Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

364results about How to "Improve restoration quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for performing automatic surfacing repair on damaged metal part

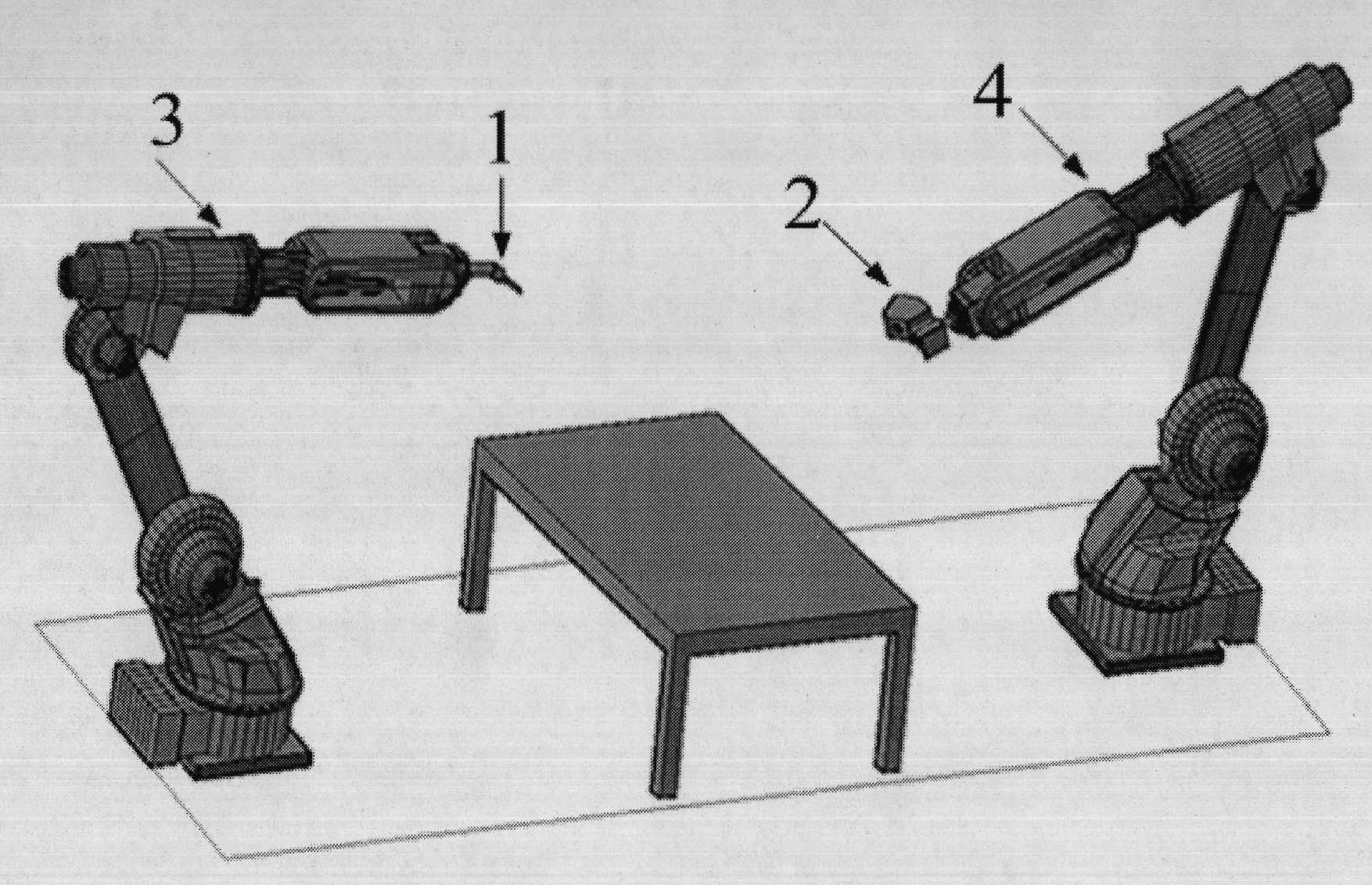

InactiveCN101927391ALabor intensiveHigh degree of automationWelding accessoriesPoint cloudRobotic arm

The invention discloses a method for performing automatic surfacing repair on a damaged metal part, which is a technical scheme used for performing automatic surfacing repair aiming at the missing part on the damaged metal part. In the method, a measuring robot and an arc welding robot are involved, wherein the measuring robot consists of a structured light sensor and a six-freedom-degree mechanical arm; and the arc welding robot consists of a welding gun and a six-freedom-degree robotic arm. The system works according to the following steps of: first, fixing a damaged part to be repaired on a working table, and scanning the damaged part by using the measuring robot to obtain three-dimensional surface point cloud data of the damage of the part; then, performing registration (geometric alignment) on the three-dimensional surface point cloud data and an original CAD model of the metal part, and extracting the point cloud data of a damaged area by calculating the error from the point cloud data to the CAD model; and finally, generating a surfacing repair path according three-dimensional information of the damaged area, and controlling the arc welding robot to finish the automatic repair of the damaged area of the part by using a computer.

Owner:DALIAN MARITIME UNIVERSITY

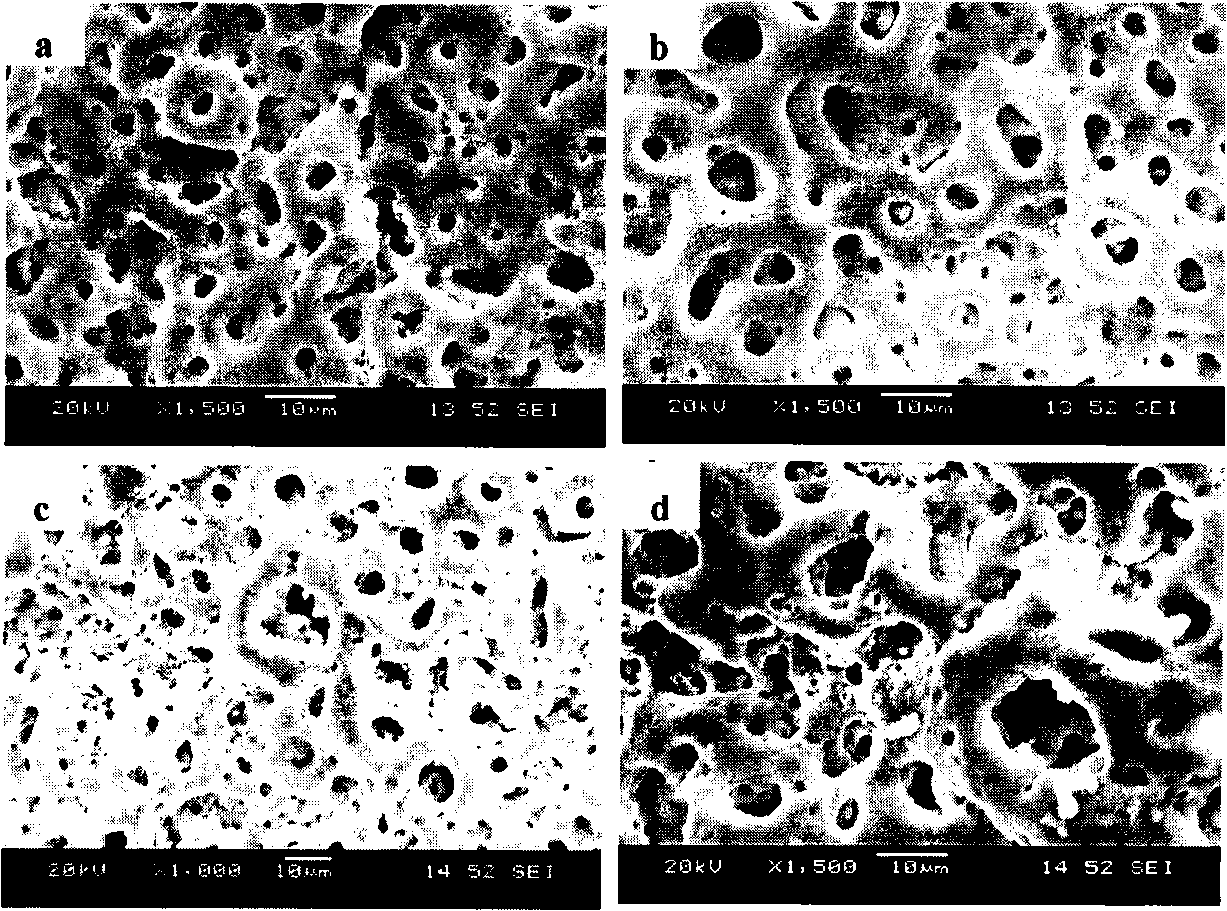

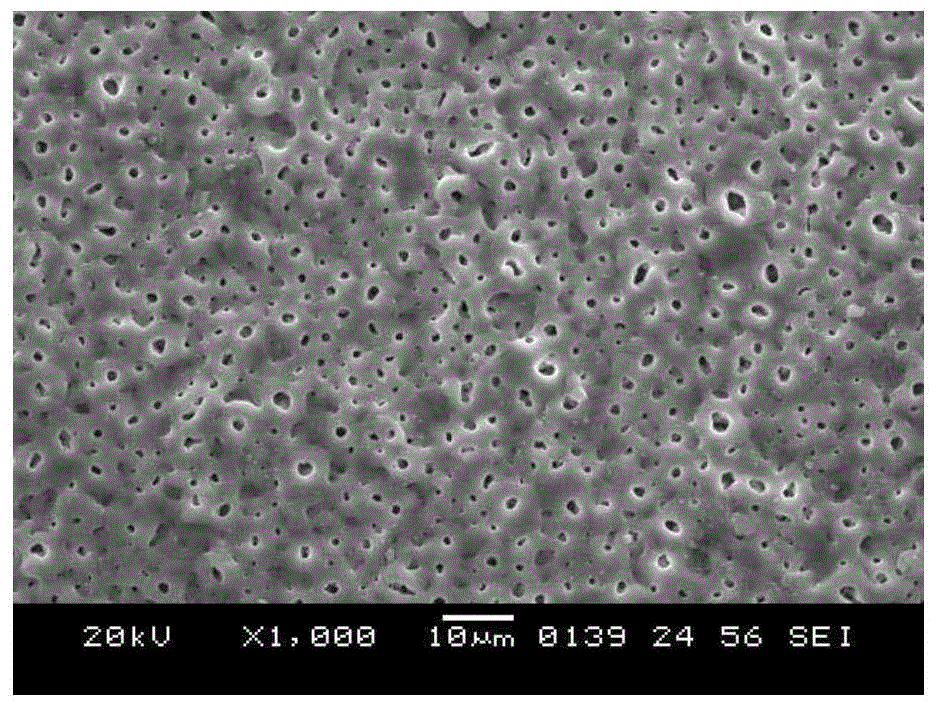

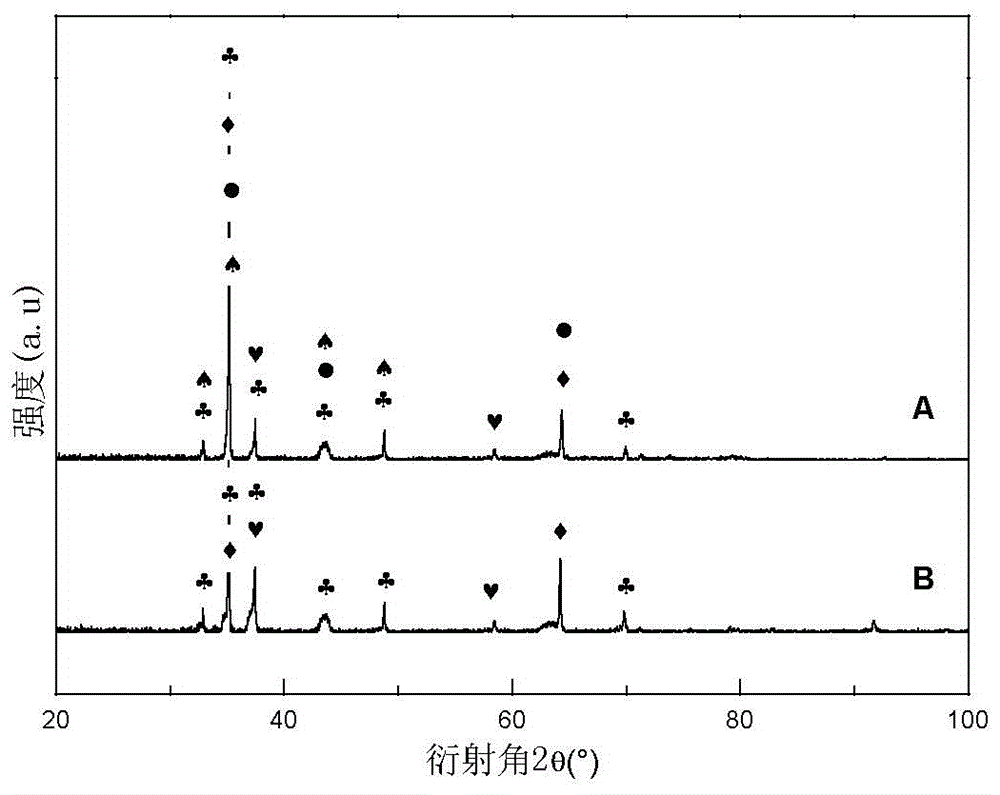

Preparation method of ultrasonic microarc oxidation silver-carrying antibiotic bioactive coating on magnesium and titanium surface

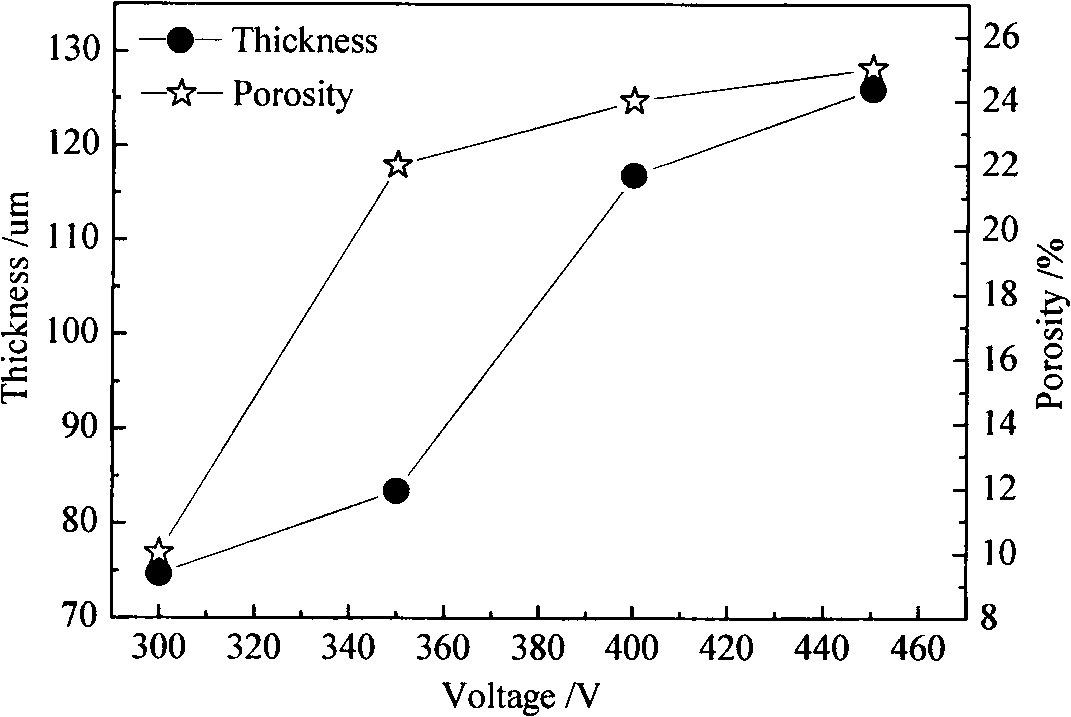

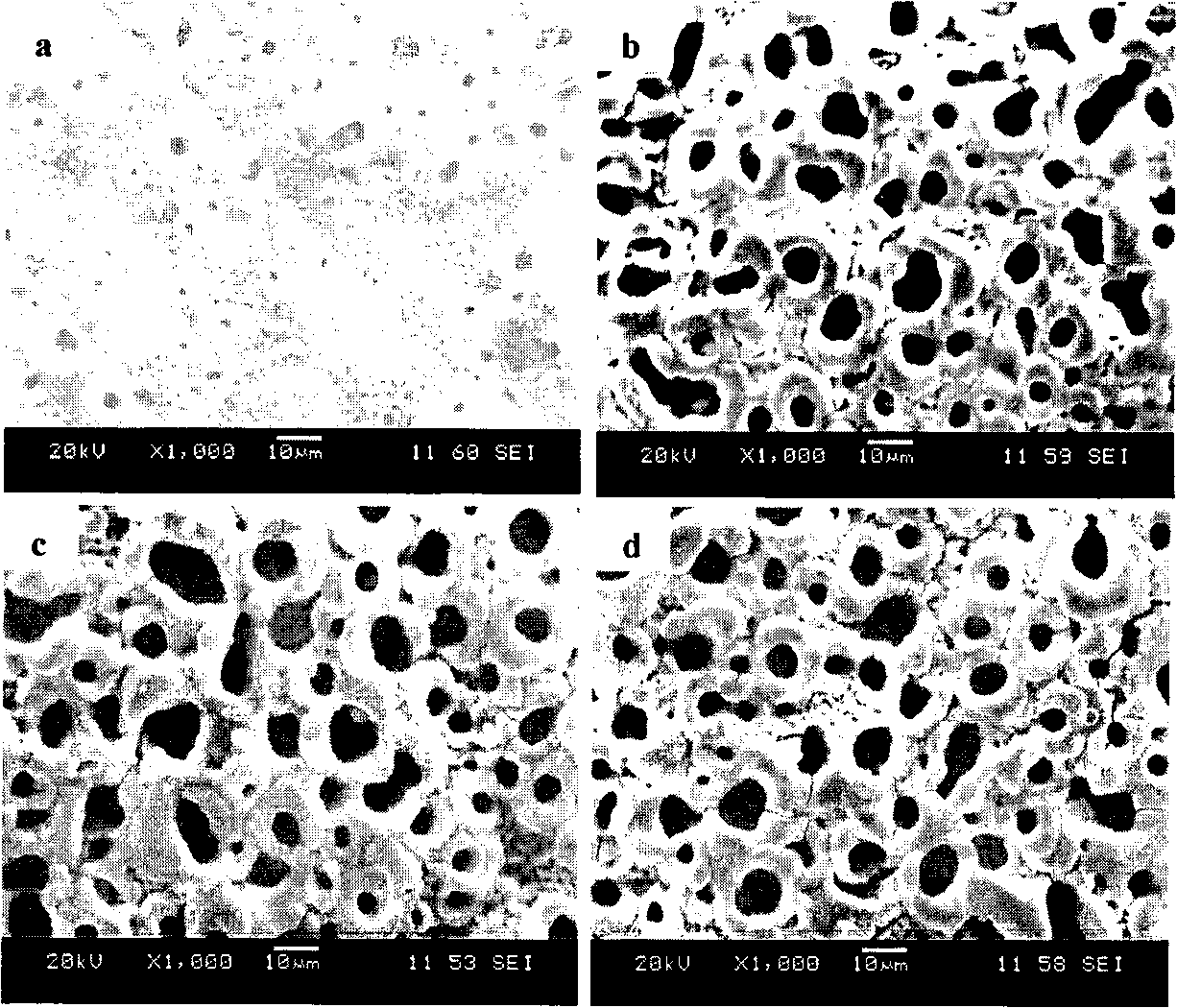

InactiveCN101899700AImprove corrosion resistanceGood resistance to friction and wear in human environmentAnodisationProsthesisPorosityPlasma electrolytic oxidation

The invention relates to a new method for preparing an antibiotic bioactive coating material on the surface of titanium alloy and magnesium alloy by ultrasonic-microarc oxidation composite technology, which can be used for obtaining a biological coating material which is compact at the bottom layer and is porous at the surface layer, wherein Ca, P and Ag contained in the coating can improve the bioactivity and the corrosion resistance of magnesium and titanium, and reduce bacterial infection caused by implantation. The invention can meet the requirements of bearing bones of human beings for mechanical properties of implanted materials, and can overcome disadvantages of the traditional surface modification method for biologic materials. In the coating composite material, the coating thickness of titanium alloy is 50-85 mu m, the surface hole diameter is 4-25 mu m, the porosity is 20-30%, and the bonding strength between the coating and the matrix is 23-40 MPa. The coating thickness of magnesium alloy is 16-22 mu m, the surface hole diameter is 5-28 mu m, the porosity is 21-30%, and the bonding strength between the coating and the matrix is 8-20 MPa.

Owner:JIAMUSI UNIVERSITY

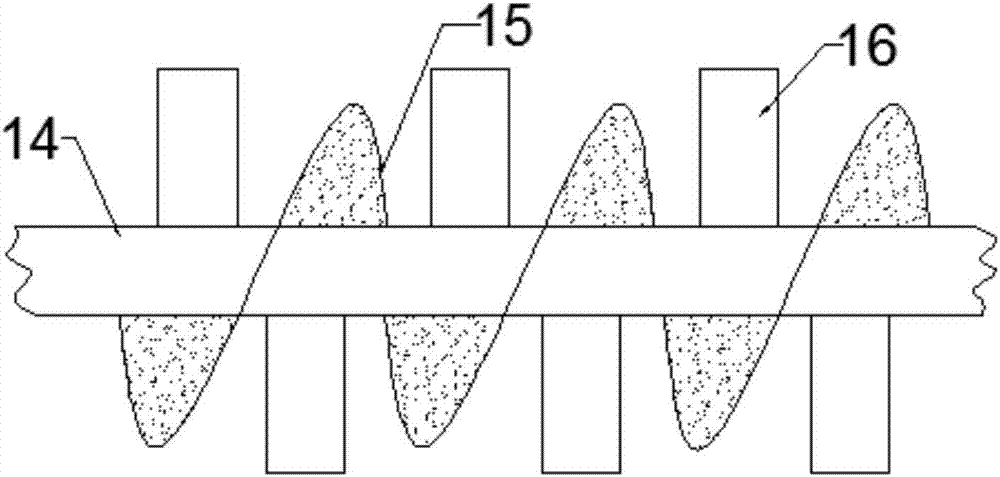

Novel full-automatic online cold welding repairing process for roll squeezers

ActiveCN103481010AReduce workloadSimplify your workflowArc welding apparatusWelding/cutting media/materialsPre treatmentEngineering

The invention discloses a novel full-automatic online cold welding repairing process for roll squeezers. The novel full-automatic online cold welding repairing process is characterized by comprising steps of (1), pre-treating roll surfaces of cement squeeze rolls to remove fatigue layers, welding check rings at two ends of each roll surface and enabling the corresponding check rings and each roll surface to be located on the same curved surface; (2), checking the roll surfaces to determine whether cracks are formed on the roll surfaces or not, grinding crack positions of the roll surfaces to remove the cracks, and performing repair welding on pits until the pits are filled; (3), performing buildup welding on the roll surfaces by means of automatic open arc welding; (4), removing the check rings and grinding and leveling the roll surfaces. The novel full-automatic online cold welding repairing process has the advantages that the buildup welding repairing quality can be guaranteed, the rolls of the roll squeezers do not need to be detached, stress relieving measures such as heating and heat insulation are omitted in buildup welding procedures, accordingly, working procedures can be greatly simplified, the construction cost can be greatly reduced, and energy can be saved.

