Ultrathin aluminum-based steel flowing tank

An ultra-thin, first-class steel technology, applied in the direction of core, mold, mold composition, etc., can solve the problems that the surface layer is easy to be peeled off, reduce the working efficiency of the smelting process, and affect the quality, so as to improve the purity and process Stability, the possibility of eliminating alloy contamination, and the effect of improving the pass rate and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

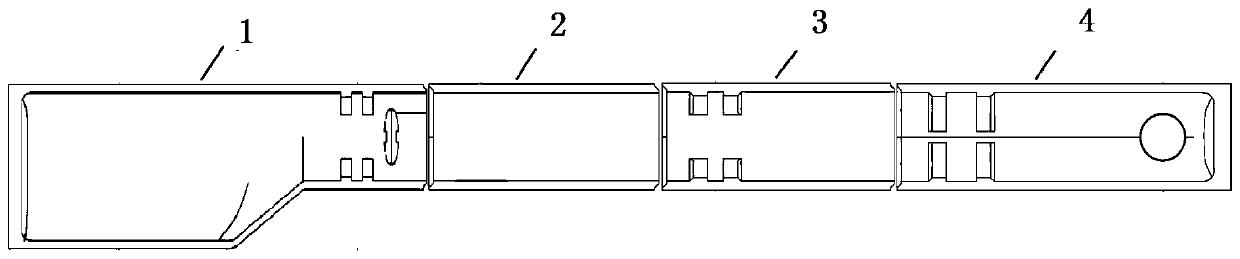

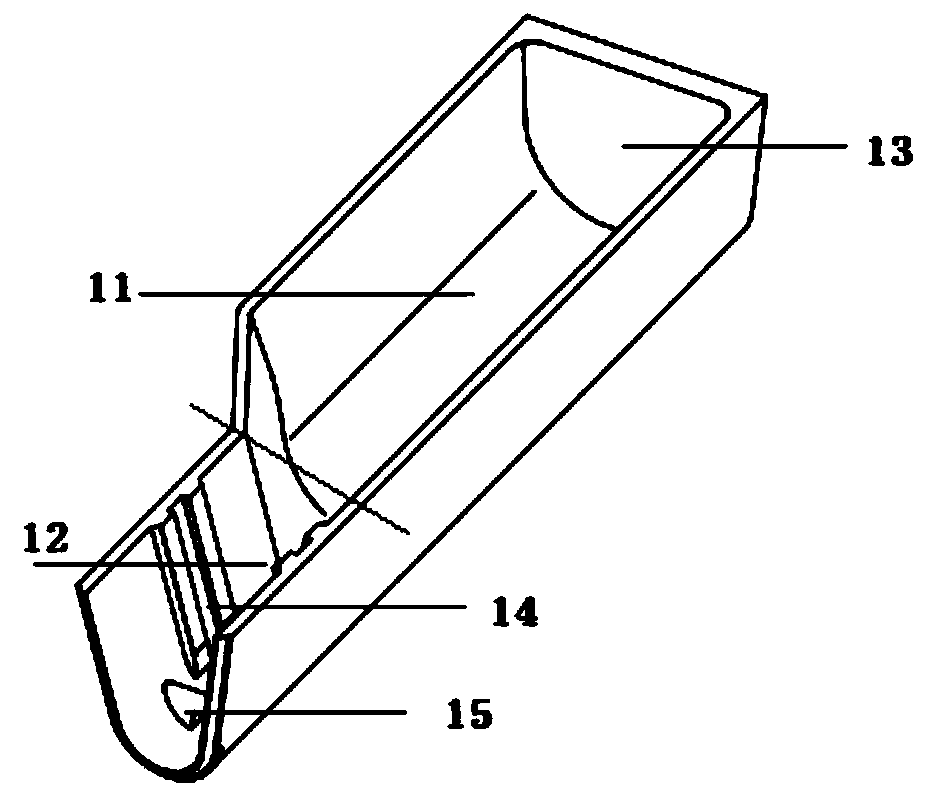

[0050] An ultra-thin aluminum-based flow channel, the channel body is a segmented structure, including a connecting steel channel 1, a first flow steel channel 2, a second flow steel channel 3 and a steel tapping channel 4 connected in sequence. 45° / 135° smooth surface connection; the tank body has a layered structure from the inner wall to the outside, specifically, such as Figure 8 The layered structure shown, from the inner wall of the tank to the outside, is the refractory layer 6, the transition layer 5, the second reinforcement layer 4, the metal mesh 1, the first reinforcement layer 2 and the protective layer 3. The above layered structures are all coated with The refractory layer 6, the transition layer 5, the reinforcement layer and the protective layer 3 are all refractory materials, and the refractory layer 6 is made of spherical and flake white corundum materials; the transition layer 5 and the protective layer 3 are all made of oxide refractory Material, the rein...

Embodiment 2

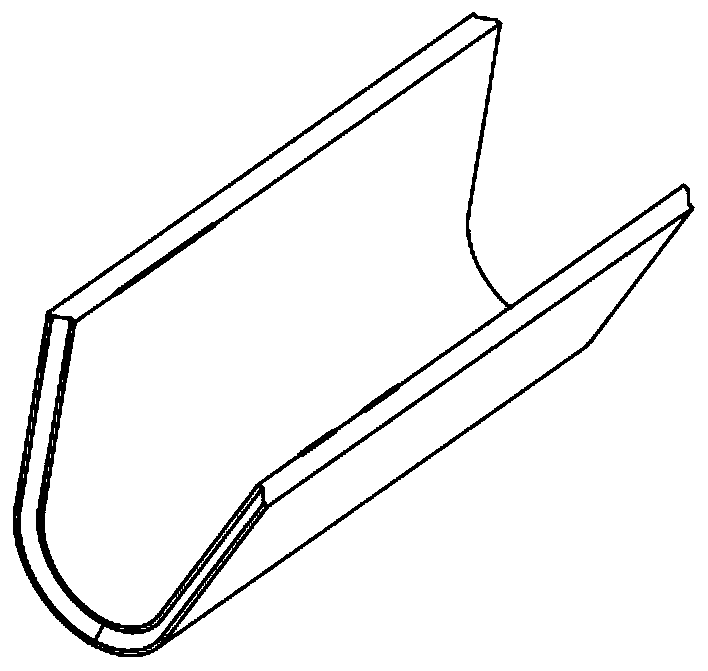

