Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Meet thin and light requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

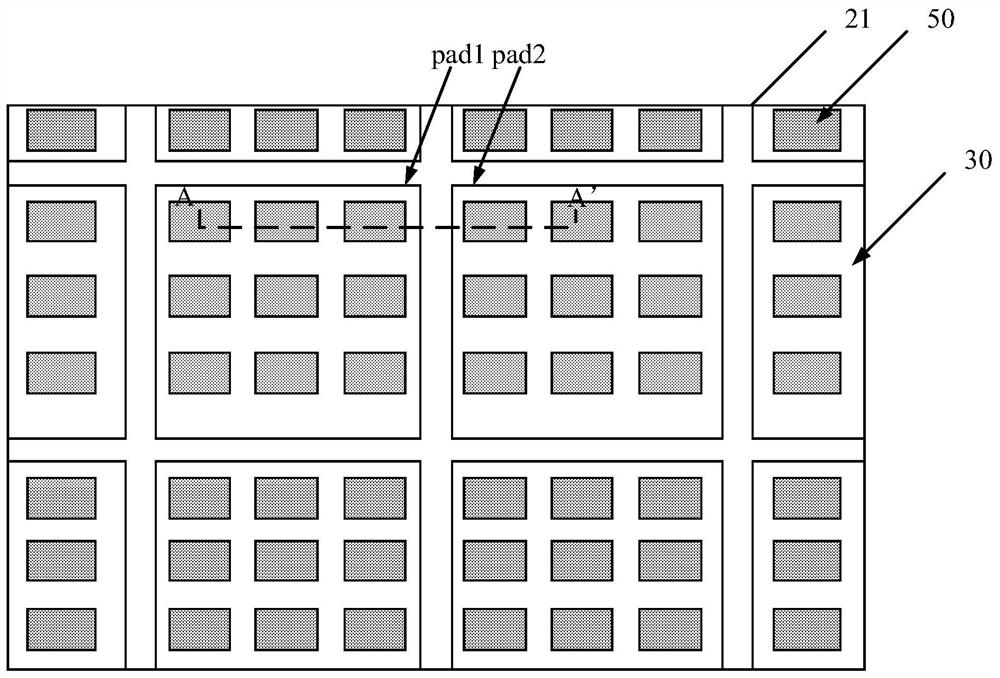

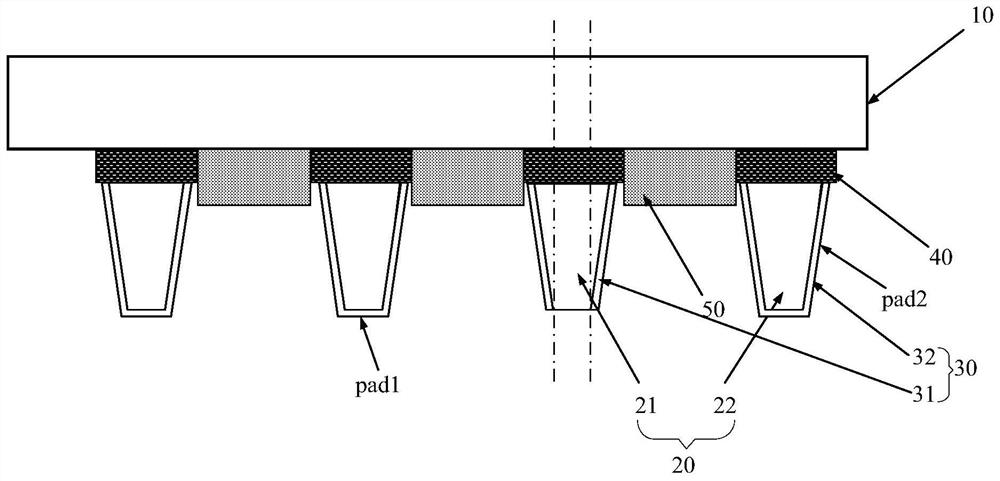

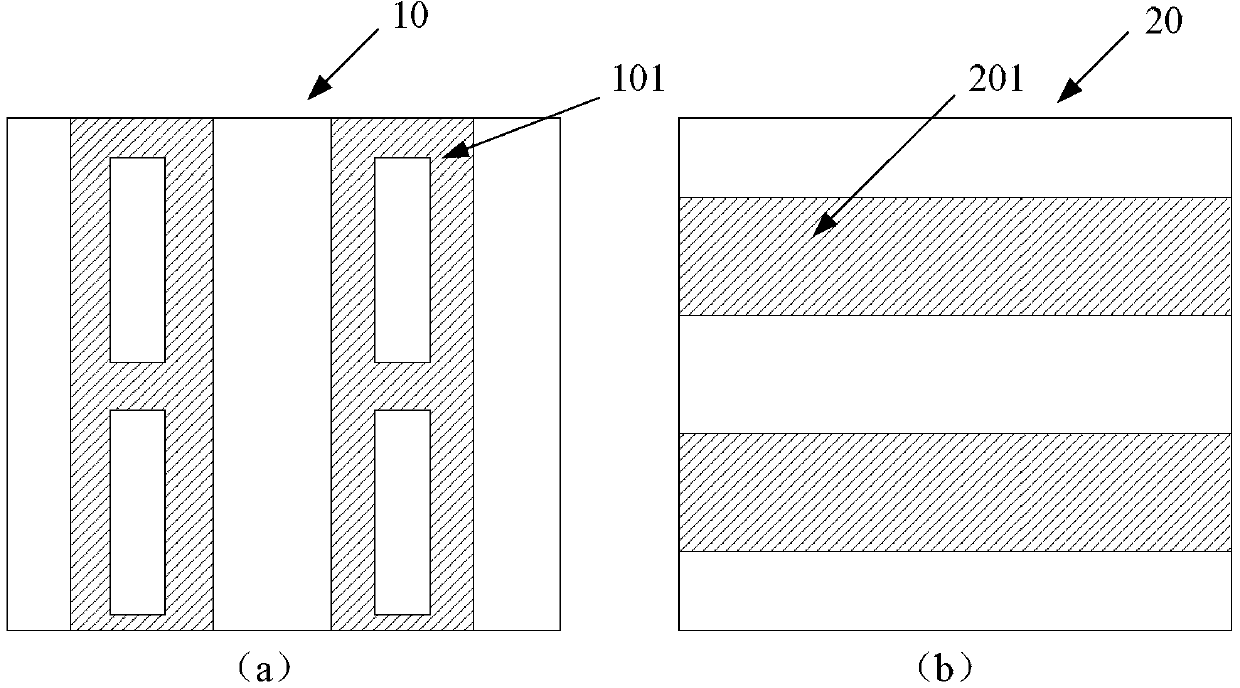

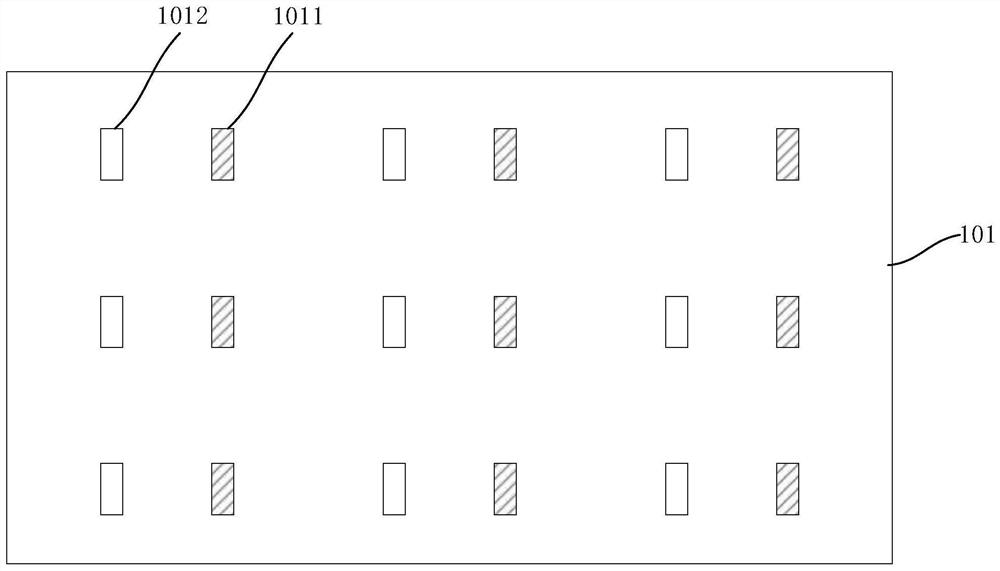

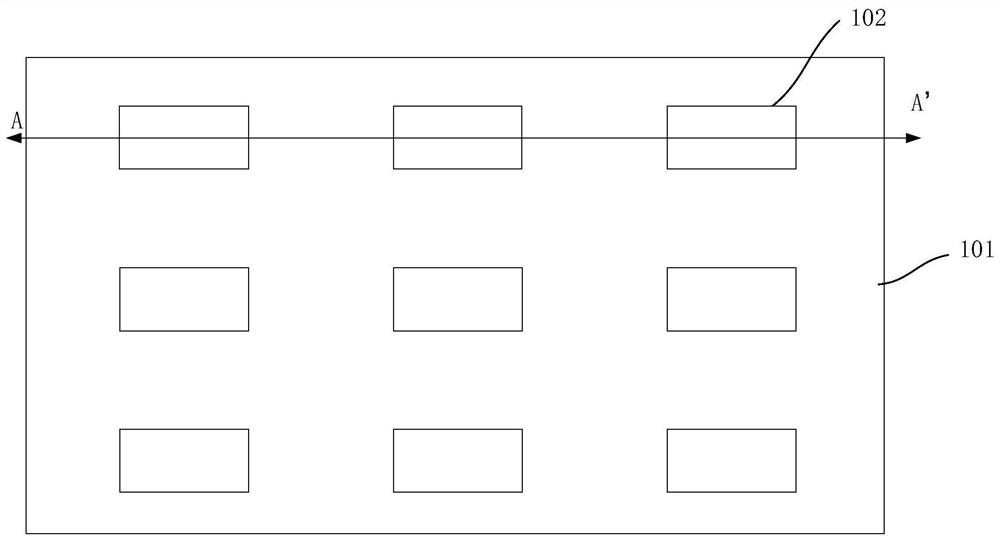

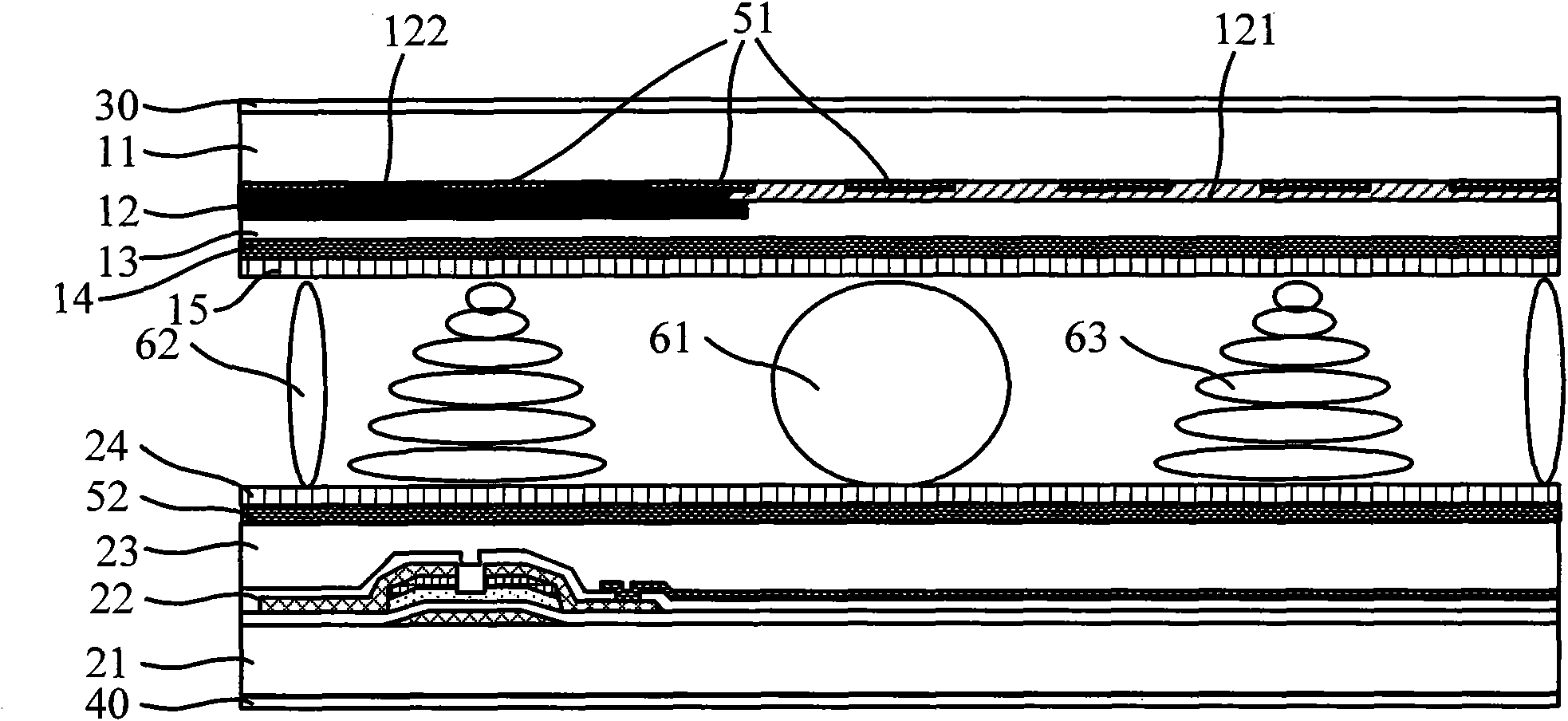

Liquid crystal panel and liquid crystal display

InactiveCN101930133AMeet thin and light requirementsLower assembly costsStatic indicating devicesAntenna supports/mountingsPolarizerElectromagnetic induction

