Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Increase thickness dimension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

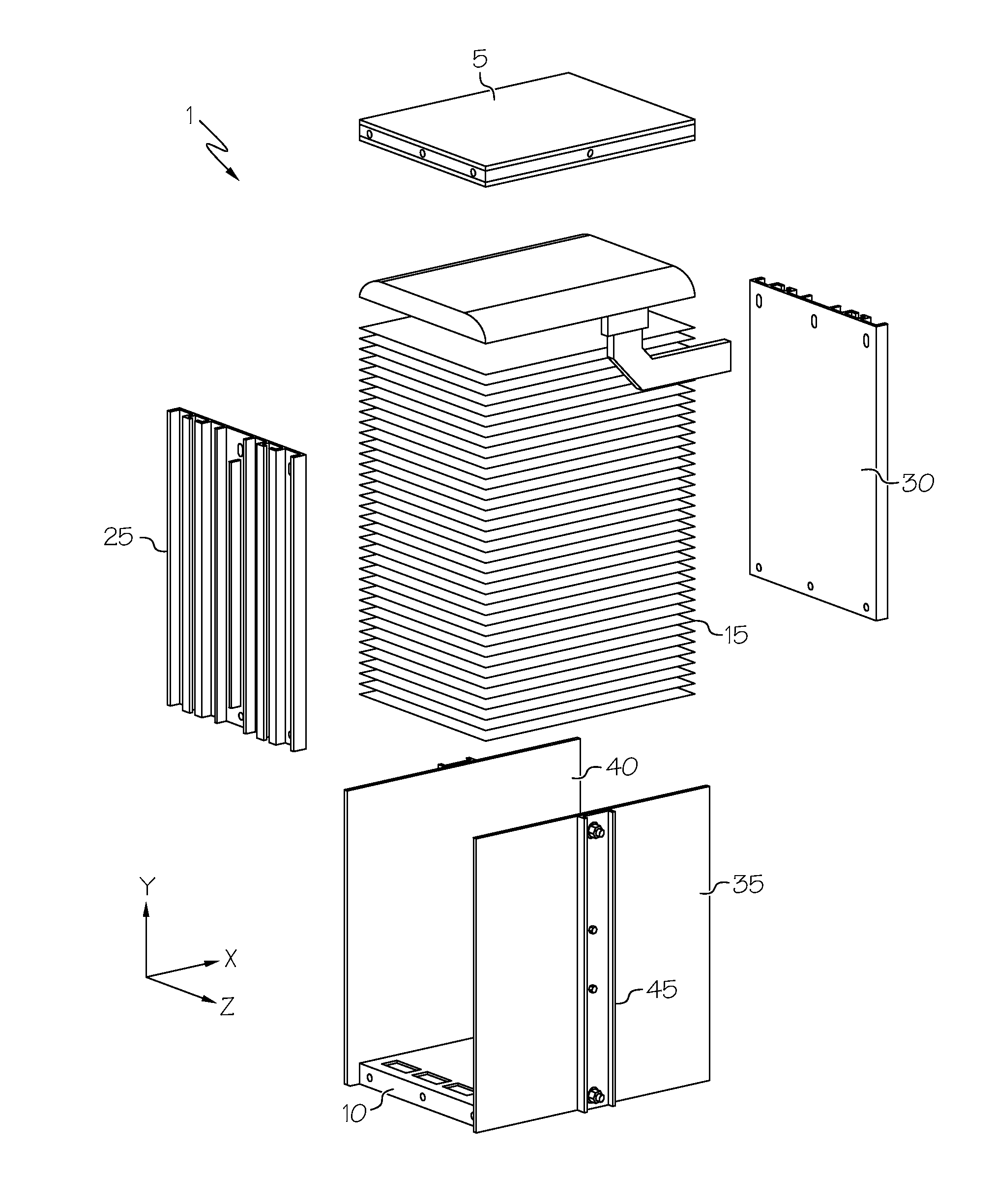

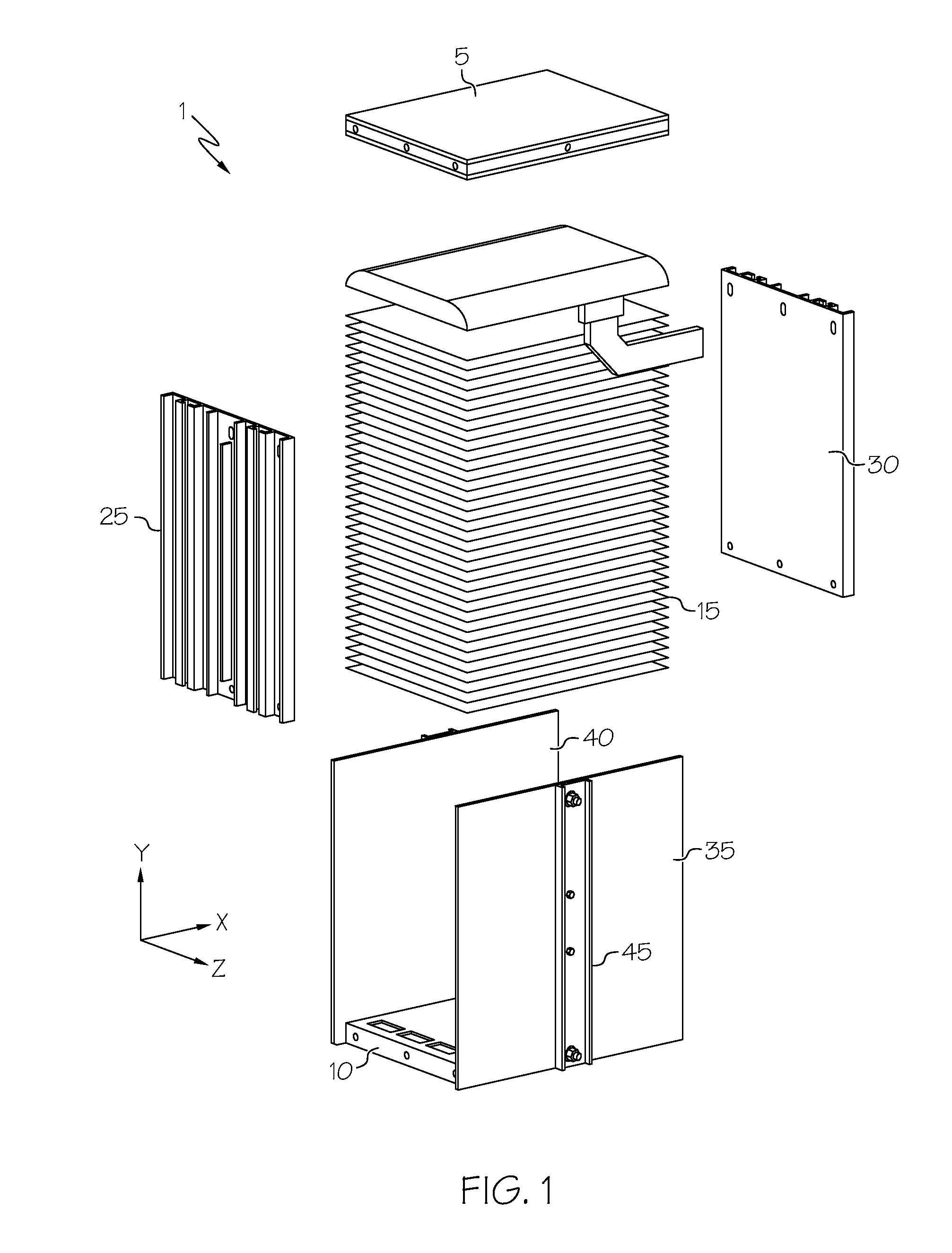

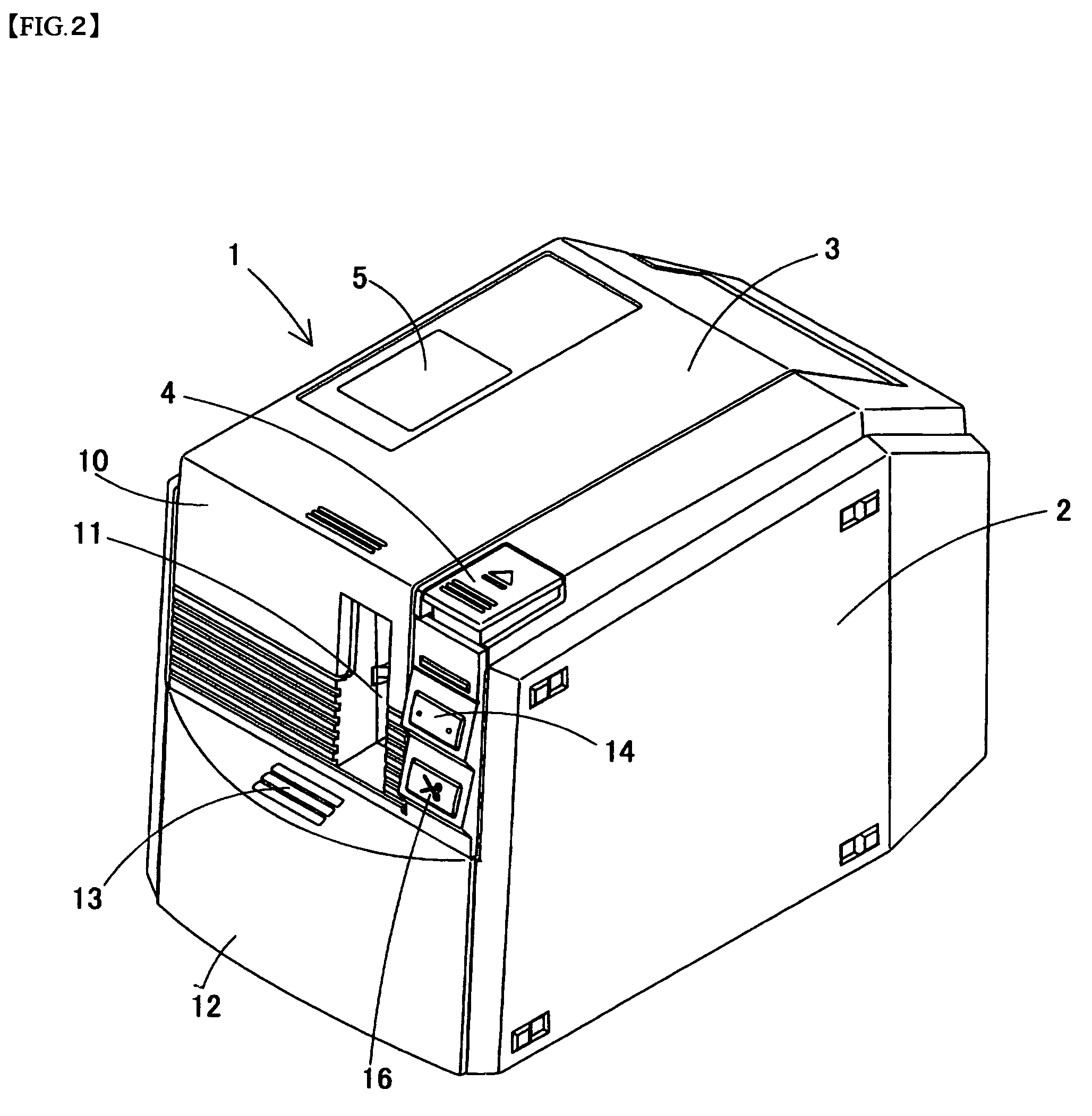

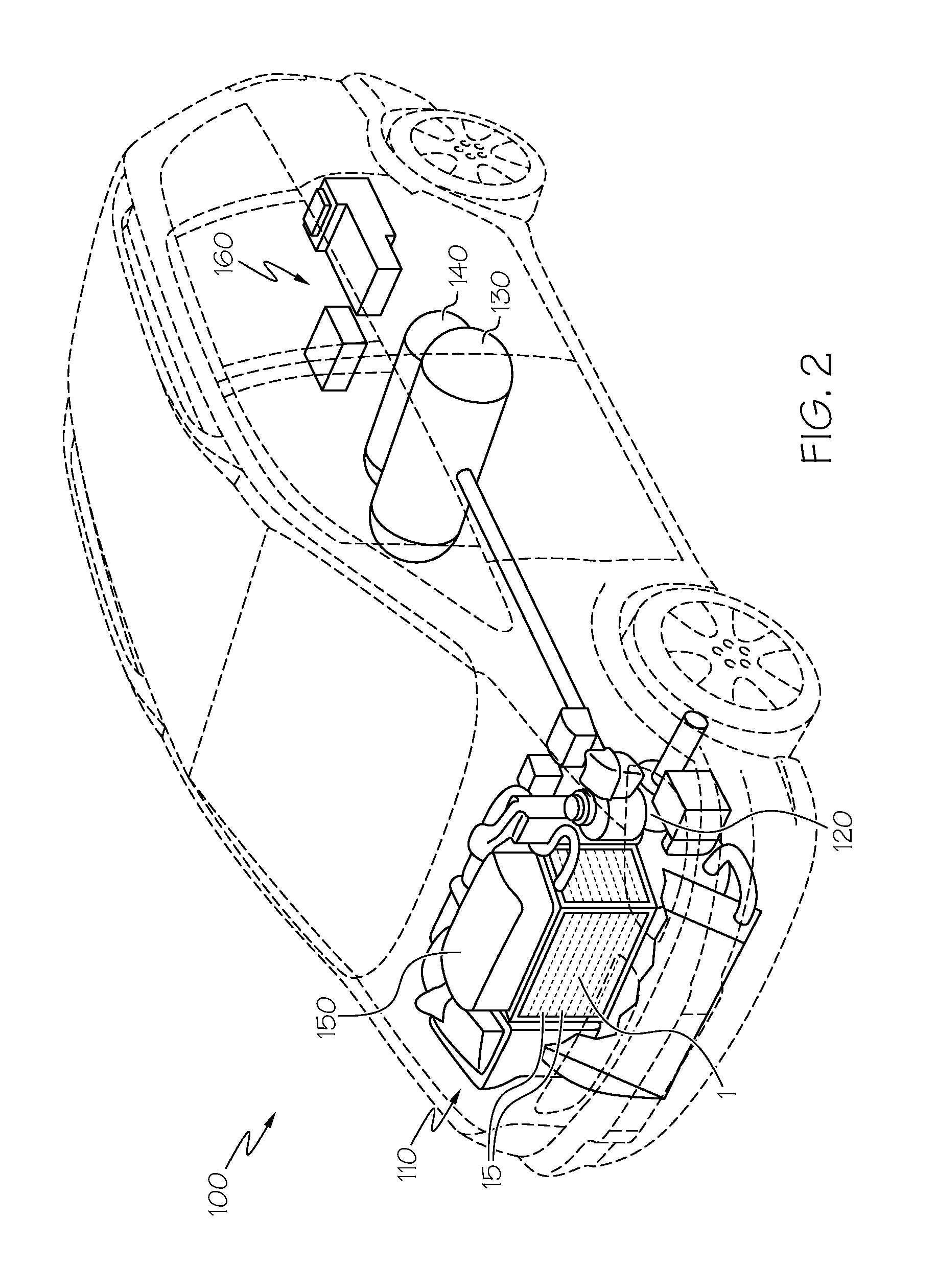

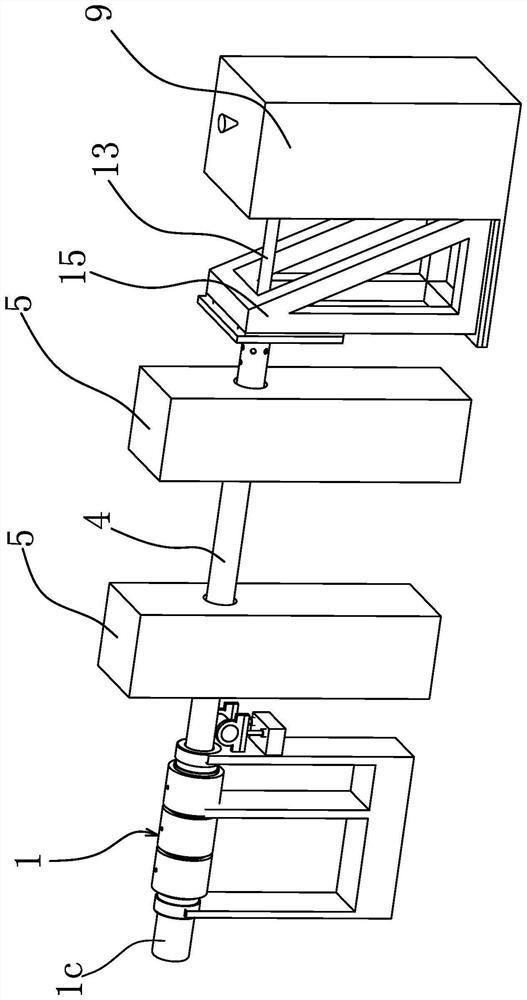

Fuel cell stack assembly - datum design for fuel cell stacking and collision protection

ActiveUS20160072145A1Improve the immunityIncrease thickness dimensionFuel cells groupingCell component detailsInterference fitFuel cells

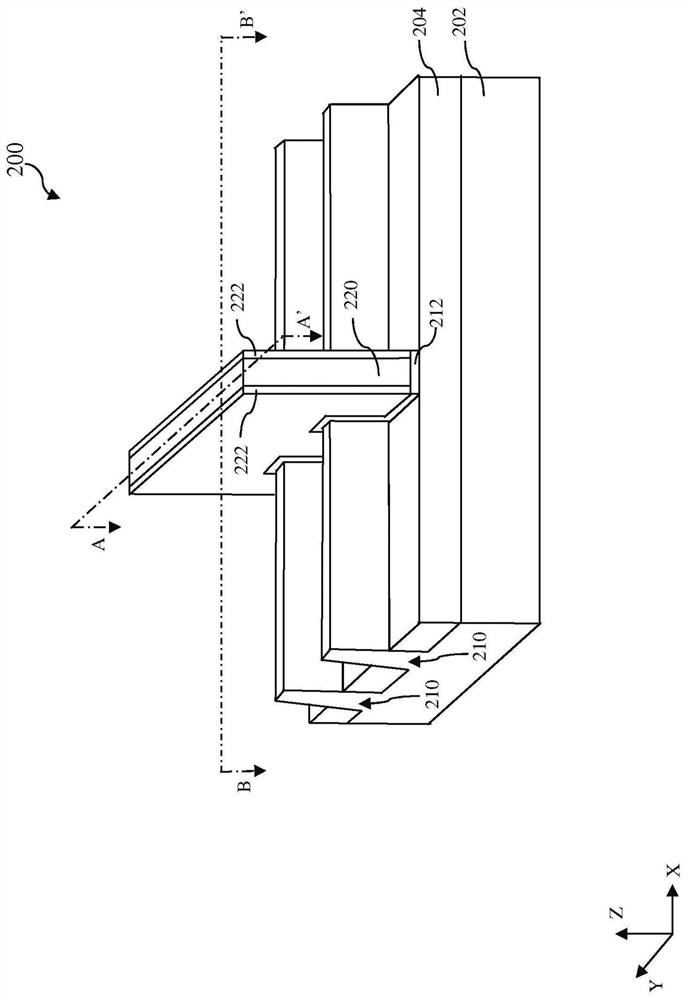

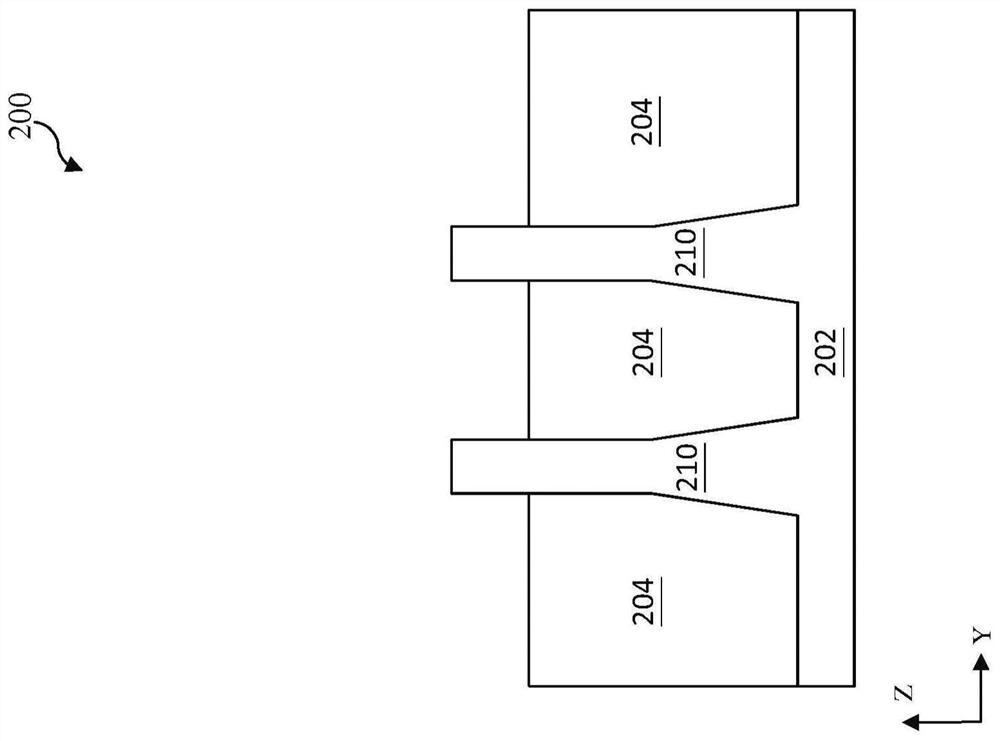

A system and method for aligning and reducing the relative movement between adjacent fuel cells within a fuel cell stack. The inter-cell cooperation between fuel cells along a stacking dimension is enhanced by one or more datum placed along the edge of a bipolar plate that makes up a part of a cell-containing assembly. The datum is shaped along a thickness dimension that substantially coincides with the cell stacking dimension to promote a nested fit with a comparable datum on an adjacently-stacked bipolar plate. This nesting facilitates an interference fit that enhances the resistance to sliding movement between respective cells that may otherwise arise out of the occurrence of a significant acceleration along the dimension that defines the major surfaces of the plates, cells and their respective assemblies. In one form, the use of welding, bonding or related attachment of the datum to the plate promotes enhanced metallic support without the need for increasing the plate footprint and without having to overmold the datum directly onto the plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