Owner:柳州市三龙耐磨焊接科技有限公司

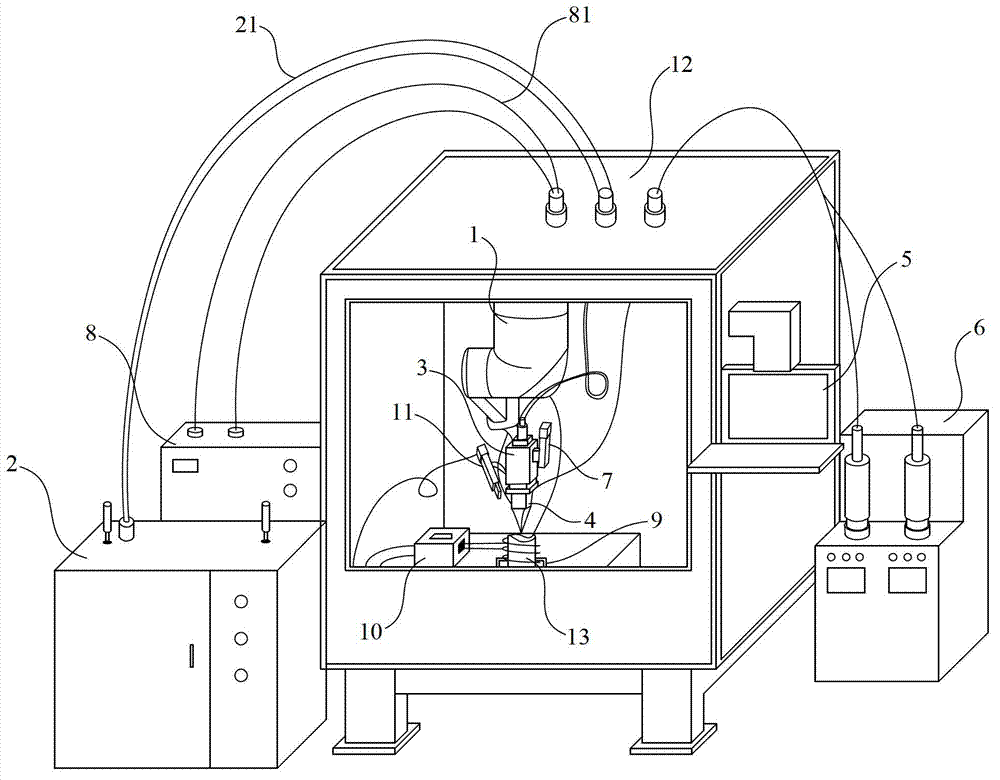

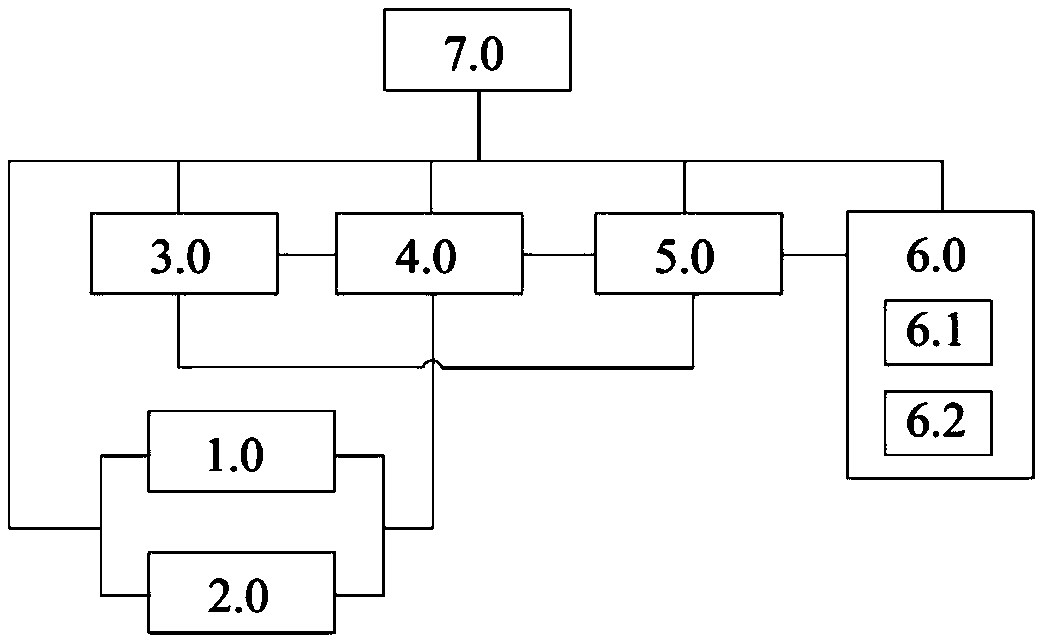

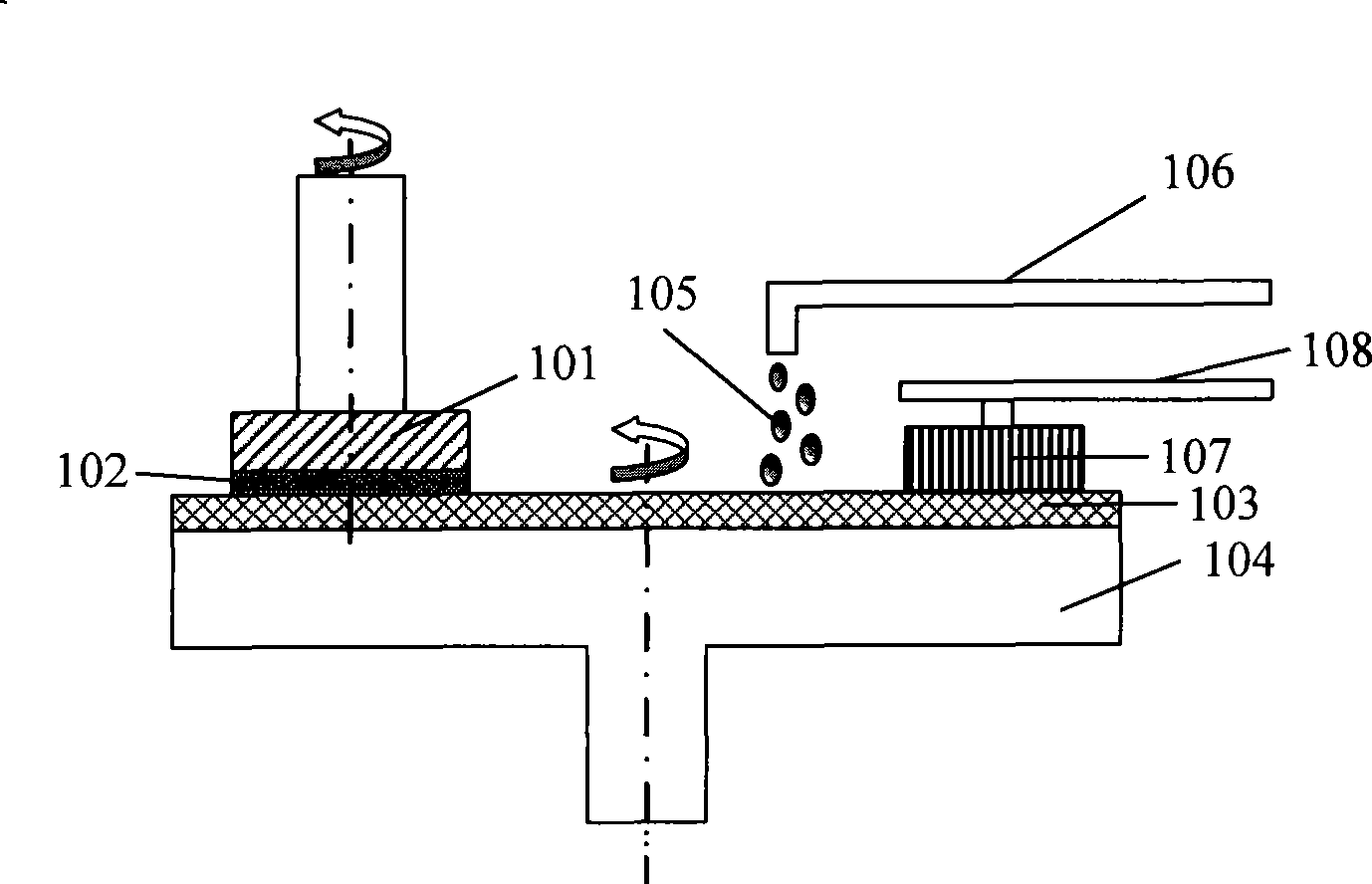

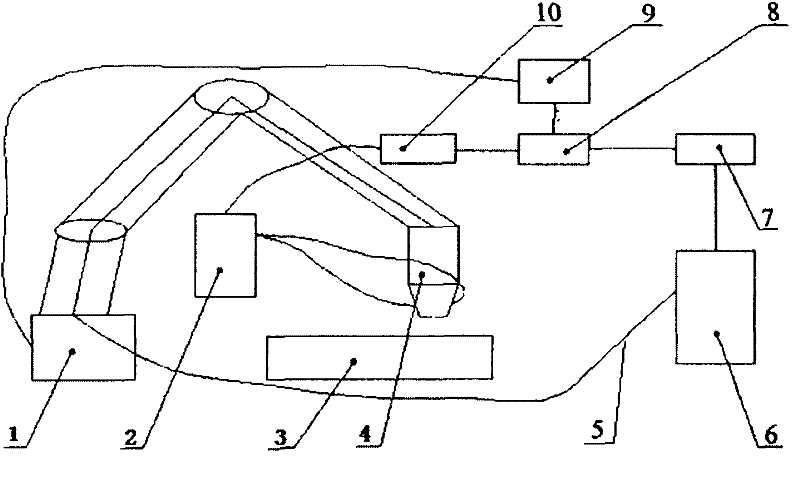

Net shape repairing system

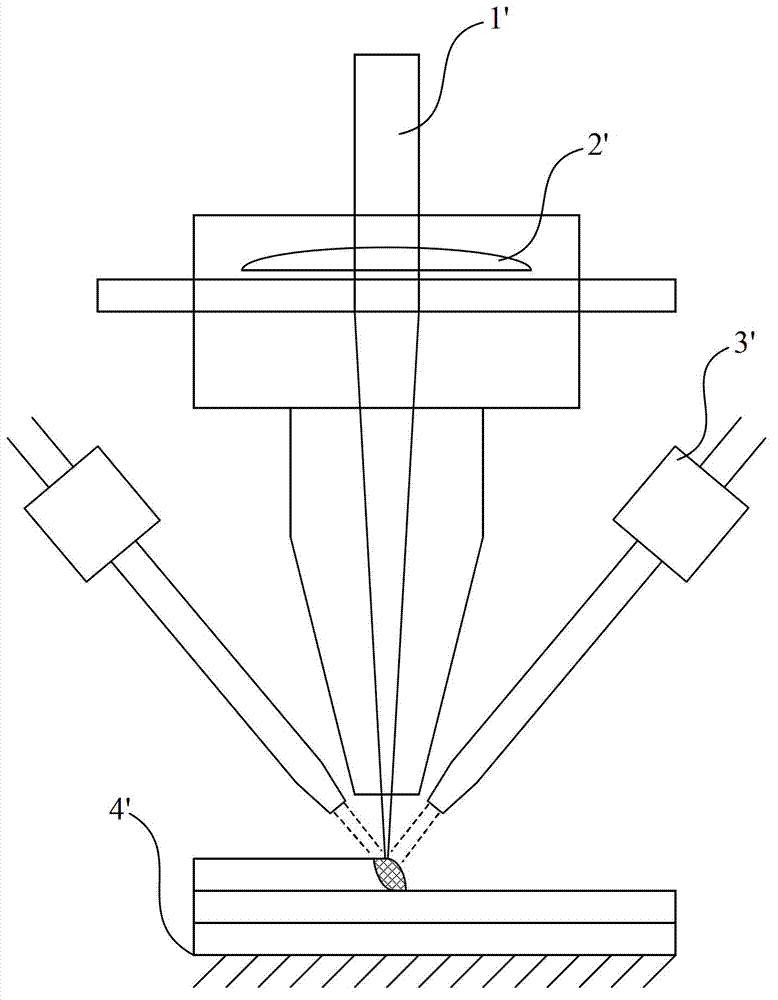

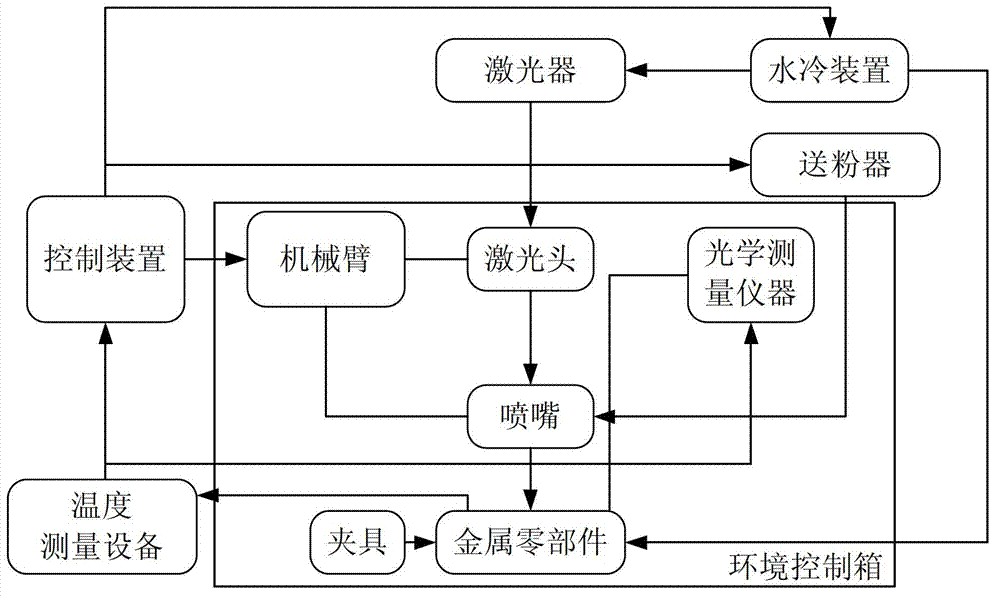

InactiveCN102922139AImprove repair efficiencyImprove restoration qualityMetallic material coating processesLaser beam welding apparatusMeasuring instrumentOptical measurements

The invention provides a net shape repairing system, which is used for repairing a high-performance material metal part. The net shape repairing system comprises a mechanical arm, a laser device, a laser head, a nozzle, a control device, a powder feeding device and an optical measuring instrument; the net shape repairing system utilizes the optical measuring instrument to measure a shape position of the metal part and transmits position information to the control device; and the control device calculates again to obtain a repairing path so as to control laser machining parameters and the mechanical arm in real time to automatically drive the laser head and the nozzle to carry out the repairing work on the metal part along the path; and the optical measuring instrument and the control device in the system are used so that the repairing efficiency and the repairing quality of the metal part of the system are greatly improved.

Owner:上海彩石激光科技有限公司

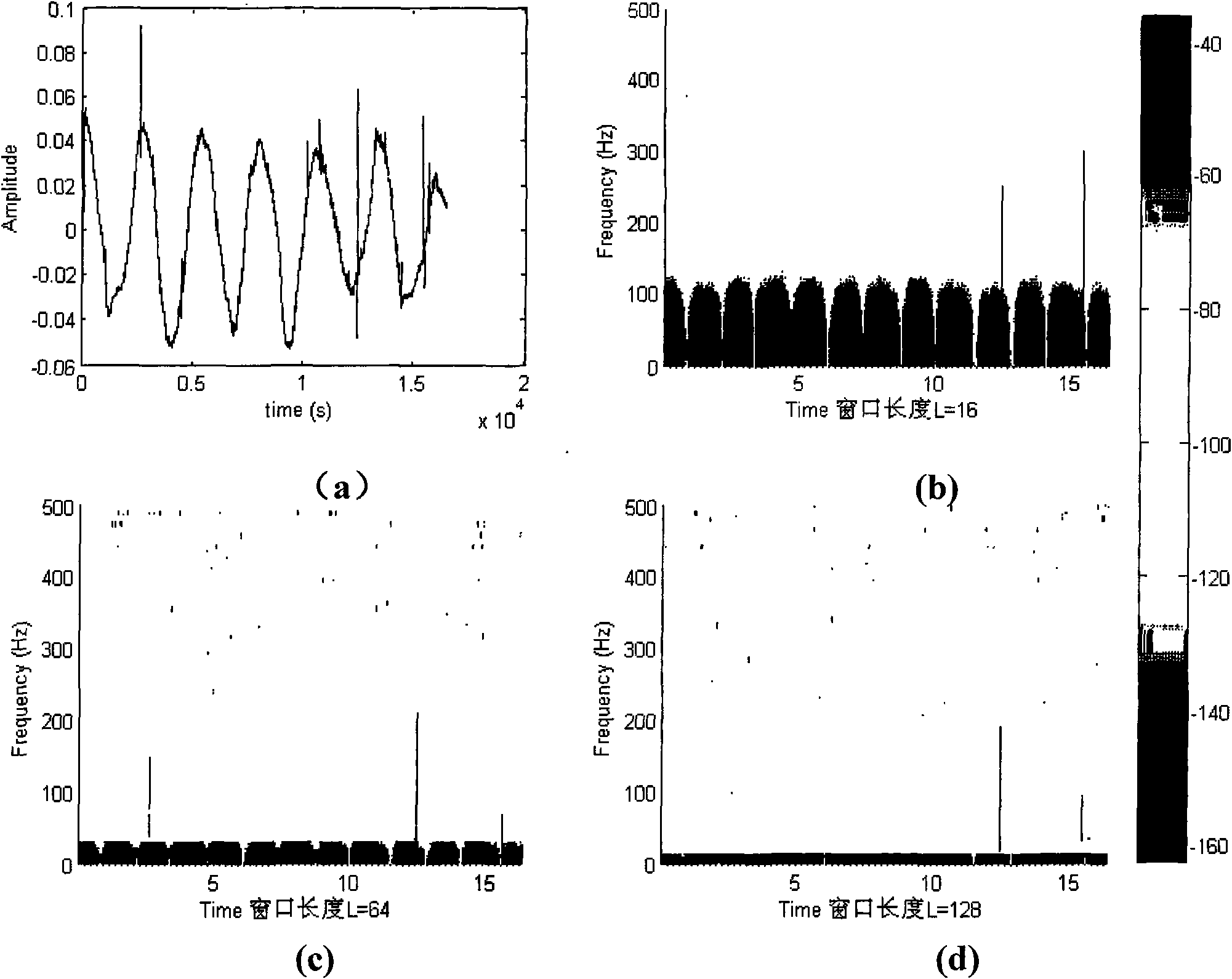

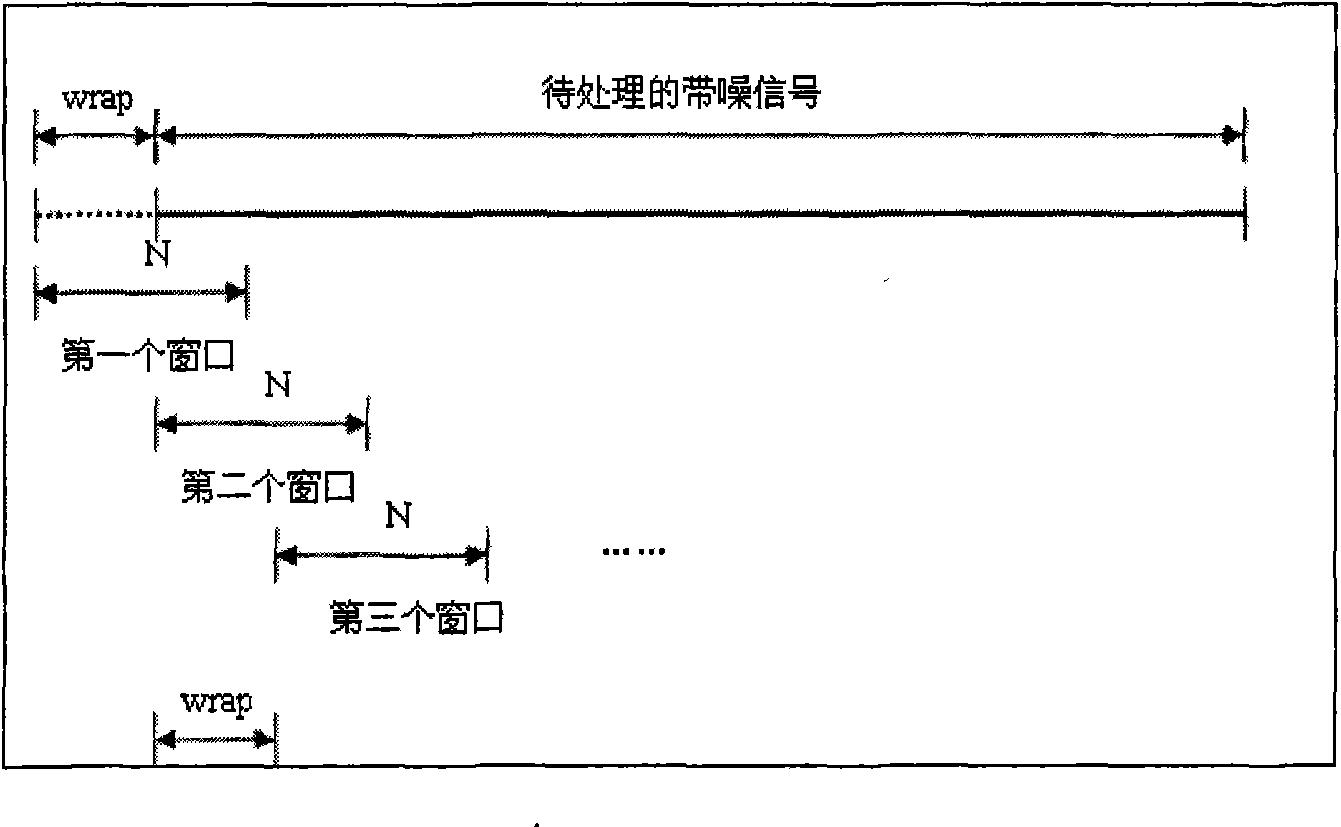

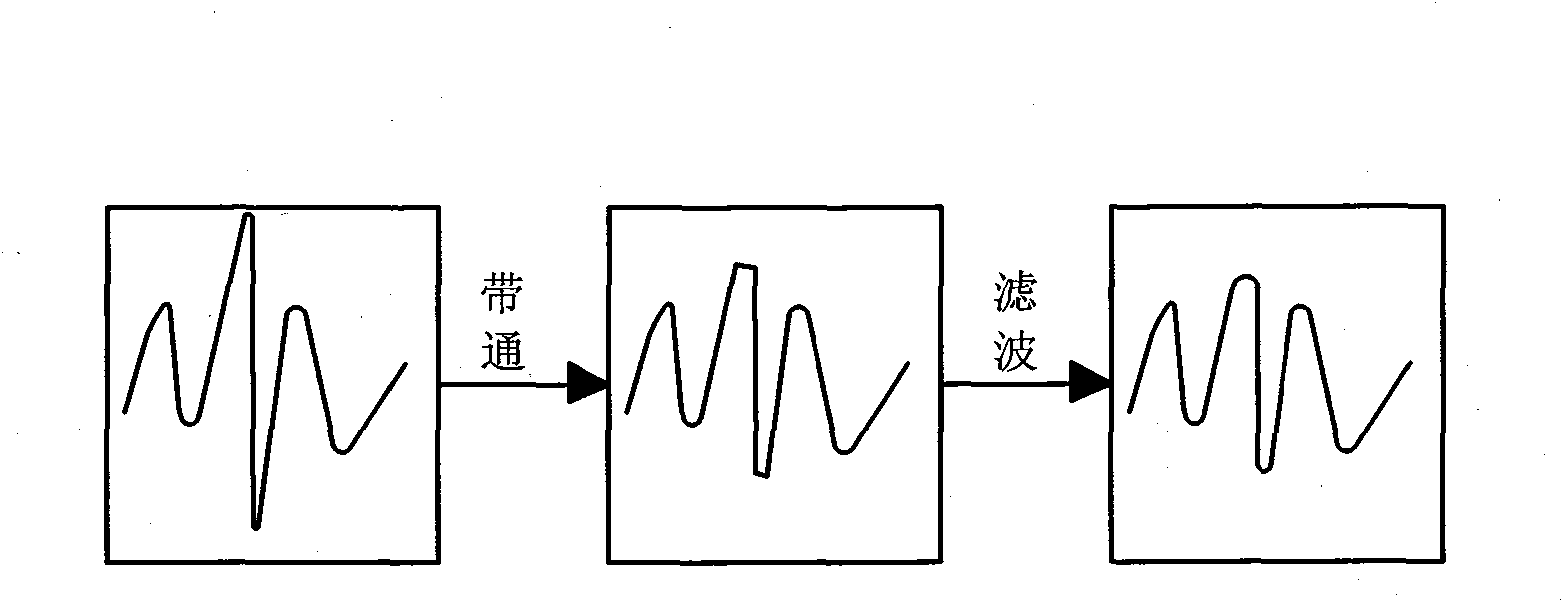

Historical voice frequency noise detection and elimination method

InactiveCN101882442AImprove restoration qualityReduce FRPSpeech analysisFrequency spectrumPhase noise

The invention discloses a historical voice frequency noise detection and elimination method. The existing historical voice frequency noise elimination method has high complexity, depends on the veracity of predicting model coefficients, has a complex algorithm and low efficiency and needs to estimate the statistical property of the noise in advance. The method of the invention comprises: (1) sound modeling: a sound signal can be described with the following method: y(k)=x(k)+j(k)*d(k); (2) short time discrete Fourier transform and spectrogram: an analysis window sliding along time is adopted for windowing and cutting off a non-stable signal so as to decompose the non-stable signal into a series of approximatively stable short signal, and Fourier transform is adopted to analyze the frequency spectrum of each stable short signal; (3) pulse noise detection; (4) pulse noise detection performance analysis; (5) signal repair and reconstruction; and (6) experiment result and analysis. The invention is used for removing the pulse noise in the audio data.