[0052] An ultra-thin aluminum-based flow channel, the channel body is a segmented structure, including a connecting steel channel 1, a first flow steel channel 2, a second flow steel channel 3 and a steel tapping channel 4 connected in sequence. Such as Figure 6 The buckle method shown is connected; the tank body is a layered structure from the inner wall to the outside, specifically, as Figure 8 The layered structure shown, from the inside to the outside, is the refractory layer 6, the transition layer 5, the second reinforcement layer 4, the metal mesh 1, the first reinforcement layer 2 and the protective layer 3, and the above layered structures are all made of coated The refractory layer 6, the transition layer 5, the reinforcement layer and the protective layer 3 are all refractory materials, and the refractory layer 6 is made of spherical and flake white corundum materials; the transition layer 5 and the protective layer 3 are all made of oxide refractory materials, T...

Embodiment 3

[0058] Utilize the ultra-thin aluminum-based flow steel channel product produced in this embodiment 1 and comparative example 1 to carry out pouring experiment:

[0059] Pouring volume: 4,000 kg cobalt-chromium-nickel-based superalloy molten steel

[0060] Pouring temperature: 1450~1570℃, pouring time: 20min

[0061] Process:

[0062] 1) Preheat the flow steel channel assembly for 8 to 10 hours, the preheating temperature is ≥1000°C, and then follow the figure 1 Assembled flow channel shown;

[0063] 2) Pour 4,000 kg of cobalt-chromium-nickel-based superalloy liquid into the assembled ladle, and send it to the pouring process through the ladle.

[0064] Experimental results: Through observation, it is found that in the one-time process from use to end, the flow steel channel product of Example 1 has no cracking, erosion resistance, no peeling, chipping and slag phenomenon, and the slag blocking effect in the first flow steel channel area Very good, it can effectively impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com