Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

516results about How to "Enlarge region" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

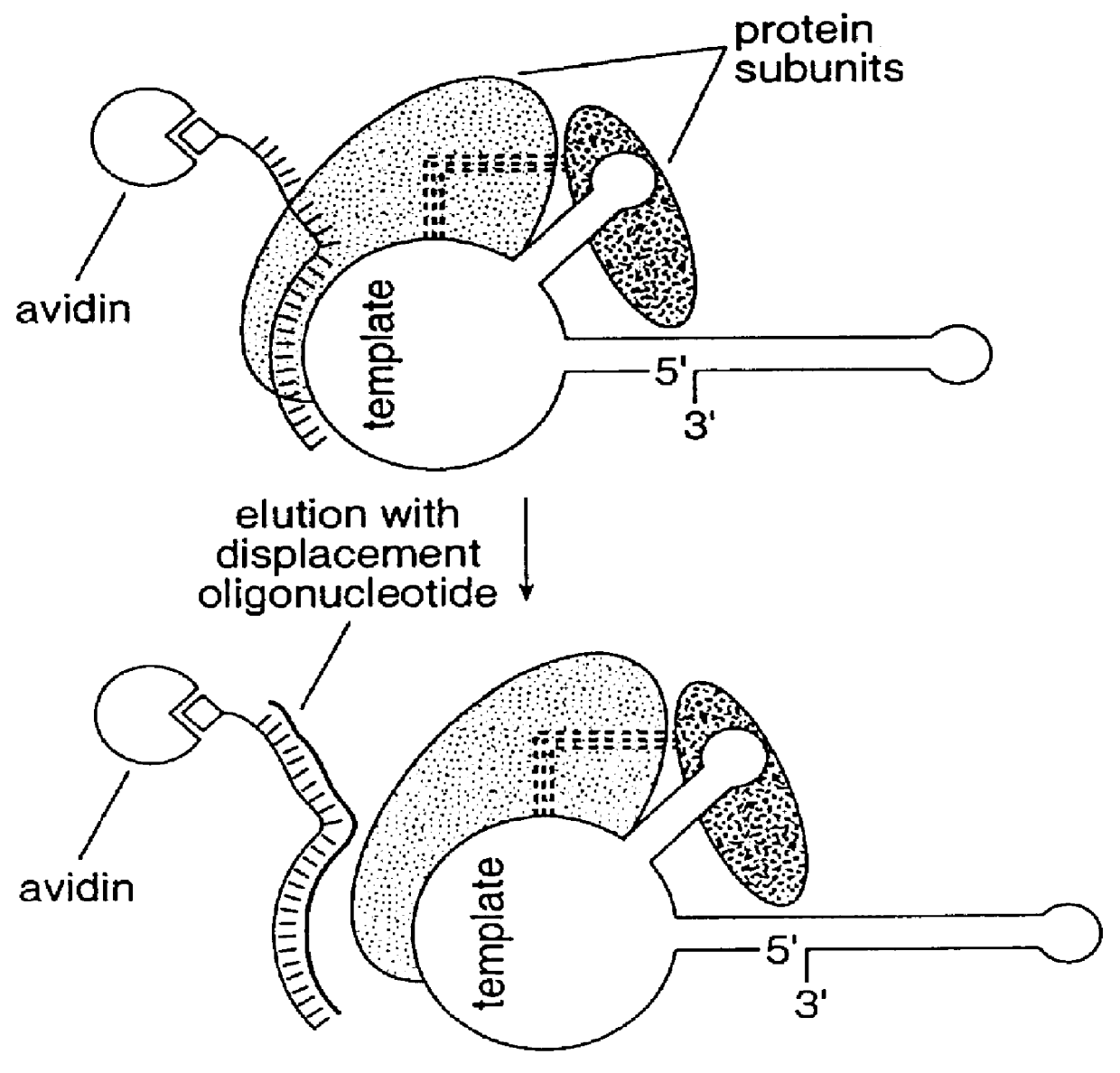

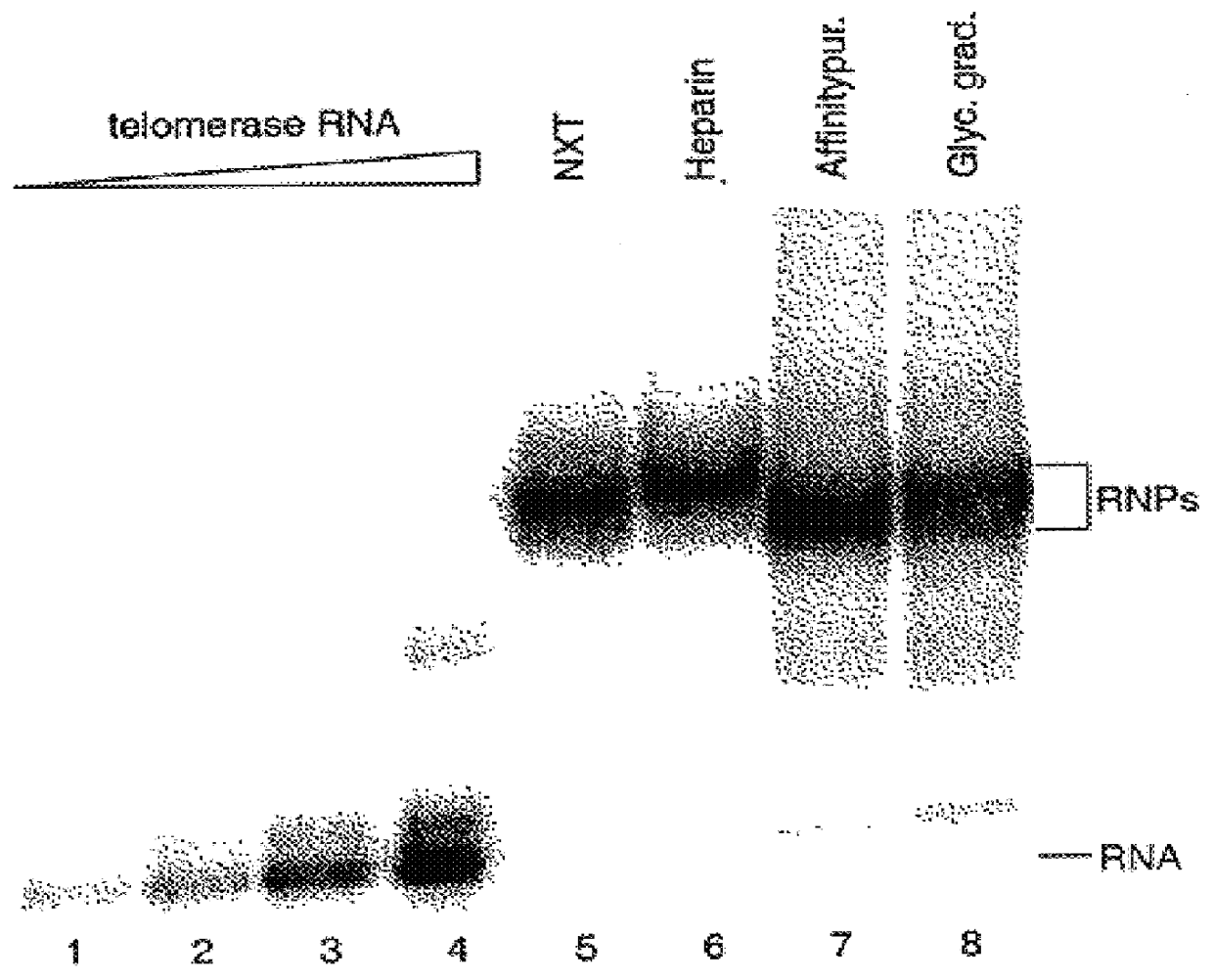

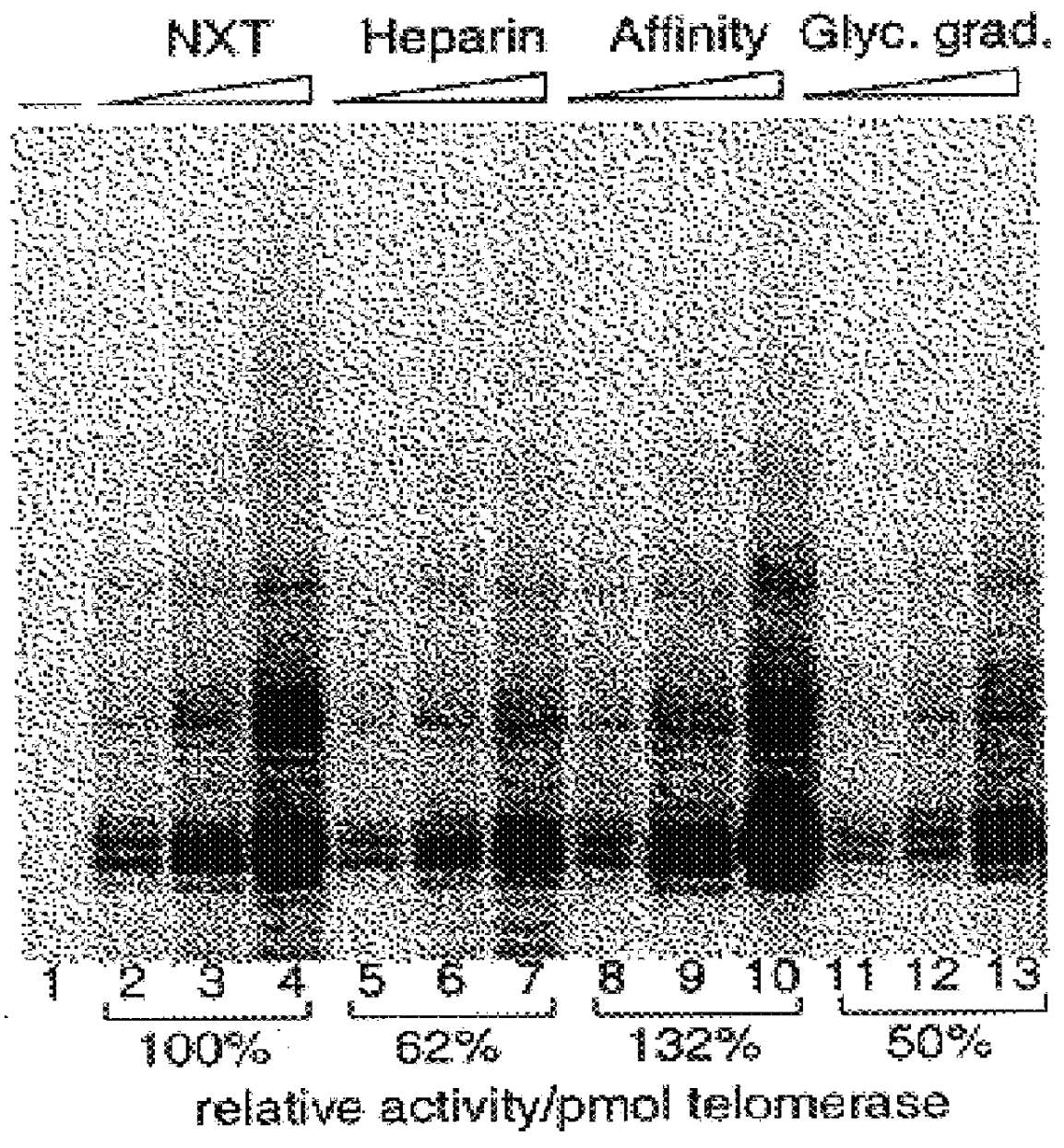

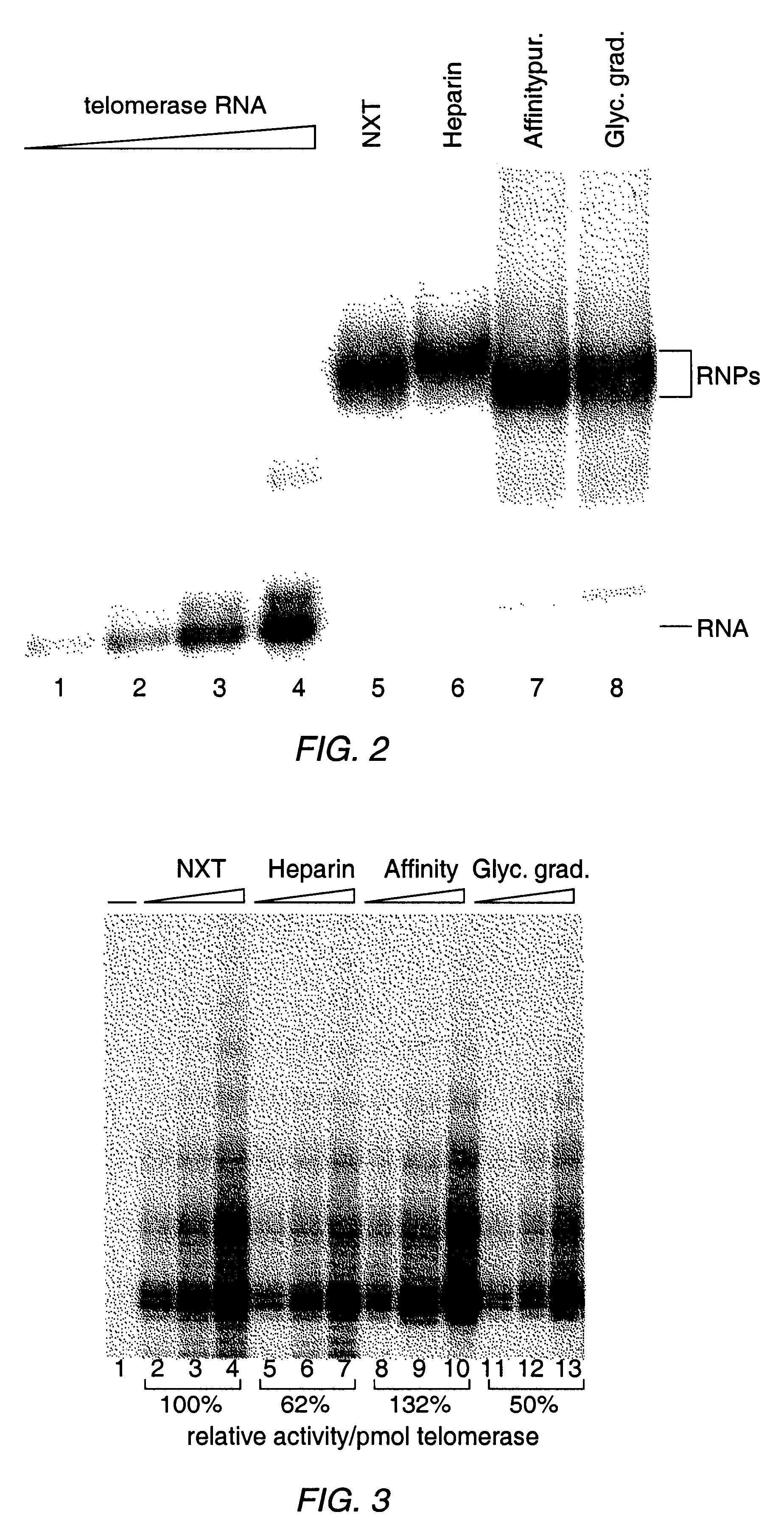

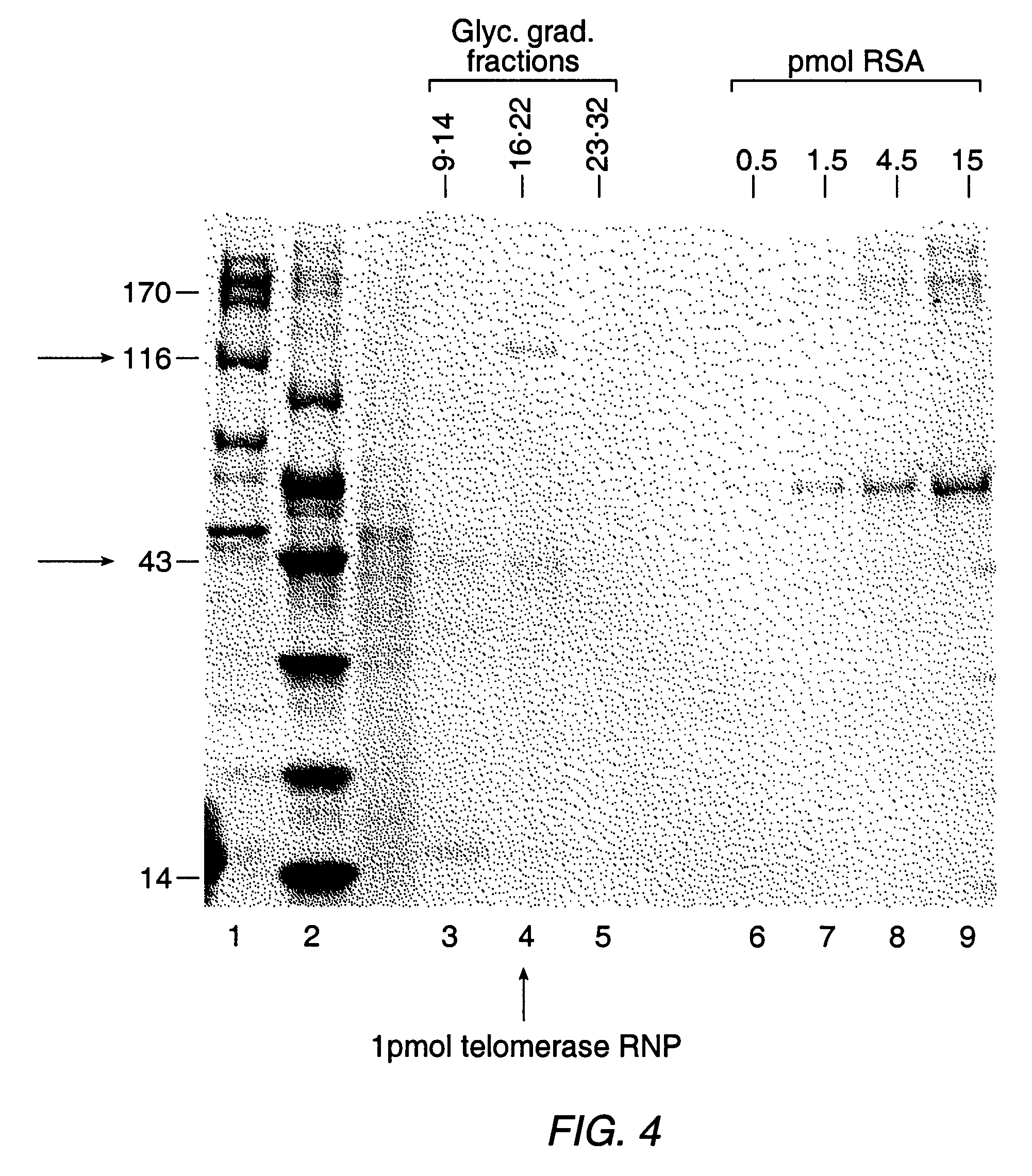

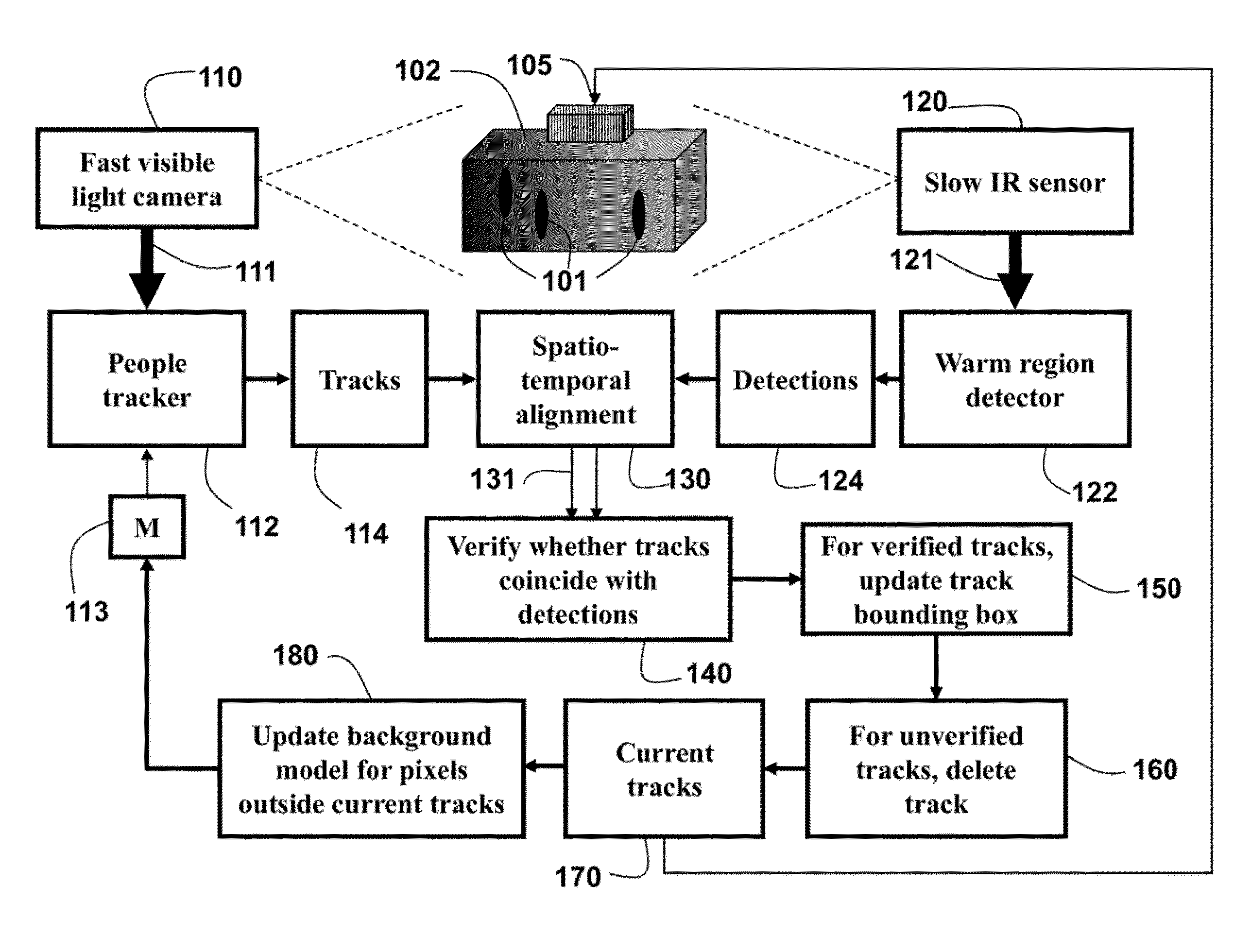

Telomerase

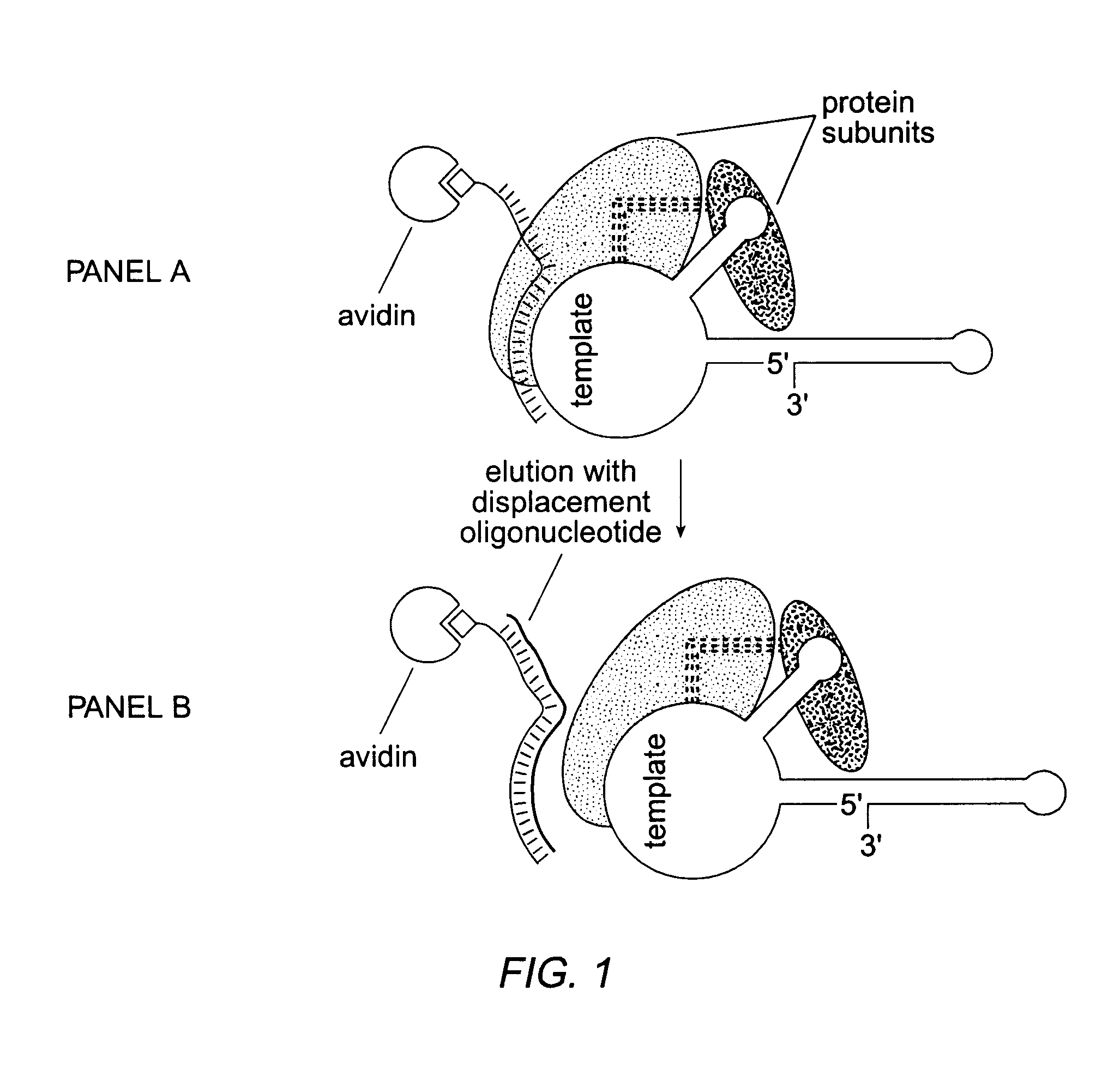

InactiveUS6261836B1Improve purification effectAvoid the needPeptide/protein ingredientsAntibody mimetics/scaffoldsTelomeraseRibonucleoprotein complex

The present invention is directed to telomerase nucleic acids and amino acids. In particular, the present invention is directed to nucleic acid and amino acid sequences encoding various telomerase protein subunits and motifs, including the 123 kDa and 43 kDa telomerase protein subunits of Euplotes aediculatus, and related sequences from Schizosaccharomyces, Saccharomyces sequences, and human telomerase. The present invention is also directed to polypeptides comprising these telomerase protein subunits, as well as functional polypeptides and ribonucleoproteins that contain these subunits.