Owner:SHANGHAI CONSERVATORY OF MUSIC +1

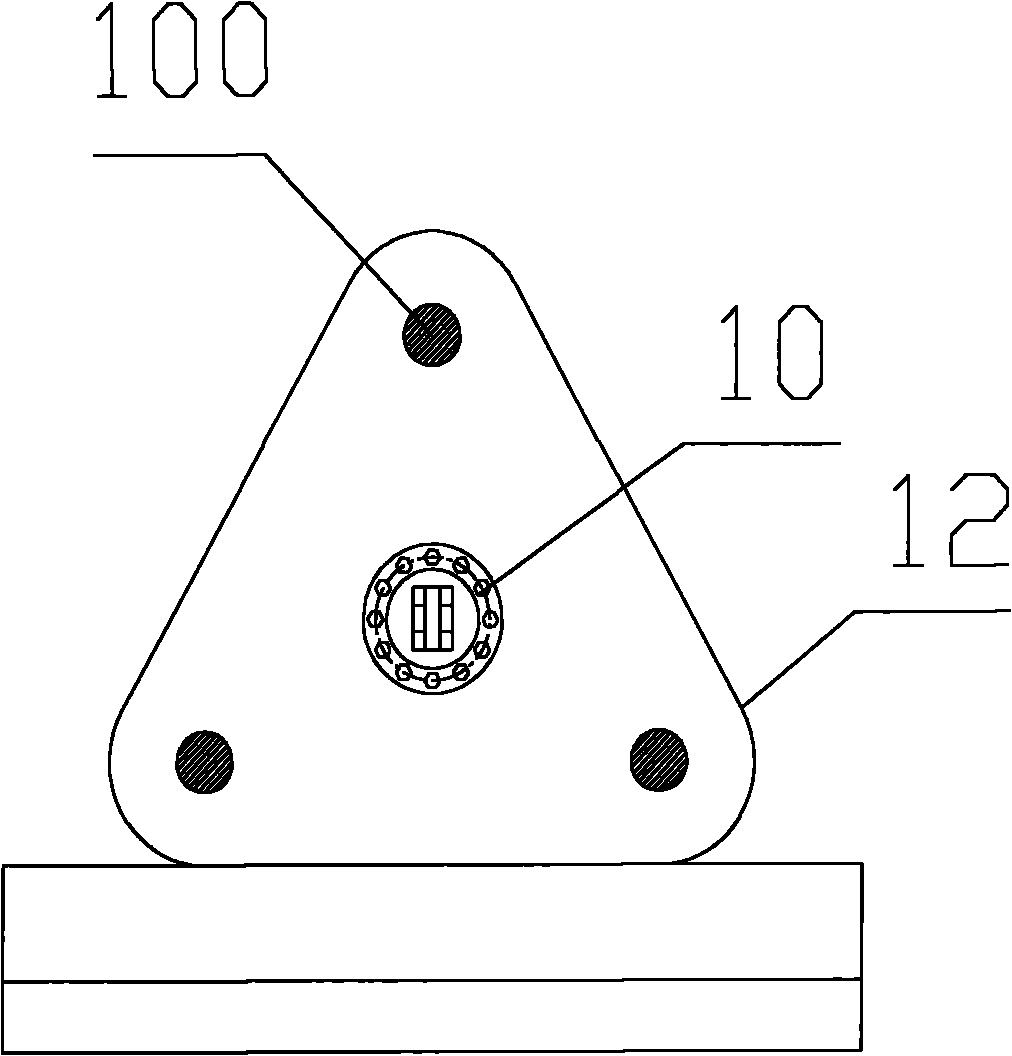

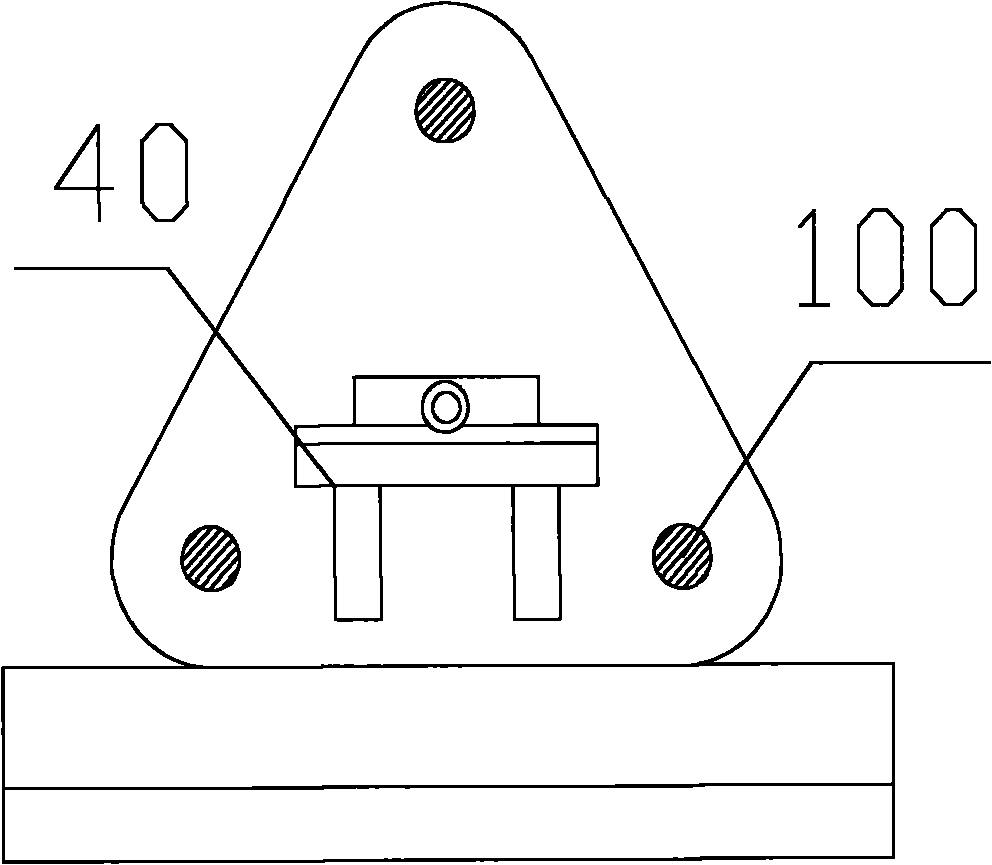

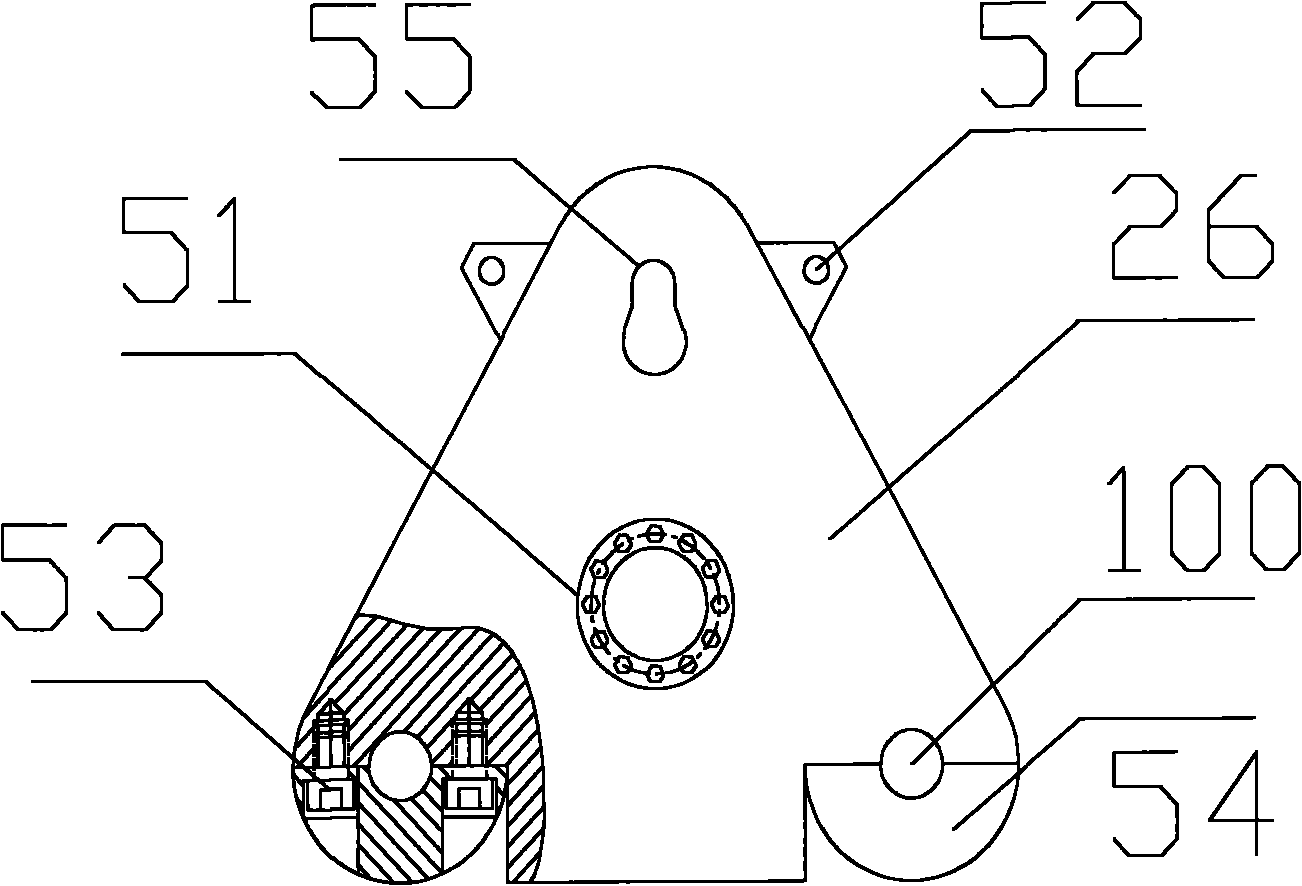

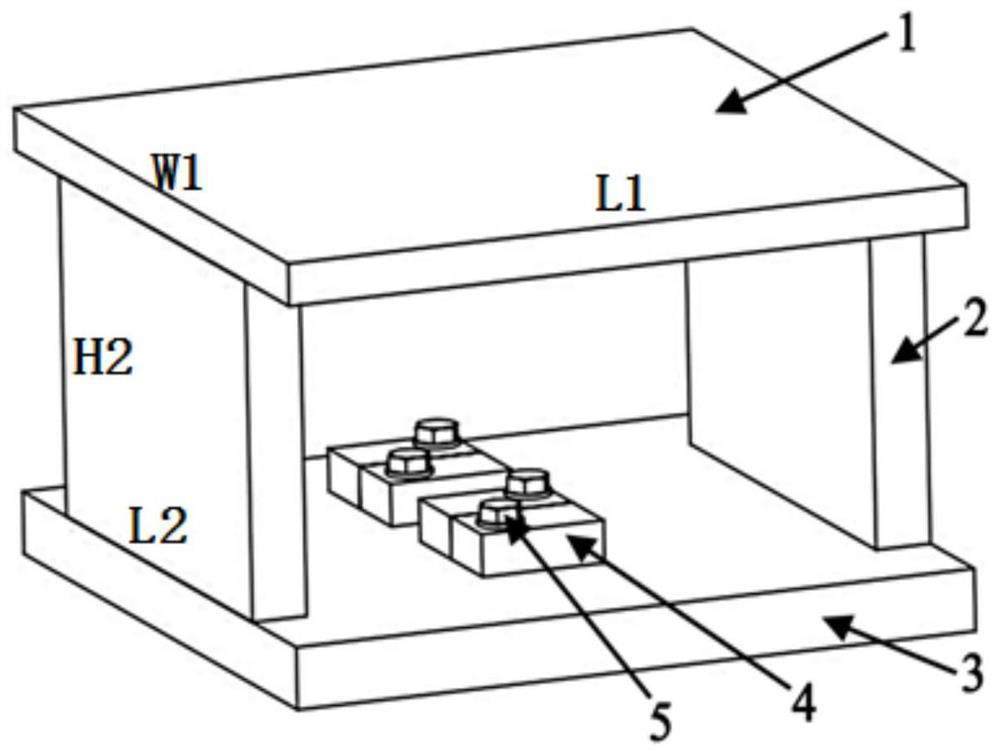

Hydraulic cylinder test device and method under simulated working condition

InactiveCN102252007AAvoid problems such as internal leakageImprove restoration qualityFluid-pressure actuator testingHydraulic cylinderEngineering

The invention relates to a hydraulic cylinder test device and method under a simulated working condition, wherein the hydraulic cylinder test device is provided with a loading oil cylinder hydraulic device, a tested oil cylinder hydraulic device and a triangle frame for the test of the oil cylinder which are connected by hydraulic pipelines. The invention also provides a hydraulic oil cylinder test method under the simulated working condition. The dependence of the hydraulic cylinder test device under the simulated working condition on the technique and experiences of inspectors is reduced, the loading test is carried out at the whole process at any position, and the test pressure can be selected according the actual working condition of the tested oil cylinder; and when in test, if the quality can not be well controlled, after the repaired hydraulic oil cylinder is used on line for a period of time, the external leakage of the hydraulic cylinder can cause serious pollution to the field environment, and simultaneously the great waste of the lubricating oil can be caused, thus the service life is influenced, and once an accident occurs, inestimable loss can be caused.

Owner:NANJING MEISHAN METALLURGY DEV

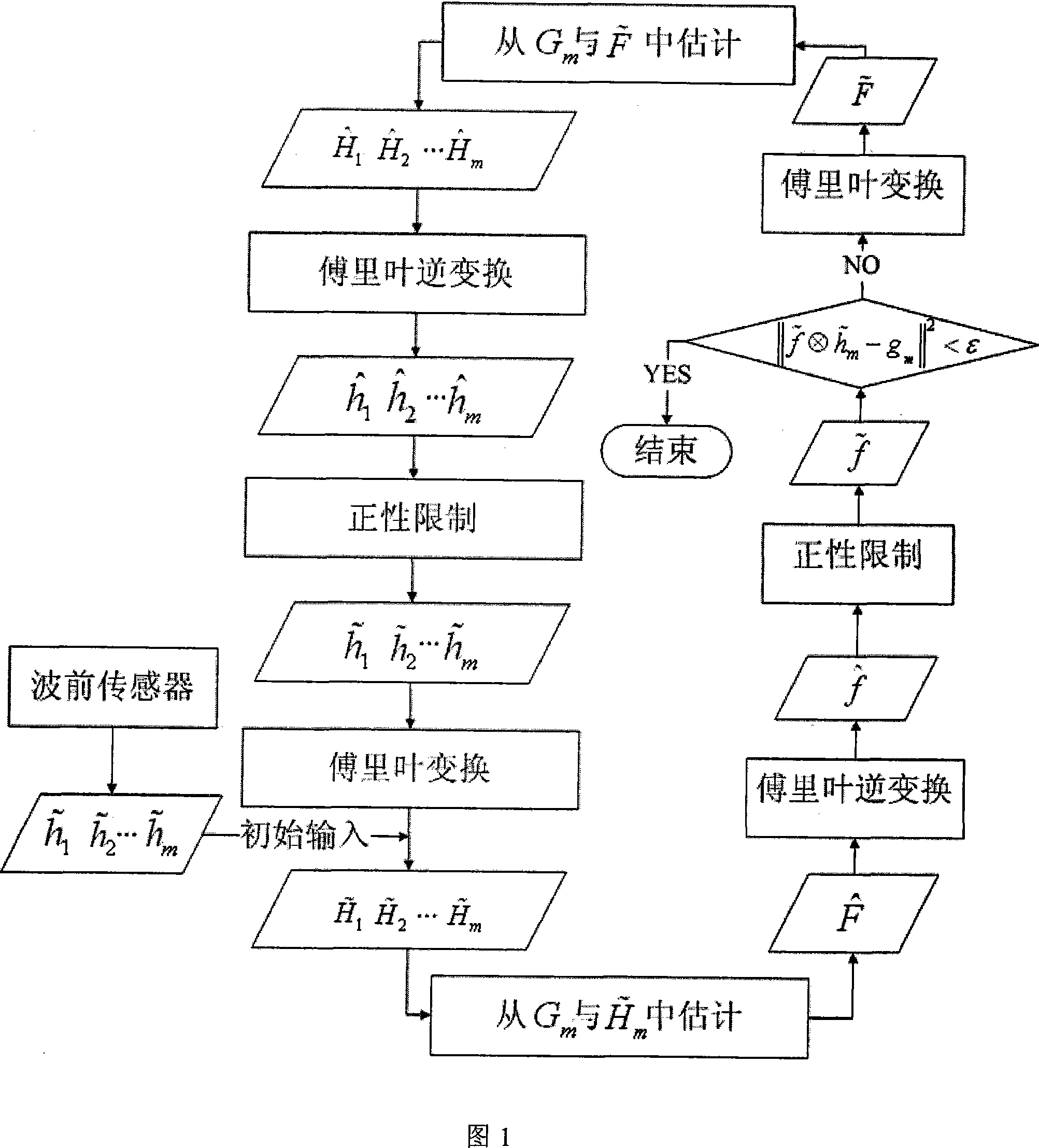

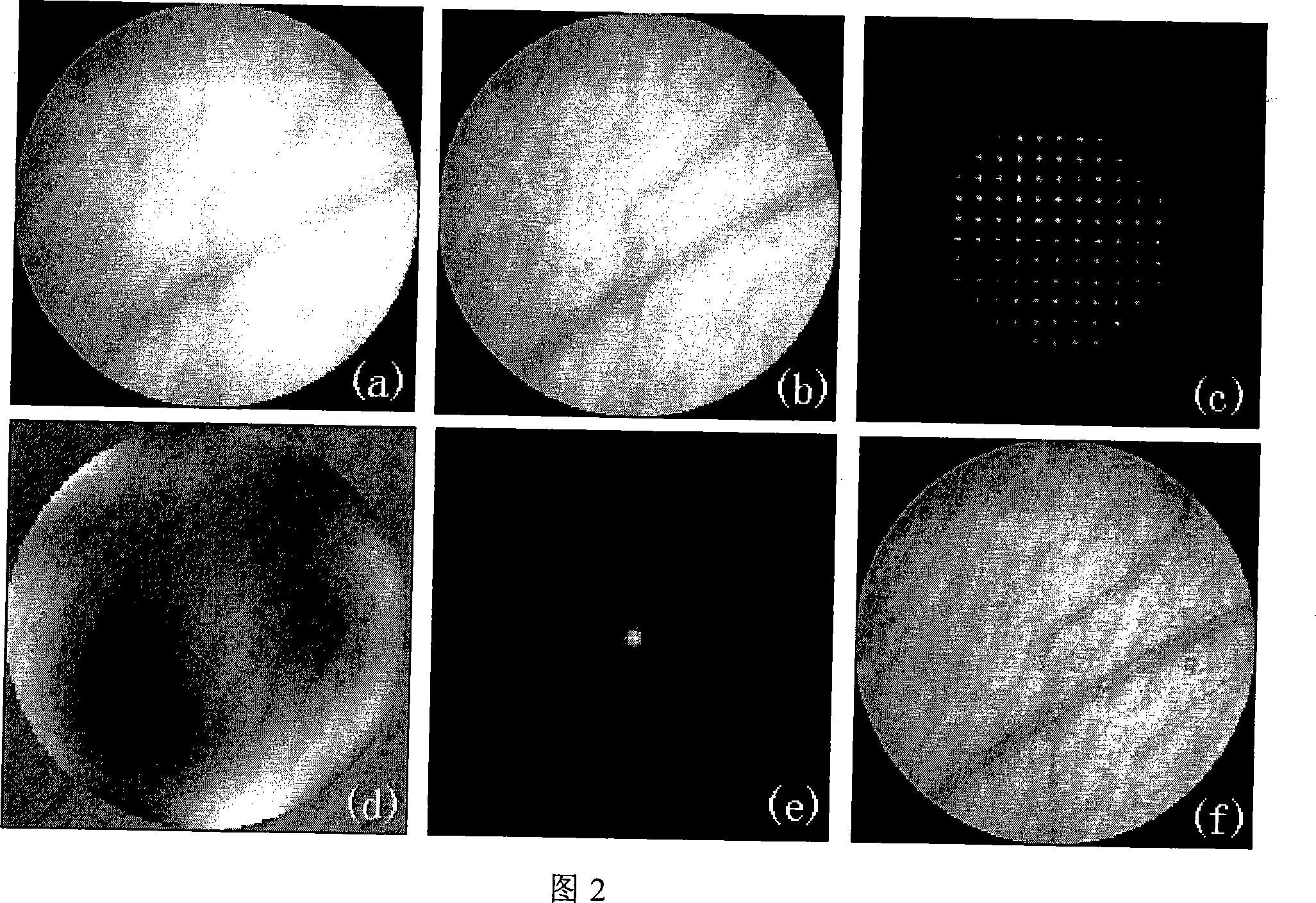

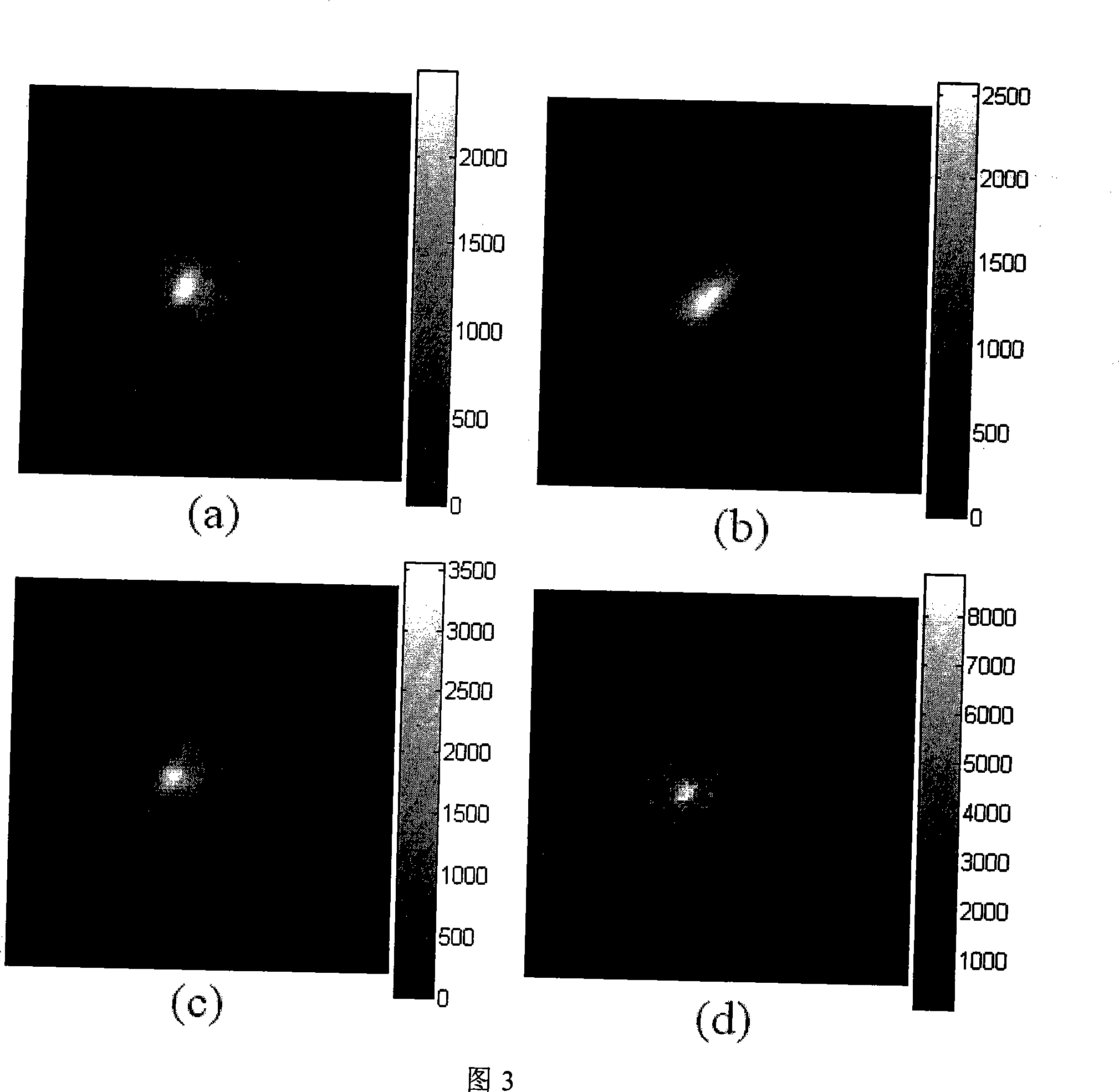

Multi-frame self-adaption optical image high resolution restoration method using wave front data