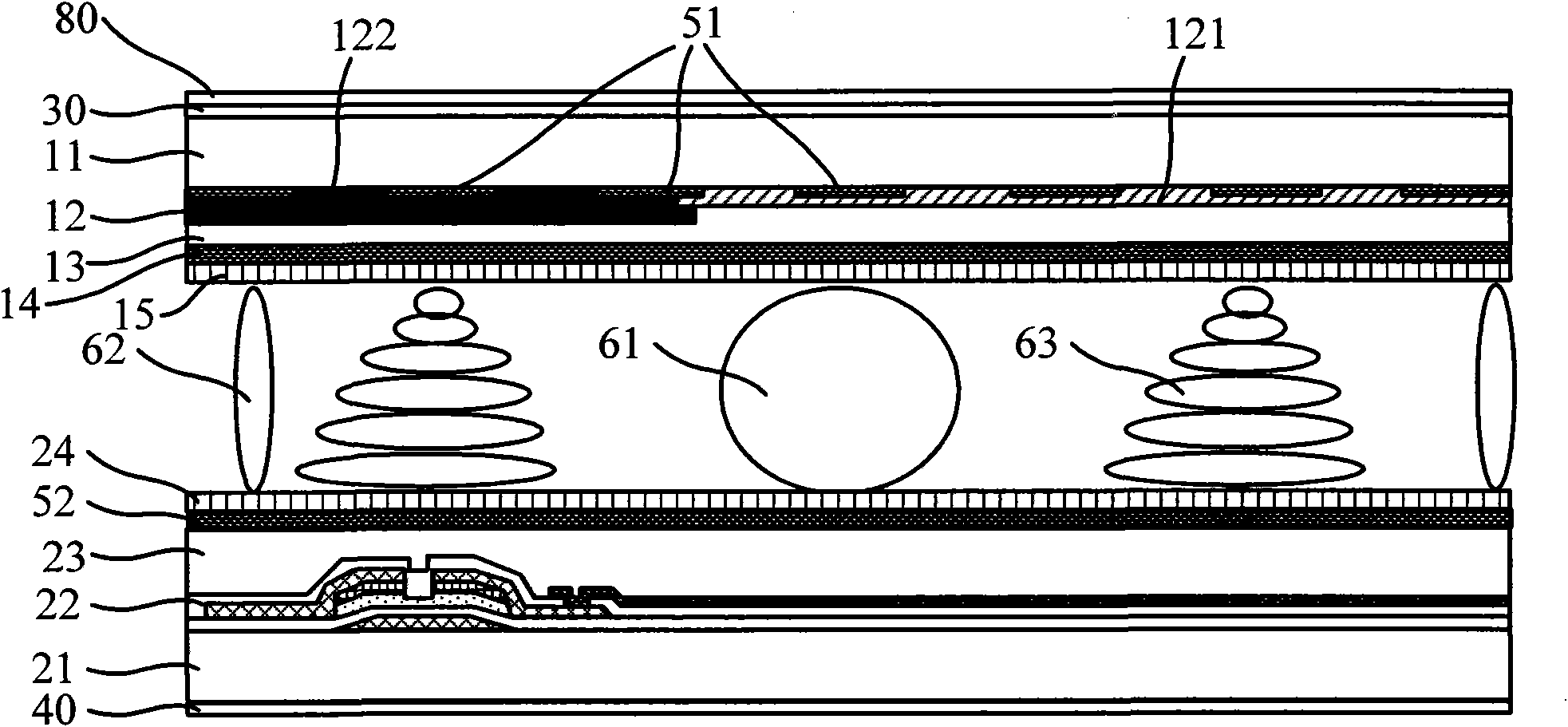

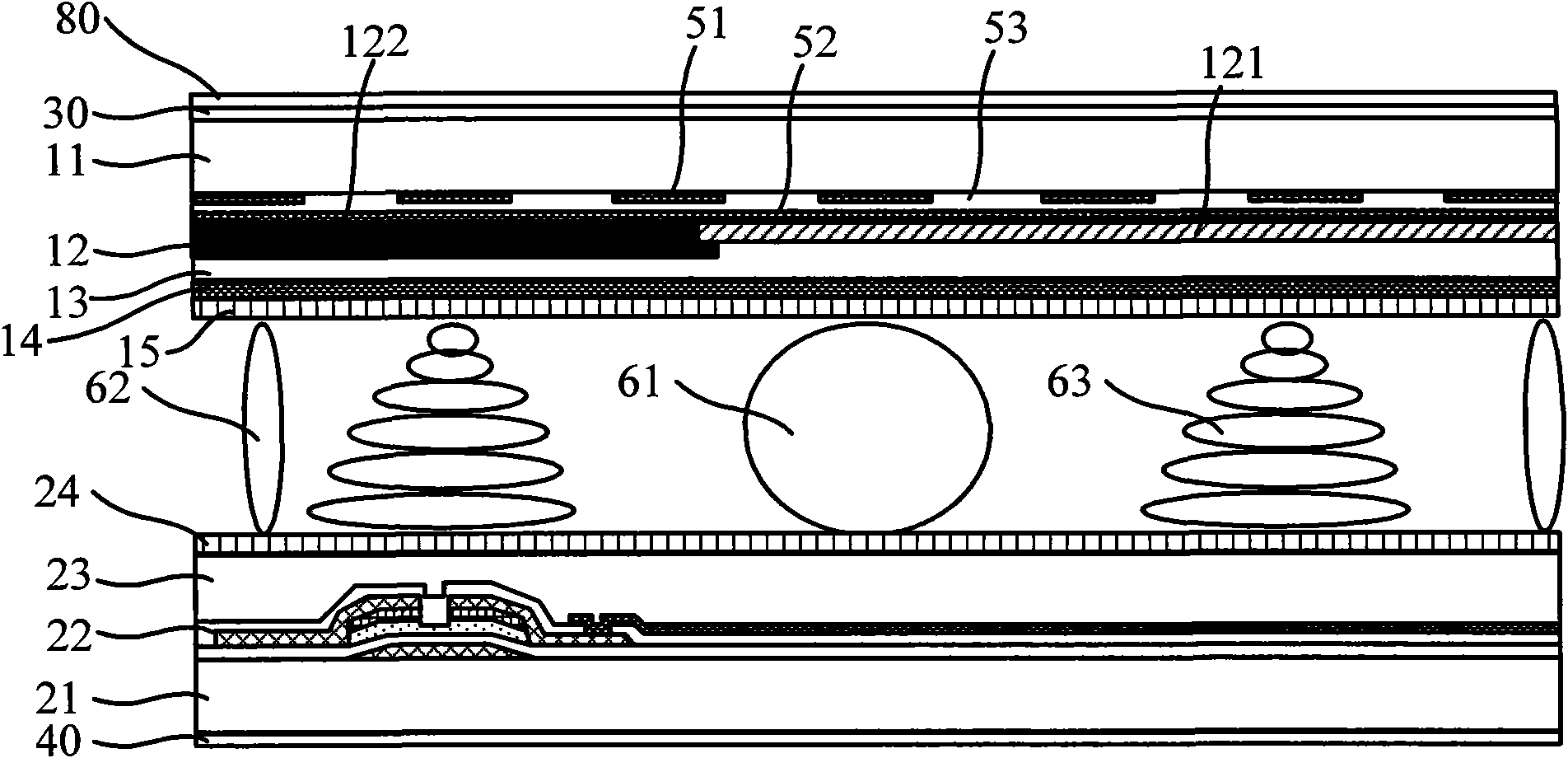

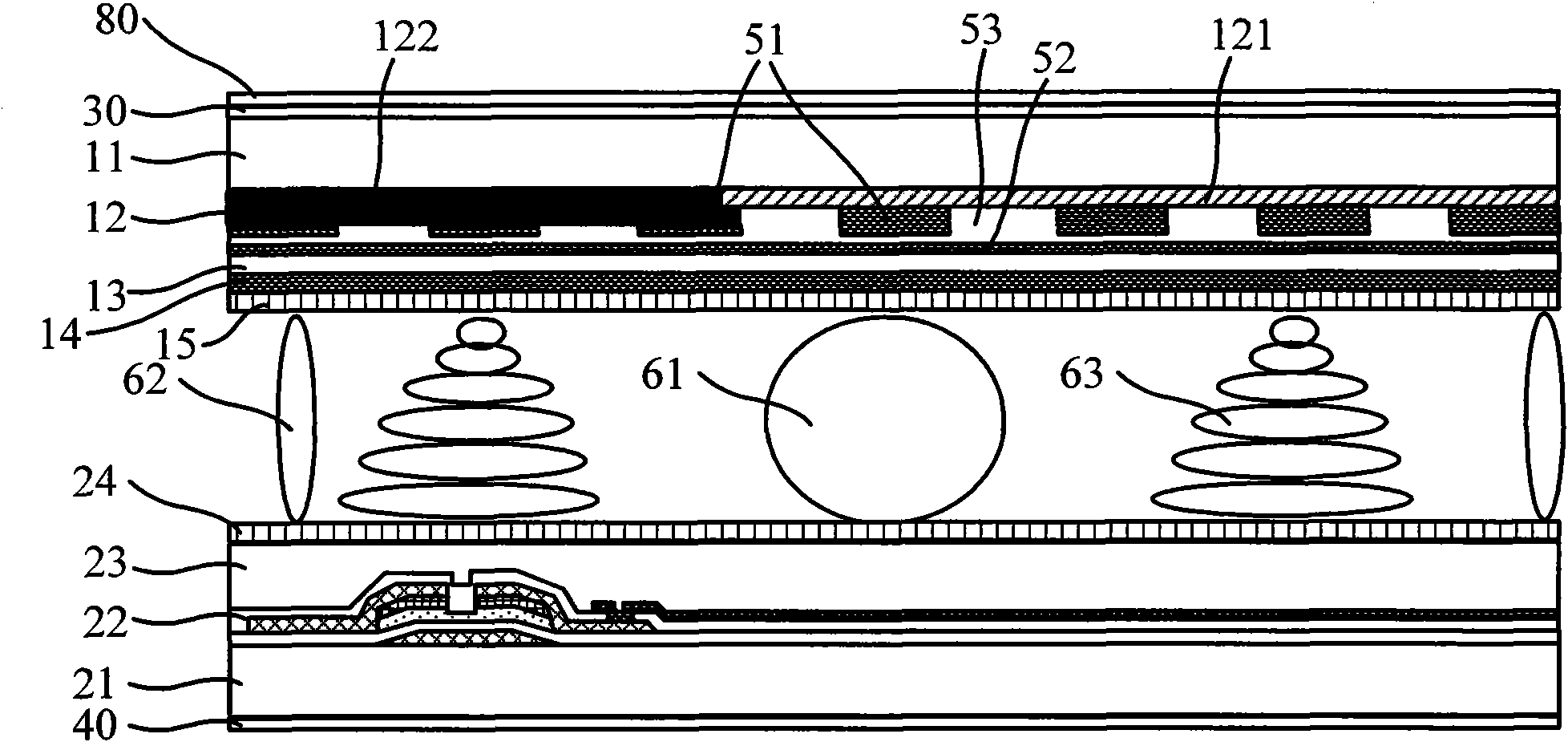

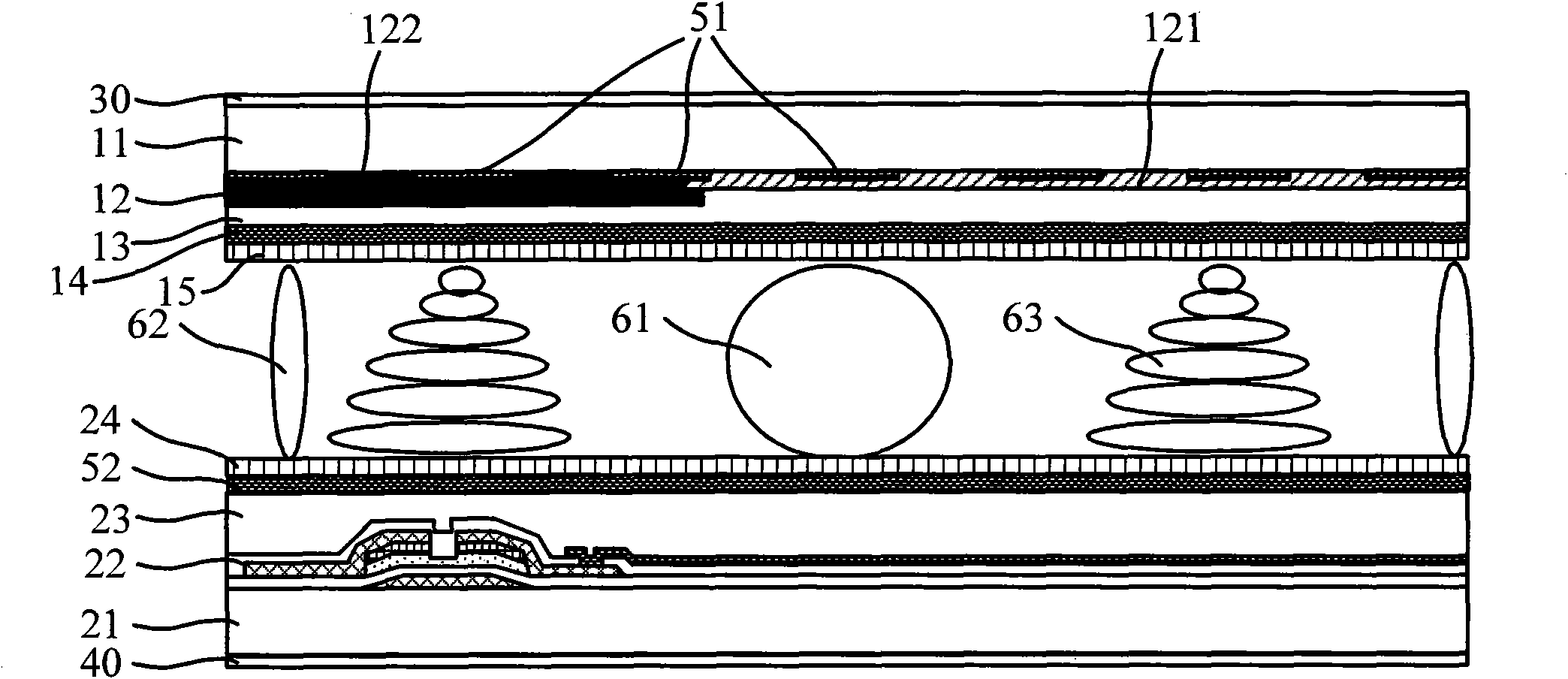

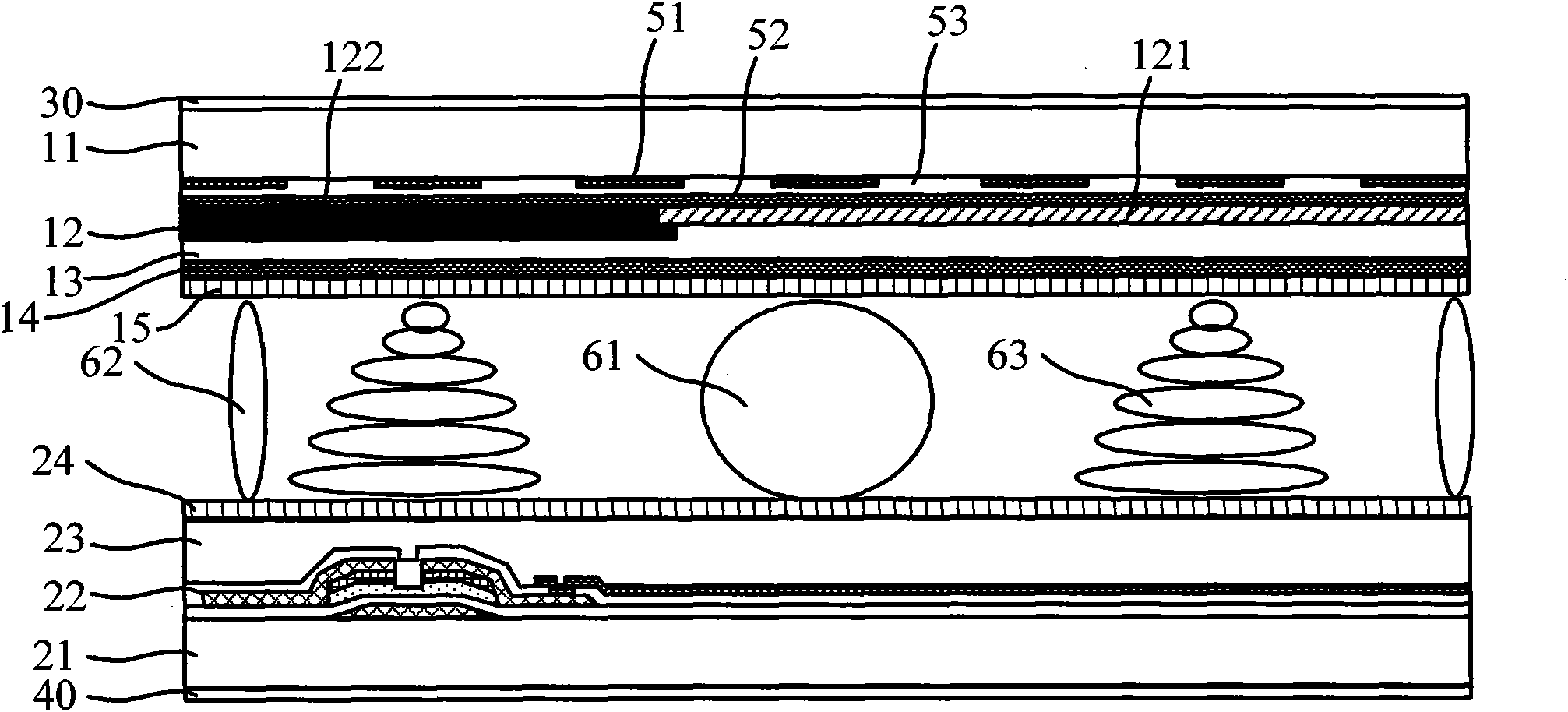

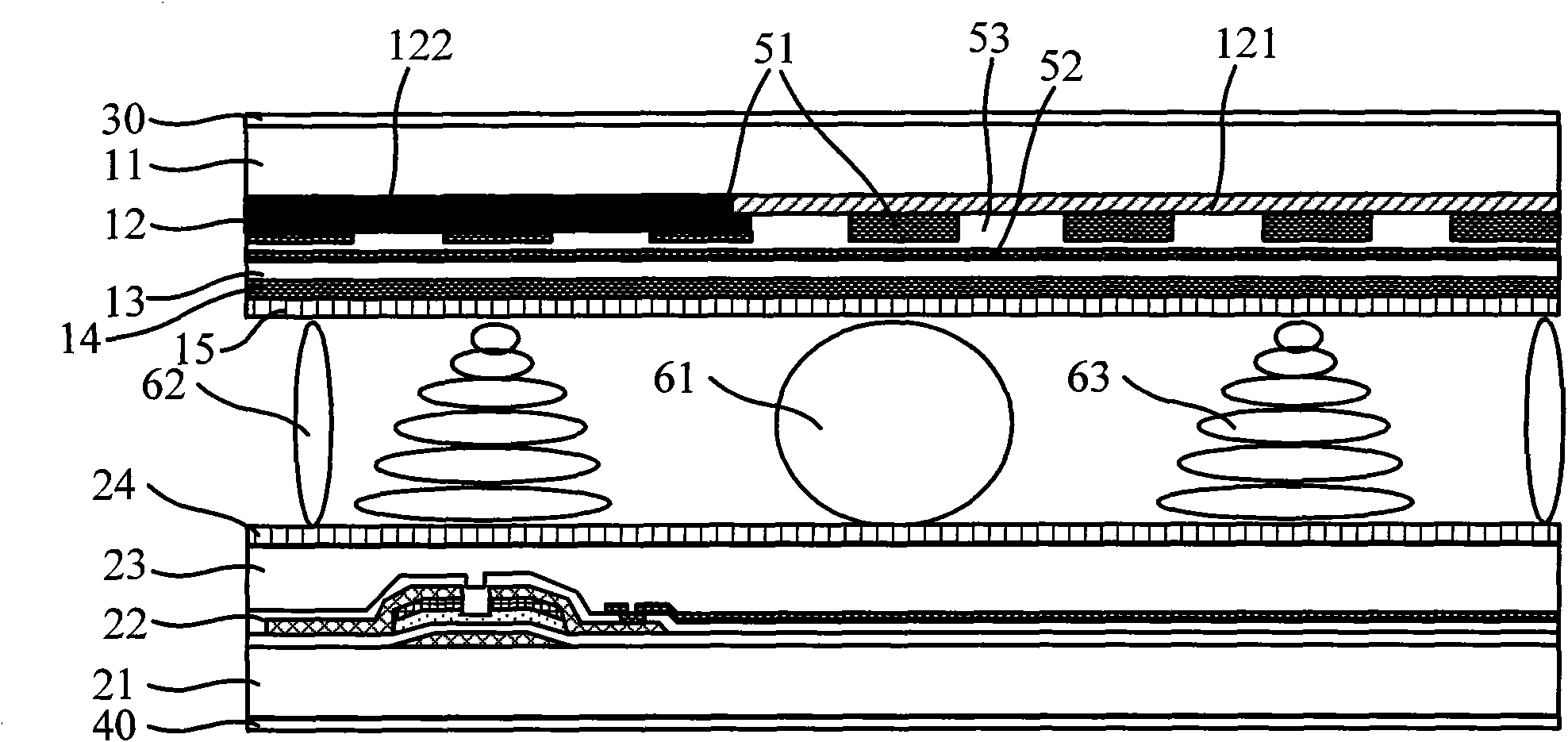

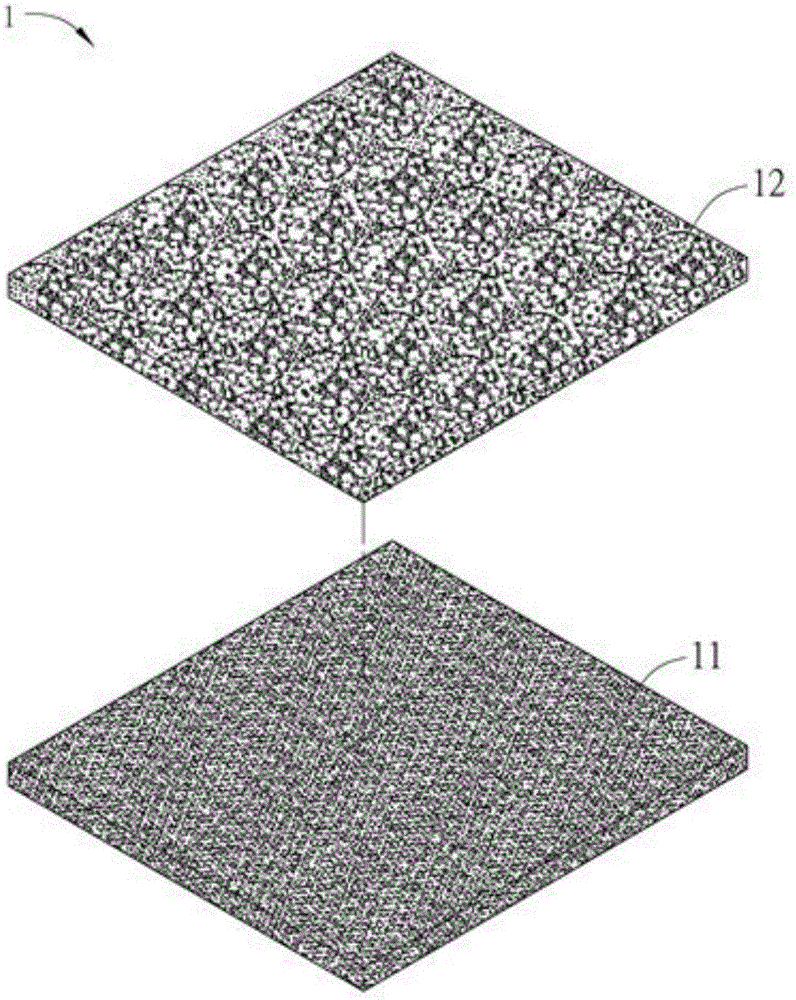

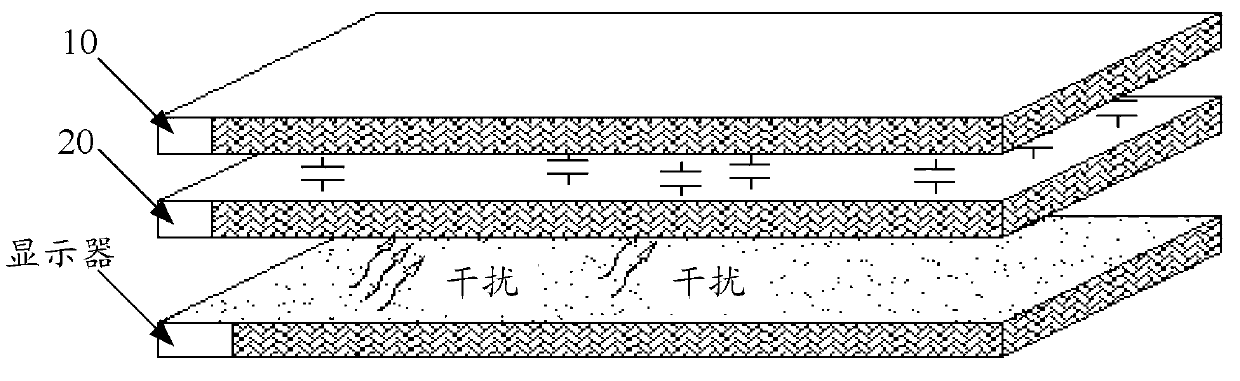

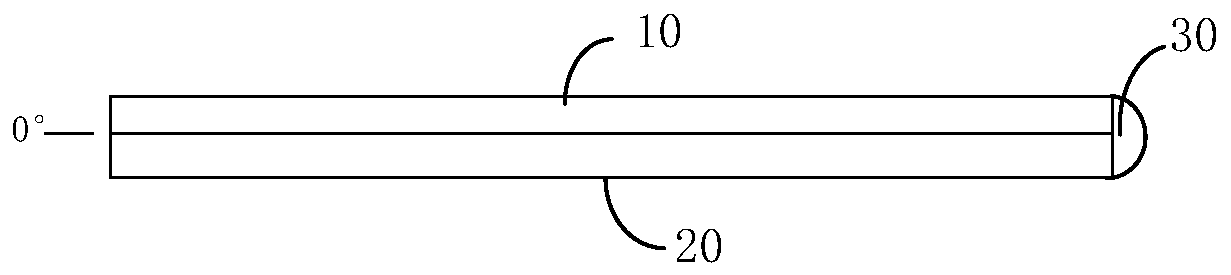

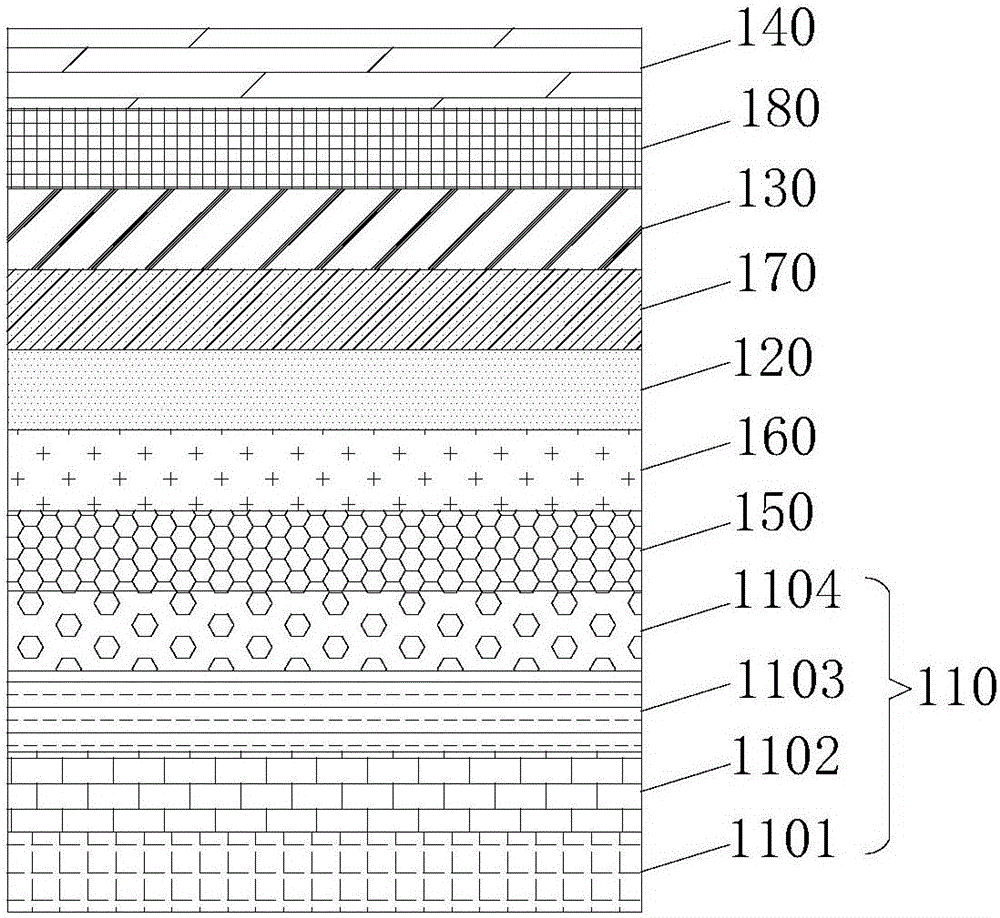

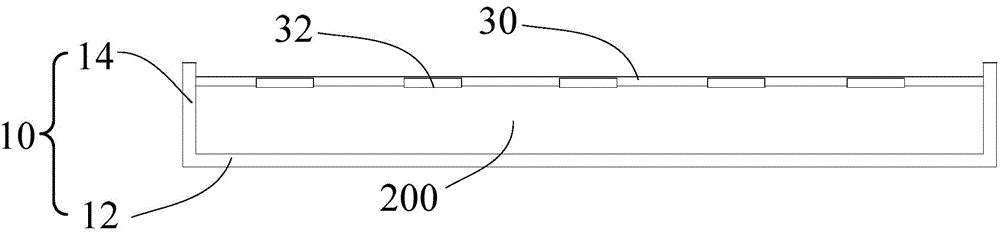

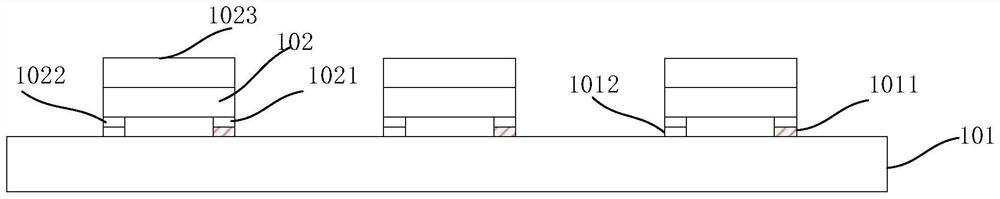

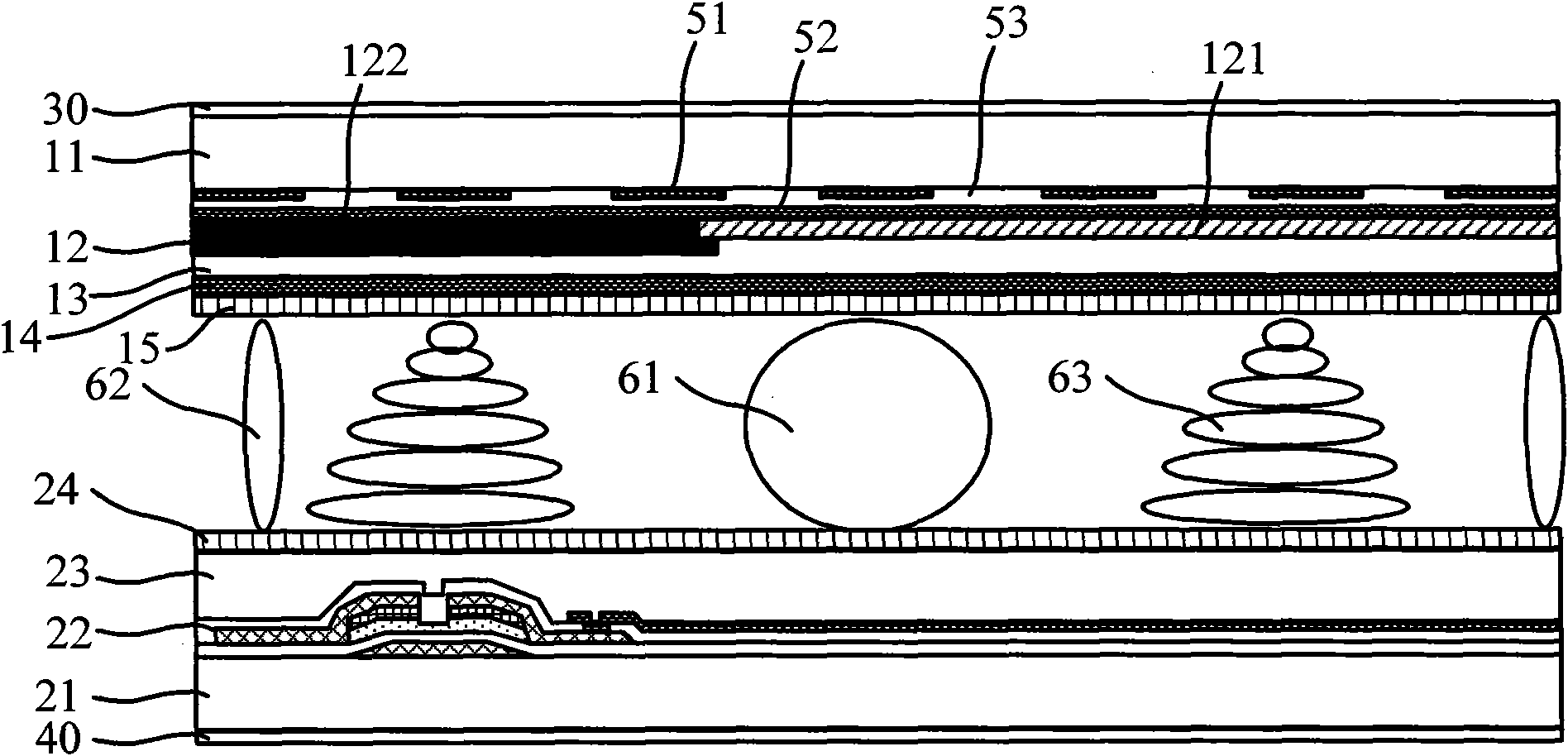

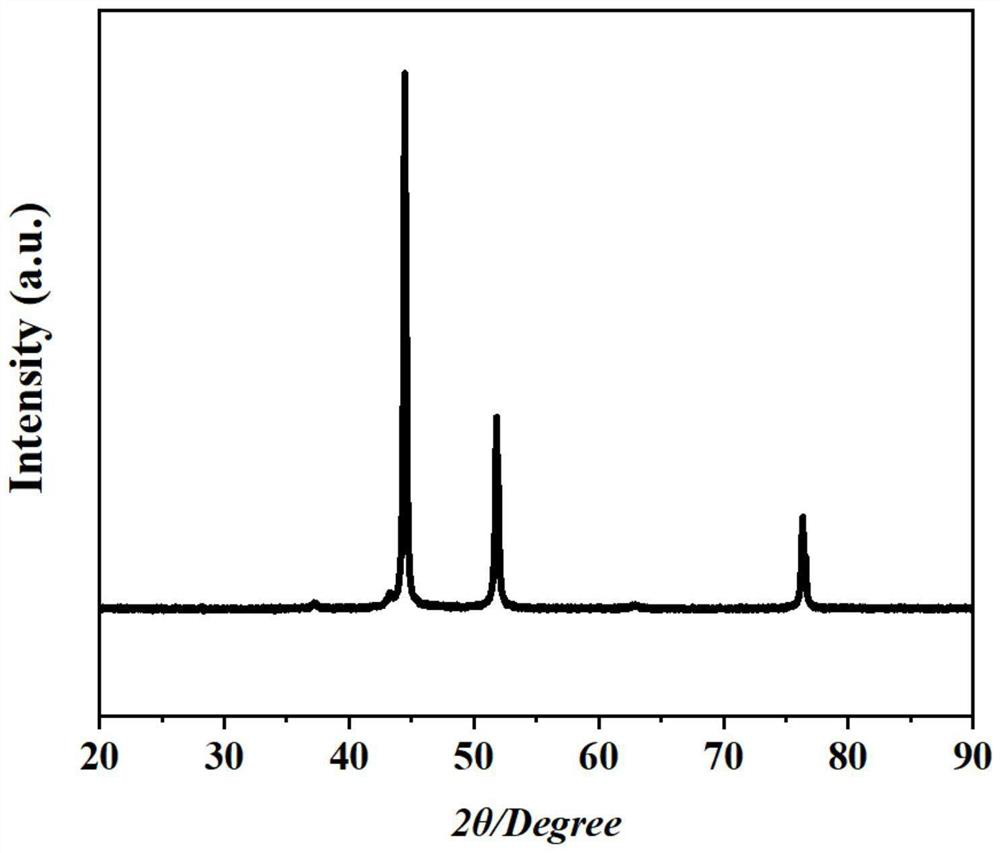

The invention relates to a liquid crystal panel and a liquid crystal display. The liquid crystal panel comprises a first substrate and a second substrate which are arranged opposite to each other, wherein a polaroid is attached to the side of the first substrate away from the second substrate; the liquid crystal panel also comprises a touch input structure and an electromagnetic antenna array; the touch input structure is attached to the outer surface of the polaroid away from the first substrate for identifying a touch signal; the electromagnetic antenna array at least comprises a first directional wire and a second directional wire which are made of conducting materials respectively and formed on any one film layer between the first substrate and the second substrate; and the antenna array is used for identifying an electromagnetic signal. The liquid crystal panel is adopted by the liquid crystal display; and the liquid crystal display also comprises a control device, wherein the control device is connected with the touch input structure and the electromagnetic antenna array for transmitting the touch signal and the electromagnetic signal for identification. The liquid crystal display simultaneously has an electromagnetic induction input function and a touch input function and meets the lightening and thinning requirements.