Owner:GERON CORPORATION +1

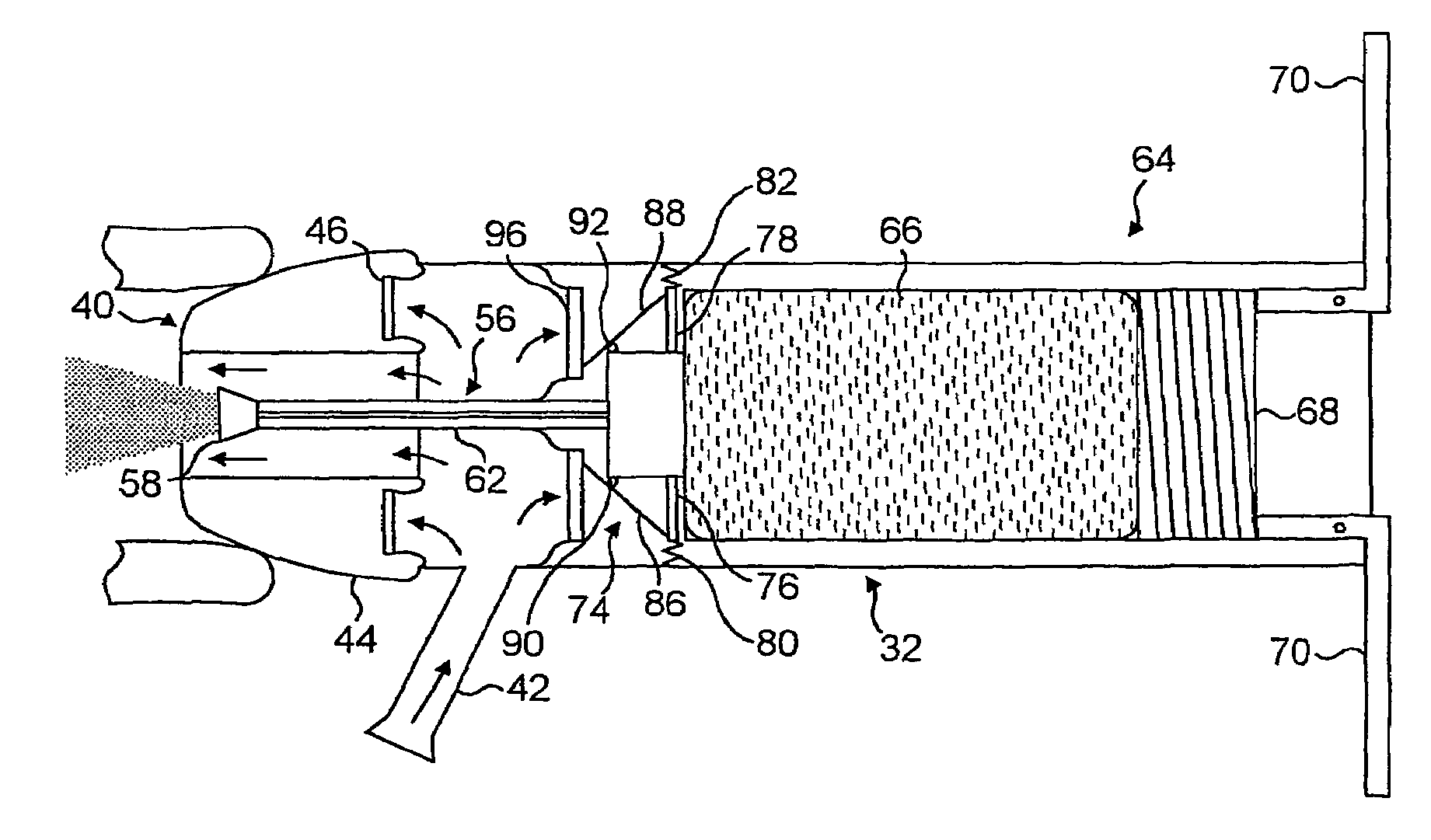

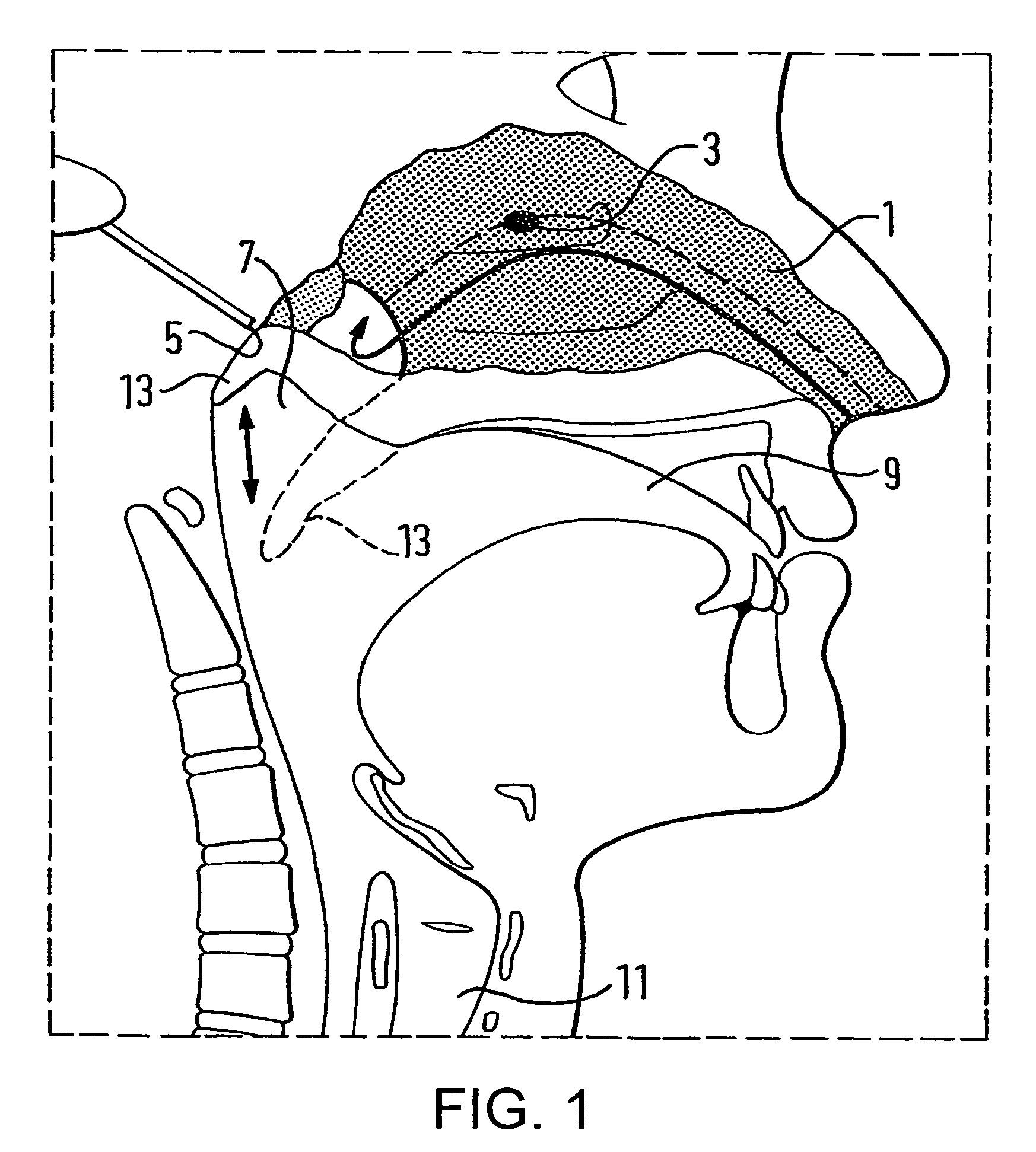

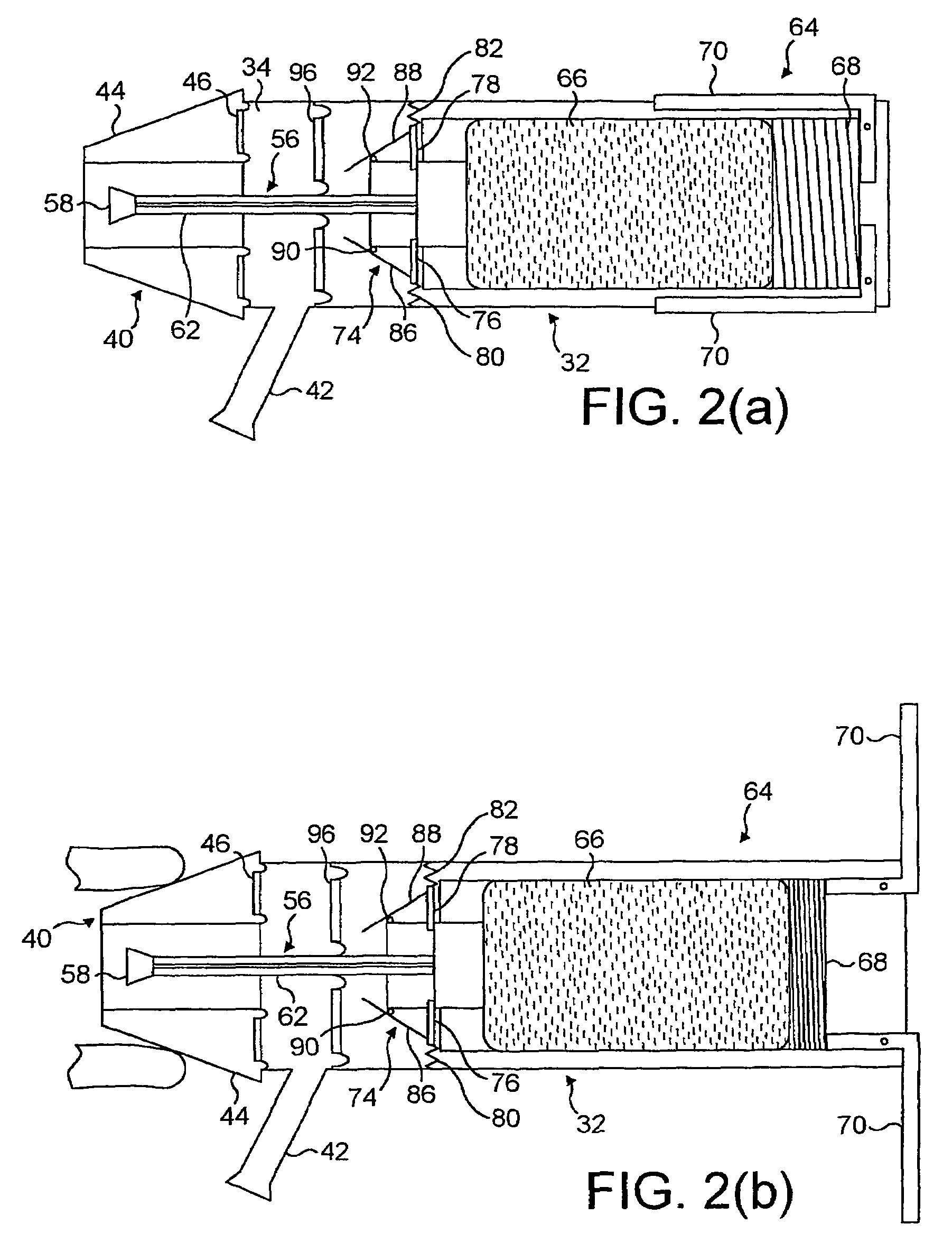

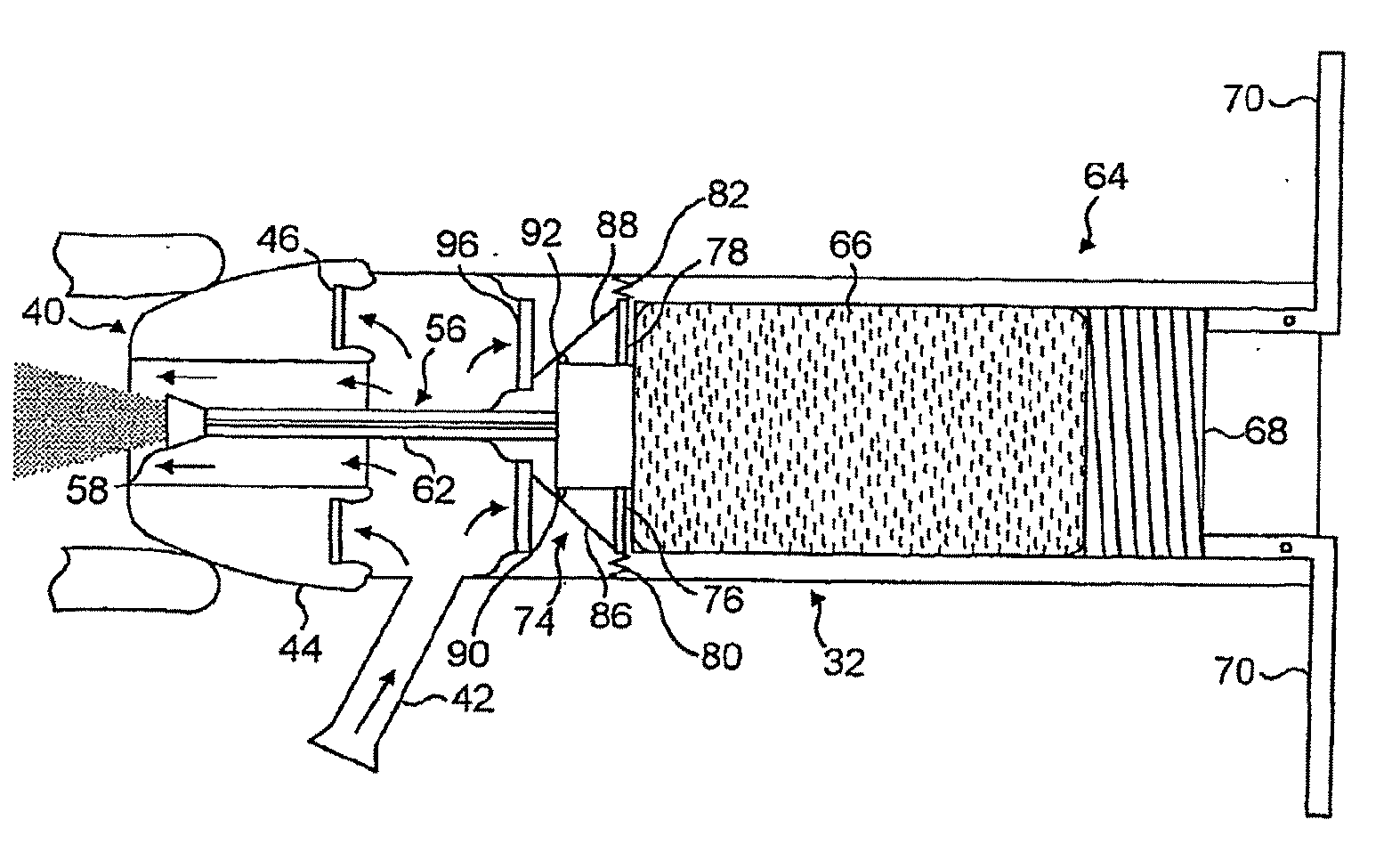

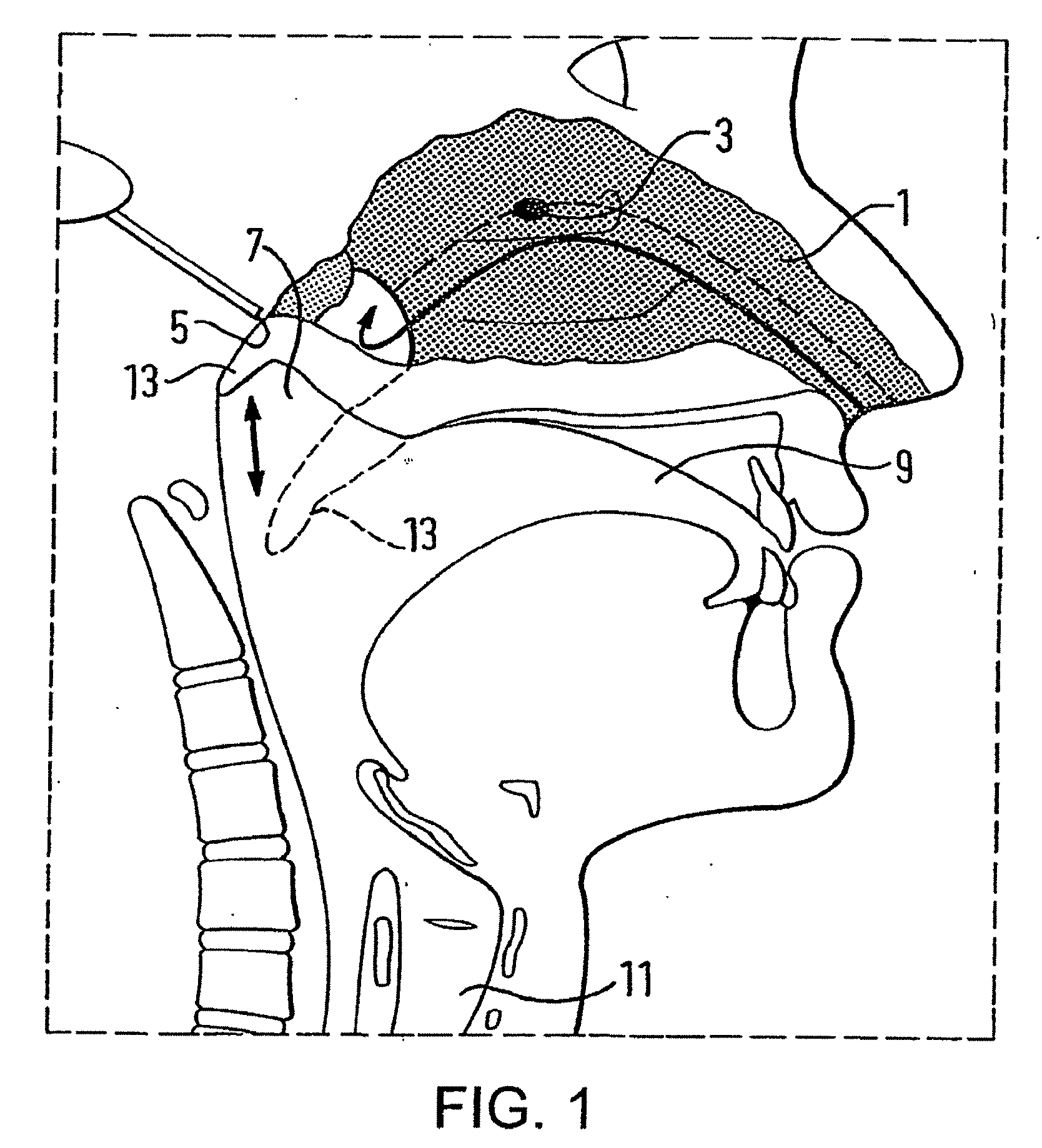

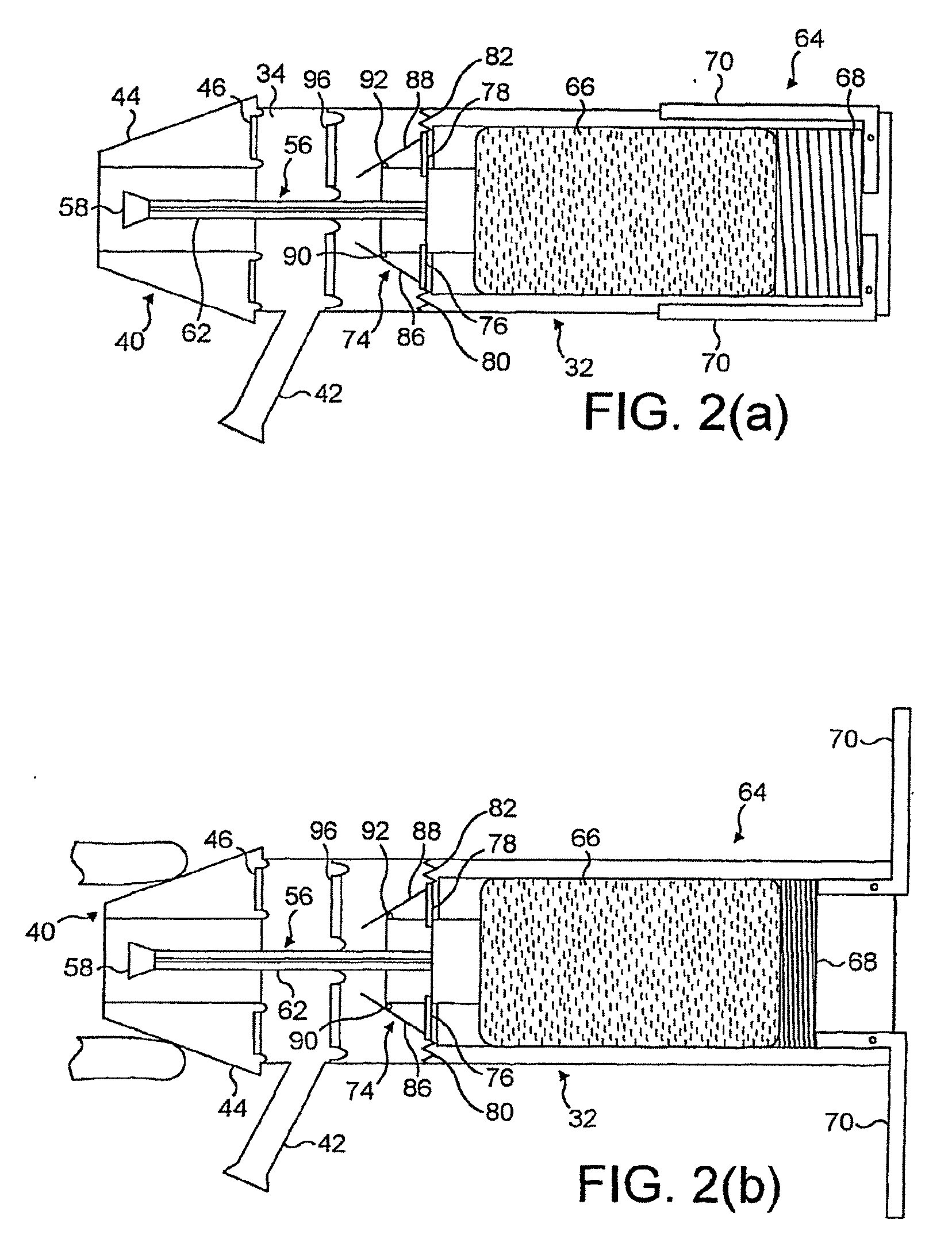

Nasal delivery devices

InactiveUS7347201B2Small particle sizeAvoid inhalationRespiratorsLiquid surface applicatorsNostrilNasal cavity

An exhalation breath-actuated nasal delivery device for and a method of delivering a substance to a nasal cavity of a subject, the delivery device comprising: a nosepiece (40) for fitting to a nostril of a subject; a mouthpiece (42) through which the subject in use exhales; and delivery unit (64), as one of a mechanical delivery pump (66) or a nebulizer (115), for delivering a substance to the nosepiece (40); and an actuation mechanism (74) for actuating the delivery unit in response to oral exhalation through the mouthpiece, and preferably when at least one or both of the pressure at or the flow rate through the nosepiece exceeds a predetermined threshold.

Owner:OPTINOSE INC

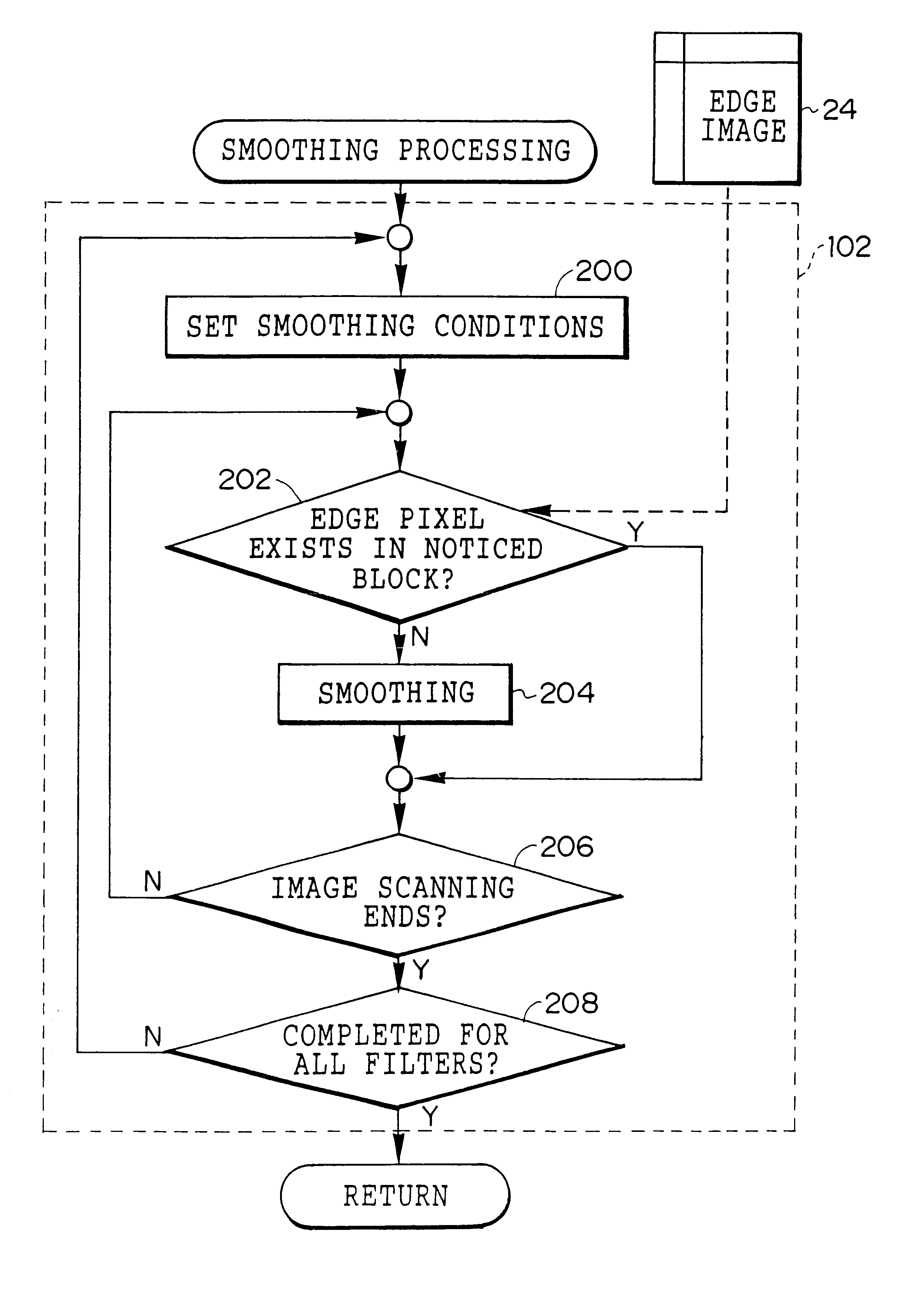

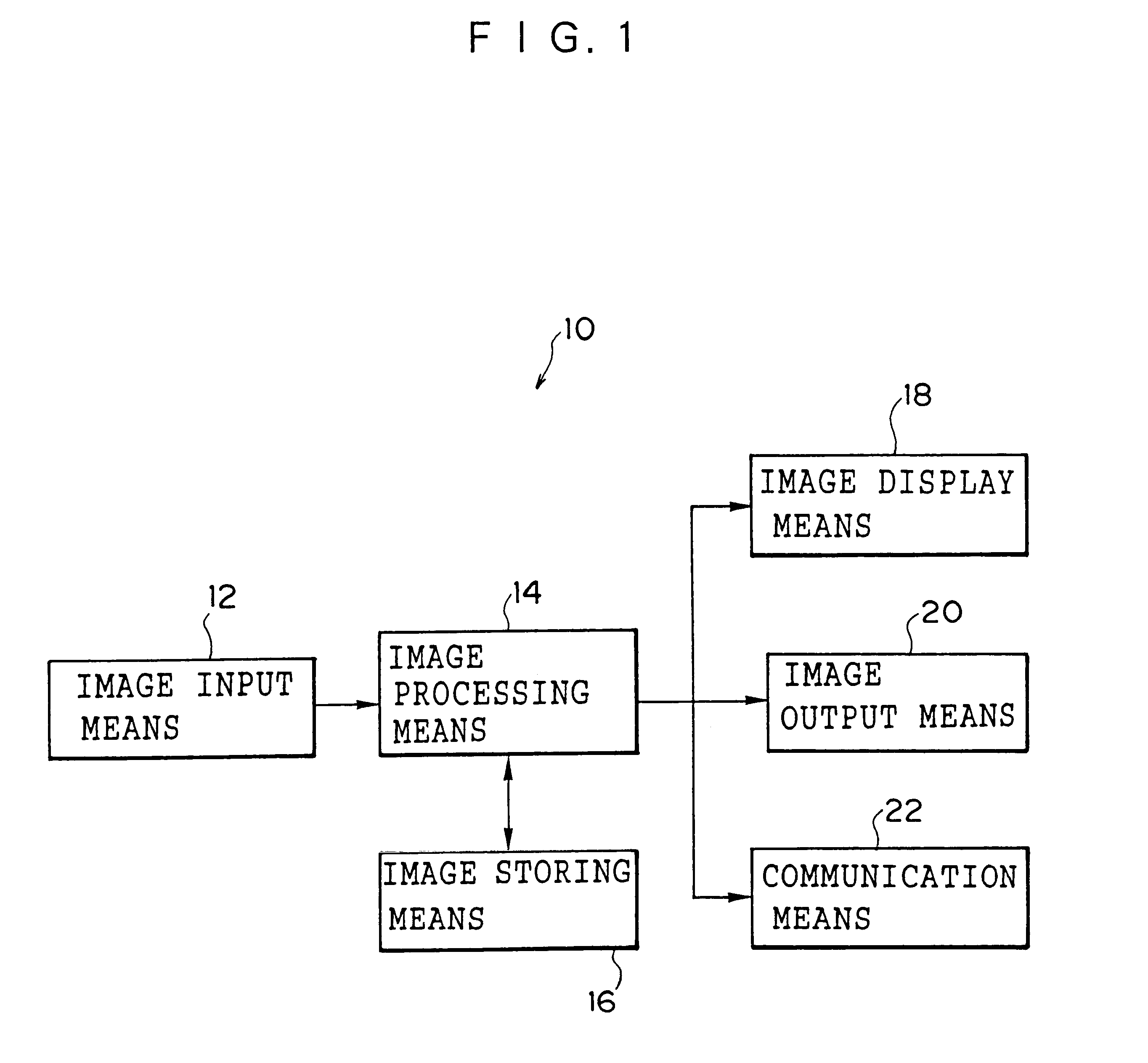

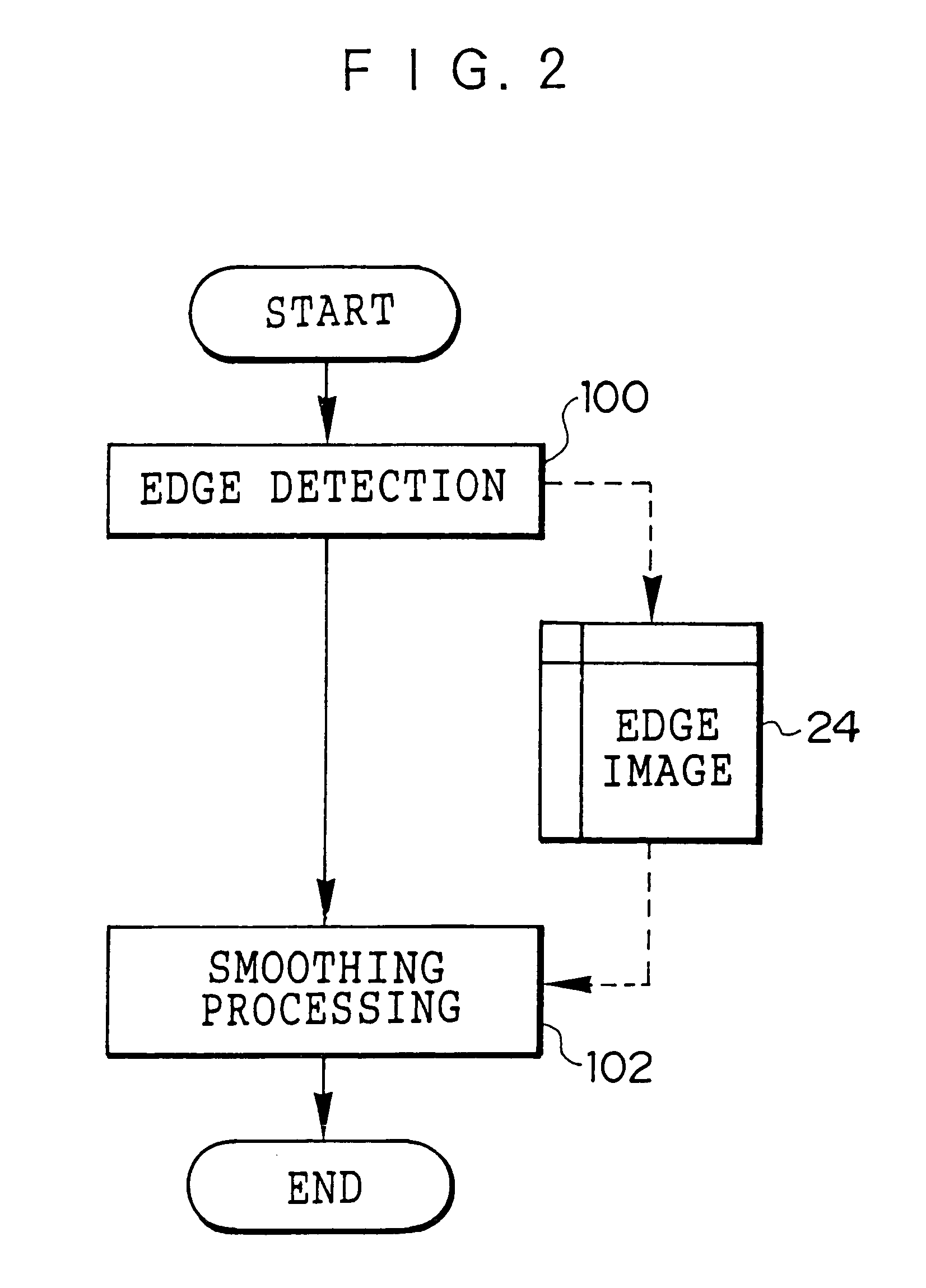

Image processing device and recording medium

InactiveUS6901170B1Low dispersionQuality imageImage enhancementImage analysisImaging processingRecording media

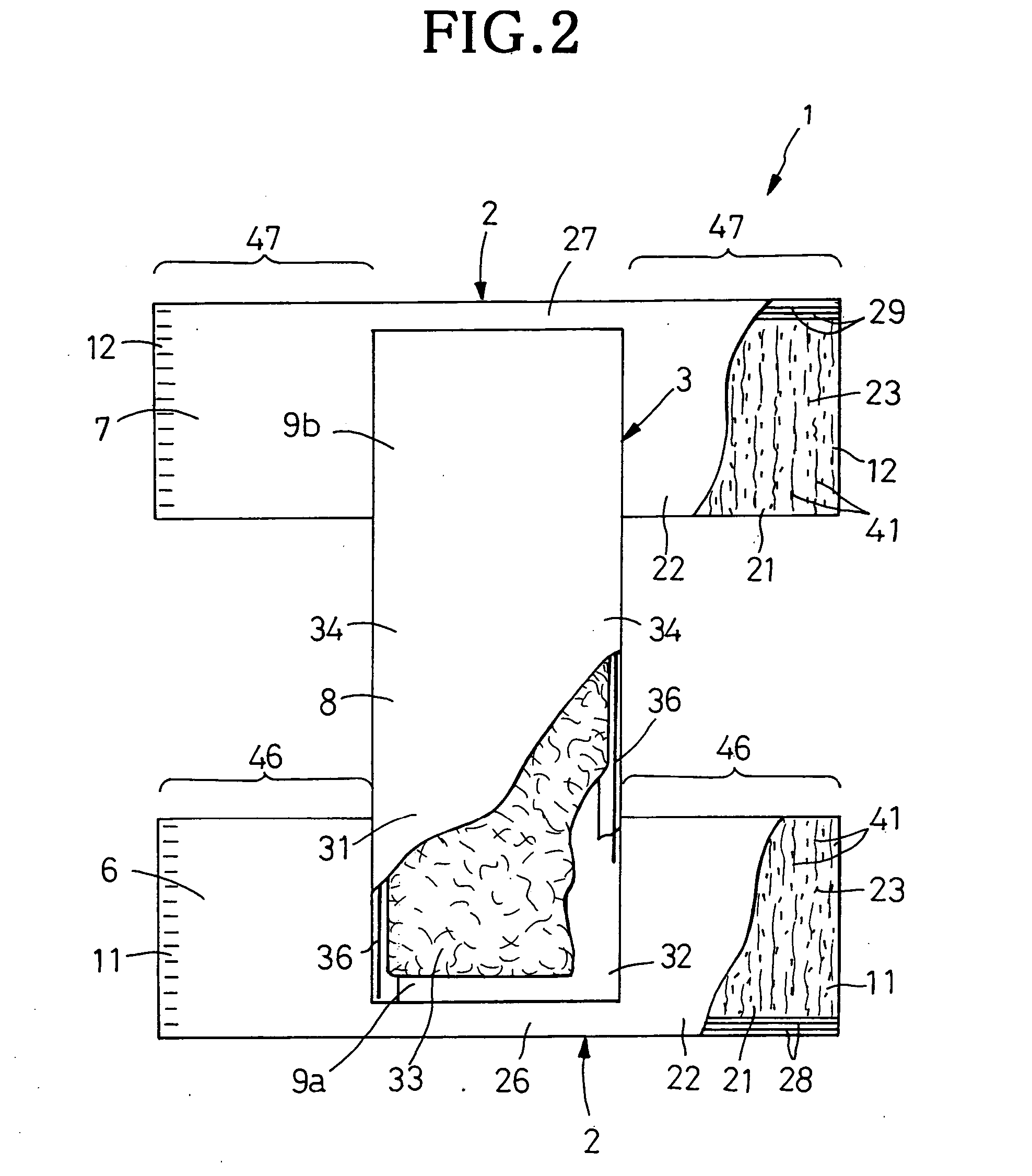