InactiveCN101206763AEasy to convergeReduce uncertaintyImage enhancementOptical measurementsWavefront sensorDiffusion function

The invention relates to a multiframe self-adaptive optical image high resolution restoration method by utilization of wavefront data, comprising the following steps: firstly, a multiframe short exposure degraded image gm (x, y) and a corresponding slope signal of a wavefront sensor are recorded continuously; secondly, the slope signal is restored into a point spread function hm (x, y) by utilization of wavefront residuals, and the function is taken as a guess starting point; thirdly, an estimated value f(x, y) of a real image is restored by utilization of the short exposure degraded image gm (x, y) and the point spread function hm (x, y), and an estimated value f(x, y) is obtained after addition of positivity limitation on the estimated value f(x, y); fourthly, an estimated value hm (x, y) of the point spread function is obtained by utilization of the short exposure degraded image gm (x, y) and the estimated value f(x, y), and an estimated value h(x, y) is obtained after addition of positivity limitation in the same way; fifthly, iteration stopping conditions are defined, if the iteration stopping conditions are not met, the third step is returned until convergence. The invention has the advantages of quick convergence speed, capability of being adaptive to different degraded images obtained under the condition of wavefront disturbances with different types and degrees, effective compensation of correction capability under hardware limitation of a self-adaptive optical system, and improvement of imaging quality.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

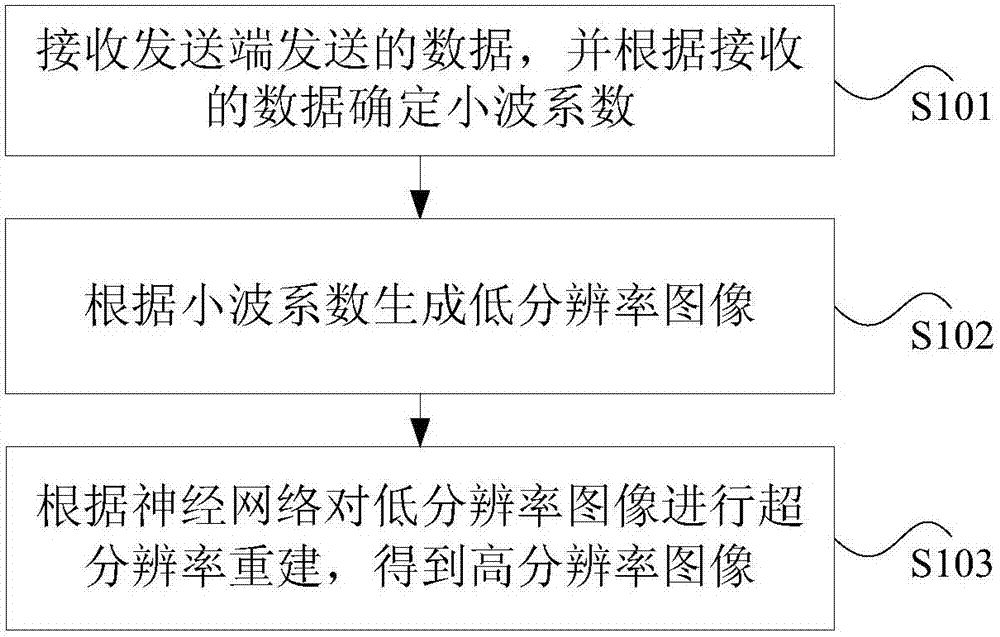

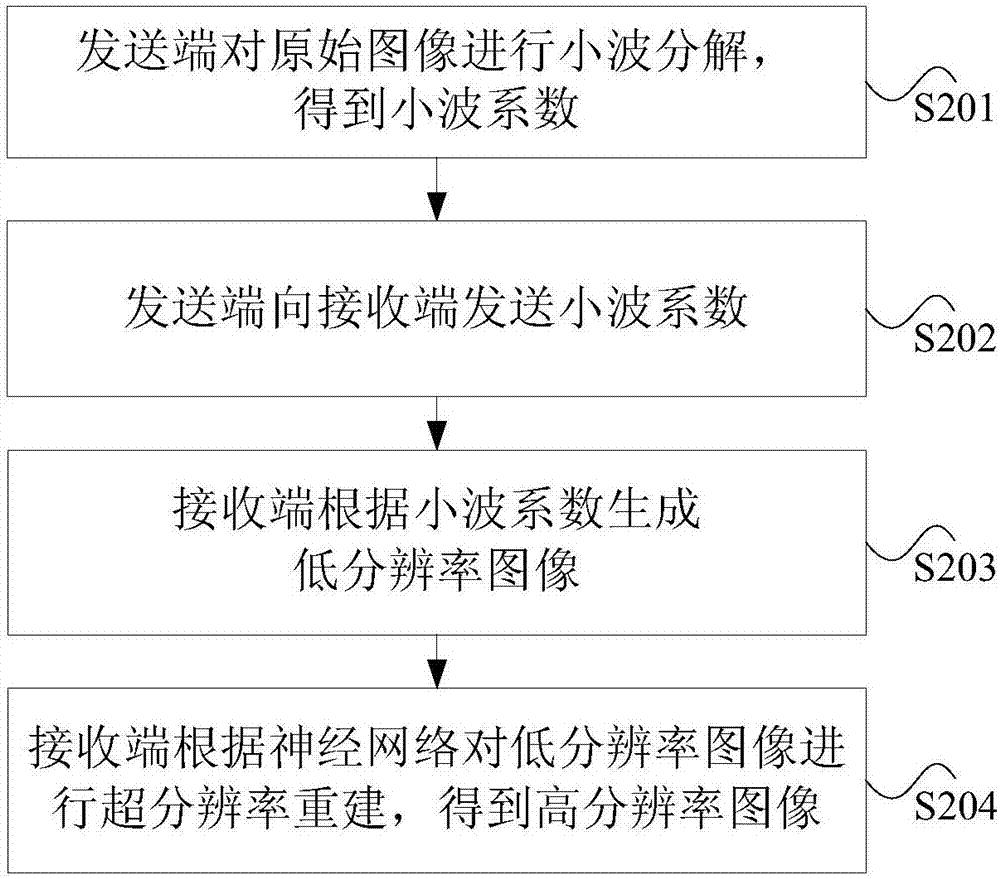

Image processing method and device

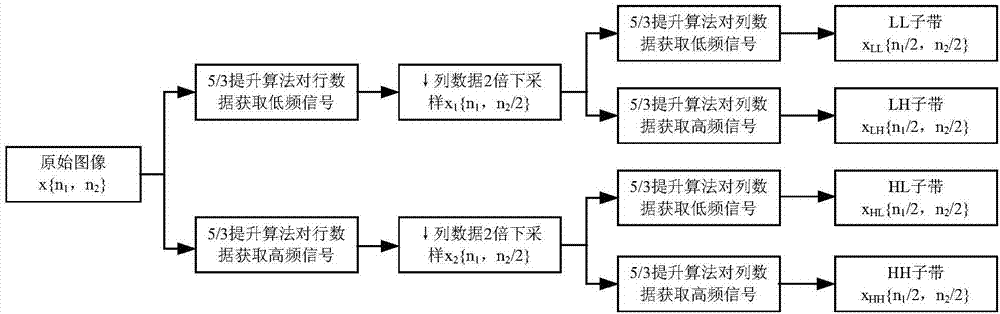

ActiveCN107087201AImprove compression efficiencyHigh Image Restoration QualityDigital video signal modificationSelective content distributionImage compressionImage resolution

The invention discloses an image processing method and device. The method comprises steps of receiving data sent by a sending end, and determining a wavelet coefficient according to the received data, wherein the data sent by the sending end comprises a wavelet coefficient obtained through wavelet decomposition performed on an original image; according to the wavelet coefficient, generating a low-resolution image; and according to a neural network, carrying out ultra-resolution reconstruction on the low-resolution image so as to obtain a high-resolution image. According to the invention, a technical problem of a failure to meet quite high compression efficiency and quite high image restoration quality in an image compression method in the prior art is solved.

Owner:XIAN WANXIANG ELECTRONICS TECH CO LTD

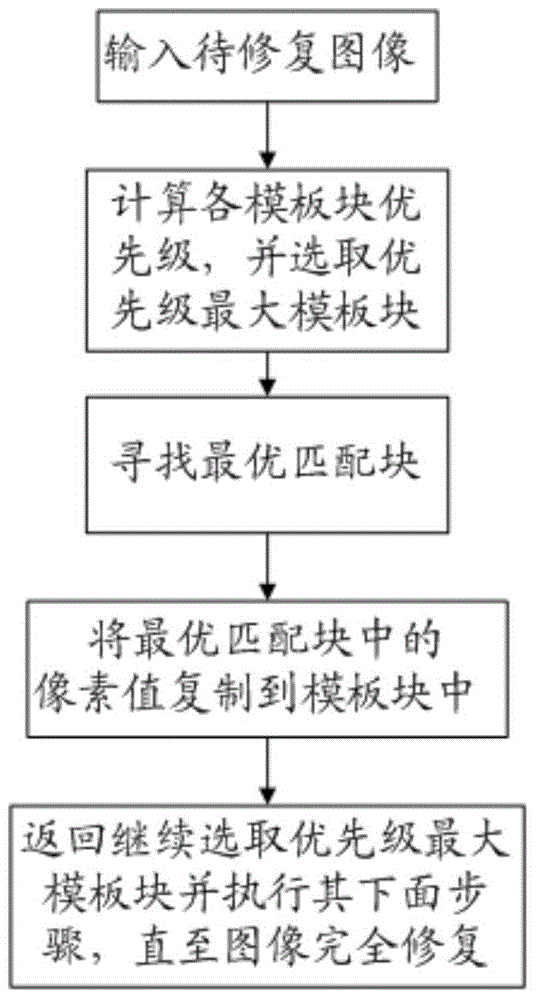

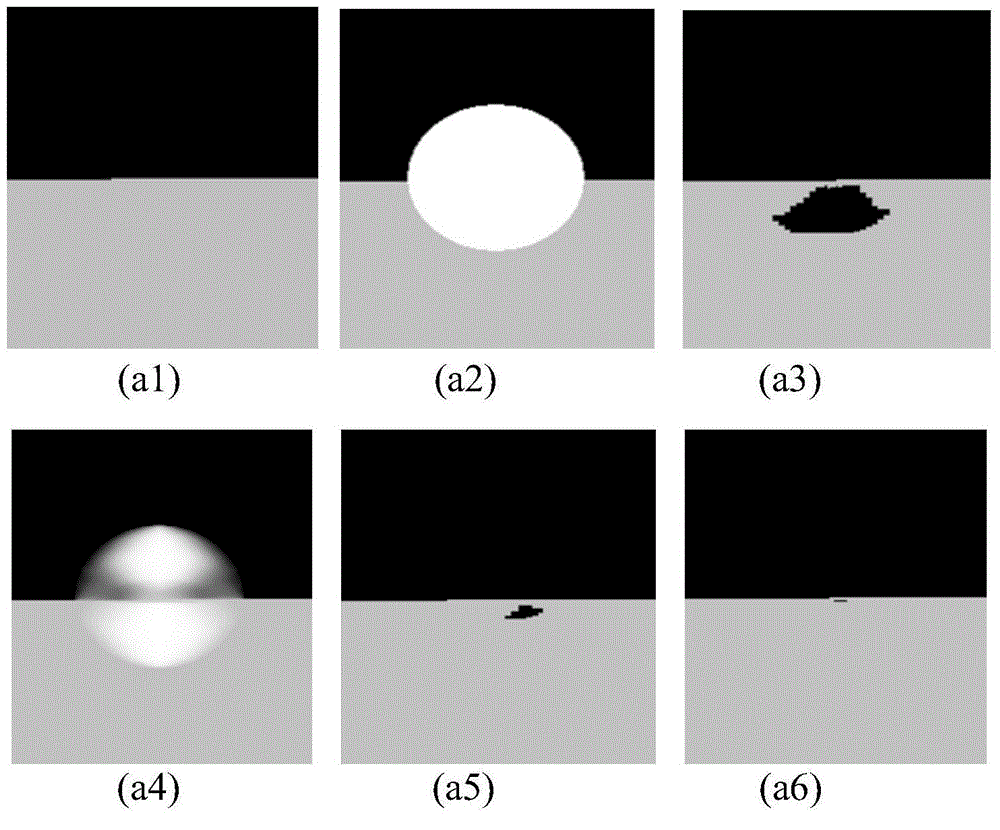

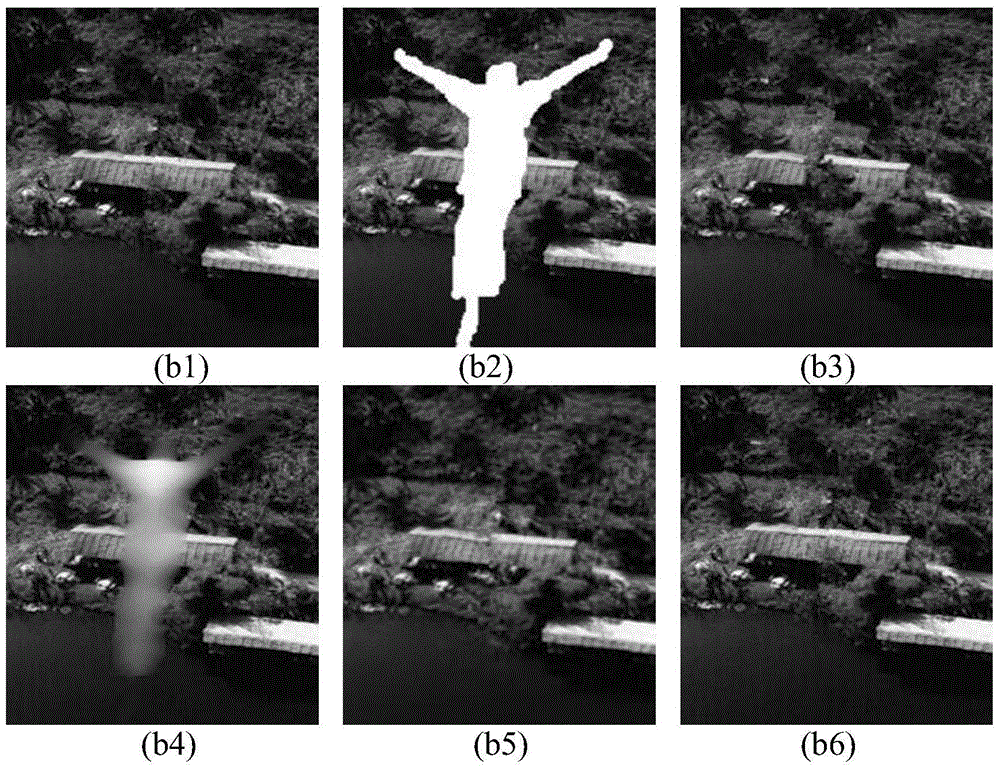

Image synthesis restoration method based on local structure features

InactiveCN104966279AImprove repair accuracyHigh similarityImage enhancementPattern recognitionRestoration method

The present invention relates to an image synthesis restoration method based on local structure features, comprising the following steps: inputting an image to be restored; initializing confidence coefficients of all pixel points in the image to be restored; selecting a template block of each pixel point by respectively taking each pixel point on a damaged boundary of the image to be restored as the center; calculating the priority of the template block where each pixel point on the damaged boundary of the image to be restored locates, and performing descending sort; searching an area which has the highest similarity with the template block having the greatest priority from an undamaged area in the image to be restored to serve as an optimal matching block; copying pixel values in the optimal matching block to the template block; and updating the confidence coefficients and returning to execute corresponding steps until the image to be restored is completely restored. The image synthesis restoration method based on local structure features provided in the present invention can improve image restoration accuracy for a damaged image with a complicated texture structure. The present invention also relates to an image synthesis restoration system based on local structure features.

Owner:LUDONG UNIVERSITY

Grouting material for repairing timber structure of antique building

The invention discloses a grouting material for repairing a timber structure of an antique building. By using the grouting material, defects of a timber component of an antique building can be repaired by grouting consolidation in a situation that a roof support does not need to be pulled down in the repairing process of the timber structure, and simultaneously internal deinsectization and anti-corrosive treatment can be effectively carried out on a worm-eaten timber component. The grouting material for repairing comprises the following components in parts by weight: 100 parts of 65% aqueous epoxy resin solution, 100-200 parts of aqueous epoxy resin curing agent, 200-600 parts of water, 800-2000 parts of cement, 1500-3000 parts of sand, 50-200 parts of water soluble wood preservative and 0-100 parts of pulverized fuel ash.

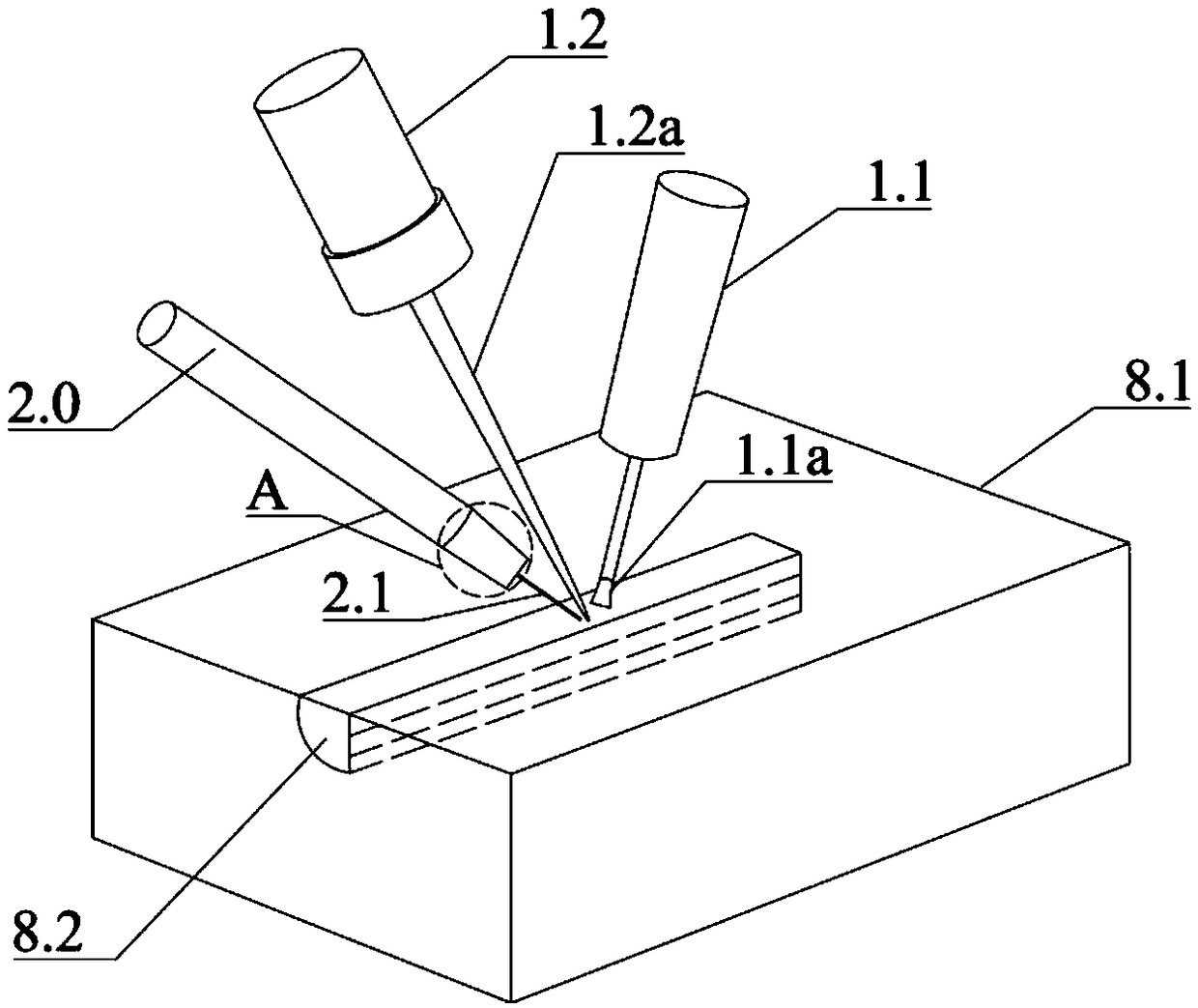

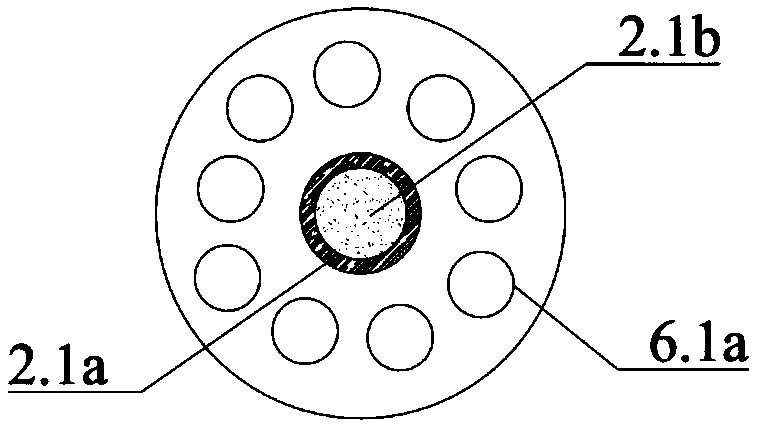

3D printing in-situ repairing system for metal part damage and repairing method thereof

ActiveCN109158599AStructural damage is smallImprove restoration qualityAdditive manufacturing apparatusIncreasing energy efficiencyQuality optimizationEngineering

The invention provides a 3D printing in-situ repairing system for metal part damage and a repairing method thereof. According to the 3D printing in-situ repairing system for metal part damage and therepairing method thereof, rapid in-situ repairment can be carried out on the damage of parts of a high-speed train, the repairing quality is good, and the efficiency is high. The repairing system comprises a mechanical arm, a laser-TIG composite welding gun, a wire feeding device, a space scanning camera shooting device, a printing path design device, an interlayer temperature monitoring device, an interlayer quality control device and a control terminal, wherein the laser-TIG composite welding gun and the wire feeding device are installed at the tail end of the mechanical arm, the space scanning camera shooting device comprises a laser contour scanner for carrying out three-dimensional outline scanning on the defect portions of the parts, the printing path design device is used for acquiring three-dimensional outline data of the defect portions of the parts, setting the layer thickness of a layer to be printed, determining the printing starting point for the layer to be printed and determining the printing path of the layer to be printed, and the interlayer quality control device comprises an interlayer temperature control sub-device and a cladding layer quality optimization sub-device.

Owner:SOUTHWEST JIAOTONG UNIV

Brazing repair method for failures of aeroengine cobalt-based superalloy parts

ActiveCN106493506AReduce scrap rateTroubleshoot such components that cannot be repairedSoldering apparatusAdhesiveSuperalloy

The invention relates to a brazing repair method for failures of aeroengine cobalt-based superalloy parts. The method comprises the following steps: S1, polishing; S2, cleaning; S3, making positioning pieces positioned; S4, filling alloy powder: filling gaps among polishing zones by using the alloy powder which is minus 100 to 325 meshes and mixed with adhesives, wherein the materials of the alloy powder are the same as or similar to the materials of the cobalt-based superalloy parts, and the filling heights exceed 1-5mm of the surfaces of the cobalt-based superalloy parts; S5, filling solders; S6, drying; S7, carrying out vacuum brazing: firstly, rising temperature to 600 to 800 DEG C, carrying out heat preservation for 10-30min, then adjusting the temperature to 1100 to 1180 DEG C, carrying out heat preservation for 1-2h, performing brazing, cooling to the temperature of 800 to 900 DEG C along with a furnace, then filling 800 to 1500-mbar argon and cooling to the temperature of 50 to 100 DEG C, and discharging from the furnace; S8, machining profiles; S9, carrying out post-welding inspection. The brazing repair method for the failures of the aeroengine cobalt-based superalloy parts disclosed by the invention has the advantages of solving the problems of incapability of repairing the parts by using the conventional fusion welding, having a good repairing effect and making the parts being capable of reused to reduce the cost.