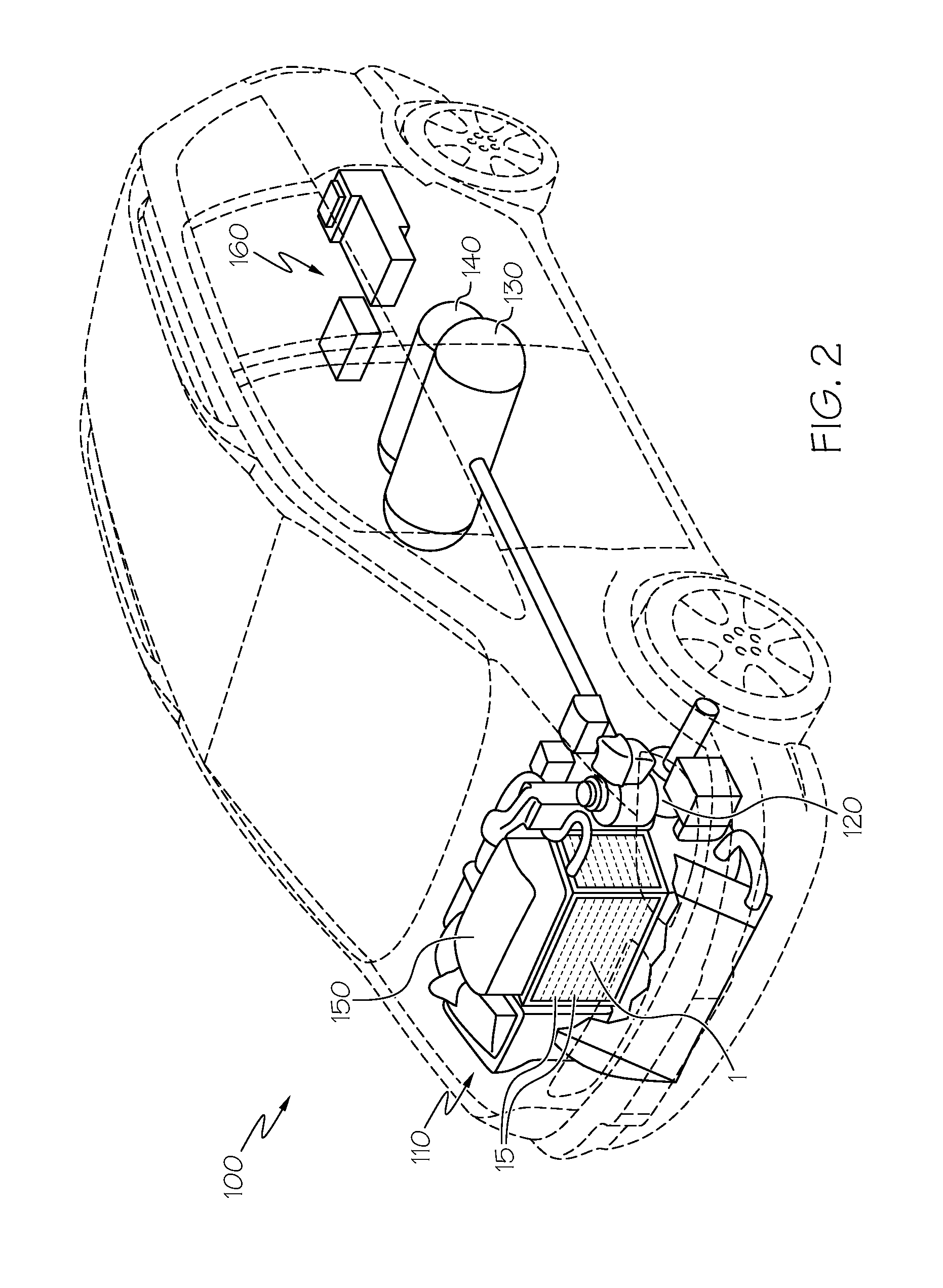

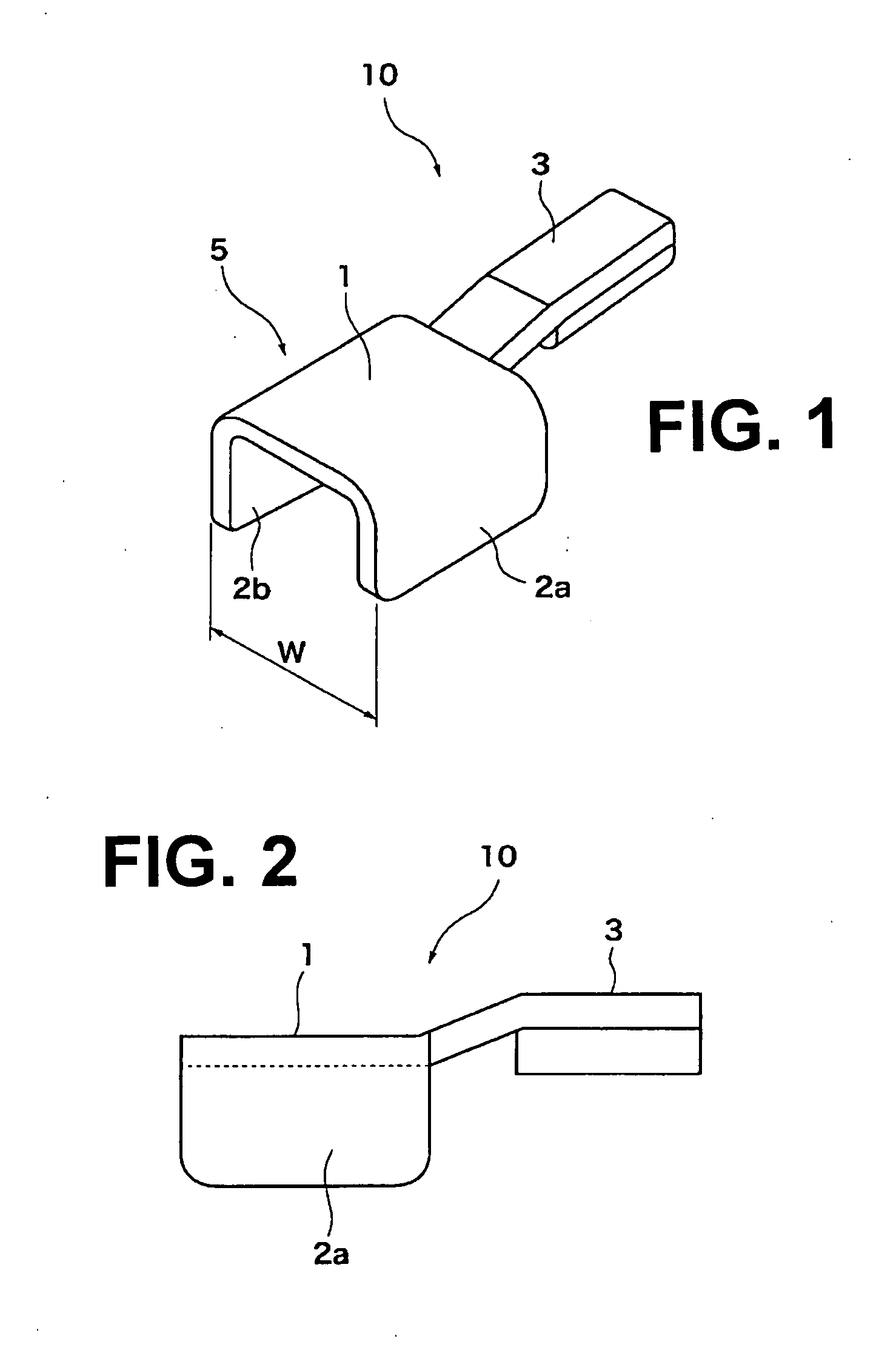

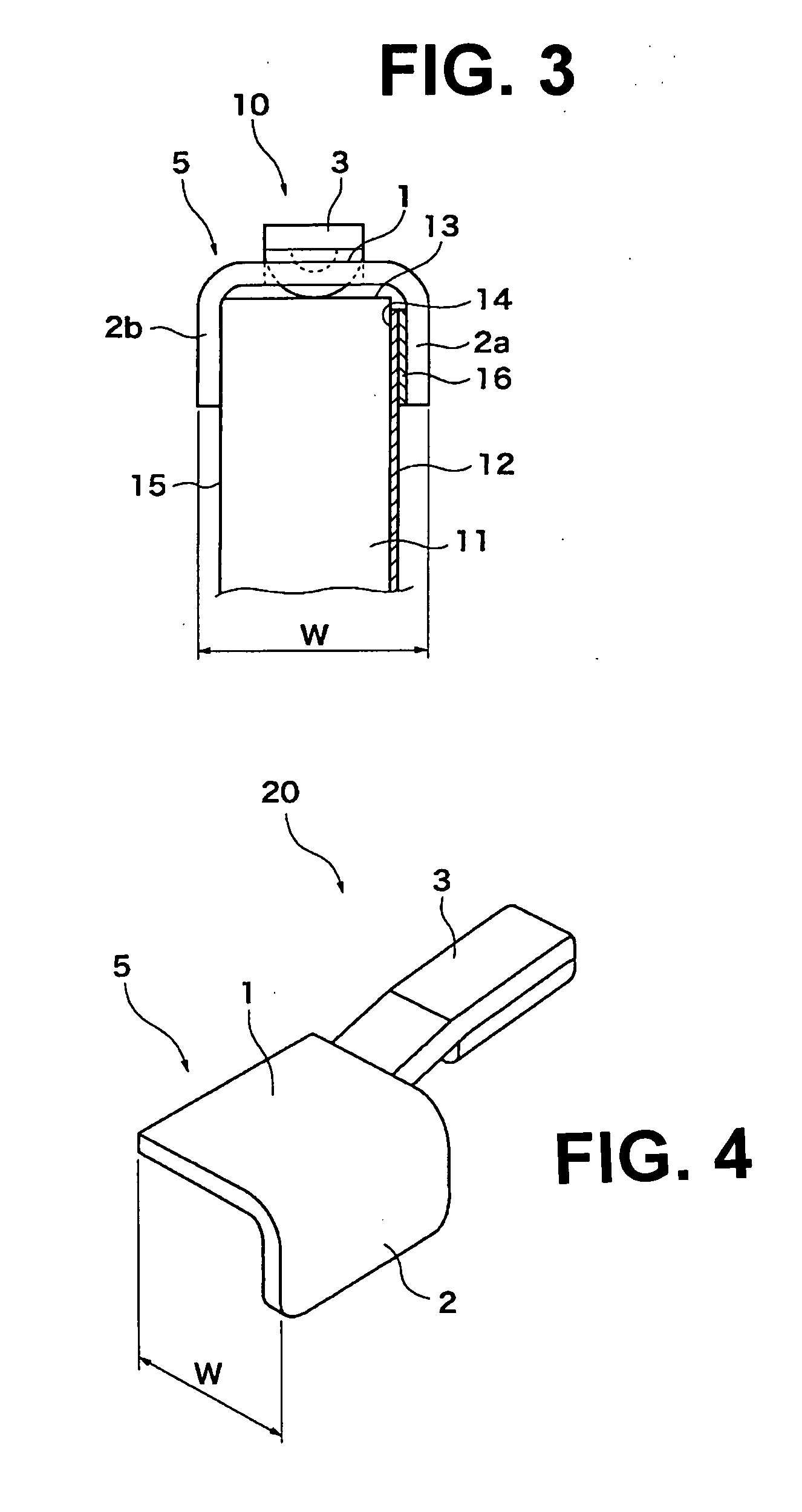

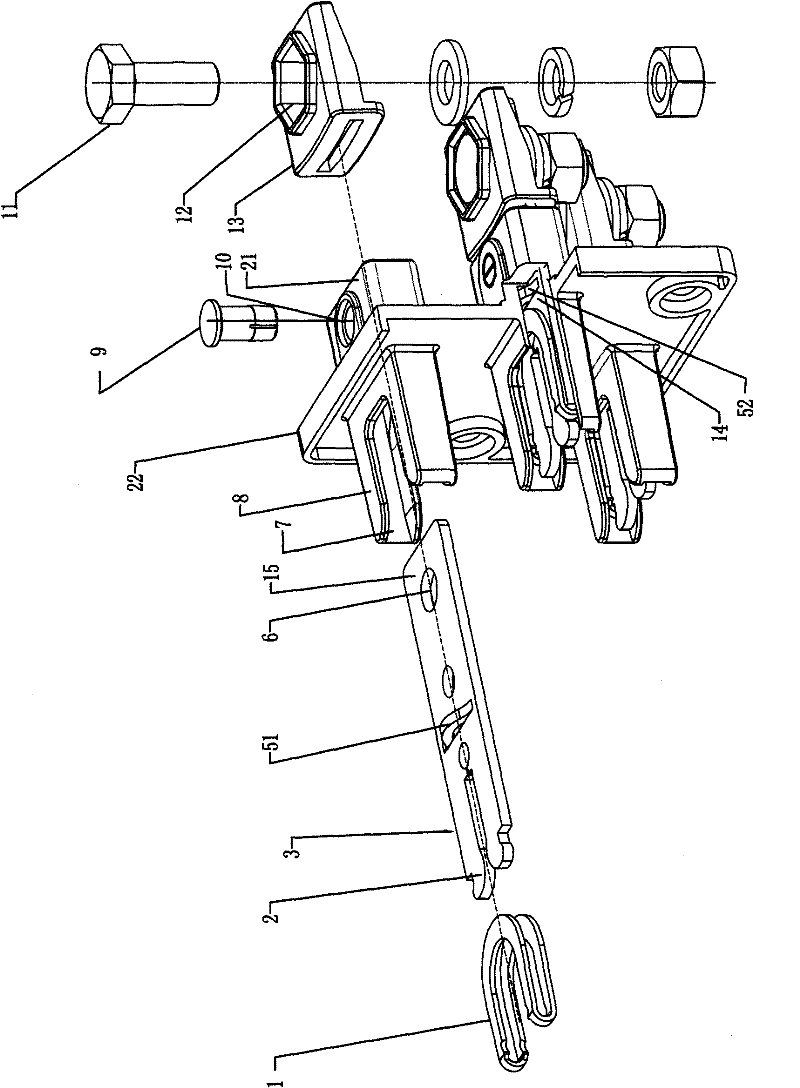

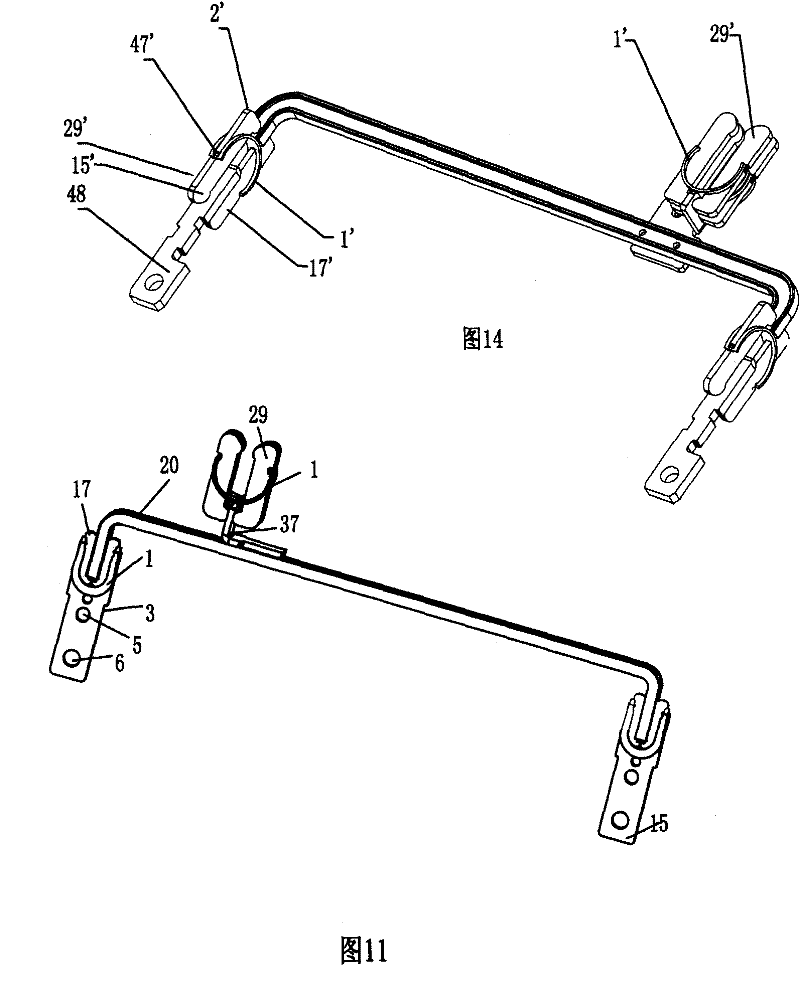

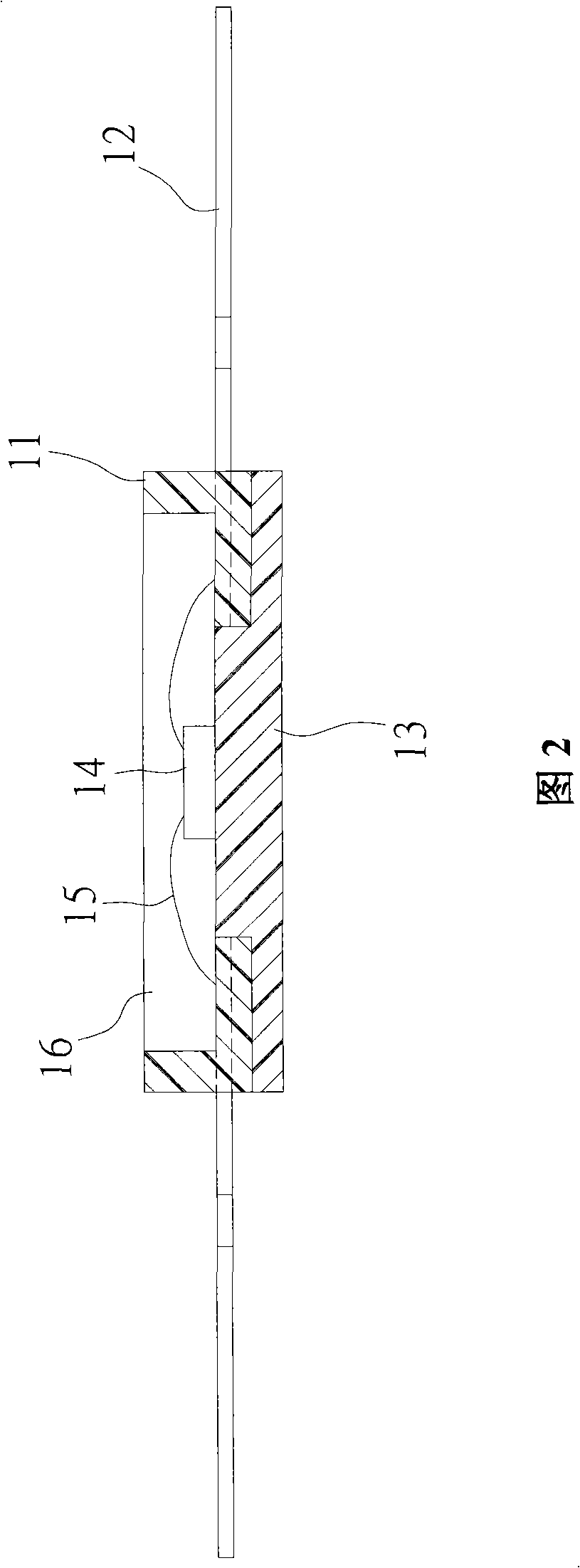

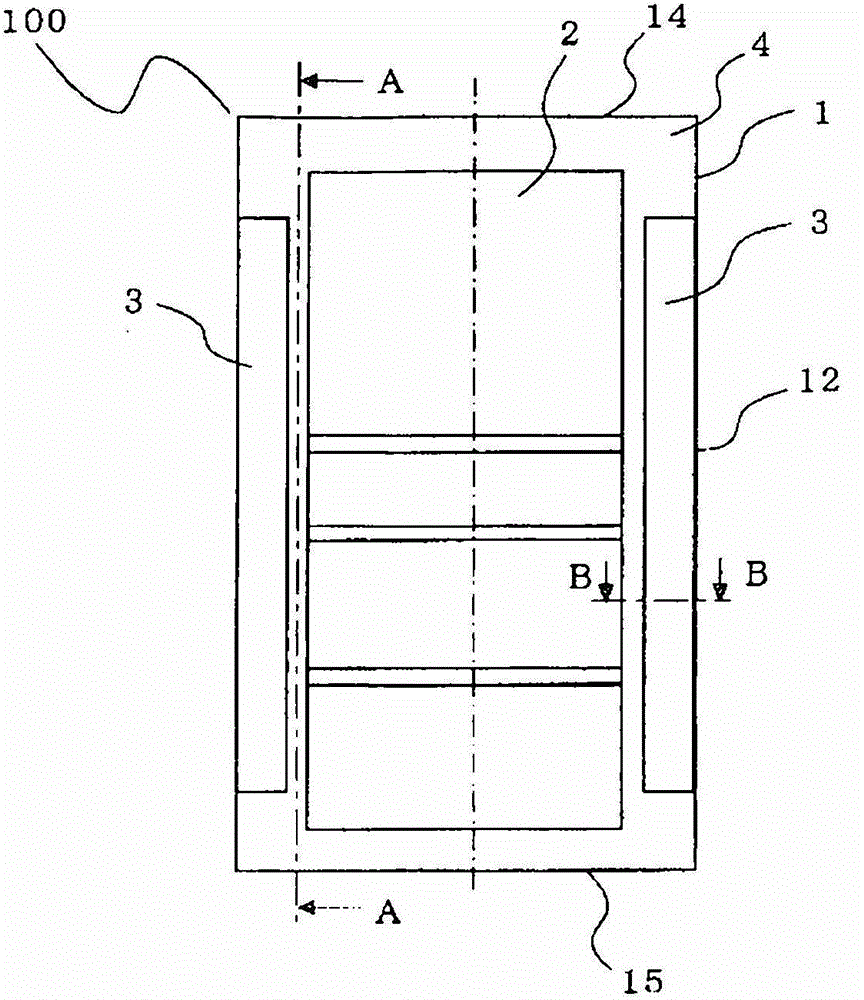

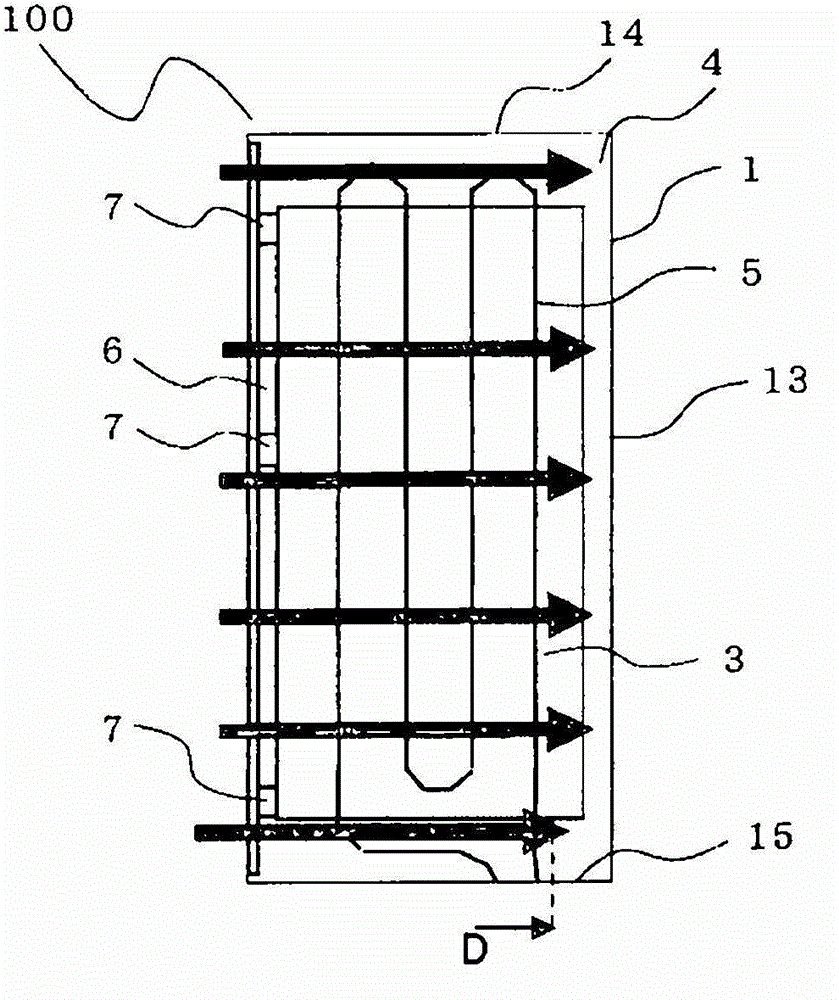

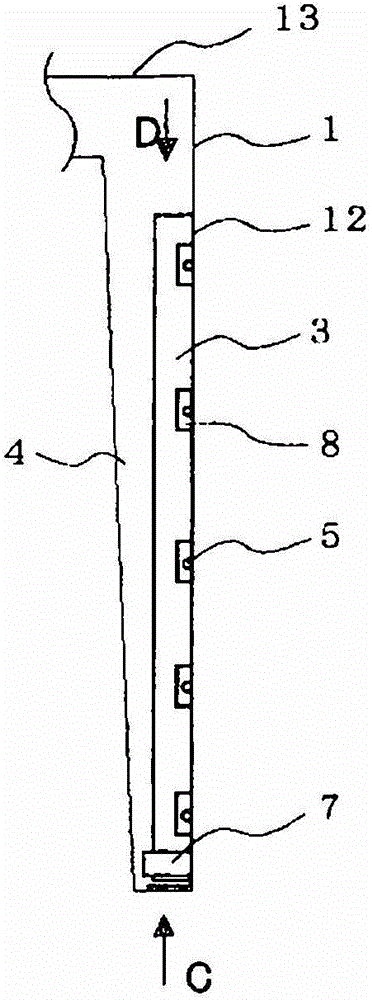

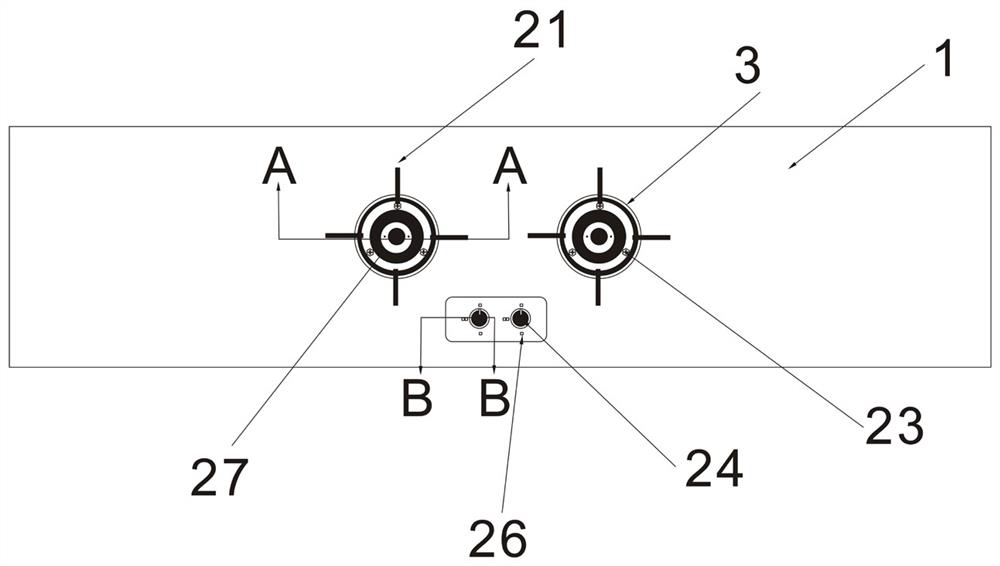

Terminal structure for plate-shaped member having conducting function, and plate-shaped member having conducting function

InactiveUS20110056747A1Increase thickness dimensionHigh connection safetyElectrically conductive connectionsCable junctionsWeather resistanceTerminal unit

Disclosed is a terminal structure, which suppresses the increase in the thickness size of a plate-shaped member disposed movably in the direction of main surfaces (14 and 15) so that it can be easily positioned and connected, and which is used in an automotive window glass pane (11) having a predetermined strength, an acid resistance and a weather resistance. The terminal structure (10) comprises a joint unit (5) and a terminal unit (3). The joint unit (5) includes an abutting portion (1) for abutting against the side faces of the end portion of the window glass pane, and protruding portions (2a and 2b) extending from the abutting portion (1) along the main surfaces (14 and 15) of the window glass pane. The terminal unit is disposed to lie within a width (W) of the joint unit in the thickness direction of the window glass pane, and at least a portion of the joint unit is jointed to a conductive film (12) so that the conductive film and the terminal unit are electrically connected.

Owner:NIPPON SHEET GLASS CO LTD

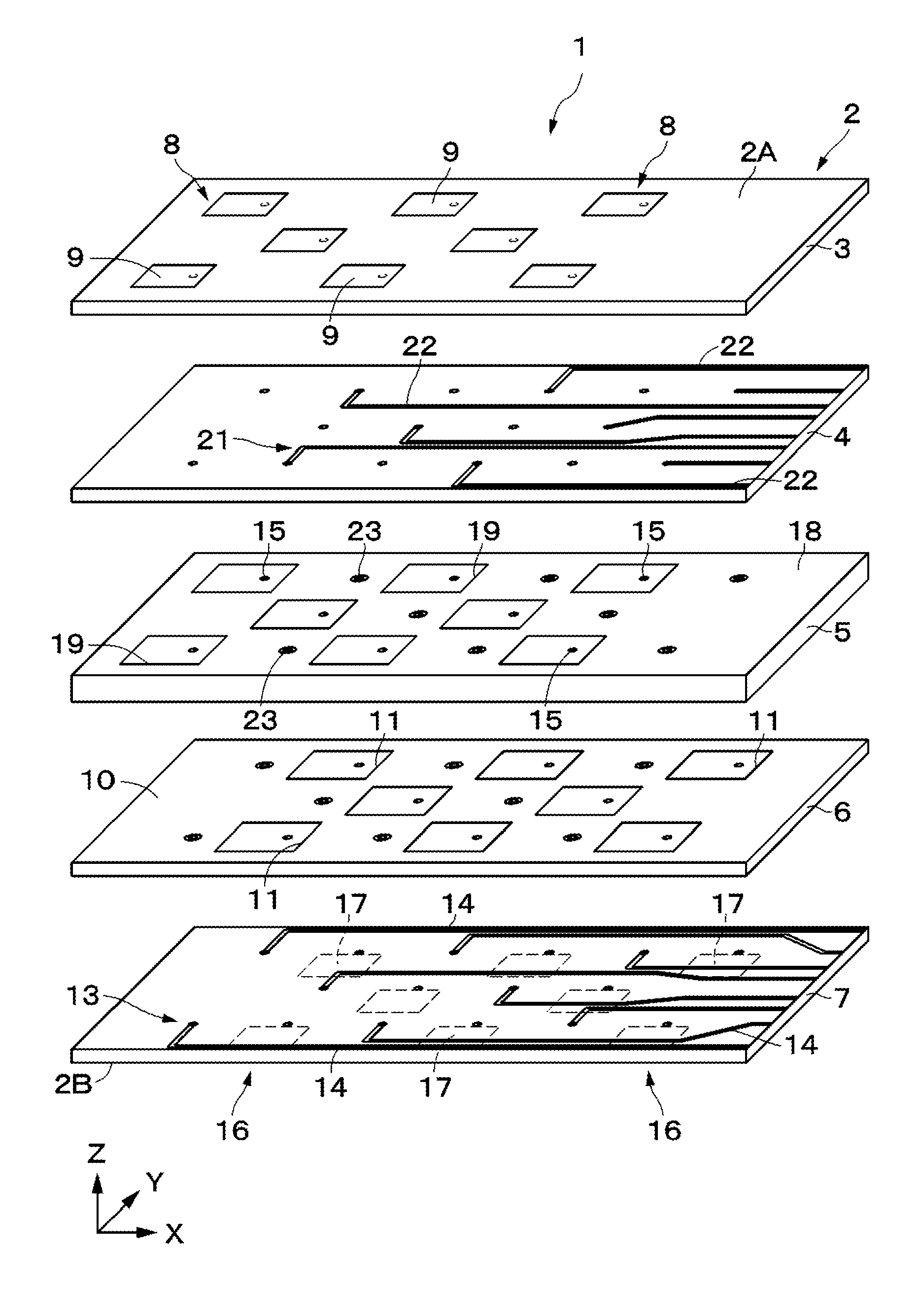

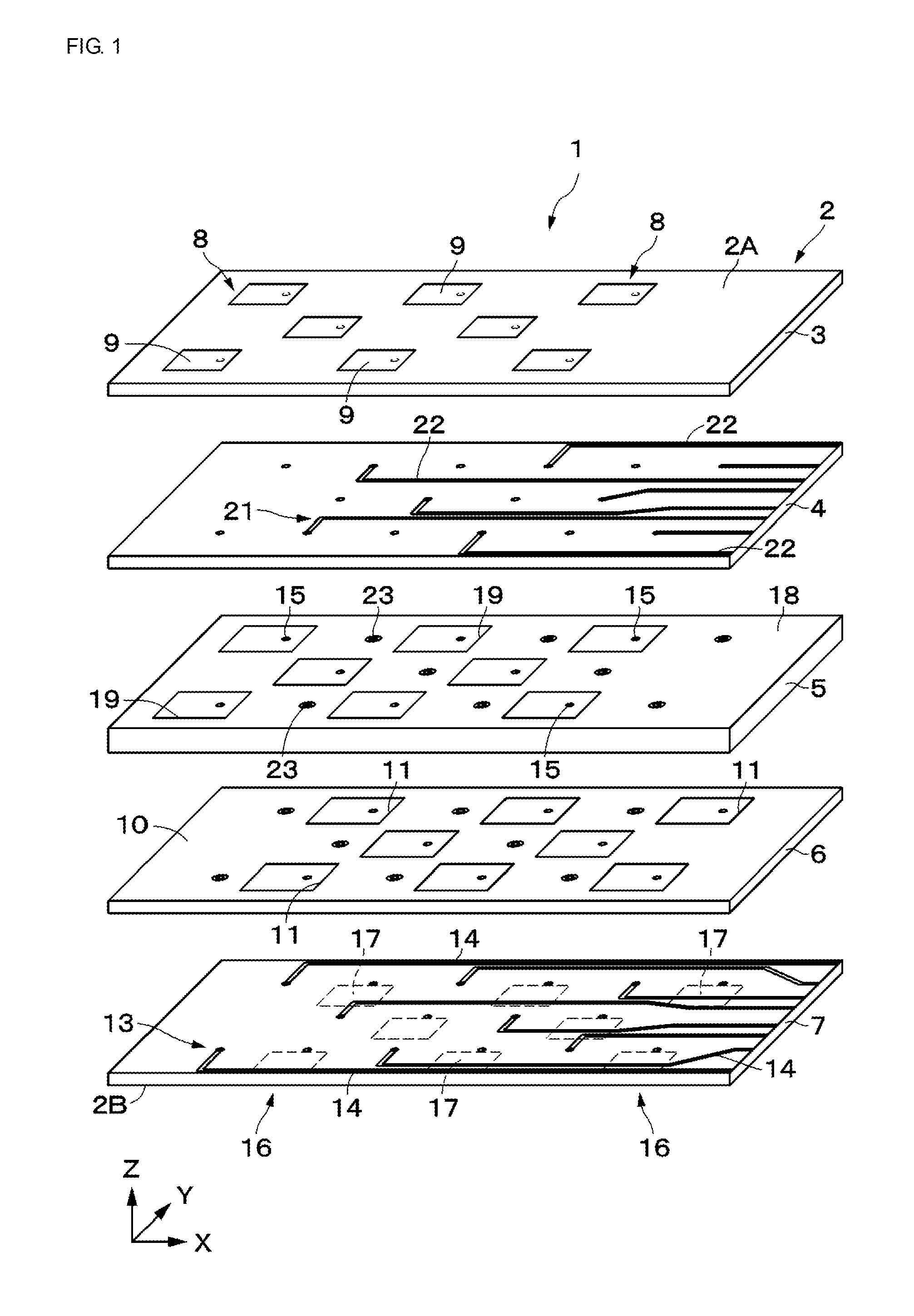

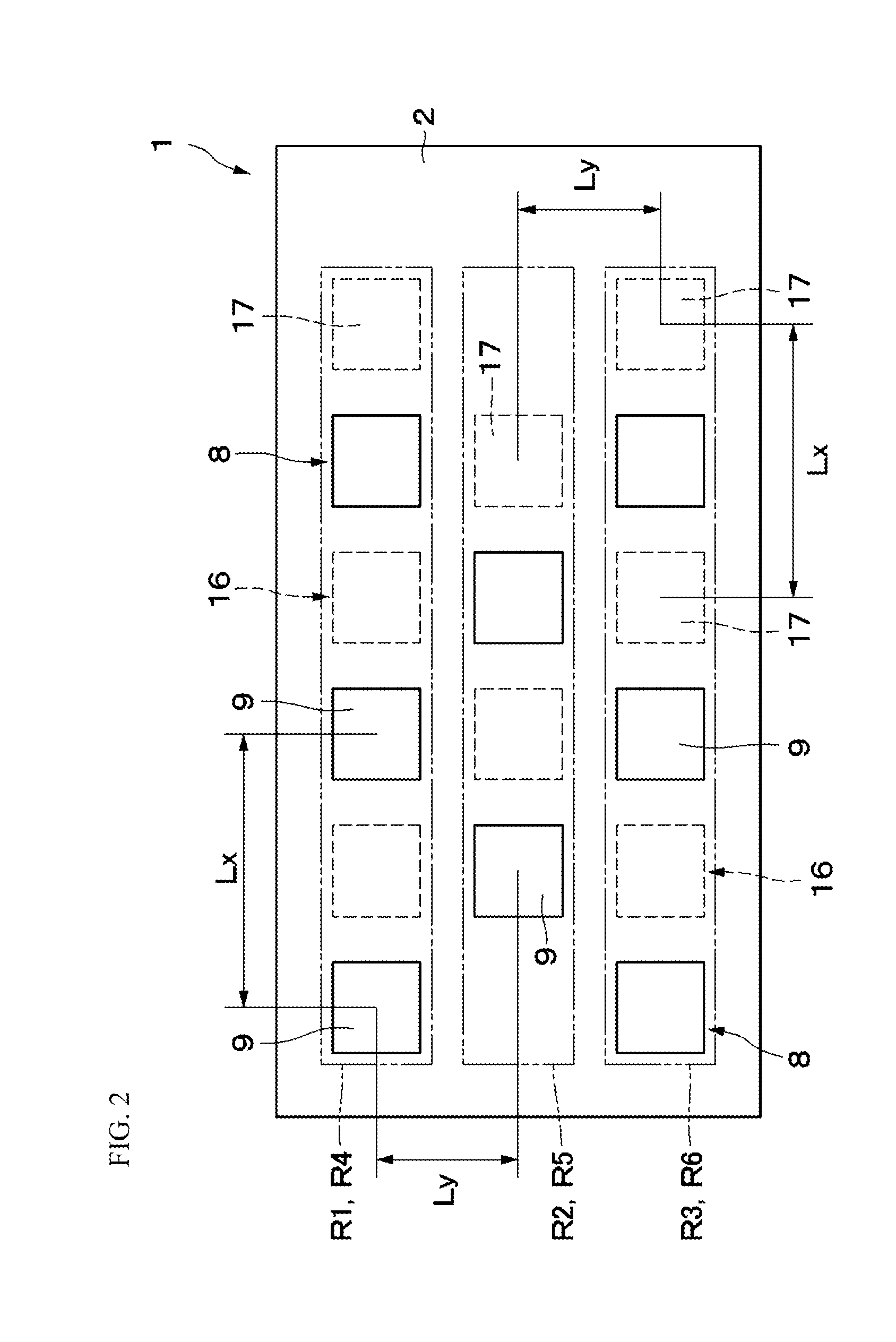

Array antenna

ActiveUS20150236425A1Small sizeArea usage efficiency is increasedParticular array feeding systemsIndividually energised antenna arraysRadiating elementPhysics

In a multilayer substrate, eight front-side antenna portions and eight back-side antenna portions are disposed. Front-side radiation elements in the front-side antenna portions and back-side radiation elements in the back-side antenna portions are arranged in a staggered pattern when being vertically projected onto an back side of the multilayer substrate. The front-side radiation elements are disposed on a front side of the multilayer substrate, and a front-side ground layer is formed near the back side of the multilayer substrate. On the other hand, the back-side radiation elements are disposed on the back side of the multilayer substrate, and a back-side ground layer is formed near the front side of the multilayer substrate. The front-side radiation element and the back-side radiation element are disposed so as not to overlap each other when being vertically projected onto the back side of the multilayer substrate.