An image processing apparatus and a recording medium which can improve the quality of a color document image. Smoothing conditions which are defined by three parameters of “filter size”, “offset”, and “overlap” are set. An edge image which was generated in an edge detection processing is referred to, and a determination is made as to whether an edge pixel exists in a noticed region. When the edge pixel does not exist in the noticed region, a smoothing processing is carried out. When the edge pixel exists in the noticed region, it is determined inappropriate to effect the smoothing processing, and the process goes to a subsequent processing without effecting the smoothing processing. The processing is carried out until the image scanning ends. When the image scanning ends, the next smoothing conditions are set and the processing which is the same as the one described above is performed.

Owner:FUJIFILM BUSINESS INNOVATION CORP +1

Nasal Delivery Devices

InactiveUS20080223363A1Increase surface areaIncrease blood flowRespiratorsMedical devicesNostrilNasal cavity

Owner:OPTINOSE AS

Telomerase

InactiveUS6093809AImprove purification effectAvoid the needSugar derivativesPeptide/protein ingredientsTelomeraseRibonucleoprotein complex

The present invention is directed to novel telomerase nucleic acids and amino acids. In particular, the present invention is directed to nucleic acid and amino acid sequences encoding various telomerase protein subunits and motifs, including the 123 kDa and 43 kDa telomerase protein subunits of Euplotes aediculatus, and related sequences from Schizosaccharomyces, Saccharomyces sequences, and human telomerase. The present invention is also directed to polypeptides comprising these telomerase protein subunits, as well as functional polypeptides and ribonucleoproteins that contain these subunits.