Owner:国营川西机器厂

Fractal image compression method based on combination of quad tree and neighborhood searching

InactiveCN102595141AEliminate block effectsImprove restoration qualityTelevision systemsDigital video signal modificationMean squareNeighborhood search

The invention provides a fractal image compression method based on the combination of a quad tree and neighborhood searching. The method comprises the following steps of: setting the maximum and minimum depths of the quad tree and an error threshold value; dividing an image into value region blocks according to the minimum depth; extracting a value region block to be matched; searching for a neighborhood definitional domain block corresponding to the value region block to be matched; calculating affinity, matching the affinity and the value region block, and calculating a mean square error of the affinity and the value region block; comparing the mean square error with the threshold value; if the mean square error is small, recording a current value region block, a current definitional domain block and the affinity; if the mean square error is greater, judging whether the current value region block is the maximum depth or not, recording the current value region block, a definitional domain block with the lowest error, and the affinity if the current value region block is the maximum depth, and if the current value region block is not the maximum depth, dividing the value region block into sub-blocks according to the quad tree as value region blocks to be matched, correspondingly reducing the corresponding definitional domain block, and repeating the matching process; and judging whether all the value region blocks to be matched are matched or not, and if not all the value region blocks to be matched are matched, repeating the matching process. Searching time is shortened, and high image recovery quality is ensured.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

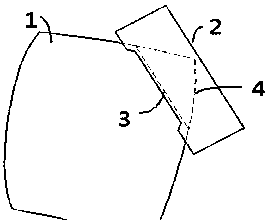

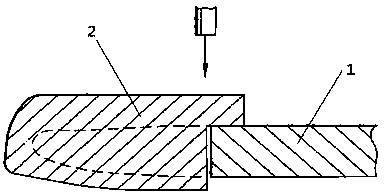

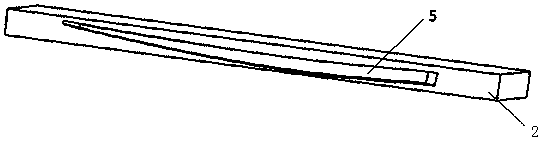

Blade-repairing type repair method of engine blade

The invention relates to a blade-repairing type repair method of an engine blade. The method comprises the steps that a patch is designed according to the cross-section shape of a removed blade, a groove is processed in the patch section, and a welding fixture is designed according to the shape of the patch, and a welding experiment is carried out on a locally simulated blade to obtain the best welding parameters; and the blade to be repaired and the patch are then welded formally. The molded surface of the groove corresponds to the upper and lower surfaces of the blade, and full-cover and half-cover grooves can be used to form an equal-thickness curved seam. The blade-repairing type repair method of the engine blade simplifies the welding process for forming a welded joint and prevents defects and deformation of the front and rear edges, the welded joint form is applicable to other welding methods, such as argon arc welding, plasma welding, laser welding and the like, the repair costcan be greatly reduced, and the welded joint quality and stability are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

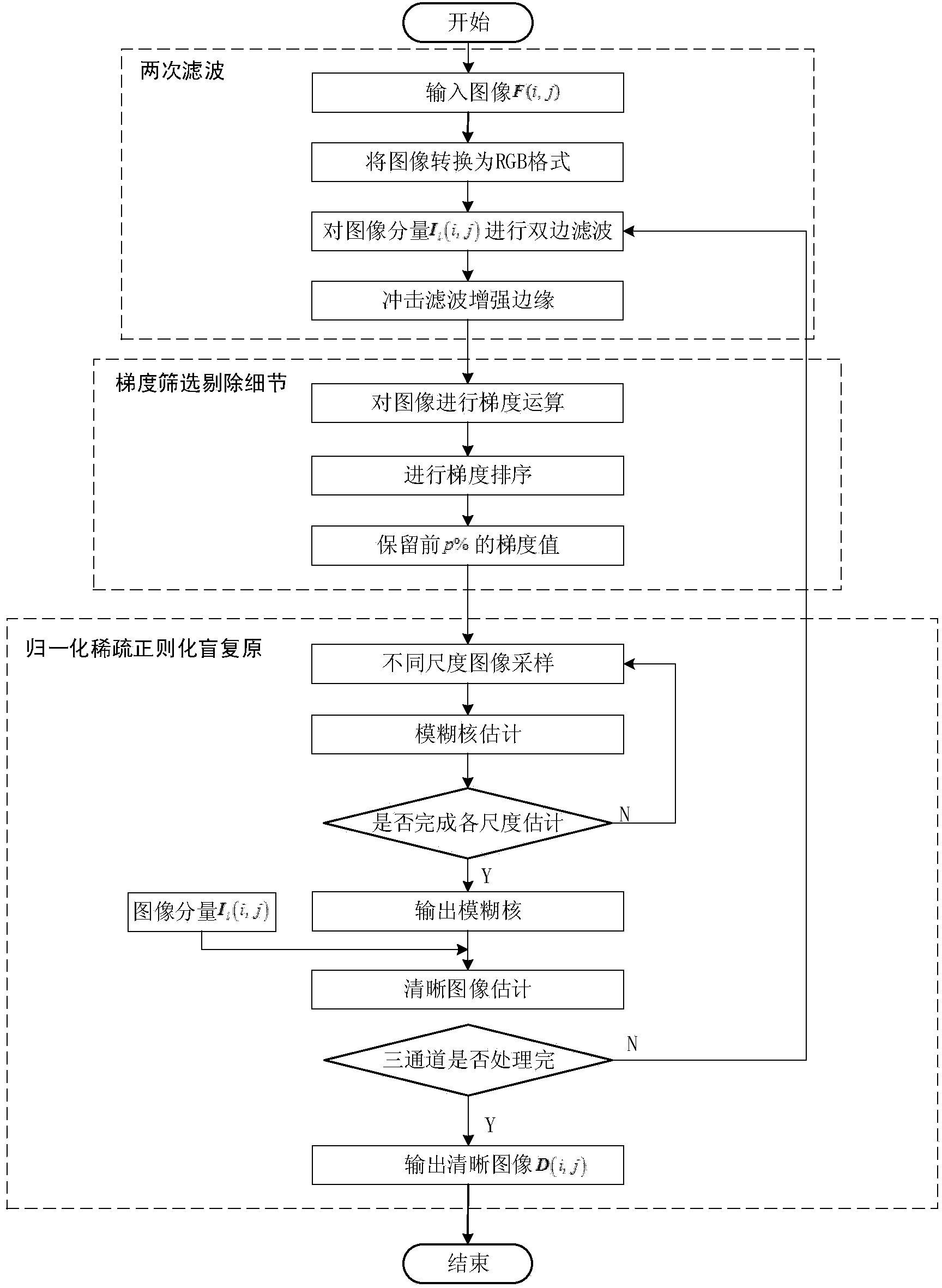

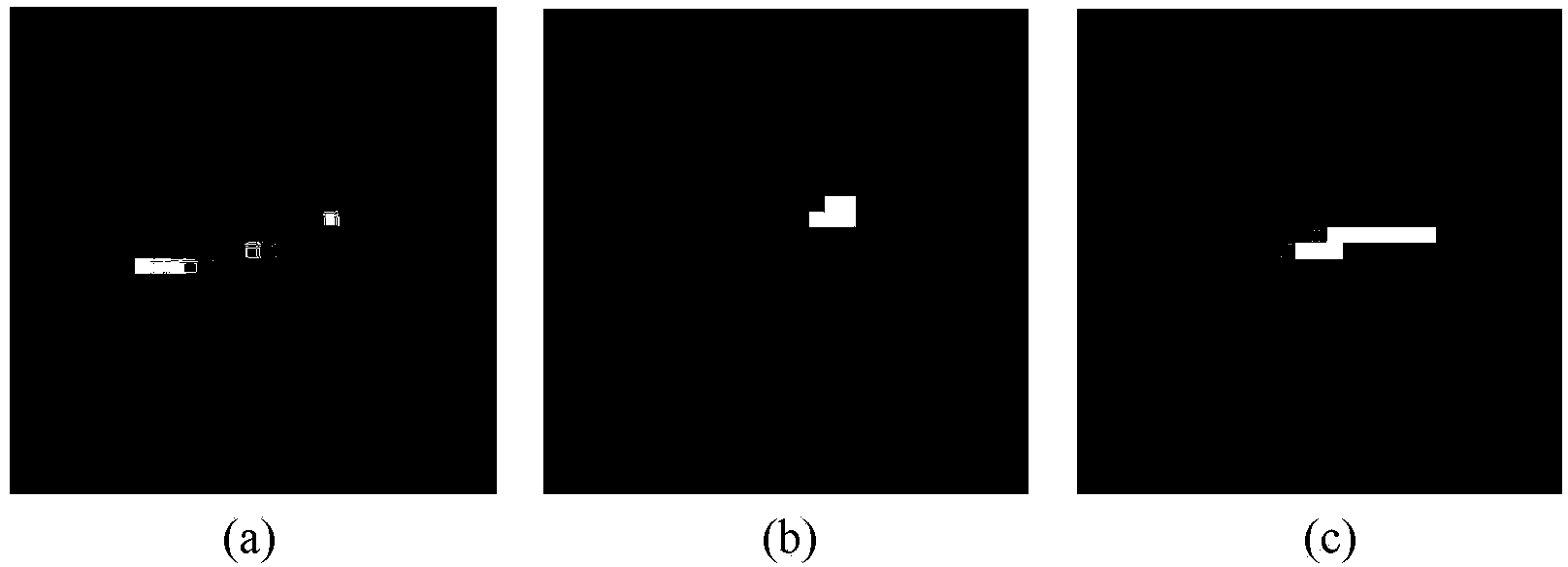

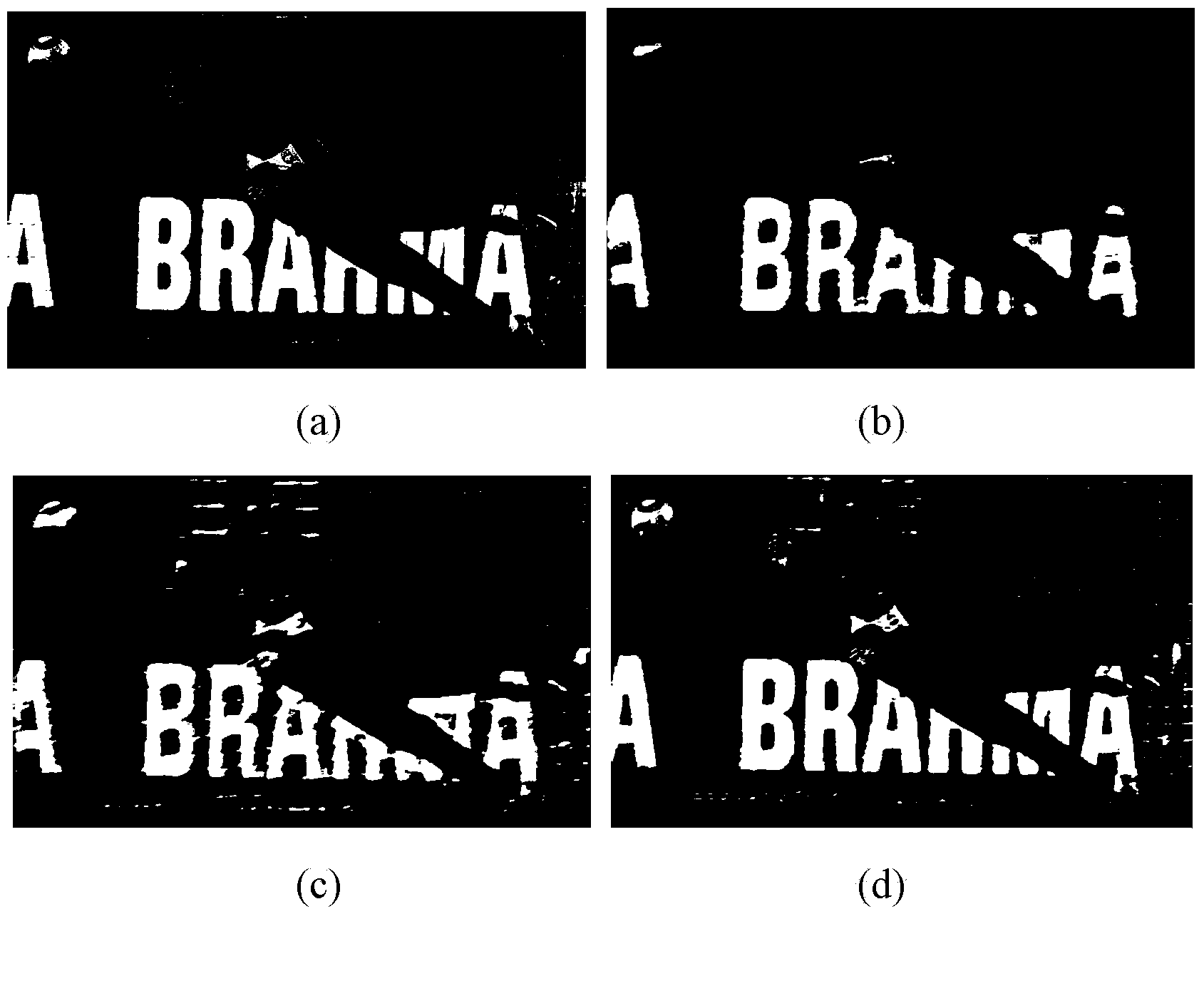

Digital blurred image blind restoration method based on gradient screening

ActiveCN104282003AEnhance resilienceWide applicabilityImage enhancementVideo monitoringRestoration method

The invention provides a digital blurred image blind restoration method based on gradient screening, and belongs to the technical field of image and video processing. The problems that the estimation of blurring kernels of compound movement is not accurate in an existing method, and a priori movement mode is needed are solved, and meanwhile the problem that the restoration effect on images with more details is poor by a normalization sparse regularization blind restoration method is solved. According to the technical scheme, an input image is subjected to bilateral filtering and impact filtering, gradient screening is conducted to get rid of small-gradient amplitude detail information, normalization sparse regularization blind restoration is conducted, and at last a clear image is output. The digital blurred image blind restoration method based on gradient screening can be applied to the fields of civilian photographing and camera shooting, intelligent video monitoring, intelligent security and protection, optical imaging and remote sensing, military imaging reconnaissance, guided missile imaging and guidance and the like.

Owner:HARBIN INST OF TECH

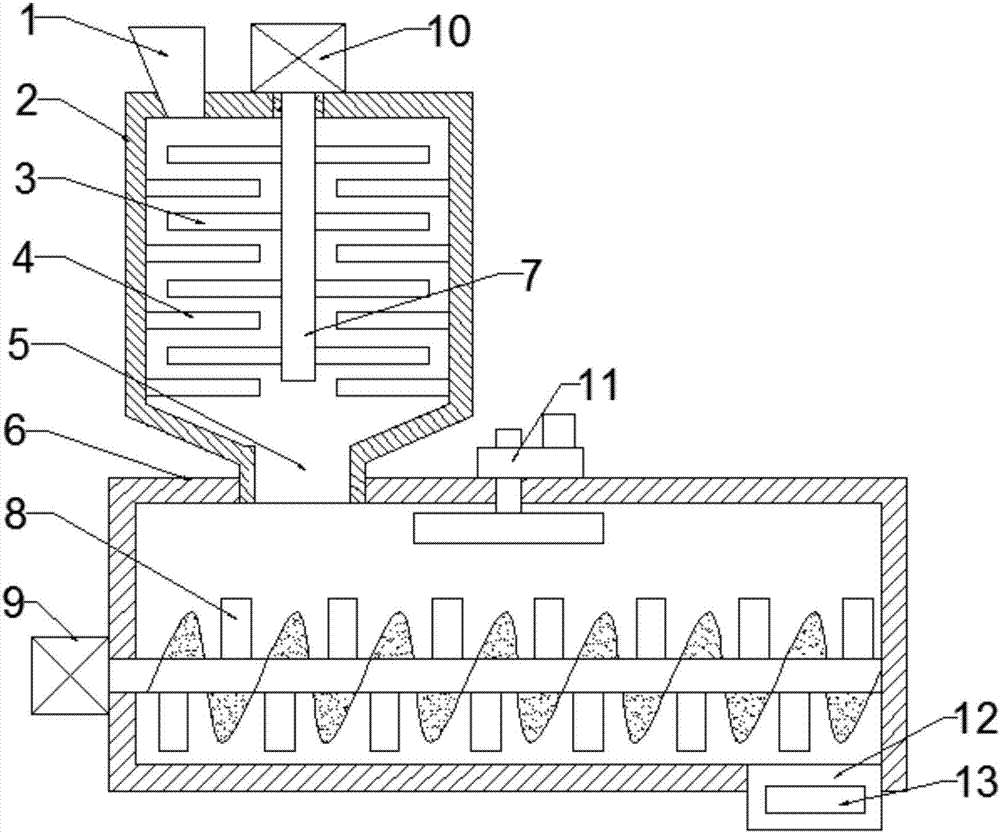

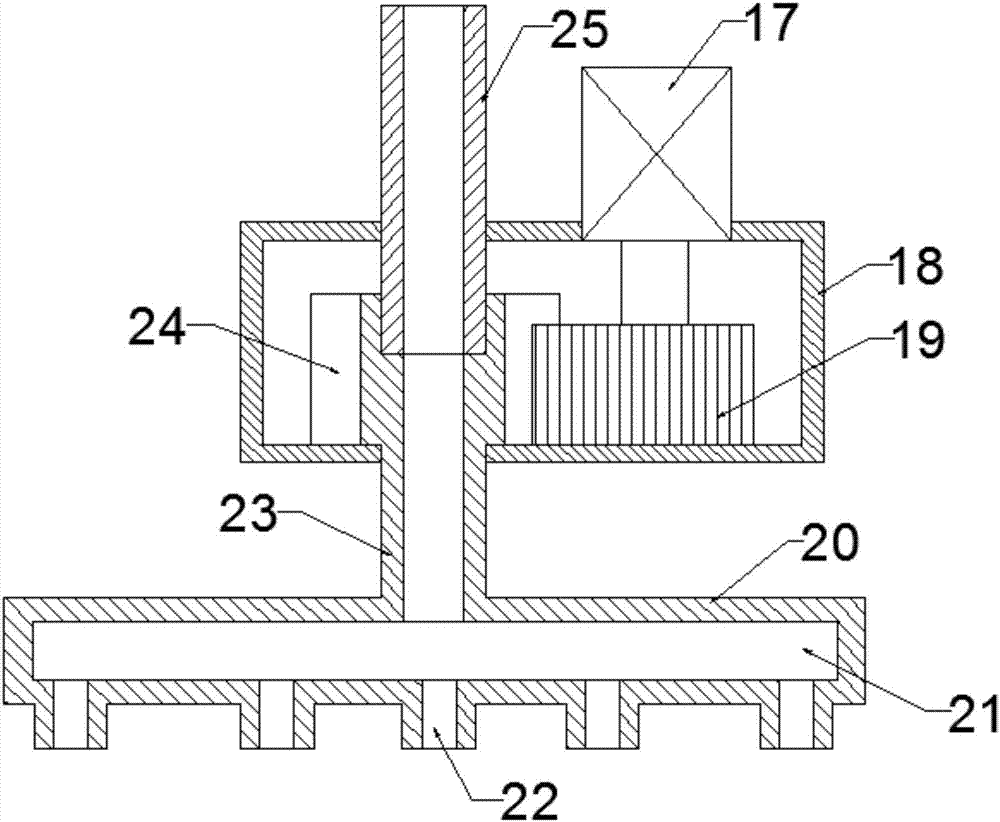

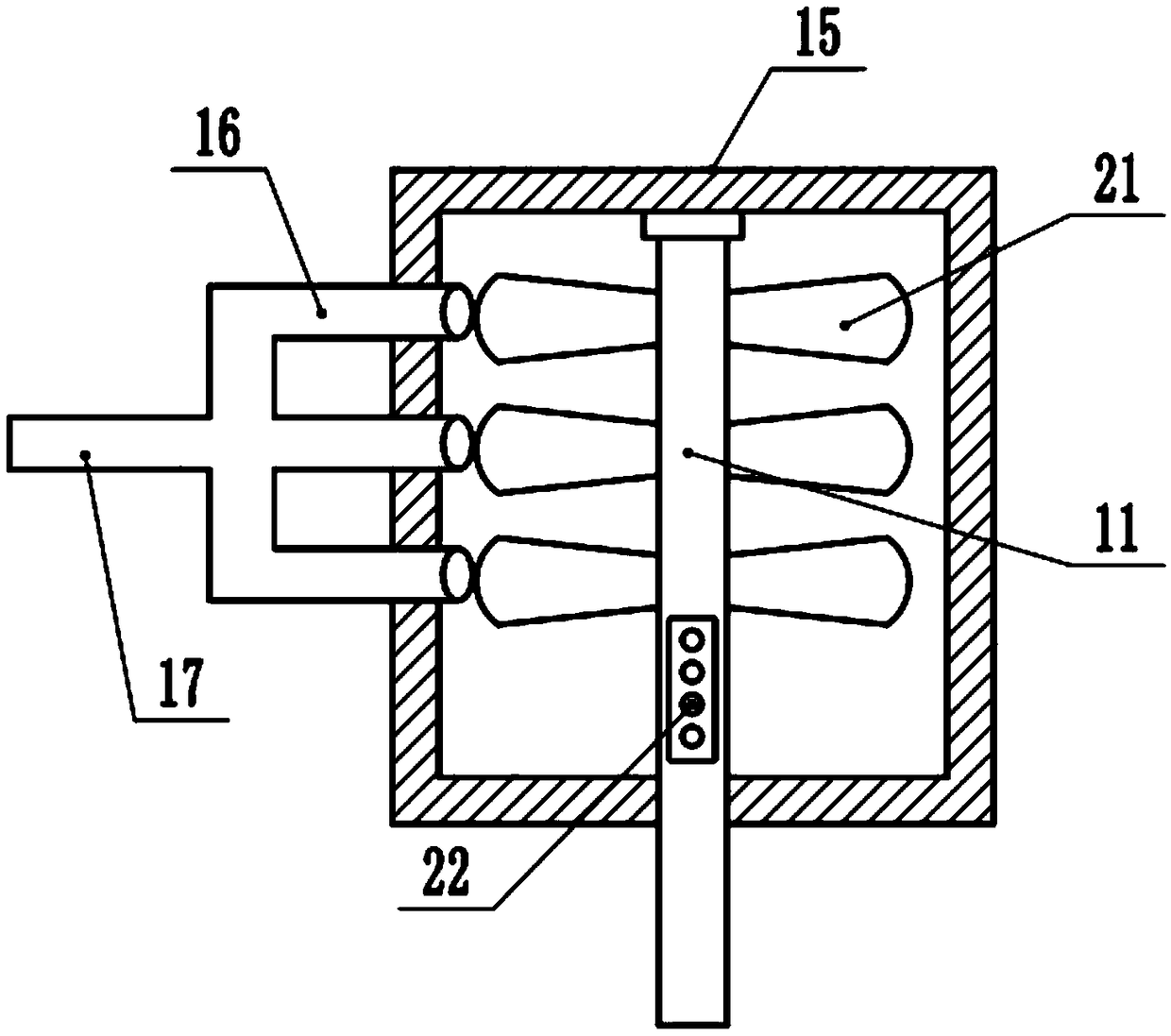

Soil restoration treatment device for garden maintenance

InactiveCN107511395AImprove restoration qualityImprove repair efficiencyContaminated soil reclamationGrain treatmentsSoil remediationElectric machinery

The invention discloses a soil restoration treatment device for garden maintenance and belongs to the technical field of garden maintenance. The soil restoration treatment device comprises a smashing box and a restoration box. A second motor is fixedly arranged on the central line of the top end of the smashing box, and the output shaft of the second motor is connected with a rotating shaft. The rotating shaft is vertically arranged in the smashing box, and rotary blades are arranged on the rotating shaft. Four layers of rotary blades are arranged on the rotating shaft, each layer includes two blades, and the two rotary blades are arranged on the same line. A discharging pipe is arranged at the bottom of the smashing box, and the smashing box is communicated with the restoration box through the discharging pipe. A first motor is fixedly arranged at the left end of the restoration box, and an output shaft off the first motor is connected with a spiral stirring device. The soil restoration treatment device is reasonable in structural design, soil can be fully smashed and stirred, restoration liquid can be evenly sprayed on the soil by arranging a rotary spraying device, and the soil restoration quality is improved.

