Preparation method of magnesium surface ultrasonic micro-arc oxidation-HF-silica sol multistage compound bioactive coating composite material

A technology of micro-arc oxidation and biological activity, which is applied in the direction of liquid-coated devices, coatings, anodic oxidation, etc., to achieve the effect of improving the speed of bone repair, improving the quality of bone repair, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

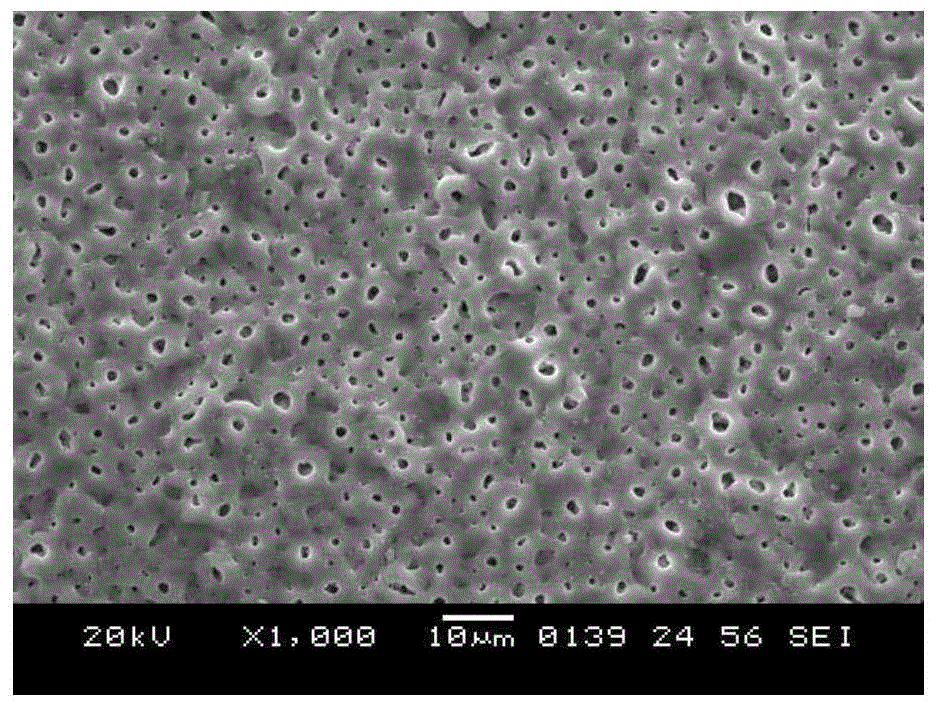

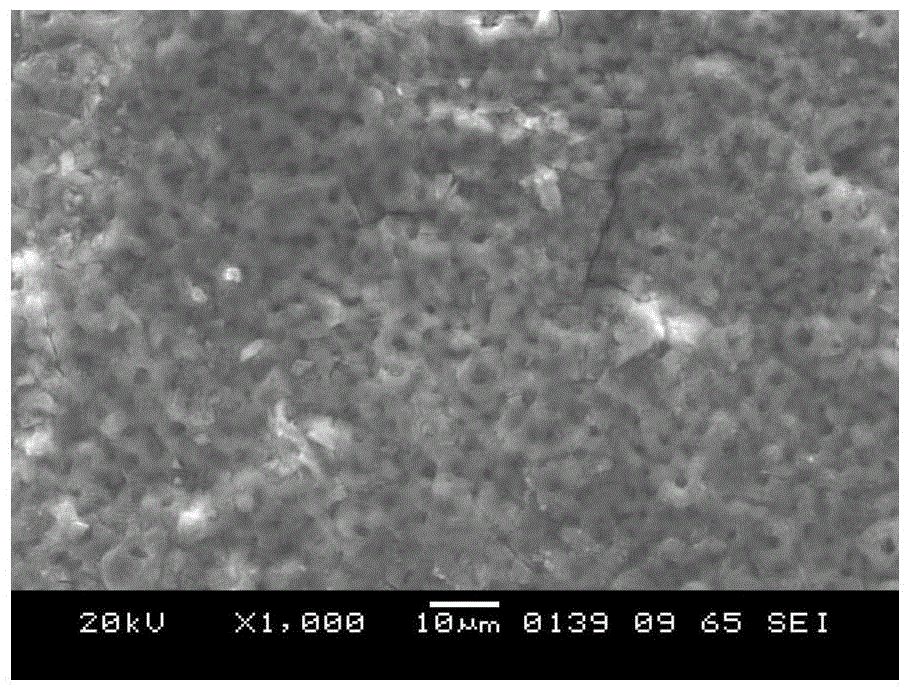

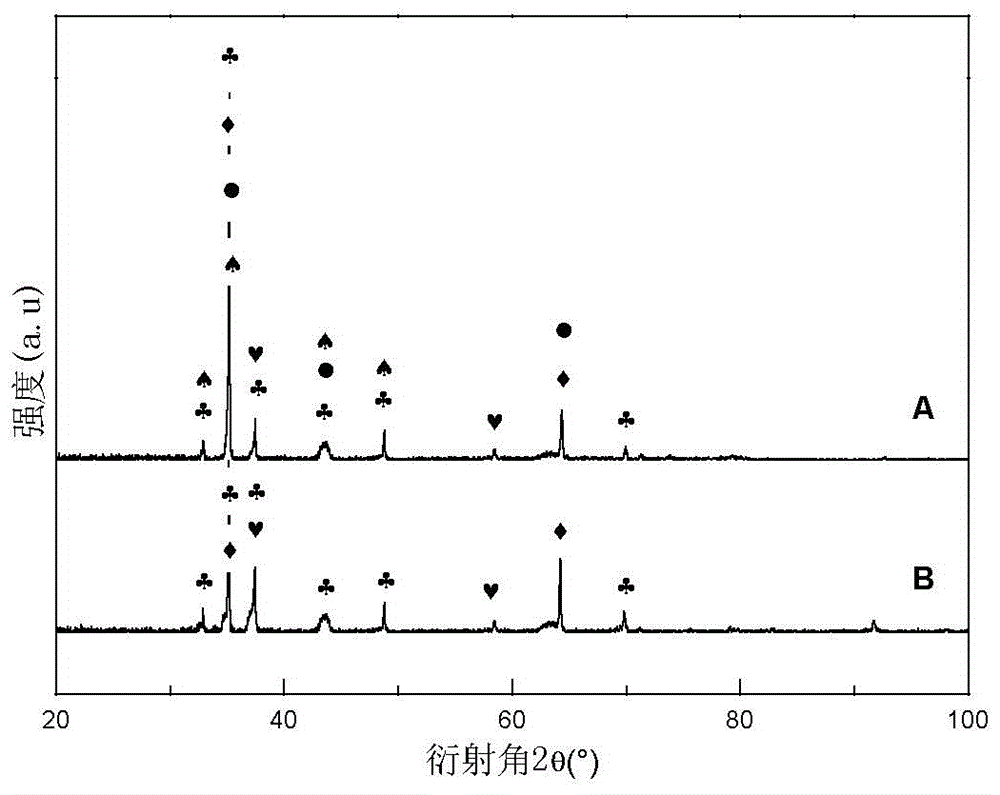

[0026] Specific embodiment one: the preparation method of magnesium surface ultrasonic micro-arc oxidation-HF-silica sol multi-stage composite bioactive coating composite material in this embodiment is carried out according to the following steps:

[0027] 1. Surface pretreatment of pure magnesium samples: use 1500-mesh sandpaper to roughly grind the surface of pure magnesium samples to obtain rough-ground pure magnesium samples, and then use acetone and distilled water in turn to rough-grind pure magnesium samples Ultrasonic cleaning was carried out, in which acetone was used for ultrasonic cleaning for 15 minutes to 25 minutes, and distilled water was used for ultrasonic cleaning for 15 minutes to 25 minutes. After natural drying, the pretreated pure magnesium sample was obtained;

[0028] Second, the configuration of the electrolyte: ①, the Na 2 SiO 3 Add it into distilled water and stir until completely dissolved to obtain Na with a concentration of 30g / L 2 SiO 3 Aqueou...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the alkaline electrolyte described in step ② in step 2 is KOH. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step three, the electrolyte solution obtained in step two is put into a stainless steel electrolytic cell, the cathode of the micro-arc oxidation equipment is connected to the stainless steel electrolytic cell, and aluminum wire is used Connect the pretreated pure magnesium sample obtained in step 1 to the anode of the micro-arc oxidation equipment, adjust the distance between the cathode and the anode to 40mm-60mm, and then set the ultrasonic frequency at 40kHZ-60kHZ, the micro-arc oxidation voltage at 150V-400V, pulse Oxidize for 20min-30min under the conditions of width 30μs-80μs, pulse frequency 300HZ-800HZ and duty ratio 0.9%-6.4%, to obtain magnesium samples after ultrasonic micro-arc oxidation treatment, and use distilled water for ultrasonic micro-arc oxidation treatment The final magnesium sample was rinsed for 3 to 5 times, and then dried naturally to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com