Owner:GERON CORPORATION +1

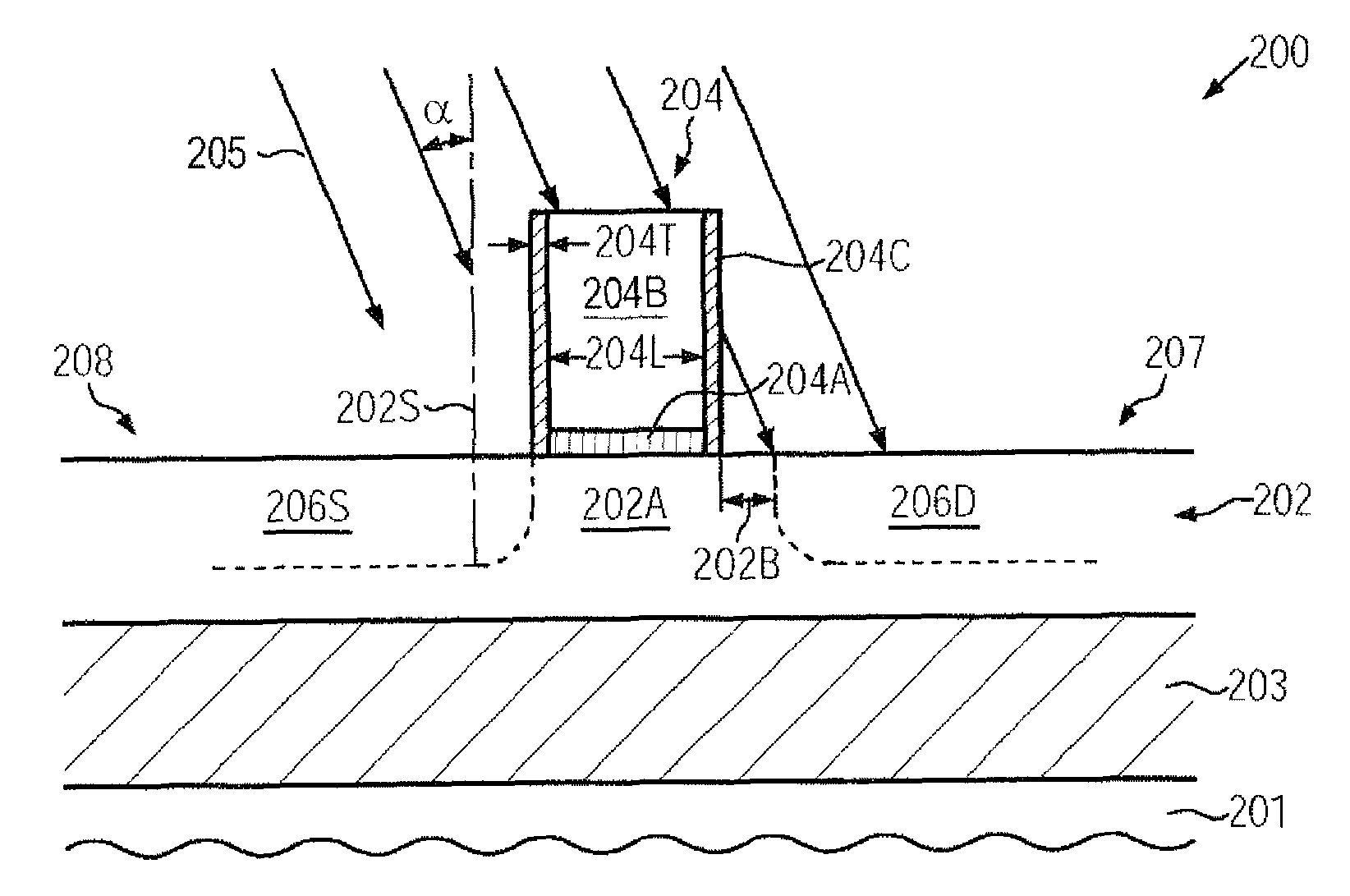

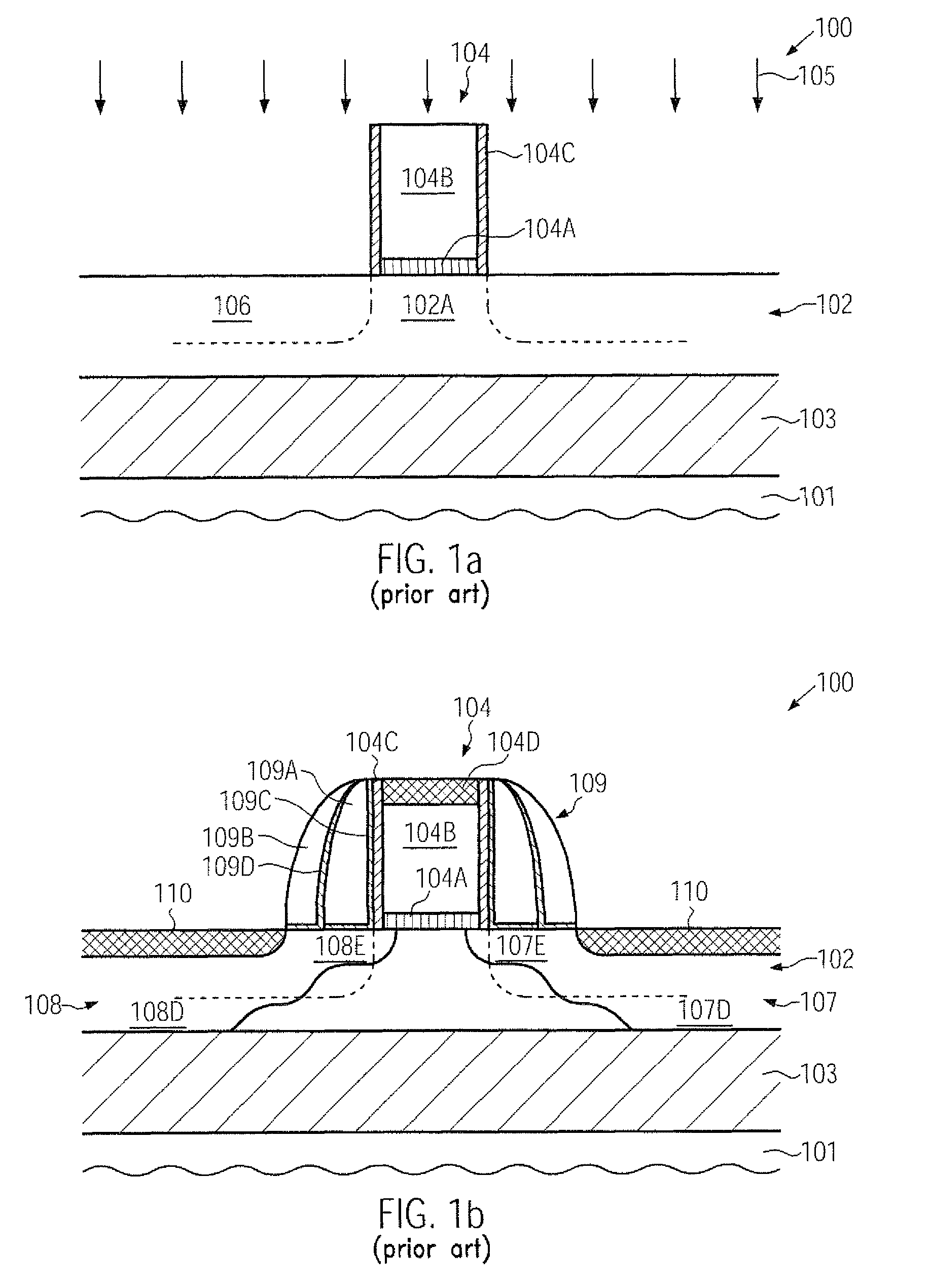

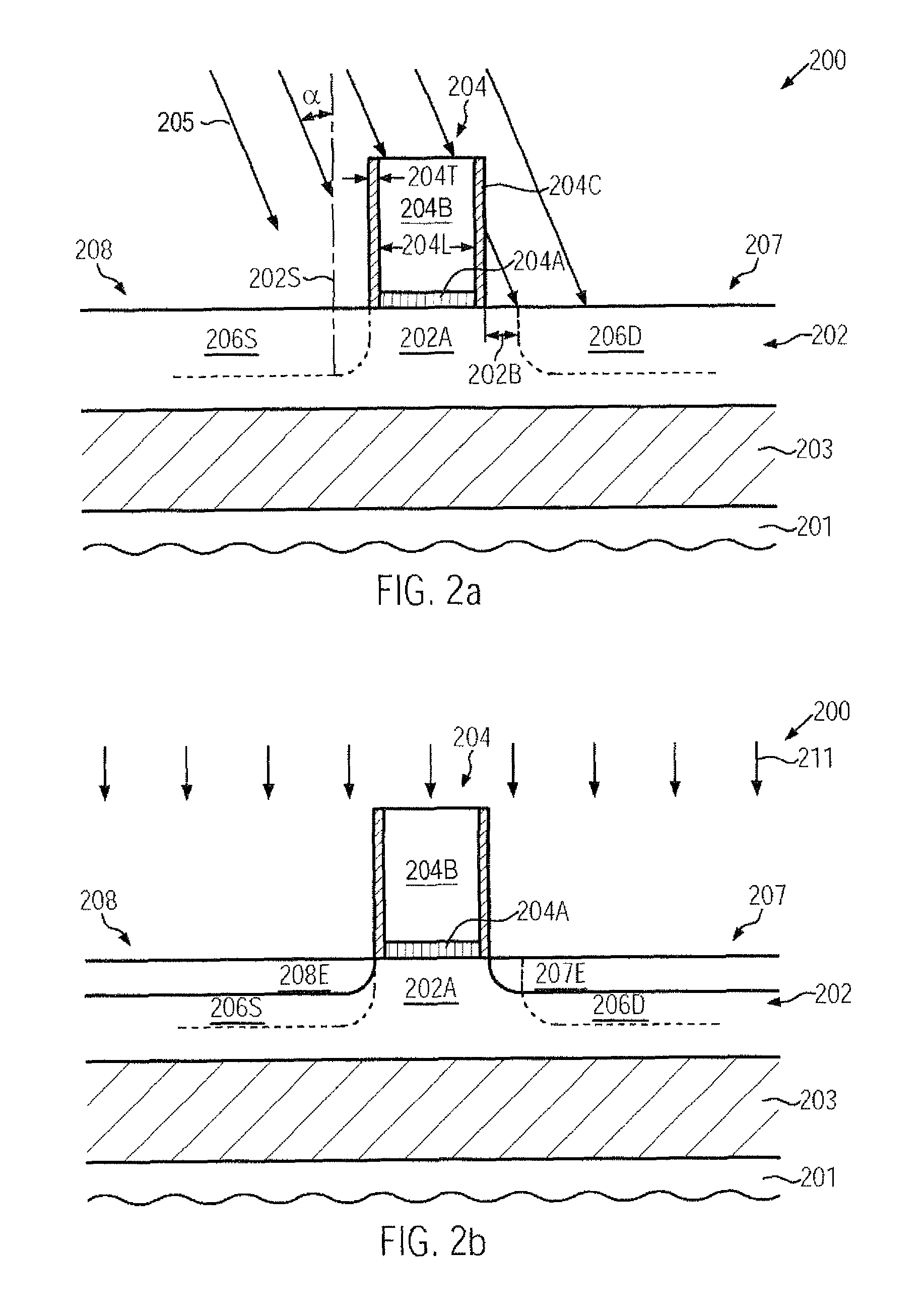

Drive current increase in transistors by asymmetric amorphization implantation

ActiveUS7855118B2Increased complexityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDriving currentNon symmetric

By providing a substantially non-damaged semiconductor region between a pre-amorphization region and the gate electrode structure, an increase of series resistance at the drain side during the re-crystallization may be reduced, thereby contributing to overall transistor performance, in particular in the linear operating mode. Thus, symmetric and asymmetric transistor architectures may be achieved with enhanced performance without unduly adding to overall process complexity.

Owner:ADVANCED MICRO DEVICES INC

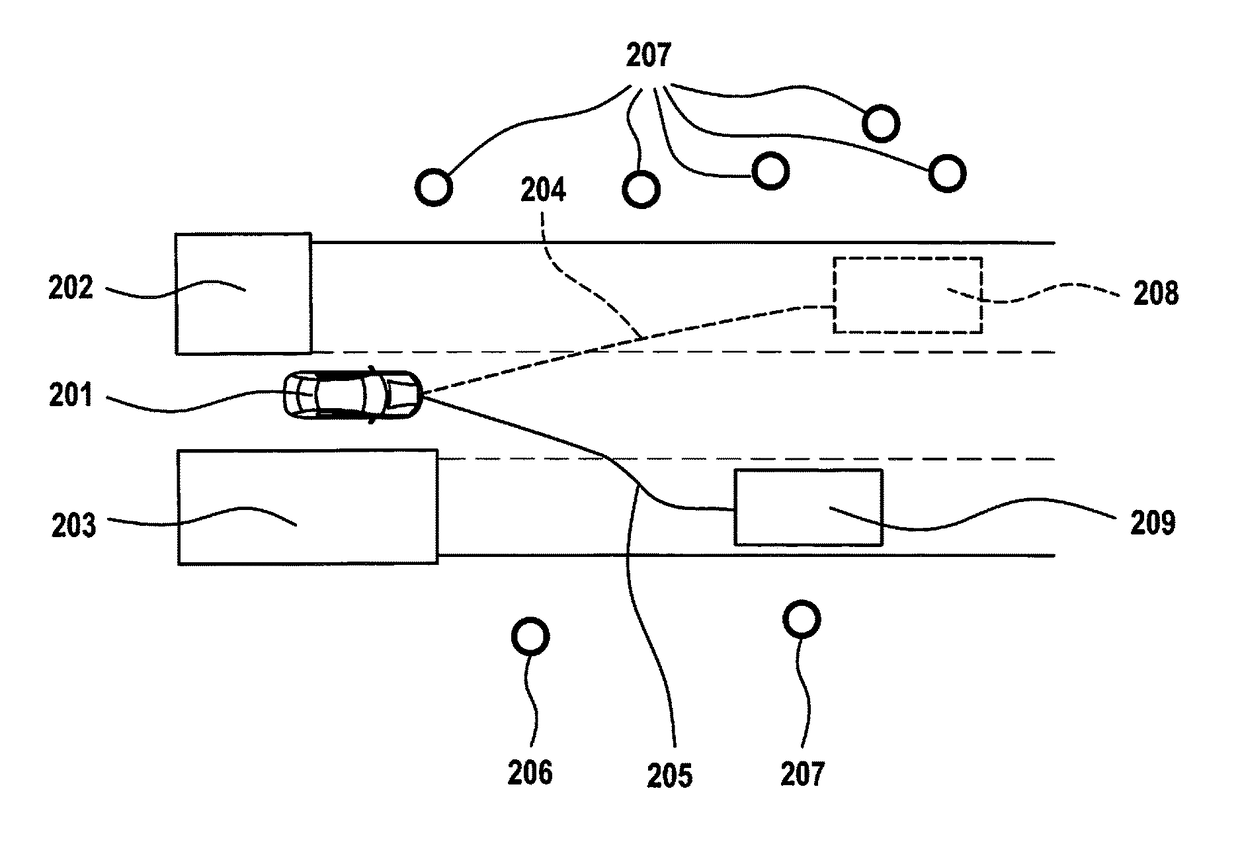

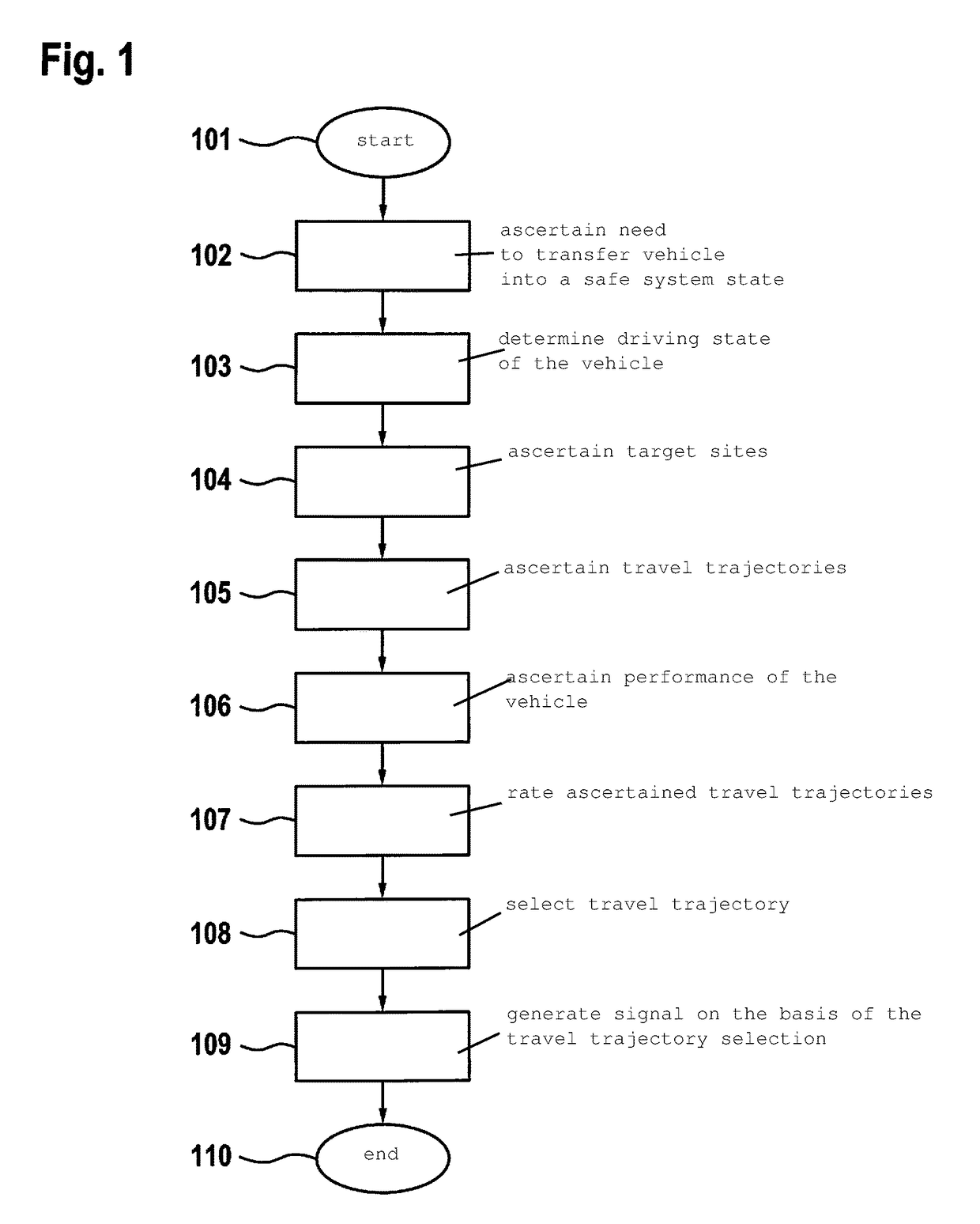

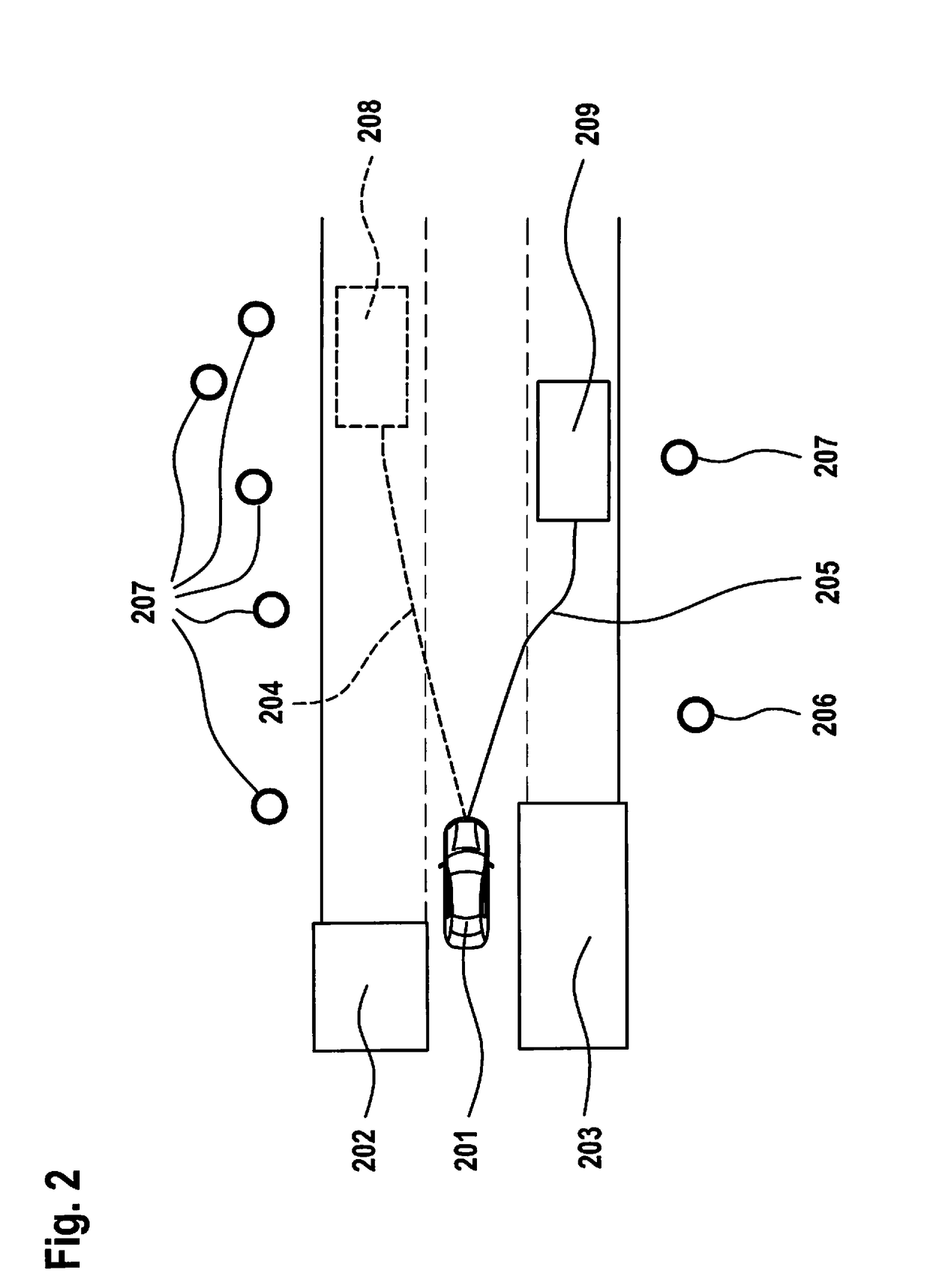

Method for selecting an optimized trajectory

ActiveUS20170108865A1Increase probabilityIncrease the number ofInstruments for road network navigationAutonomous decision making processReal-time computingAutomotive engineering

A method for generating a signal for transferring a partly or highly automated vehicle into a safe system state at a target site. First, a need to transfer the vehicle into a safe system state is ascertained. A vehicle state is then determined, the vehicle state encompassing the current vehicle position. At least one target site is ascertained. Travel trajectories are ascertained from the current vehicle position to the at least one target site. The travel trajectories are related. One of the travel trajectories is selected based on the rating that has been carried out. A signal is generated on the basis of the selected travel trajectory.

