Dual-crank arm type piezoelectric-electromagnetic composite power generation device

An electromagnetic composite and power generation device technology, which is applied to electromechanical devices, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve problems such as small power generation, poor adaptability, and poor low-frequency adaptability , to achieve the effect of increasing the power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

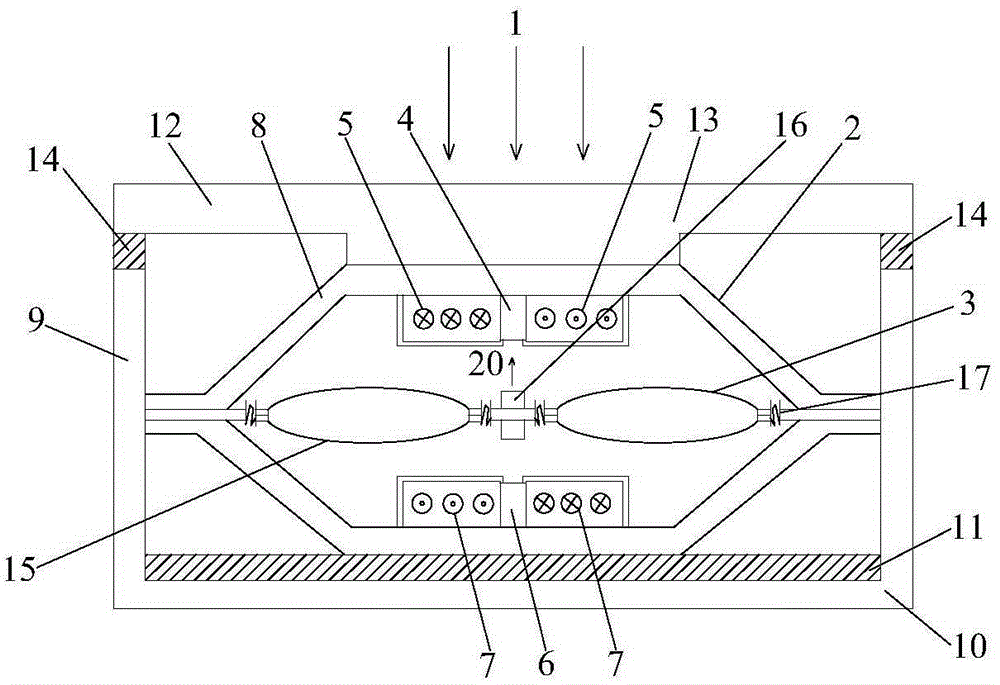

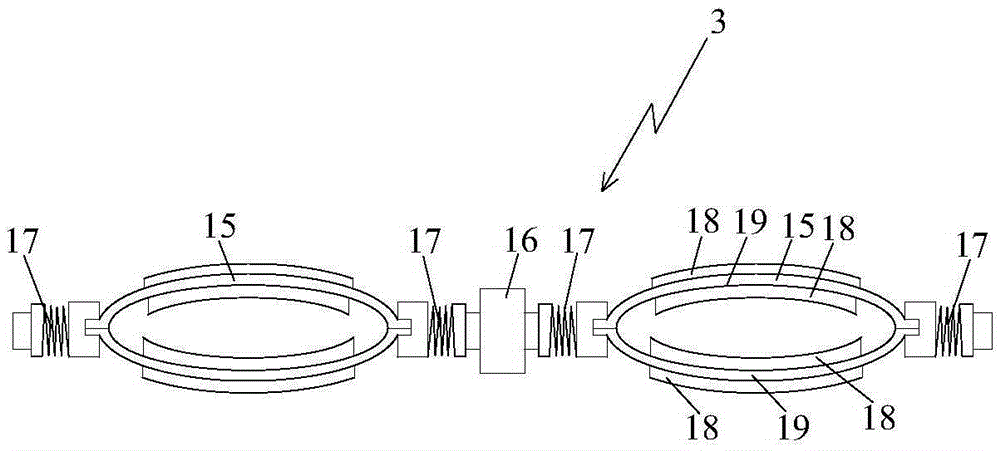

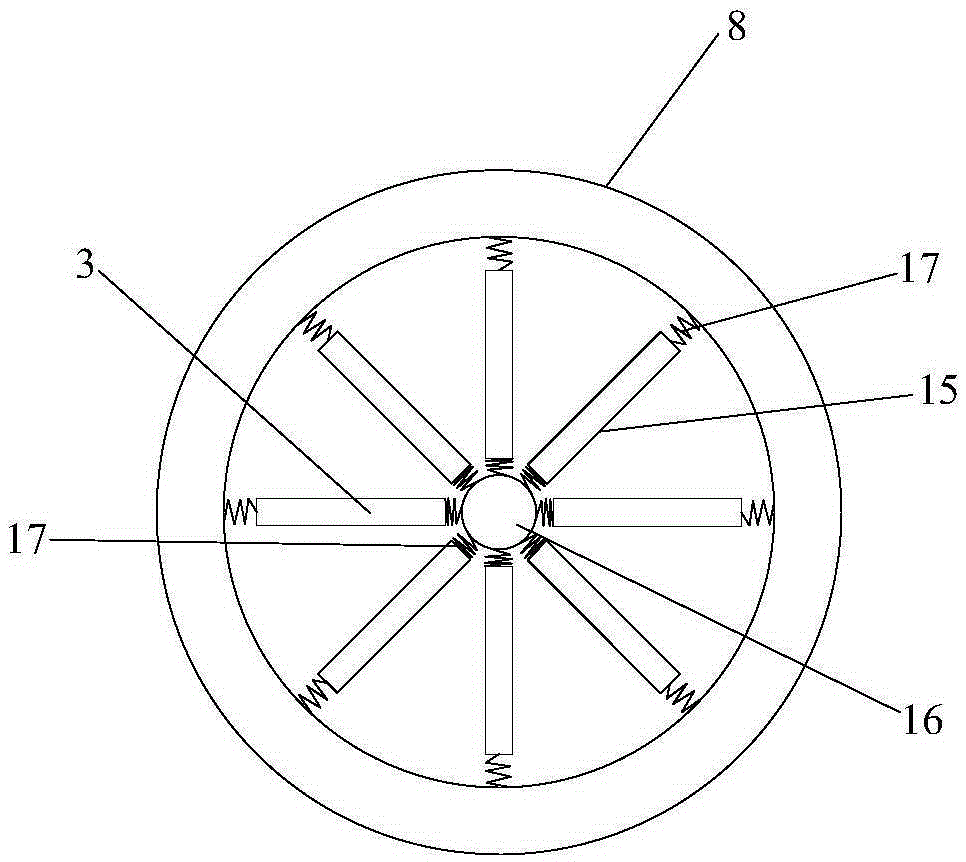

[0029] The structural longitudinal section schematic diagram of the hyperbolic arm type piezoelectric-electromagnetic composite power generation device of the present invention is as follows: figure 1 As shown, it includes: a hyperbolic piezoelectric-electromagnetic composite transducer 2 . The hyperbolic piezoelectric-electromagnetic composite transducer 2 includes: the hyperbolic piezoelectric-electromagnetic composite generator vibrator 3, the upper permanent magnet 4, the upper induction coil 5, the lower permanent magnet 6, the lower induction coil 7 and the piezoelectric - Electromagnetic composite transducer box 8 . The piezoelectric-electromagnetic composite transducer box 8 adopts a cymbal-shaped structural bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com