LED backlight source, LED backlight module and preparation method

A technology of LED backlight and backlight module, which is applied in optics, nonlinear optics, instruments, etc., can solve the problem of large thickness of LED display screen, and achieve the effect of thickness reduction and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

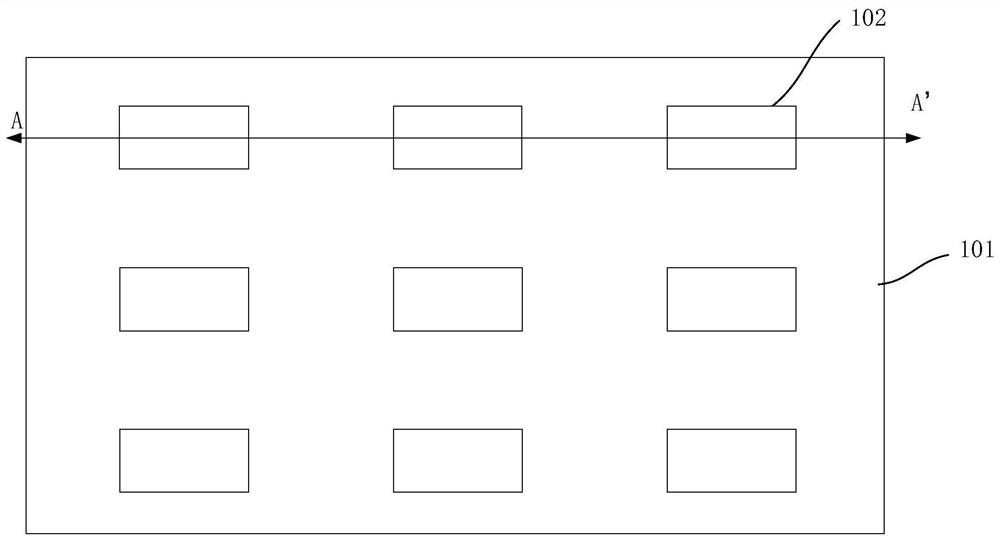

[0043] Such as Figure 1 to Figure 7 As shown, the present embodiment provides a method for preparing an LED backlight, and the LED backlight can be applied to a liquid crystal display, and the preparation method includes steps:

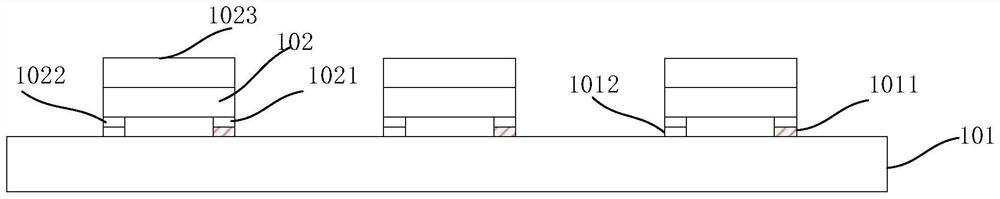

[0044] Such as Figure 1~4 As shown, step 1) is first performed, providing a substrate 101 and LED chip 102, the LED chip 102 has a substrate 1023, and the LED chip 102 is crystal-bonded on the substrate 101 by flip-chip, so that An LED array is formed on the substrate 101 .

[0045] The substrate 101 may be one of a PCB substrate and a glass substrate, and the type of the PCB substrate may be FR4, BT, BT-like, FPC or the like.

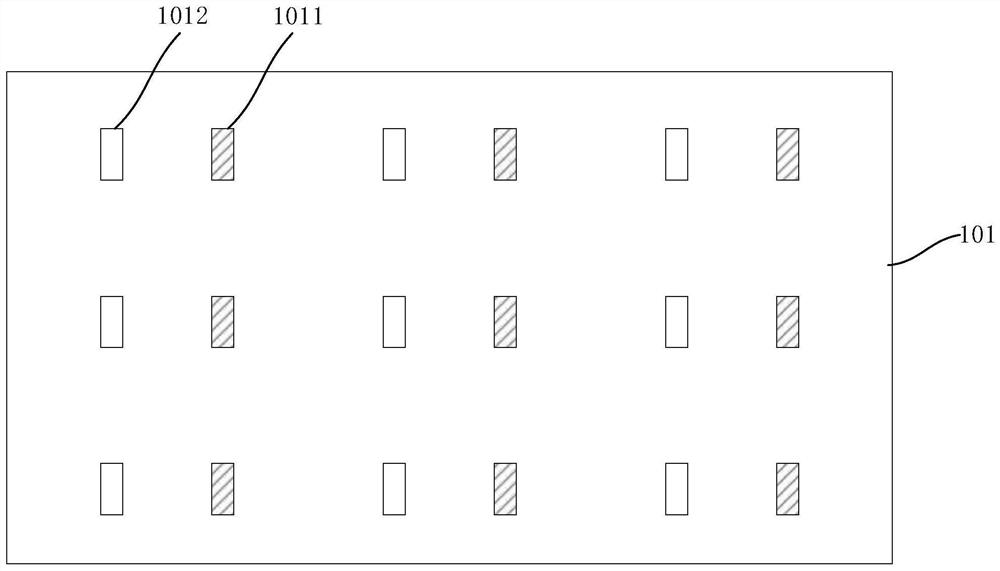

[0046] Such as figure 1As shown, the substrate 101 has a thin film transistor array (TFT Array) and an electrode array, the electrode array includes a first electrode 1011 array and a second electrode 1012 array, and the first electrode 1011 array includes a first electrode array arranged in an array electrode 1011, the...

Embodiment 2

[0066] Such as Figure 1 to Figure 9 Shown, the present invention provides a kind of preparation method of LED backlight module, described LED backlight module can be applied to liquid crystal display, and described preparation method comprises:

[0067] Such as Figure 1 to Figure 8 As shown, step 1) is first carried out, and the LED backlight is prepared by the method for preparing the LED backlight as described in Example 1.

[0068] Such as Figure 9 As shown, then proceed to step 2) to fabricate a color conversion layer 203 on the LED backlight.

[0069] The color conversion layer 203 may be one of quantum dot film and phosphor film.

[0070] For example, the color conversion layer 203 is a quantum dot film, and there are quantum dots in the quantum dot film, and the quantum dots emit red light and green light under the excitation of the blue light emitted by the blue LED chip; or, the quantum dots Red light is emitted under the joint excitation of blue light or green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com