Owner:ROBERT BOSCH GMBH

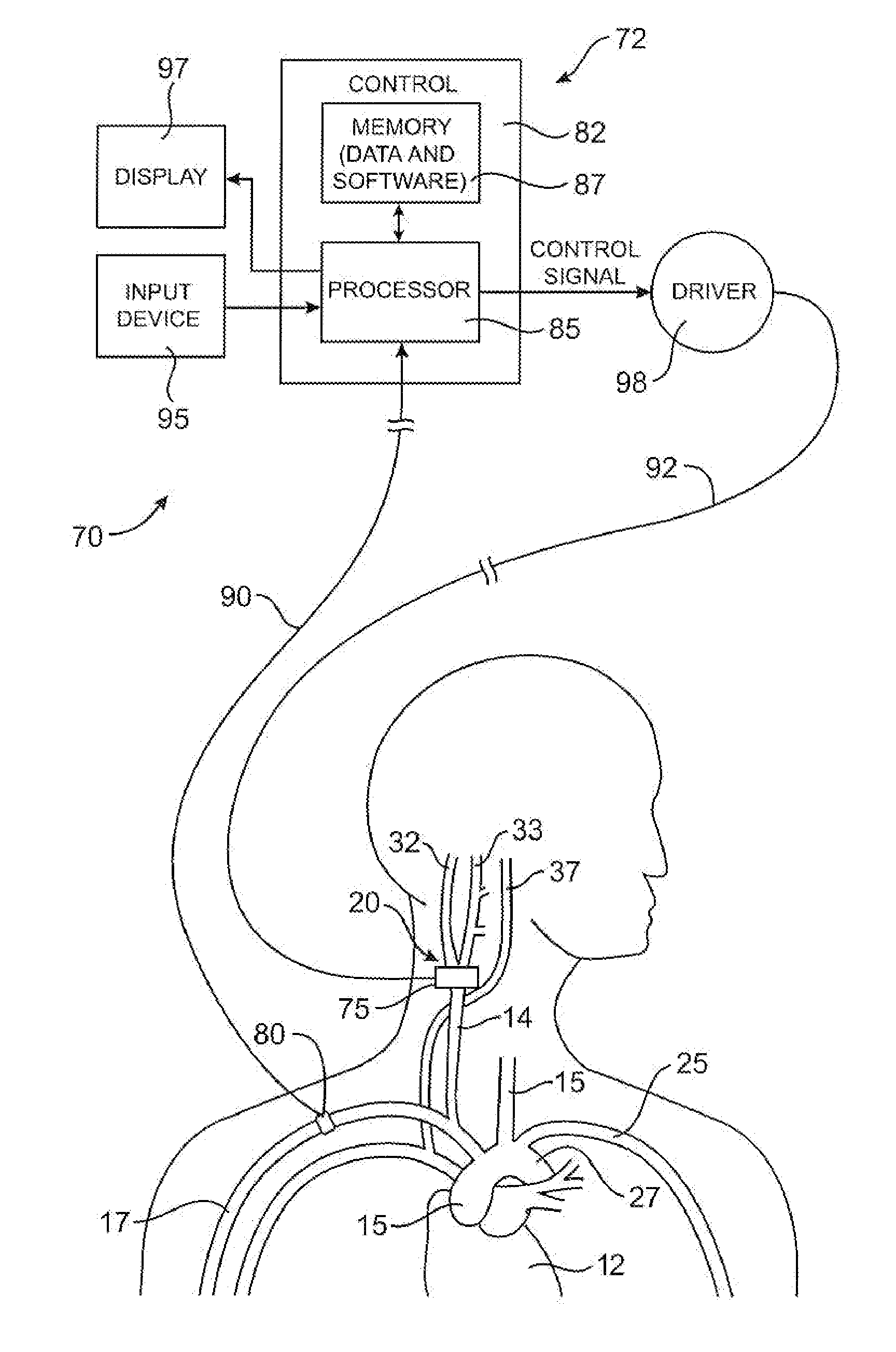

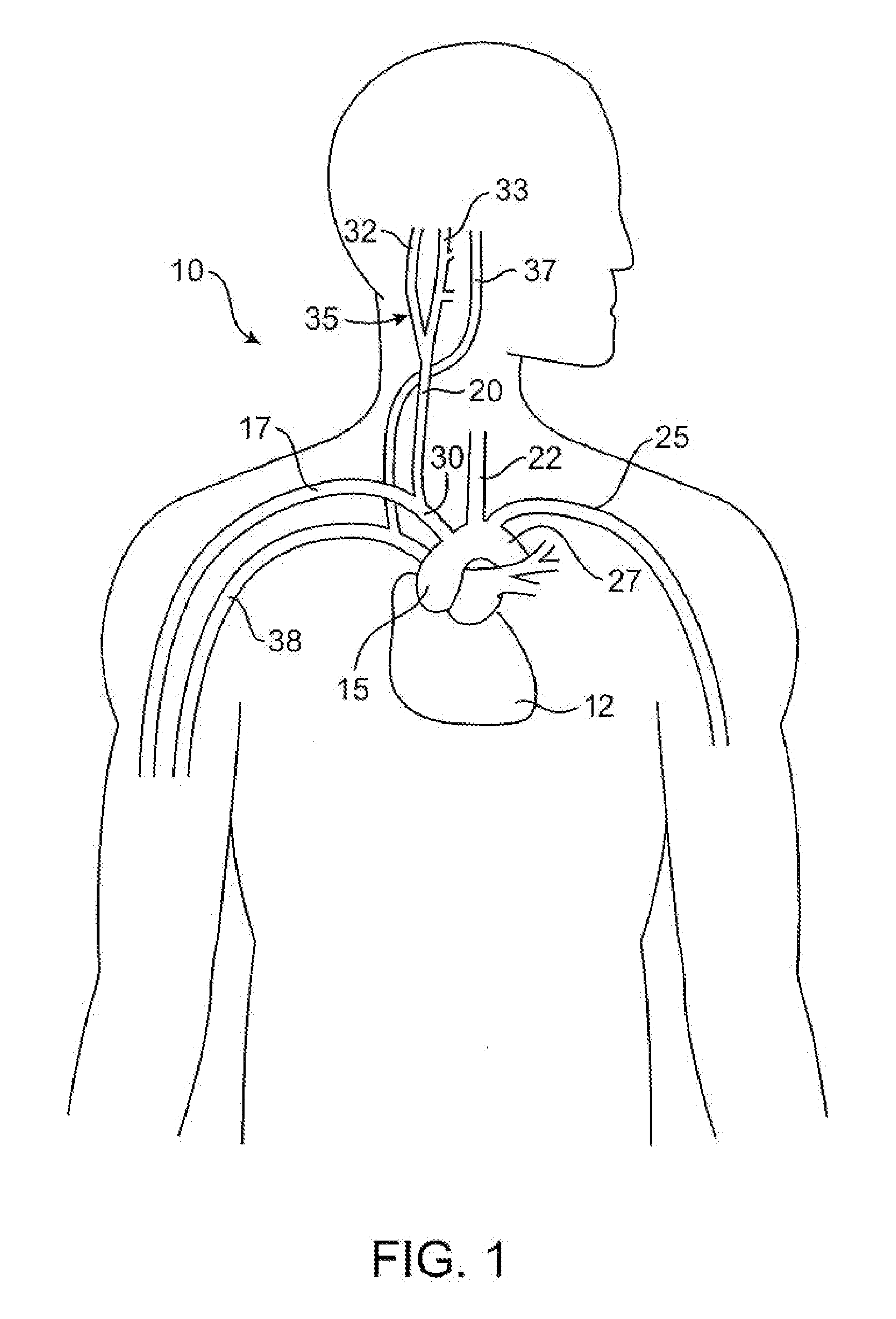

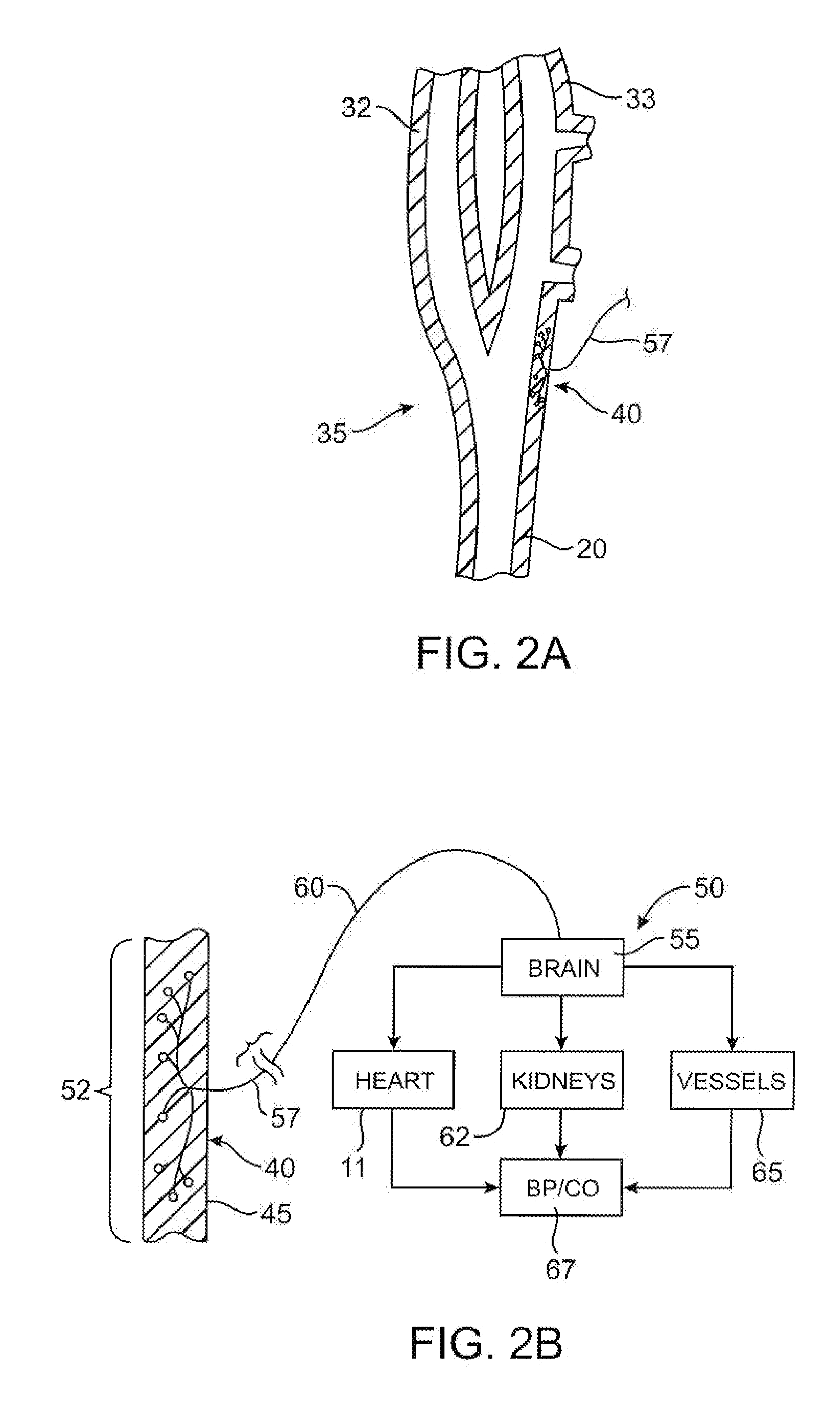

Stimulus waveforms for baroreflex activation

A method and apparatus for stimulation of a baroreflex system of a patient is provided. A method comprises establishing a therapy regimen including at least one pulse which includes at least two phases. Each phase has a polarity which is different than that of the other phase. The baroreflex system of the patient is activated with at least one baroreflex activation device which is responsive to the therapy regimen.