Owner:邓雨佳

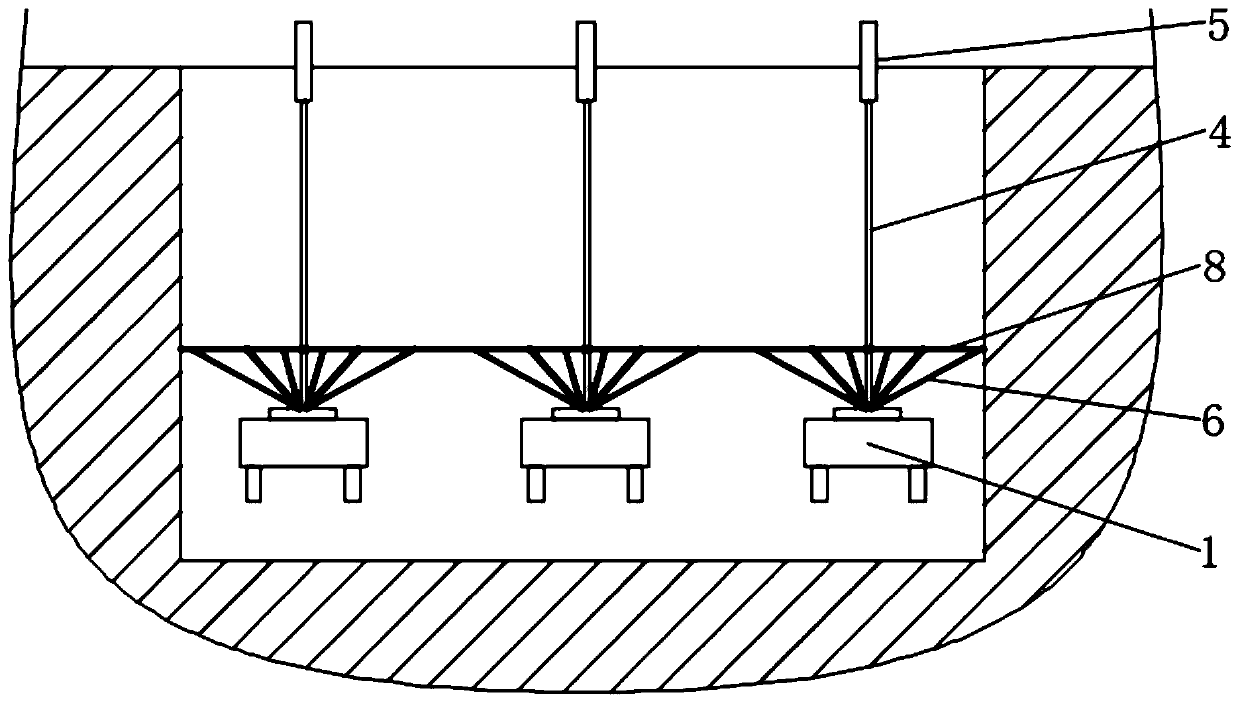

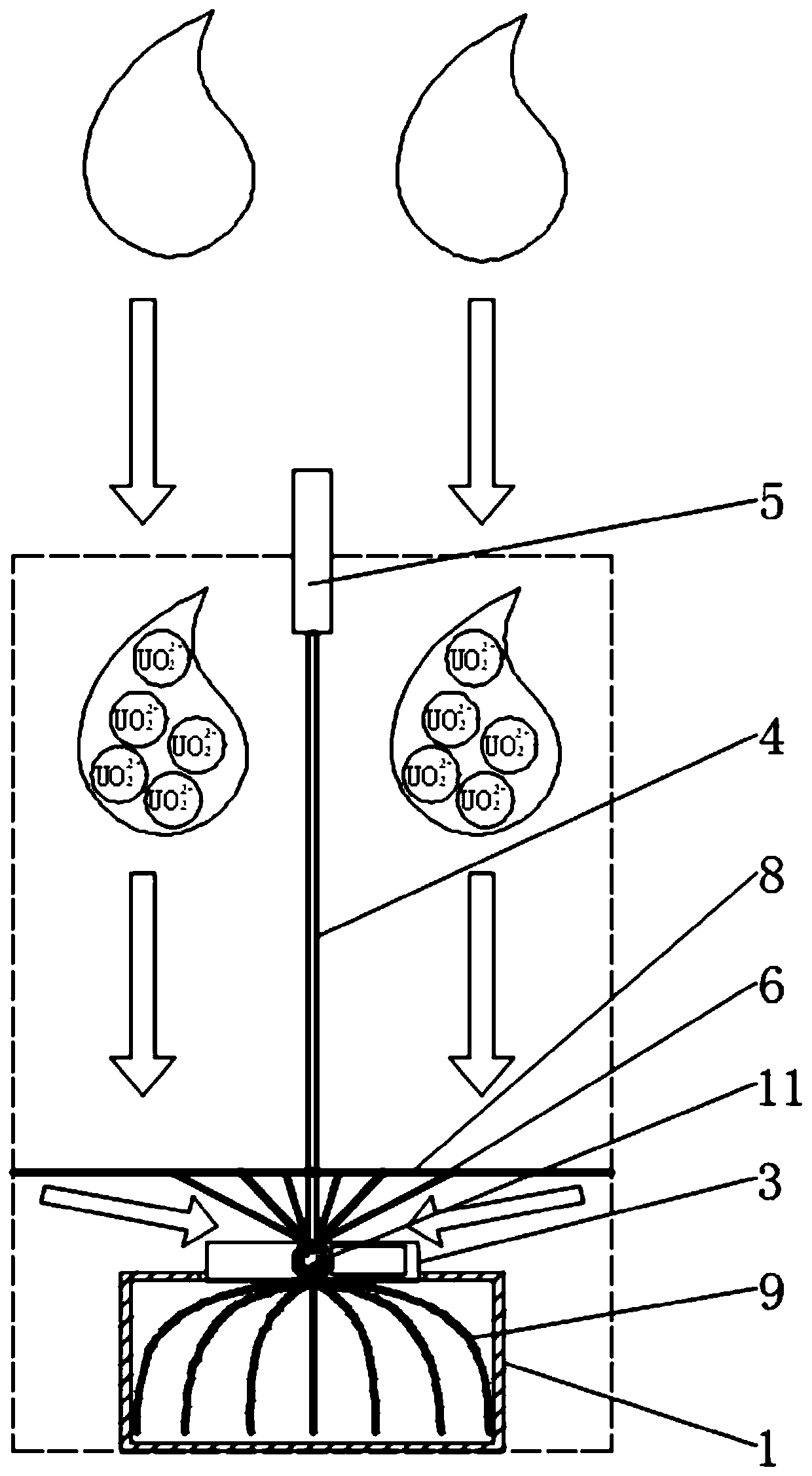

Pre-embedded bag for multi-stage remediation of uranium-contaminated soil and use method thereof

ActiveCN110369481AHigh organic contentImprove fertilityContaminated soil reclamationOrganic fertilisersEngineeringContamination

The invention discloses a pre-embedded bag for multi-stage remediation of uranium-contaminated soil and a use method thereof, and belongs to the technical field of uranium-contaminated soil remediation. The pre-embedded bag for multi-stage remediation of uranium-contaminated soil can be pre-embedded by a soil cleaning and per-embedding manner, on the one hand, uranyl ions in the soil are transferred through a strict water-conducting network, a large amount of uranyl ions are actively and quickly collected into the pre-embedded bag to facilitate fixed-point remediation, on the other hand, a special soil remediation agent is used to greatly improve adsorption and accumulation for uranyl ions, agglomeration of uranyl ions is improved based on nano porous properties, and uranyl ions are filledin micro-pores to avoid contamination and diffusion. After the active primary remediation, uranyl ions in the uranium-contaminated soil are reduced to a certain value, then natural secondary remediation, namely heavy metal uranium enrichment plant remediation, is followed, the soil organic matter content and soil fertility are increased, a soil surface structure is improved and maintained, and asolid foundation for direct use of the soil after uranium pollution remediation is laid.

Owner:绍兴市上虞区武汉理工大学高等研究院

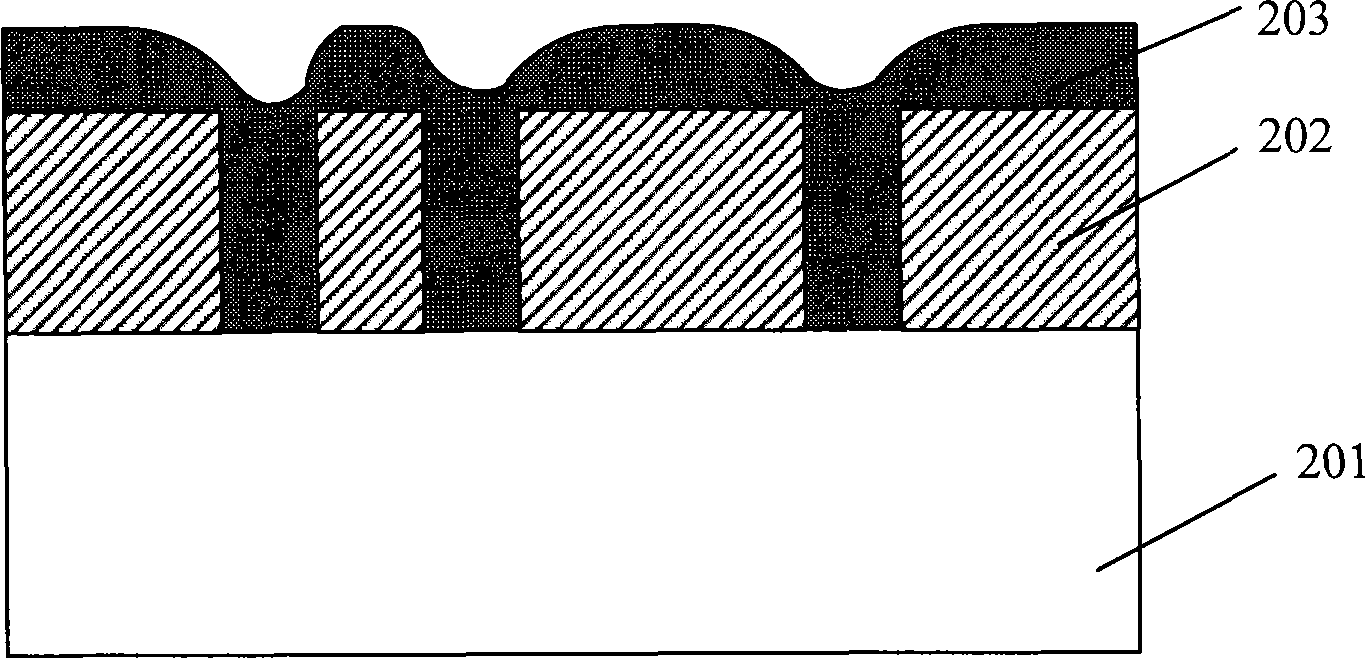

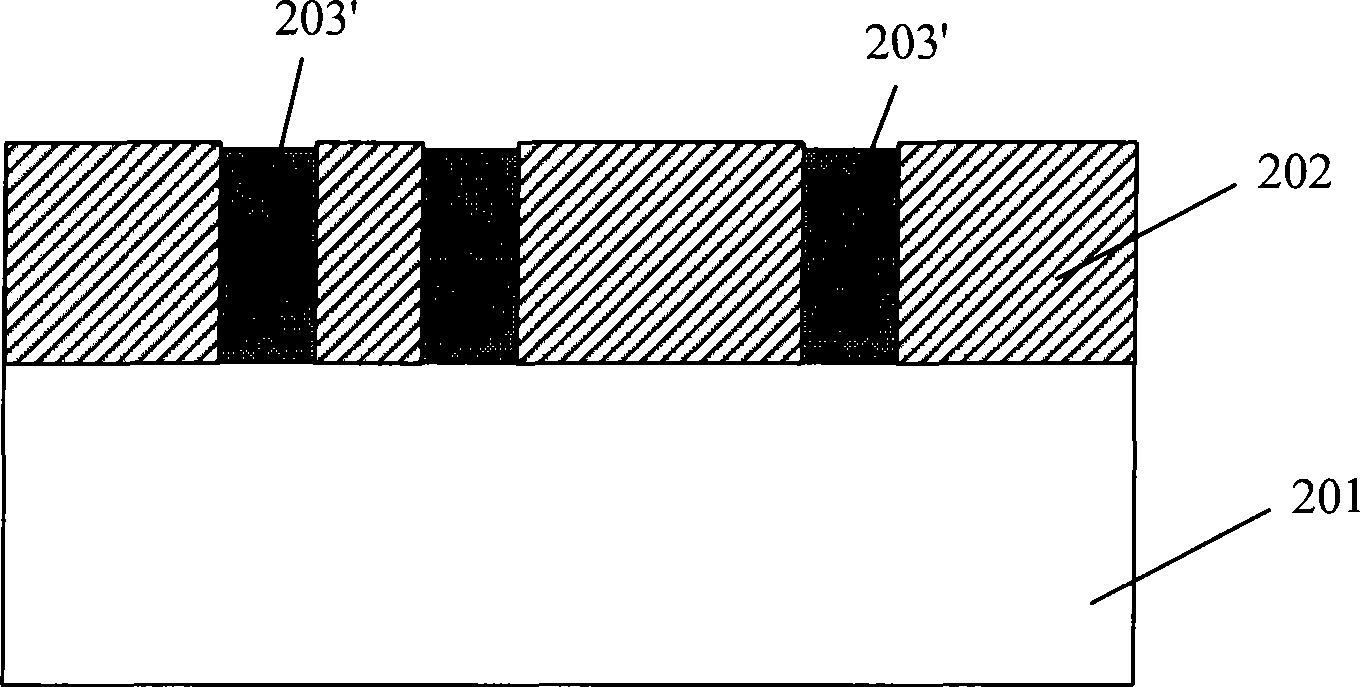

Chemical mechanical grinding method and wafer cleaning method

ActiveCN101459124AReduce the number of particle defectsImprove restoration qualitySemiconductor/solid-state device manufacturingCleaning using liquidsIonChemical-mechanical planarization

The invention discloses a method of chemical mechanical polishing, which comprises steps of placing a chip to-be-polished on a chemical mechanical polishing device, wherein a dielectric layer, a through hole opening arranged in the dielectric layer, and a metal layer arranged in the through hole and on the dielectric layer are formed on the chip, performing first polishing on the chip to expose the surface of the chip out of the dielectric layer and form a metal structure in the through hole opening, performing second polishing on the chip to lead the metal structure in the through hole opening to be higher than the dielectric layer, mixing de-ionized water with hydrofluoric acid to form hydrofluoric acid solution of concentration ranging from 0.03% to 0.08%, and finally utilizing the hydrofluoric acid solution to clean the polished chip. The invention further correspondingly discloses a cleaning method for polished chips. By utilizing the mechanical polishing method and the chip cleaning method, defected particle number on the chip surface after the metal layer is polished can be effectively reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

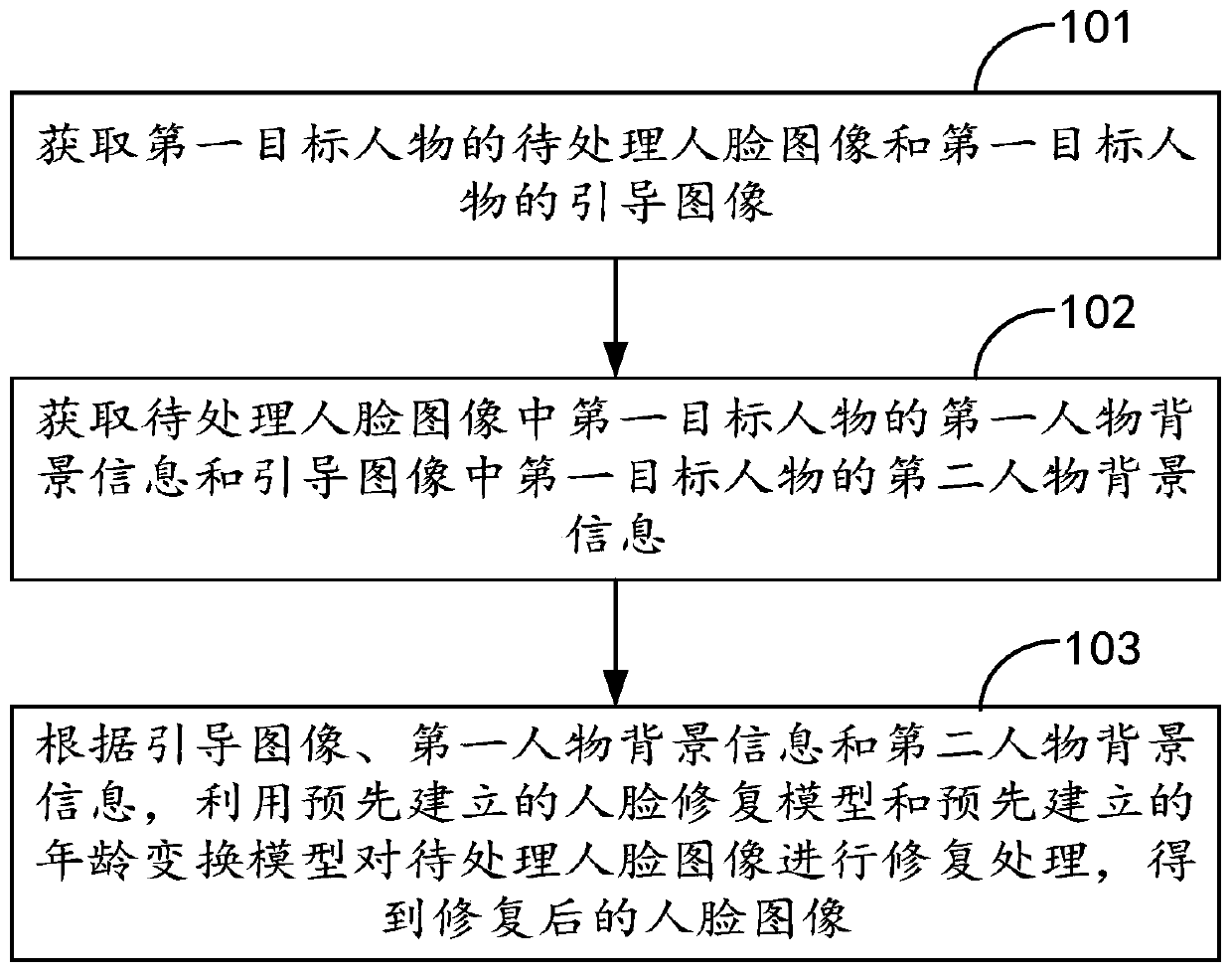

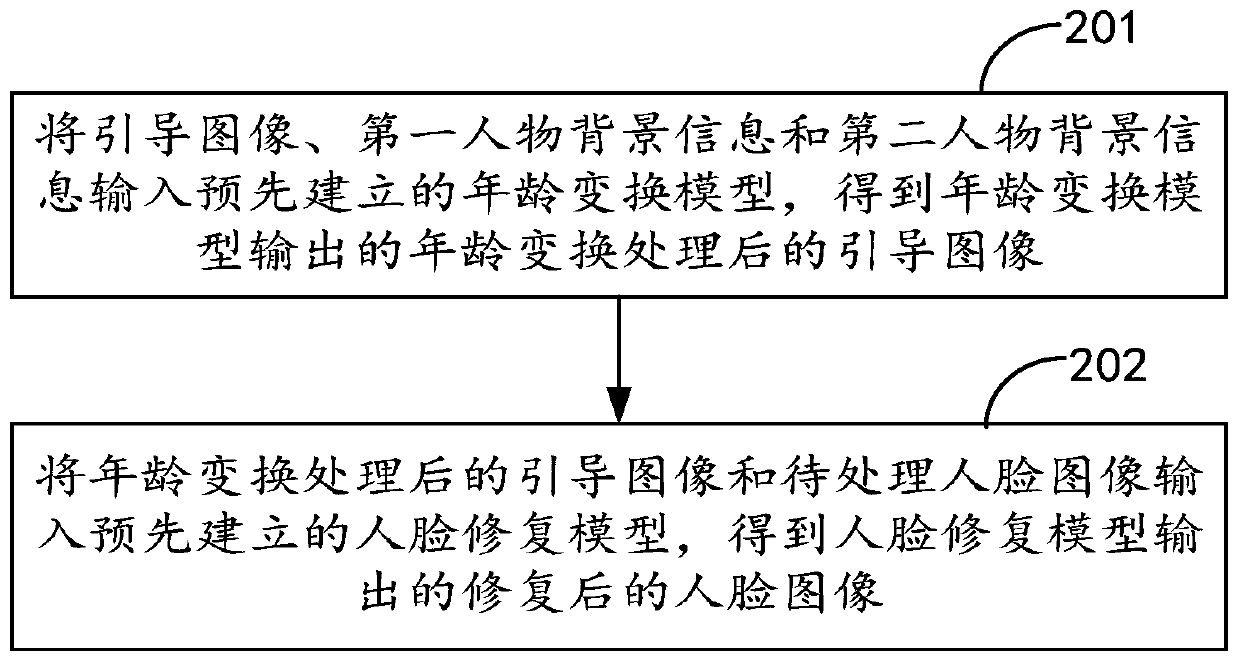

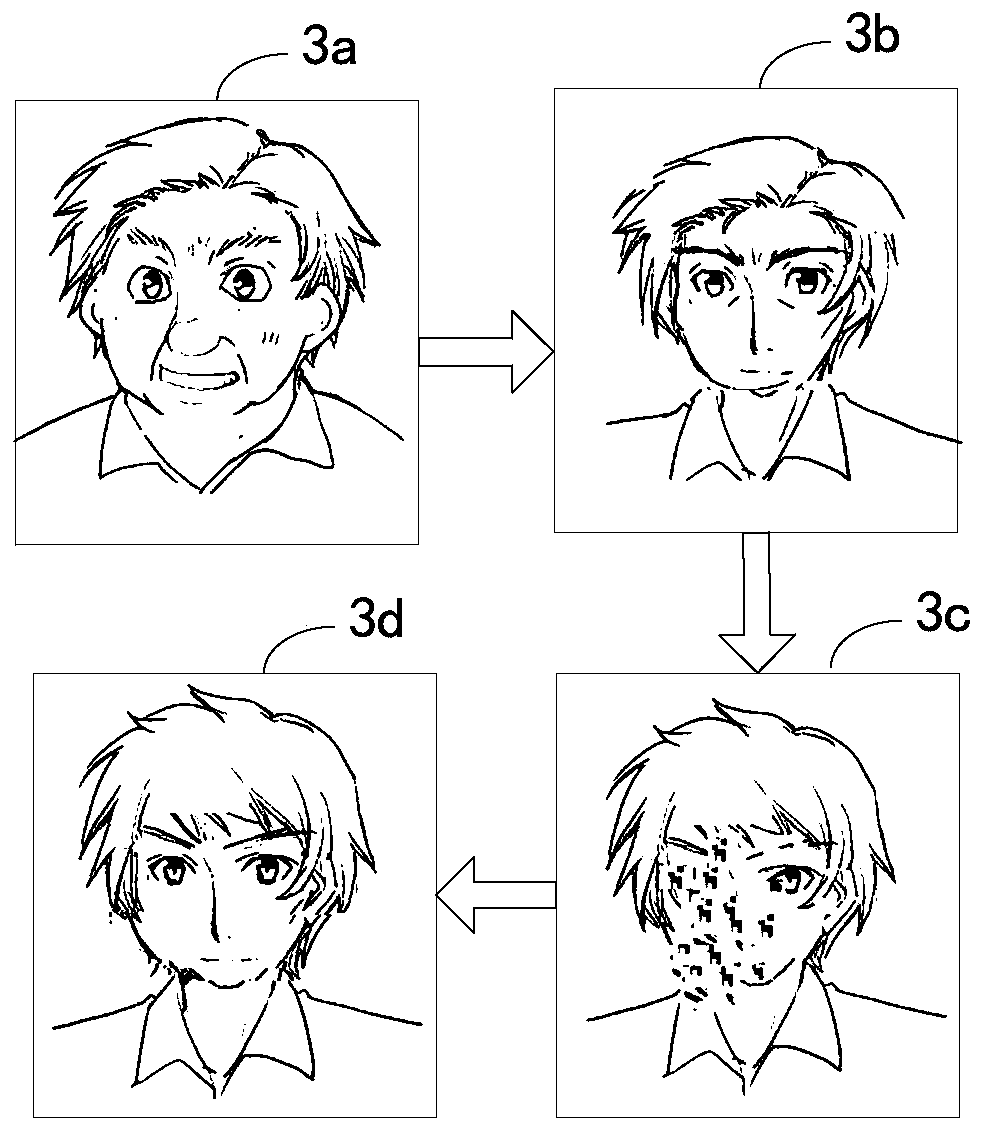

Image processing method and device, terminal and computer readable storage medium

