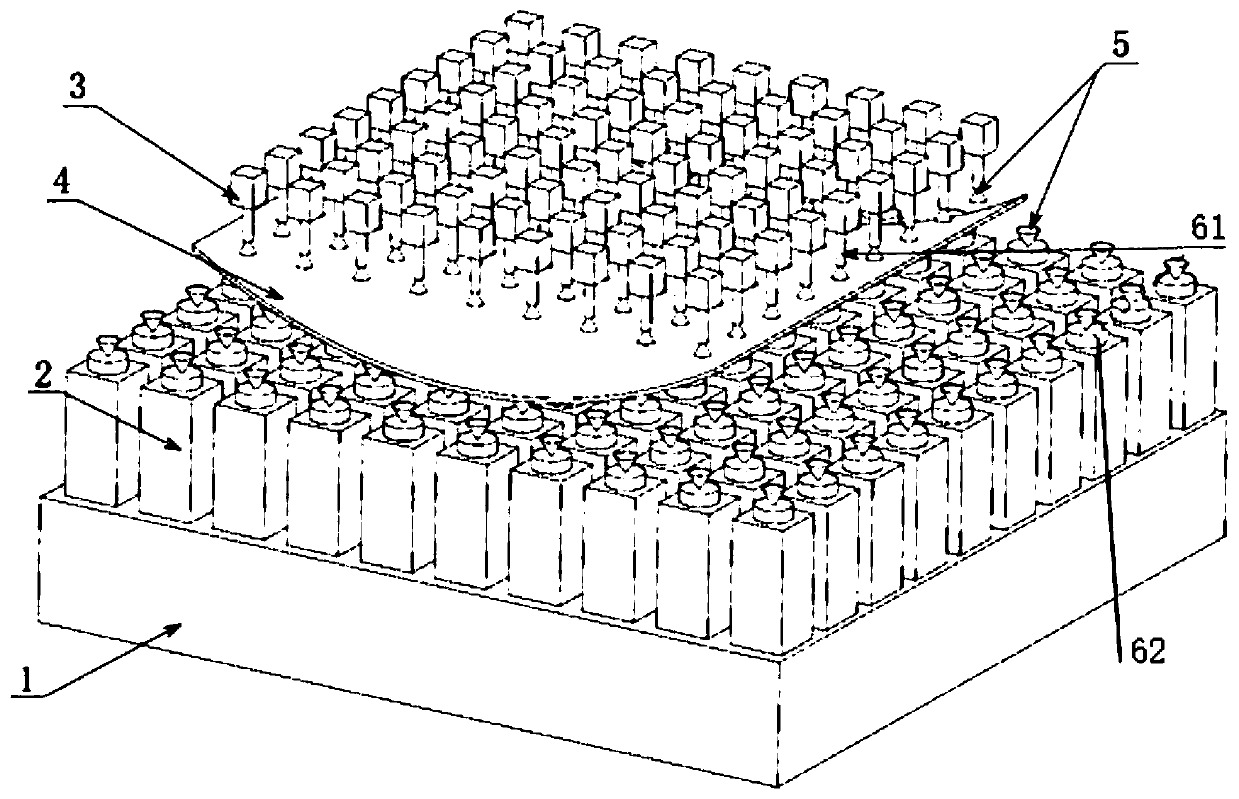

[0046] Embodiment 1 of the present invention provides a flexible laser welding tool for workpieces with curved surface structures. The system includes: a lattice support system, a lattice compression system, a control system, a base 1 and a substrate, such as figure 1 shown.

[0047] The base 1 is located at the bottom of the flexible laser welding tool, and the lattice support system is located on the upper part of the base 1 and is fixedly connected with the base 1 . The base 1 is preferably made of steel, and its size is designed according to actual needs, preferably 1m×1m to 3m×3m.

[0048] The dot matrix support system is composed of a plurality of dot matrix support units 2 arranged in a matrix. The dot matrix support system is mainly used to provide support for the back of the workpiece 4 to be welded. Each dot matrix support unit 2 is individually connected to the control system, and can Achieve the effect of independent control. The position and quantity of the lattic...

Embodiment 2

[0057] Embodiment 2 of the present invention relates to a method for controlling the use of flexible laser welding tooling for workpieces with curved surface structures:

[0058] S1. Use three-dimensional modeling software to calculate the lifting height of each lattice support unit 2 in the lattice flexible support system and the distance of each lattice pressing unit 3 to press down according to the workpiece model to be welded. The three-dimensional modeling software is preferably UG , SolidWorks calculation distance function.

[0059] S2. Assemble the workpiece 4 to be welded to the tooling, and according to the lifting height of each lattice support unit 2 and the pressing distance of each lattice pressing unit 3 calculated in S1, the tooling is initially adjusted through the control system, so that The position of each end pallet 5 can basically match the profile of the workpiece.

[0060] The preliminary adjustment process is as follows: set the lifting height of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com