Owner:CVRX

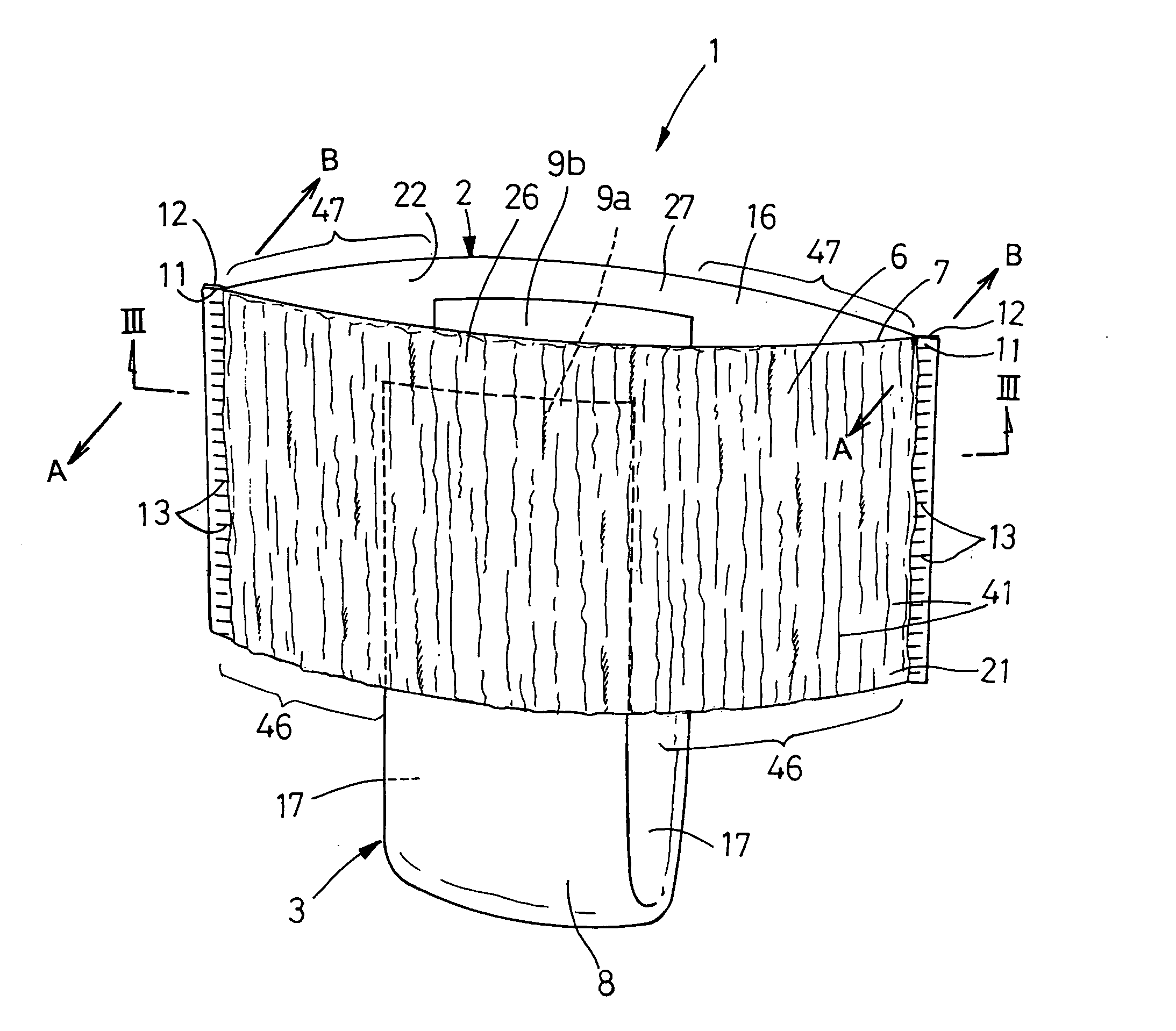

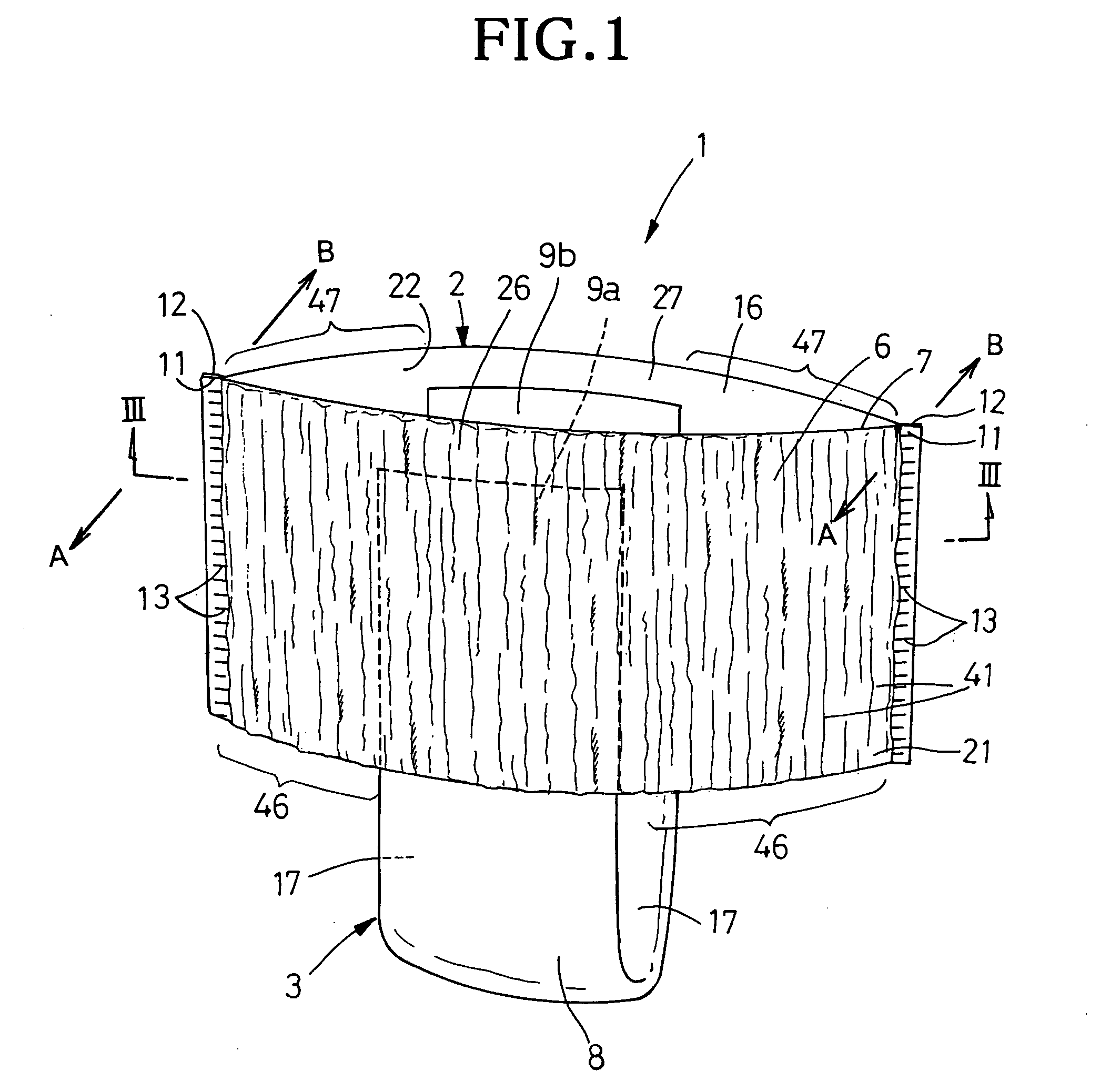

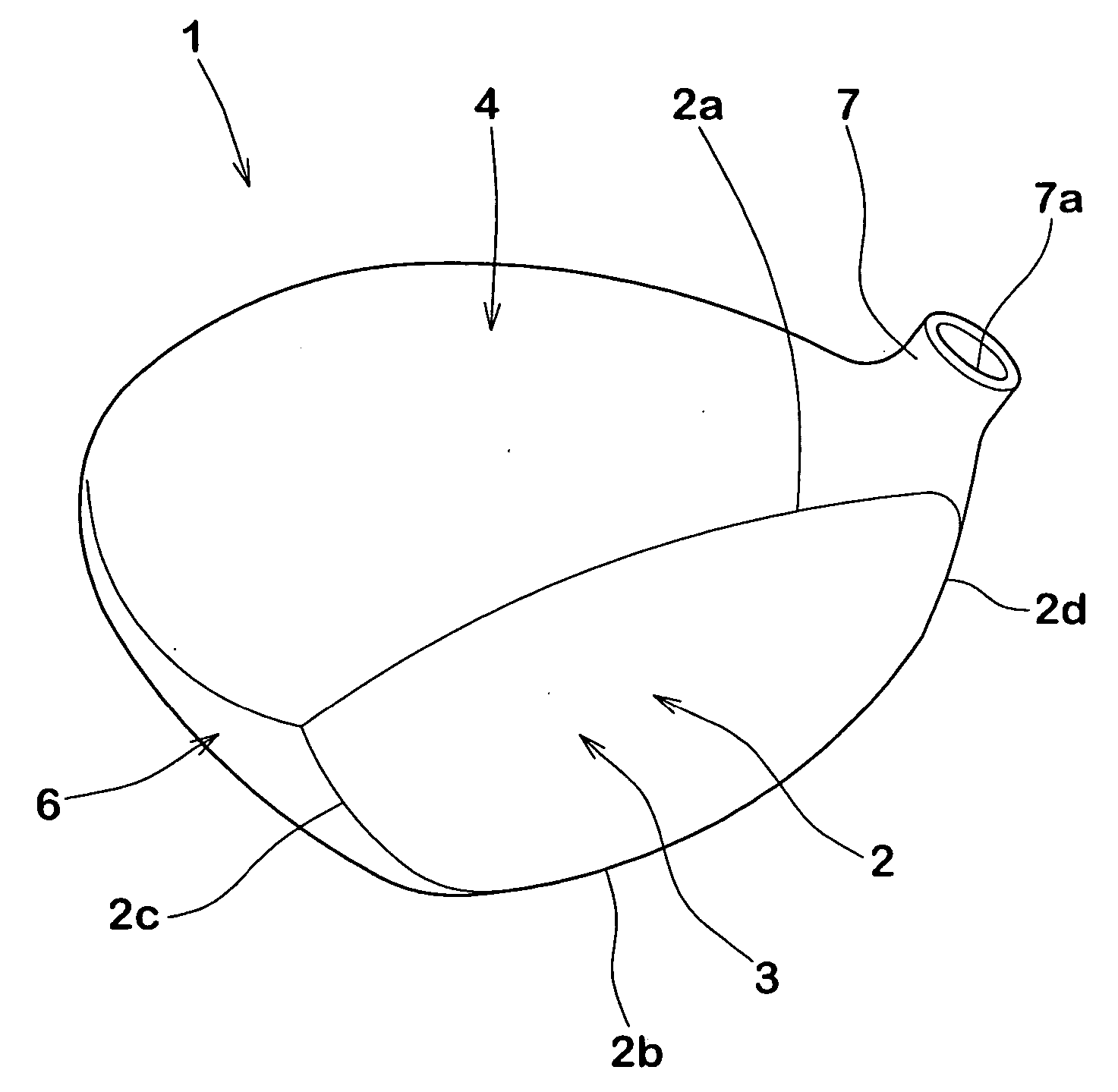

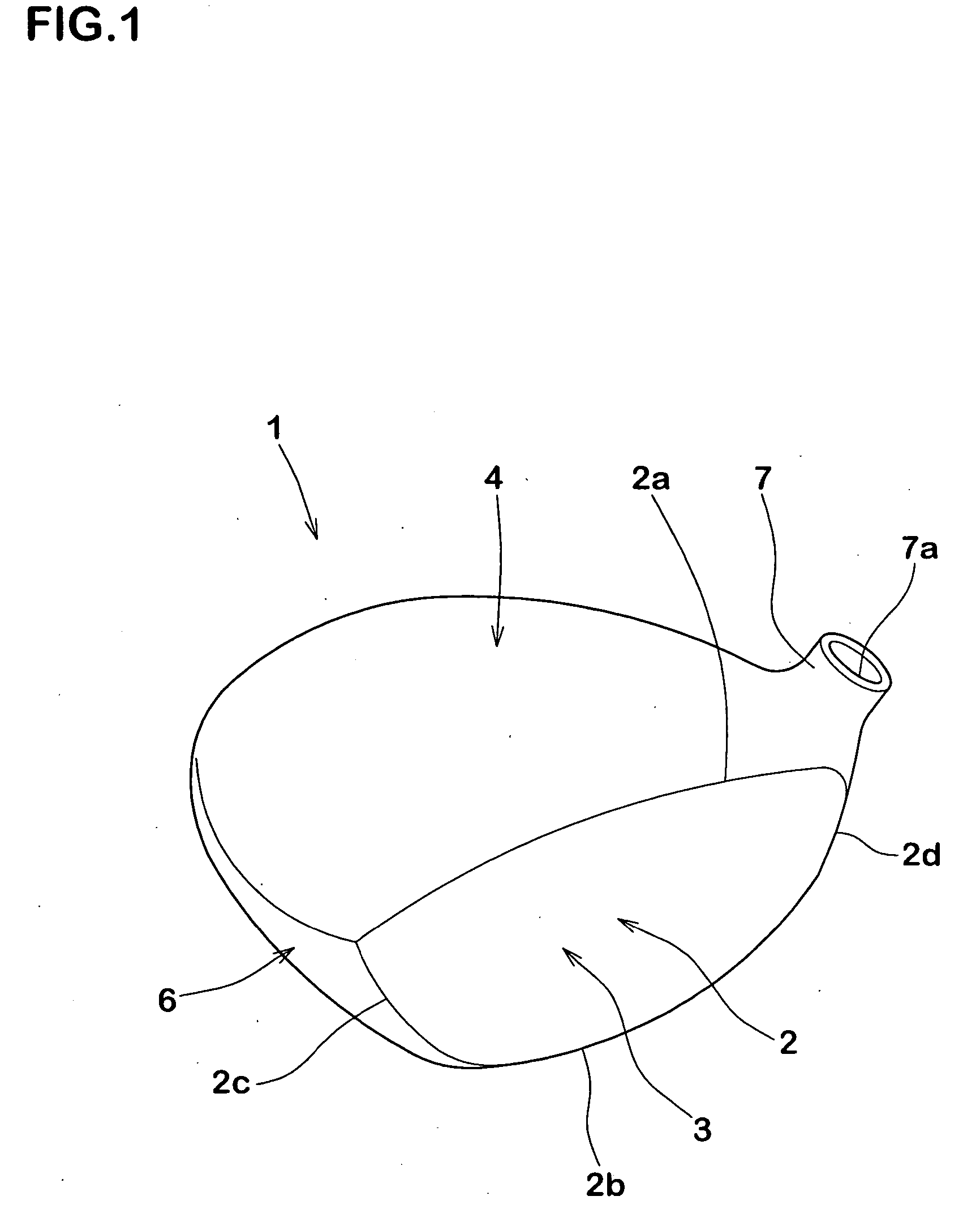

Disposable wearing article

Here is disclosed a disposable wearing article such as a disposable diaper. The article has a front waist covering panel, a rear waist covering panel and a crotch covering panel, a body facing sheet and an undergarment facing sheet in the front and rear waist covering panels are elastically stretchable in a waist-surrounding direction. These sheets are made of nonwoven fabrics and have regions in which these sheets are placed upon each other and the undergarment facing sheet repetitively undulates in the waist-surrounding direction to form a plurality of gathers.

Owner:UNI CHARM CORP

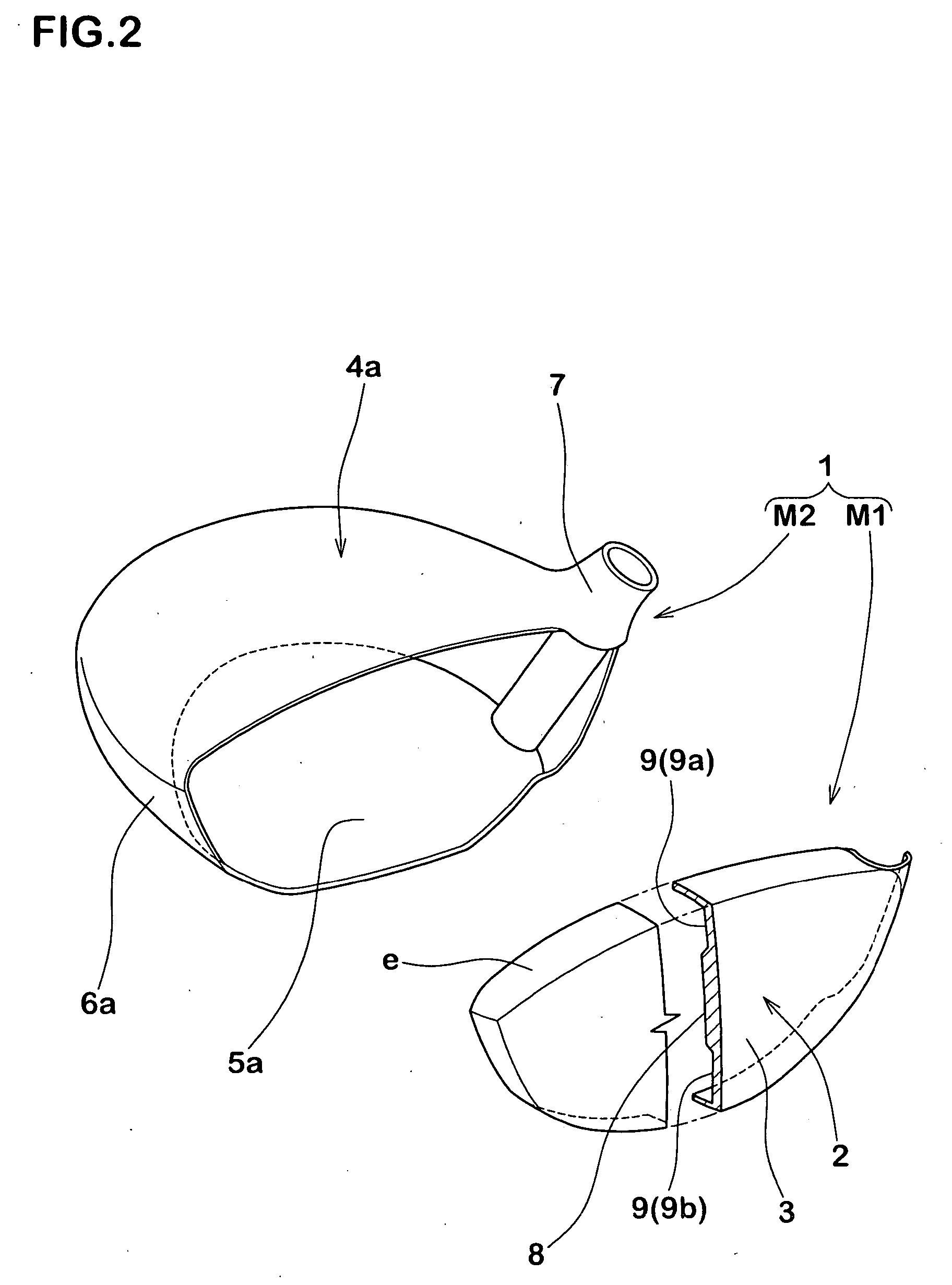

Golf club head

ActiveUS20050101407A1Enlarge regionHigh recovery coefficientGolf clubsRacket sportsEngineeringGolf Ball

A golf club head having a face portion that hits a ball, which includes: a center thick portion; a portion of a varying thickness in annular form; and a peripheral thin portion provided around the portion of a varying thickness, where the peripheral thin portion of which the thickness is the smaller than that of the center thick portion. The peripheral thin portion includes a first thin portion and a second thin portion. The first thin portion is provided in at least one portion of a sole portion, a toe portion and a heel portion of the peripheral thin portion.

Owner:SUMITOMO RUBBER IND LTD

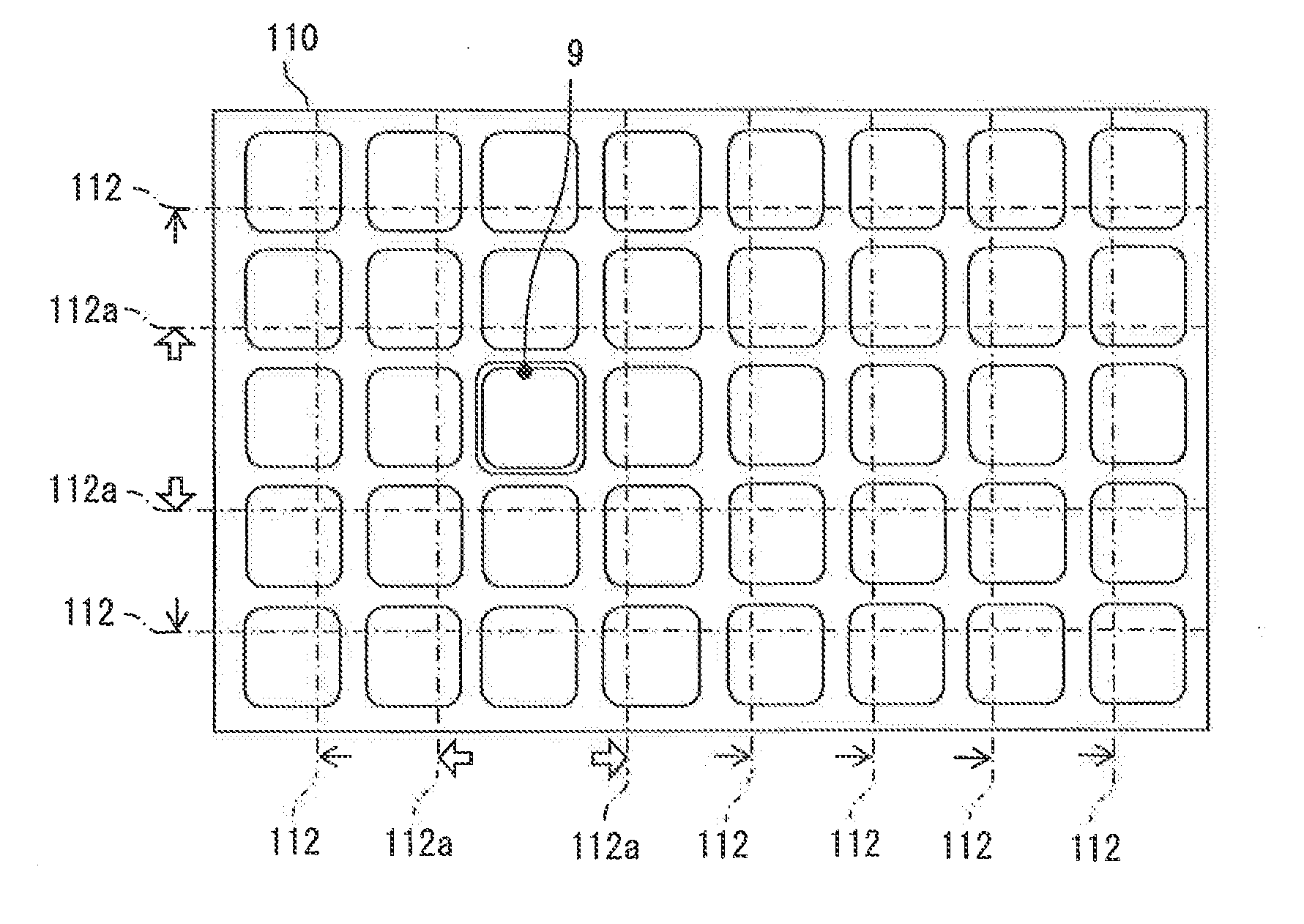

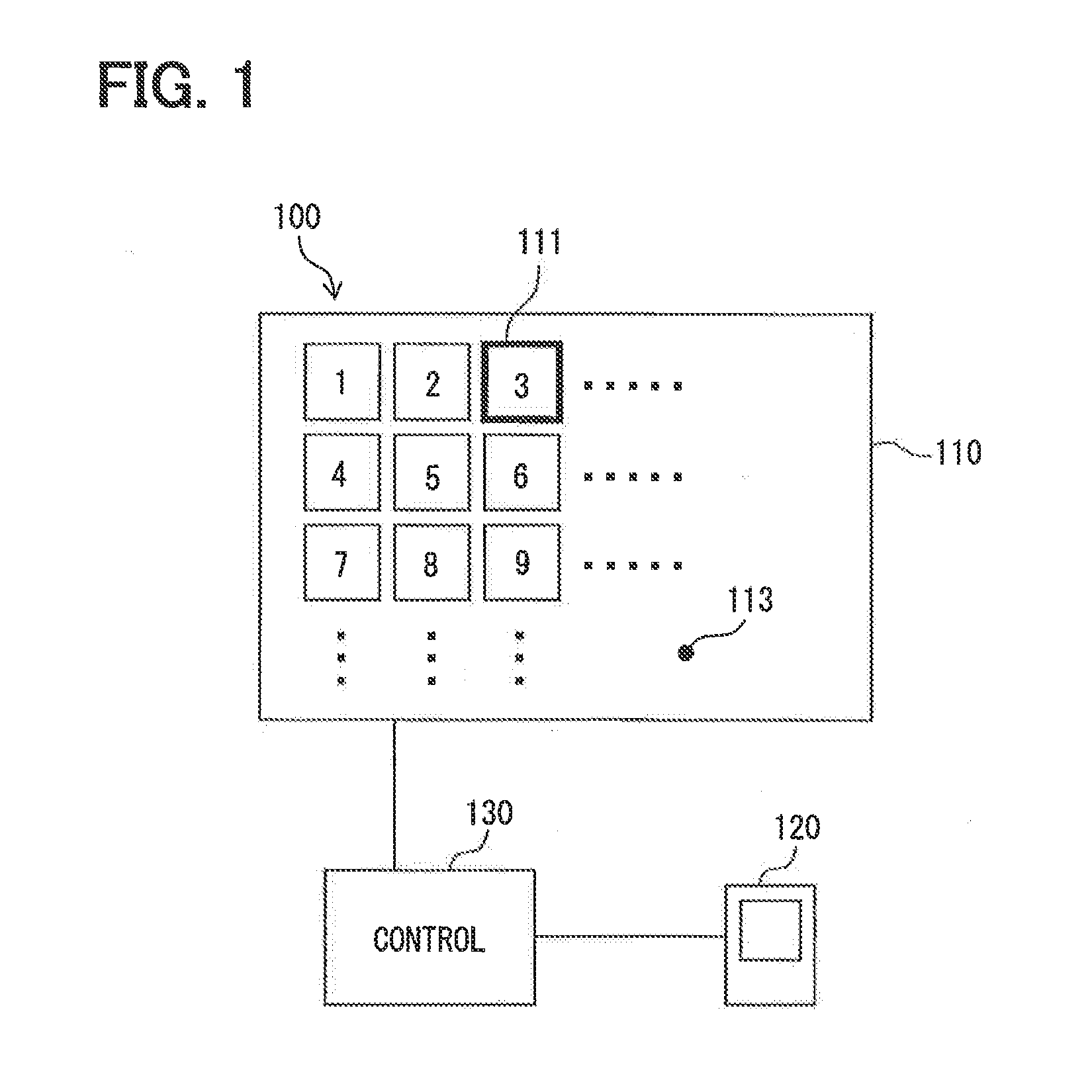

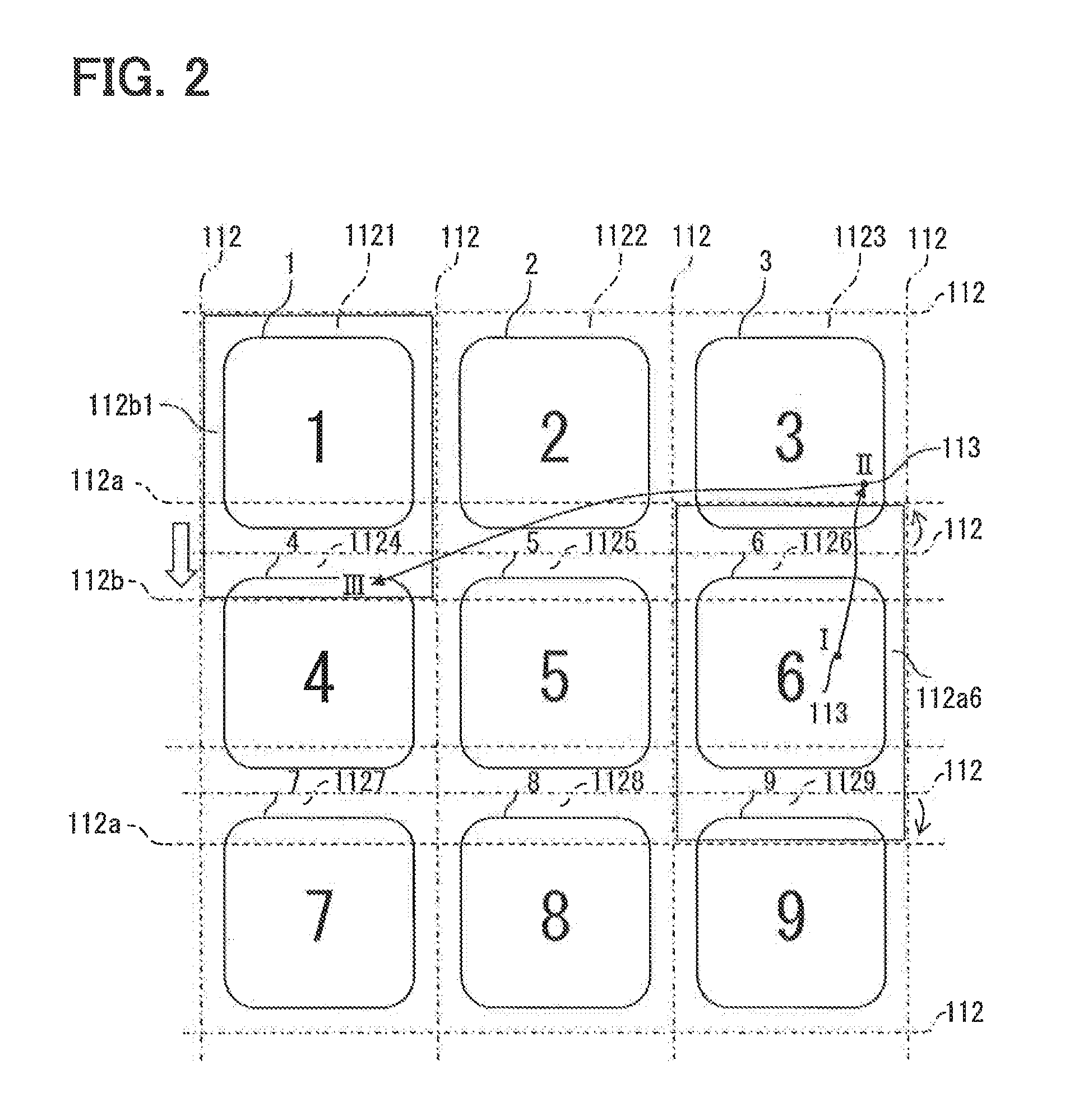

Input apparatus and display control apparatus

InactiveUS20130097564A1Prevent erroneous erroneous inputPrevent erroneous selection erroneousInput/output processes for data processingComputer scienceComputer hardware