Owner:TAIGUEN TECH SHEN_ZHEN

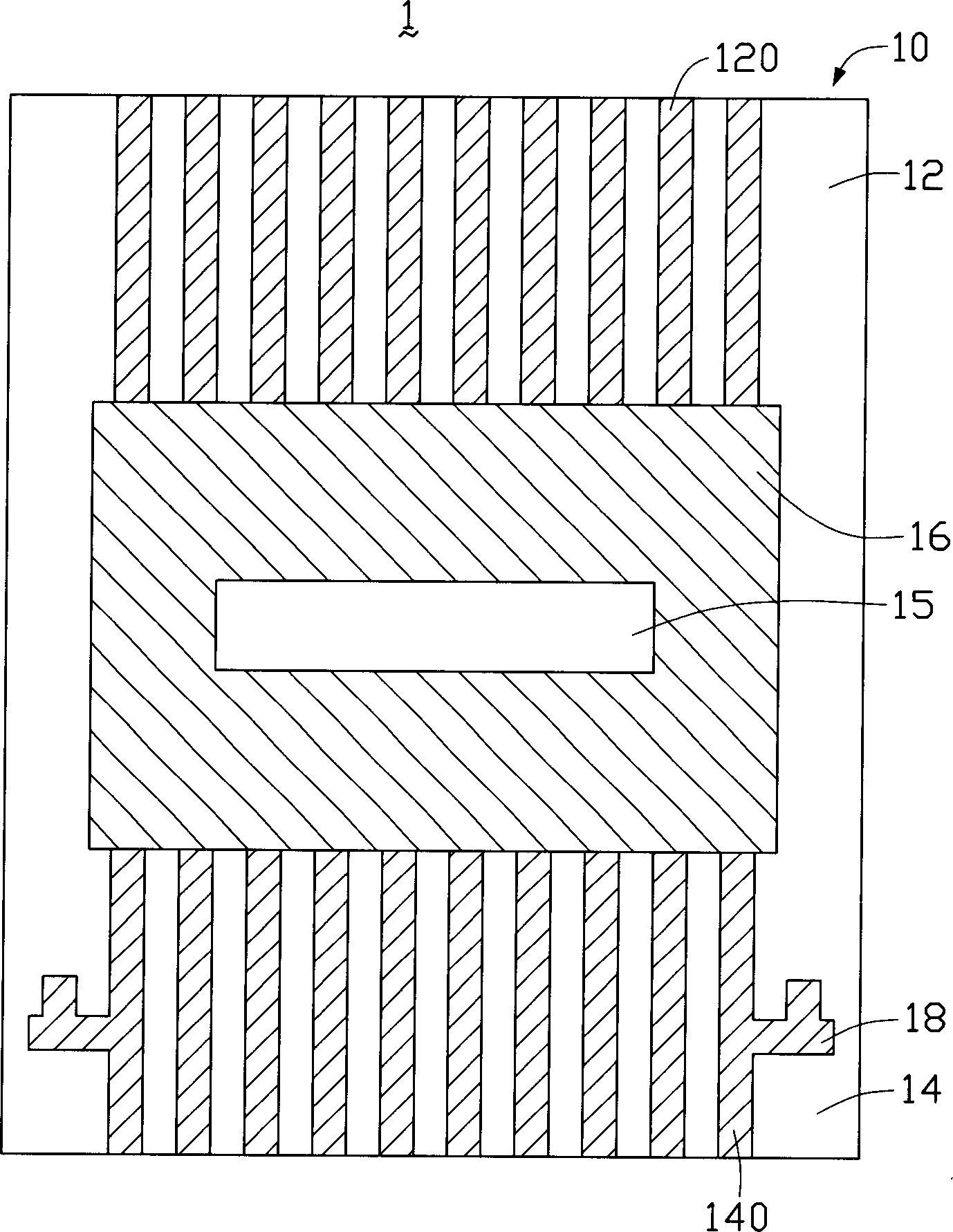

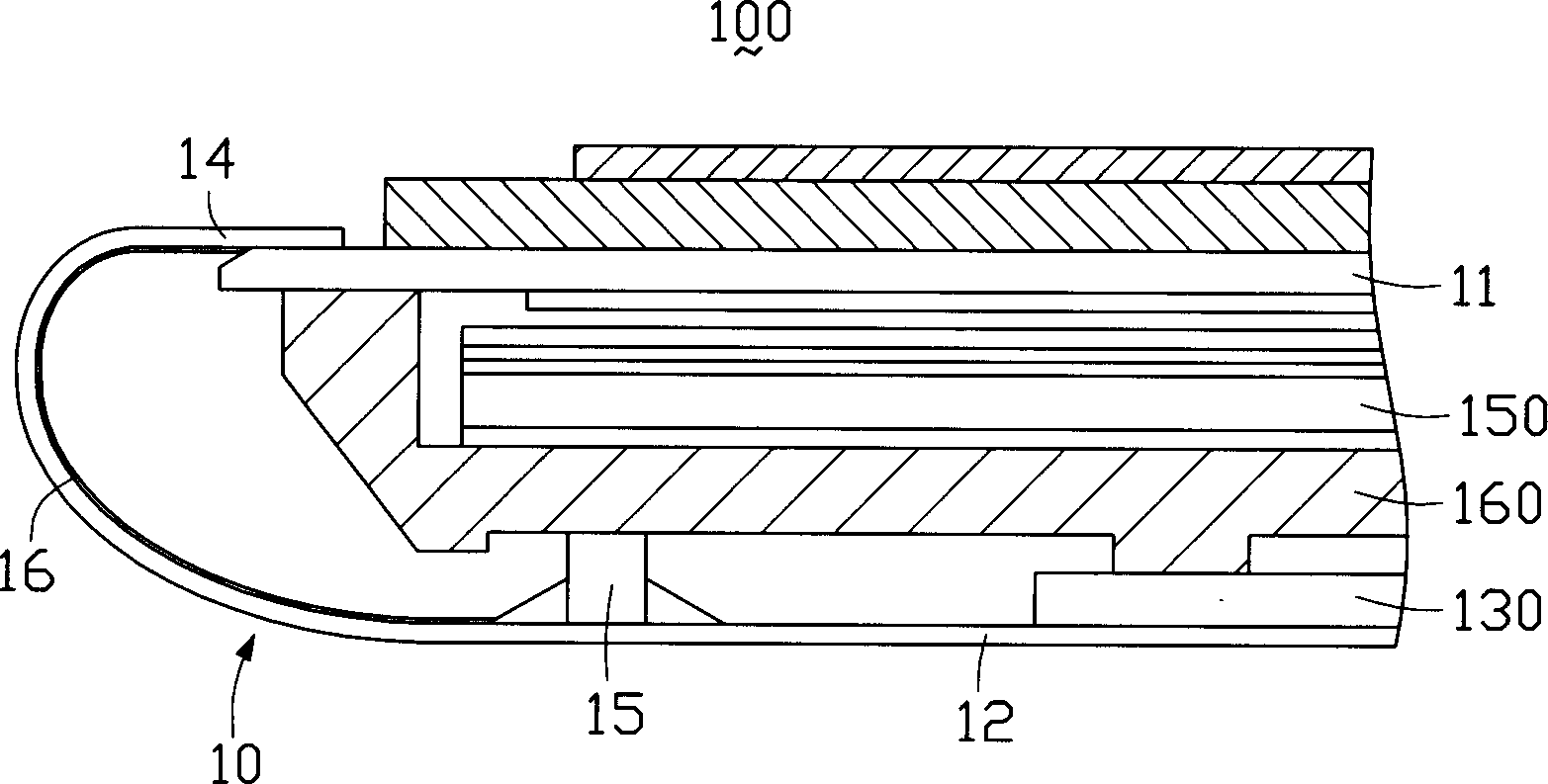

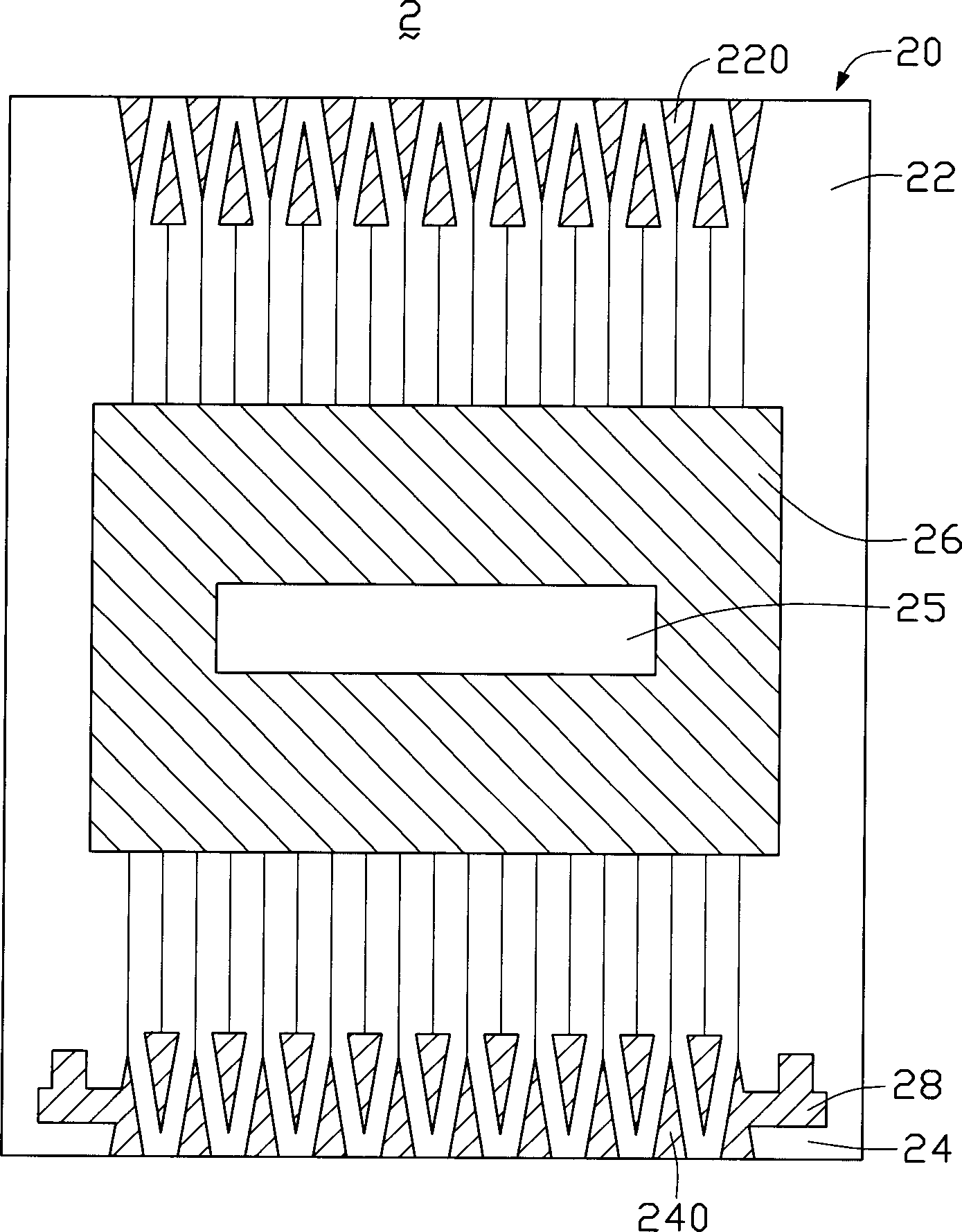

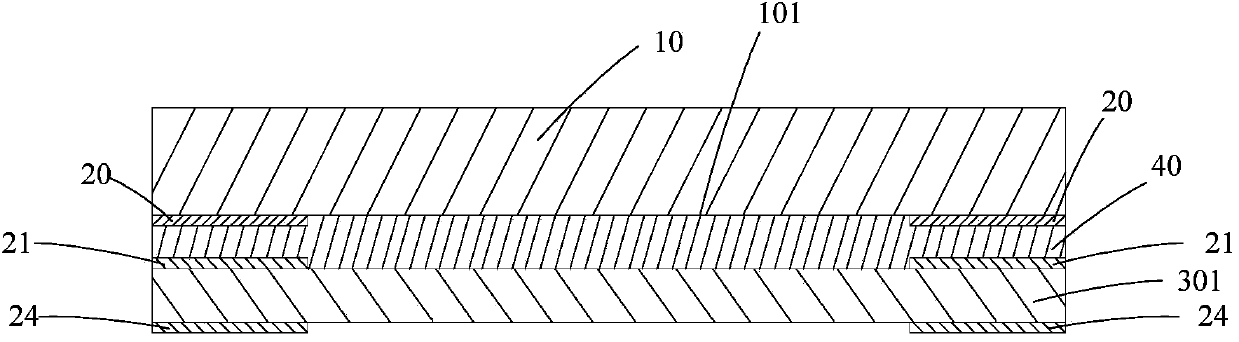

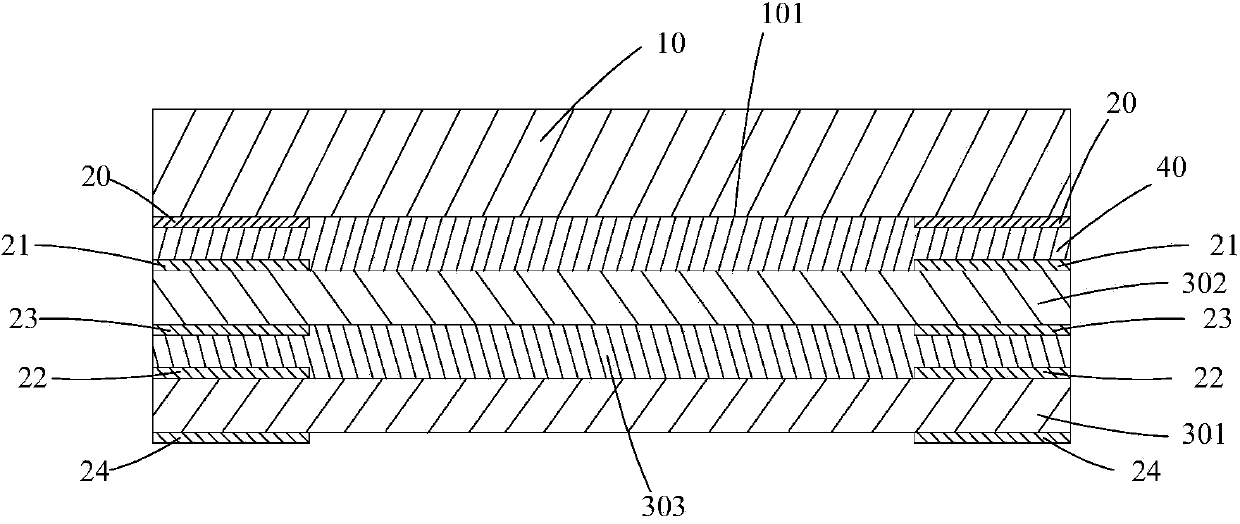

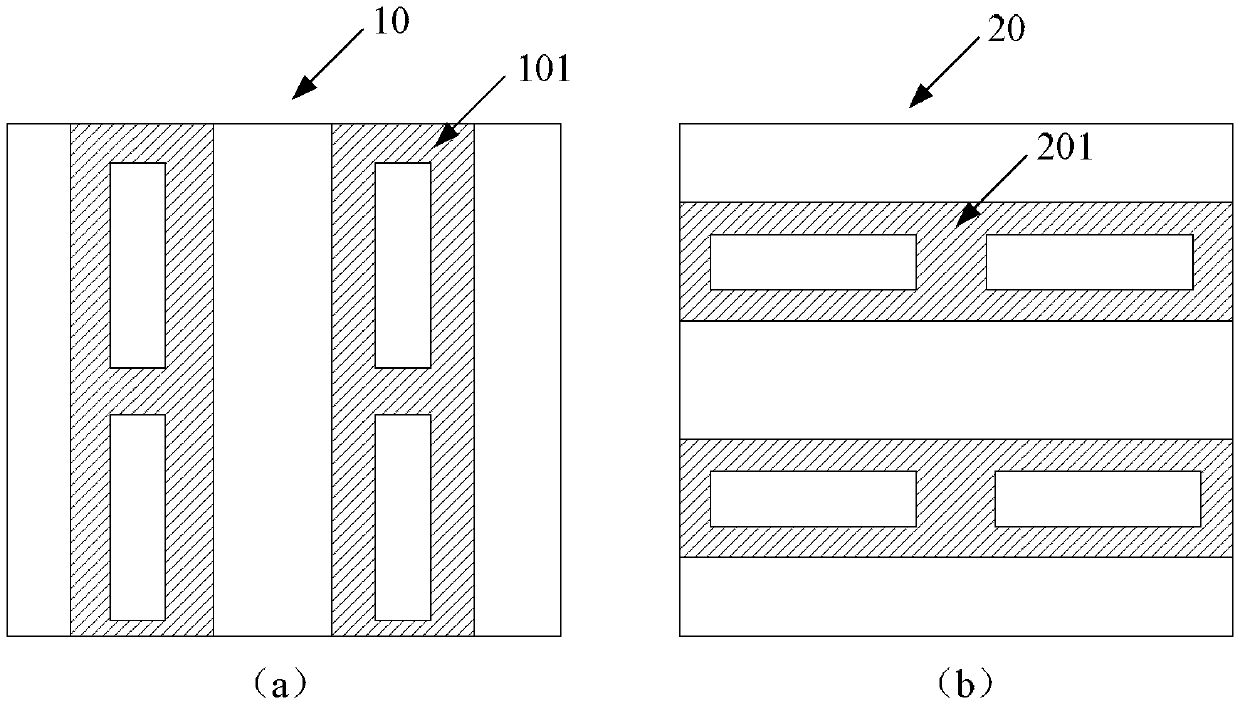

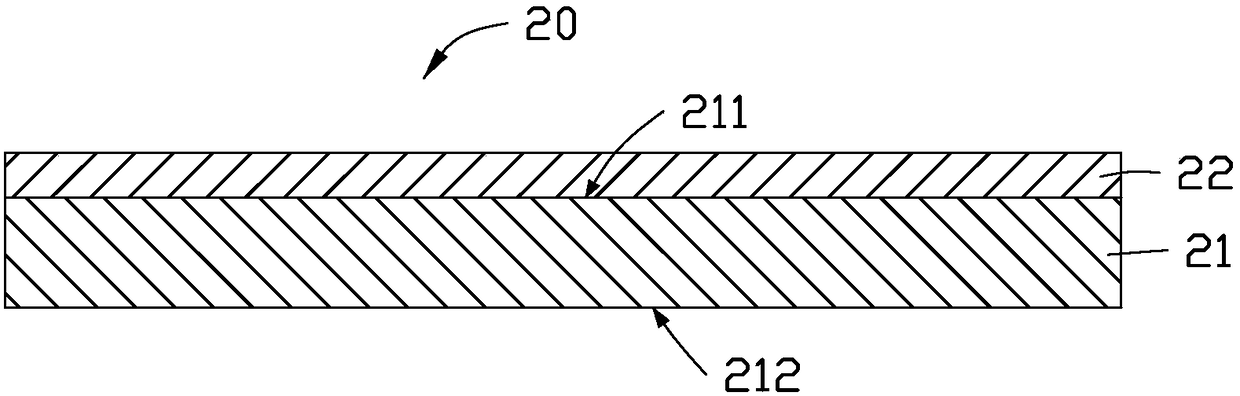

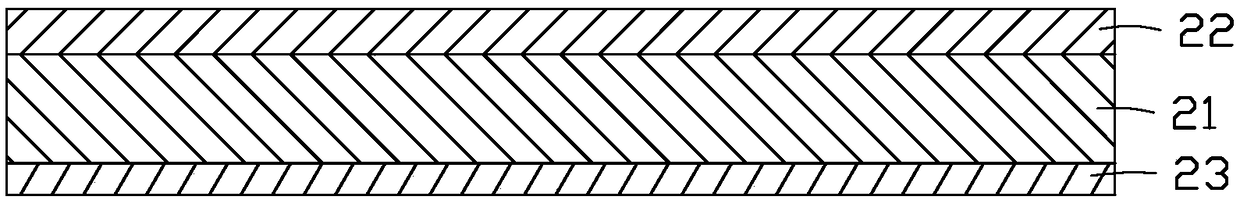

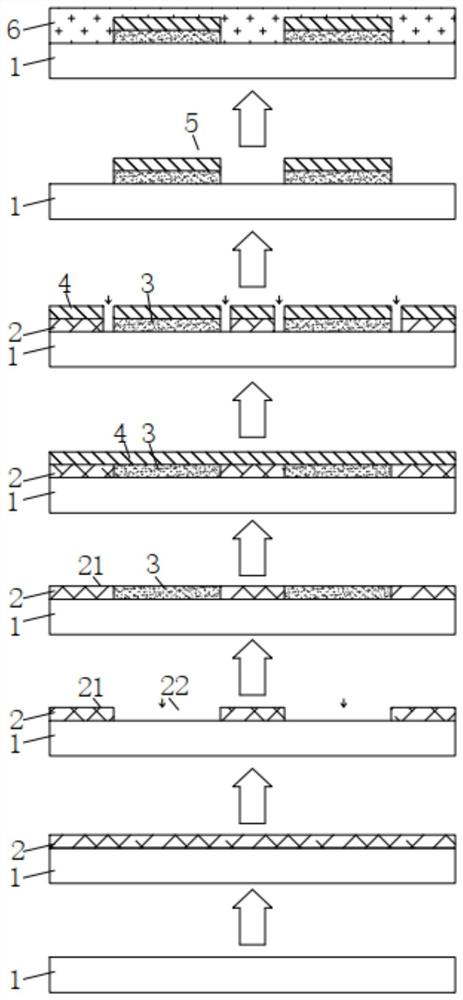

Electromagnetic induction type liquid crystal panel as well as manufacture method thereof and liquid crystal display (LCD)

ActiveCN101930134AHigh precisionImprove reliabilityAntenna arraysStatic indicating devicesLiquid-crystal displayIntegrated antenna