ActiveCN110310247AImprove restoration qualityAvoid distortionImage enhancementImage analysisPattern recognitionImaging processing

The invention belongs to the technical field of computers, and particularly relates to an image processing method and device, a terminal and a computer readable storage medium, and the method comprises the steps: obtaining a to-be-processed face image of a first target person and a guide image of the first target person; obtaining first character background information of the first target character in the to-be-processed face image and second character background information of the first target character in the guide image; according to the guide image, the first character background information and the second character background information, obtaining a guide image; and carrying out restoration processing on the to-be-processed face image by using a pre-established face restoration modeland a pre-established age transformation model. The image distortion caused by direct image fusion or style migration and the like when the face image is repaired is avoided and the repairing qualityof the face image is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

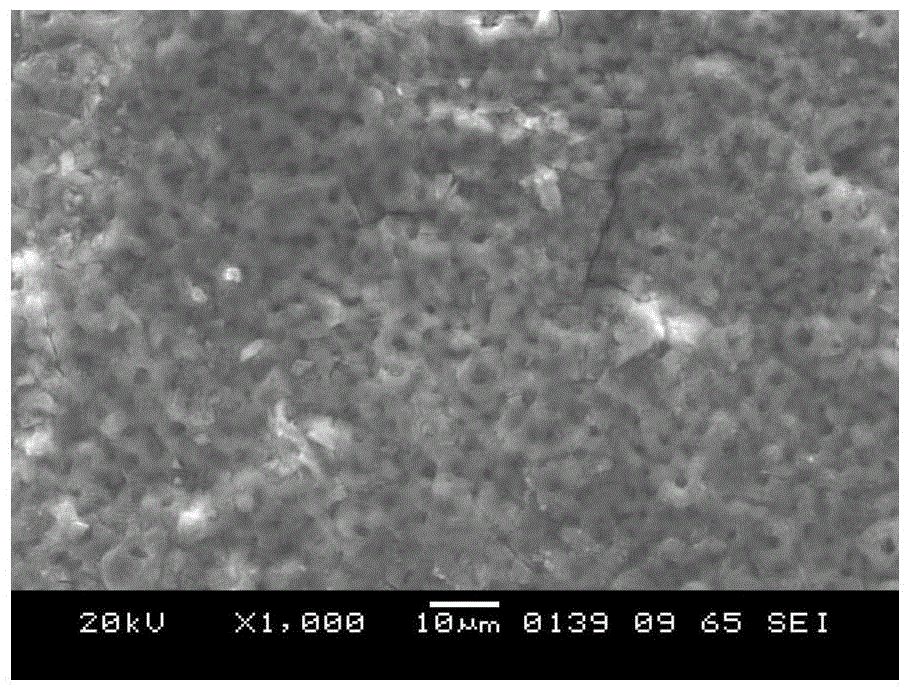

Preparation method of magnesium surface ultrasonic micro-arc oxidation-HF-silica sol multistage compound bioactive coating composite material

InactiveCN103556203AImprove mechanical propertiesCorrosion resistantAnodisationPretreated surfacesMicro arc oxidationPlasma electrolytic oxidation

The invention provides a preparation method of a magnesium surface ultrasonic micro-arc oxidation-HF-silica sol multistage compound bioactive coating composite material, relates to a method for preparing a pure magnesium bioactive coating composite material, and aims to solve the problem that matched human bone density and elastic modulus, certain bioactivity and degradability and controllable dissolution rate can not be simultaneously achieved for the existing bone fixing material and short-term hard tissue implantation material. The method comprises the following steps: 1, performing surface pretreatment on a pure magnesium sample; 2, preparing an electrolyte; 3, performing ultrasonic micro-arc oxidation treatment; and 4, soaking, and performing heating aftertreatment. According to the invention, for the prepared bioactive coating composite material, the bottom layer is compact, the surface layer is porous, and both the corrosion resistance and wear resistance of the prepared composite material are superior to those of a simplex micro-arc oxidation coating. The method provided by the invention can be used for preparation of the magnesium surface ultrasonic micro-arc oxidation-HF-silica sol multistage compound bioactive coating composite material.

Owner:JIAMUSI UNIVERSITY

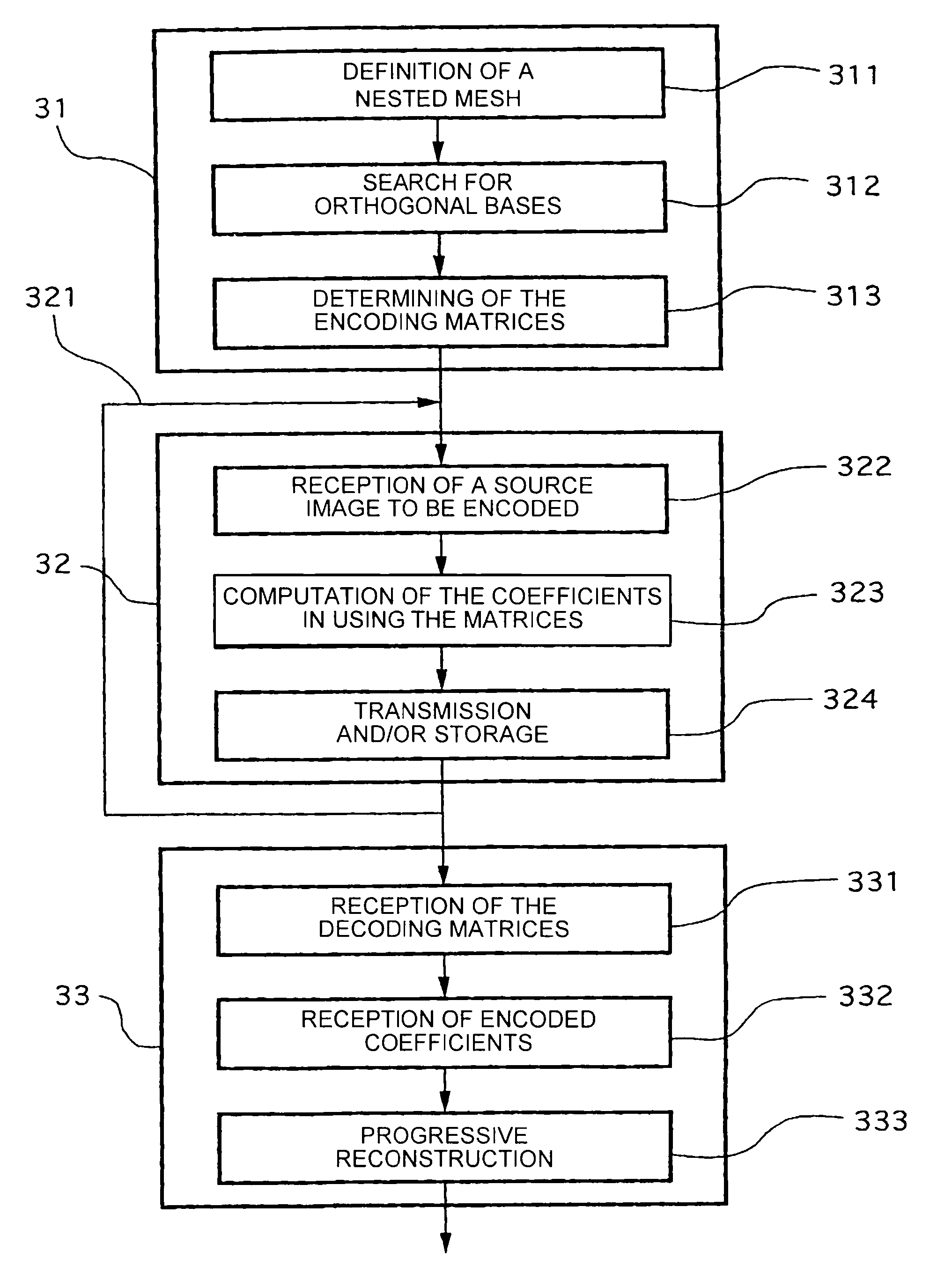

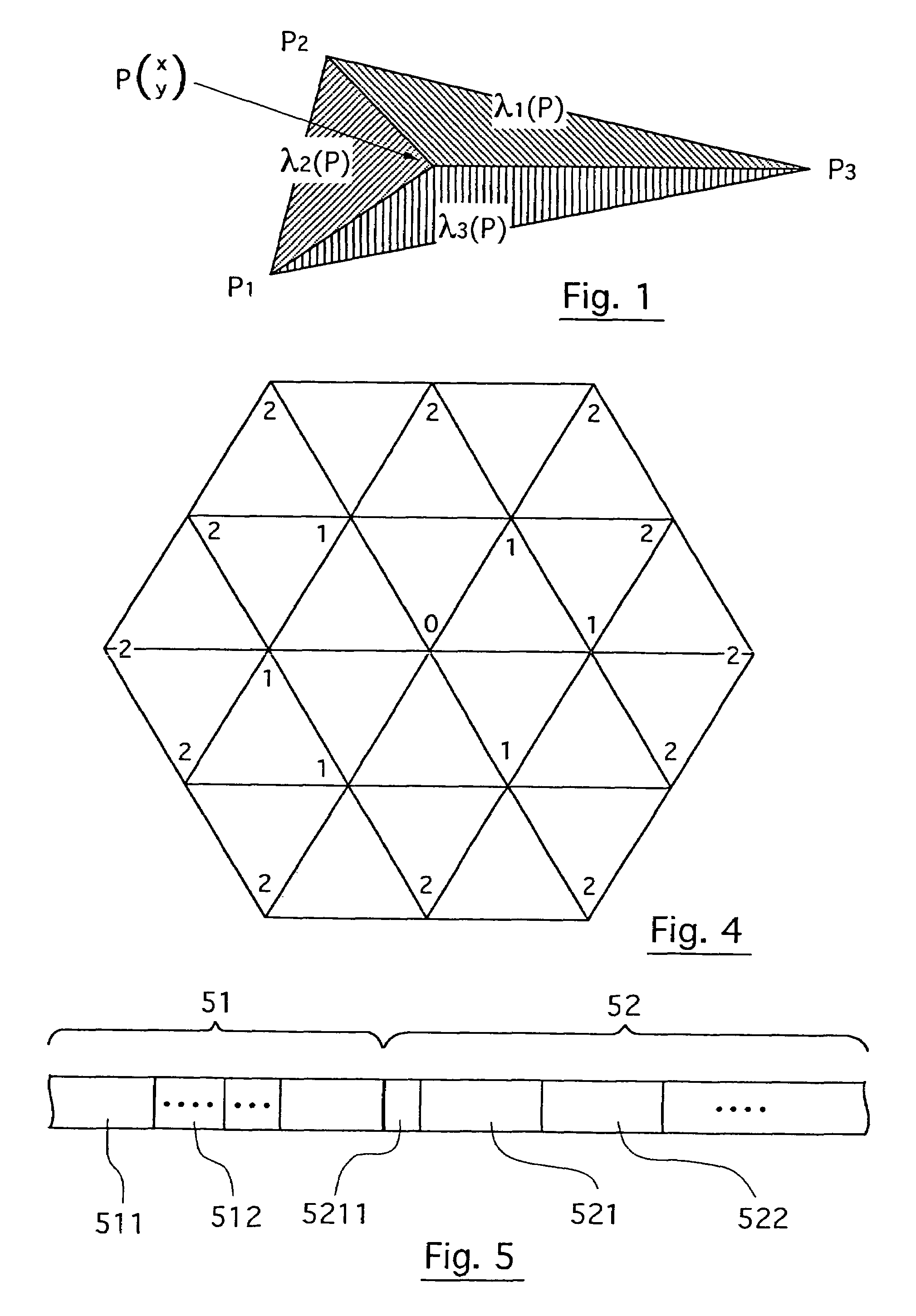

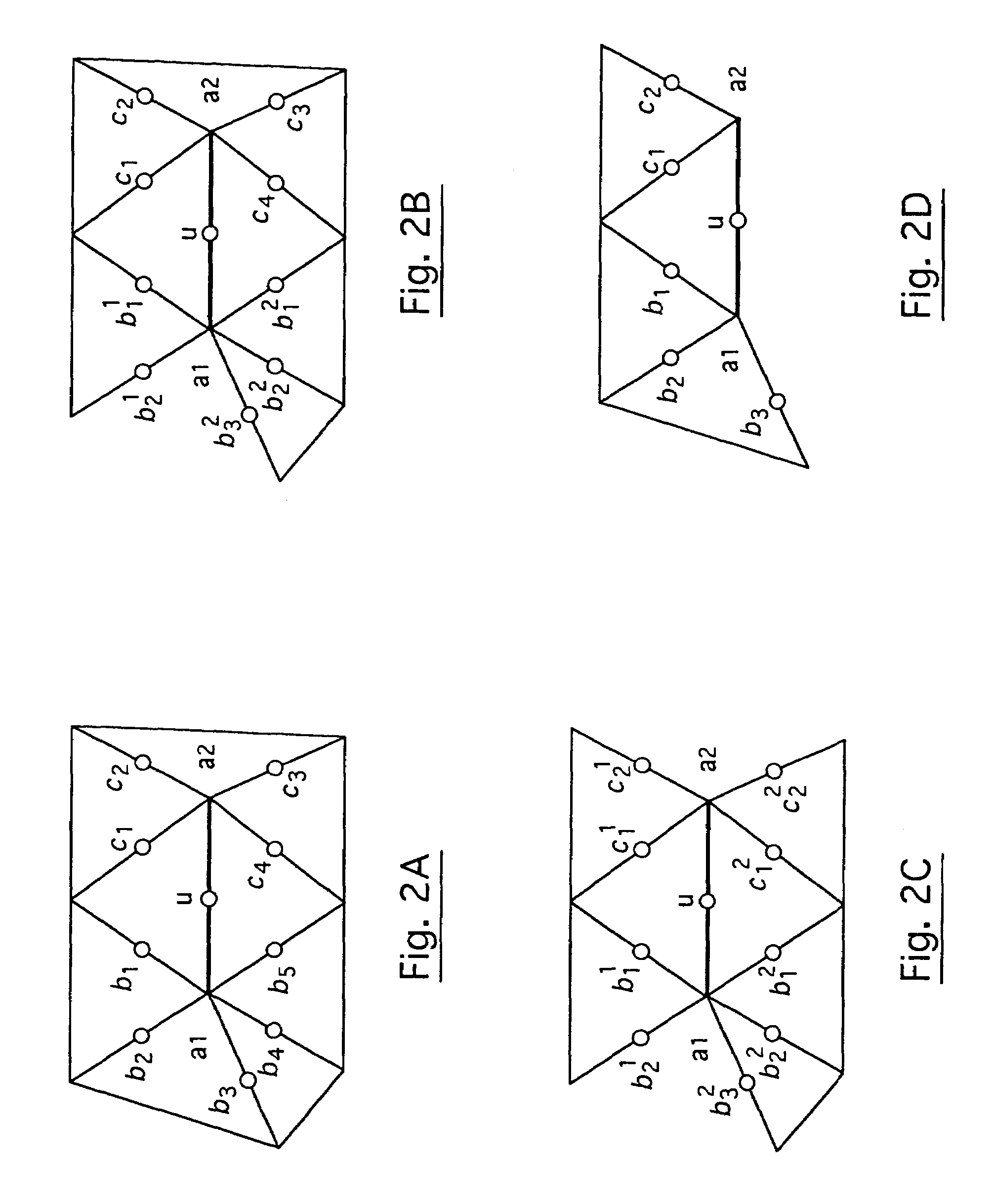

Methods and devices for encoding and decoding images using nested meshes, programme, signal and corresponding uses

InactiveUS7346219B2Optimize bit rateImproved statistical distributionPicture reproducers using cathode ray tubesCode conversionAlgorithmDecomposition

The invention concerns a method for encoding at least a source image using a hierarchical mesh defining at least two nested spaces corresponding each to a decomposition level of said meshing, which consists, at least at a decomposition level n (except the first decomposition level), in delivering only image coefficients expressed in a base of functions defined in a space orthogonal to the space corresponding to the preceding decomposition level n−1, said functions being selected so that said image coefficients enable to optimize for said decomposition level n the data already transmitted for the preceding decomposition level n−1, so as to produce a reconstructed image, representing said source image, with optimized restoration quality for said decomposition level n.

Owner:FRANCE TELECOM SA

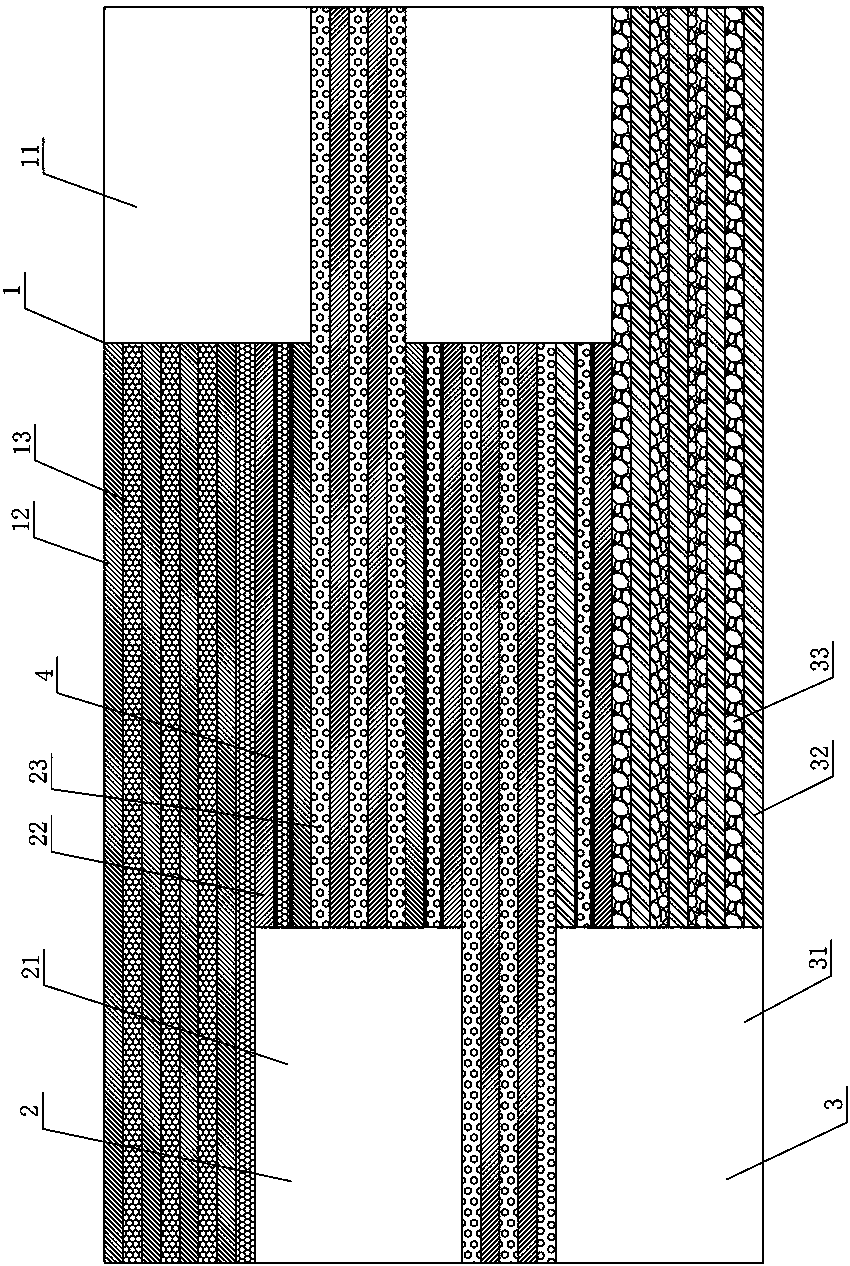

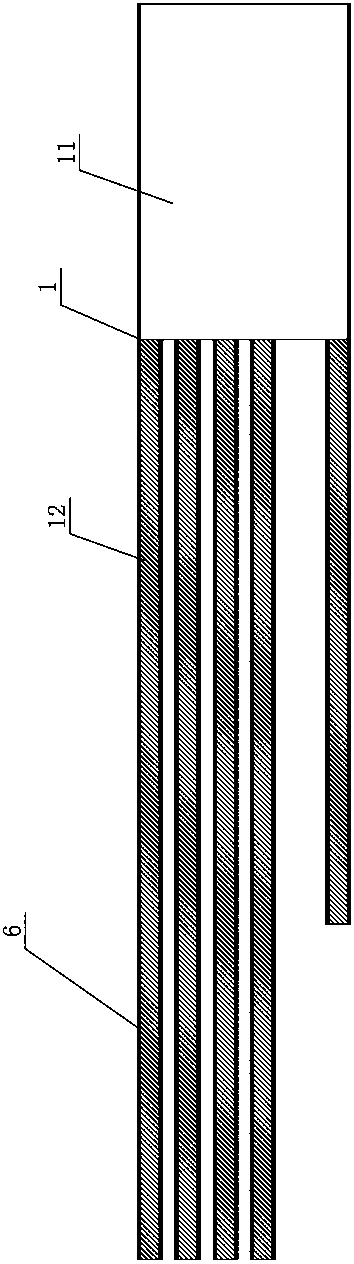

Three-phase tissue engineering scaffold

ActiveCN107669371AAccelerates the decellularization processRetain structureCosmetic implantsPharmaceutical delivery mechanismThree-phaseBiomedical engineering

The invention discloses a three-phase tissue engineering scaffold, which comprises a bone scaffold, a cartilage scaffold and a tendon scaffold, wherein a bone fixing wrapping page part is arranged atone end of the bone scaffold; bone page sheets are arranged at the other end of the bone scaffold in a tangent mode; bone differentiation cell sheets are arranged between the various bone page sheets;a cartilage fixing wrapping page part is arranged at one end of the cartilage scaffold; cartilage page sheets are arranged at the other end of the cartilage scaffold in a tangent mode; cartilage differentiation cell sheets are arranged between the various cartilage page sheets; a tendon fixing wrapping page part is arranged at one end of the tendon scaffold; tendon page sheets are arranged at theother end of the tendon scaffold in a tangent mode; tendon differentiation cell sheets are arranged between the various tendon page sheets; the bone page sheet at the lowest part of the bone scaffoldis connected to the cartilage page sheet at the topmost side of the cartilage scaffold; and the cartilage page sheet at the lowest part of the cartilage scaffold is connected to the tendon page sheetat the topmost side of the tendon scaffold. The tissue engineering scaffold has the advantages of being simple to prepare, convenient to uses and capable of shortening a cell removal time and improving repair quality.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

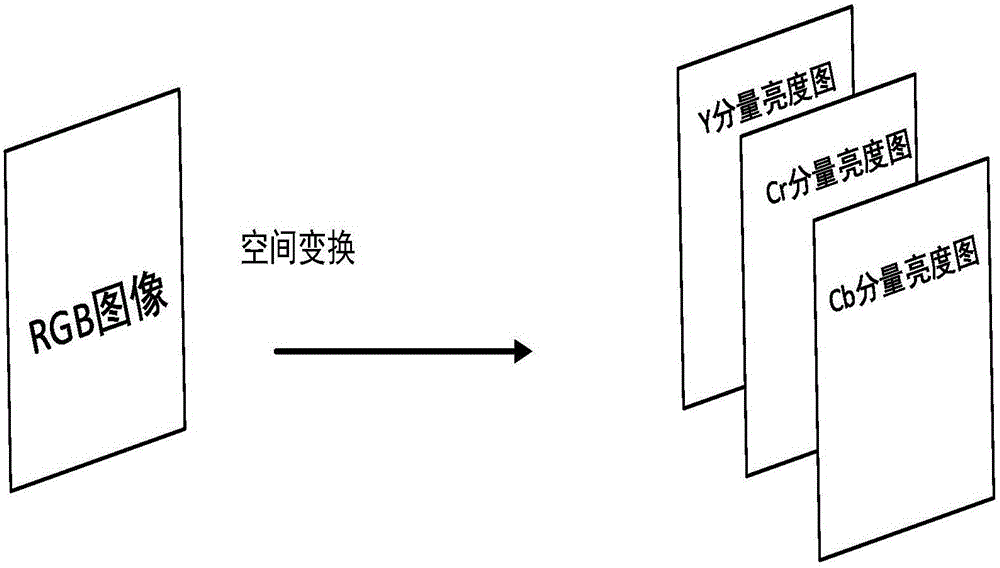

Visual perception correction image compression method based on DCT transform

InactiveCN106612436AIncrease the compression ratioReduced compression efficiencyDigital video signal modificationImage compressionSpatial transformation

