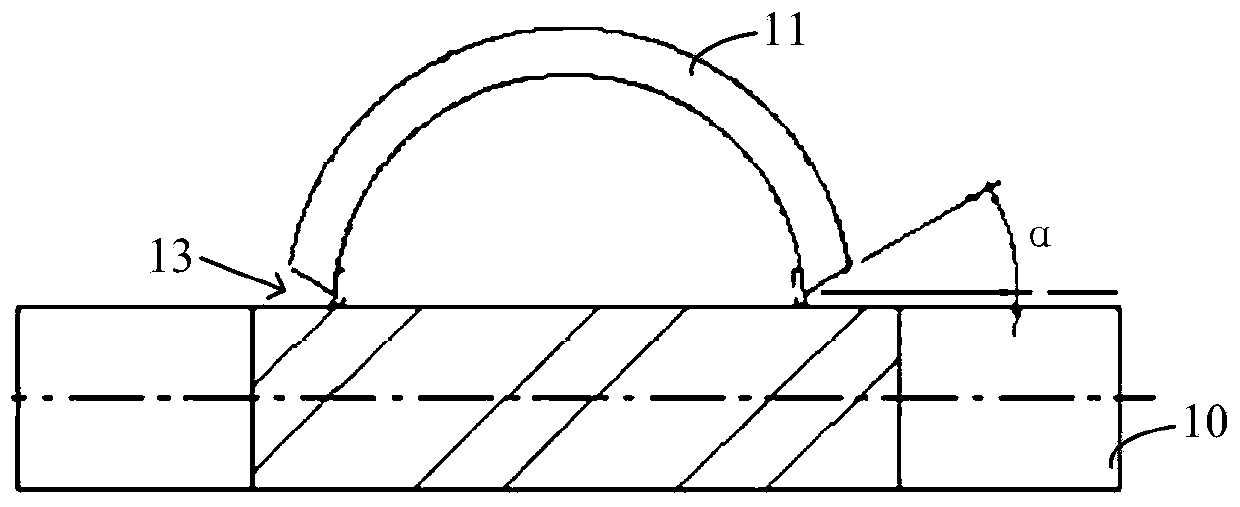

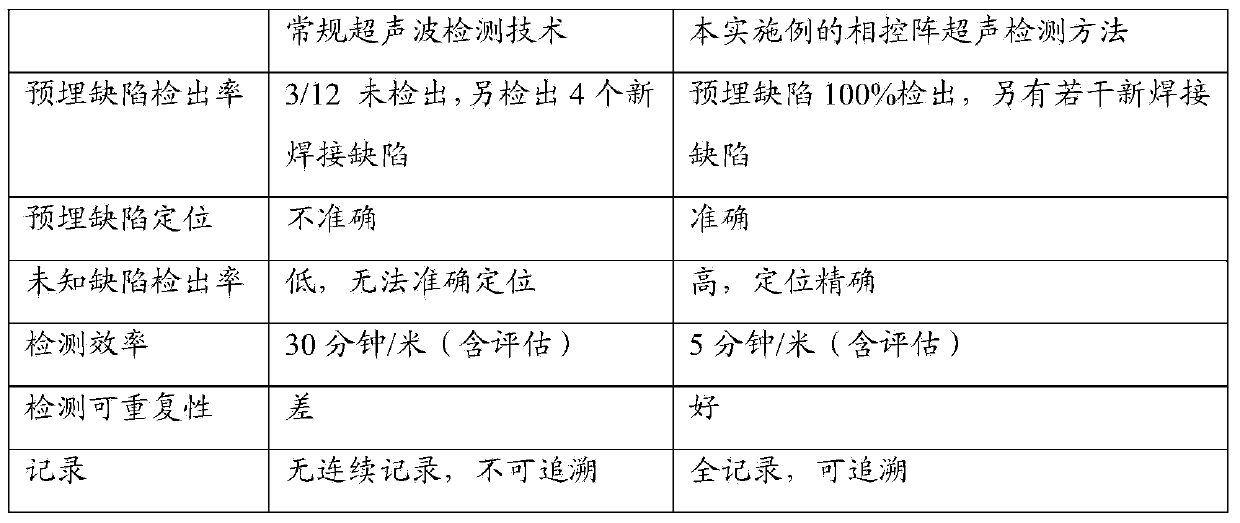

Phased array ultrasonic detection method for curved surface fillet weld of pile leg racks of drilling platform

A technology for drilling platform leg and ultrasonic detection, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of poor detection repeatability, difficulty in on-site detection, and difficulty in quantification and positioning, reducing labor, overcoming inefficiency, Overcome the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0018] Phased array ultrasonic detection is to control the excitation pulse time delay of each array element in the transducer, and change the phase relationship when the sound wave emitted (or received) by each array element reaches (or comes from) a certain point in the object to achieve focusing and sound beam For the effect of deflection, the electronic technology of the delay circuit is used to control the synthesis of the phased array probe to realize the functions of ultrasonic transmission and reception. The phased array probe has multiple small chips, and each chip is independently excited. According to the different sound paths of each chip relative to the target to be detected, different delay times are applied to achieve changes in the angle and focus of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com