Owner:MURATA MFG CO LTD

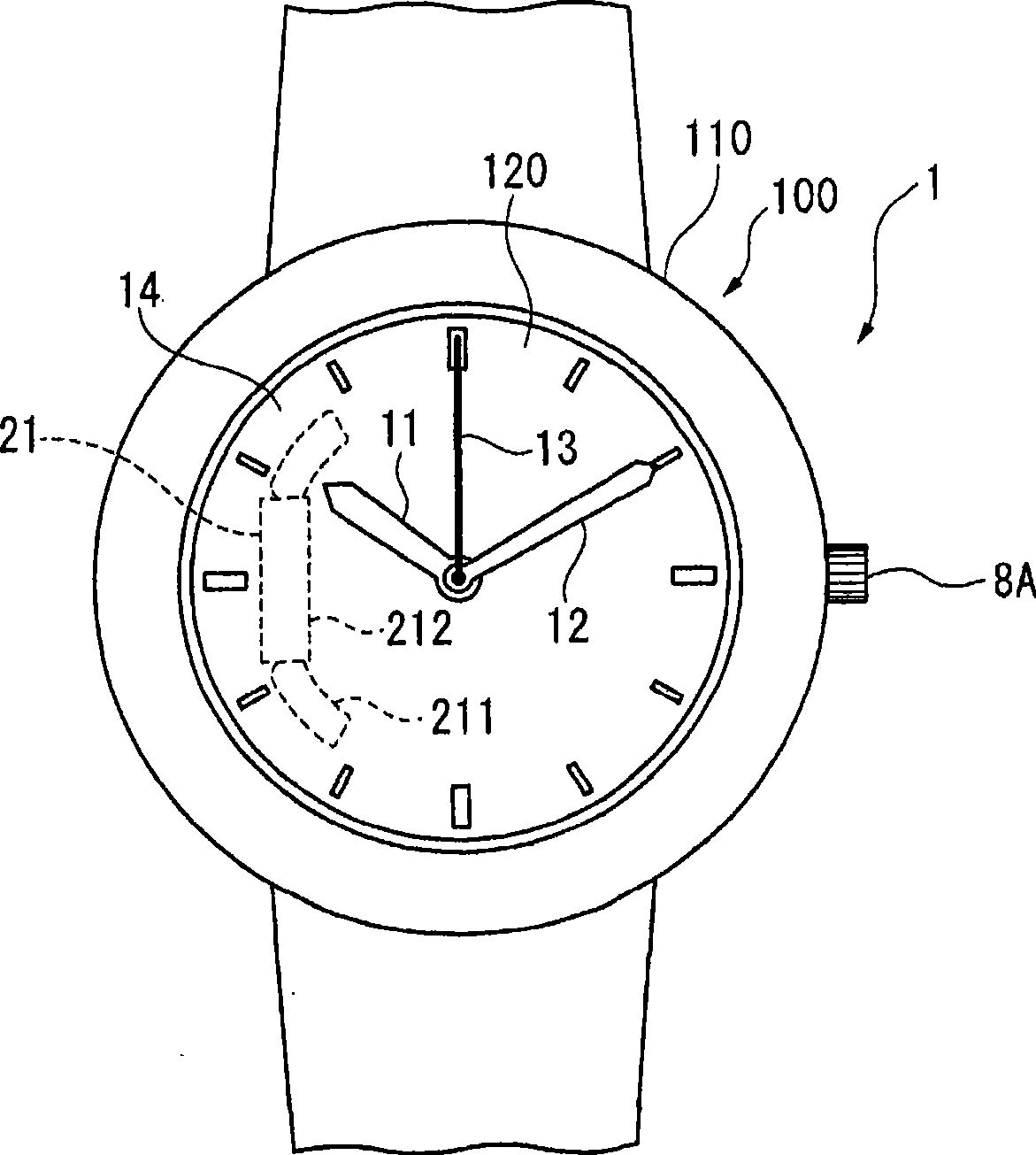

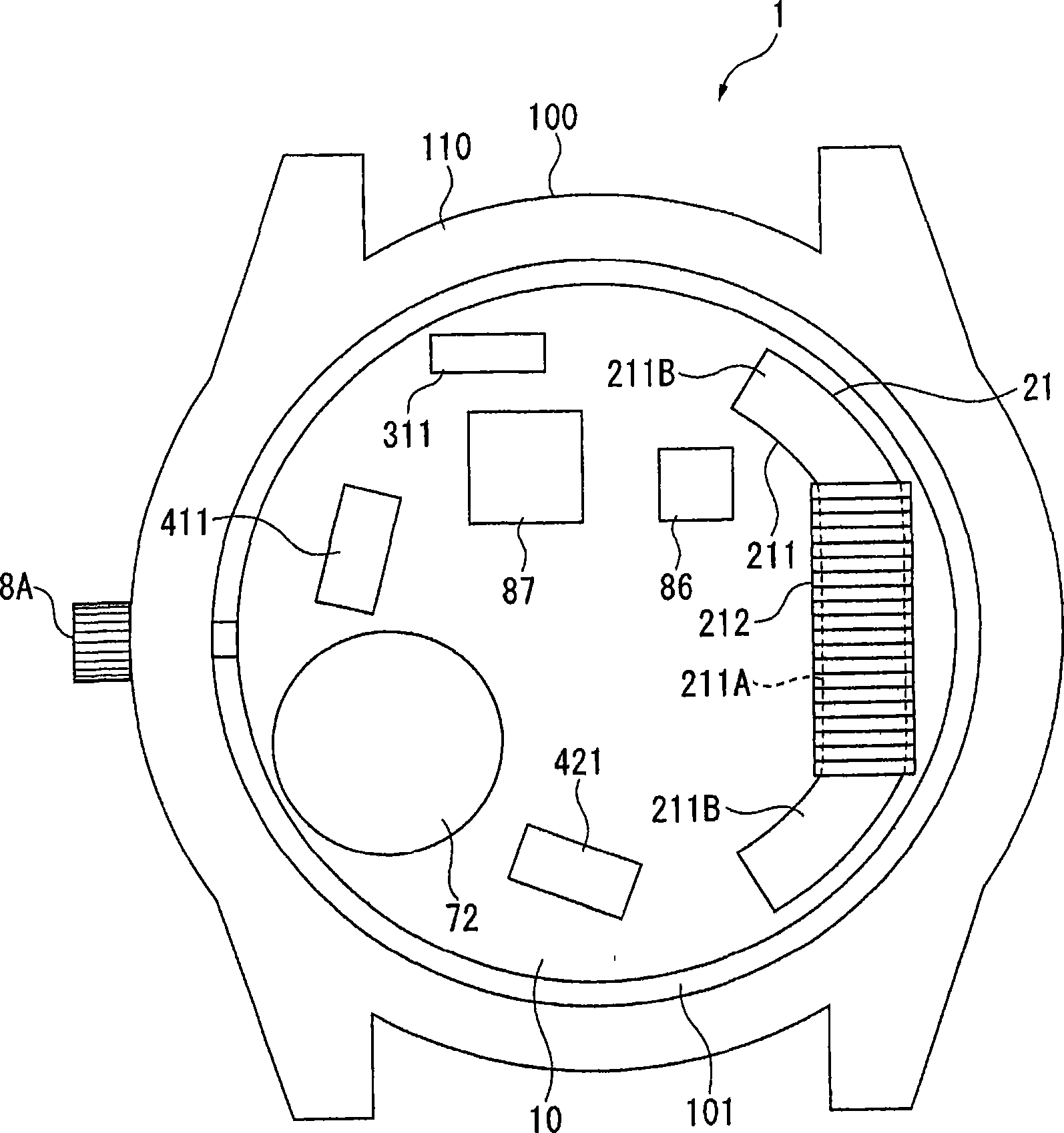

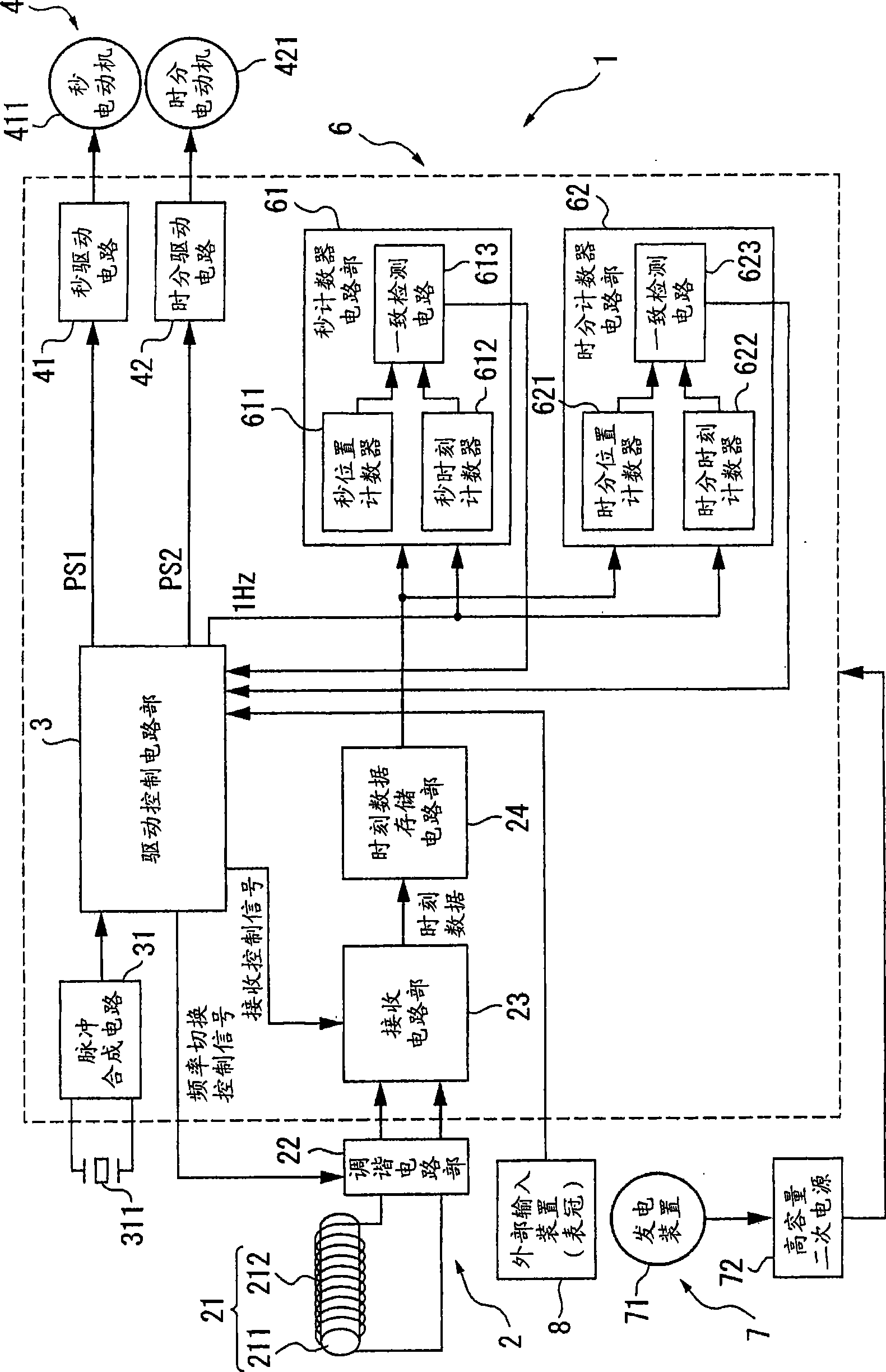

Electronic timepiece with internal antenna

InactiveCN101504535AIncrease thickness dimensionGather moreLoop antennas with ferromagnetic coreAntenna supports/mountingsComputer moduleEngineering

The present invention provides an electronic timepiece with an internal antenna, which can increase the characteristic of antenna without causing the large size of timepiece. An electric wave correcting clock (1) comprises the following components: the antenna which is provided with an elongated magnet core (211) formed by magnet and a coil (212) coiled on the magnetic core (211); a module (10) for containing the antenna (21); and a dial plate (14) which is formed by non-conductive material. Furthermore, an amorphous foil (140) which has a magnetic conductivity larger than that of the dial plate (14) is installed between the dial plate (14) and a module (10) of the electric wave correcting clock (1) in a vertical view for observing the surface orthogonal with the direction from the dial plate (14) to the module (10) at the position that is not overlapped with the coil overlapping area (104) overlapped with the coil winding part (211A) and is overlapped with the guiding overlapping area (105) overlapped with the guiding part (211B).

Owner:SEIKO EPSON CORP

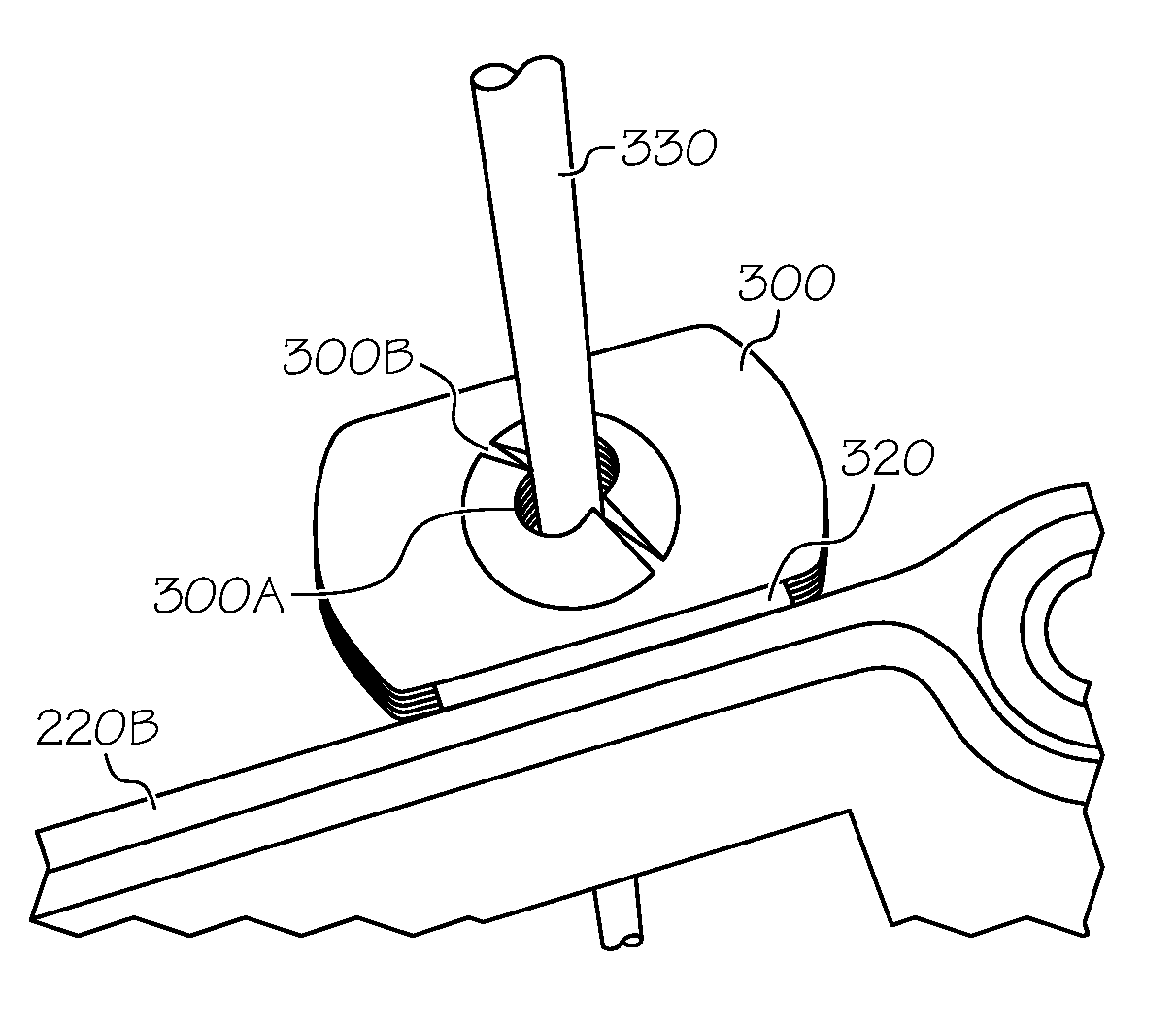

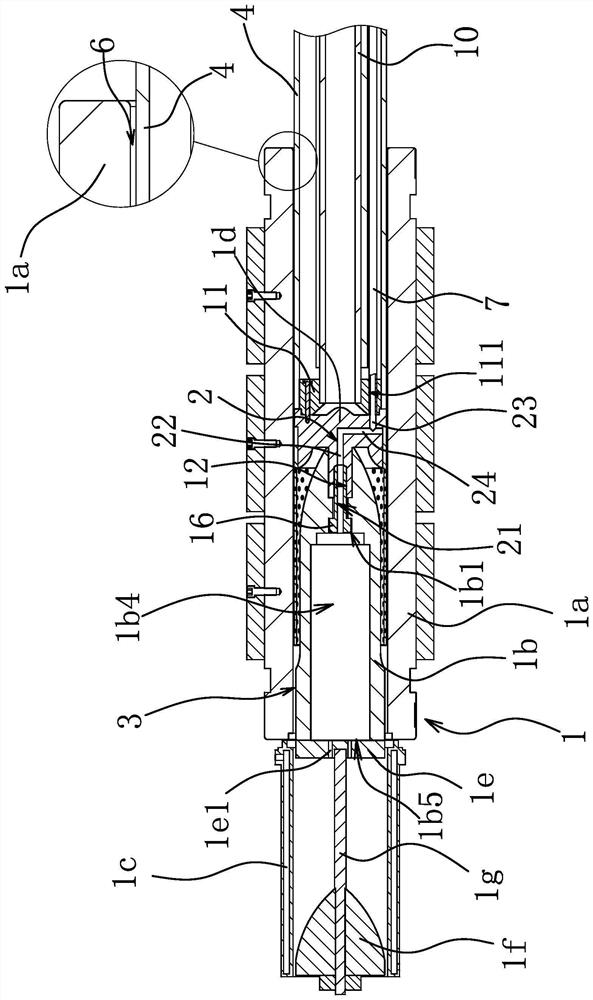

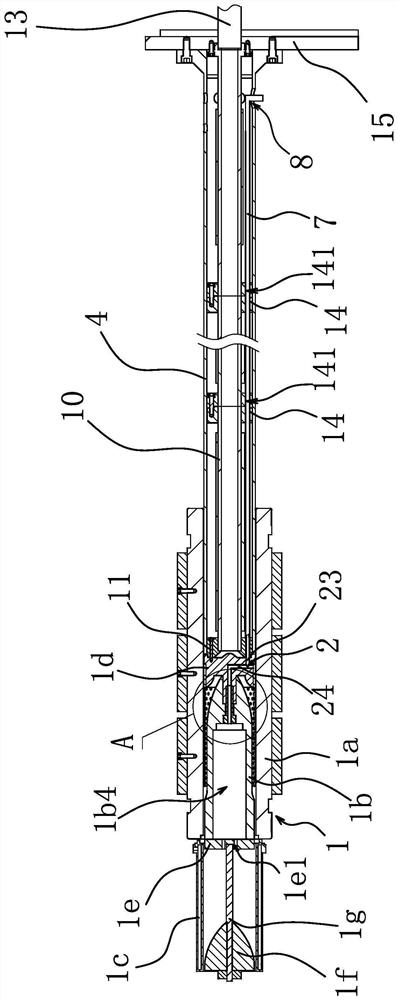

Solenoid valve

InactiveUS7344119B2Dimensional accuracyIncrease thickness dimensionOperating means/releasing devices for valvesCheck valvesSolenoid valveEngineering

A solenoid valve includes a poppet formed by a valve body and a supporting plate, the supporting plate having a front surface which the valve body is firmly fixed and a rear surface contacting a tip surface of a plunger. The solenoid valve further includes a cap having: a cylindrical portion which is fitted to an outer circumference of the plunger; an inward projecting portion which projects inwardly from the cylindrical portion so as to abut an outer circumferential portion of the front surface of the supporting plate; and an outward projecting portion which projects outwardly from the cylindrical portion so as to be engaged with a spring member. The poppet is press-inserted into the cap such that the inward projecting portion of the cap and the outer circumferential portion of the front surface of the supporting plate abut each other, and the cap is press-inserted into a tip portion of the plunger such that the poppet is attached on the tip surface of the plunger.

Owner:KOGANEI

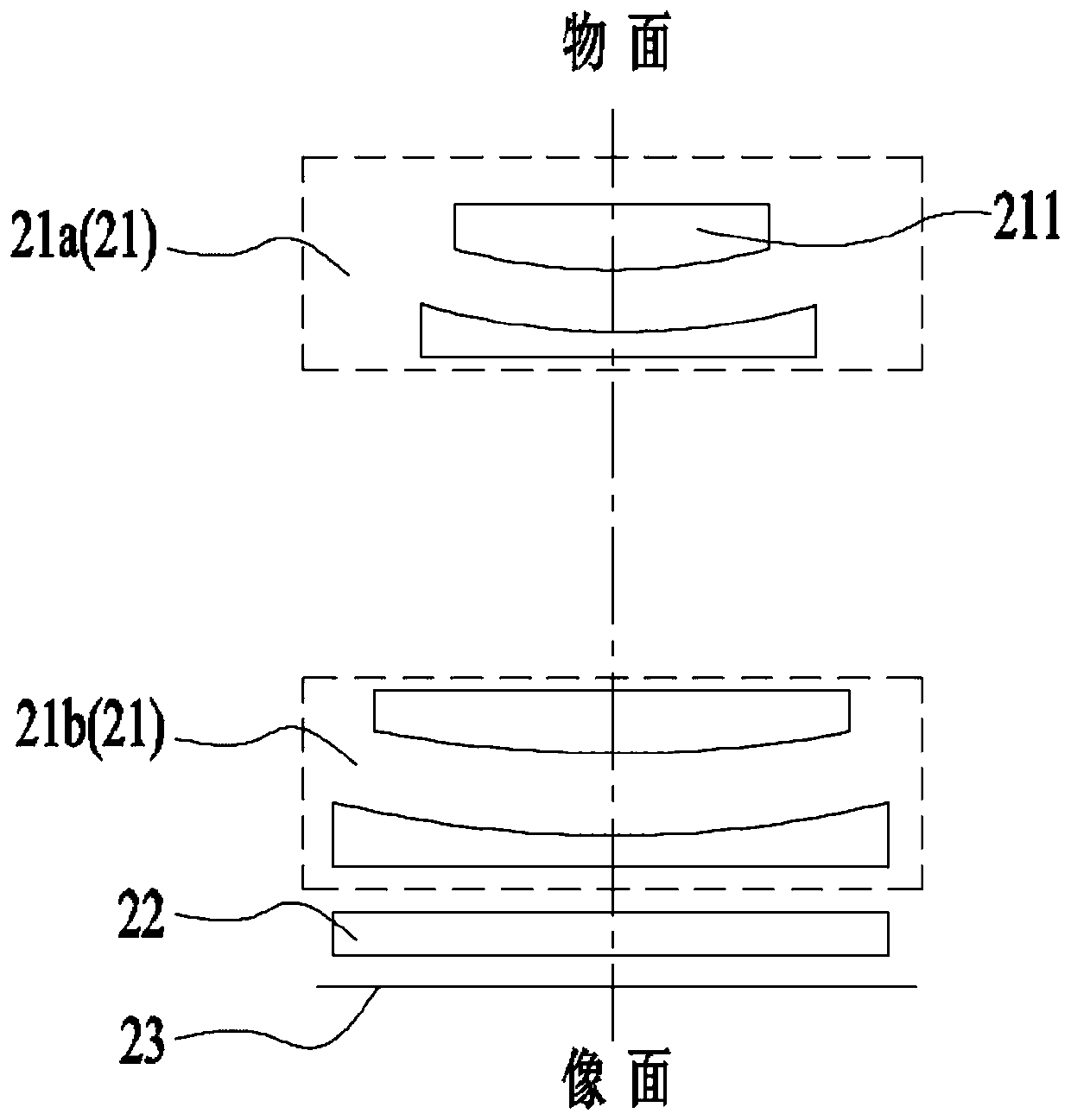

Terminal equipment and shooting method

ActiveCN110418046AMeet thin and light requirementsGrowth EFLTelevision system detailsColor television detailsOptical axisTerminal equipment

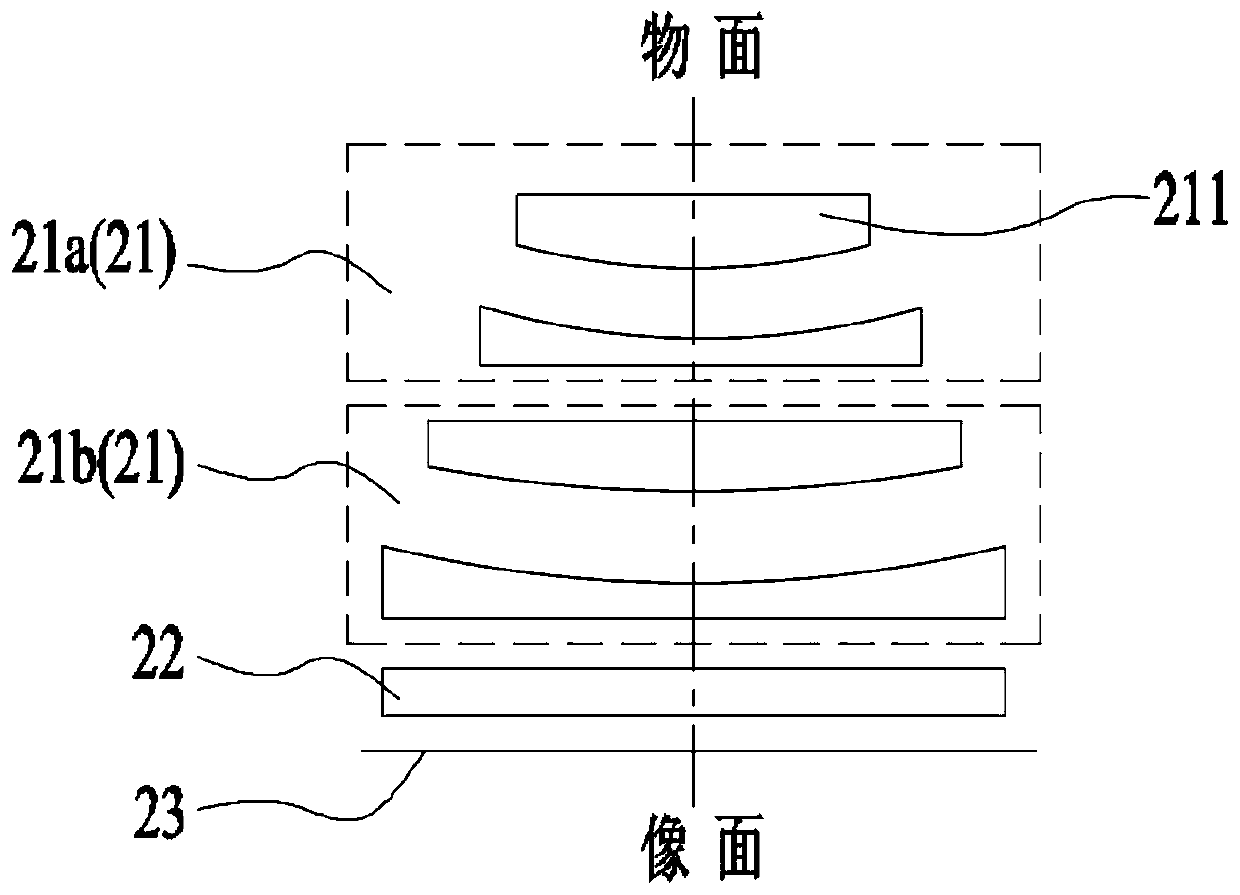

The embodiment of the invention provides terminal equipment and a shooting method. The terminal equipment comprises a shell, a fixed-focus camera, a driving mechanism and a control unit, wherein the shell is provided with an accommodating cavity; the fixed-focus camera has an accommodating state and a shooting state; the accommodating state is that the fixed-focus camera is accommodated in the accommodating cavity, and the shooting state is that at least part of the structure of the fixed-focus camera extends out of the accommodating cavity to protrude out of the outer end surface of the shell; the fixed-focus camera comprises at least two lens groups, and at least the lens group close to the object plane can move along the optical axis, so that the fixed-focus camera can be switched between an accommodating state and a shooting state; the driving mechanism is in driving connection with the movable lens group; the control unit is electrically connected with the driving mechanism so asto control the driving mechanism to drive the movable lens group to move along the optical axis. According to the terminal equipment, the EFL of the fixed-focus camera can be increased and the thickness of the Sensor can be increased while the lightening and thinning requirements are met, so that the shooting quality of the fixed-focus camera can be greatly improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Array antenna

ActiveUS9698487B2Reduce directivityIncrease in sizeParticular array feeding systemsIndividually energised antenna arraysRadiating elementPhysics

In a multilayer substrate, eight front-side antenna portions and eight back-side antenna portions are disposed. Front-side radiation elements in the front-side antenna portions and back-side radiation elements in the back-side antenna portions are arranged in a staggered pattern when being vertically projected onto an back side of the multilayer substrate. The front-side radiation elements are disposed on a front side of the multilayer substrate, and a front-side ground layer is formed near the back side of the multilayer substrate. On the other hand, the back-side radiation elements are disposed on the back side of the multilayer substrate, and a back-side ground layer is formed near the front side of the multilayer substrate. The front-side radiation element and the back-side radiation element are disposed so as not to overlap each other when being vertically projected onto the back side of the multilayer substrate.

