Mono dimension X-ray composite lens

A combination of lens and X-ray technology, which is applied in the fields of lens, radiation/particle processing, optics, etc., can solve the problem of unsatisfactory focusing performance of the lens, and achieve the effect of increased thickness size, small material limitation, and improved X-ray efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

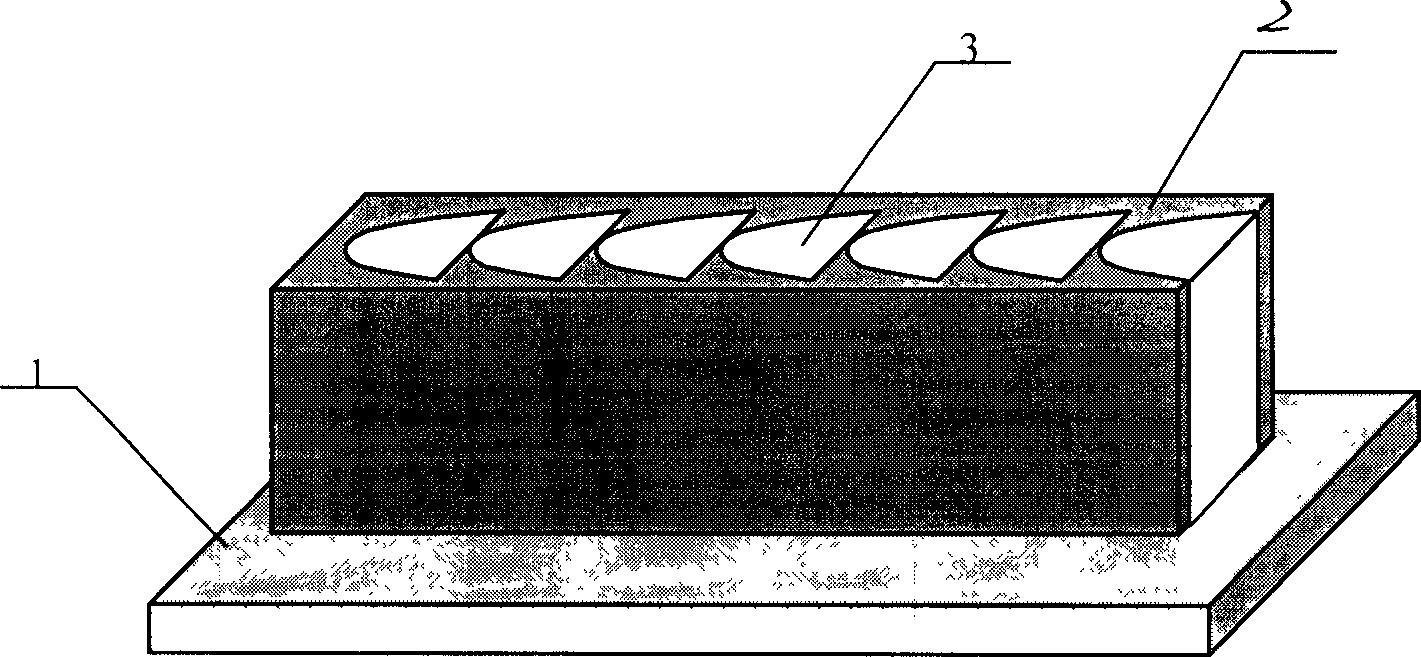

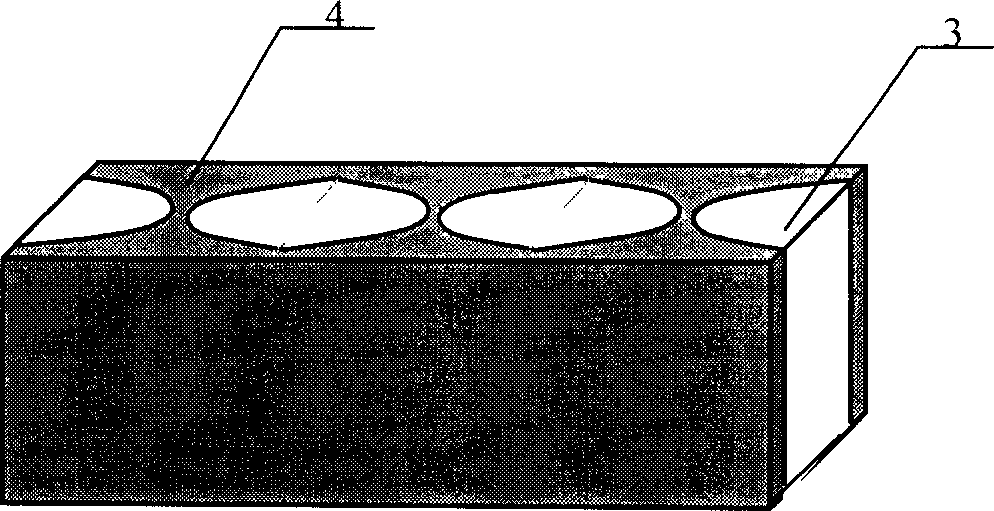

[0016] Such as figure 1 As shown, the one-dimensional X-ray combined lens includes a lens body 2 and a substrate 1 located below the lens body. The lens body is provided with a plurality of through-hole air gap units 3 of the same shape arranged in a straight line sequence. The cross-sectional shape of the air gap unit is an ellipse, and the major axes of the ellipse corresponding to the air gap unit are located on the same straight line. The lens main body is made of aluminum, and the lens base is made of organic glass. The thickness of the lens is 600 microns.

Embodiment 2

[0018] The one-dimensional X-ray composite lens comprises a lens body 2 and a substrate 1 located below the lens body. The lens body is provided with a plurality of through-hole-shaped air gap units 3 of the same shape arranged in a straight line sequence. The air The cross-sectional shape of the gap unit is an ellipse, and the major axes of the ellipse corresponding to the air gap unit are located on the same straight line. The lens main body is made of alumina material, and the lens substrate is made of glass material. The lens has a thickness of 1000 micrometers.

Embodiment 3

[0020] The one-dimensional X-ray composite lens comprises a lens body 2 and a substrate 1 located below the lens body. The lens body is provided with a plurality of through-hole-shaped air gap units 3 of the same shape arranged in a straight line sequence. The air The cross-sectional shape of the gap unit is an ellipse, and the major axes of the ellipse corresponding to the air gap unit are located on the same straight line. The lens main body is made of aluminum material, and the lens base is made of glass material. The thickness of the lens is 1500 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com