The invention proposes a visual perception correction image compression method based on DCT transform. The method is used for lossy compression of an image, and comprises the following steps: firstly, converting the image into a Ycrcb format via domain space transformation; secondly, decomposing the image into 8x8 image subblocks, and performing DCT transform on each image subblock; thirdly, in a DCT coefficient of each subblock, processing the coefficient through a judgment method and then decomposing the coefficient into a high frequency coefficient and a low frequency coefficient, wherein an error compensation mechanism is adopted for the high efficiency coefficient and visual perception correction transformation is performed on the low frequency coefficient, and then encoding; and finally, the process of reconstructing the image is an inverse operation of the compression process. Through the method of the invention, the image can not only get a higher compression ratio, but also the compression efficiency of the image is not reduced due to the increase of the amount of calculation; and meanwhile, the reconstructed image is analyzed, the image restoration degree is increased, the signal to noise ratio is enhanced, and the image restoration quality is obviously improved, therefore, the visual perception correction image compression method based on the DCT transform provided by the invention has strong practicability.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

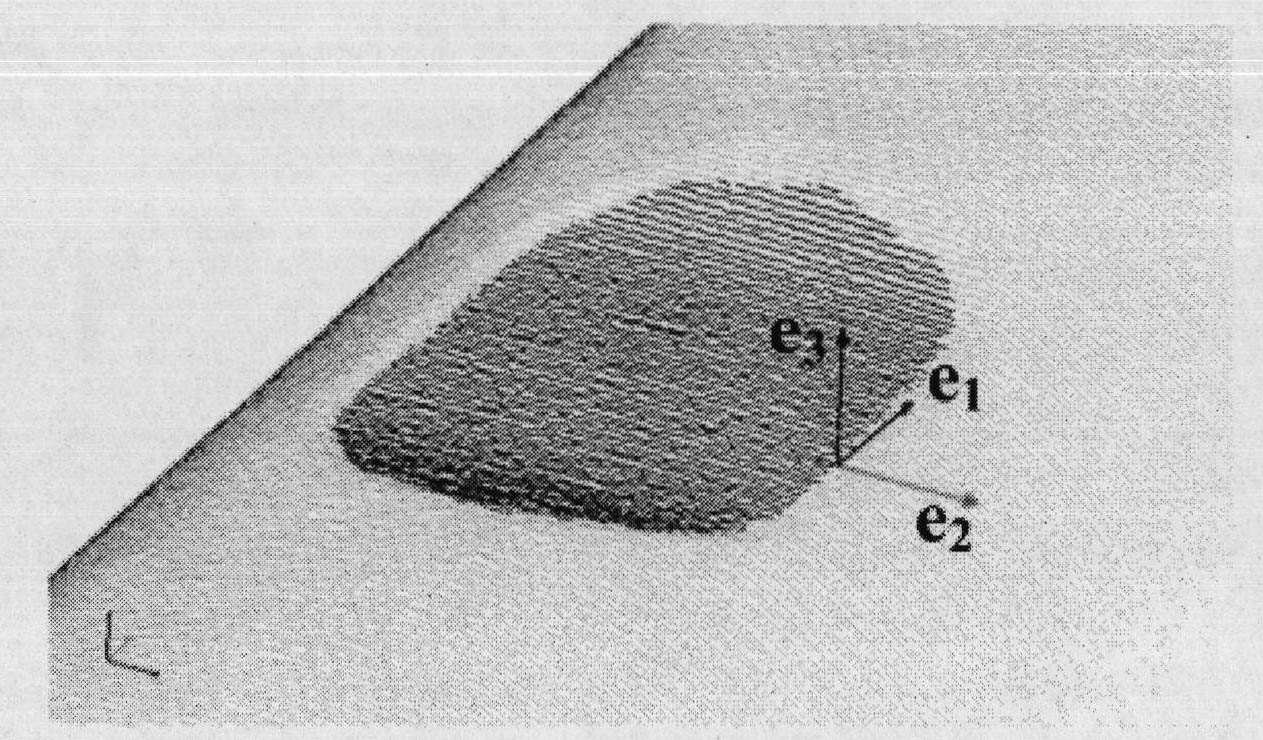

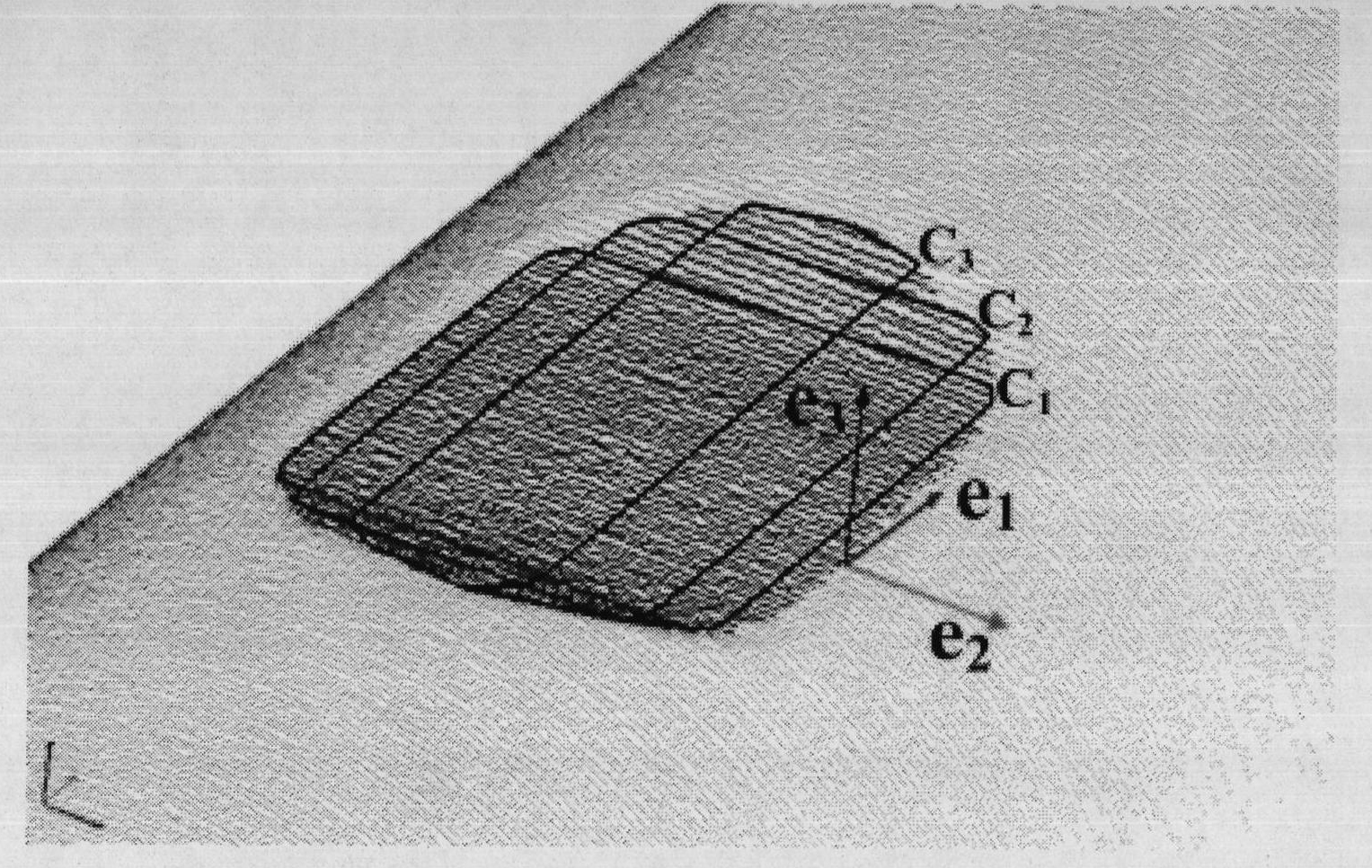

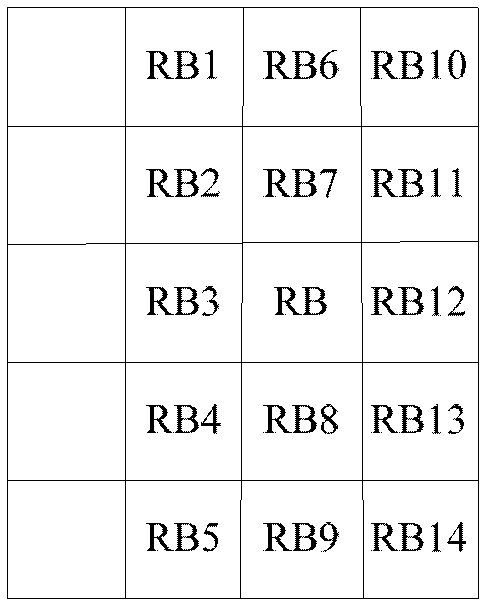

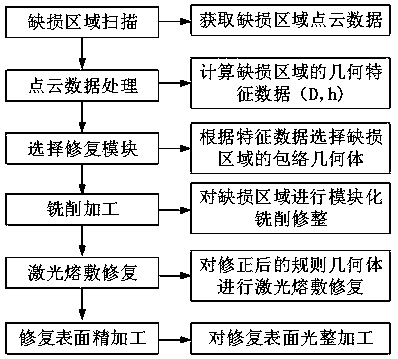

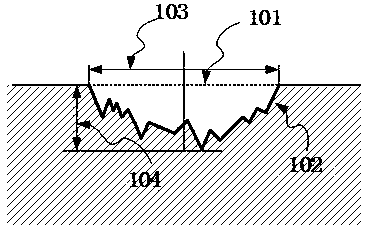

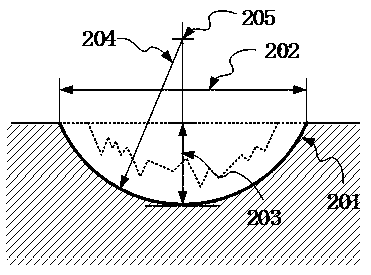

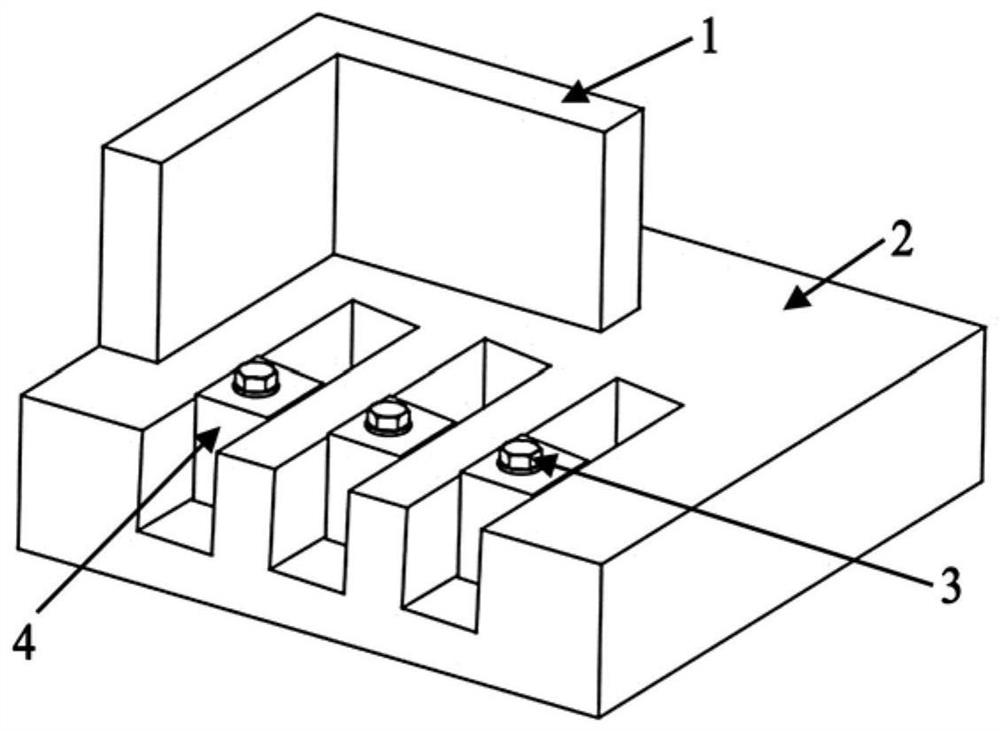

Modularization type material addition and reduction composite repairing method for defective region of component surface

ActiveCN110640146AImprove repair efficiencyImprove restoration qualityAdditive manufacturing apparatusIncreasing energy efficiencyPoint cloudStructural engineering

The invention provides a modularization type material addition and reduction composite repairing method for a defective region of a component surface and relates to the technical field of machining. The main process of the method comprises the following steps of: implementing three-dimensional scanning on the defective region of the component surface and acquiring point cloud data of a to-be-repaired region; calculating the characteristic parameters of the defective region according to the point cloud data; selecting a corresponding geometric module according to the characteristic parameters;implementing modular milling and removal on the defective region to obtain a regular to-be-repaired region; implementing modular laser melt-coating repairing on the to-be-repaired region; and precisely milling the laser-repaired surface to end the repairing. By adopting a material addition and reduction composite way, the method provided by the invention repairs a complicated irregular defective appearance into a regular geometry; on the basis, the modular to-be-repaired geometry is subjected to laser melt-coating repairing; and the operation route is conveniently and quickly planned, so the overall repairing efficiency is improved. Beside, the precise milling for the laser melt-coating region can maintain the repairing precision of the contour of the repaired surface, and the use performance of the repaired surface is also improved.

Owner:NANJING INST OF TECH

Composite casting technology

The composite casting process includes the following steps: 1. designing twice or more than twice pouring casting size; 2. casting out primary poured casting; 3. making pattern for secondary pouring on the primary poured casting surface of surface of damaged metal component; 4. moulding sand mould for pouring; 5. using primary poured casting or damaged metal component and secondary pouring sand mould to form mould cavity for secondary pouring; 6. feeding them into drying kiln and drying sand mould; 7. after the sand mould is heated, taking out the sand mould from kiln, maing secondary pouring; and 8. cleaning sand mould material from casting system.

Owner:国成军

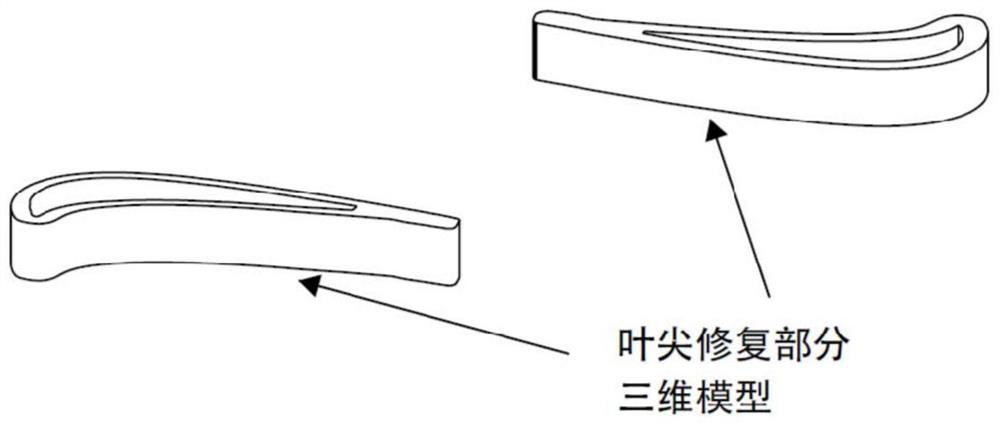

Cast isometric crystal high-temperature alloy turbine rotor blade tip repairing method and tool

ActiveCN112045186AOvercoming positioningOvercoming the lack of fusion at the repair interfaceAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringReverse modeling

The invention belongs to the technical field of aero-engine maintenance, and relates to a cast isometric crystal high-temperature alloy turbine rotor blade tip repairing method and tool. According tothe method, repairing is completed through a laser selective melting or electron beam selective melting process, a blade can be placed in a forming area of laser selective melting or electron beam selective melting equipment and formed at a blade tip through the tool, data are obtained through three-dimensional scanning for reverse modeling, a model needing to be repaired and formed and related position information are obtained, the corresponding tool and blade clamping are designed, the structure and form of the tool are not limited, and the tool can be used for completing blade clamping, auxiliary positioning and position calibration; printing repairing forming is conducted after positioning calibration, and finally aftertreatment and detection are completed; and the positioning precision of blade repairing is well controlled, and the beneficial effects that the cast isometric crystal high-temperature alloy turbine rotor blade tip repairing method and tool is small in heat input, fine in grains, excellent in mechanical property, small in deformation, excellent in surface roughness and high in size precision, near-net forming does not need machining, and forming is rapid and efficient are achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Mobile semiconductor laser mould repairing system

InactiveCN102126104AMeet organizational performance requirementsAchieve Field RepairLaser beam welding apparatusLight guideSemiconductor package

The invention discloses a high-efficiency flexible laser repairing system for a mould in a complicated shape. The system integrates a high-power semiconductor laser device, 6-axis full-joint type industrial robot, an optical fiber light guiding system and the like. According to the invention, as a semiconductor laser device with small volume and light weight and a movably-mounted industrial robot are adopted, the movement of the entire system can be realized conveniently so as to realize field repair of the mould. The invention provides a method for integrating the semiconductor laser device, the industrial robot, a laser working head and the like, and the method comprises the following steps: transmitting semiconductor laser through the optical fiber light guiding system which has good flexibility and is flexible and convenient; after the semiconductor laser reaches the laser working head held in the wrist of the industrial robot, collimating and focusing the semiconductor laser and irradiating the damaged part; and meanwhile, heating the powder and workpiece surface material, and cladding the repaired part layer by layer under the program control to realize repair of the damaged part. According to the invention, the field processing of large and ultra-large moulds or parts which are inconvenient to move can be realized, and the system disclosed by the invention is particularly suitable for flexible production of multiple varieties and batches.

Owner:HUNAN UNIV

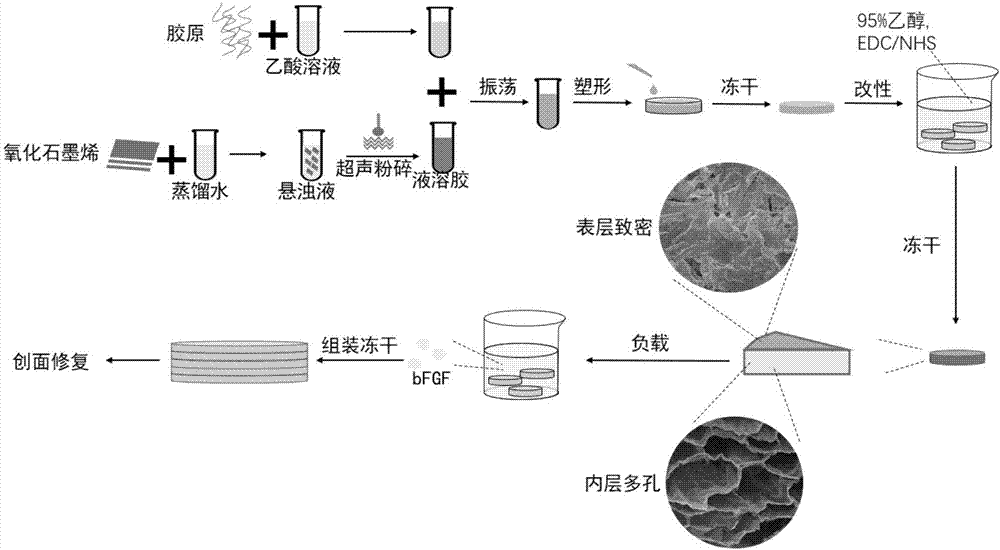

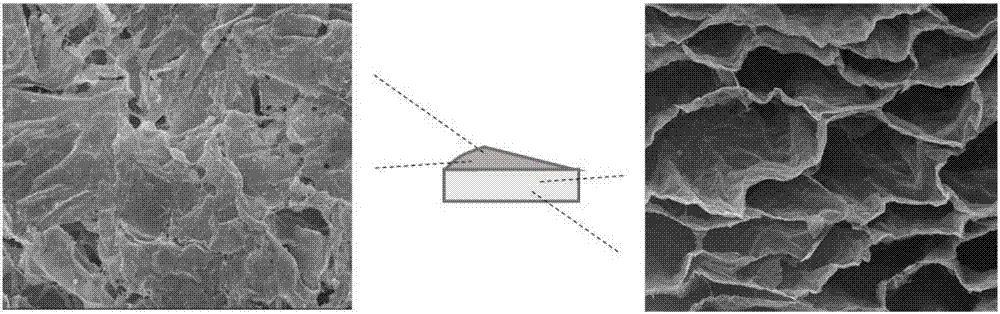

Preparation method and application of skin regeneration aerogel type dressing

ActiveCN107998444APromote wound healingUniform distribution of poresBandagesWound healingPore distribution

The invention provides a preparation method and the application of a skin regeneration aerogel type dressing. Based on collagen and oxidized graphene, in virtue of a preparation technology of aerogel,a relatively compact collagen film on the surface of collagen-oxidized graphene aerogel is used, fibroblast growth factors are slowly released through physical encapsulation and an assembling mannerof a sandwich multilayered structure, and the aerogel dressing which is capable of slowly releasing fibroblast growth factors, promoting climbing and adhesion of fibroblast and promoting wound healing, and is uniform in pore distribution, light in texture and high in moisture absorption, moisture preservation, water absorption, gas permeability and porosity is prepared by adopting a freeze dryingmethod.

Owner:湖北皮可力医疗科技有限公司

Wrought superalloy and stainless steel gas compressor rotor blade tip repair method and tool

ActiveCN111962069AOvercoming positioningOvercoming the lack of fusion at the repair interfaceIncreasing energy efficiencyMetallic material coating processesSelective laser meltingAviation

The invention belongs to the technical field of aero-engine maintenance and relates to a wrought superalloy and stainless steel gas compressor rotor blade tip repair method and tool. According to themethod, repairing of the tip of a gas compressor rotor blade is completed through a selective laser melting or selective electron beam melting process; by the aid of the tool, the blade can be arranged in a forming area of selective laser melting or selective electron beam melting equipment and the tip of the blade can be formed; data are obtained through 3D scanning to conduct reverse modeling toobtain a model requiring repair forming and the related position information, the corresponding tool is designed for clamping the blade; the structure and form of the tool are not limited, and the tool can be used for completing blade clamping, auxiliary locating and position correction; after locating correction, printing repair forming is carried out, and finally, aftertreatment and detection are completed; and the locating precision for blade repairing is controlled well. Moreover, the wrought superalloy and stainless steel gas compressor rotor blade tip repair method and tool have the advantages of small thermal input, fine grain particles, good mechanical performance, little deformation, good surface roughness, high dimensional precision, near-net forming without machining, rapid andefficient forming and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Environment-friendly contaminated soil off-site control device

ActiveCN109127708AImprove repair effectReasonable structureContaminated soil reclamationGear wheelAgricultural engineering

The invention discloses an environment-friendly contaminated soil off-site control device which comprises a traveling base. Supporting frames are mounted on two sides of the upper end of the travelingbase, a repairing cylinder is mounted between middles of the supporting frames, a top frame is mounted at the upper ends of the supporting frames, a power box is mounted in the middle of the upper end of the top frame, a chemical tank is mounted on the right side of the upper end of the top frame, a power shaft is mounted in the power box, power blades are uniformly arranged at the upper end of the power shaft positioned in the power box, the lower end of the power shaft penetrates the top frame and is connected with stirring blades, a rotating cylinder is arranged in the repairing cylinder,a rotating shaft is connected in the middle of the low end of the rotating cylinder, a first gear is connected at the lower end of the rotating shaft, a second gear is connected at the lower end of the first gear, a rotating shaft is mounted in the middle of the second gear, and a drying cylinder is mounted on the left side of the upper end of the traveling base. According to the device, a liquidrepair agent and a solid repair agent are mixed and stirred in a divided manner, the repair effects of the contaminated soil are improved, the repaired soil is dried and secondly mixed, and the repairquality of the soil is further improved.

Owner:HEBEI HUAQING ENVIRONMENTAL TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com