Owner:MURATA MFG CO LTD

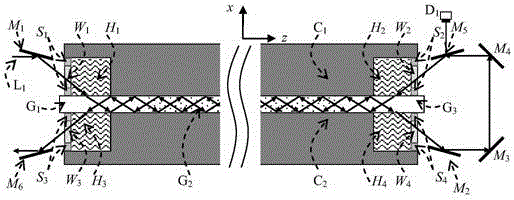

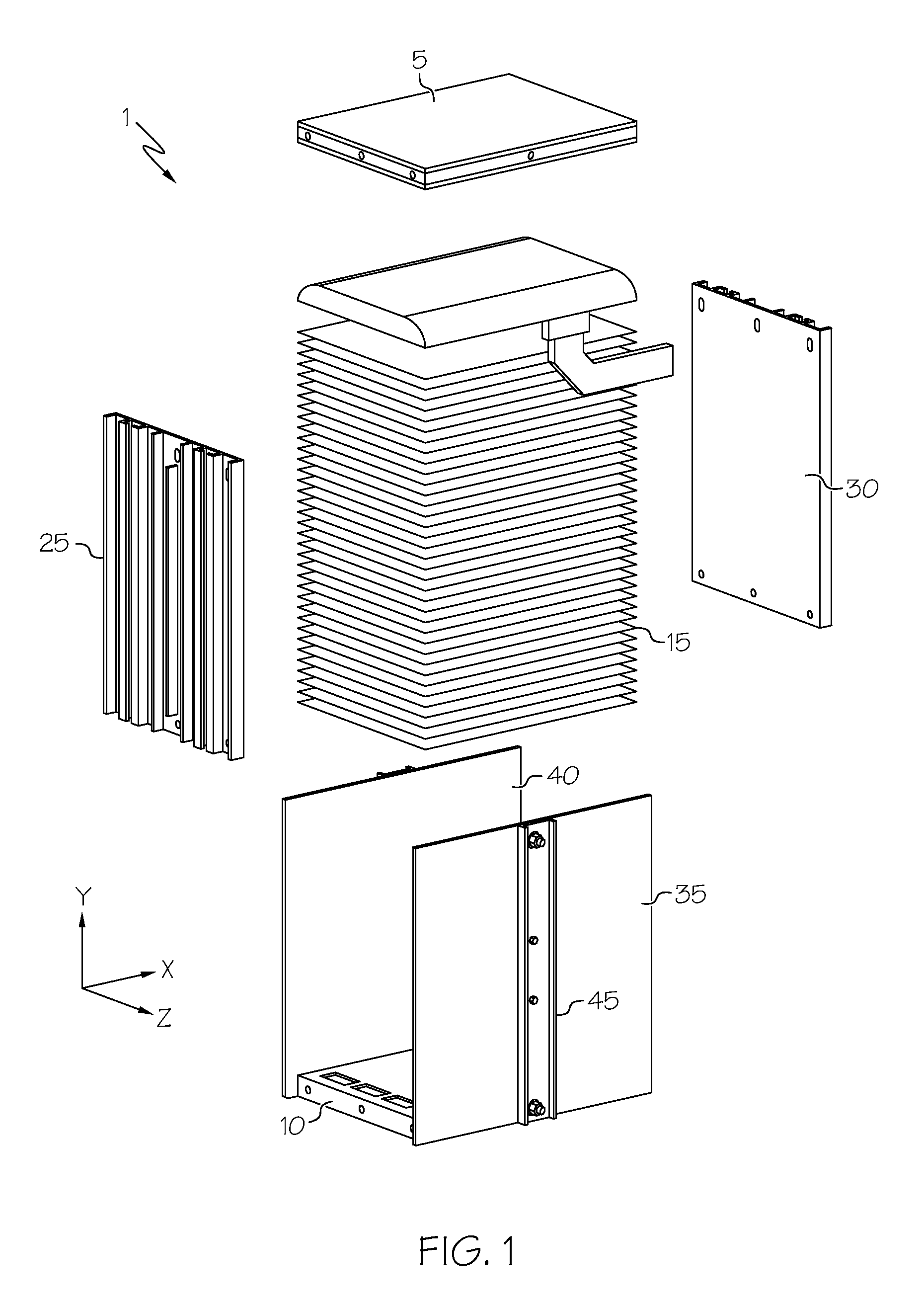

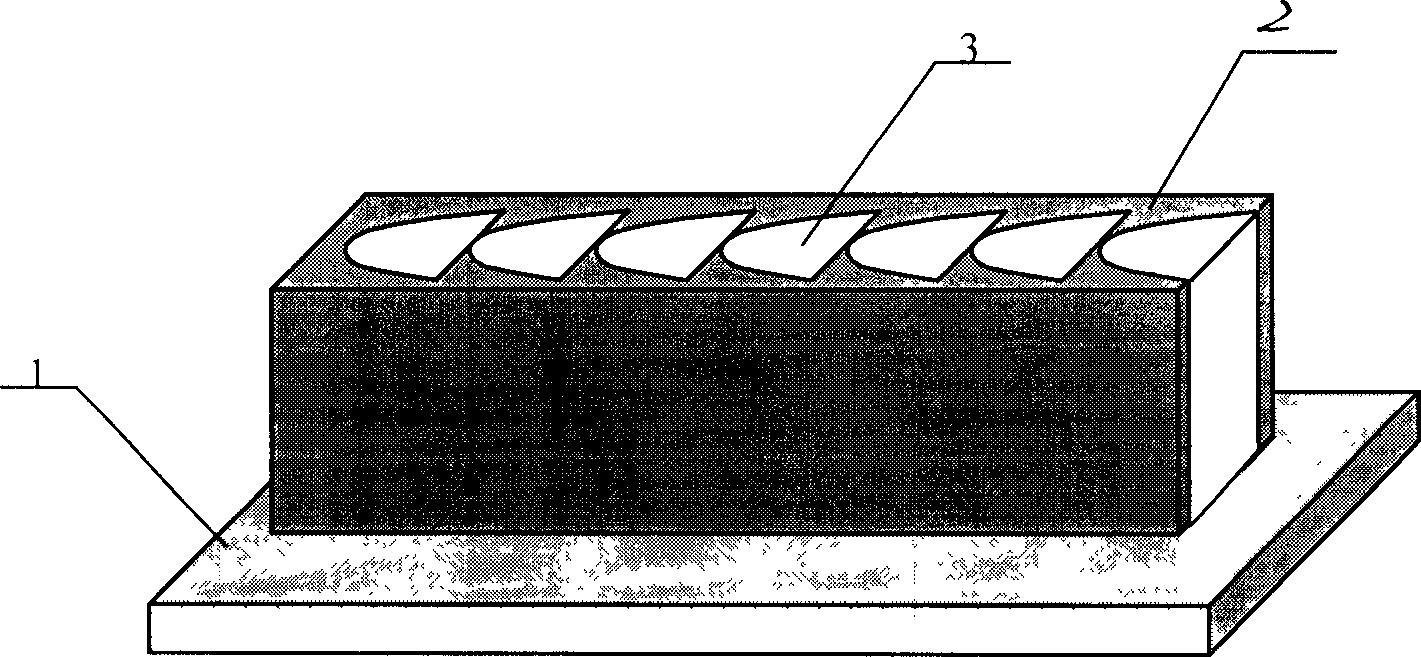

Slab laser module with wave-front distortion self-correction ability

ActiveCN106602391ADoes not change the number of total reflectionsIncrease powerExcitation process/apparatusComputer moduleLight beam

The invention provides a slab laser module with wave-front distortion self-correction ability through optimizing thermal management and optical path design. The slab laser module comprises a laser reflection device and a slab medium used as a gain medium. The upper and lower surfaces at the two ends of the slab medium are evanescent-membrane-free areas, and the middle part between the upper and lower surfaces is an evanescent membrane area. Incident laser L1 enters the inside of the slab medium from the evanescent-membrane-free area at one end of the slab medium, is transmitted along the length direction of the slab medium, and goes out from the evanescent-membrane-free area at the other end of the slab medium. The laser reflection device reflects the output incident laser L1 into the slab medium for second transmission, and the incident laser L1 goes out from the incidence end of first transmission. The constraint condition for the point-of-incidence position of second transmission of the incident laser L1 is that the wave-front distortion waveform generated when the incident laser L1 passes through the slab medium for the first time and the wave-front distortion waveform generated when the incident laser L1 passes through the slab medium for the second time are opposite. Thus, output laser featuring no wave-front distortion, high power and high beam quality is obtained.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA +1

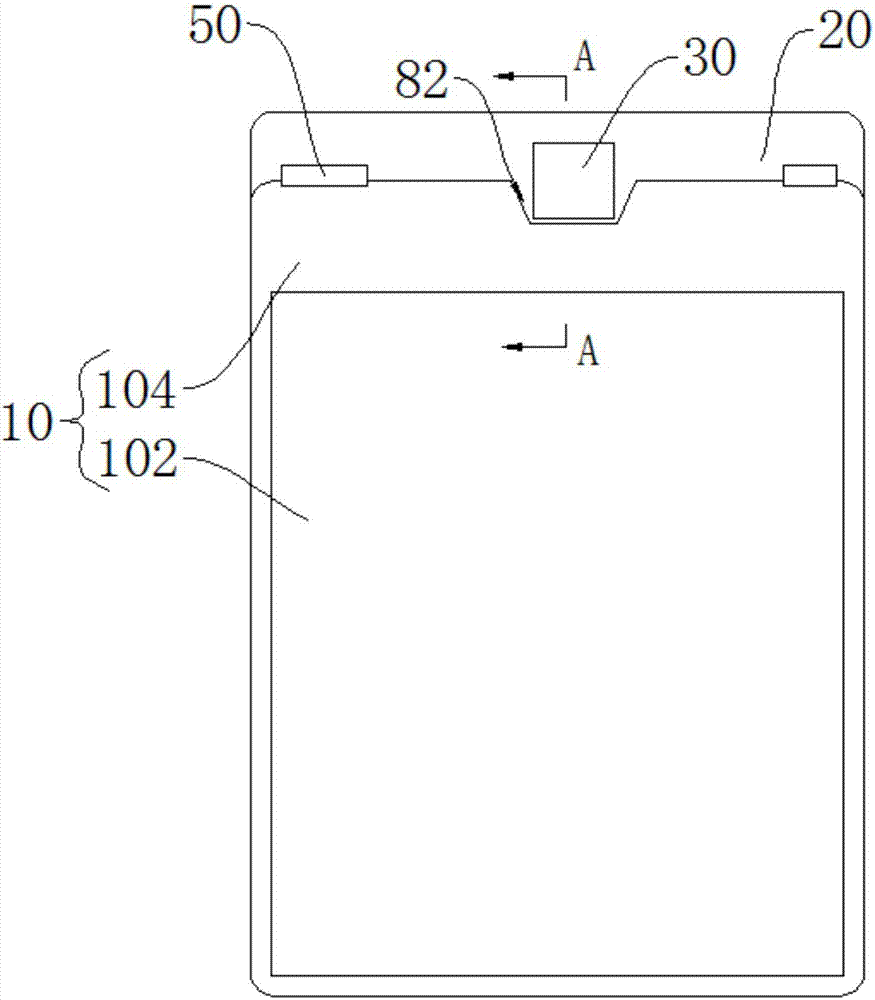

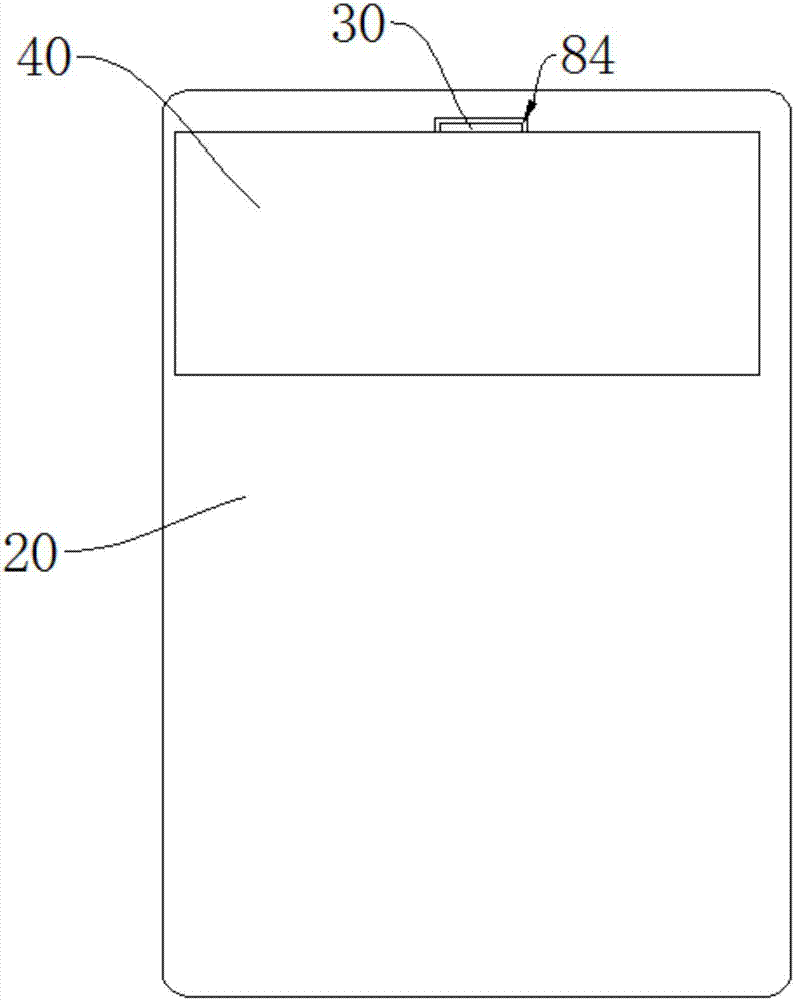

Display module and mobile terminal

ActiveCN106982524AIncrease plane sizeIncrease thickness dimensionCasings with display/control unitsPortable casingsElectricityComputer terminal

The invention discloses a display module. The display module comprises a display panel, a middle frame, a connecting piece, a printed circuit board and a functional device, wherein the display panel, the middle frame and the printed circuit board are arranged in a laminated manner in sequence; the functional device is fixedly connected to the middle frame; the display panel is provided with a first accommodating space for accommodating the functional device; the middle frame is provided with a second accommodating space for accommodating the connecting piece; and the functional device is electrically connected to the printed circuit board through the connecting piece. The invention also discloses a mobile terminal. The portability of the mobile terminal is improved, the multi-functionalization of the mobile terminal is facilitated, and the user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Production method for nano focusing X ray lens combination

InactiveCN101221829AImprove light gathering abilityIncrease light collecting apertureHandling using diffraction/refraction/reflectionPhotoresistAluminium

Owner:ZHEJIANG UNIV OF TECH

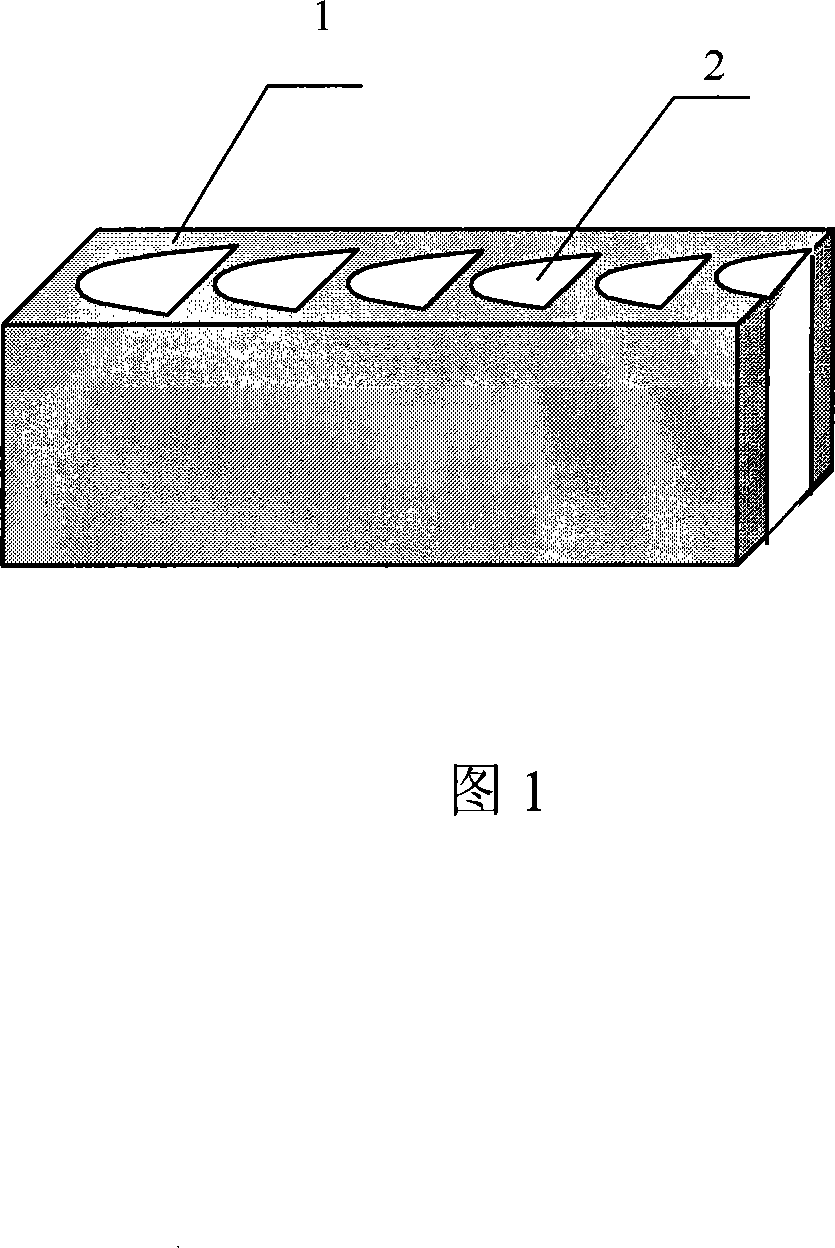

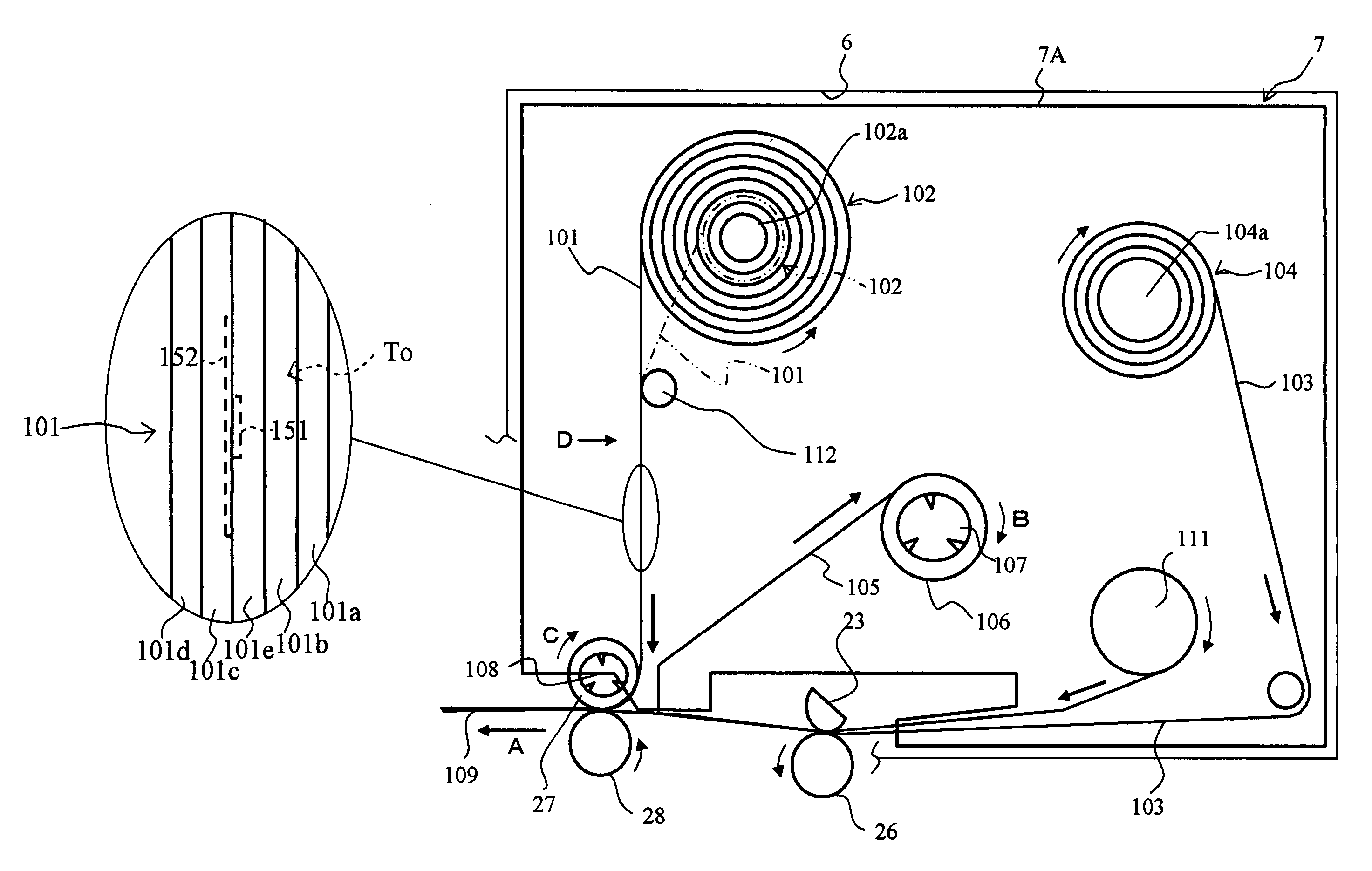

Tag tape and tag label tape with print

ActiveUS7656298B2Inhibition formationIncrease thickness dimensionRecord carriers used with machinesBurglar alarm by hand-portable articles removalMagnetic tapeEngineering

A base tape includes: a plurality of RFID circuit elements each including an IC circuit part for storing information and a loop antenna connected to the IC circuit part; and an adhesive layer, a base film, an adhesive layer, an adhesive layer, and a separation sheet that are arranged so as to sandwich each of the RFID circuit elements from both sides in the thickness direction. The base tape is formed such that the ratio c of the sum of the thickness dimensions of the adhesive layer, base film, adhesive layer, adhesive layer, and separation sheet to the thickness dimension of the RFID circuit element is 0.8≦c≦9.8.

Owner:BROTHER KOGYO KK

Process for mfg. one-dimensional X ray refracted diffraction micro structural component of polymethyl methyl acrylate material

InactiveCN1786741AReduce absorptionIncrease thickness dimensionMaterial analysis using wave/particle radiationPhotomechanical exposure apparatusPhotoengravingX-ray

The invention relates to poly methyl methacrylate material one dimension X ray diffraction refraction microstructure device manufacturing method. It includes the following steps: making photolithography mask edition; processing silicon substrate; coating polyimide and baking and solidifying; producing metallic film to use as electro forming cathode; coating thick photoresist; exposing, developing, and hardening; producing metallic film to use as X ray photolithography mask absorbent; removing the photoresist an electro forming cathode; back photoengraving and silicon corroding; making titanium slice as supporting; coating poly methyl methacrylate, backing, and solidifying; X ray photoengraving and developing.