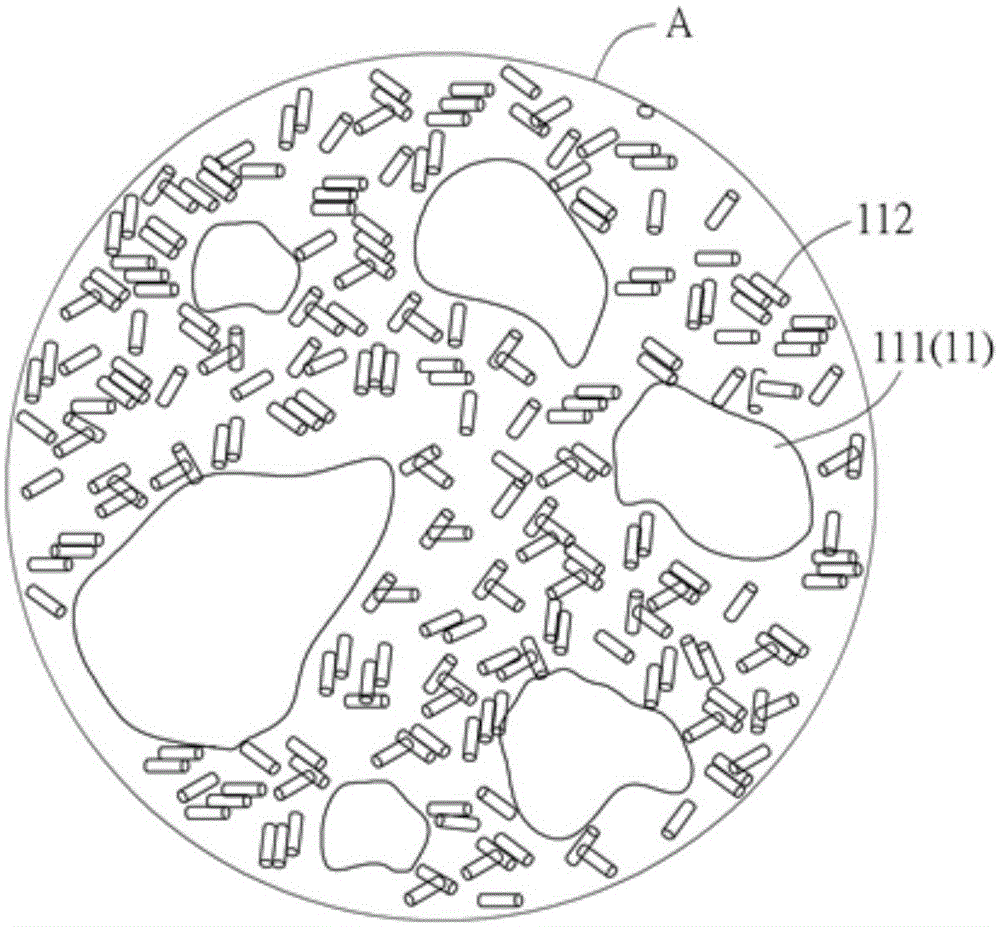

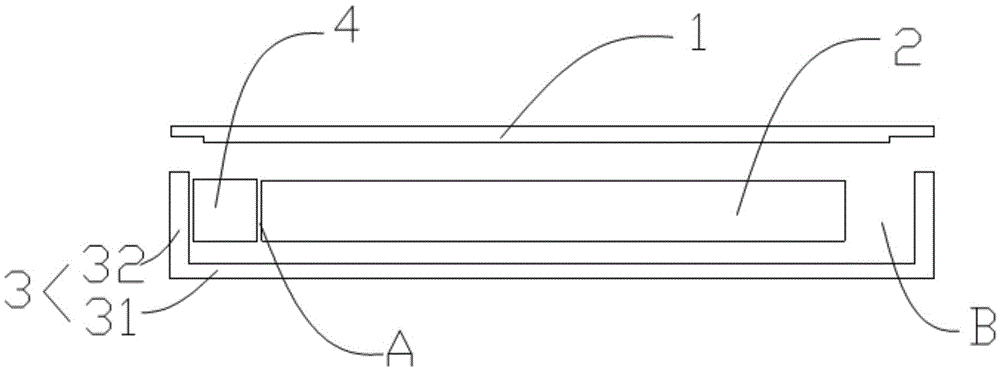

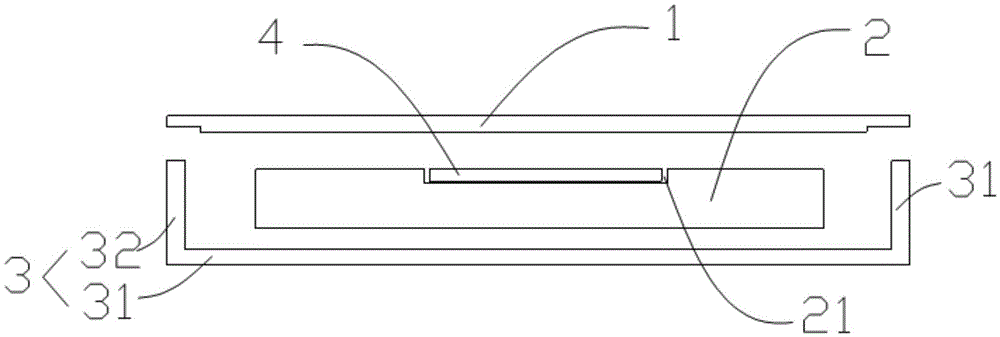

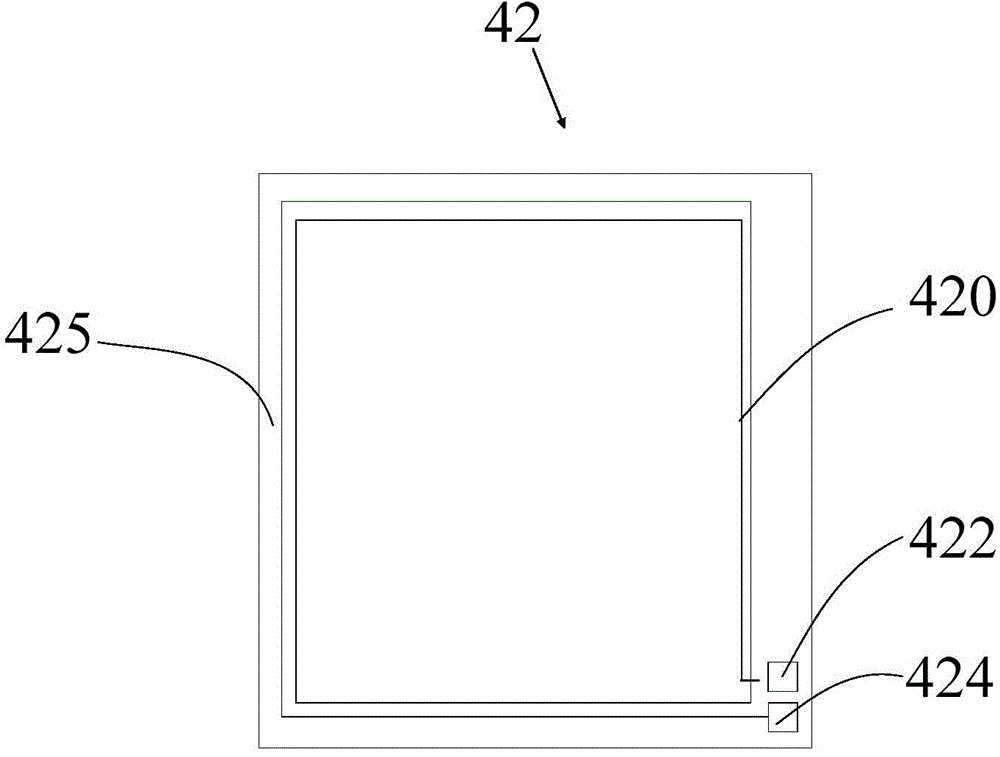

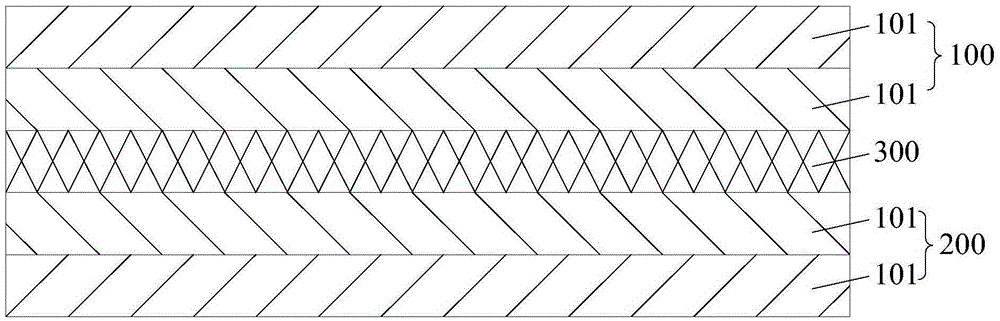

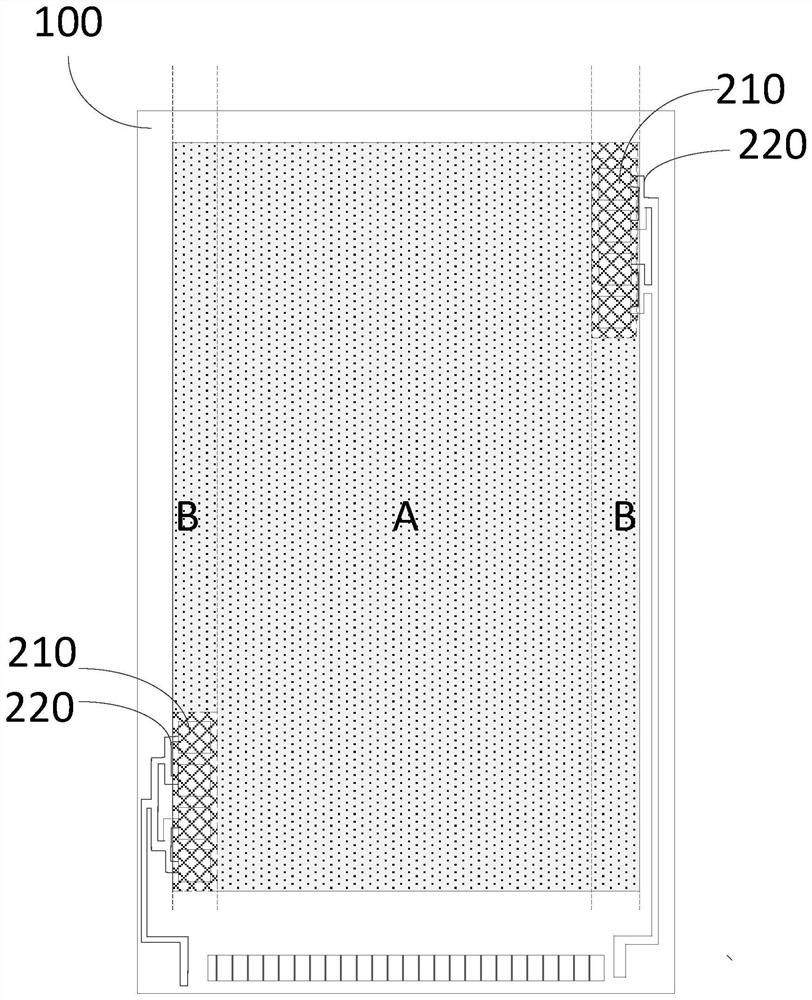

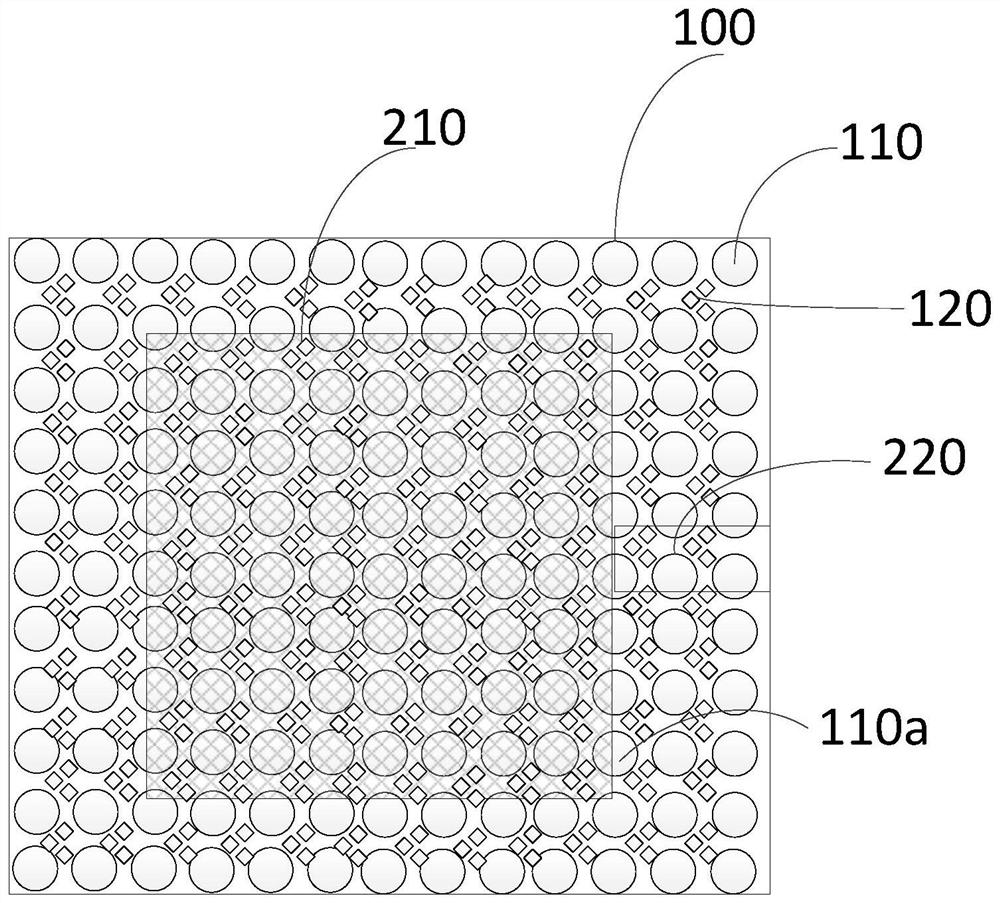

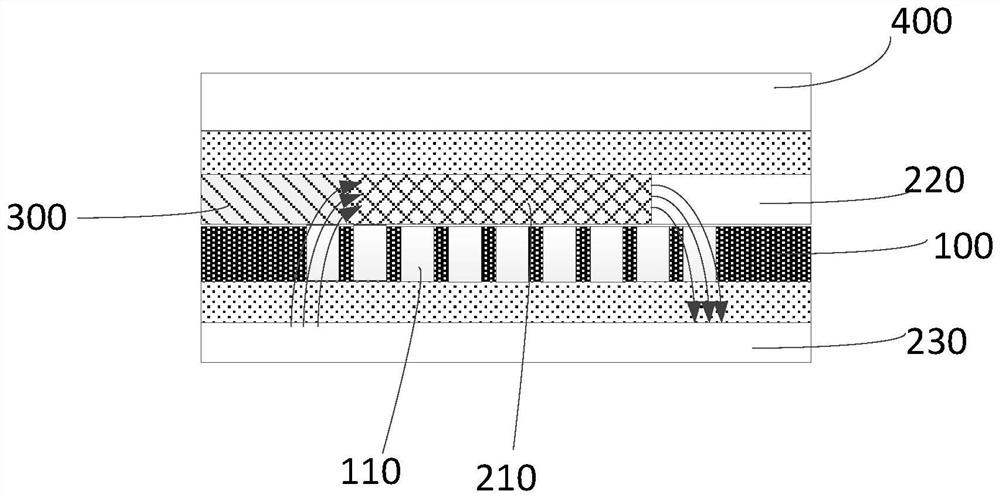

The invention relates to an electromagnetic induction type liquid crystal panel as well as a manufacture method thereof and a liquid crystal display (LCD). The liquid crystal panel comprises a first base plate and a second base plate cassette to cassette, wherein a liquid crystal layer is filled between the first base plate and the second base plate; the liquid crystal panel also comprises an antenna array; the antenna array is made of conducting materials, formed between the first substrate base plate and the second substrate base plate and insulated from the conducting materials in a multi-film layer structure; and the antenna array is used for recognizing an electromagnetic signal. The LCD of the invention comprises the electromagnetic induction type liquid crystal panel and also comprises an input recognizing circuit which is connected with the output end of the antenna array. By adopting a technical approach for integrating the antenna array in the liquid crystal panel, the invention meets the light-weight and thin requirement of the LCD and reduces the assembly cost.

Owner:东莞凌尚触控科技有限公司

Heat-conducting structure and heat-dissipation device

ActiveCN105101755AChannel quickly and dissipateMeet thin and light requirementsSemiconductor/solid-state device detailsIndirect heat exchangersHeat conductingCarbon nanotube

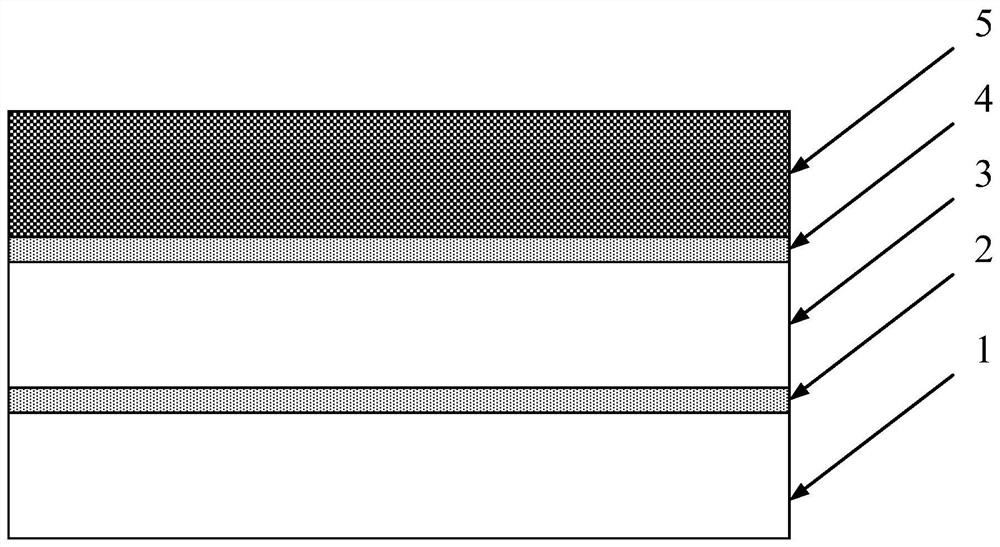

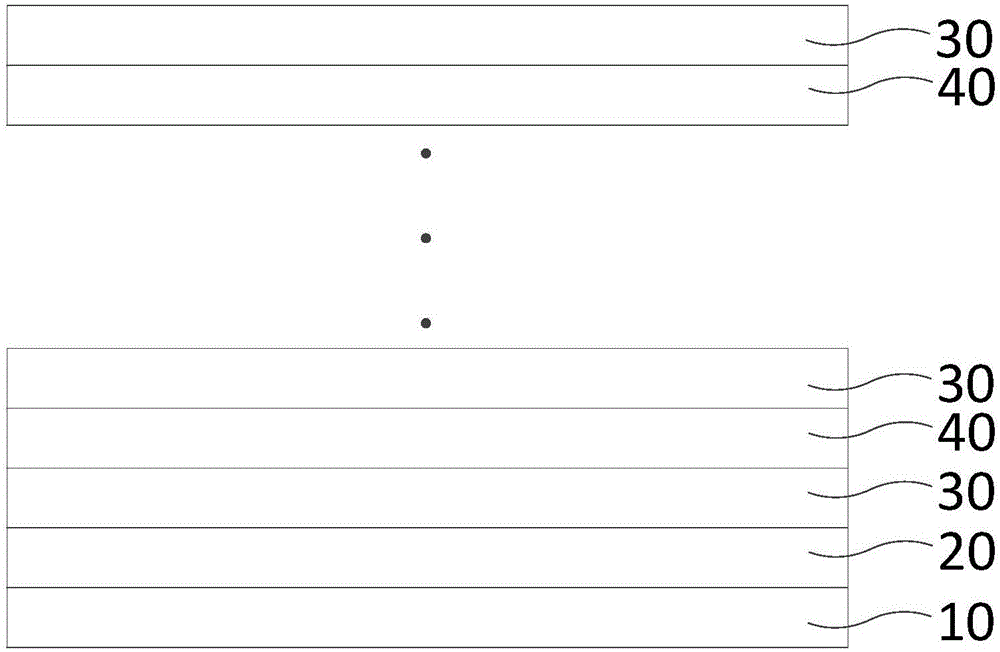

The invention discloses a heat-conducting structure and a heat-dissipation device. The heat-conducting structure comprises a first heat-conducting layer and a second heat-conducting layer, wherein the first heat-conducting layer comprises a graphene material and first carbon nanotubes; the first carbon nanotubes are dispersed into the graphene material; the second heat-conducting layer is stacked on the first heat-conducting layer and comprises a porous material and second carbon nanotubes; and the second carbon nanotubes are dispersed into the porous material. The invention further discloses the heat-dissipation device. The heat-dissipation device comprises the heat-conducting structure and a heat-dissipation structure; the heat-conducting structure contacts a heat source; and the heat-dissipation structure is connected with the heat-conducting structure. The heat-conducting structure and the heat-dissipation device disclosed by the invention have the thinning characteristics, and conform to the lightweight requirements of current thin electronic products.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

Mobile terminal

ActiveCN105552526AMeet thin and light requirementsImprove integrityAntenna supports/mountingsAntennas earthing switches associationEngineeringElectrical and Electronics engineering

The invention provides a mobile terminal, comprising a display screen, a main body, an enclosure and an NFC antenna; the enclosure comprises a shell body part and a side frame; the display screen, the main body and the shell body part are stacked; the side frame is connected between the shell body part and the display screen; the NFC antenna is contained in the containing space located between the main body and the side frame, or the NFC antenna is contained at the side of the main body being away from the shell body part; the signal transceiving path of the NFC antenna passes by the display screen. According to the mobile terminal of the invention, the space between the main body of the mobile terminal and the enclosure is utilized fully through the arrangement of the NFC antenna; the lighting and thinning demands of the mobile terminal can be satisfied; when the mobile terminal adopts a metal enclosure, through swiping a card at the display screen side of the mobile terminal, the signal of the NFC antenna will not be transmitted through the metal enclosure; therefore, the metal enclosure is unnecessarily slit, and further the integrality of the metal appearance can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Quantum dot color film substrate and preparation method thereof, display panel and display device

ActiveCN111736388AReduce the number of layersIncrease profitNon-linear opticsInput/output processes for data processingColor filmDisplay device

The invention discloses a quantum dot color film substrate and a preparation method thereof, a display panel and a display device. The quantum dot color film substrate comprises a base, a retaining wall layer and a reflecting metal layer. The retaining wall layer is positioned on one side of the substrate, and comprises a plurality of retaining wall structures and a plurality of retaining wall openings. The reflecting metal layer covers the side surface of the retaining wall structure, and is used for reflecting light emitted by a light-emitting unit to improve the utilization rate of emergentlight. Meanwhile, the reflecting metal layer is also used for receiving a touch signal for touch detection. According to the quantum dot color film substrate, the touch function is integrated in thequantum dot color film substrate, the touch function is achieved without an externally-hung touch panel, the number of film layers of the quantum dot display panel can be reduced, and therefore the overall thickness of the quantum dot display panel is reduced, and the requirement of users for a light and thin quantum dot display panel is met.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

