Equipment and method for milling inner surface of bent pipe

A technology of milling processing and inner surface, which is applied in the direction of metal processing equipment, milling machine equipment, milling machine equipment details, etc., can solve the problems of low precision and low transmission efficiency, and achieve the effect of high precision, stable transmission and consistent cutting state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

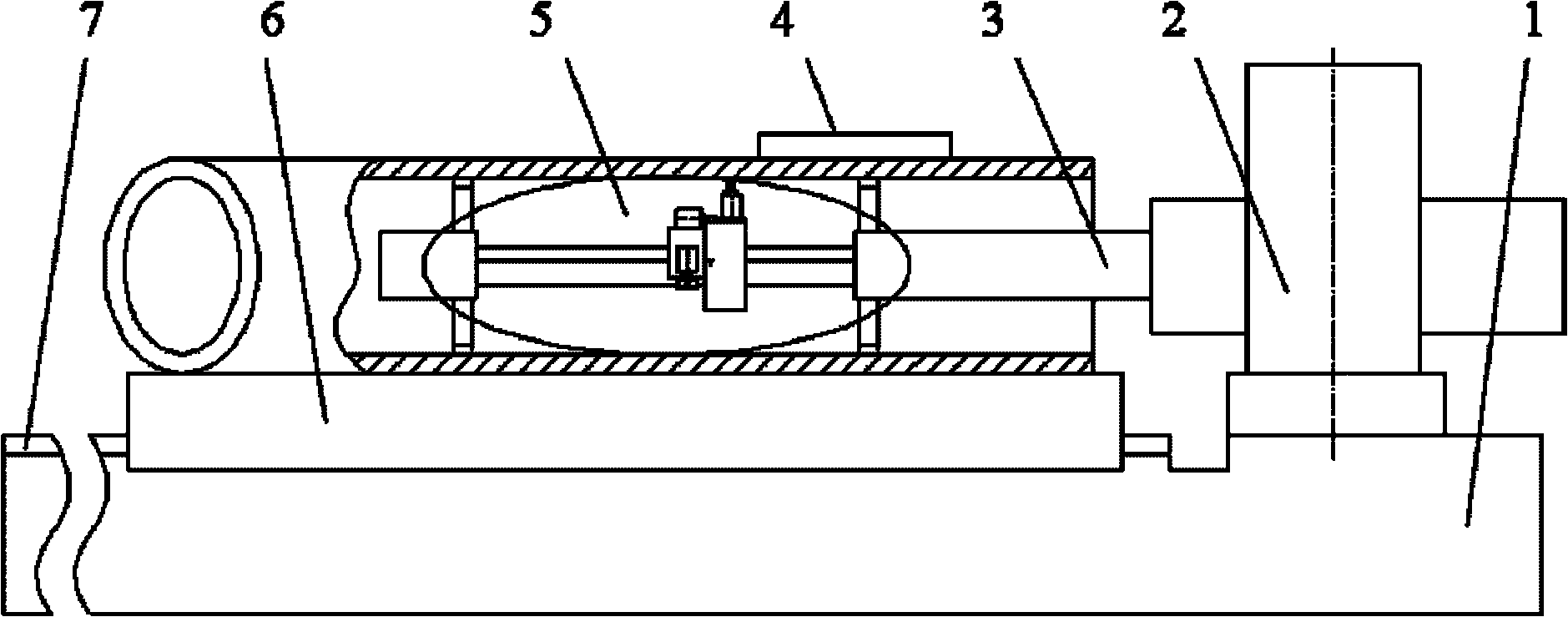

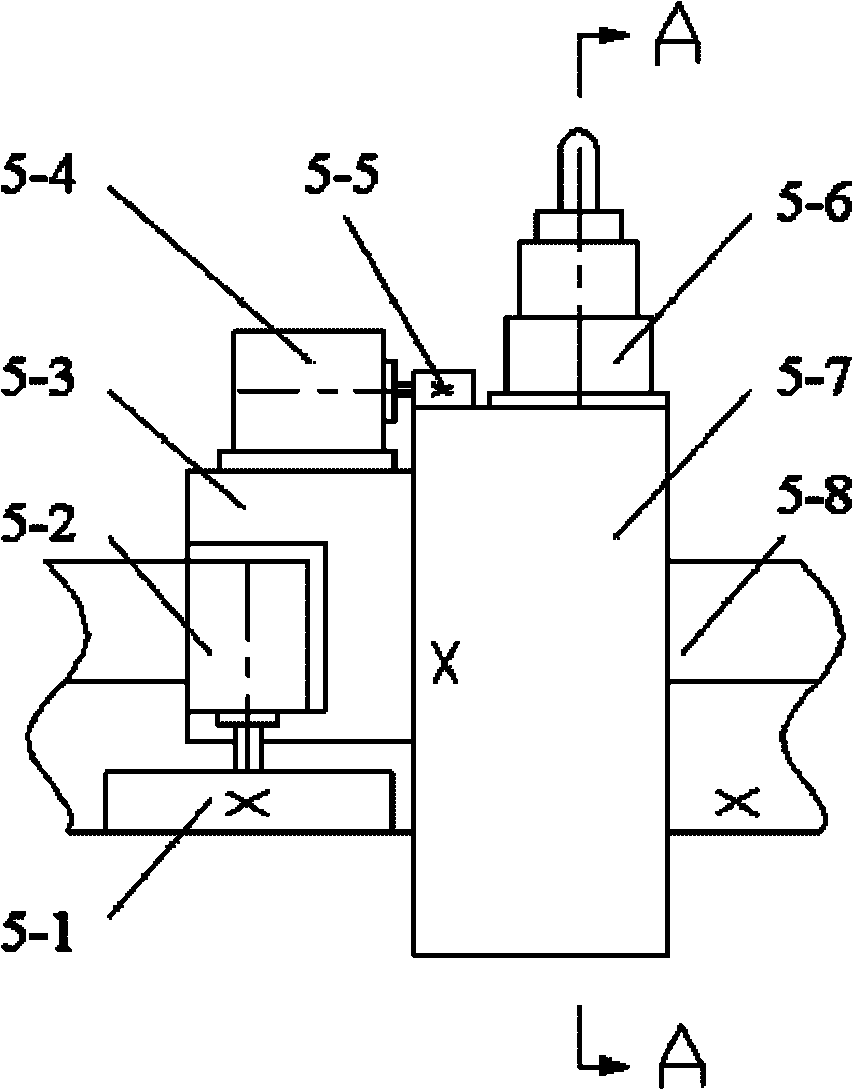

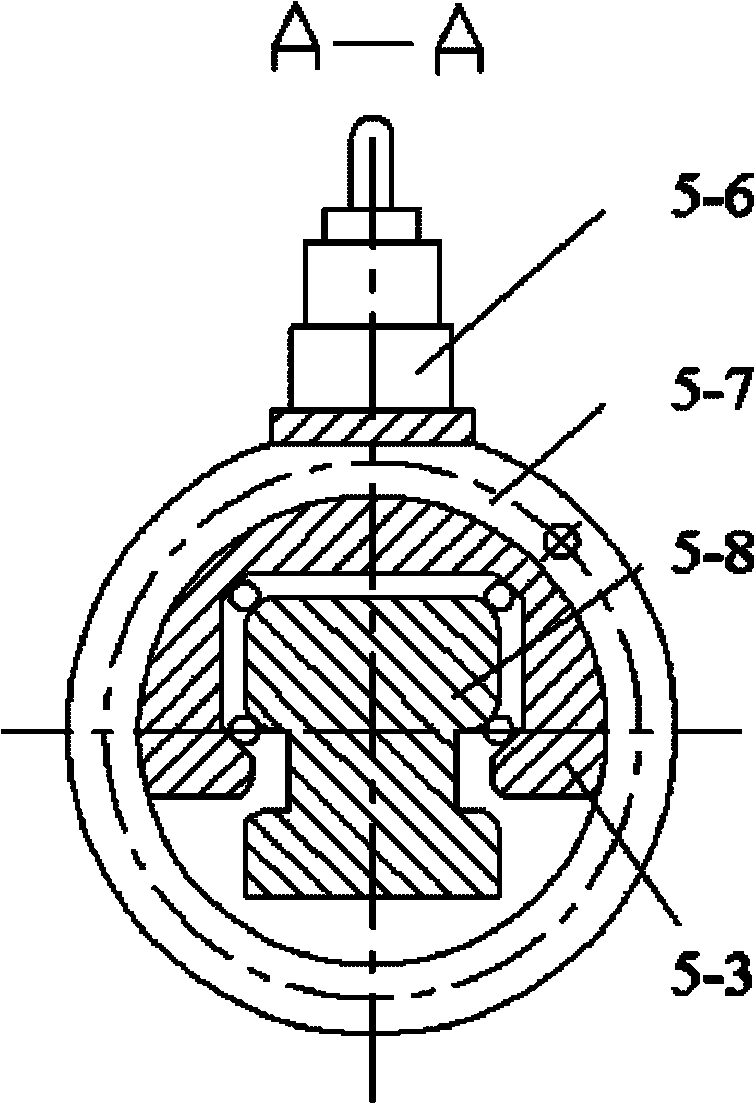

[0022] The specific implementation of the present invention is described in detail in conjunction with the accompanying drawings and technical solutions. The equipment and method are implemented on typical main pipe parts, and the processing of the inner surface of the arc section is completed. The main pipeline is a large thick-walled pipeline, weighing about 11 tons. There are two nozzles at a certain angle on the outer surface, and the straight and arc sections at both ends are connected tangentially. The pipe size is Φ785mm in inner diameter, Φ965mm in outer diameter, the bending angle of the arc section is 56.4°, and the lengths of the straight sections at both ends are 2560.3mm and 1234.2mm respectively. Such as figure 1 As shown, the processing equipment is based on the equipment bed, including the equipment bed, columns, support rods, clamping devices, rotary milling devices, worktables and guide rails. There are guide rails installed on the equipment bed, and a workt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com