Owner:乐孜纯

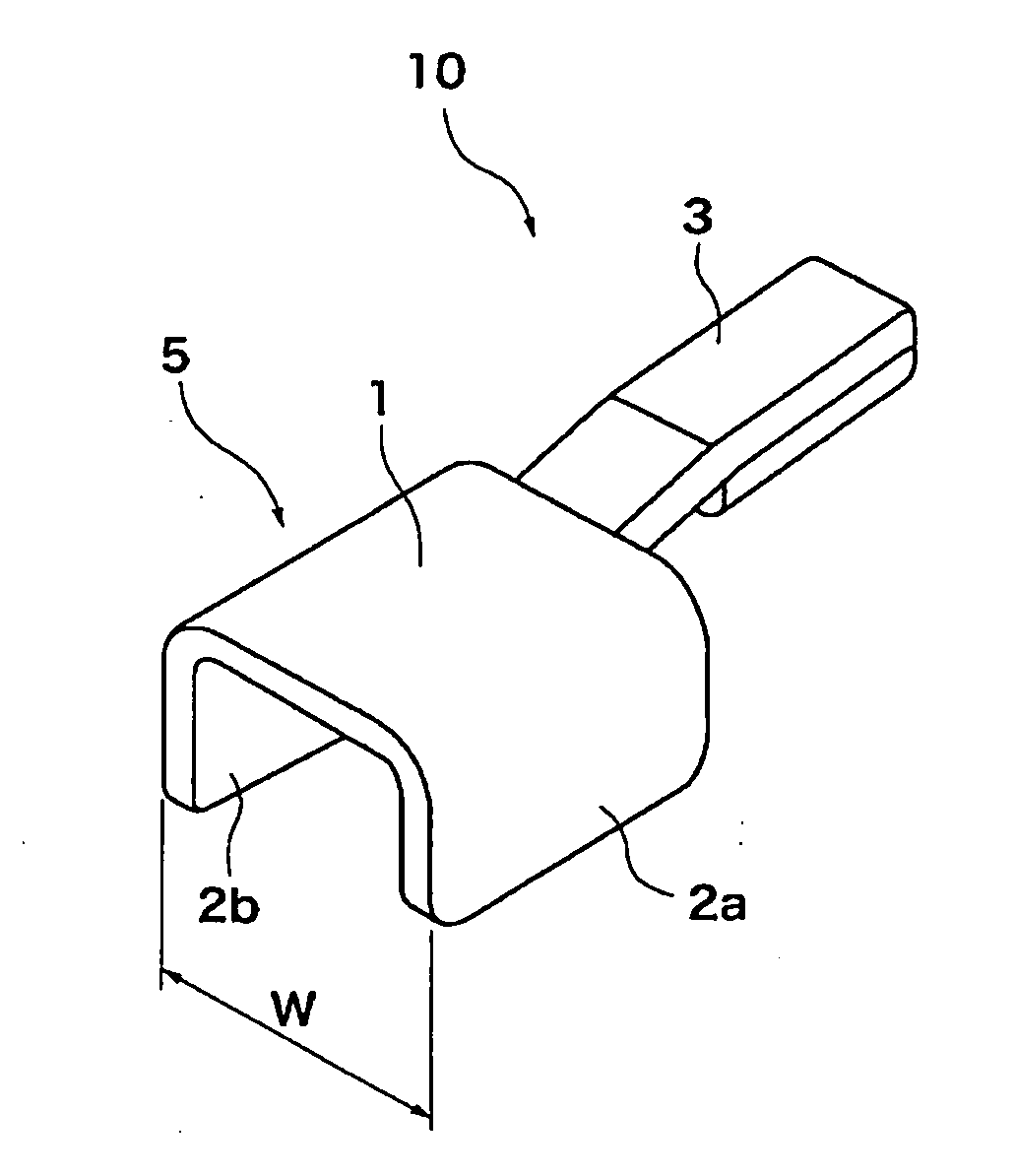

Fuel cell stack assembly—datum design for fuel cell stacking and collision protection

ActiveUS9590263B2Improve the immunityIncrease thickness dimensionFuel cells groupingFuel cell auxillariesInterference fitFuel cells

A system and method for aligning and reducing the relative movement between adjacent fuel cells within a fuel cell stack. The inter-cell cooperation between fuel cells along a stacking dimension is enhanced by one or more datum placed along the edge of a bipolar plate that makes up a part of a cell-containing assembly. The datum is shaped along a thickness dimension that substantially coincides with the cell stacking dimension to promote a nested fit with a comparable datum on an adjacently-stacked bipolar plate. This nesting facilitates an interference fit that enhances the resistance to sliding movement between respective cells that may otherwise arise out of the occurrence of a significant acceleration along the dimension that defines the major surfaces of the plates, cells and their respective assemblies. In one form, the use of welding, bonding or related attachment of the datum to the plate promotes enhanced metallic support without the need for increasing the plate footprint and without having to overmold the datum directly onto the plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

Circuit allocation switching unit

ActiveCN102244370ASave thickness spaceIncrease depth using spaceBus-bar/wiring layoutsSwitchgear detailsEmbedded systemElectricity

The invention discloses a circuit allocation switching unit, comprising a circuit allocation adapter and a low-current unit drawer, wherein the circuit allocation adapter comprises a metal shell; the metal shell is internally provided with an incoming line bus and an outgoing line bus; an outgoing line end of the incoming line bus and an outgoing line end of the outgoing line bus pass through a jack of the drawer on a metal shell panel respectively to form a static bus socket; and the low-current unit drawer is provided with a movable plug which is electrically connected with the static bus socket of the circuit allocation adapter in an insertion mode. Only one movable contact exists between the circuit allocation adapter and the low-current unit drawer when the circuit allocation adapter is connected with the low-current unit drawer in an insertion mode, thus the temperature is low, the inserted connection reliability is high and the manufacturing cost is reduced.

Owner:周金隆

Manufacturing method for heat radiating base of surface adhesive diode support and construction thereof

InactiveCN101286455AIncrease thickness dimensionImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSurface mountingEngineering

The invention relates to a method for producing a radiating base of a surface-mount diode bracket and structure thereof, and provides a radiating base which can produce various different sizes and thicknesses; the radiating base structure of the diode bracket comprises a colloid, a radiating base connected with the colloid fixedly and a plurality of metal pins connected with the colloid fixedly; the radiating base is provided with a first metal plate and a second metal plate which are mutually stacked and combined in sequence; therefore, the radiating base which consists of the first metal plate and the second metal plate mutually stacked and combined in sequence can produce various different sizes and thicknesses according to the actual requirements so as to provide the diode bracket which can produce various sizes in an adjustable way, thus improving the convenience of producing process, etc. aspects.

Owner:I-CHIUN PRECISION IND CO LTD

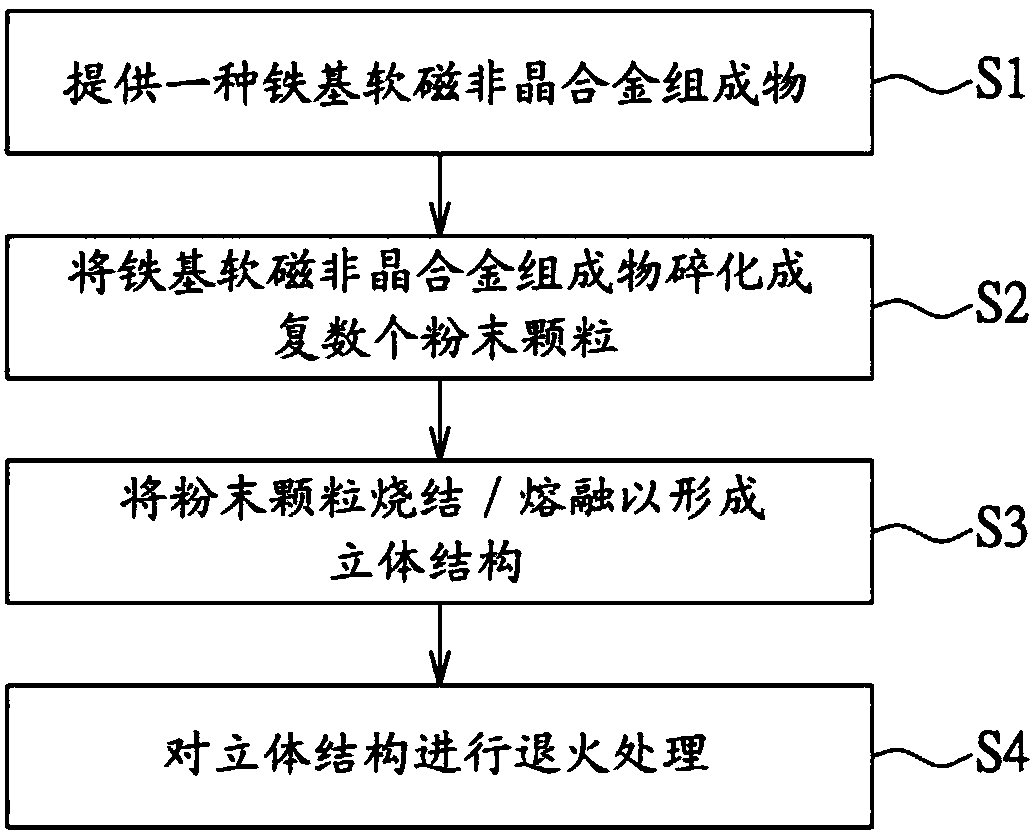

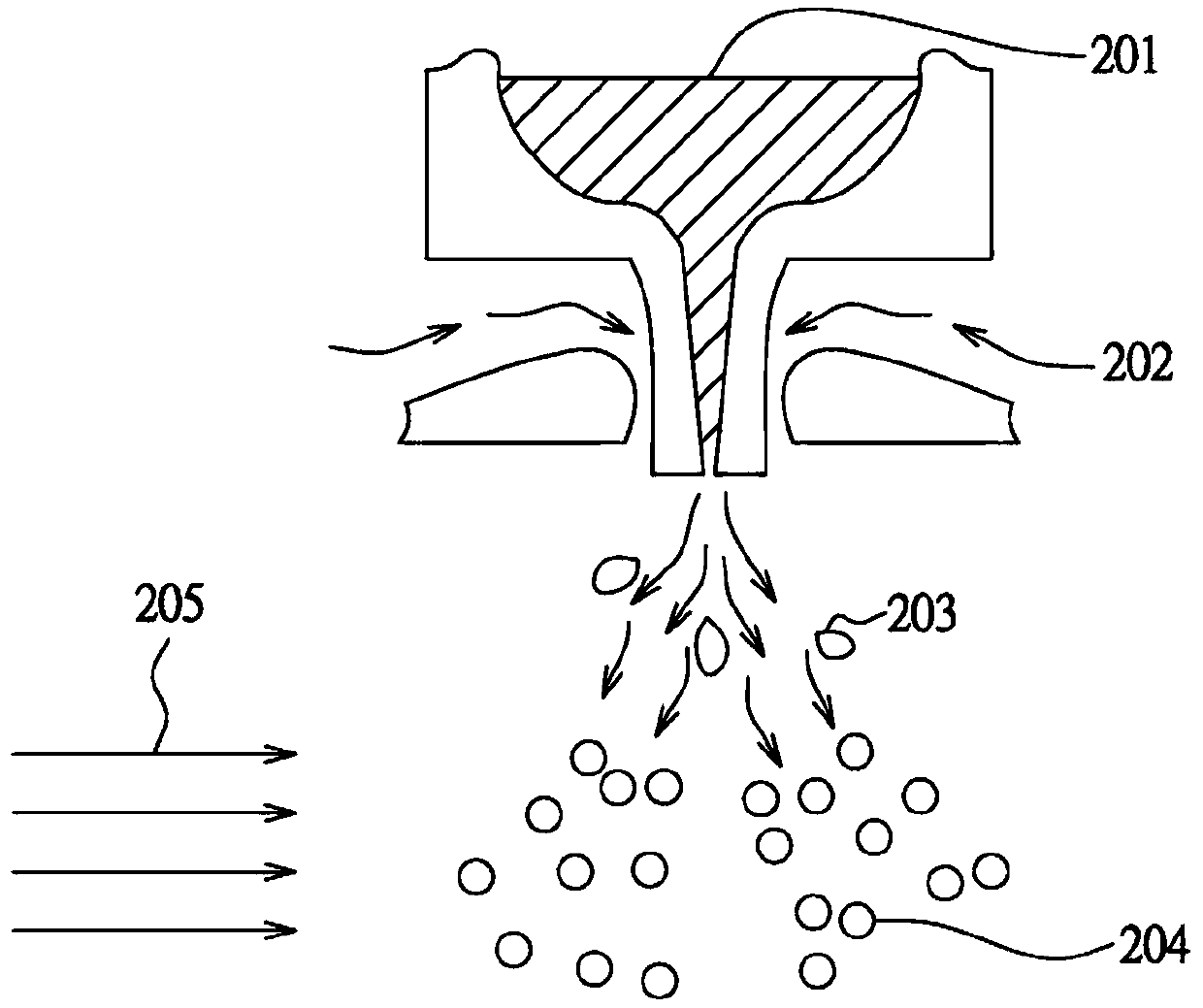

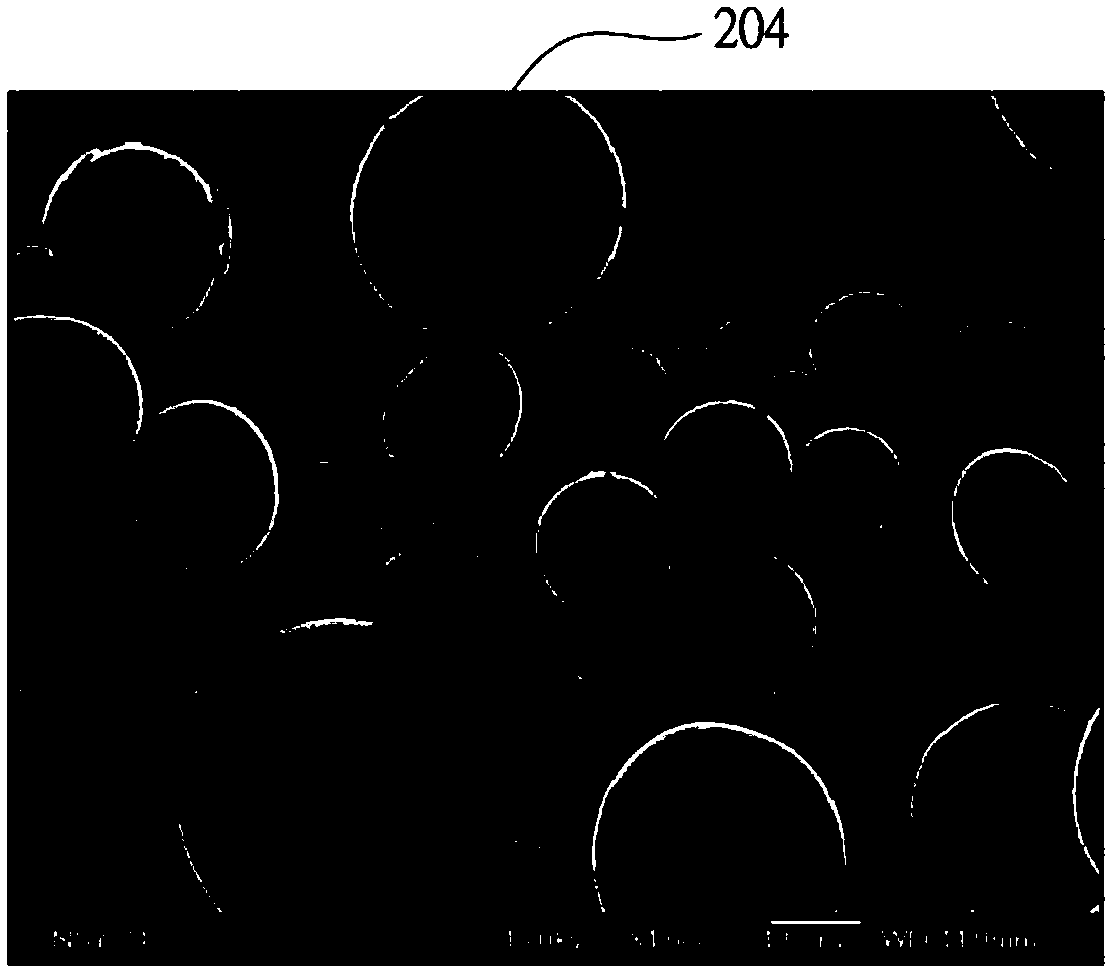

Fe-based amorphous soft magnetic bulk alloy, method for fabricating same and applications thereof

InactiveCN108022710AIncrease thickness dimensionReduce eddy current lossAdditive manufacturing apparatusMagnetic circuit rotating partsAlloyMaterials science

The present invention discloses a Fe-based amorphous soft magnetic bulk alloy. The Fe-based amorphous soft magnetic bulk alloy has a three dimensional structure which includes a Fe-based amorphous soft magnetic component consisting of FeaCobPcBdSie, wherein a, b, c d and e is the atomic percentage (at %) of each component to meet 76<=a<=80, 1<=b<=4, 9<=c<=11, 3<=d<=5 and 5<=e<=7.

Owner:IND TECH RES INST

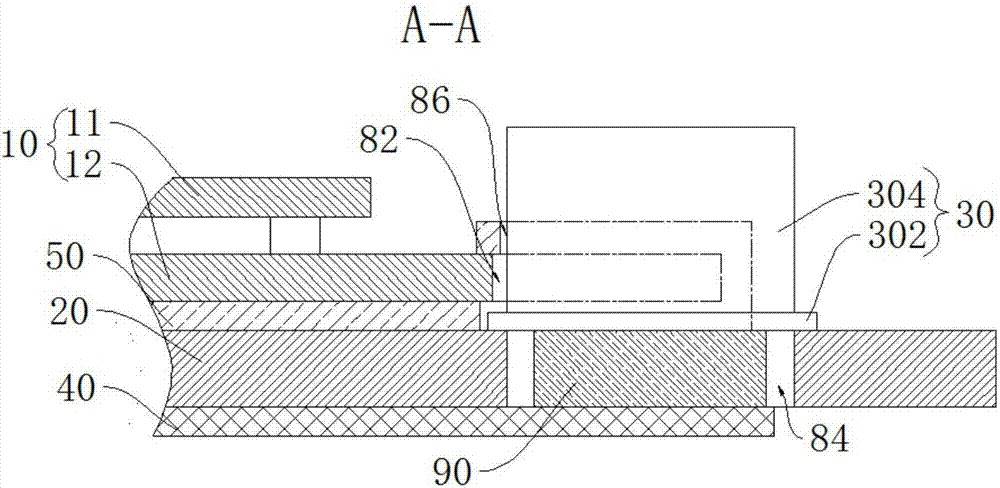

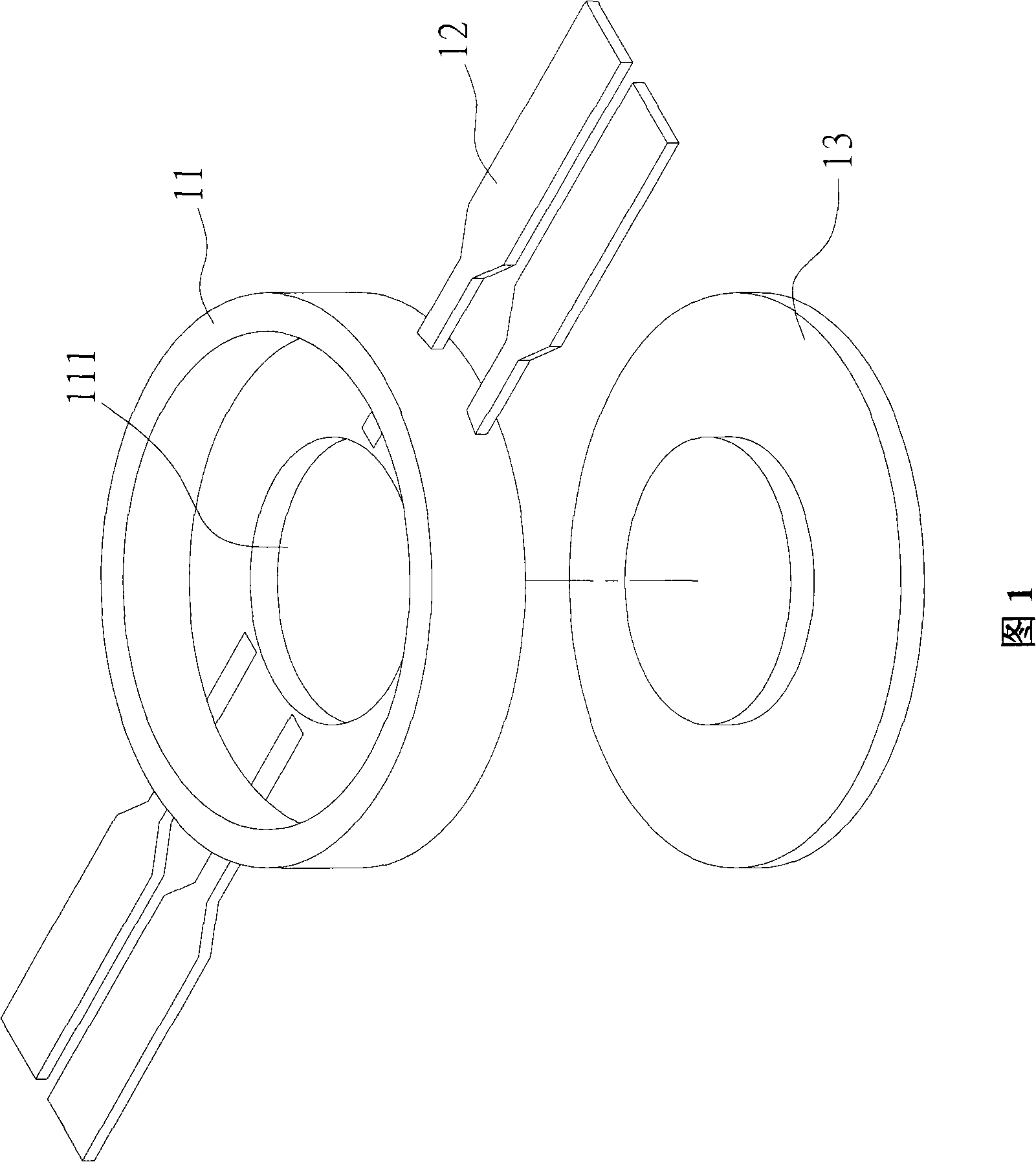

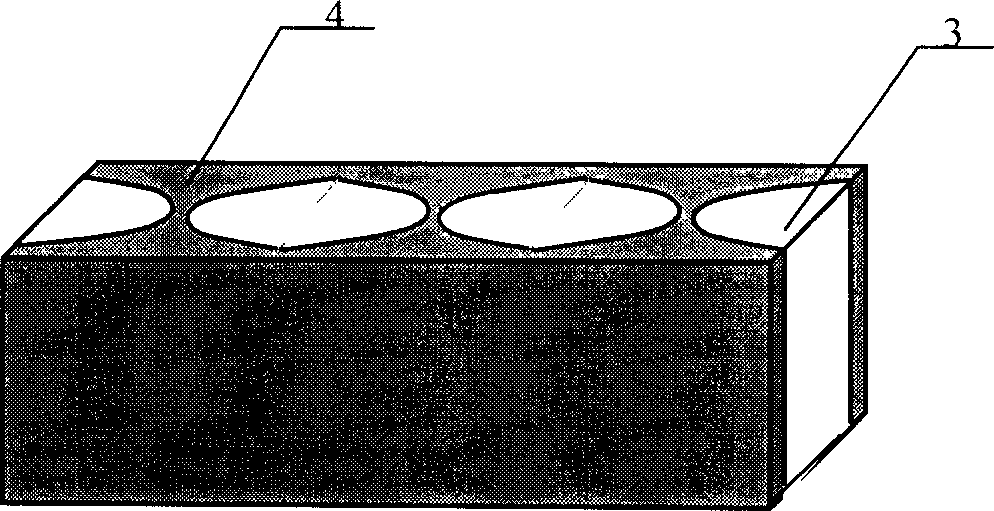

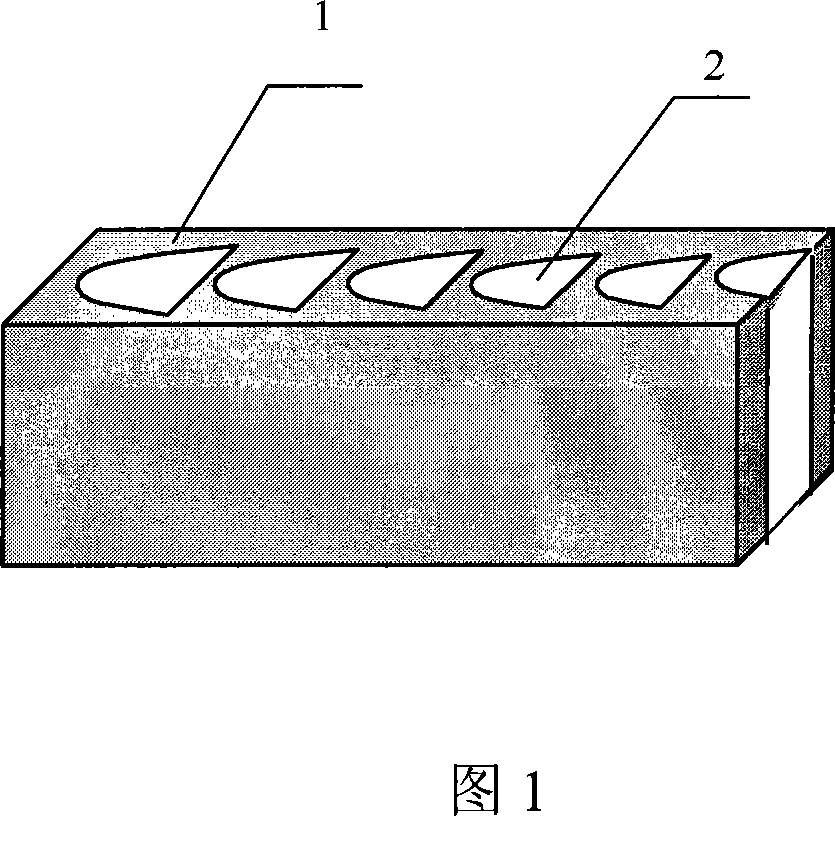

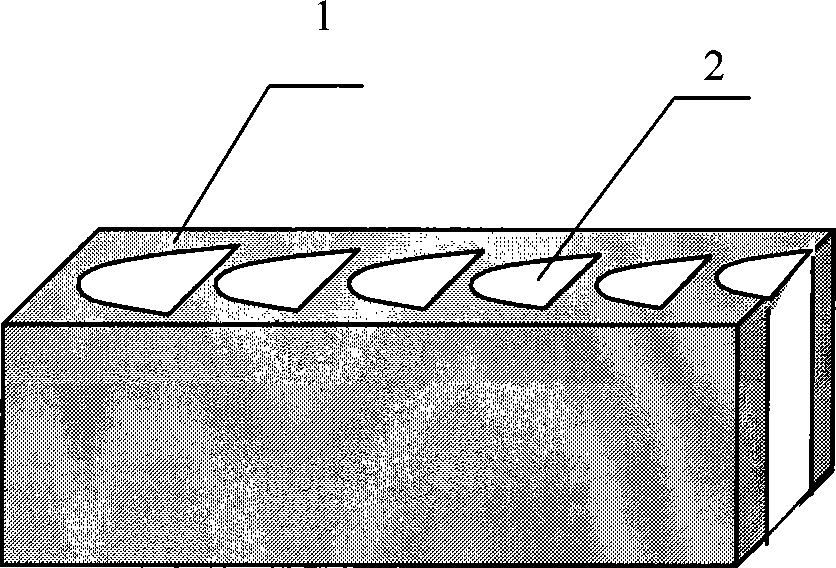

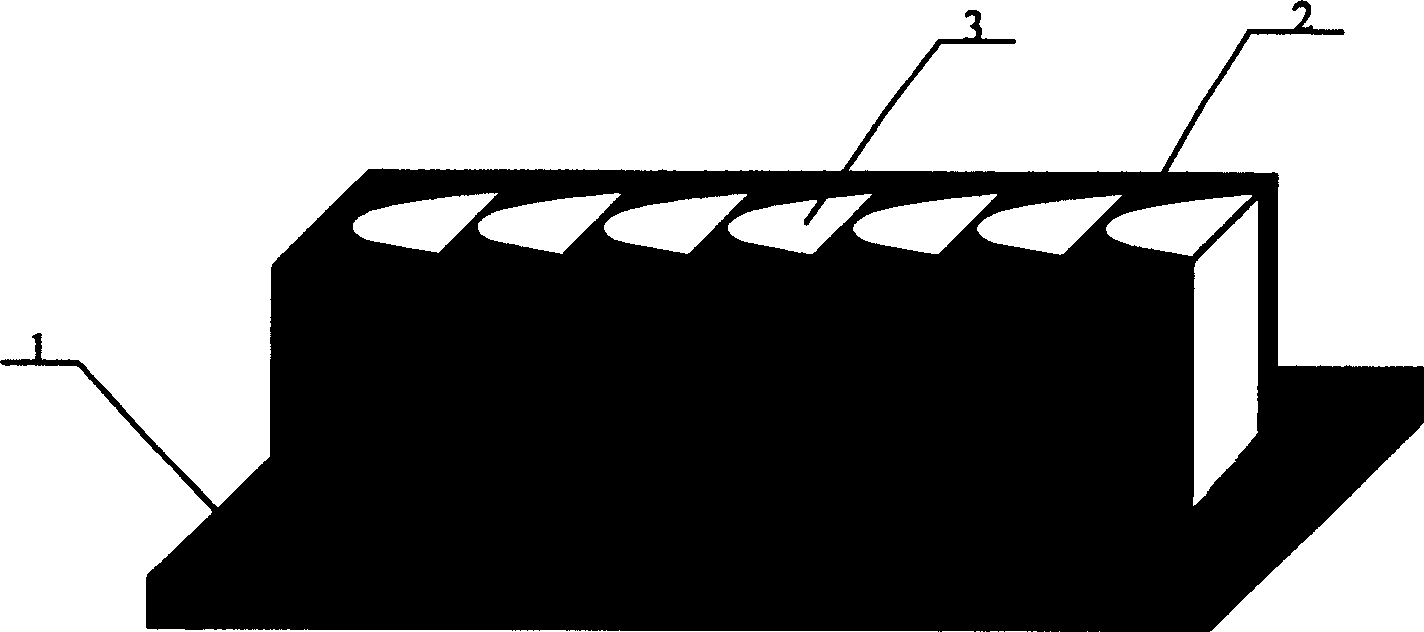

Mono dimension X-ray composite lens

InactiveCN1719284AOptimize face shapeIncrease thickness dimensionRadiation/particle handlingLensEllipseX-ray

The present invention relates to a one-dimensional X-ray combined lens, including lens main body and substrate positioned in the lower portion of lens main body. On the described lens main body several through-hole-like air gap units which are arranged according to straight-line order and have identical form are cut, and the described lens main body is made of aluminium material or aluminium oxide material, and said lens substrate is organic glass or glass material, and the thickness range of the described lens is 500microns-2000microns.