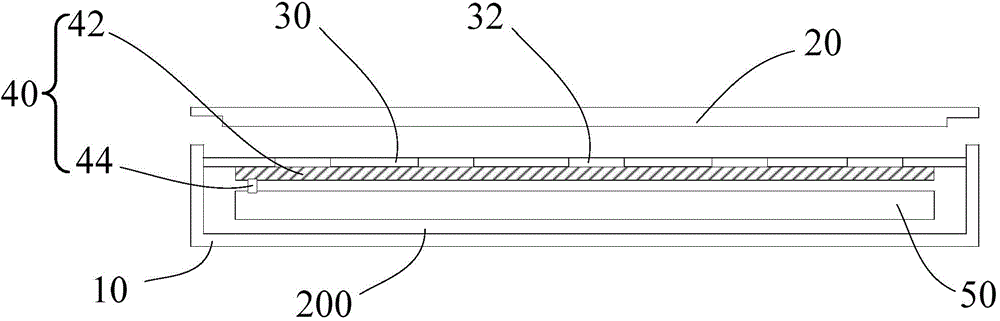

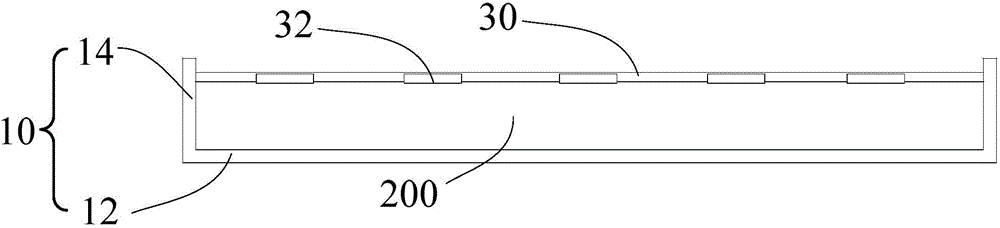

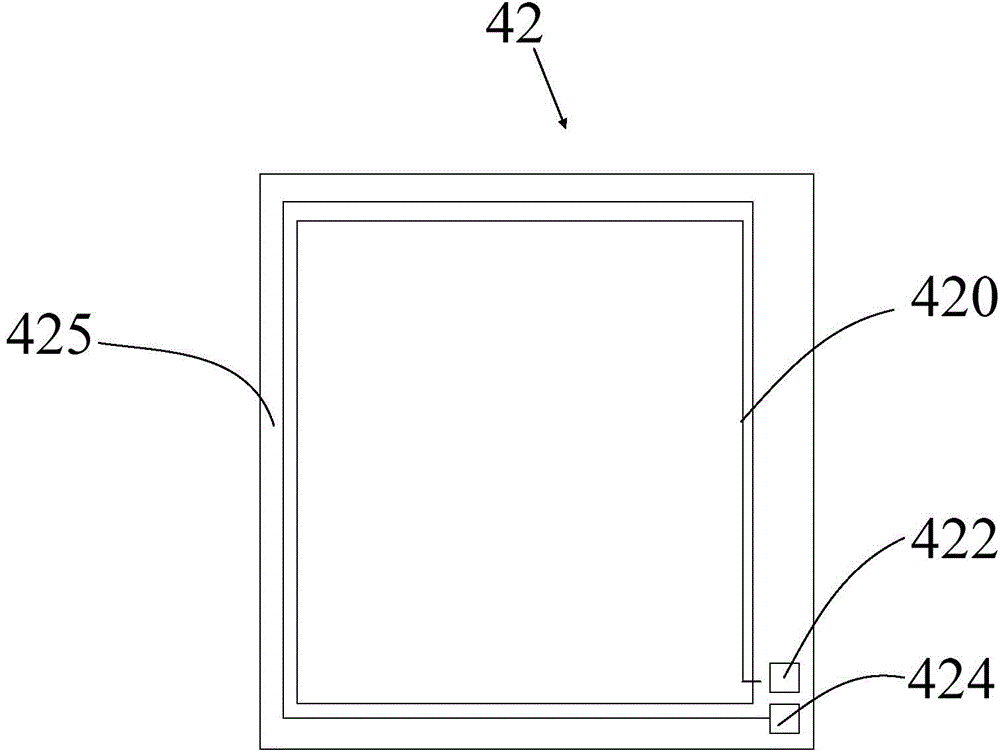

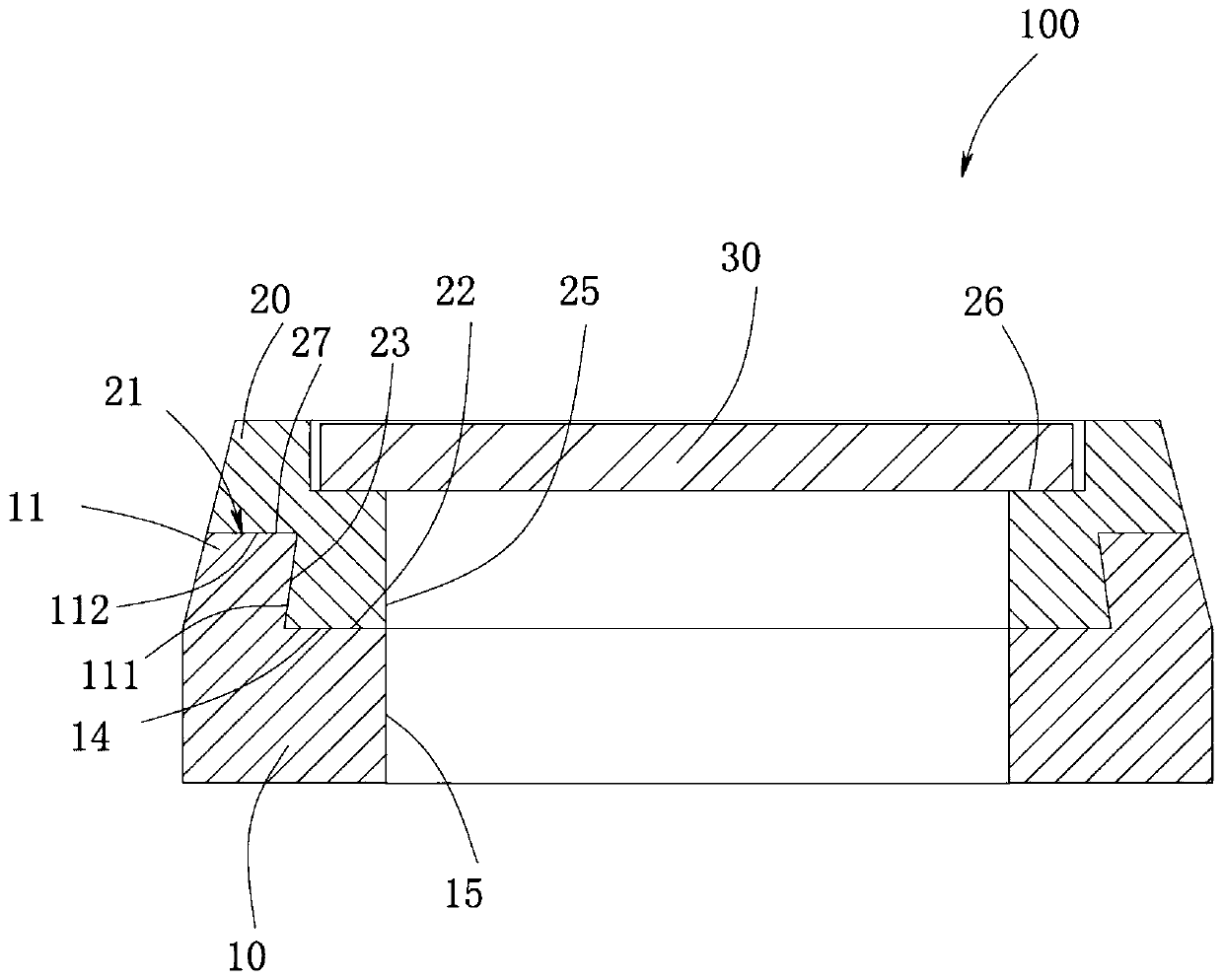

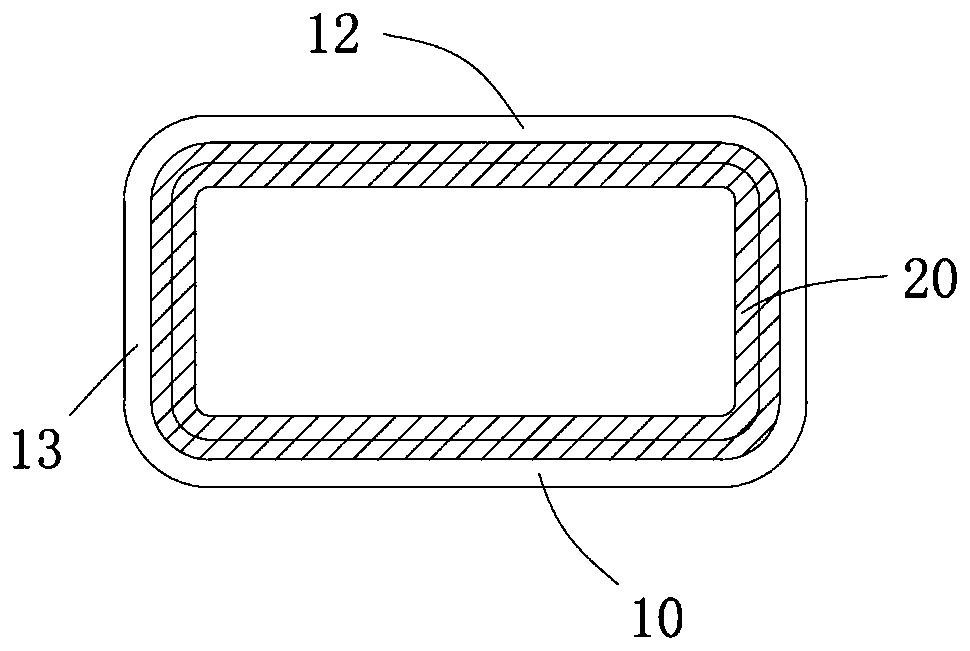

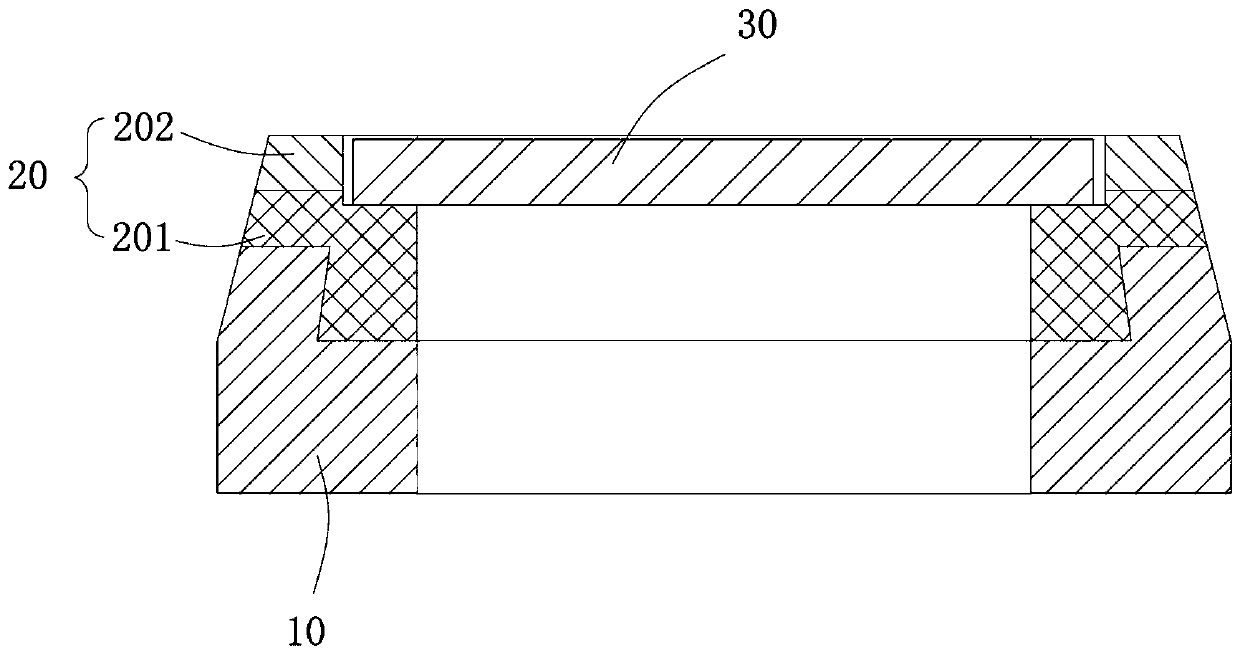

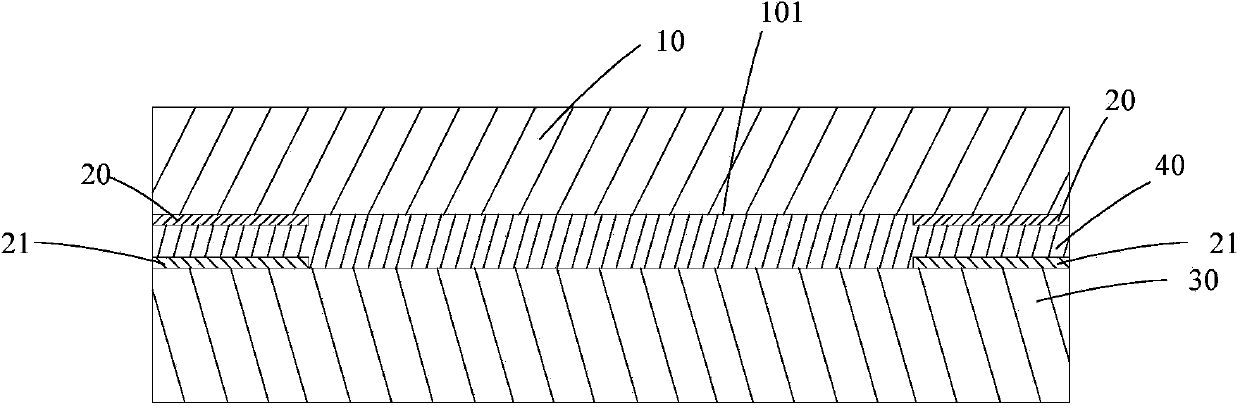

Backlight module for providing light to a display panel and display device therewith

ActiveCN103133945AAdjust lighting uniformityReduce the numberPoint-like light sourceOptical light guidesLight guideDisplay device

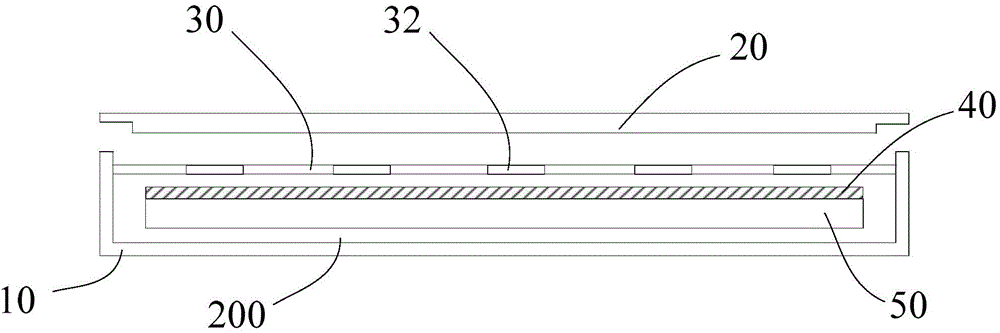

The present invention discloses a backlight module for providing light to a display panel and a display device therewith. The backlight module includes a light emitting unit for emitting light, a light guide plate disposed on a side of a display panel for guiding the light emitted by the light emitting unit to the display panel, a back cover installed outside the light emitting unit and the light guide plate, and a frame combined with the back cover for accommodating the light emitting unit and the light guide plate with the back cover. The frame includes a first side facing a surface of the light guide plate, and a second side opposite to the first side. The backlight module further includes an optical material layer disposed between the second side of the frame and the display panel for misting and focusing the light refracted from the light guide plate so as to provide uniform and bright light to the display panel.

Owner:WISTRON CORP

Terminal equipment and shooting method

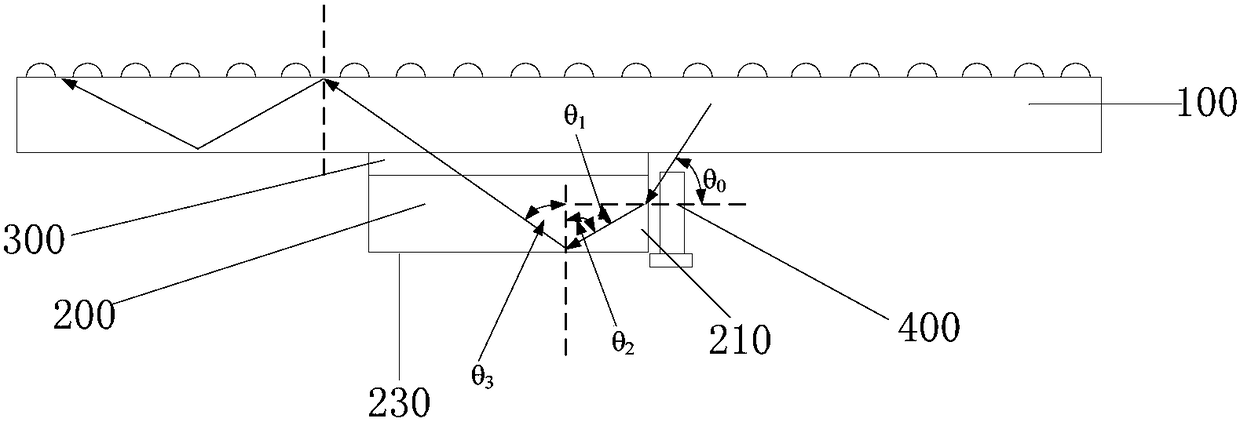

ActiveCN110418046AMeet thin and light requirementsGrowth EFLTelevision system detailsColor television detailsOptical axisTerminal equipment

The embodiment of the invention provides terminal equipment and a shooting method. The terminal equipment comprises a shell, a fixed-focus camera, a driving mechanism and a control unit, wherein the shell is provided with an accommodating cavity; the fixed-focus camera has an accommodating state and a shooting state; the accommodating state is that the fixed-focus camera is accommodated in the accommodating cavity, and the shooting state is that at least part of the structure of the fixed-focus camera extends out of the accommodating cavity to protrude out of the outer end surface of the shell; the fixed-focus camera comprises at least two lens groups, and at least the lens group close to the object plane can move along the optical axis, so that the fixed-focus camera can be switched between an accommodating state and a shooting state; the driving mechanism is in driving connection with the movable lens group; the control unit is electrically connected with the driving mechanism so asto control the driving mechanism to drive the movable lens group to move along the optical axis. According to the terminal equipment, the EFL of the fixed-focus camera can be increased and the thickness of the Sensor can be increased while the lightening and thinning requirements are met, so that the shooting quality of the fixed-focus camera can be greatly improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Liquid crystal display and its soft circuit board

InactiveCN1782786ALarge capacityMeet thin and light requirementsStatic indicating devicesLiquid-crystal displayEngineering

The present invention relates to a kind of soft circuit board, which has input side conducting pattern with average width smaller than the maximum width, output side conducting pattern with average width smaller than the maximum width, input side conducting pattern with closely set smaller width part and greater width part, and output side conducting pattern with closely set smaller width part and greater width part. Under the condition of the same width, the soft circuit board of the present invention has even great capacity of transmitted signal compared with available technology. The LCD with the soft circuit board of the present invention is light and thin.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Mobile terminal

ActiveCN104466346AMeet thin and light requirementsImprove experienceLoop antennas with ferromagnetic coreAntenna supports/mountingsElectrical batteryComputer terminal

The invention is applicable to the technical field of communication and provides a mobile terminal. An NFC antenna is arranged between a fixing support and a battery, and the mobile terminal aims at solving the technical problem how to arrange the NFC antenna in a metal housing environment for meeting the light and thin design requirement and ensuring normal NFC antenna communication. The mobile terminal comprises a housing and a cover body module, wherein the housing and the cover body module are oppositely arranged and jointly form an accommodating space, a circuit board, a battery, the fixing support fixedly arranged between the cover body module and the battery and the near-field communication NFC antenna arranged between the battery and the fixing support are arranged in the accommodating space, the NFC antenna comprises an antenna body and a transmission element, the antenna body is arranged on the lower surface of the fixing support, and the transmission element is electrically coupled with the antenna body and the circuit board respectively. The NFC antenna is arranged between the metal fixing support and the battery to fully utilize the gap between the fixing support and the battery, so that the mobile terminal meets the light and thin requirement, and user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Camera decorating part, manufacturing method thereof and electronic equipment

ActiveCN110913108AReduce weightMeet thin and light requirementsTelevision system detailsColor television detailsCamera lensStructural engineering

The invention discloses a camera decorating part, a manufacturing method thereof and electronic equipment. The camera decorating part comprises a metal ring, a non-metal ring and a camera lens. The metal ring and the non-metal ring are integrally formed. The top of the metal ring is provided with a dovetail protrusion extending in the circumferential direction. A dovetail groove matching the dovetail protrusion is formed in the bottom of the non-metal ring. A peripheral side face of the non-metal ring is flush with the peripheral side face of the metal ring, chromatic aberration exists betweenthe outer surface of the non-metal ring and the outer surface of the metal ring, and the camera lens is fixed to the inner side of the non-metal ring. The non-metal ring and the metal ring are integrally formed, and the camera lens is fixed on the inner side of the non-metal ring, so that the weight of the camera decorating part is reduced, and the lightening and thinning requirements of electronic equipment are met.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Display device and manufacturing method thereof

InactiveCN104216565ASolve the problem of thickening the structureReduce gapLamination ancillary operationsSynthetic resin layered productsDisplay deviceEngineering

The invention relates to a display device and a manufacturing method thereof. The display device comprises a display module, a cover plate and an adhesive layer arranged between the display module and the cover plate, wherein a first ink layer is arranged on at least one part between the cover plate and the adhesive layer; the first ink layer is 5-7 microns thick; the display module is provided with a second ink layer. The ink layers are respectively arranged on all structural layers, and the single ink layer is as thin as 5 microns, so that offset generated by the ink layers is greatly reduced; therefore the adhesive layer can adopt a smaller thickness during laminating, and the whole structure of the display device is thinned and can meet requirements of people on light weight and thinness of electronic products; the problem that an optical glue layer is thicker in the prior art is solved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Capacitive touch screen and electronic device

InactiveCN103135862AGuaranteed performanceMeet thin and light requirementsInput/output processes for data processingPhysicsMicrometer

An embodiment of the invention discloses a capacitive touch screen and an electronic device and is applied to the technical field of electronic equipment. Induction electrodes on a drive electrode layer and a receiving electrode layer of the capacitive touch screen are spaced, so that the distance between the receiving electrode layer and the drive electrode layer can be small as far as possible, particularly smaller than 45 micrometers, and the requirements of the touch screen for light weight and thickness are met. Specifically, the area of the induction electrodes on the drive electrode layer and the receiving electrode layer is decreased, the distance between the two electrode layers is decreased moderately to increase mutual capacitance, the mutual capacitance formed between the two electrode layers is finally formed in the measurement range of a detection unit, and the performance of the capacitive touch screen is guaranteed.

Owner:ORISE TECHNOLOGY CO LTD

Hinge structure and foldable electronic equipment

ActiveCN110879643ALean structureReduce partsDetails for portable computersRotational axisEngineering

The invention provides a hinge structure and foldable electronic equipment. The hinge structure comprises a seat body, a locking plate, a first rotating shaft and a second rotating shaft, wherein thefirst rotating shaft and the second rotating shaft are parallel to each other, the locking plate can be movably mounted on the seat body along the arrangement direction of the first rotating shaft andthe second rotating shaft, so that the locking plate has a locking state and an unlocking state; the locking plate is provided with long circular holes and shaft holes in the arrangement direction ofthe first rotating shaft and the second rotating shaft, and locking notches are formed in the sides, facing the long circular holes, of the shaft holes. The first rotating shaft and the second rotating shaft are matched with the locking plate; a first limiting part is formed on the first rotating shaft; a second limiting part is formed on the second rotating shaft; the first limiting part and thesecond limiting part are matched to enable the first rotating shaft to switch the rotating state when the first rotating shaft rotates relative to the second rotating shaft, and finally 360-degree rotation of the first rotating shaft relative to the second rotating shaft is achieved, the structure and parts can be reduced, the height size can be reduced, and lightening and thinning of products are facilitated.

Owner:HUAWEI TECH CO LTD

Touch display panel

ActiveCN106383614AReduce stack thicknessImprove bending resistanceNon-linear opticsInput/output processes for data processingComposite filmOptical transmittance

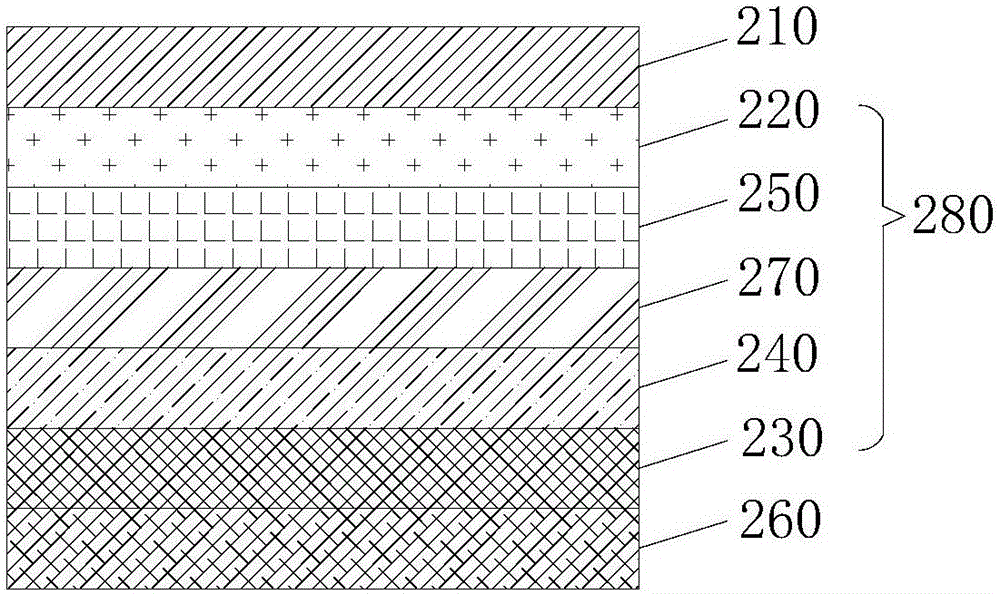

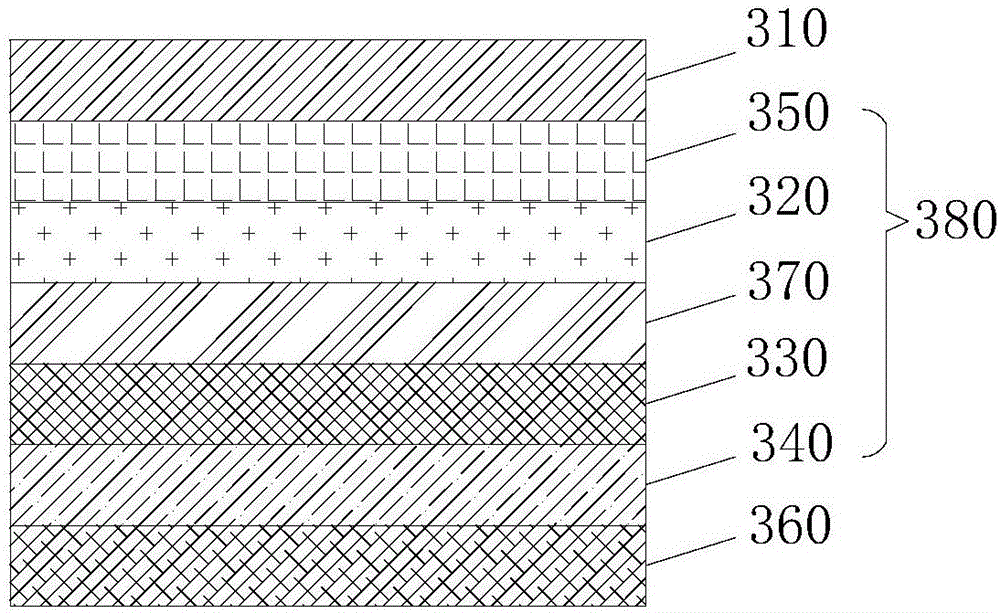

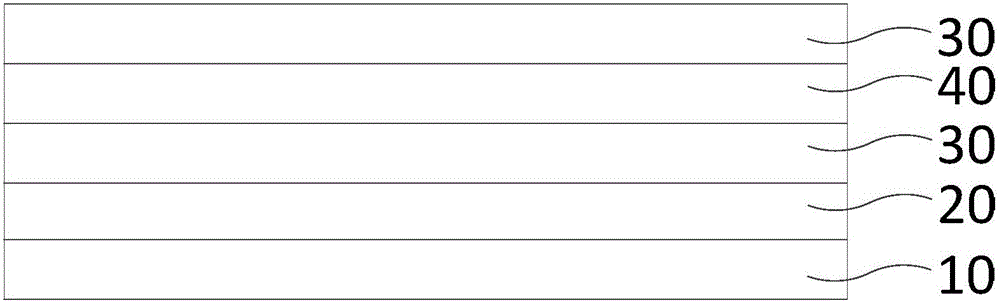

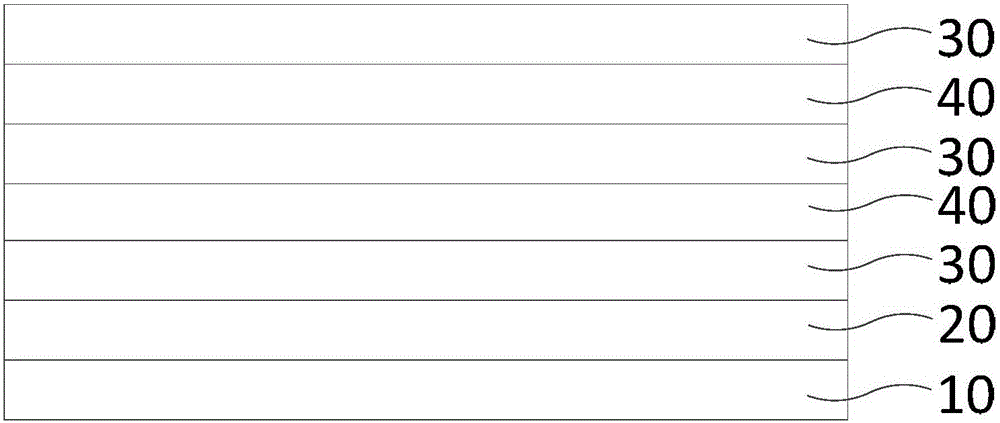

The invention discloses a touch display panel. The touch display panel comprises a display module, a linear polarizer and a composite film, wherein the linear polarizer is formed at one side of the display module; the composite film is arranged between the linear polarizer and the display module and comprises a 1 / 2 lambda wave plate, a 1 / 4 lambda wave plate, a first touch electrode layer and a second touch electrode layer; the 1 / 4 lambda wave plate is formed at the side, far from the linear polarizer, of the 1 / 2 lambda wave plate; the first touch electrode layer is formed at any side of the 1 / 4 lambda wave plate; the second touch electrode layer is formed at any side of the 1 / 2 lambda wave plate; the first touch electrode layer and the second touch electrode layer are insulated from each other. The touch display panel has the beneficial effects that touch film layers are internally arranged between the linear polarizer and the display module and are respectively bonded and fixed with the 1 / 2 lambda wave plate and the 1 / 4 lambda wave plate to form the integrated composite film, so that the lamination thickness of the panel is reduced, thus increasing the bending resistance and optical transmittance of the panel, meeting the lightening and thinning requirements of products and being applicable to flexible display panels.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Mobile terminal

InactiveCN104468895AMeet thin and light requirementsMeet usage habitsTelephone set constructionsElectricityComputer terminal

The invention belongs to the technical field of communication, and provides a mobile terminal. An NFC antenna is arranged on the surface of a battery, so that the technical purpose of meeting the requirement for the thin design by arranging the NFC antenna under a metal outer shell is achieved. The mobile terminal comprises the metal outer shell and a cover body component, the metal outer shell and the cover body component are oppositely arranged to jointly form an accommodating space, and a circuit board, the battery electrically connected with the circuit board and the NFC antenna are arranged in the accommodating space, wherein the NFC antenna is arranged between the battery and the cover body component and comprises an antenna body and a transmission element. The NFC antenna is arranged on the side, facing the cover body component, of the battery, so that radiation signals of the NFC antenna are emitted out of the mobile terminal from the side where the cover body component is located, the mobile terminal is convenient to use and better meets use habits of a user, the mobile terminal is made to meet the requirement for thinning, and user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Film packaging structure, preparation method and organic light emitting apparatus with same

InactiveCN106299149AImprove water and oxygen barrier performanceExtend your lifeSemiconductor/solid-state device detailsSolid-state devicesOrganic filmOxygen

The invention provides a film packaging structure which is used for packaging a functional device on a substrate. The film packaging structure is composed of inorganic films and organic films which are laminated alternately, wherein the bottommost layer and the topmost layer are inorganic films, the total number of the inorganic films and the organic films is not less than three, and at least one inorganic film is composed of at least two inorganic materials. The invention further provides a preparation method of the film packaging structure. The invention further provides an organic light emitting apparatus which comprises a substrate, an OLED device disposed on the substrate and the film packaging structure used for packaging the OLED device. The alternately laminated inorganic films and organic films have good water oxygen blocking performance, and can effectively extend the service life of the device. The film packaging structure makes the device flexible, and meets the requirement for a lightweight device. The packaging process is suitable for mass production and is environment-friendly.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