Owner:DENSO CORP

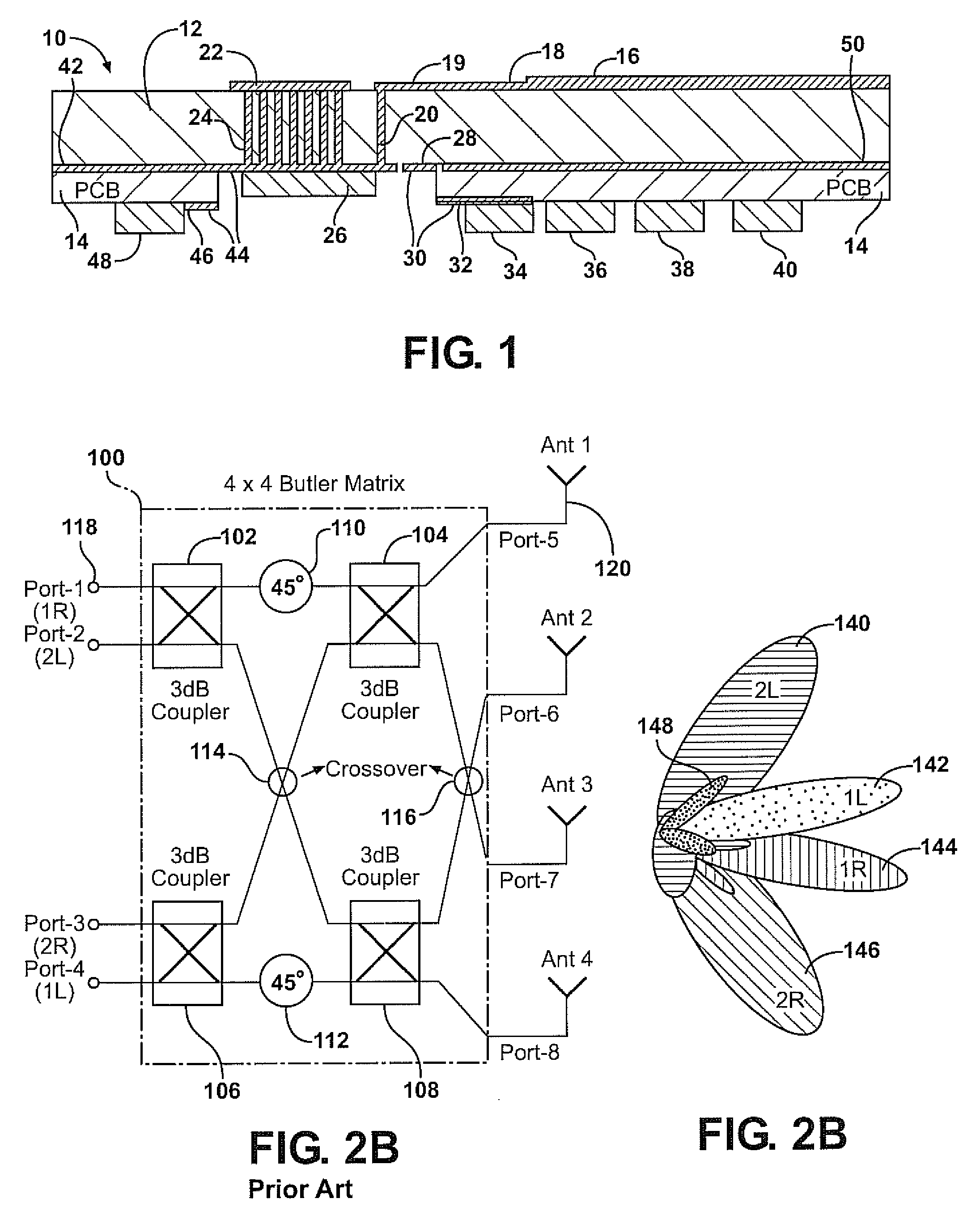

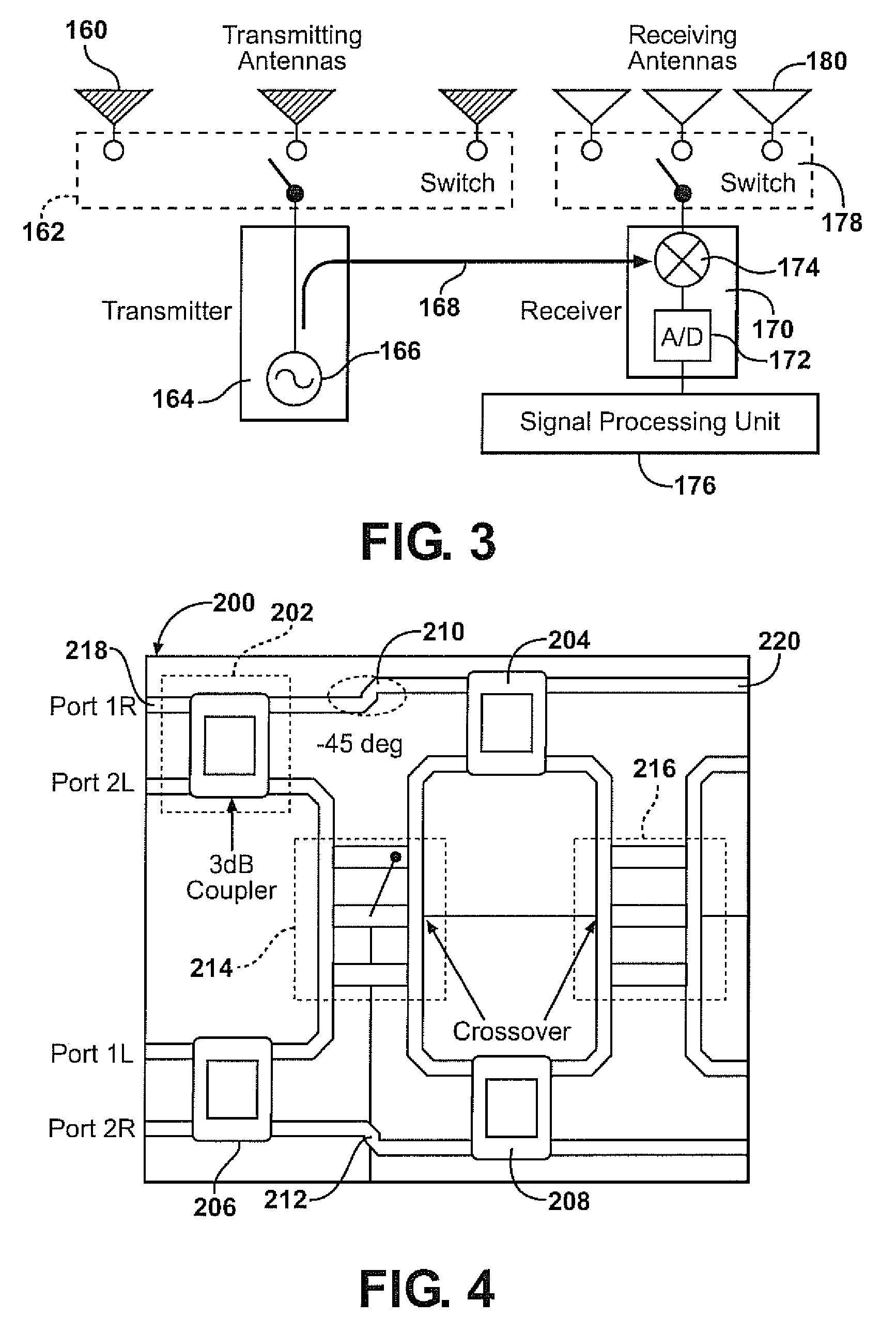

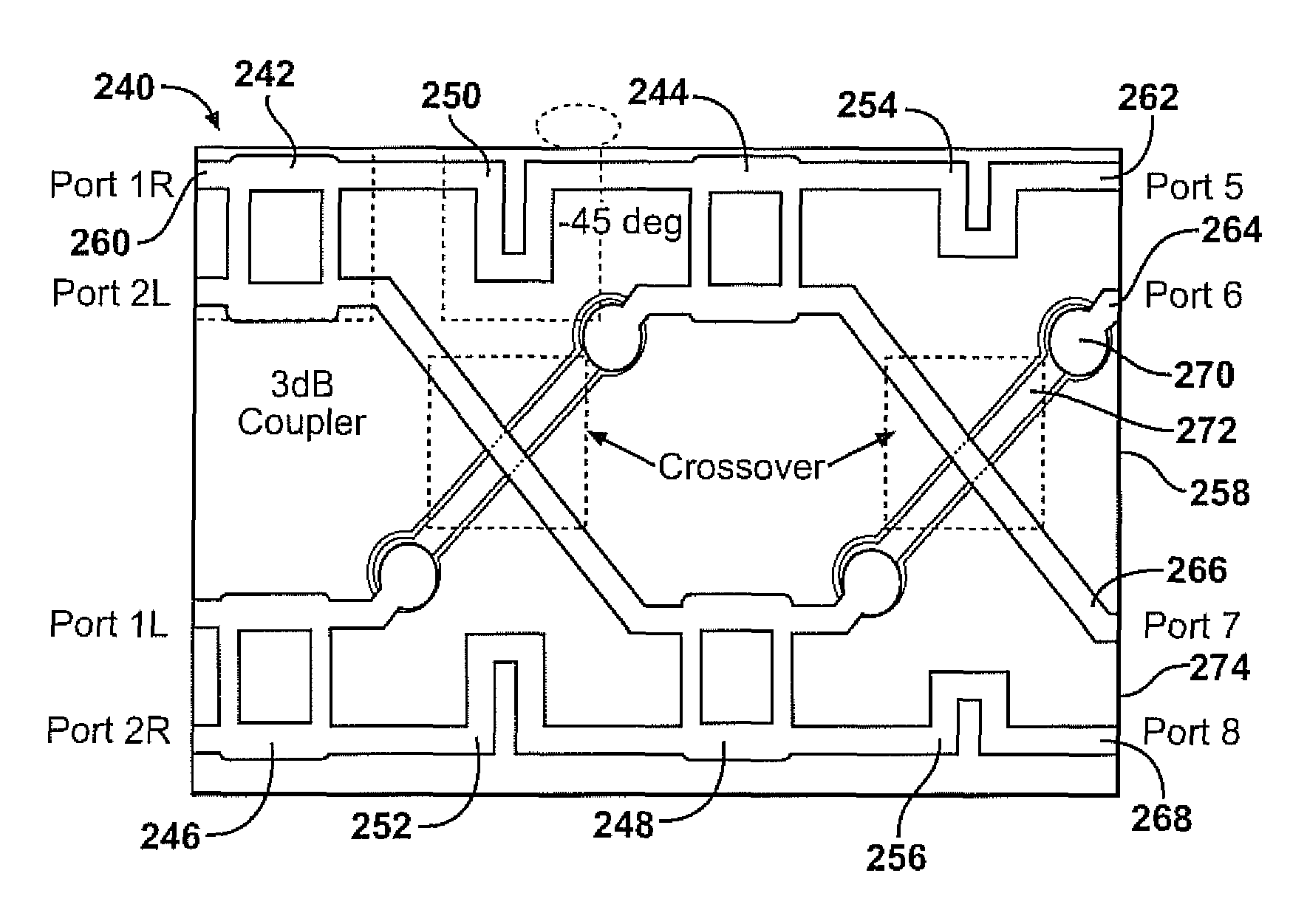

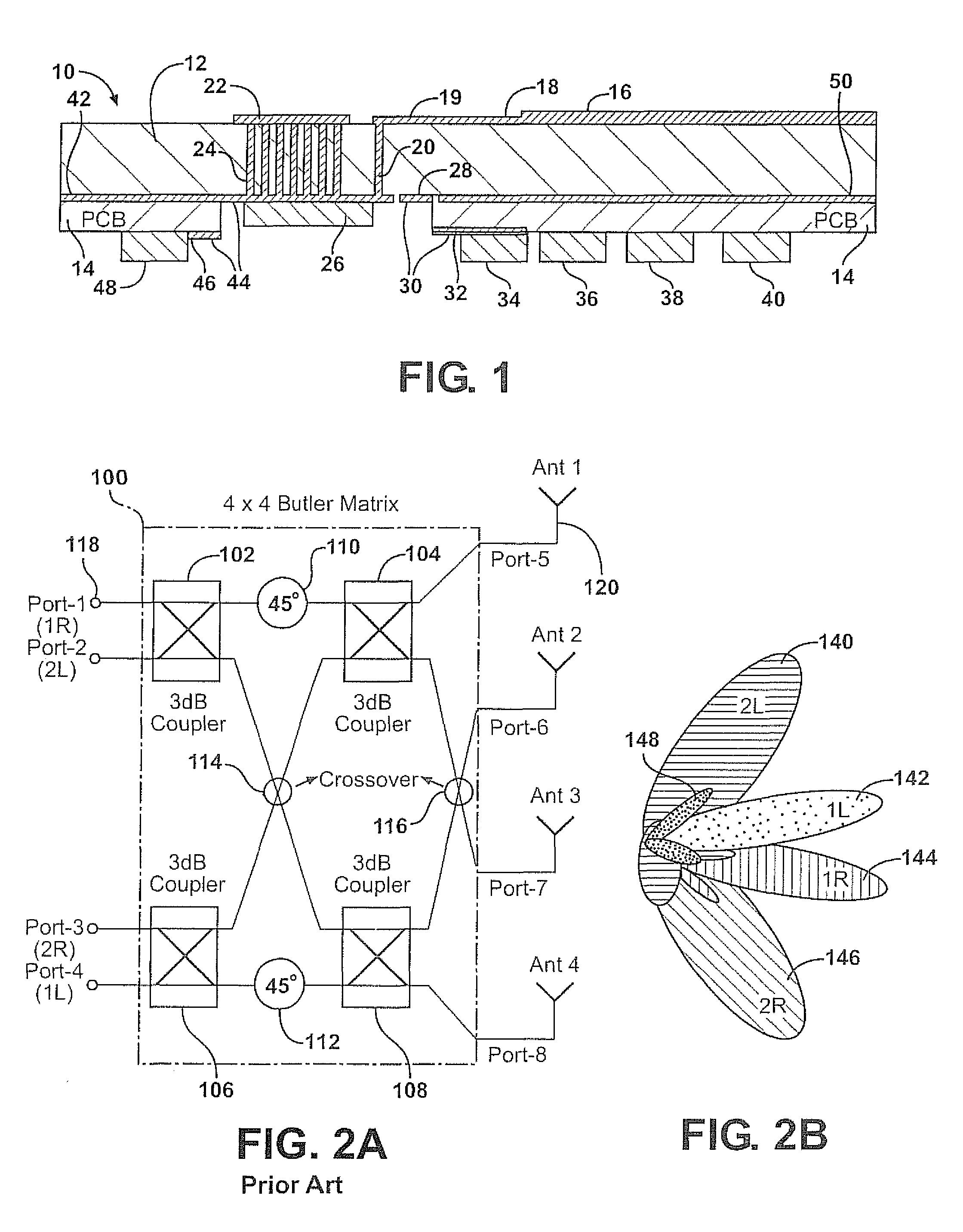

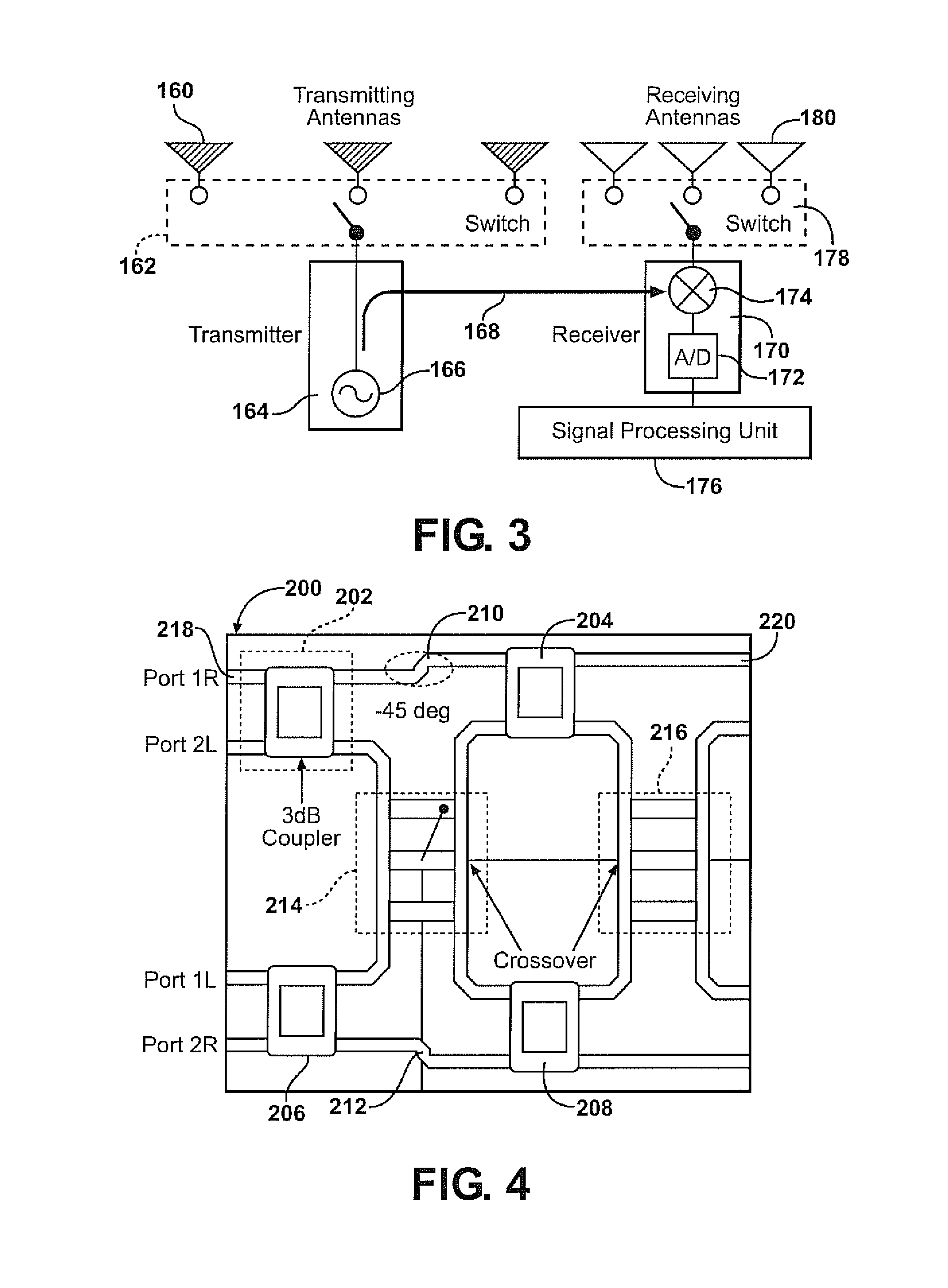

Butler matrix for 3D integrated RF front-ends

ActiveUS20100225539A1Reduce lossApparatus is enlargedAntenna arraysRadio wave reradiation/reflectionElectricityRF front end

Examples of the present invention include a radar apparatus comprising a substrate, an antenna disposed on a first side of the substrate, a Butler matrix supported by same the substrate, output ports of the Butler matrix being electrically connected with a group of radiative elements; and input ports configured to be in communication with a radio frequency (RF) circuit. The RF circuit may be supported proximate or adjacent the substrate.

