Cast isometric crystal high-temperature alloy turbine rotor blade tip repairing method and tool

A high-temperature alloy and turbine rotor technology, which is applied in the direction of additive processing, energy efficiency improvement, process efficiency improvement, etc., can solve problems such as interference in the process of parts and equipment, difficulty in accurately positioning the electron beam, and the combination of printing materials and base materials. , to achieve the effect of improving repair efficiency and quality, small heat input, and small machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0048] EOS M290 laser selective melting (SLM) equipment was used to repair the wear damage of the K4002 cast equiaxed crystal superalloy turbine blade tip of a certain type of engine. The specific steps are as follows:

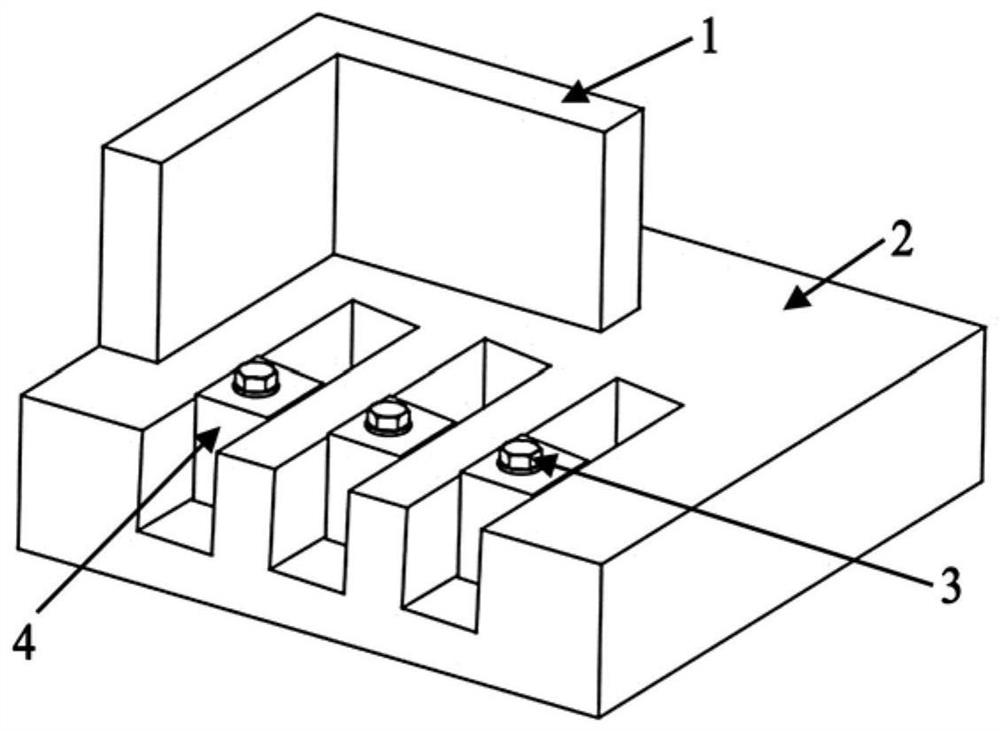

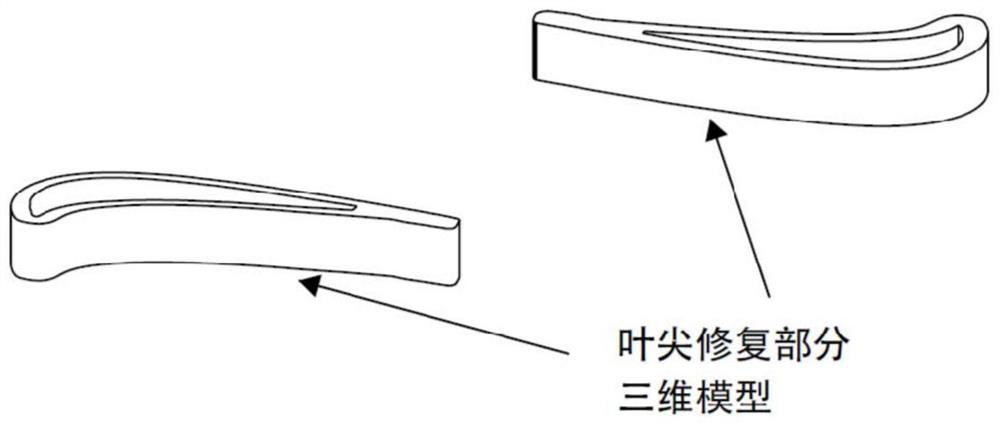

[0049] S1. Tool design and blade clamping: Design a tool to assist blade positioning, clamping and laser selective melting (SLM) repair. For the designed tooling shape and clamping method, see figure 1 and figure 2 .

[0050] see Figure 1 to Figure 4 , The tooling designed in the present invention includes a base block 1 , a substrate base 2 , a bolt 3 and a locking block 4 .

[0051] The size of the base block 1 is 150mm (length) × 50mm (width) × 120mm (height), welded to the surface of the substrate base, and the angle between the two base blocks is 90° and placed at a right angle;

[0052] The size of the substrate base 2 is 252mm (length) × 252mm (width) × 45mm (thickness). There are M5 threaded holes on the substrate base, which can cooperate with b...

specific example 2

[0068] Arcam A2X Electron Beam Selective Melting (EBM) equipment was used to repair the tip wear damage of K4002 cast equiaxed superalloy turbine blades of a certain type of engine. The specific steps are as follows:

[0069] S1. Tool design and blade clamping: Design a tool to assist blade positioning, clamping and electron beam melting (EBM) repair. For the designed tooling shape and clamping method, see figure 1 and figure 2 .

[0070] see Figure 1 to Figure 4 , The tooling designed in the present invention includes a base block 1 , a substrate base 2 , a bolt 3 and a locking block 4 .

[0071] The size of the base block 1 is 150mm (length) × 50mm (width) × 120mm (height), welded to the surface of the substrate base, and the angle between the two base blocks is 90° and placed at a right angle;

[0072] The size of the substrate base 2 is 252mm (length) × 252mm (width) × 45mm (thickness), and there are M5 threaded holes in the substrate base, which can cooperate with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com