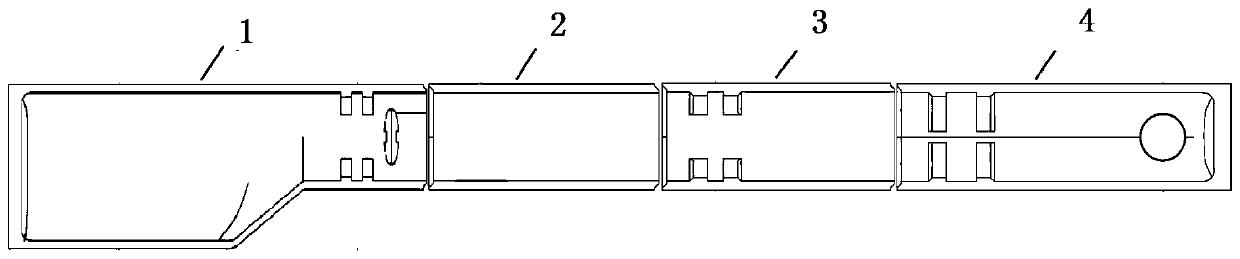

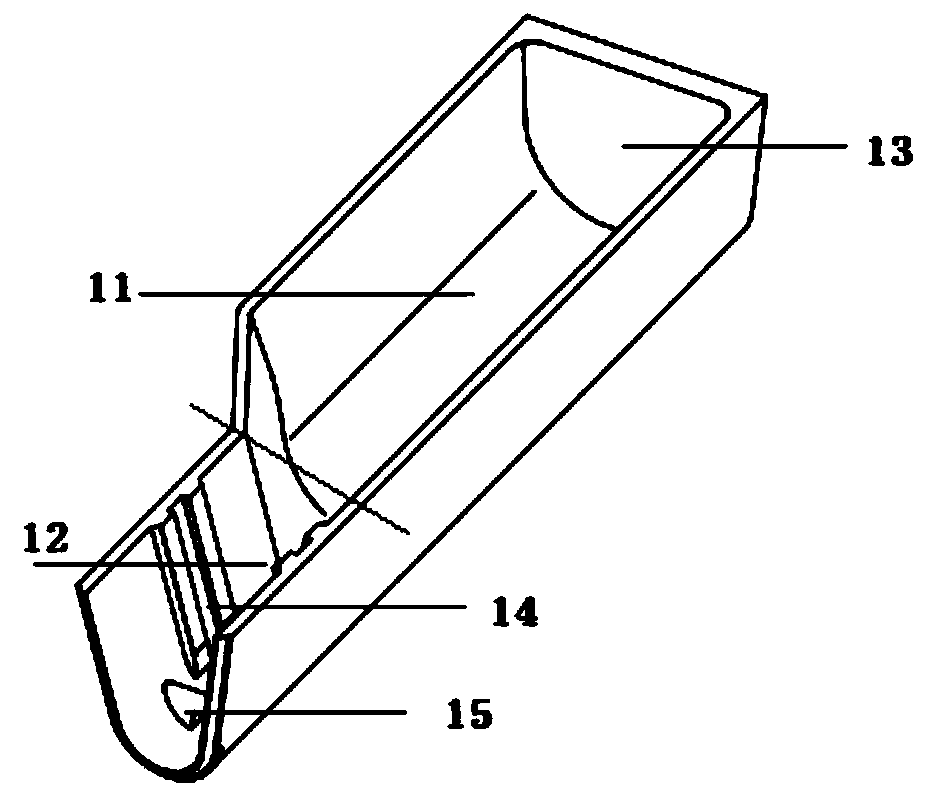

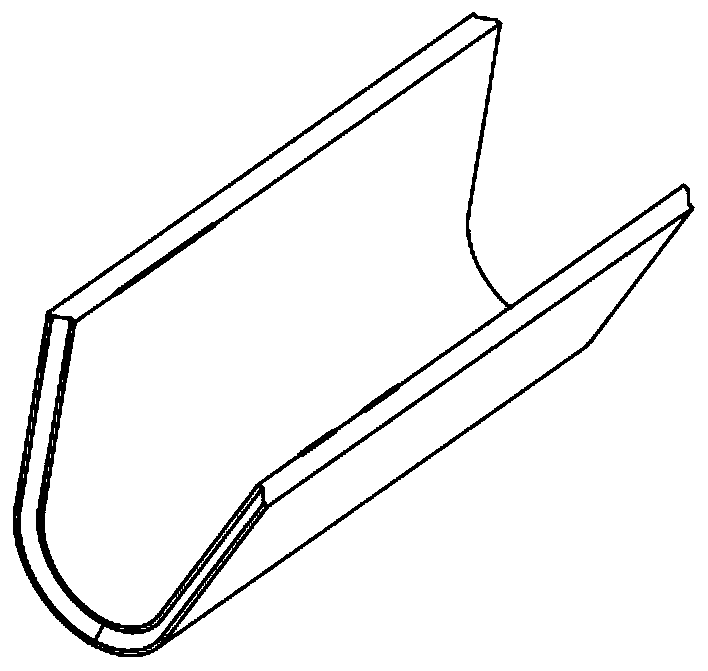

Ultrathin aluminum-based steel flowing tank

ActiveCN110479971AAvoid crackingReduce thicknessFoundry mouldsCasting cleaning apparatusRepair materialAlloy

The invention relates to the field of alloy smelting facilities and provides an ultrathin aluminum-based steel flowing tank. The wall thickness of a tank body of the steel flowing tank is 12-25 mm, and the tank body of the steel flowing tank is of a segmental structure and comprises a steel receiving tank, a first steel flowing tank, a second steel flowing tank and a tapping tank connected successively. The tank body of the steel flowing tank is lighter and thinner. As the wall thickness and the weight are reduced greatly, the production and application costs are lowered. A connecting mode between the tank body assemblies is also changed, so that the tank body assemblies are more easily replaced. Therefore, the risk that a repair material pollutes an alloy solution is reduced fundamentally.

Owner:SHENYANG HENGTAI XINYUAN PRECISION CASTING REFRACTORY MATERIAL CO LTD

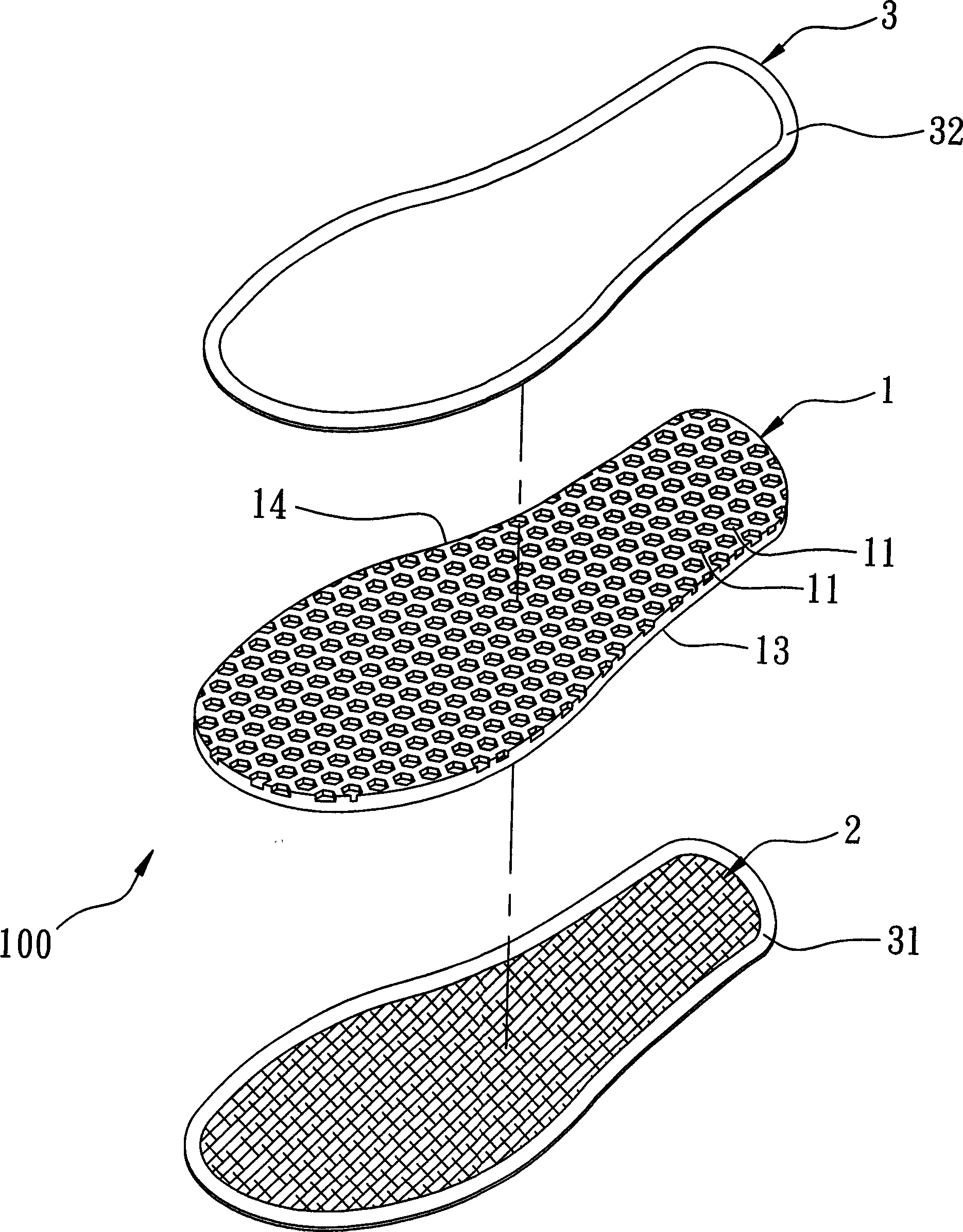

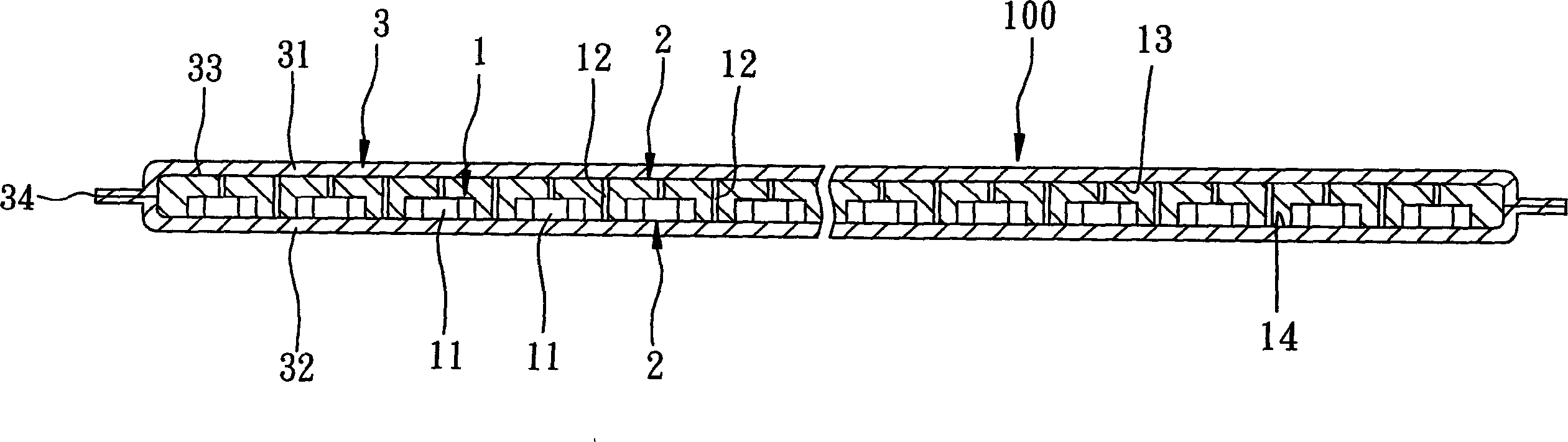

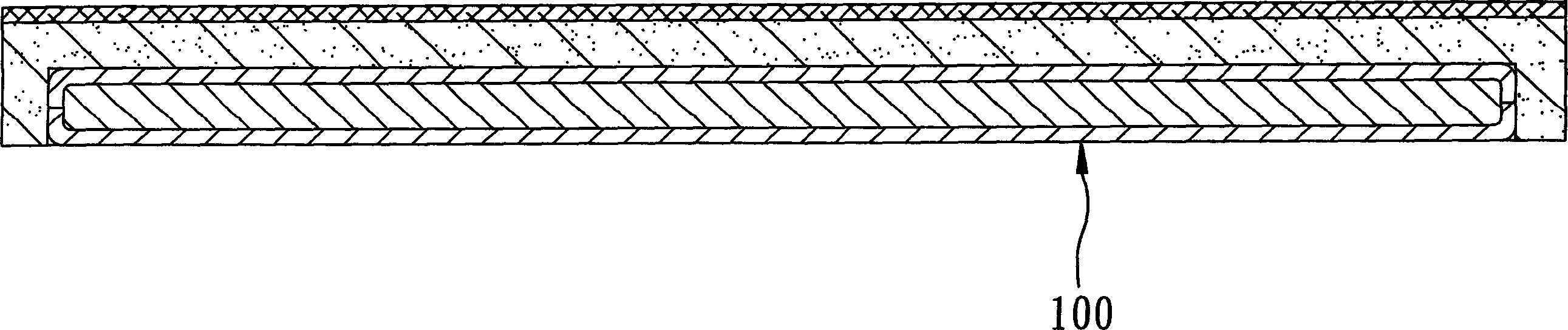

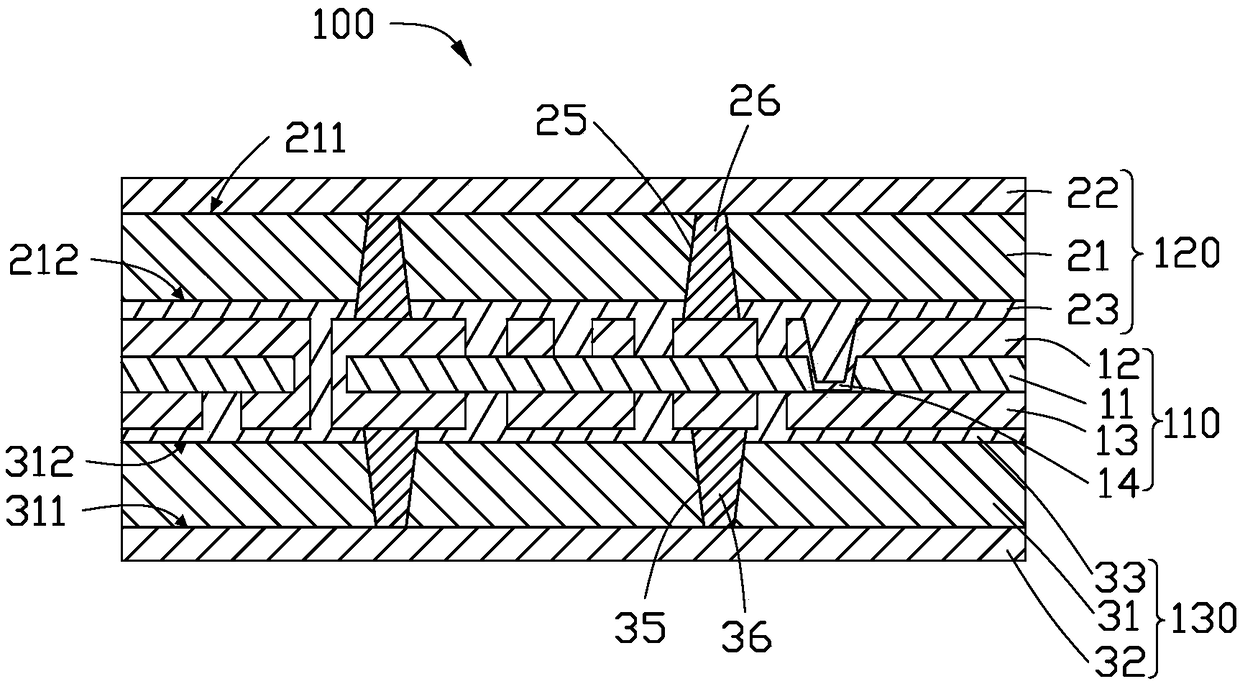

Footwear articles with winter proofing and thermal shield set

A kind of shoes with cold-resistant and heat-insulating mechanism is disclosed. Said mechanism is composed of at least one porous layer and an encapsulating layer for said porous layer and made of the air-tight thermoplastic material. Said encapsulating layer consists of an internal sheet, an external sheet and a sealed internal cavity made of said internal and external sheets and with a sealed vacuumizing opening.

Owner:竞元有限公司

Circuit board with electromagnetic shielding function, and manufacturing method of circuit board

ActiveCN109429420AReduce processThe production process is simplePrinted circuit detailsConductive pattern formationCopper foilOptoelectronics

Disclosed is a manufacturing method of a circuit board with an electromagnetic shielding function. The manufacturing method comprises the following steps that a single-sided copper-clad substrate is provided, wherein the single-sided copper-clad substrate comprises a first base material layer and a first copper foil layer; the first base material layer comprises a first surface and a second surface opposite to the first surface, and the first copper foil layer is formed on the first surface; a first low-loss dielectric layer is formed on the second surface; at least one first containing hole which penetrates through the first low-loss dielectric layer and the first base material layer is formed, and a first conductive paste is filled in the first containing hole, so as to form a first electromagnetic shielding layer; and a circuit substrate is provided, and the first electromagnetic shielding layer is pressed on the circuit substrate, wherein the circuit substrate comprises a first conductive circuit layer, and the first conductive paste is directly electrically connected with the first conductive circuit layer and the first copper foil layer. The invention further relates to the circuit board with the electromagnetic shielding function.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

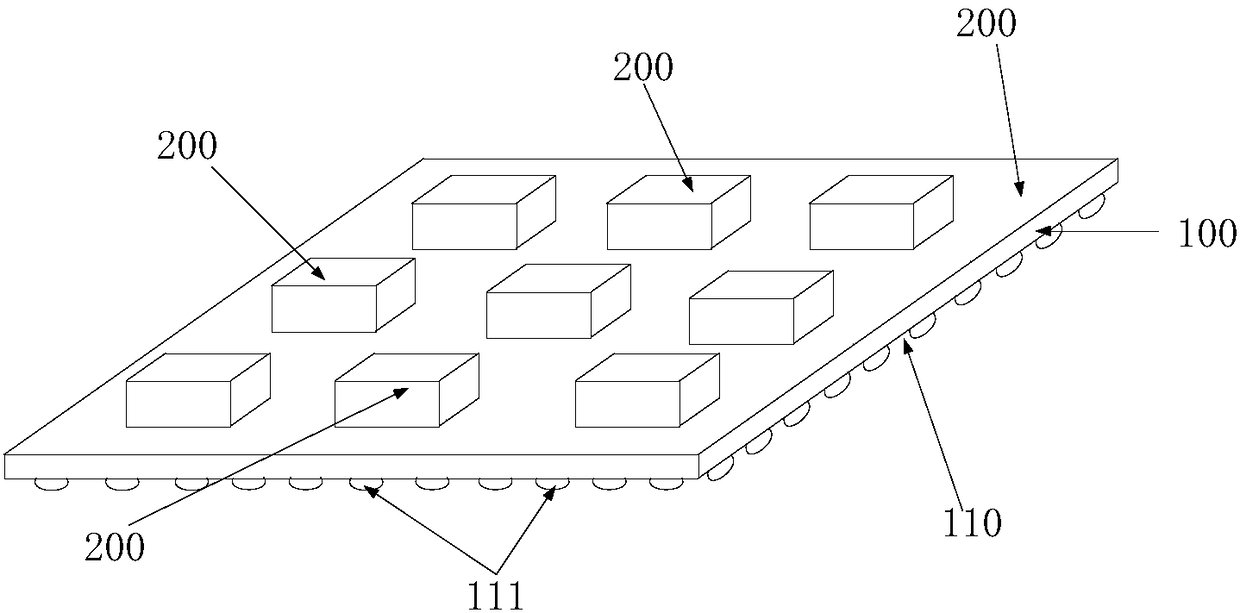

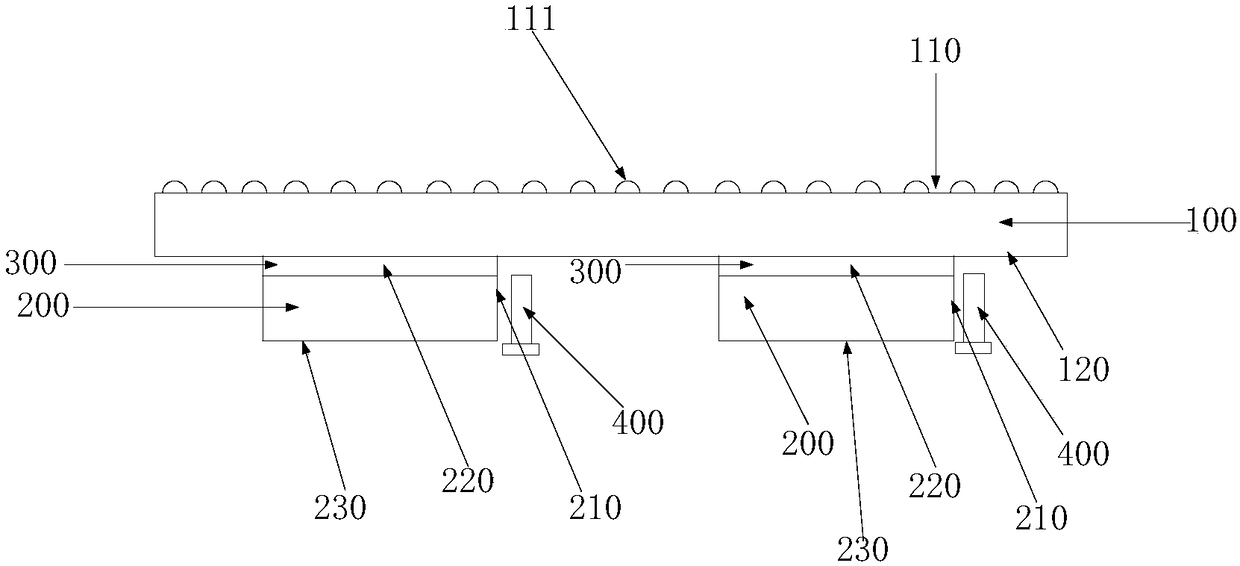

LED backlight source, LED backlight module and preparation method

InactiveCN111781772AReduce thicknessMeet thin and light requirementsSolid-state devicesNon-linear opticsLiquid-crystal displayLED display

The invention provides an LED backlight source, an LED backlight module and a preparation method. The LED backlight source comprises a substrate; a LED array, wherein a substrate of an LED chip of theLED array is removed, and the LED chip is connected to the base plate in an inverted mode. According to the LED backlight source, the Mini LED array is bonded on the substrate in an inverted manner,the substrate of all Mini LED chips of the Mini LED array is removed, so that the thickness of the liquid crystal display backlight module is greatly reduced, and compared with a traditional liquid crystal display backlight module, the thickness of the liquid crystal display backlight module can be reduced by more than 85 microns. The LED backlight source is suitable for consumer electronics suchas mobile phones and tablet personal computers, and the requirement of the market for lightness and thinness of the LED display screen is met.