Owner:ZHEJIANG UNIV OF TECH

Production method for nano focusing X ray lens combination

InactiveCN101221829BImprove radiation transmittanceIncrease thickness dimensionHandling using diffraction/refraction/reflectionX-raySpins

Owner:ZHEJIANG UNIV OF TECH

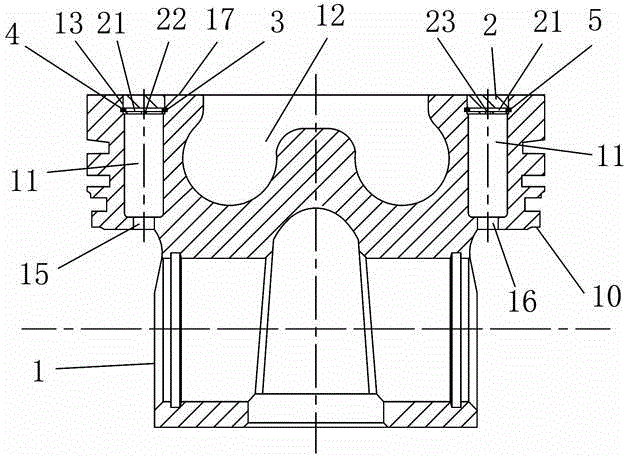

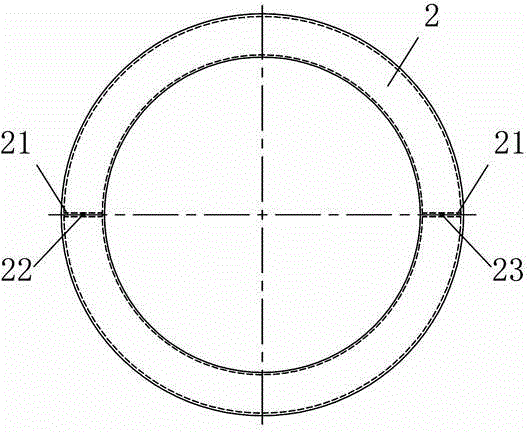

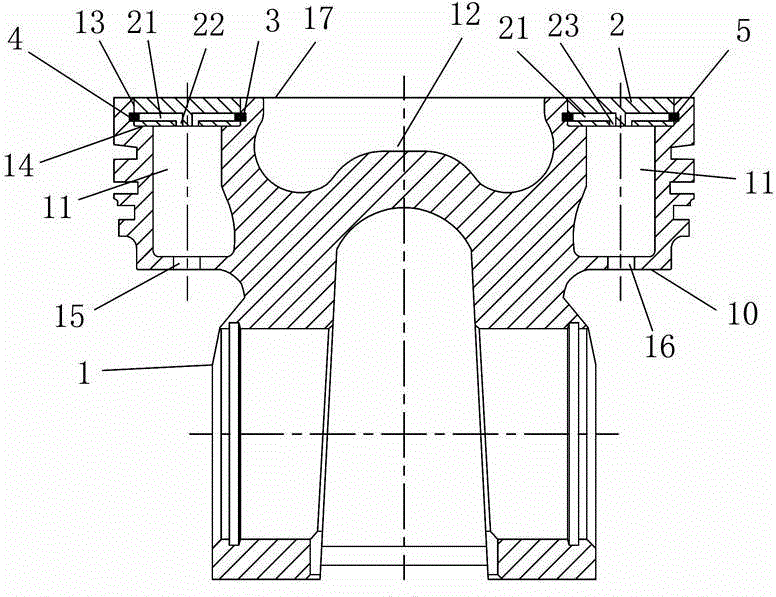

Steel piston forming inner cooling oil way based on laser welding and machining method of steel piston

ActiveCN106150749AExtended service lifeReduce weightMachines/enginesPistonsCombustion chamberEngineering

The invention discloses a steel piston forming an inner cooling oil way based on laser welding and a machining method of the steel piston. The steel piston comprise a piston body and an annular sealing plate; a piston head part of the piston body is provided with the inner cooling oil way and a combustion chamber; the inner cooling oil way surrounds the combustion chamber, and the piston head part is further provided with an oil inlet hole and an oil outlet hole which communicate with the inner cooling oil way; an annular opening is formed in the upper end of the inner cooling oil way and located in the top end of the piston head part; the annular sealing plate is embedded in the annular opening and connected and fixed through laser welding, the upper end of the inner cooling oil way is sealed, an inner annular channel is formed by the inner circle of the annular sealing plate and the side wall of the annular opening in a surrounding manner, an outer annular channel is formed by the outer circle of the annular sealing plate and the side wall of the annular opening in a surrounding manner, and the inner annular channel and the outer annular channel are filled with high-temperature-resisting heat isolation rings used for forming a laser welding pool. The method comprises the first step of component machining, the second step of laser welding and assembling, the third step of heat treatment and the fourth step of post machining. The steel piston and the machining method have the beneficial effects of being high in machining cost, good in quality stability and low in machining cost.

Owner:强哲菲

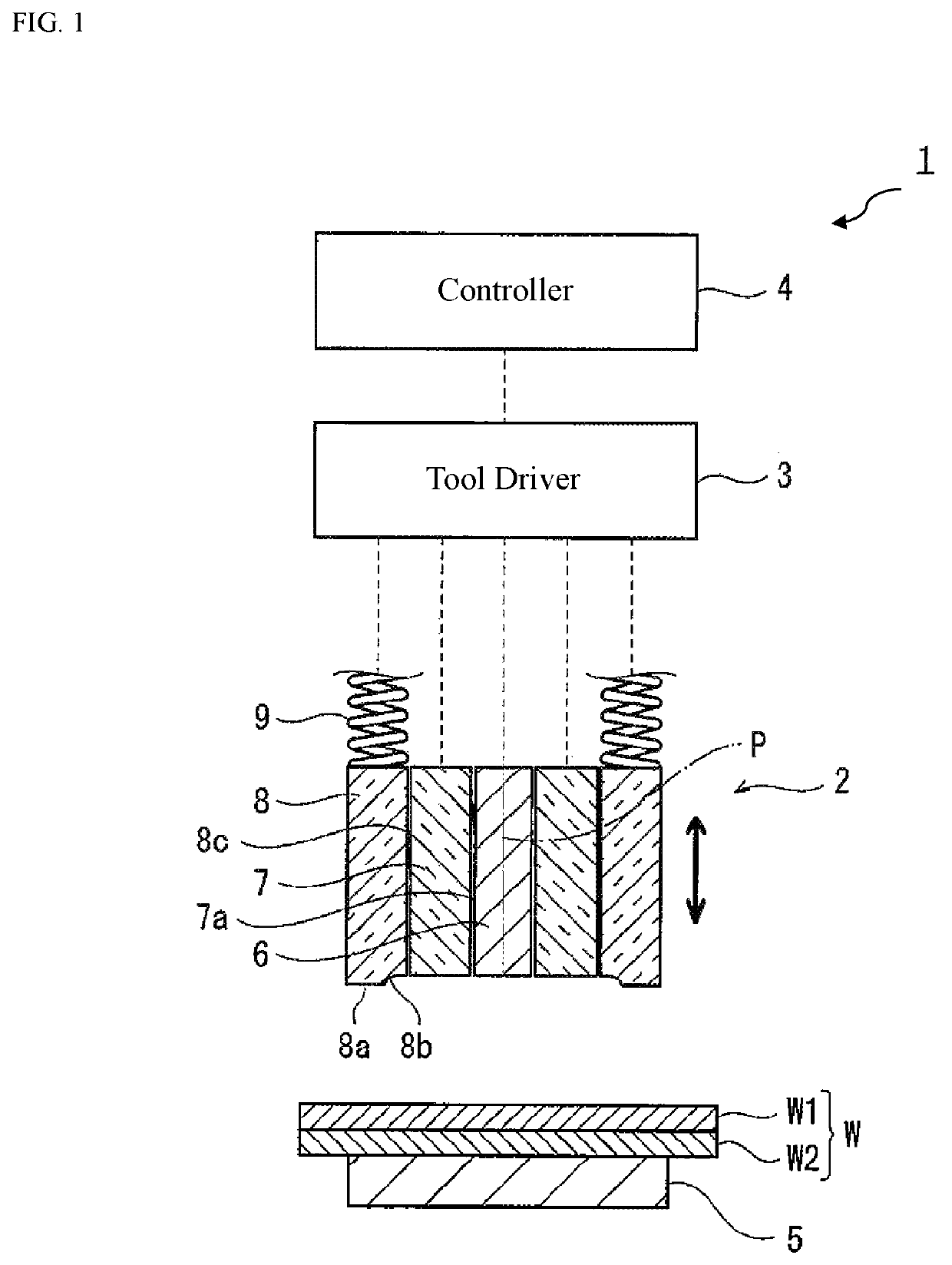

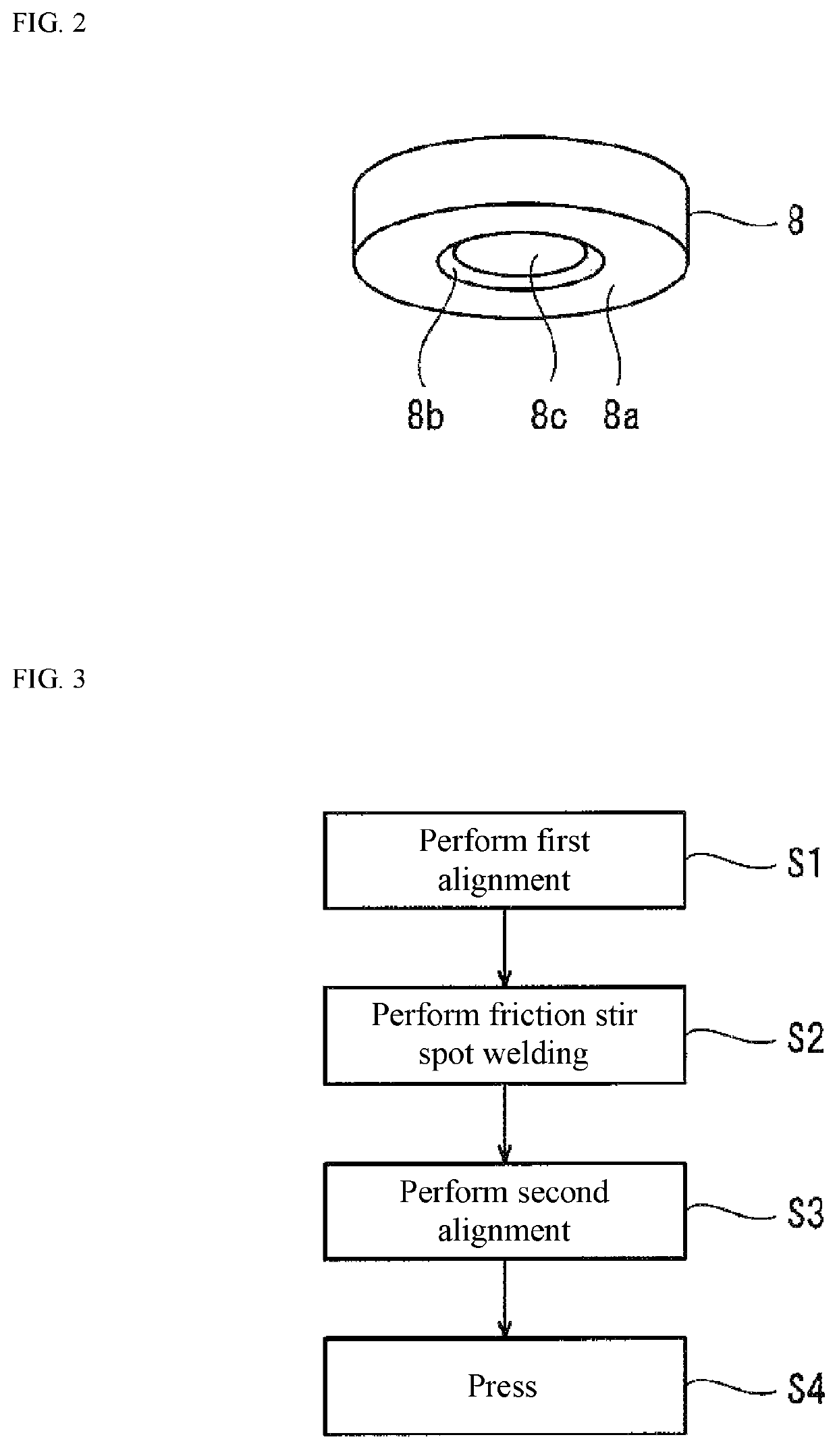

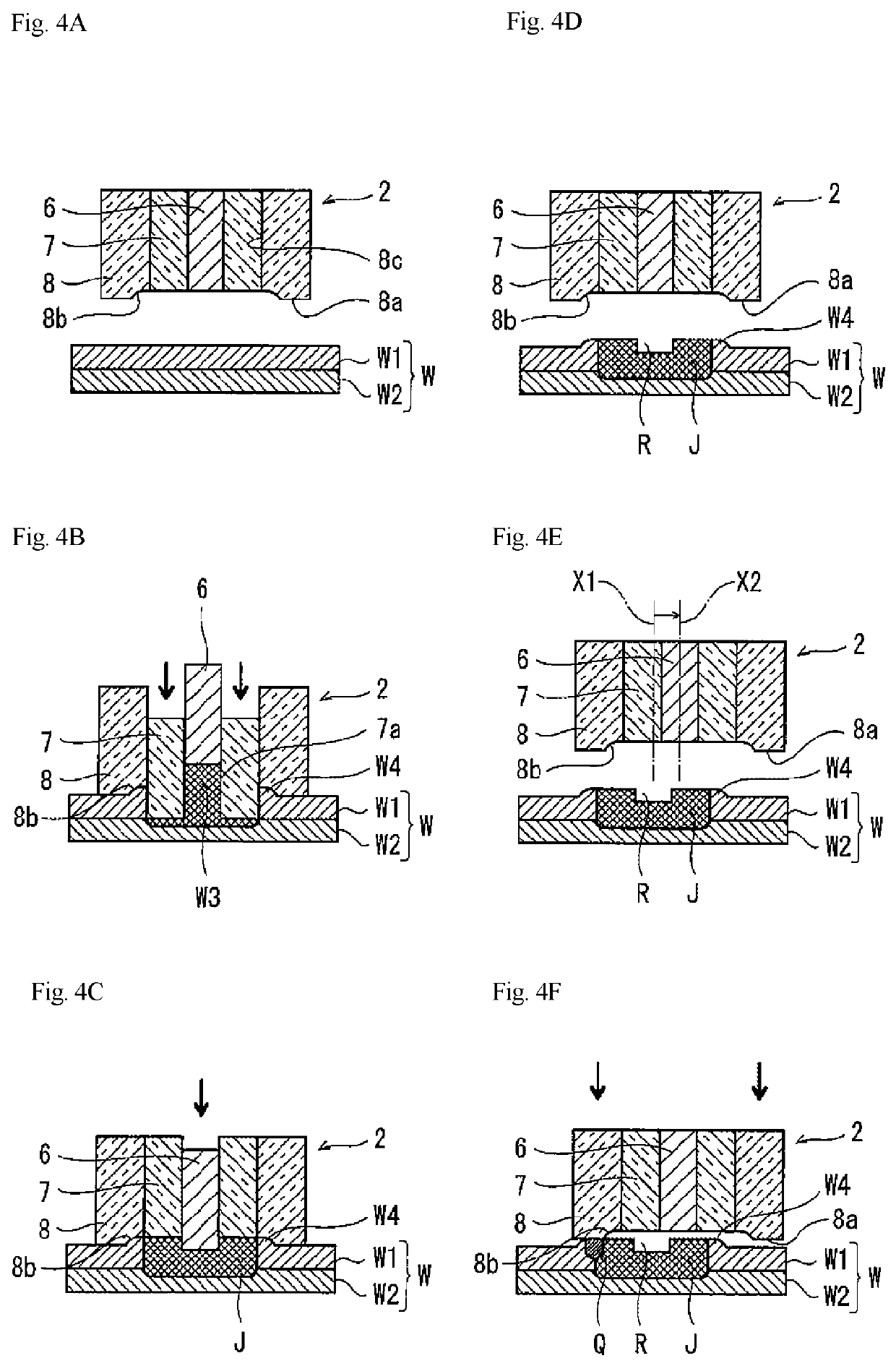

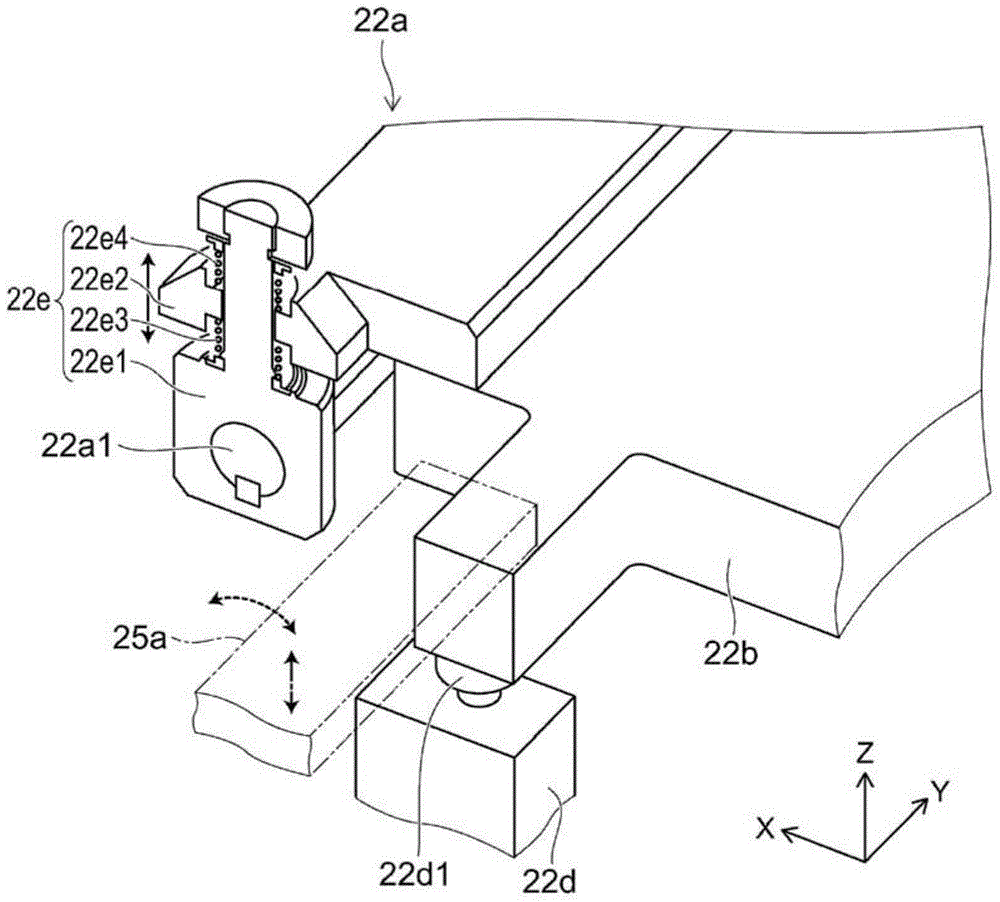

Double-acting friction stir spot welding method and apparatus

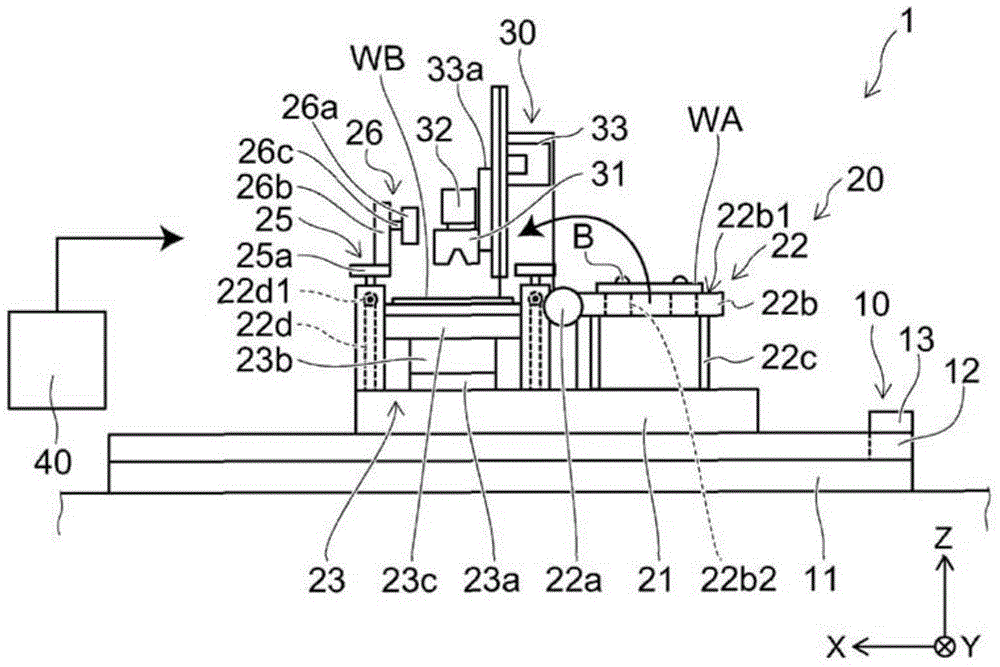

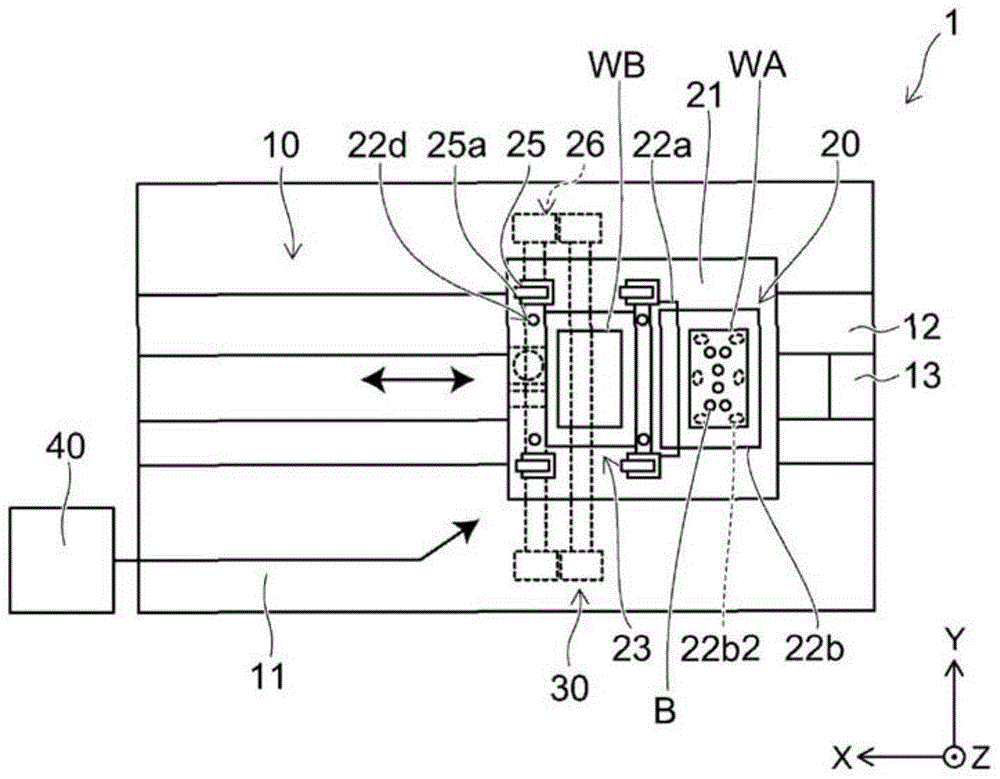

A friction stir spot welding method includes a welding step of forming a build-up portion on a workpiece by friction-stirring the workpiece, using a pin and a shoulder, while pressing a surface of the workpiece with an end face of a clamp, and filling a portion of the workpiece being softened in a chamber portion of the clamp by press-fitting at least one of the pin and the shoulder into a plastic flow portion of the workpiece. and the friction stir spot welding method further includes a pressing step of pressing a surface of at least one of a region of the build-up portion, which is frictionally stirred by the shoulder, and an adjacent region of the build-up portion against the end face of the clamp with the pin and the shoulder retracted into an accommodation space.

