Display device and manufacturing method thereof

A technology for a display device and a manufacturing method, which is applied in lamination devices, lighting devices, chemical instruments and methods, etc., can solve the problems of OCA optical adhesive layer thickness, device overall structure thickening, ink gap, etc., and achieve a thinner overall structure , reduce the thickness, reduce the effect of the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

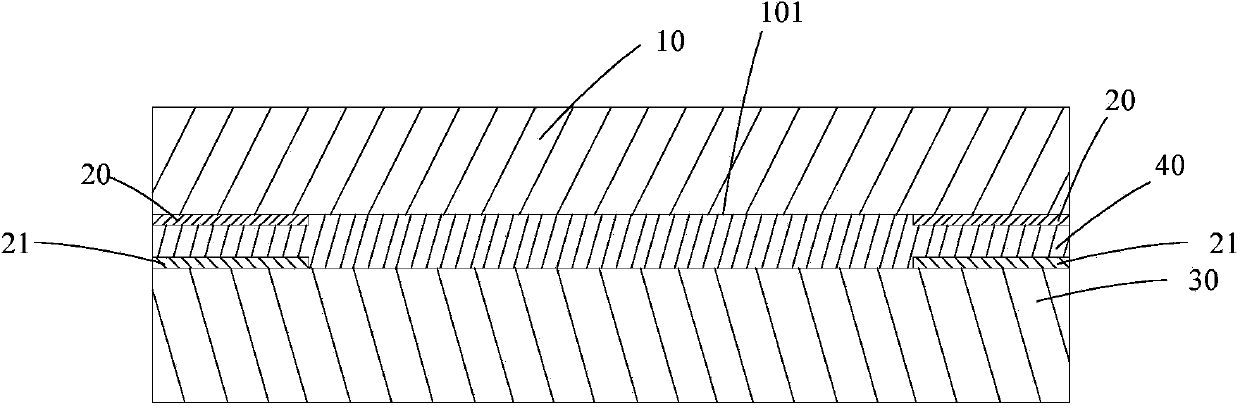

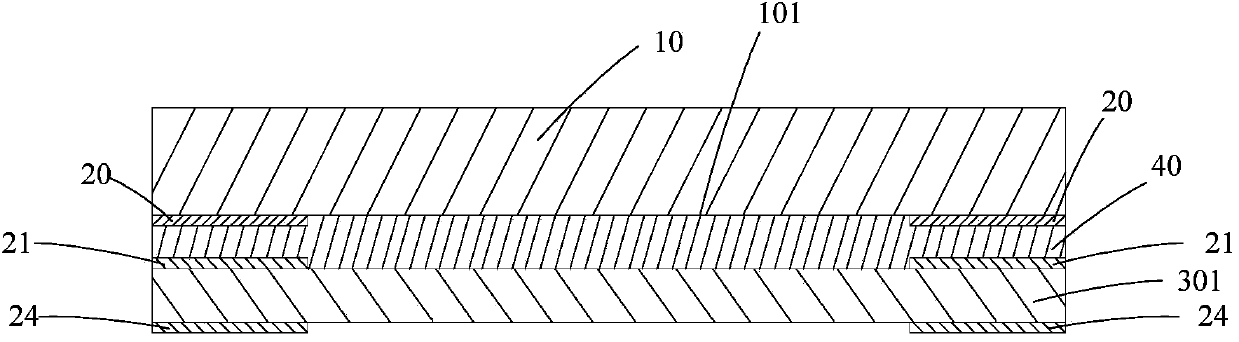

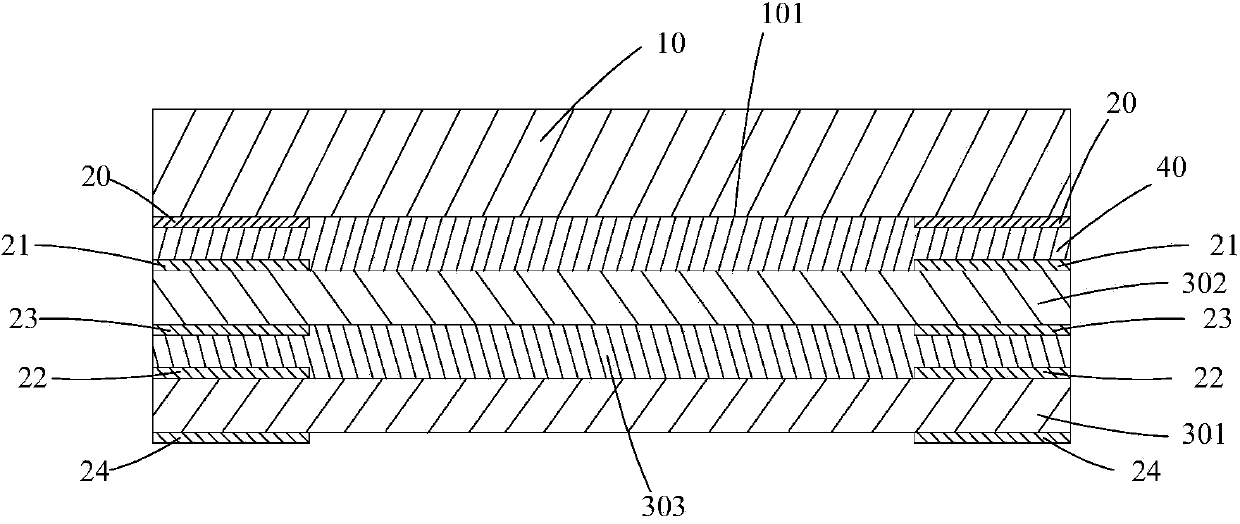

[0030] see figure 1 Shown is a cross-sectional view of the display device of the present invention. The display device and its manufacturing method of the present invention, under the condition that the thickness of the ink remains unchanged, the ink layer is respectively arranged on the surface of each structural layer of the display device, so that the single-layer ink layer can be the thinnest, and the thinnest reaches 5um, which effectively reduces the gap caused by the ink layer. In this way, when OCA optical glue is used for lamination, no air bubbles are guaranteed, and thicker OCA optical glue is not needed. In practice, OCA optical glue can use 50um To realize the lamination between the structural layers, compared with the existing 200um thick optical glue, the optical glue layer is greatly thinned, so that the overall thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com