Owner:HCP TECH CO LTD

Backlight module and manufacturing method thereof

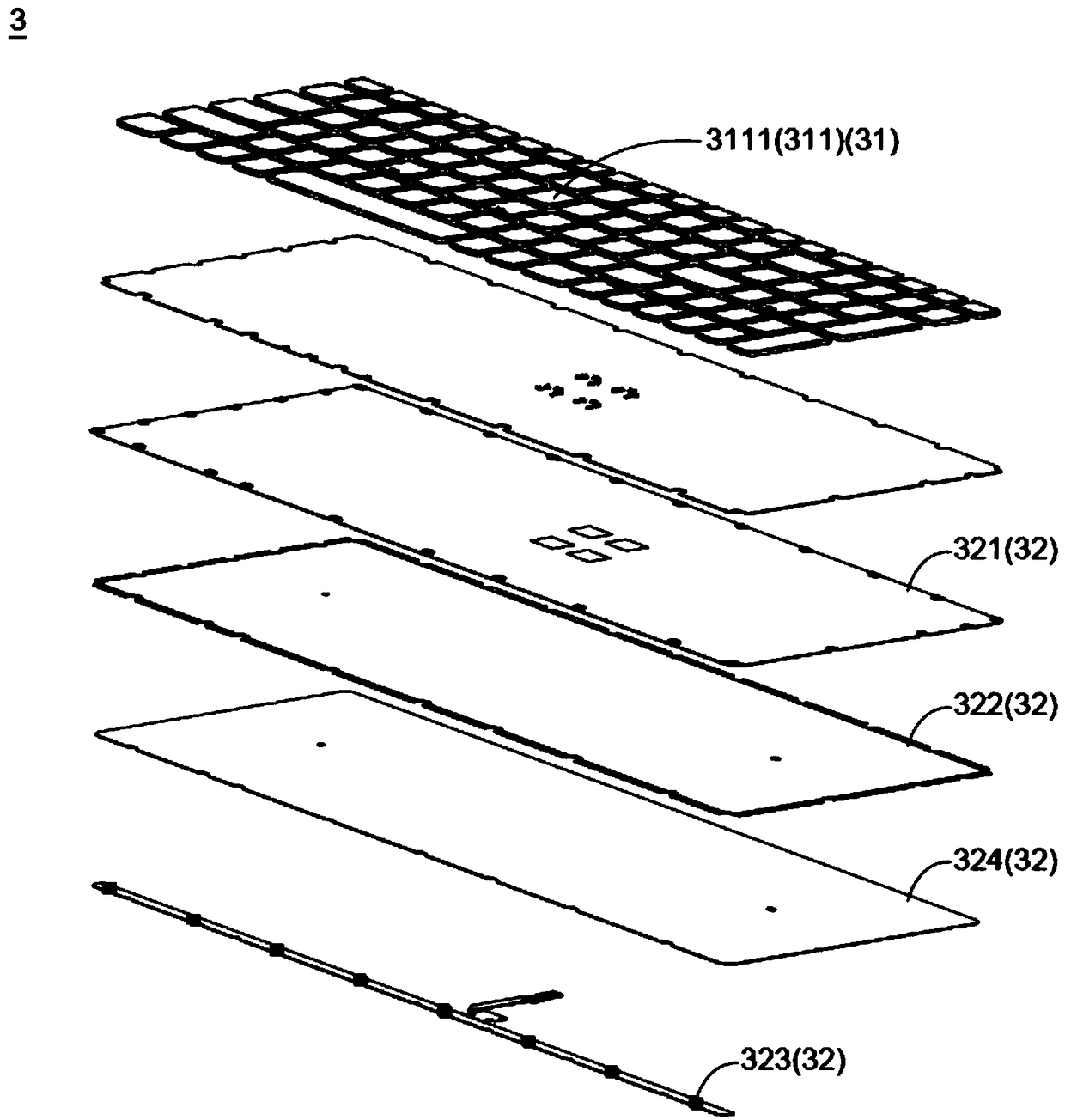

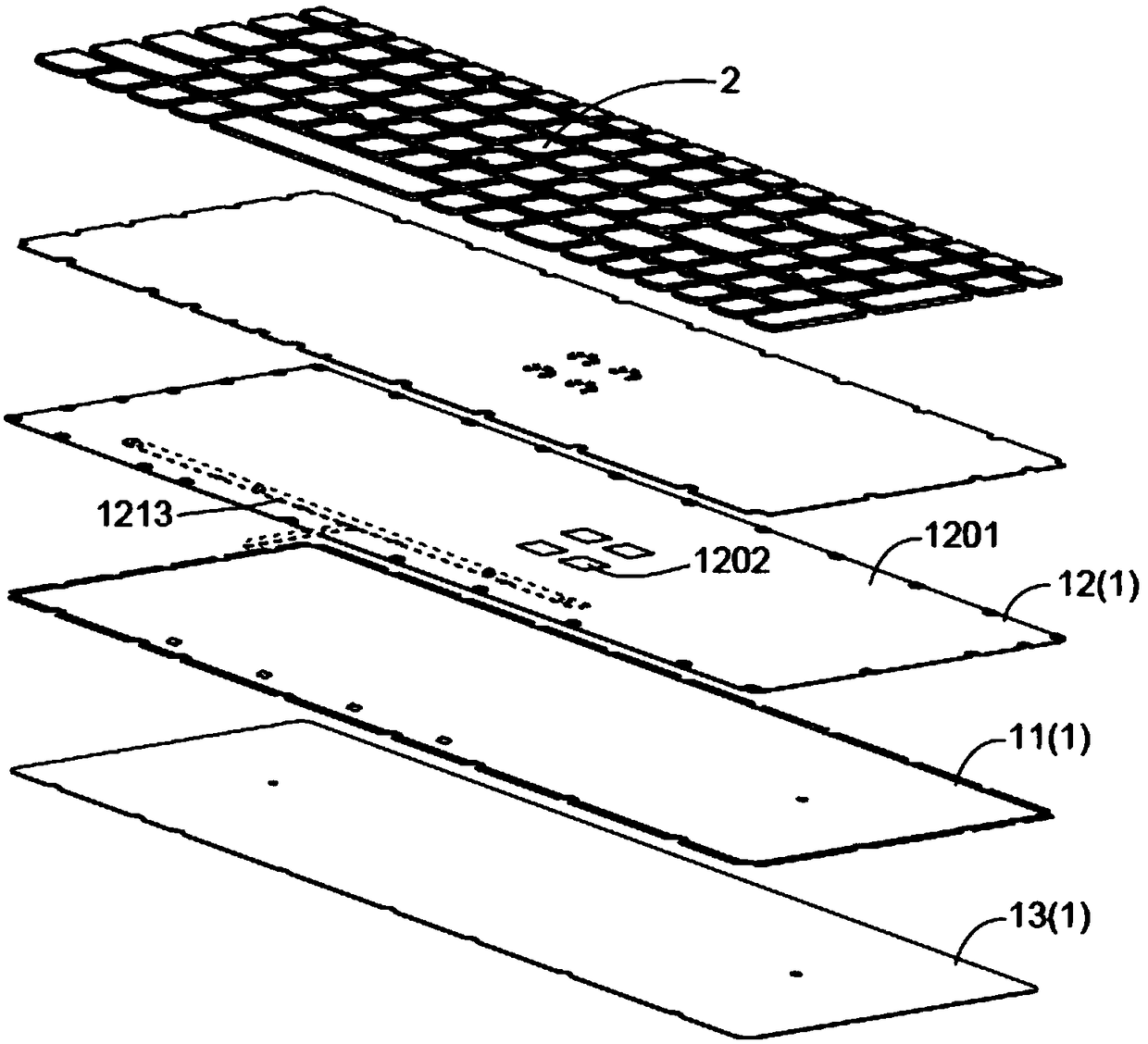

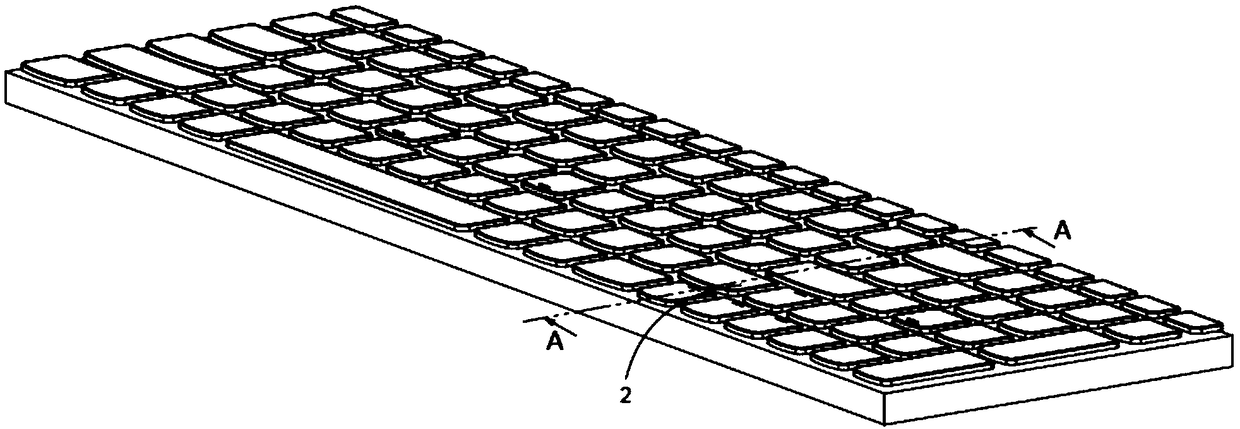

InactiveCN108878202AMeet thin and light requirementsReduce in quantityLegendsPlanar/plate-like light guidesLight guideEngineering

The invention discloses a backlight module and a manufacturing method thereof. The backlight module includes a light guide plate and a light shielding plate. The light guide plate is located under a plurality of key caps and is provided with a scattering structure, and the scattering structure is located below the key caps. The light shielding plate is provided with a light shielding plate body, alight shielding part, a plurality of light exposing parts, a circuit and a light shielding plate light emitting element, the light shielding part and the light exposing parts are located on the side,close to the multiple key caps, of the light shielding plate body, and the circuit and the light shielding plate light emitting element are located on the side, away from the multiple key caps, of the light shielding plate body. The circuit provides electrical energy to the light shielding plate light emitting element, and the light shielding plate light emitting element emits light to the lightguide plate. The backlight module optionally arranges a light source in the light shielding plate or a reflection plate to enables the backlight module not to be needed to be internally provided witha light source circuit board, can further choose the light guide plate of the backlight module to combine the function of the reflection plate to enables the backlight module not to be needed to be internally provided with the reflection plate, and the backlight module can reduce the number of components to reduce the thickness and conforms to the requirements of the industry for the lighting andthinning of the backlight module.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Carbon fiber plate and electronic device

InactiveCN105415775AIncrease stiffnessReduce thickness and weightLayered productsElectrical equipmentFiber layerThinning

The invention discloses a carbon fiber plate. The carbon fiber plate comprises a first carbon fiber layer set, a middle layer and a second carbon fiber layer set. The middle layer is clamped between the first carbon fiber layer set and the second carbon fiber layer set and is a non-immersed non-woven fabric structural layer. The arrangement directions of carbon fibers of every two adjacent carbon fiber layers in each carbon fiber layer set are perpendicular to each other. The rigidity of the carbon fiber plate can be improved, the thickness of the carbon fiber plate can be reduced on the basis that the requirement of an electronic device for the rigidity of a shell made of the carbon fiber plate is met, the thickness can be set to range from 0.7 mm to 0.9 mm, the thickness and the weight of the carbon fiber plate can be reduced, and light weight and thinning of the electronic device with the shell made of the carbon fiber plate can be achieved. The invention further discloses the electronic device. The shell of the electronic device is made of the carbon fiber plate. The rigidity of the shell can meet use requirements; in addition, the shell is small in thickness and weight, and the requirements of a user for light weight and thinning of the electronic device can be met.

Owner:LENOVO (BEIJING) CO LTD

Display device and manufacturing method thereof

ActiveCN111638813AMeet thin and light requirementsImprove Radiation PerformanceRadiating elements structural formsAntenna earthingsDisplay deviceEngineering

The embodiment of the invention provides a display device and a manufacturing method thereof. The display device comprises a display module which comprises a display surface and a non-display surfacewhich are arranged oppositely; the antenna comprises a radiation element, a microstrip feed and a grounding layer; the radiation element is connected with the microstrip feed. Wherein the radiation element and the microstrip feed are both arranged on the display surface of the display module, the grounding layer is arranged on one side of the non-display surface of the display module, and the display module is periodically provided with a plurality of hollow parts in an area where the antenna is located so as to form a clearance area of the antenna. According to the display device and the manufacturing method thereof provided by the embodiment of the invention, the signal radiation performance of the on-screen integrated antenna can be improved, and the light and thin design requirements of the display device are met.

Owner:BOE TECH GRP CO LTD +1

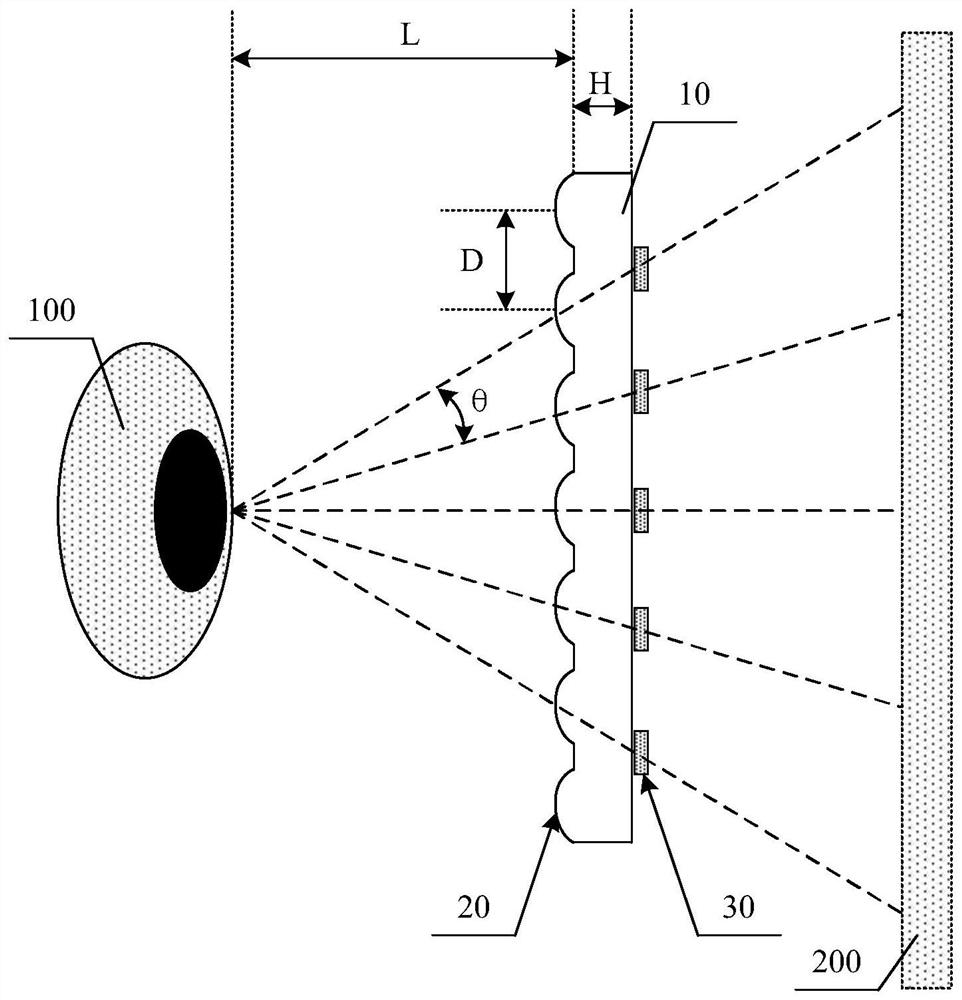

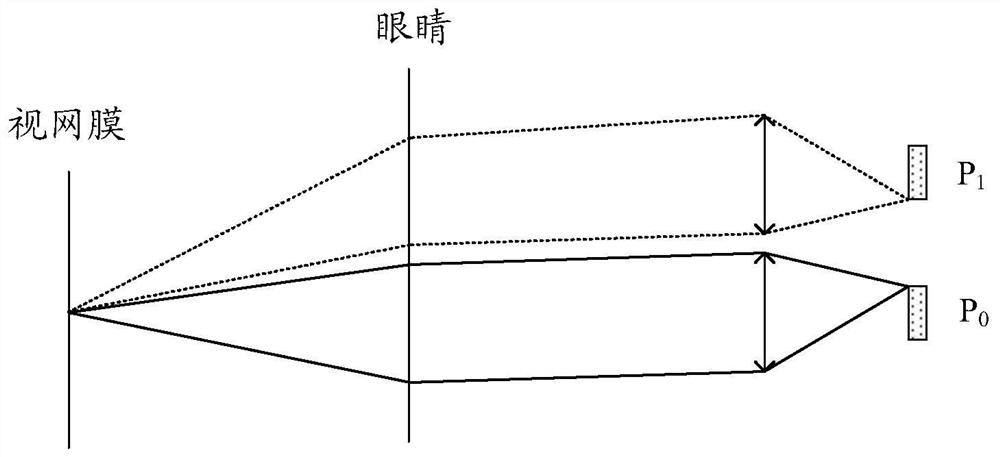

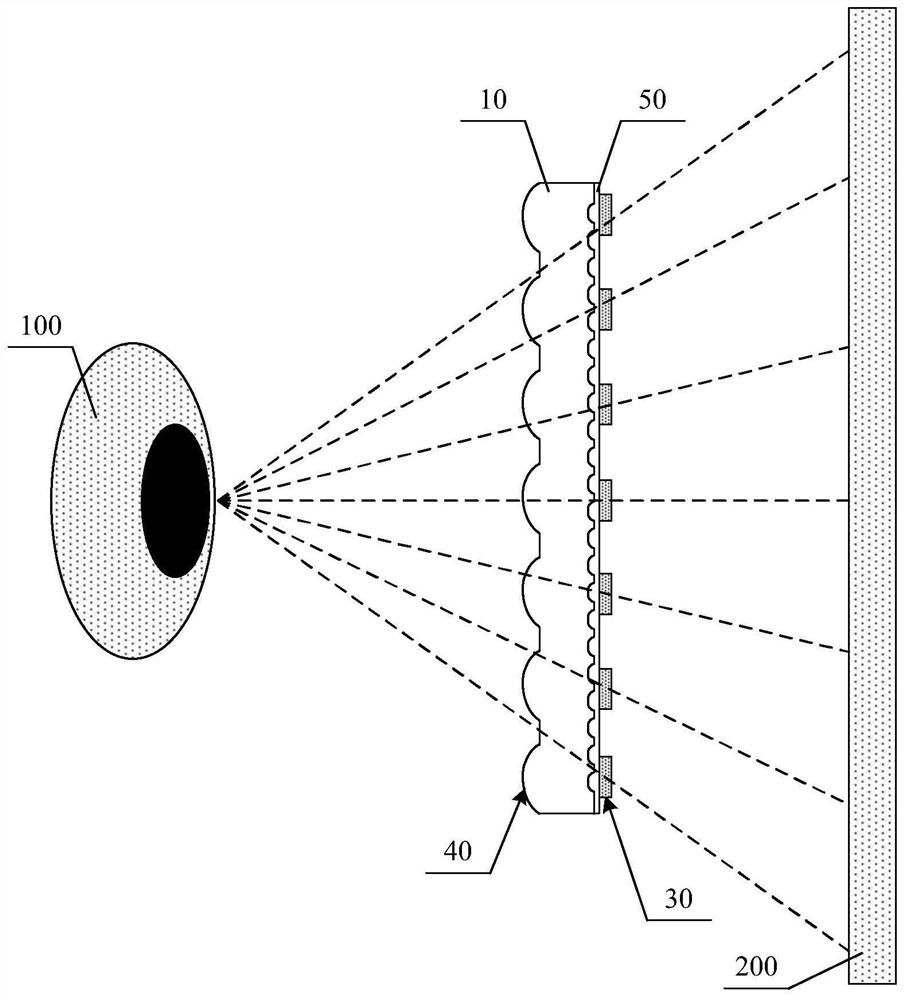

Near-eye display device and virtual/augmented reality equipment

The embodiment of the invention provides a near-eye display device and virtual / augmented reality equipment. The near-to-eye display device comprises a substrate, a combined microlens array arranged on the substrate and a pixel island array located on the side, away from eyes, of the substrate, the combined microlens array comprises a plurality of combined microlenses arranged at intervals, and the pixel island array comprises a plurality of pixel islands arranged at intervals. Each pixel island corresponds to one combined micro lens, and each pixel island is arranged at the focal point of the corresponding combined micro lens; and each combined microlens comprises a first microlens arranged on the surface of the side, facing the eye, of the substrate and an additional microlens arranged between the first microlens and the pixel island. Through the arrangement of the combined microlens array, the pixel points at the edge parts of the pixel islands can form an effective view field, the number of the pixel points under each lens view field angle is increased, and the display resolution is improved on the premise of meeting the requirements of light and thin near-to-eye display.

Owner:BOE TECH GRP CO LTD

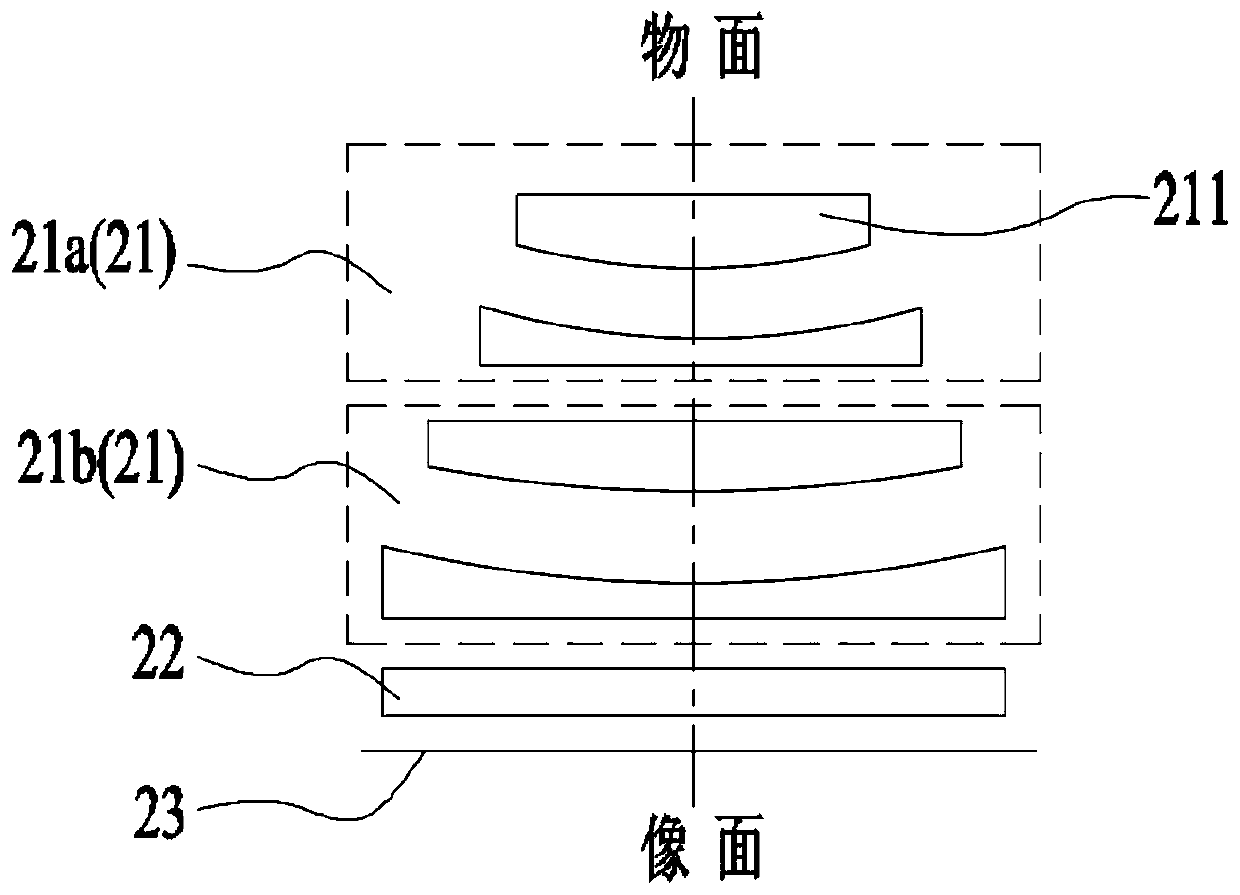

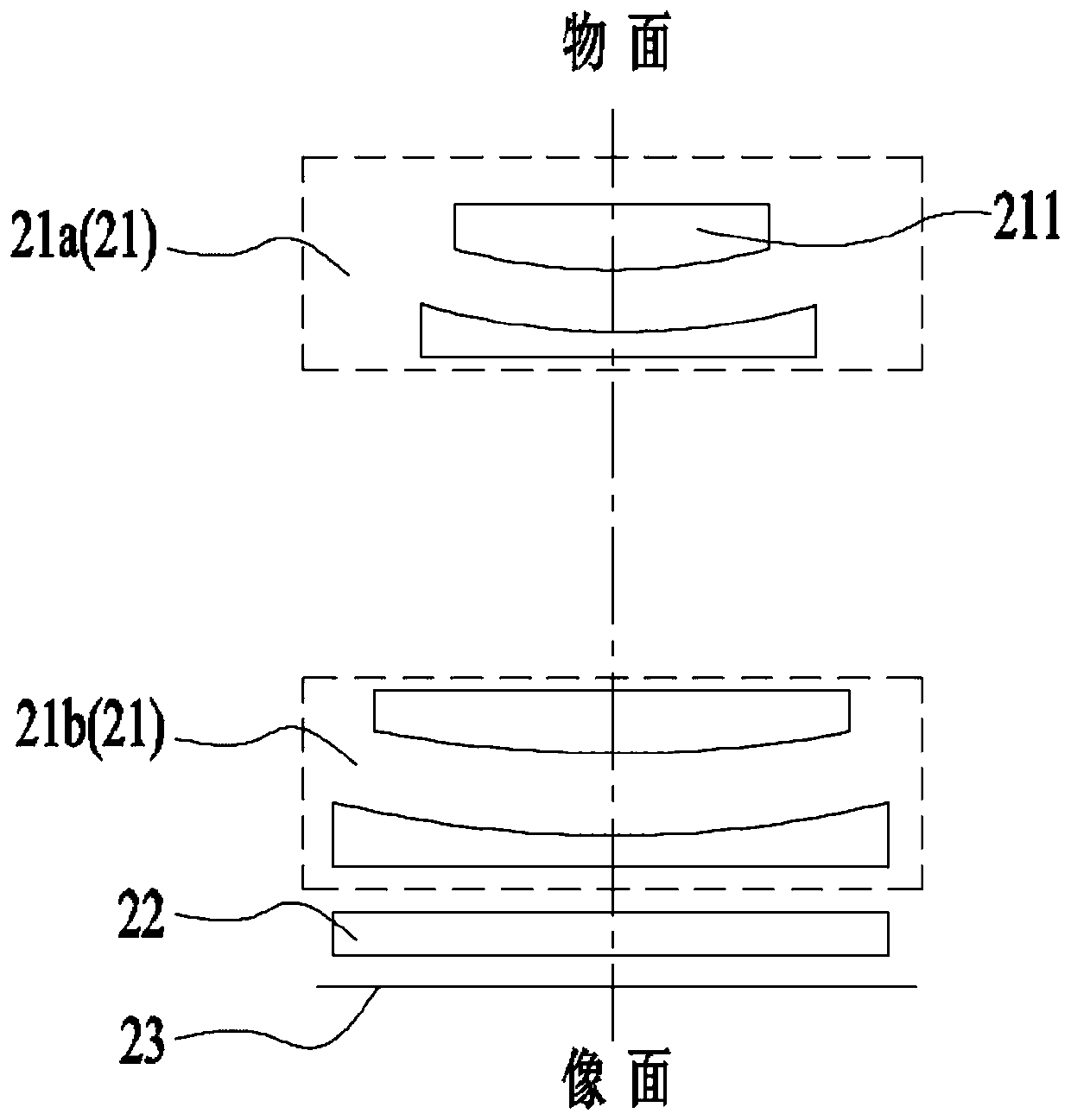

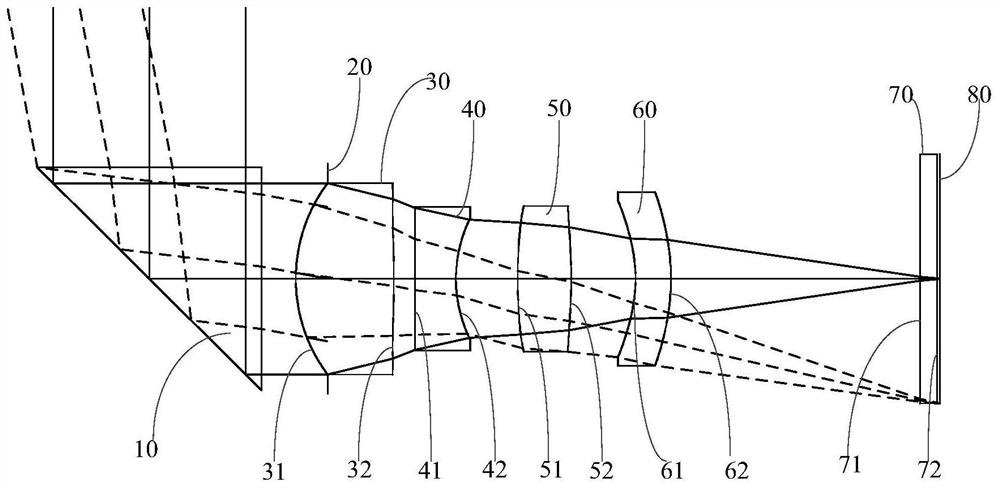

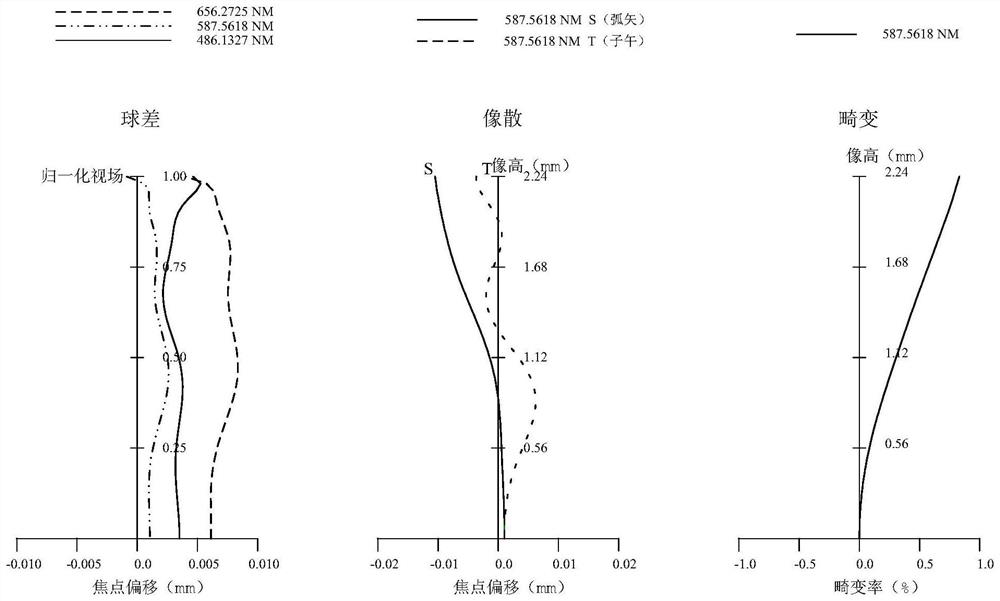

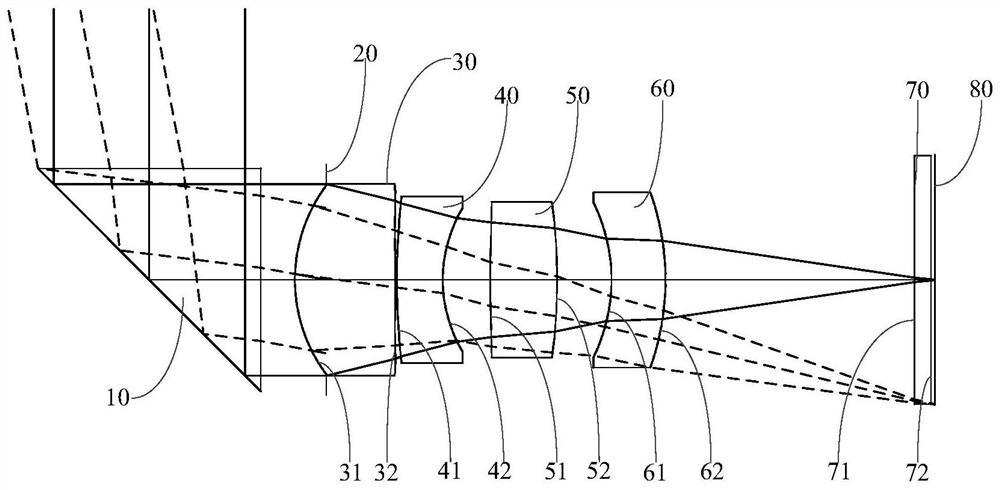

Imaging lens, camera module and electronic equipment

PendingCN112327457AGuaranteed assembly manufacturabilityShorten the lengthOptical elementsGrismOphthalmology