Owner:KAWASAKI HEAVY IND LTD

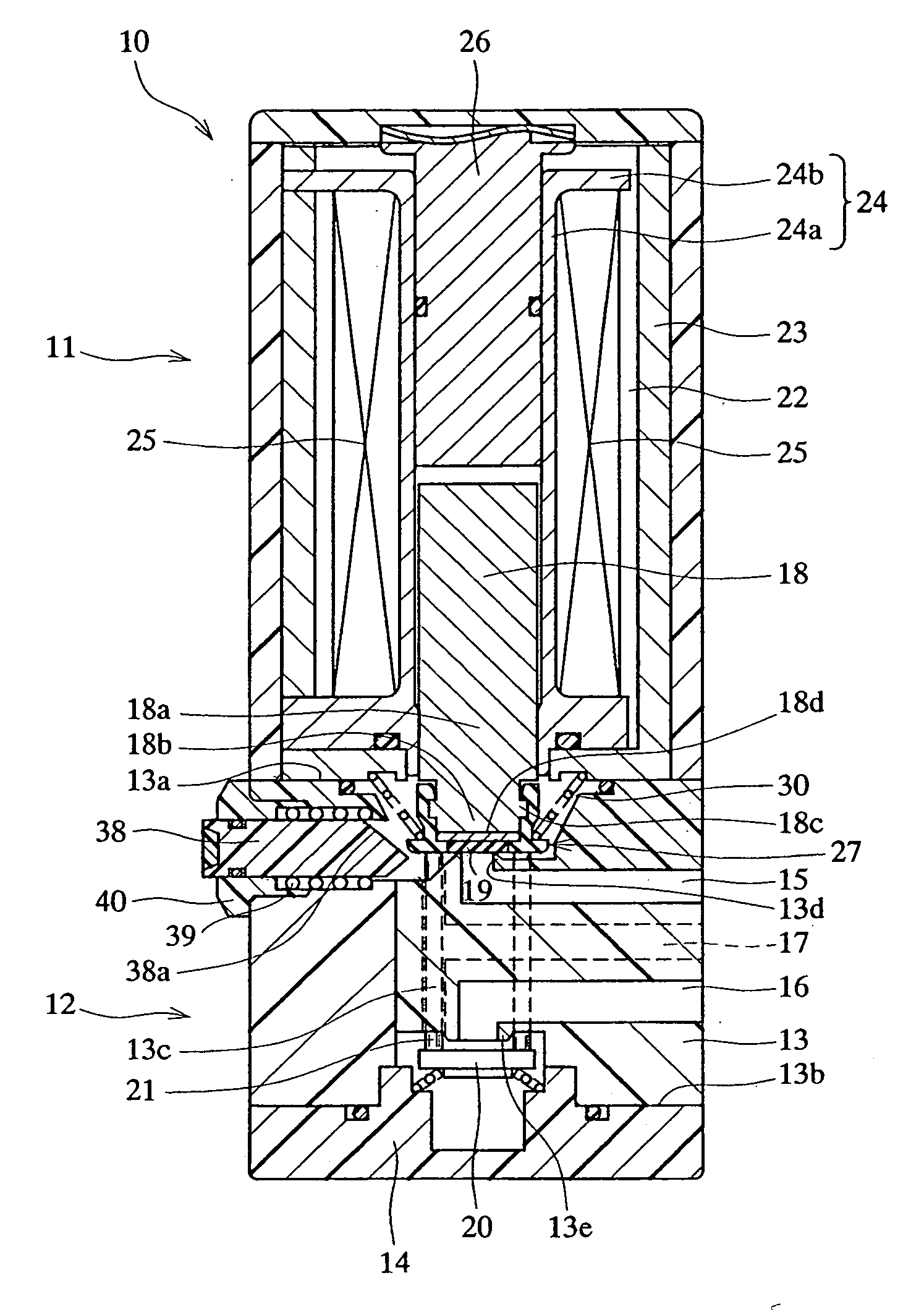

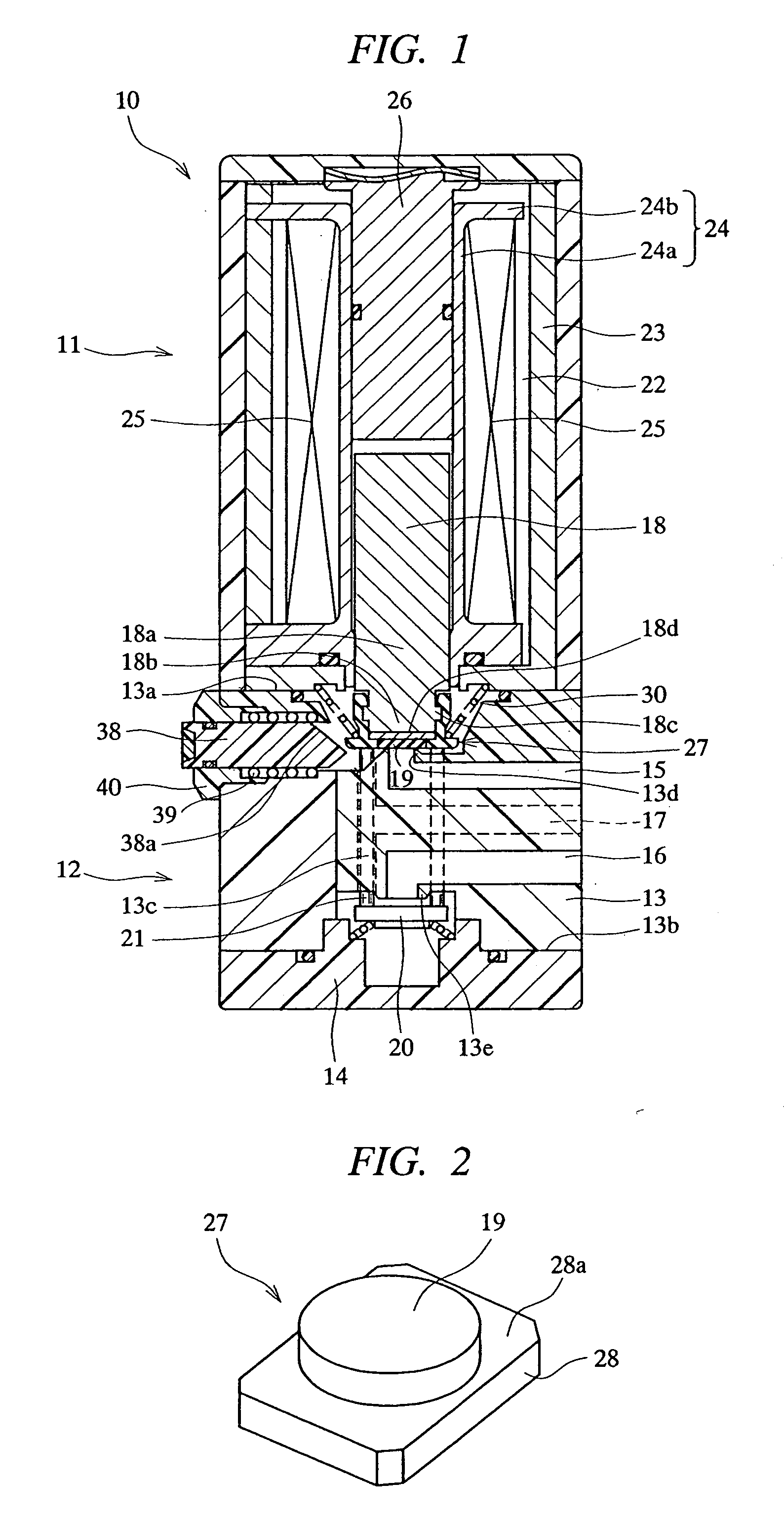

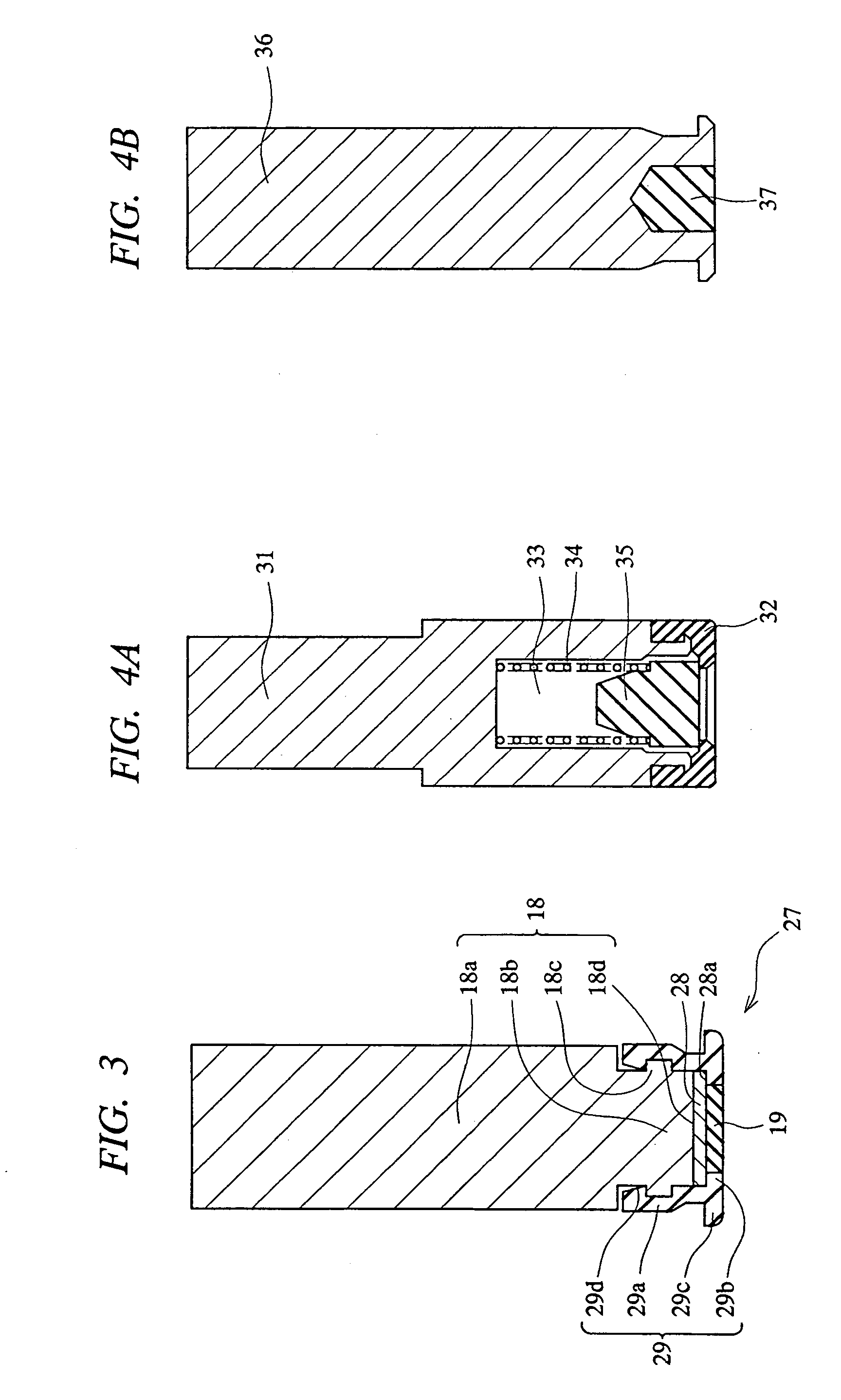

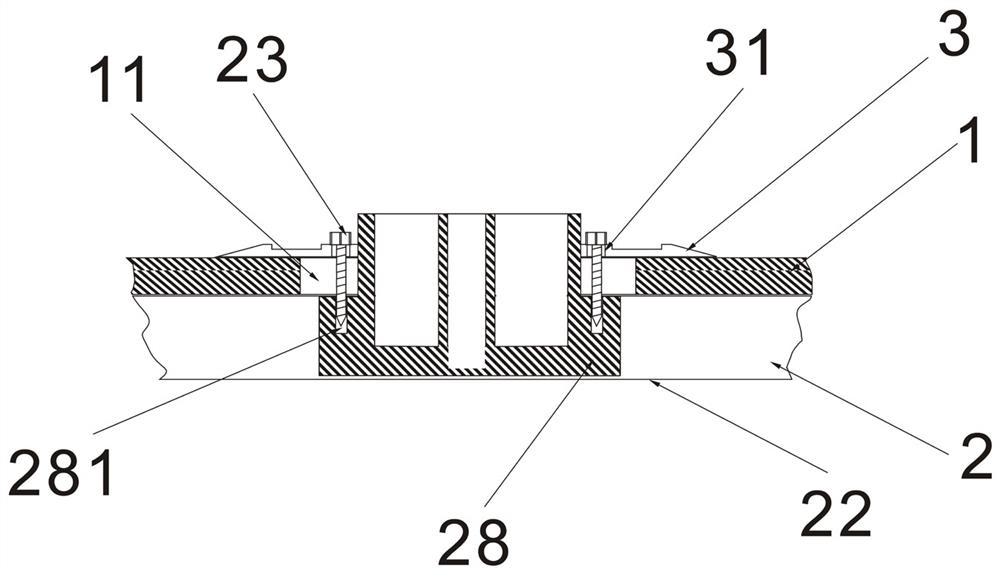

Solenoid valve

InactiveUS20070181839A1Improve productivityReduce manufacturing costOperating means/releasing devices for valvesCheck valvesSolenoid valveEngineering

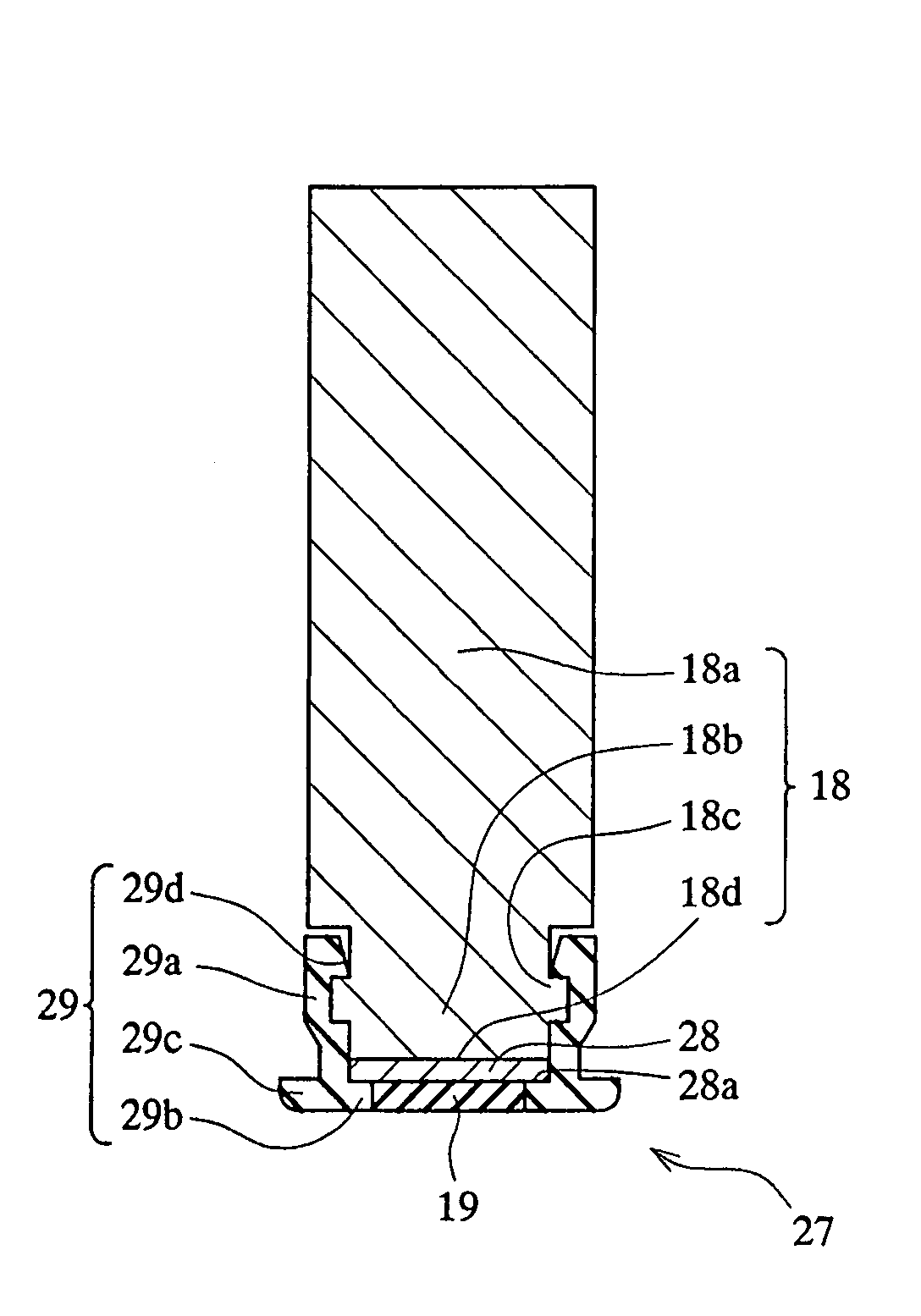

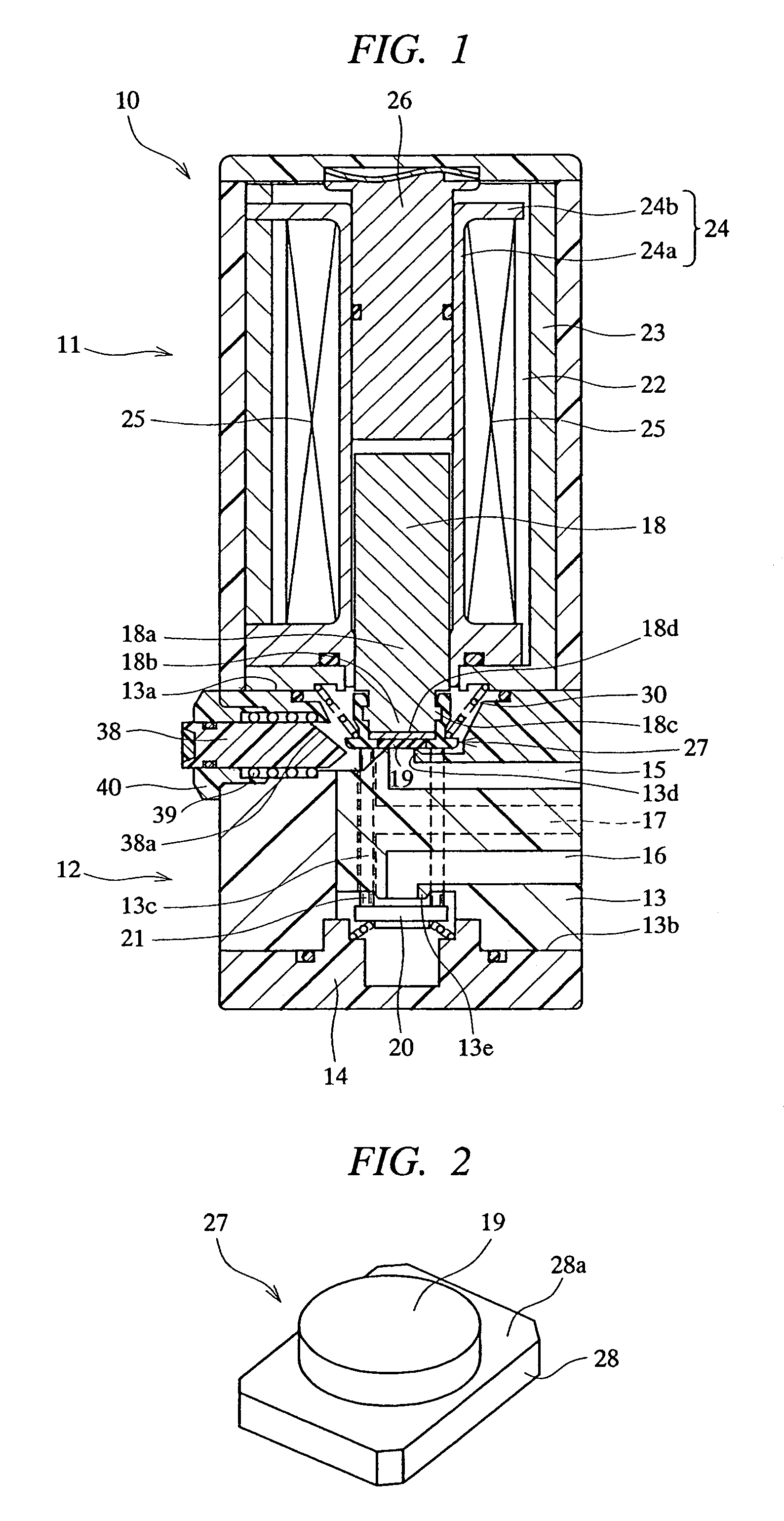

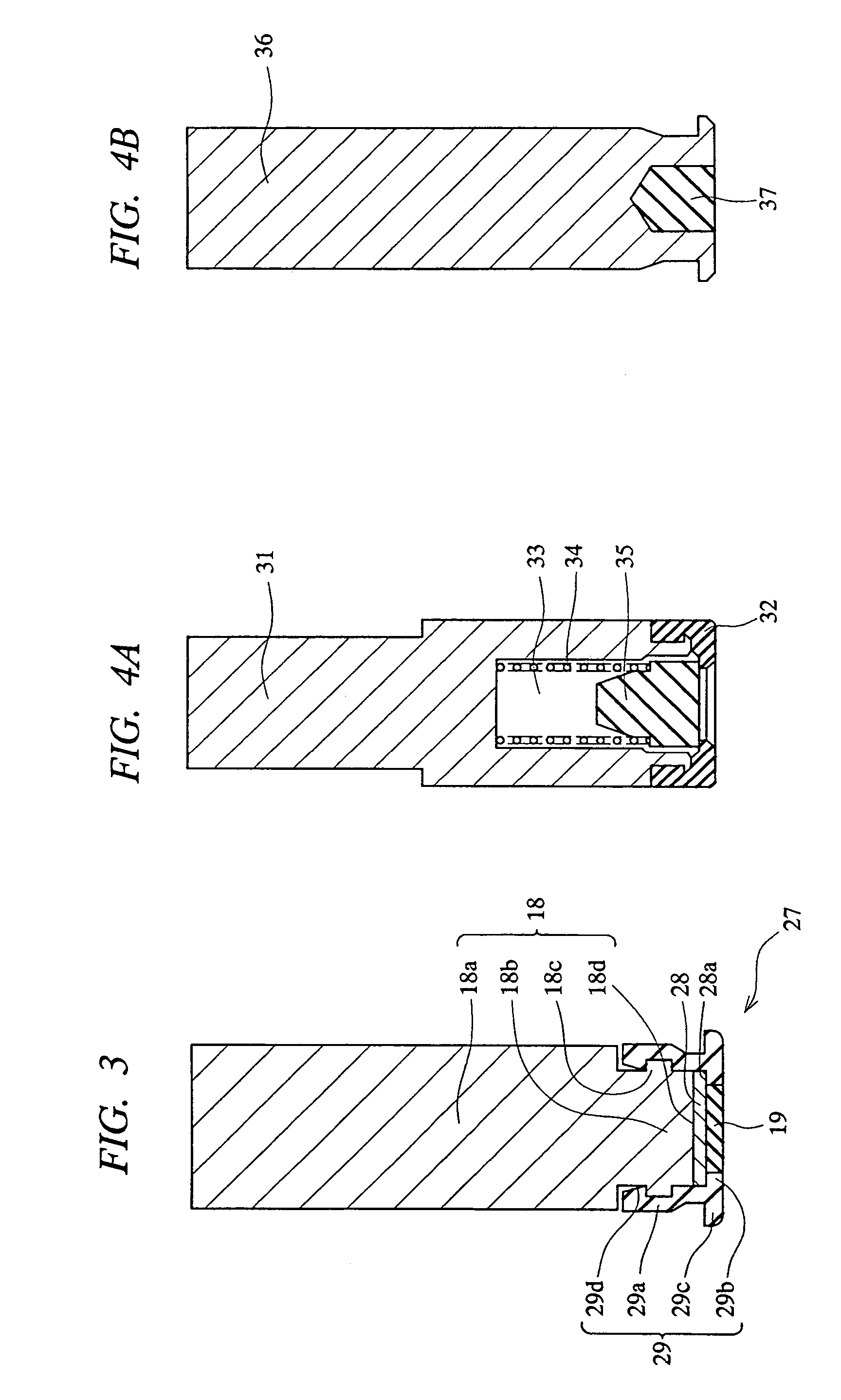

As shown in FIG. 3, a poppet 27 is formed by a valve body 19 and a supporting plate 28, to a front surface of which the valve body is firmly fixed and with a rear surface of which a tip surface of a plunger 18 contacts. A cap 29 has: a cylindrical portion 29a which is fitted to an outer circumference of the plunger 18; an inward projecting portion 29b which projects inwardly from this cylindrical portion 29a so as to abut on a surface outer circumferential portion 28a of the supporting plate 28; and an outward projecting portion 29c which projects outwardly from the cylindrical portion 29a so as to be engaged with a spring member. The poppet 27 is press-inserted into the cap 29 in a direction in which the inward projecting portion 29b of the cap 29 and the surface outer circumferential portion 28a of the supporting plate 28 abut on each other, and the cap 29 into which the poppet 27 is press-inserted is press-inserted into the tip portion 18b of the plunger 18, whereby the poppet 27 is assembled in the tip surface 28d of the plunger 18.

Owner:KOGANEI

Production for aluminium-material X-ray assembled lens

InactiveCN1285925CIncrease thickness dimensionIncrease light collecting apertureRadiation/particle handlingPhotomechanical exposure apparatusX-rayPhotoresist

A method for manufacturing an X-ray composite lens made of aluminum material, comprising the following steps: coating a coating on the surface of a silicon substrate, baking and curing; growing an electroformed cathode film on the surface of a sample; coating photoresist on the surface of the electroformed cathode film, Carry out photolithography, development, hard mold; grow metal thin film on photoresist pattern structure; remove photoresist and electroform cathode film; backside photolithography and corrode silicon substrate to form window, as X-ray lithography mask; preparation Titanium sheets were used as substrates for X-ray lithography, and NaOH / H 2 o 2 Surface treatment; apply X-ray photoresist on the surface, bake and cure the above-mentioned photoresist to form an X-ray lithography substrate; perform X-ray lithography and development on the X-ray lithography substrate, and use X-ray photoresist Engraving the mask; filling the silicone rubber into the sample structure and curing; filling the removed silicone rubber mold with aluminum material, and separating the mold after curing. The retained structure includes the scale chassis, lens body, and air gap.

