Mobile focusing optical lens group

A technology of optical lens and lens group, applied in the field of optical lens group, can solve the problem of high power consumption of optical lens group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

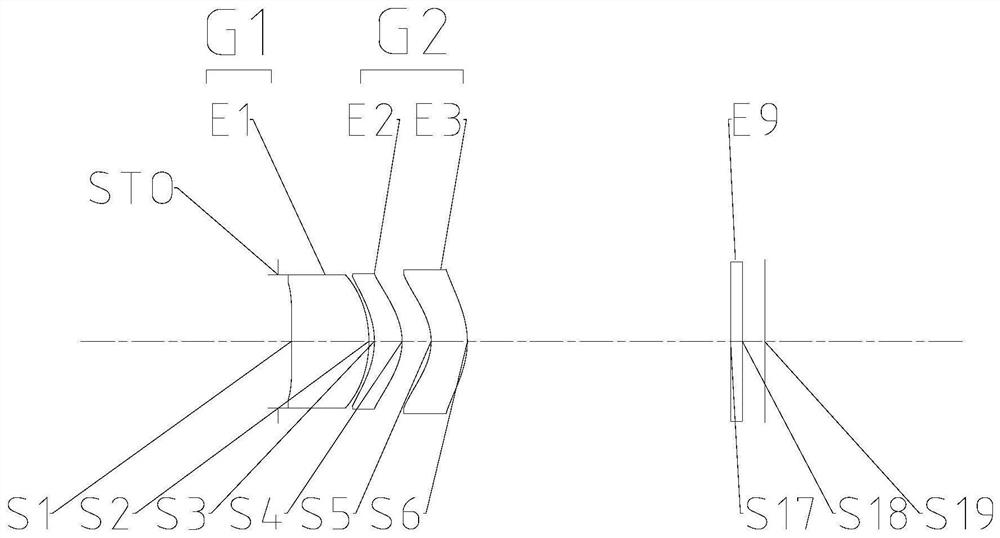

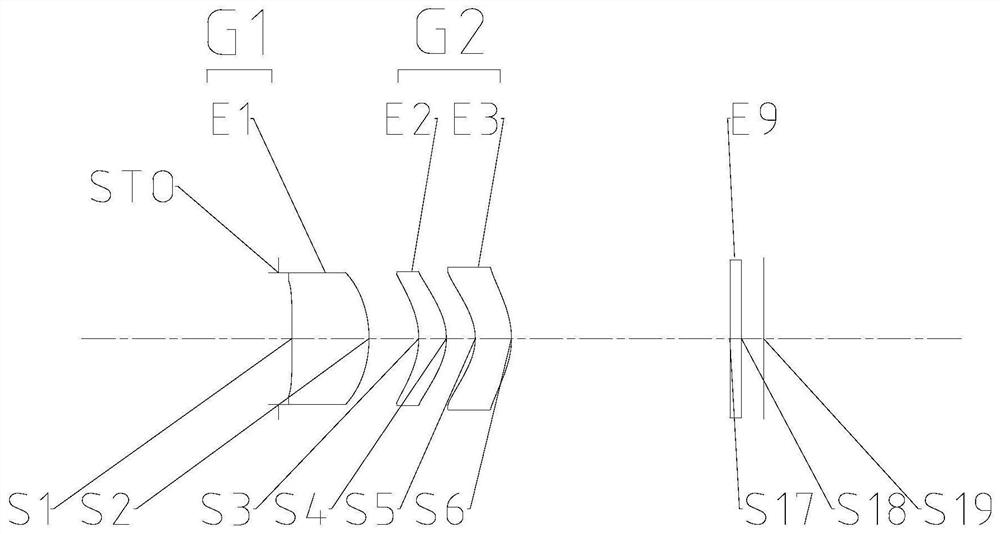

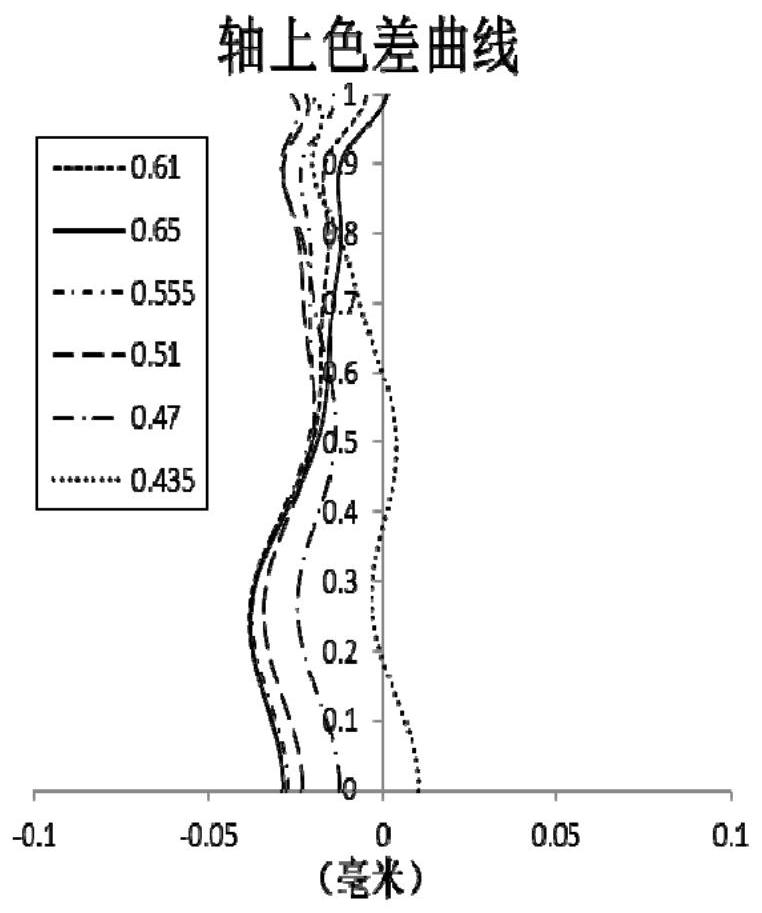

[0097] Such as Figure 1 to Figure 60 As shown, the object side to the image side of the optical lens group that moves the focus includes a first lens group and a second lens group in sequence, the first lens group has a positive refractive power, and the first lens group includes at least one lens with a refractive power lens; the second lens group includes two lenses with optical power; wherein, when the subject moves from infinity to macro distance relative to the optical lens group that moves the focus or when the subject moves relative to the optical lens that moves the focus When the group moves from macro distance to infinity, the second lens group moves on the optical axis to achieve focusing, and the sum ΣCT of the center thicknesses of the first lens of the optical lens group to the last lens of the optical lens group on the optical axis is equal to the first The distance TTL from the object side of a lens to the imaging plane on the optical axis satisfies: 0.2<∑CT / T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com