The invention discloses an imaging lens, a camera module and electronic equipment. The imaging lens comprises a prism, a first lens, a second lens, a third lens and a fourth lens which are sequentially arranged from the object side to the image side. The imaging lens satisfies the conditional expression that 0.4 mm<ET12+ ET23+ET34<2.5 mm, wherein ET12 is the distance from the maximum effective aperture of the image side surface of the first lens to the maximum effective aperture of the object side surface of the second lens on the optical axis, ET23 is the distance from the maximum effective aperture of the image side surface of the second lens to the maximum effective aperture of the object side surface of the third lens on the optical axis, and ET34 is the distance from the maximum effective aperture of the image side surface of the third lens to the maximum effective aperture of the object side surface of the fourth lens on the optical axis. The imaging lens achieves the long-focuscharacteristic, is short in transverse distance, and can meet the light and thin requirements of a cellphone.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Light guiding component, backlight module, and display device

ActiveCN109212656AMeet thin and light requirementsMeet the needs of sub-regional controlOptical light guidesLight guideDisplay device

The invention provides a light guiding component, a backlight module, and a display device. The light guiding component comprises a first light guiding member and a plurality of second light guiding members. The first light guiding member comprises opposite first and second surfaces. The first surface is provided with a plurality of dots for light exiting. The second light guiding members respectively fixedly connected to the second surface. Each of the second light guiding members respectively comprises a light incident end surface for light entering the second light guiding member in a side-entry manner. The light guiding component can solve the problem that the backlight module of the light guide plate in the prior art cannot meet the requirements of light and thinning and the sub-areacontrol of the light source by providing the first light guiding member and the plurality of second light guiding members.

Owner:BOE TECH GRP CO LTD +1

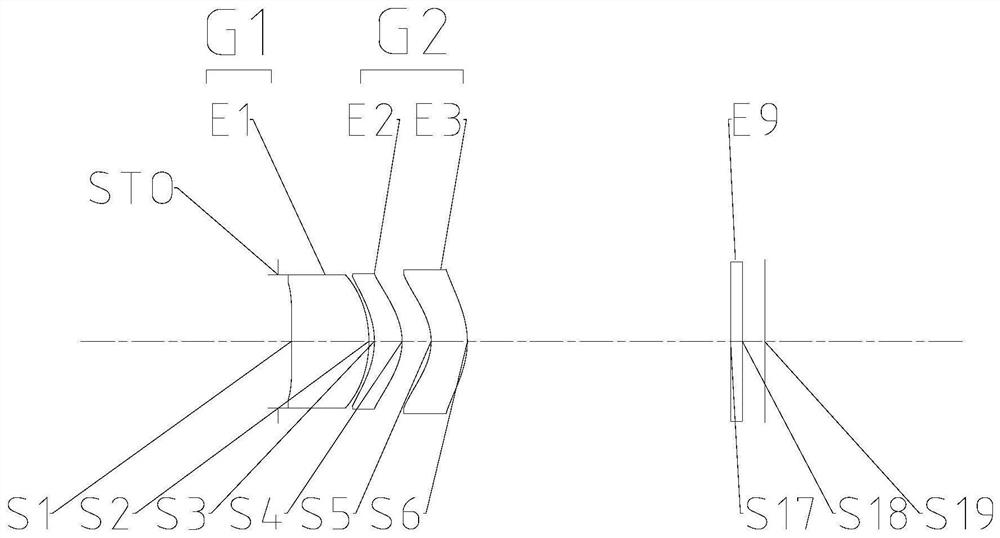

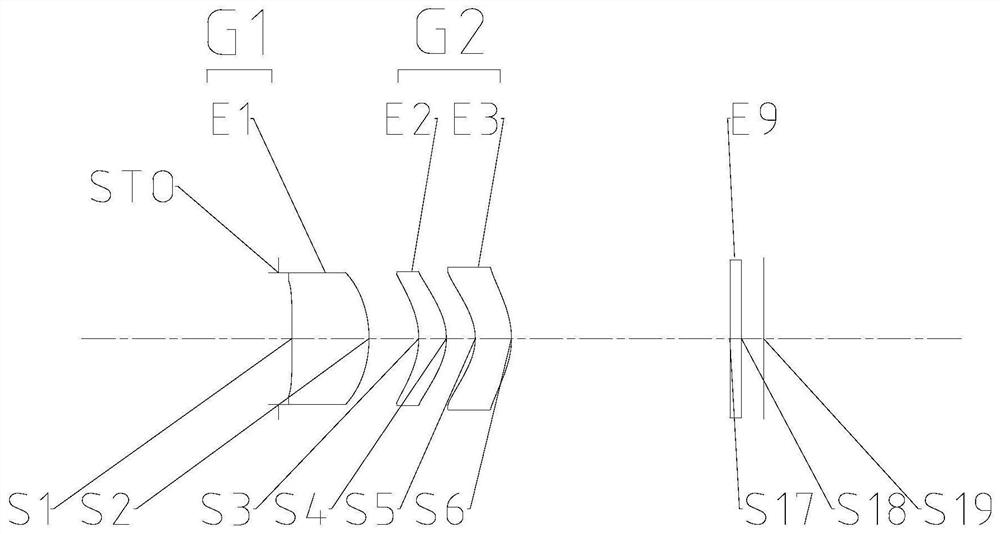

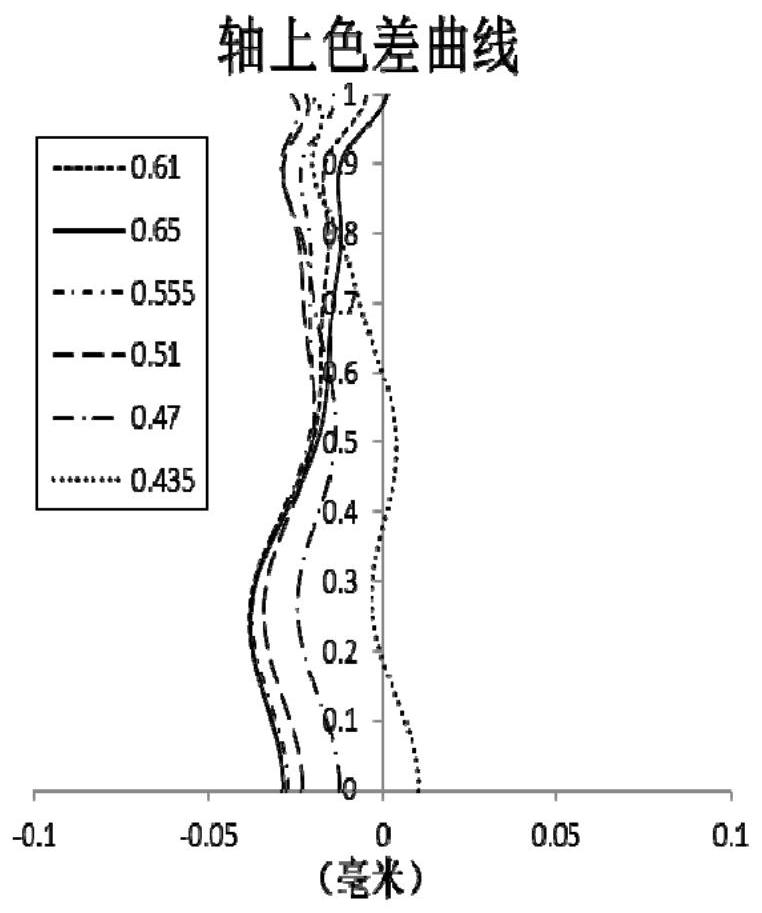

Mobile focusing optical lens group

PendingCN114167572AImprove image qualityCompliant with miniaturizationMountingsOphthalmologyOptical axis

The invention provides an optical lens group for mobile focusing. From the object side to the image side of the optical lens group for moving focusing, the optical lens group sequentially comprises: a first lens group having positive focal power, the first lens group comprising at least one lens having focal power; the second lens group comprises two lenses with focal power; when the object to be shot moves from infinity to macro relative to the optical lens group for mobile focusing or when the object to be shot moves from macro to infinity relative to the optical lens group for mobile focusing, the second lens group moves on the optical axis to realize focusing. When the optical lens group is located at the close-shooting position and the optical lens group is located at the far-shooting position, the interval difference quantity T of the first lens group and the second lens group on the optical axis and the distance TTL from the object side surface of the first lens of the optical lens group to the imaging surface of the optical lens group on the optical axis meet the following condition: T / TTLlt; and 0.25%. According to the invention, the problem of high power consumption of an optical lens group in the prior art is solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

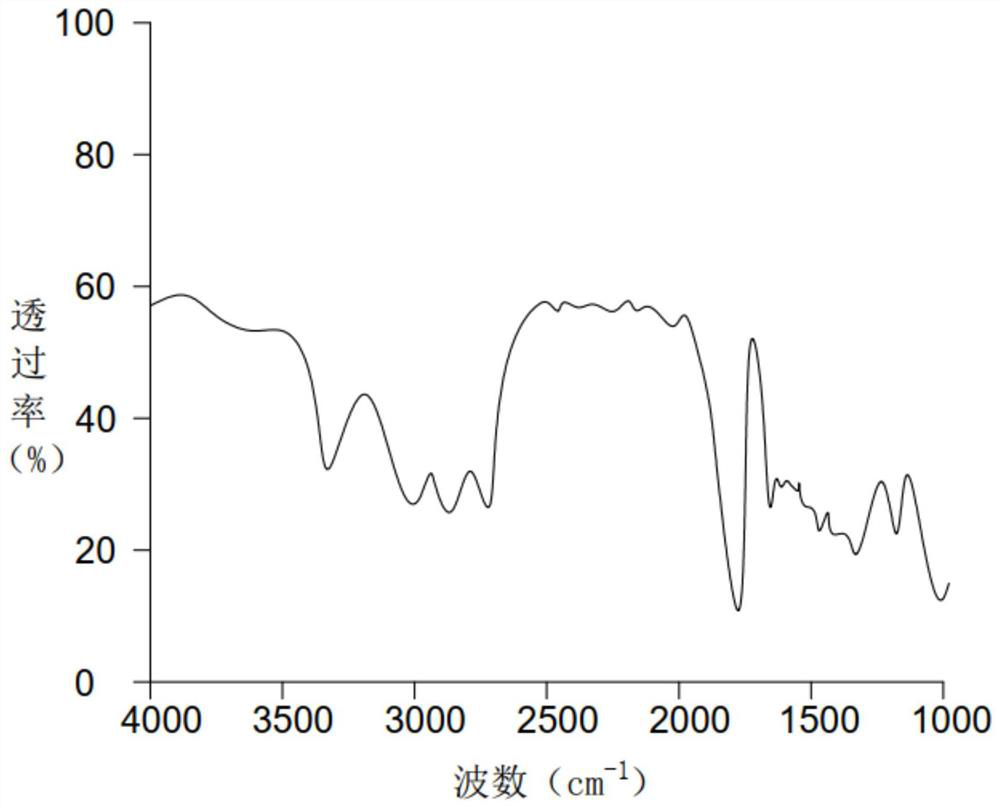

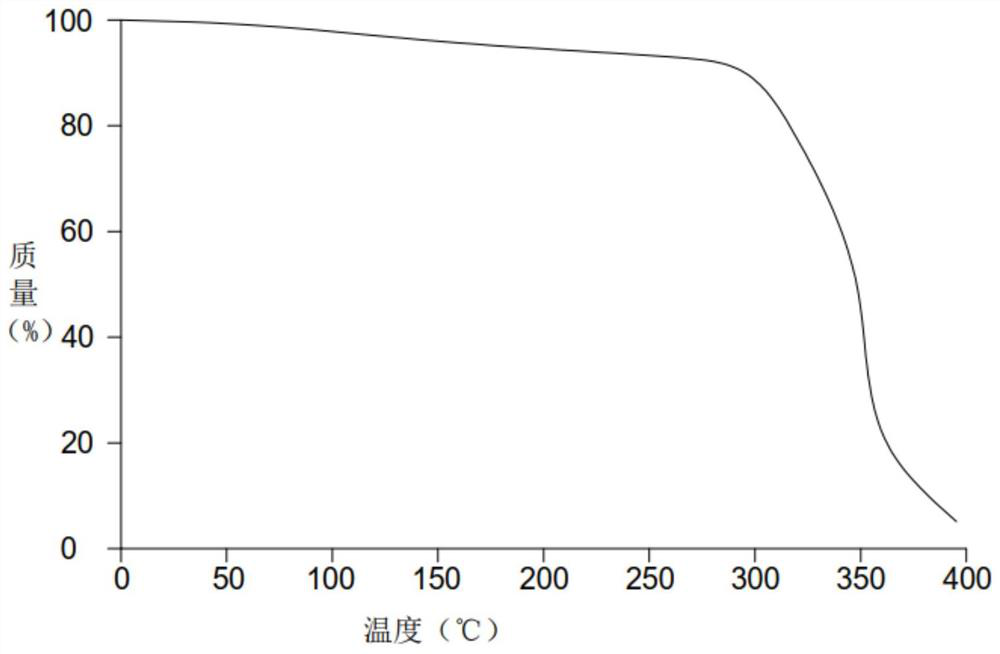

A kind of preparation method of high-precision ultra-thin PCB

ActiveCN112118687BImprove transmission qualityHigh bonding strengthInsulating substrate metal adhesion improvementPrinted circuits stress/warp reductionEthylene Glycol MethacrylateEthylene glycol

The invention belongs to the technical field of circuit board manufacturing, and specifically relates to a method for preparing a high-precision ultra-thin PCB. The steps include: forming a mask on the surface of a substrate; The pattern of the area and the raised area; the nickel-based metal ion-polyethylene glycol methacrylate resin mixture is injected into the recessed area to form a primer layer; the Cu layer is deposited on the surface of the primer layer and the raised area; it will be located in the raised area The Cu layer and the remaining mask are removed; a flat insulating layer is formed to obtain a high-precision ultra-thin PCB. By adding poly(ethylene glycol methacrylate) resin to form a mixture with nickel-based metal ions, the bonding strength between the primer layer and the substrate is improved, and the Cu layer is deposited on the primer layer, which strengthens the bonding strength between the Cu layer and the primer layer, and finally achieves The bonding strength between the copper line and the base material, there is no problem of short circuit or open circuit caused by the lifting of the copper line, ensuring high-quality transmission of PCB signals.

Owner:光臻精密制造(苏州)有限公司

Electromagnetic induction type liquid crystal panel as well as manufacture method thereof and liquid crystal display (LCD)

ActiveCN101930134BHigh precisionImprove reliabilityAntenna arraysStatic indicating devicesLiquid-crystal displayDisplay device

Owner:东莞凌尚触控科技有限公司

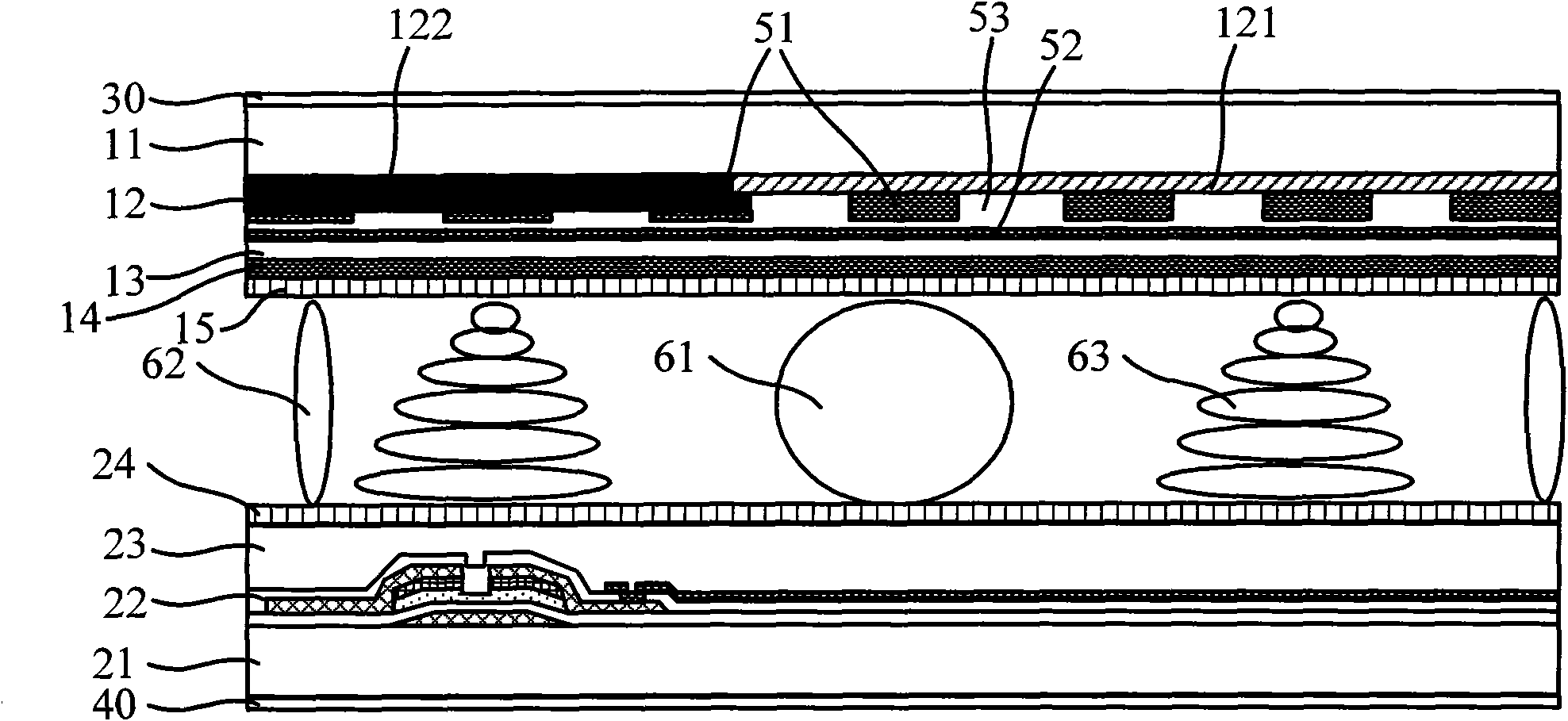

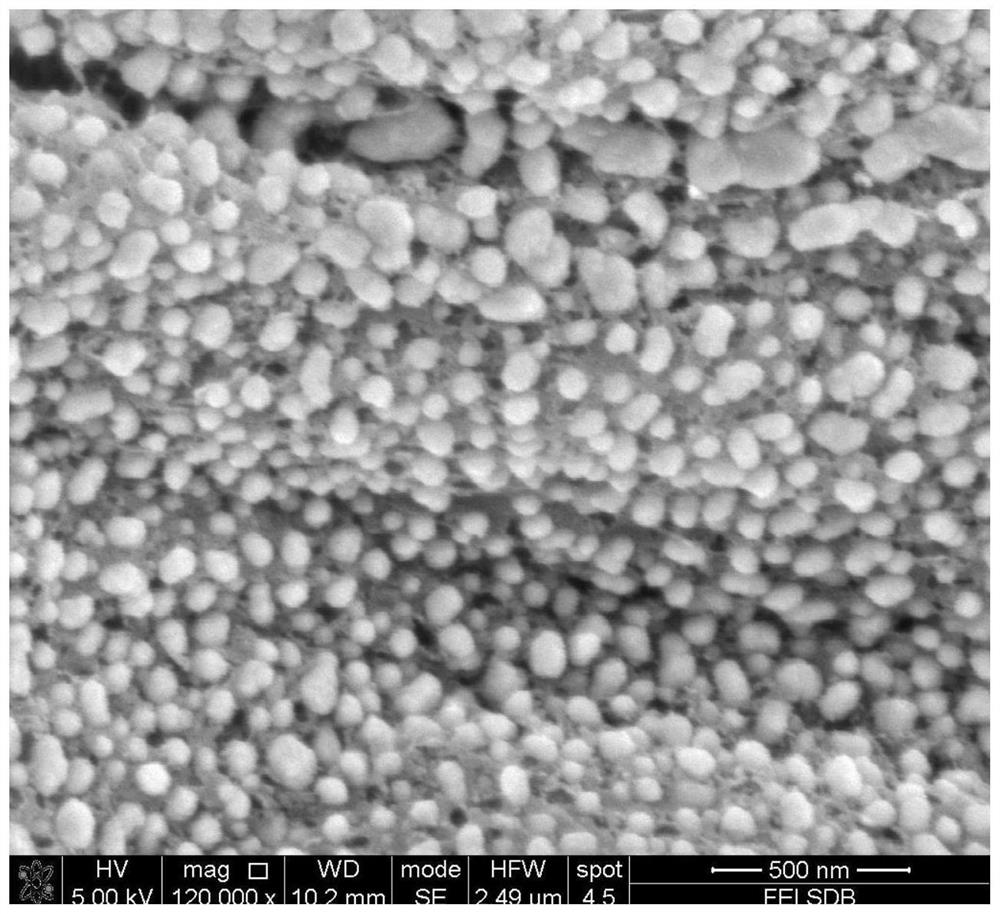

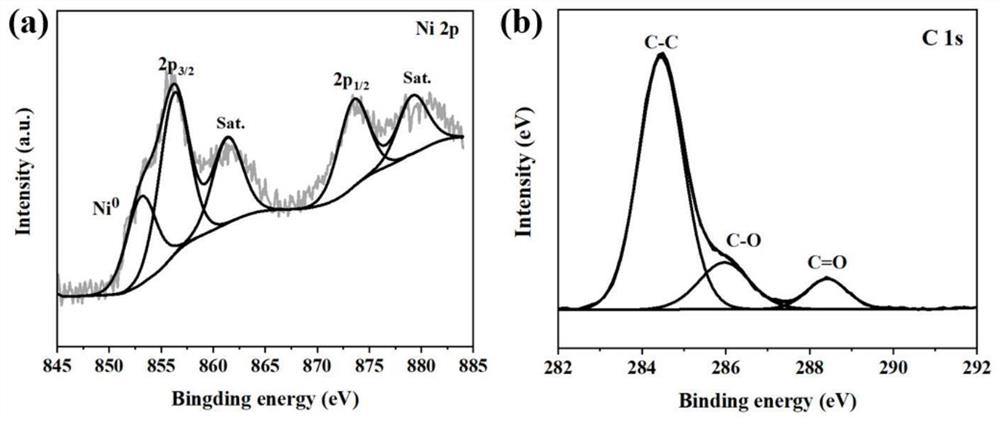

Preparation method of nickel nanoparticle/graphene electromagnetic wave absorbing material

PendingCN114845537ARealize multi-bandMeet thin and light requirementsScreening rooms/chambersAntennasGraphite oxideSodium borohydrate

The invention provides a preparation method of a nickel nanoparticle and graphene electromagnetic wave absorption composite material, and belongs to the technical field of electromagnetic wave absorption material preparation. According to the method, nickel sulfate is used as a nickel ion source, sodium borohydride is used as a reducing agent, stronger ammonia water is used as a precipitator, and graphene oxide is used as an attachment carrier. The nickel nanoparticle / graphene electromagnetic wave absorption composite material is synthesized by two steps of a controllable liquid drop method and heat treatment reduction. The electromagnetic wave absorption composite material is formed by tightly attaching and combining nickel nanoparticles and graphene, and formed graphene wrinkles effectively inhibit agglomeration of the nickel nanoparticles and promote dielectric magnetic synergistic loss of electromagnetic waves. The electromagnetic wave absorbing material has the characteristics of small density, small addition amount, simple preparation process and excellent wave absorbing performance, and can be widely applied to the fields of electromagnetic protection and microwave stealth as an electromagnetic shielding or loss material.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com