Owner:ZHEJIANG UNIV OF TECH

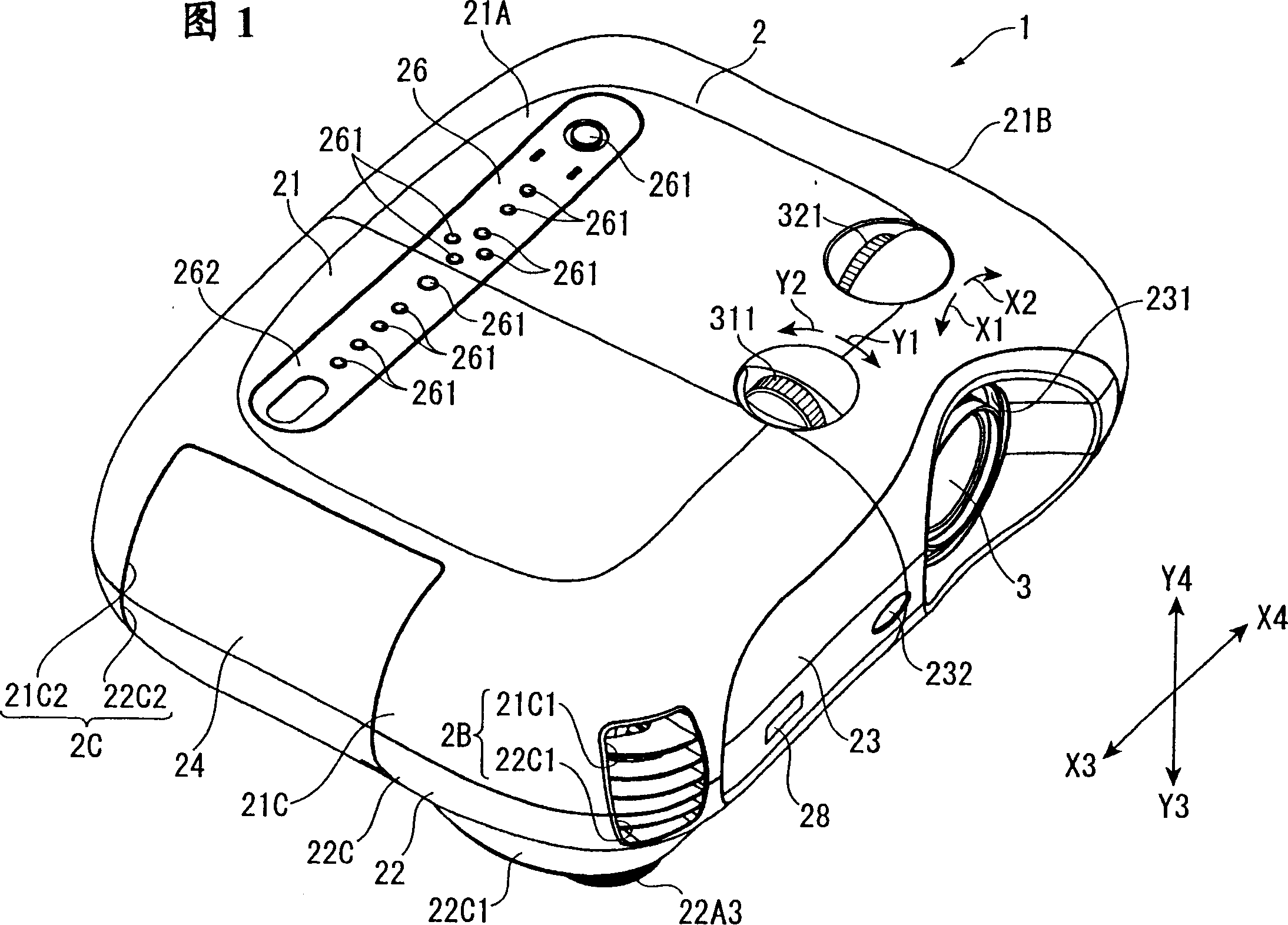

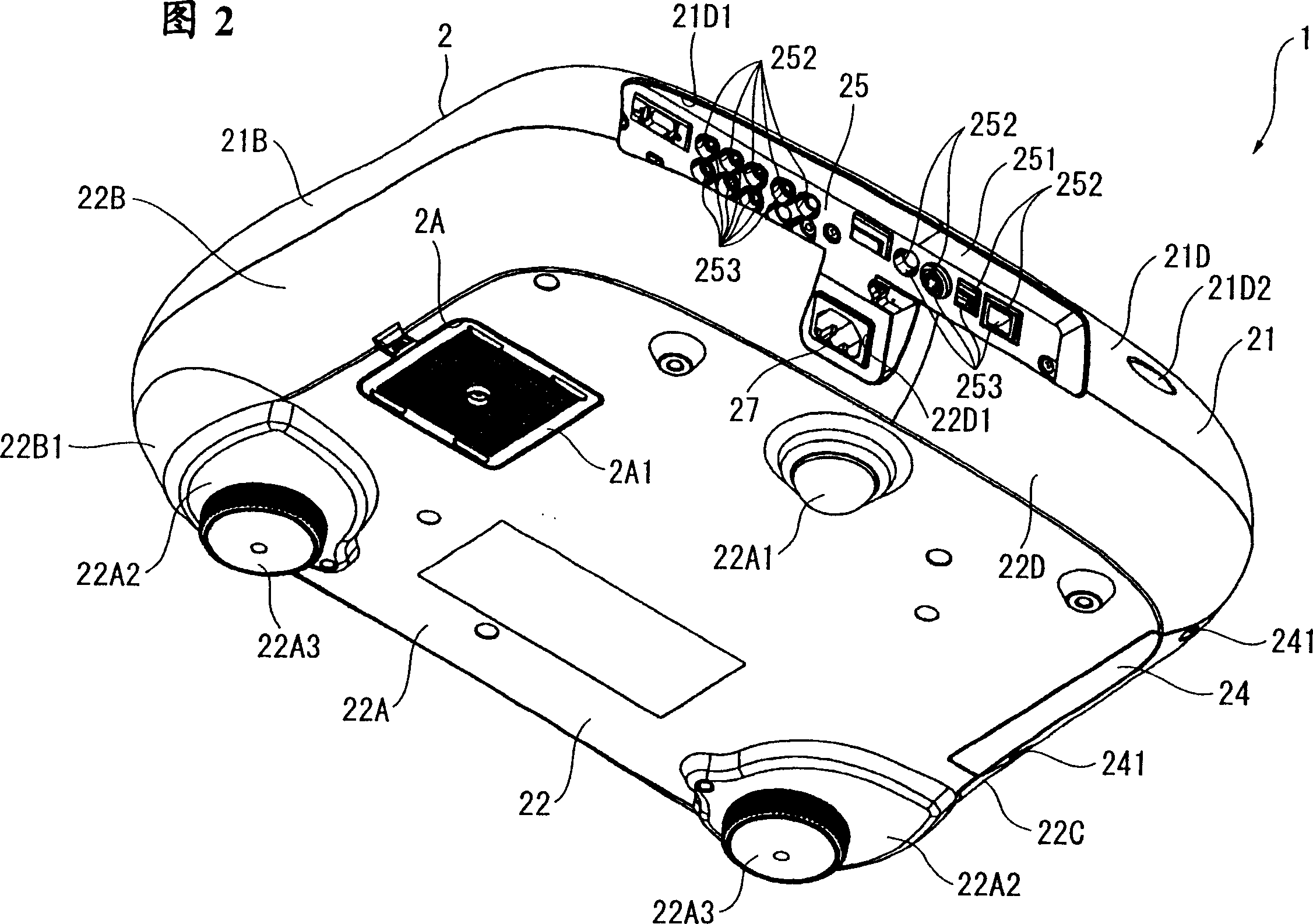

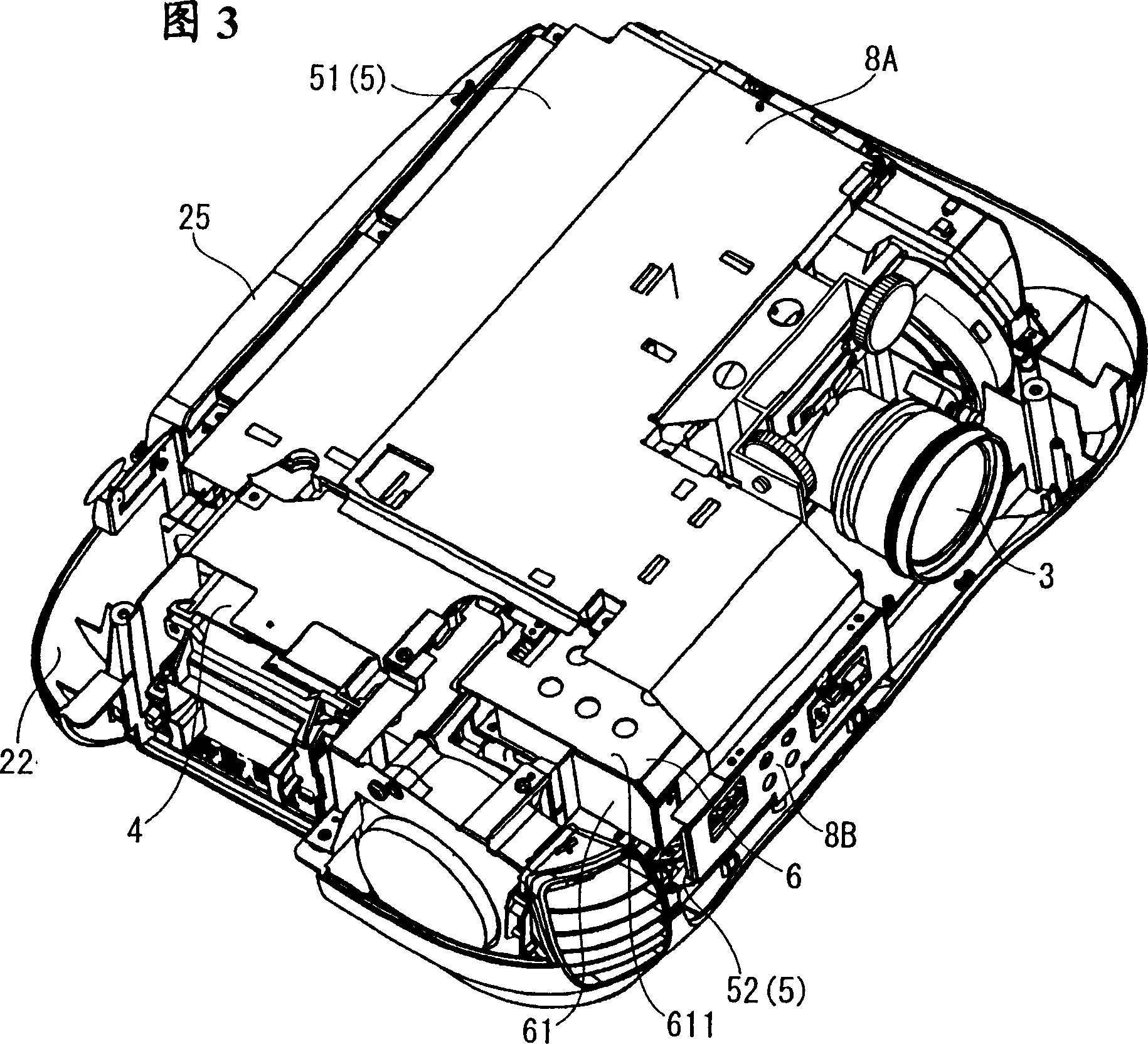

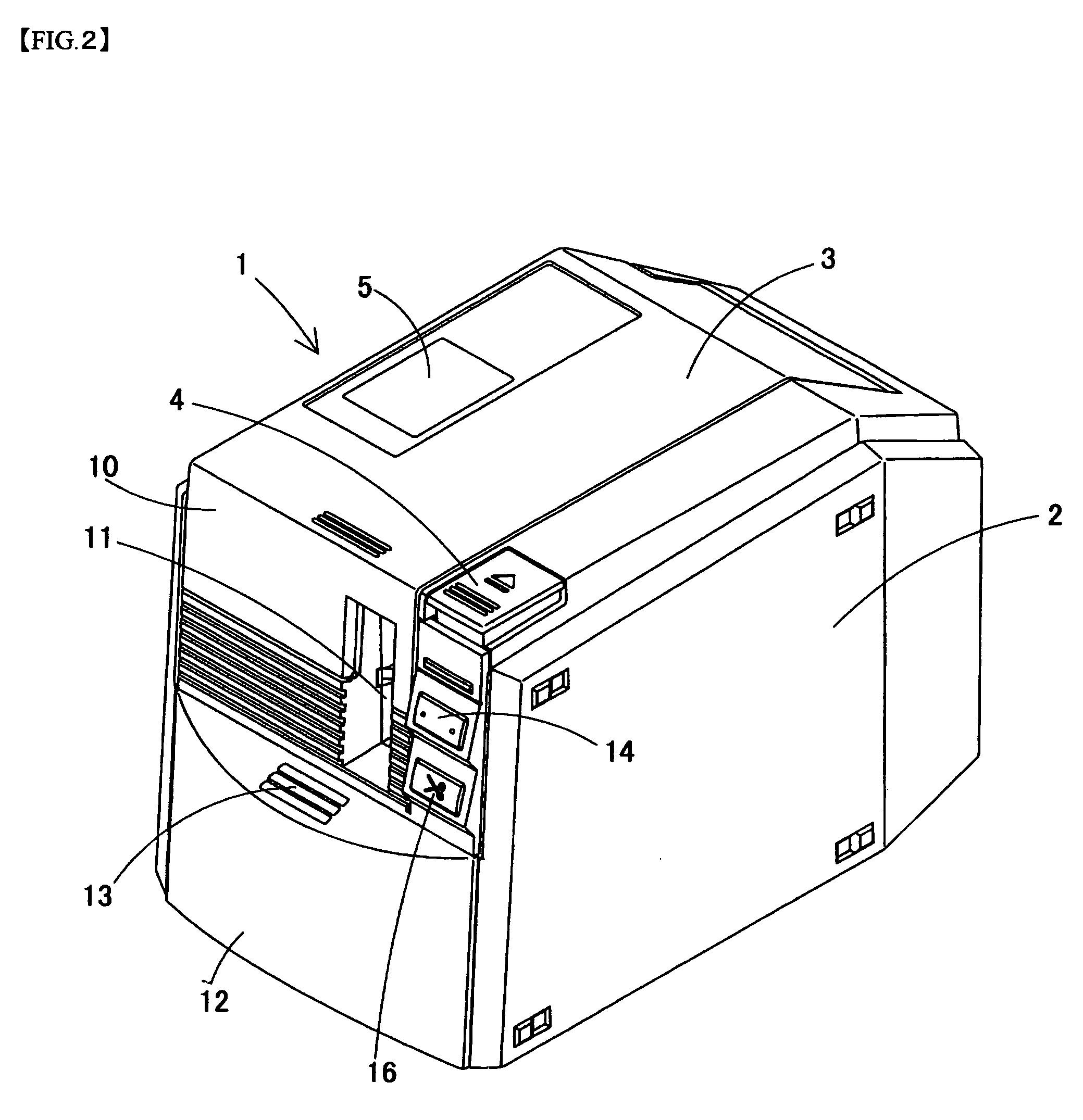

Projector

InactiveCN1717623AIncrease thickness dimensionEfficient dischargeProjectorsNon-linear opticsDevice formRoad surface

A projector, comprising a multiblade fan (762) as an exhaust fan oppositely disposed to an exhaust port (2B) formed in an external case (2), sucking air inside the external case (2), and exhausting the air to the outside through the exhaust port (2B). The multiblade fan (762) is disposed so that the suction surface thereof is positioned along a surface perpendicular to an optical path surface formed by a light source device, light modulators, and projection optical device forming the device body of the projector. Also, the multiblade fan (762) is formed such that an exhaust port (762A) is tilted in the rotating direction of a fan, and exhausts sucked air to the end face of the external case where the exhaust port (2B) is formed at the generally center portion in the thickness direction. Thus, an exhausting efficiency can be increased by efficiently sucking inside air without increasing the rotational speed of the exhaust fan, and the thickness dimension can be reduced.

Owner:SEIKO EPSON CORP

Refrigerator

ActiveCN102944098AIncrease thickness dimensionAvoid broken bagsDomestic cooling apparatusLighting and heating apparatusDepth directionFront edge

The invention provides a refrigerator capable of reducing the heat energy intruding into the refrigerator. The refrigerator is provided with a front surface flange (17), a back surface flange (18), an inner case flange (19), and a buffer material (7). The front surface flange (17) is integratedly connected with a front edge of an outer case (1), and is formed by being bent towards an inner side. The back surface flange (18) is integratedly connected with the front surface flange (17), and is formed on a back surface side of the front surface flange (17), and also can be bent together with the front surface flange (17) to form an embedded concave part (18a), then can be extended towards the depth direction of the refrigerator. The inner case flange (19) is integratedly connected with the front edge part of the inner case (2), and can be bent outwards, and then is clamped with the embedded concave part (18a) to fix the outer case (1) and the inner case (2). The buffer material (7) is disposed between the front side of the refrigerator (100) of the vacuum heat insulation material (3) and the back surface flange (18).

Owner:MITSUBISHI ELECTRIC CORP

Production equipment of fiber reinforced composite pipe

ActiveCN114193800AHigh strengthImprove bindingRigid pipesPipe protection against damage/wearWinding machineFiber-reinforced composite

The invention provides production equipment of a fiber reinforced composite pipe, and belongs to the technical field of composite pipelines. The problem that in the prior art, a composite pipeline is low in strength is solved. The production equipment of the fiber reinforced composite pipe comprises a forming mold, the forming mold comprises an outer mold sleeve, a core mold, a sizing sleeve connected with the outlet end of the outer mold sleeve and an air inlet channel communicated with an inner cavity of the sizing sleeve, and a forming cavity channel is formed between the outer mold sleeve and the core mold; the production equipment further comprises an outer pipe and a winding machine capable of wrapping the outer peripheral wall of the outer pipe with reinforced fibers, the tail end of the outer pipe extends into the outer die sleeve from the inlet end of the outer die sleeve, an annular cavity channel right opposite to the forming cavity channel is formed between the outer peripheral wall of the outer pipe and the inner peripheral wall of the outer die sleeve, and an air inlet pipe communicated with the air inlet channel is further arranged in the outer pipe. The strength of the fiber reinforced composite pipe can be improved, and meanwhile the stability of the product size is guaranteed.

Owner:YONGGAO CO LTD

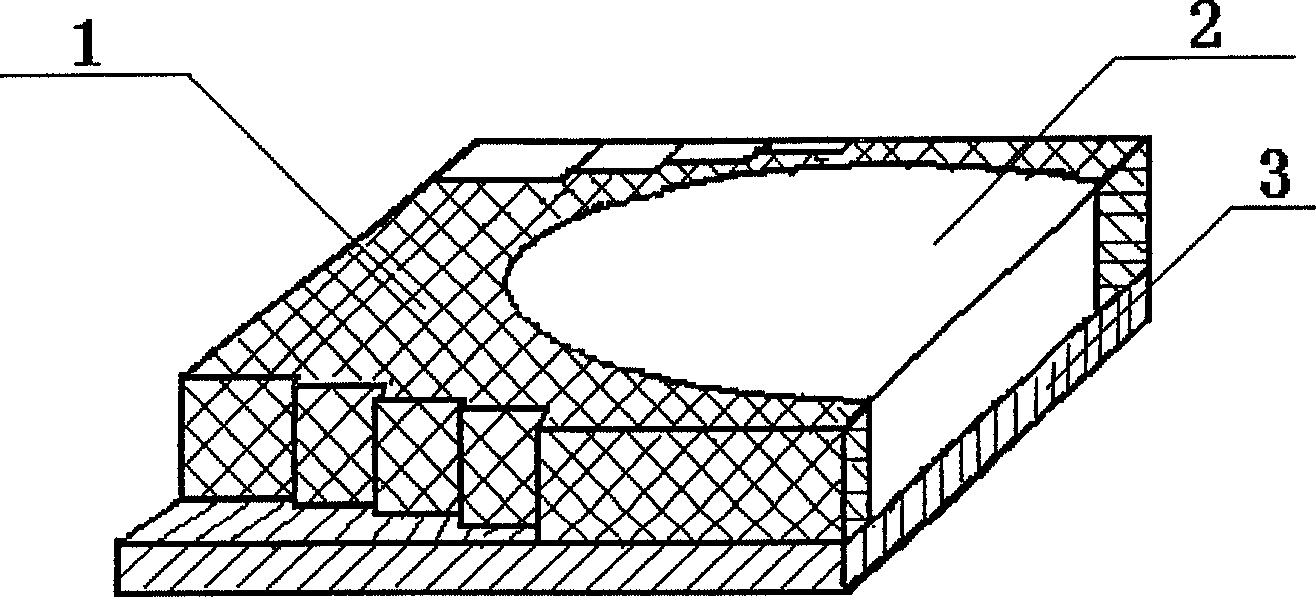

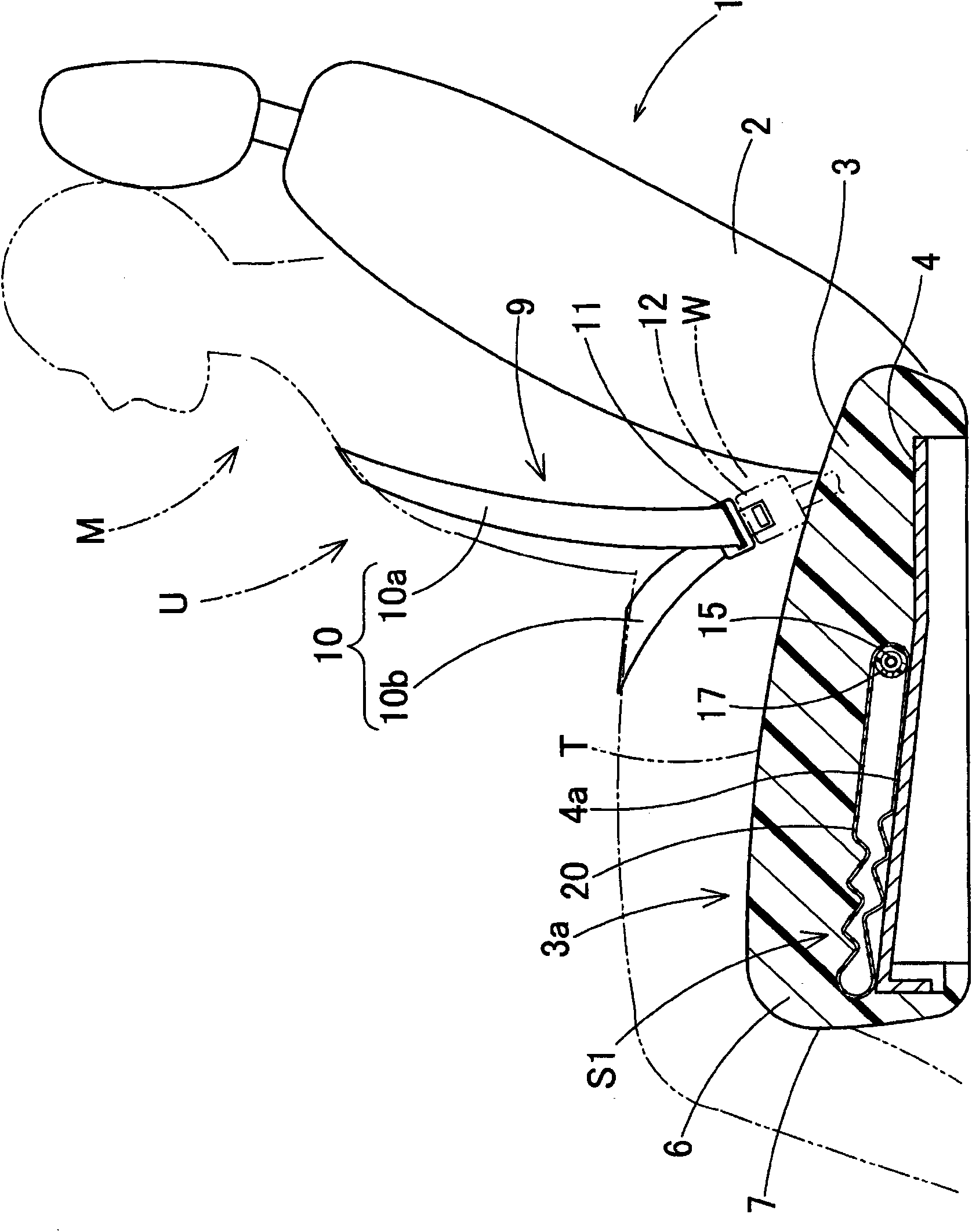

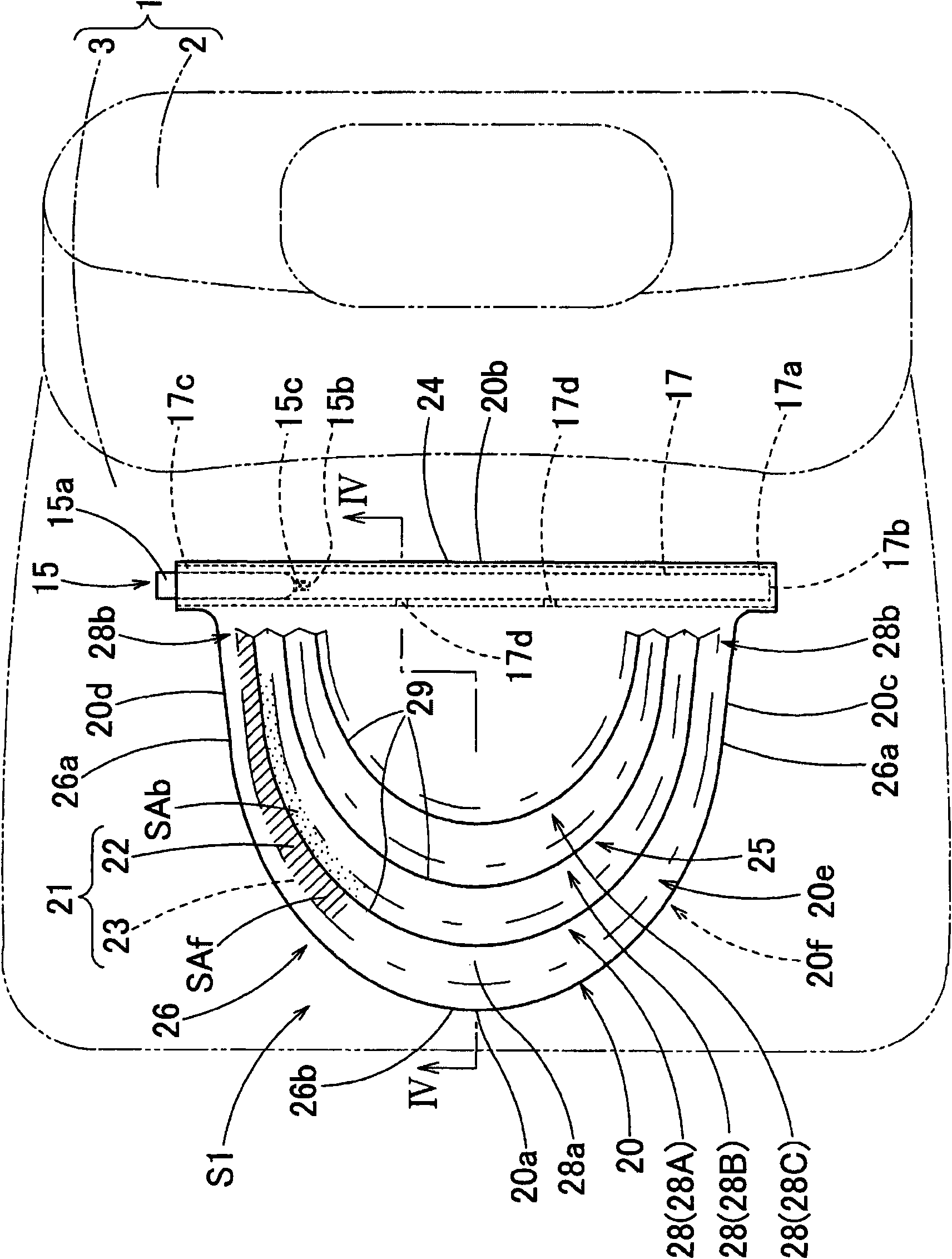

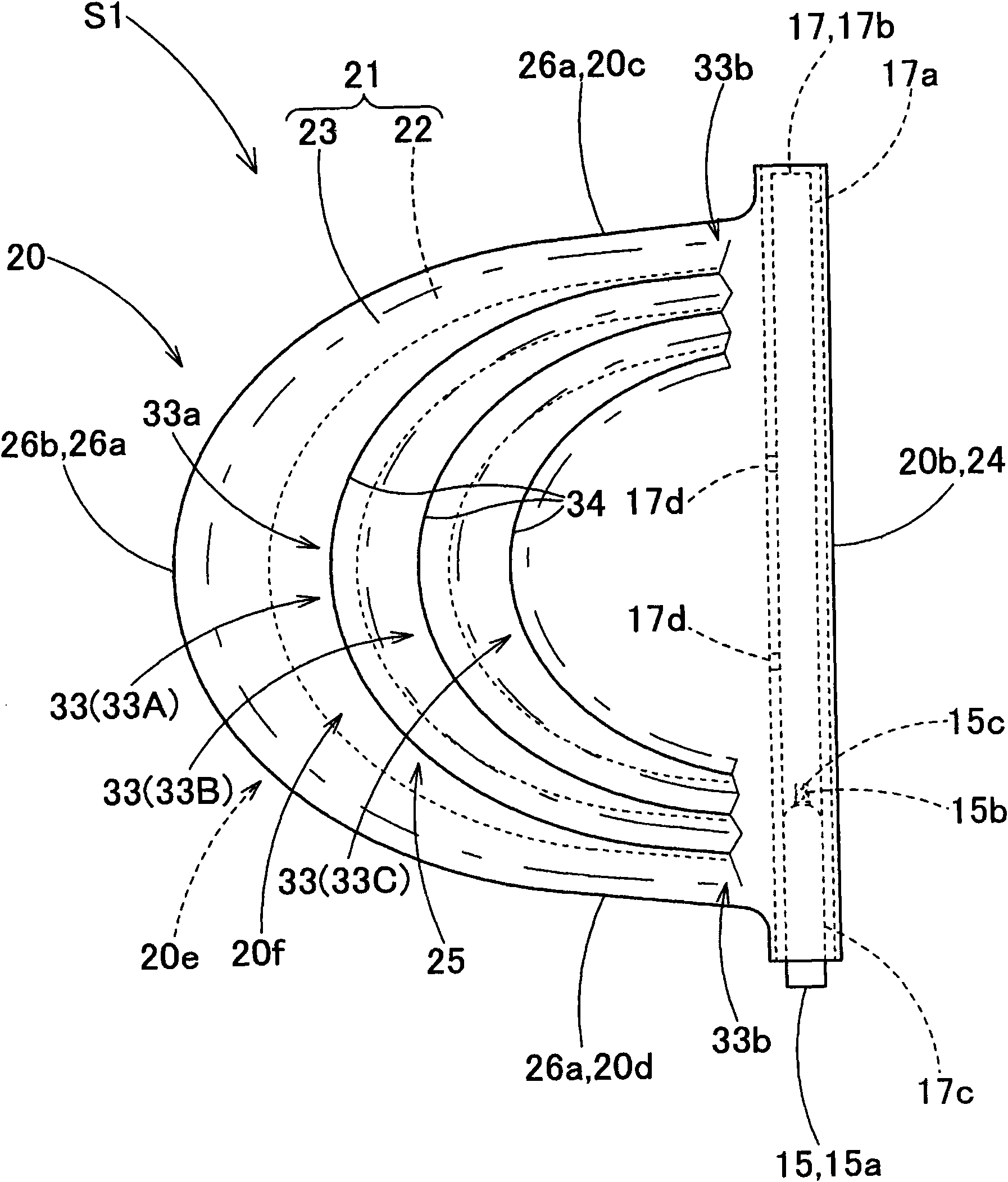

Resin airbag

InactiveCN102029969AIncrease width sizeIncrease thickness dimensionPedestrian/occupant safety arrangementCurve shapeEngineering

The invention provides a resin airbag and the circumferential wall of the airbag is made of sheet-shaped synthetic resin.When inflation gas flows into the airbag, the upper wall portion and the lower wall portion of the airbag expand in a separation mode.The three sides surrounded the expansion area are surrounded with outer peripheries.The upper and lower wall portions are connected with each other in a semi-circular arc shape by the section of the airbag along the thickness direction.A continuous curve shape expanding outwardly is formed when viewed downwardly.In the expansion area, foldingportions are concentrically configured toward the inner side thereof, which are in a curve shape surrounding the outer peripheries in three sides and expanding toward the outer peripheries.Each folding portion is in a V shape with two inclined parts along the section of the airbag in the thickness direction.The two inclined parts extend from the bottom of a recess.When inflation gas flows into the airbag, the width of the opening is enlarged due to the plastic deformation of the folding portions, so that the air bag expands.The wall thickness is set within a predetermined range, so that the turning of the wall toward the outer surface thereof is avoided.

Owner:TOYODA GOSEI CO LTD

Tag tape and tag label tape with print

ActiveUS20070169880A1Inhibition formationIncrease thickness dimensionDecorative surface effectsRecord carriers used with machinesEngineeringLoop antenna

A base tape includes: a plurality of RFID circuit elements each including an IC circuit part for storing information and a loop antenna connected to the IC circuit part; and an adhesive layer, a base film, an adhesive layer, an adhesive layer, and a separation sheet that are arranged so as to sandwich each of the RFID circuit elements from both sides in the thickness direction. The base tape is formed such that the ratio c of the sum of the thickness dimensions of the adhesive layer, base film, adhesive layer, adhesive layer, and separation sheet to the thickness dimension of the RFID circuit element is 0.8≦c≦9.8.

Owner:BROTHER KOGYO KK

Method and device for integrating kitchen range on cabinet table top

PendingCN113558400AIncrease thickness dimensionEliminate installation gapsDomestic stoves or rangesLighting and heating apparatusKitchen utensilsCupboard

The invention provides a method and device for integrating a kitchen range on a cabinet table top and relates to the technical field related to kitchen utensils. According to the technology, the height of a furnace end and a switch device of the kitchen range is increased by thickness of the cabinet table top, and the position, where the kitchen range is installed, of the cabinet table top, a furnace end hole is formed in the cabinet table top corresponding to the size, the shape and the position of the furnace end, a switch hole is formed in the cabinet table top corresponding to the size, the shape and the position of the switch device, the kitchen range is arranged below the cabinet table top, a furnace end can extend out of the furnace end hole, the switch device extends out of the switch hole, the furnace end and the switch device are fixed on the cabinet table top, so a kitchen range panel is integrated on the cabinet table top, the cabinet table top and the kitchen range panel are combined into one, an installation gap between the kitchen range panel and the cabinet table top is eliminated, cleaning is facilitated, and production and installation cost is low, and maintenance, disassembly and assembly are simple.

Owner:张军

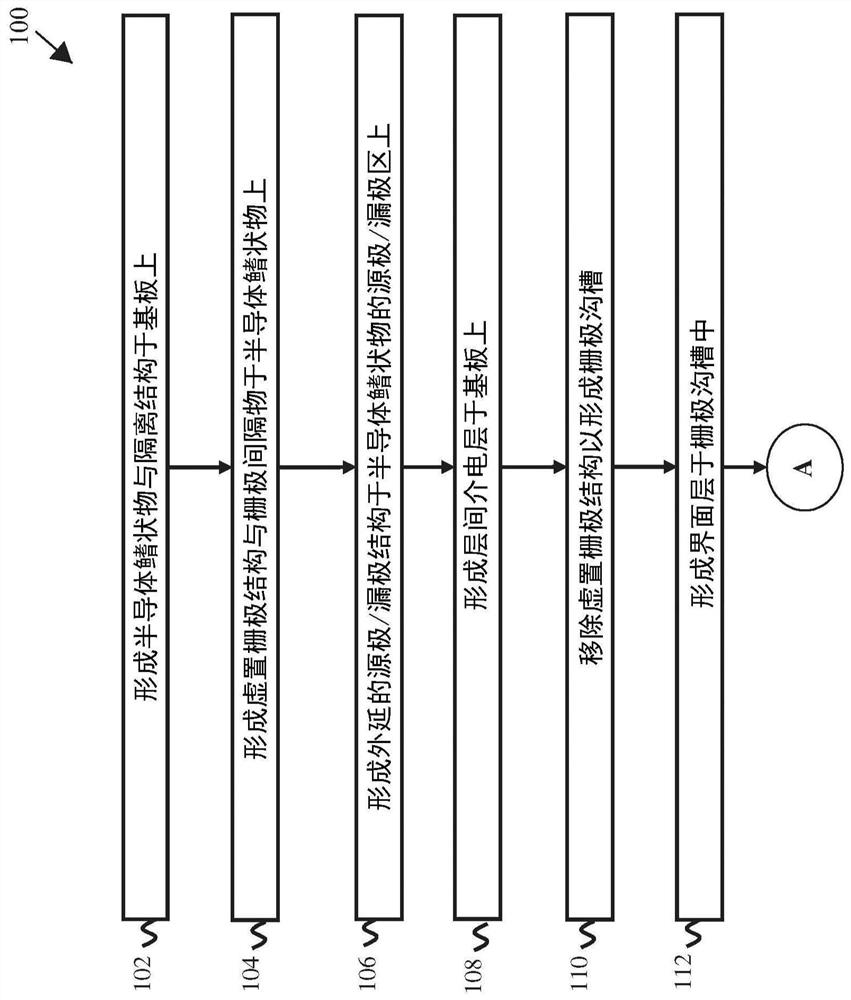

Method for forming semiconductor device

PendingCN114038802AReduce thicknessIncrease thickness dimensionSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialSemiconductor

A method of forming a semiconductor device is disclosed. An exemplary semiconductor device includes a first semiconductor stack and a second semiconductor stack on a substrate, where each of the first semiconductor stack and the second semiconductor stack includes semiconductor layers stacked upward and separated from each other, a dummy spacer between the first semiconductor stack and the second semiconductor stack, wherein the dummy spacer contacts a first sidewall of each semiconductor layer of the first semiconductor stack and the second semiconductor stack, and a gate structure wraps the second side wall, the upper surface and the lower surface of each semiconductor layer of the first semiconductor stack and the second semiconductor stack.

Owner:TAIWAN SEMICON MFG CO LTD

Display device manufacturing device and display device manufacturing method

ActiveCN104062779BIncrease thickness dimensionHigh precisionNon-linear opticsIdentification meansDisplay deviceEngineering

According to one embodiment, an apparatus for manufacturing a display device, includes: a first holding section configured to hold a first substrate; a second holding section configured to hold a second substrate; a turning section configured to turn the first holding section such that the first substrate and the second substrate face each other; a support section configured to support the first holding section after the turning; an adjustment section; and an elevation section. The adjustment section is provided at an upper end of the support section and is configured to adjust a distance between the first holding section after the turning and the upper end of the support section. The elevation section is configured to elevate the second holding section and attach the first substrate and the second substrate via an adhesive layer.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com