Owner:TOYOTA MOTOR CO LTD

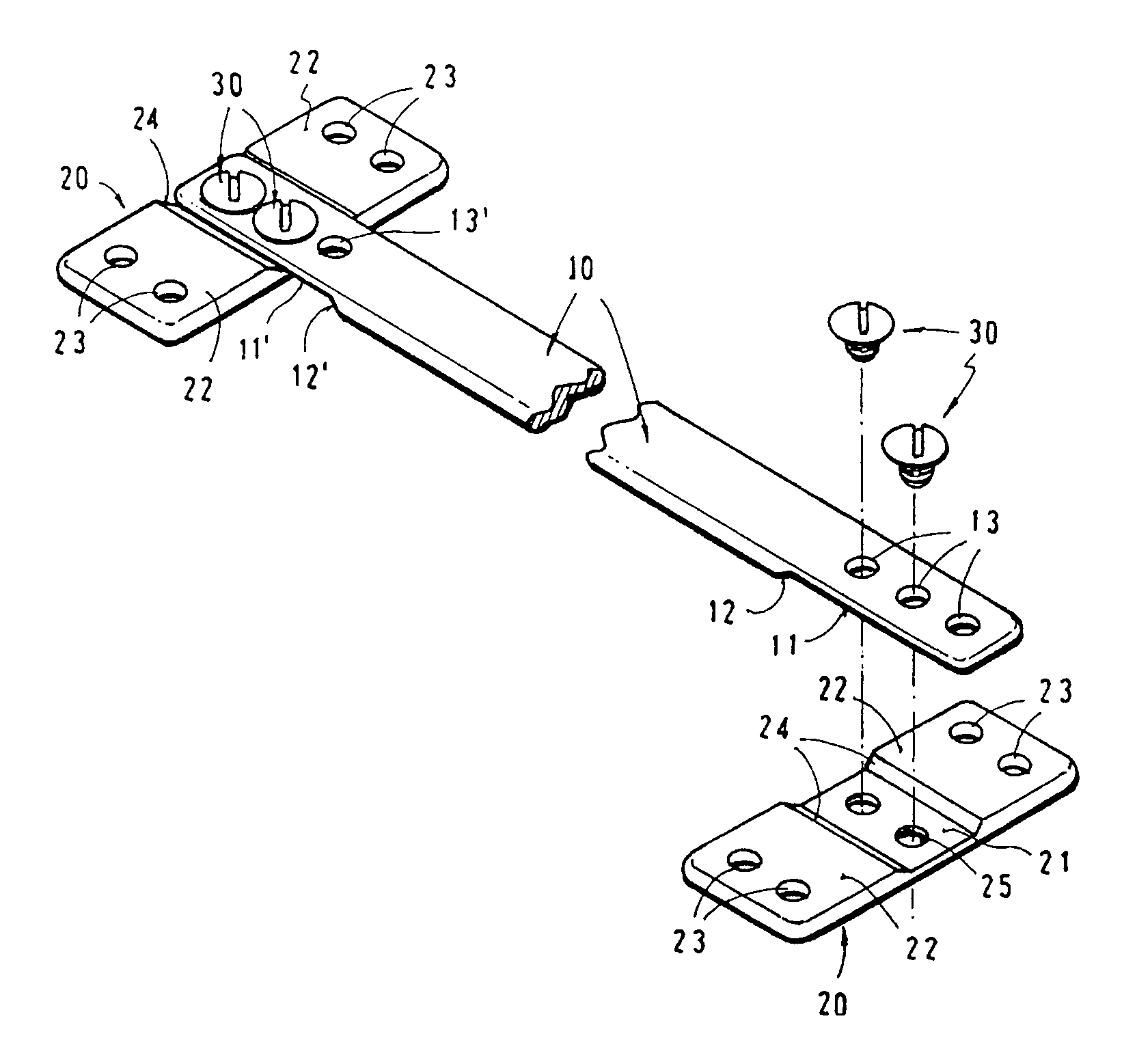

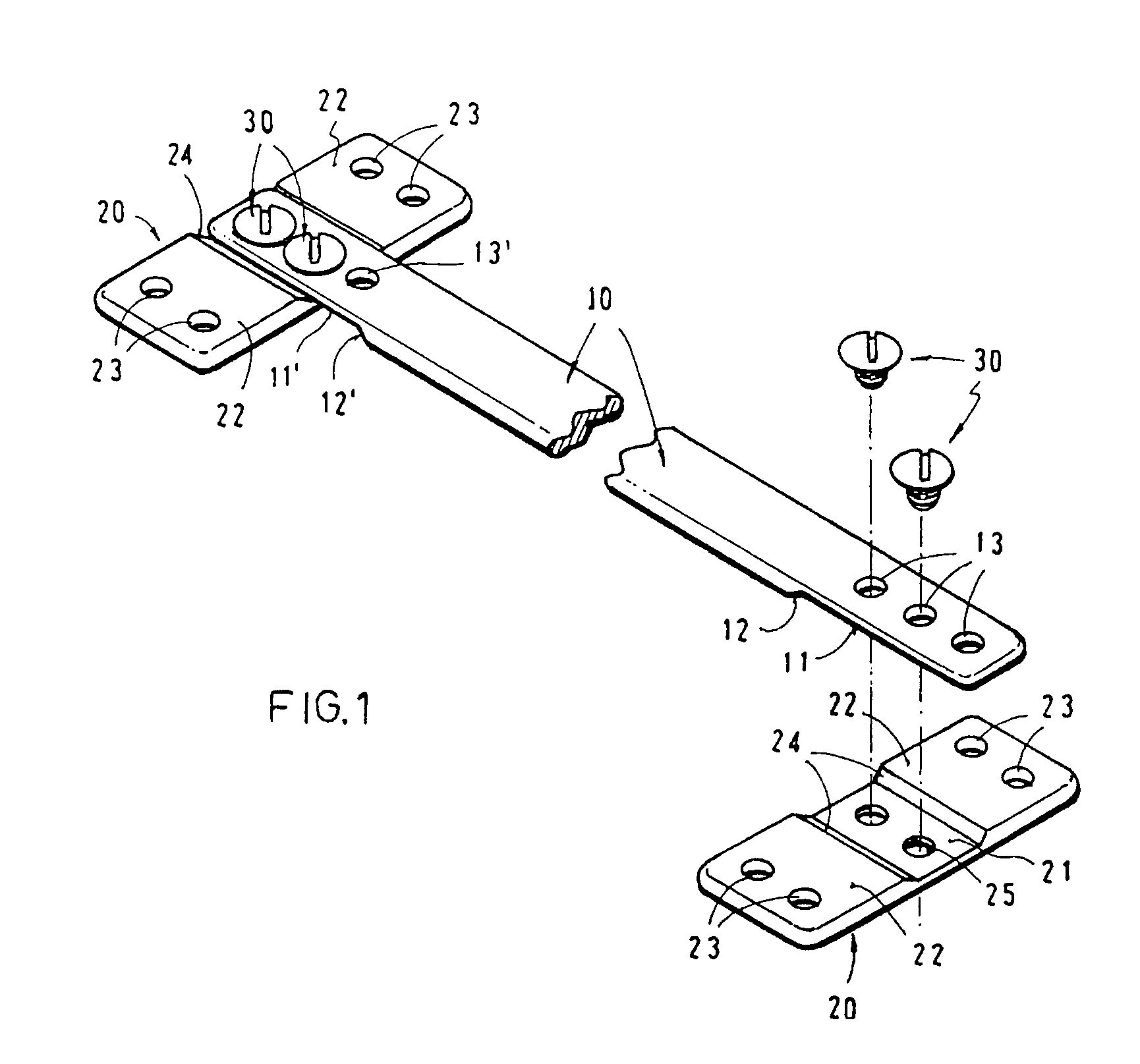

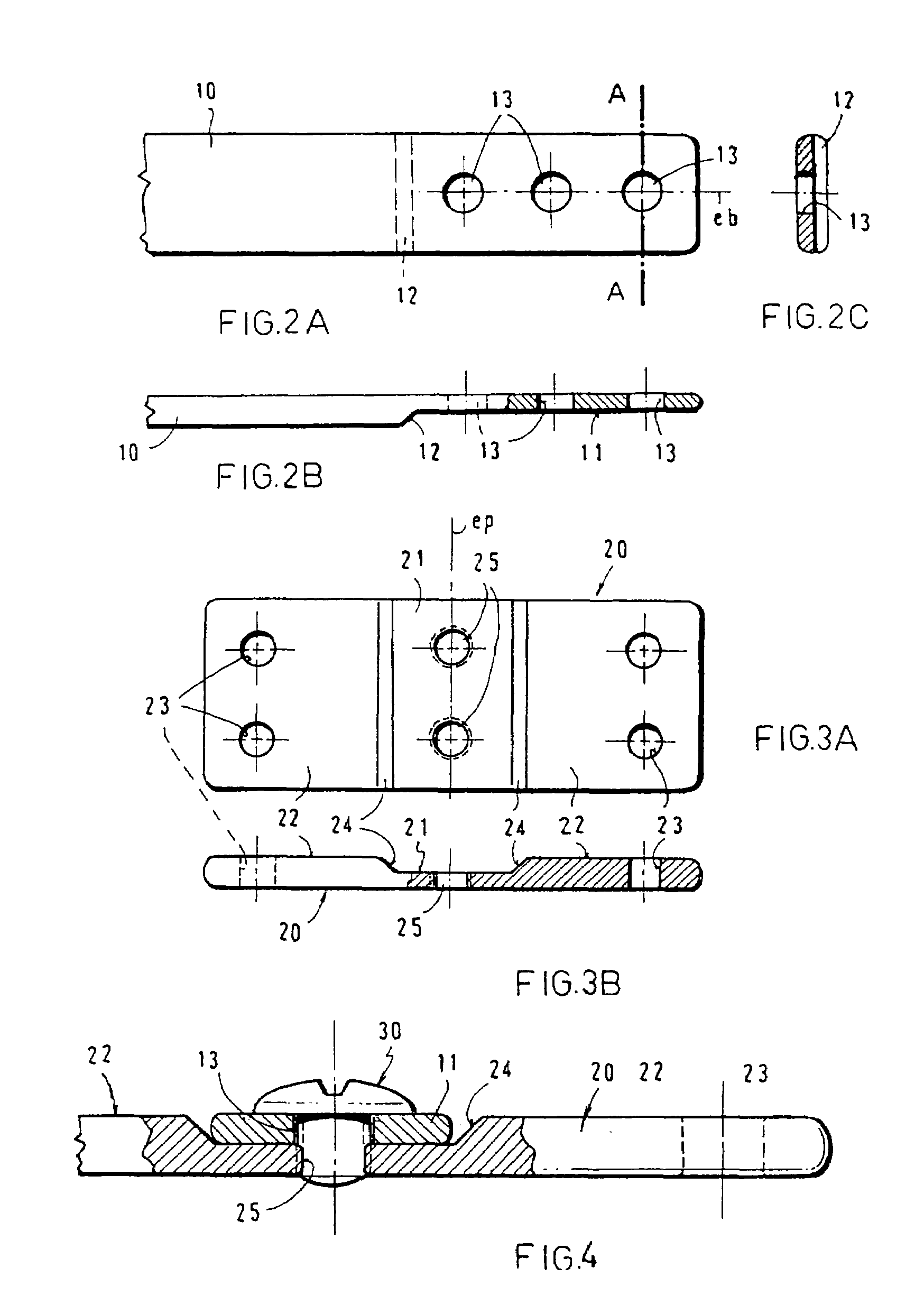

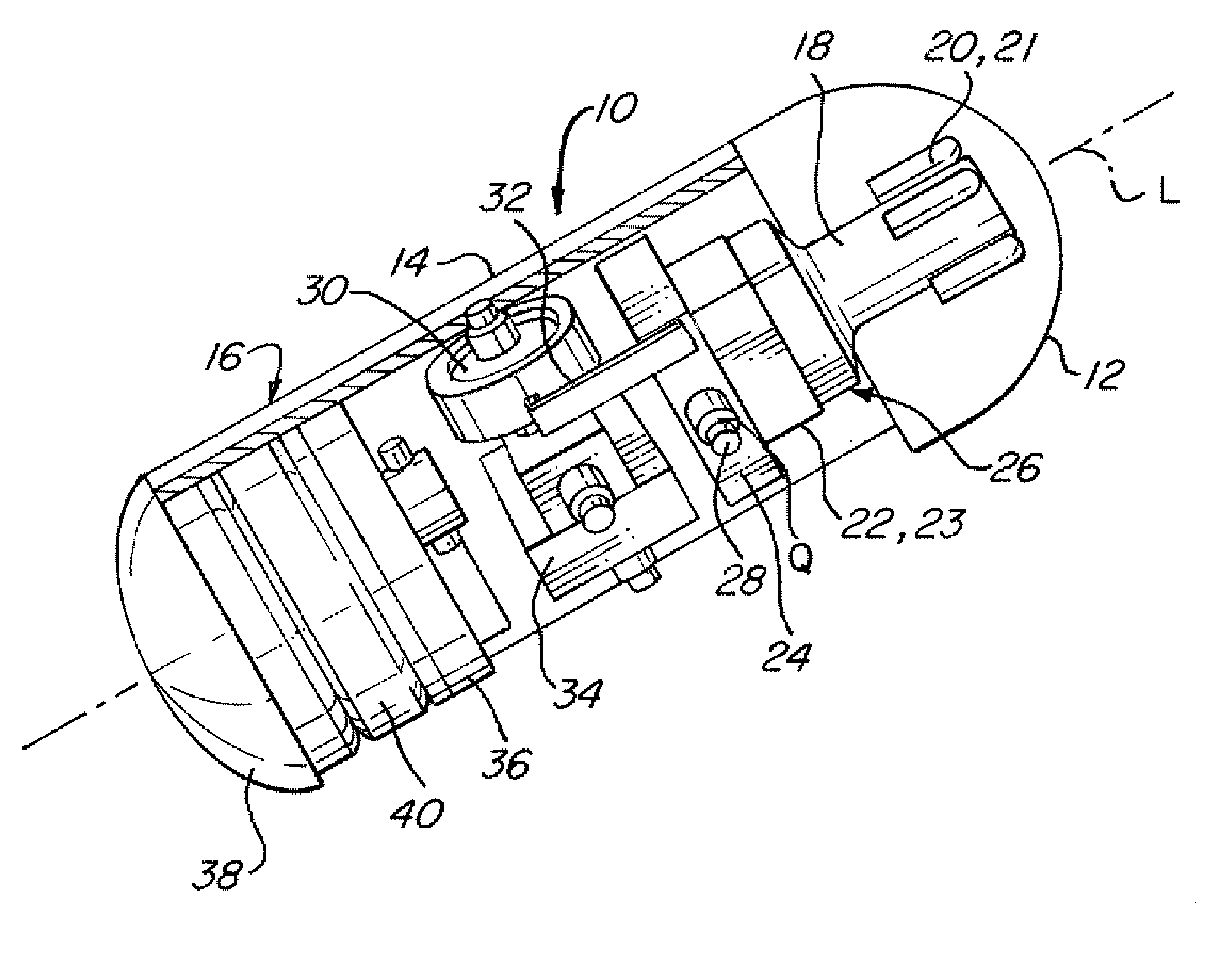

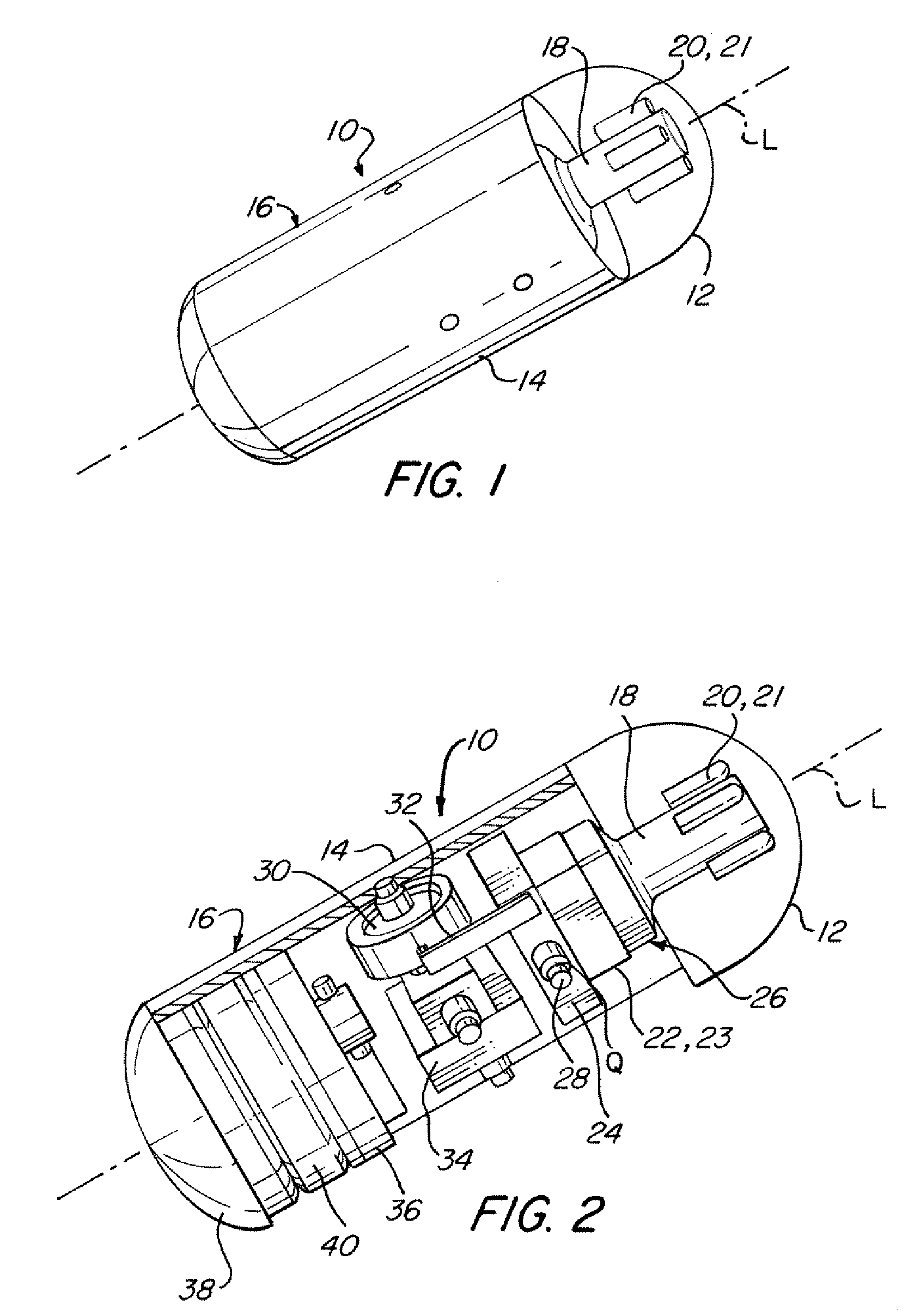

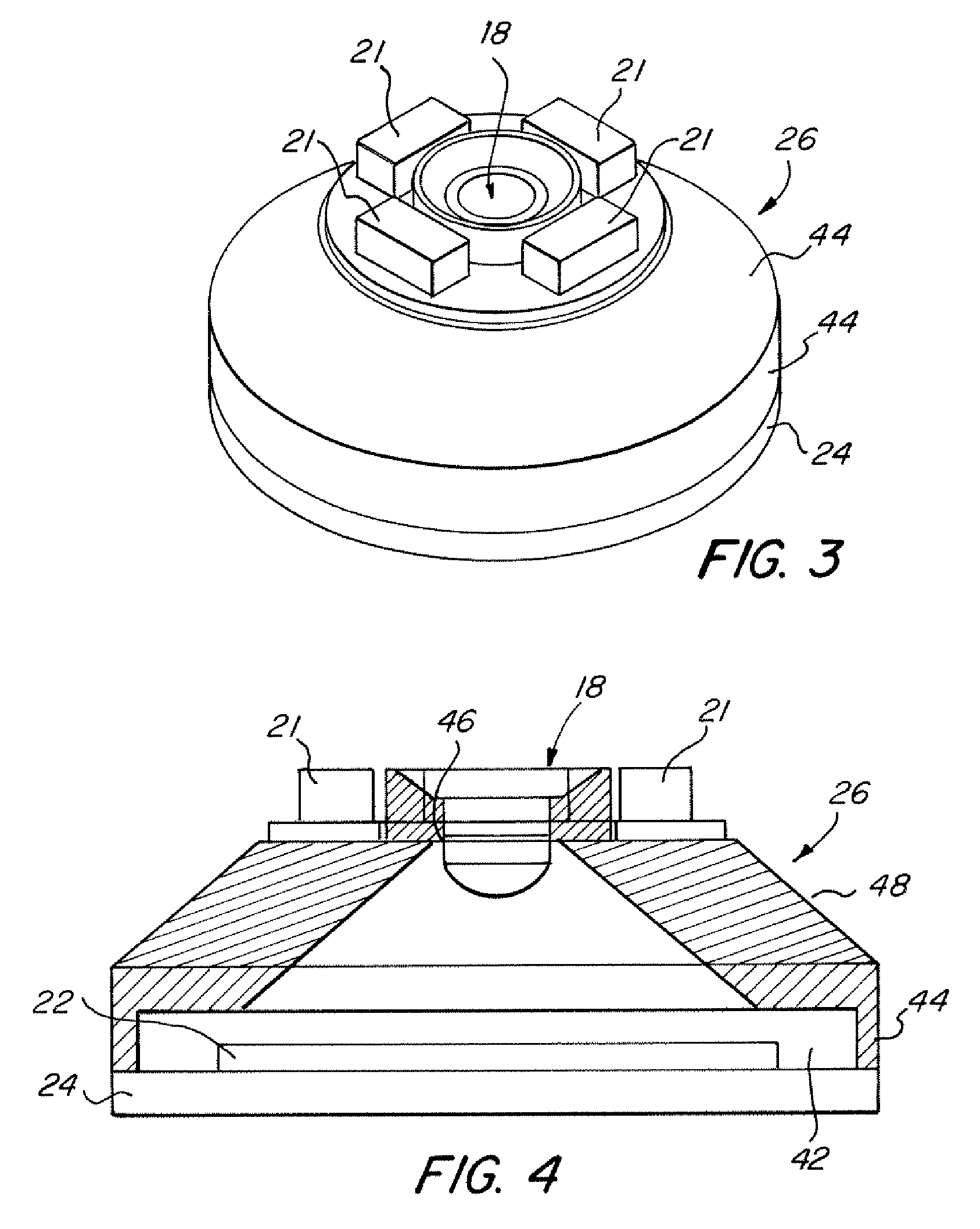

Apparatus for the correction of chest wall deformities such as Pectus Carinatum and method of using the same

InactiveUS7156847B2Enlarge regionEasy to compressBone implantJoint implantsEngineeringChest wall deformity

An apparatus for the correction of wall chest deformities, such as “Pectus Carinatum”, comprising: a bar (10) having a flattened cross-section, having a minimum bending strength according to the values defined by ASTM F382-95, plates (20) having a slot (21) in the medium portion so as to fit the corresponding end of the bar (10) and peripheral holes (23) for securing the bone parts. The bar ends comprise planar grooves (11–11′) determining the wall thickness substantially similar to the height of the slot (21) of the plate (20). The wall of the grooves (11–11′) has aligned holes (13) in order to form with the respective plate (20) and by using screws (30), a fixed removable attachment that allows the axial registration of the bar (10). Method for the correction of Pectus Carinatum using said apparatus in order to achieve a normal anatomic shape of the chest wall.

Owner:ABRAMSON HORACIO

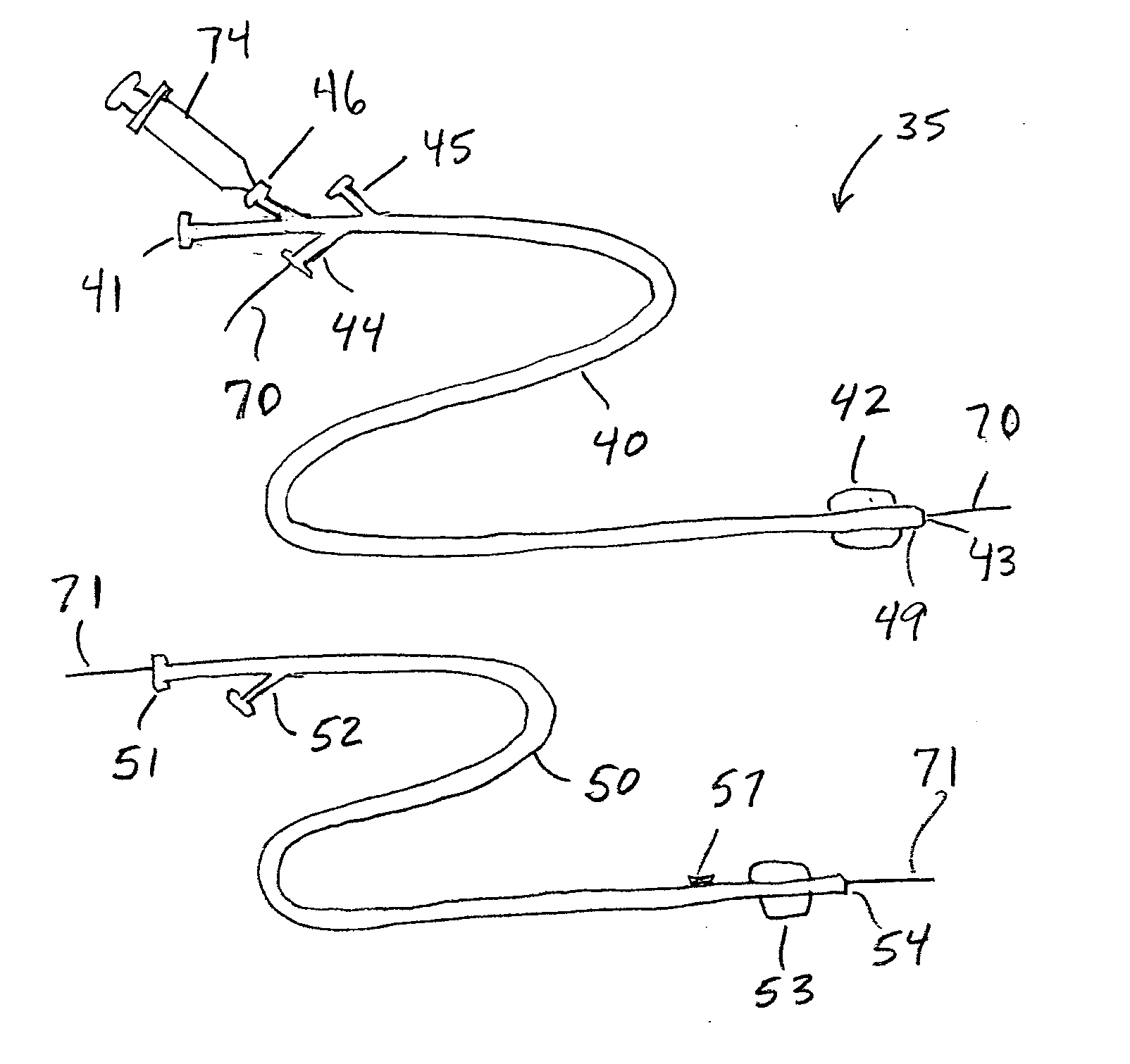

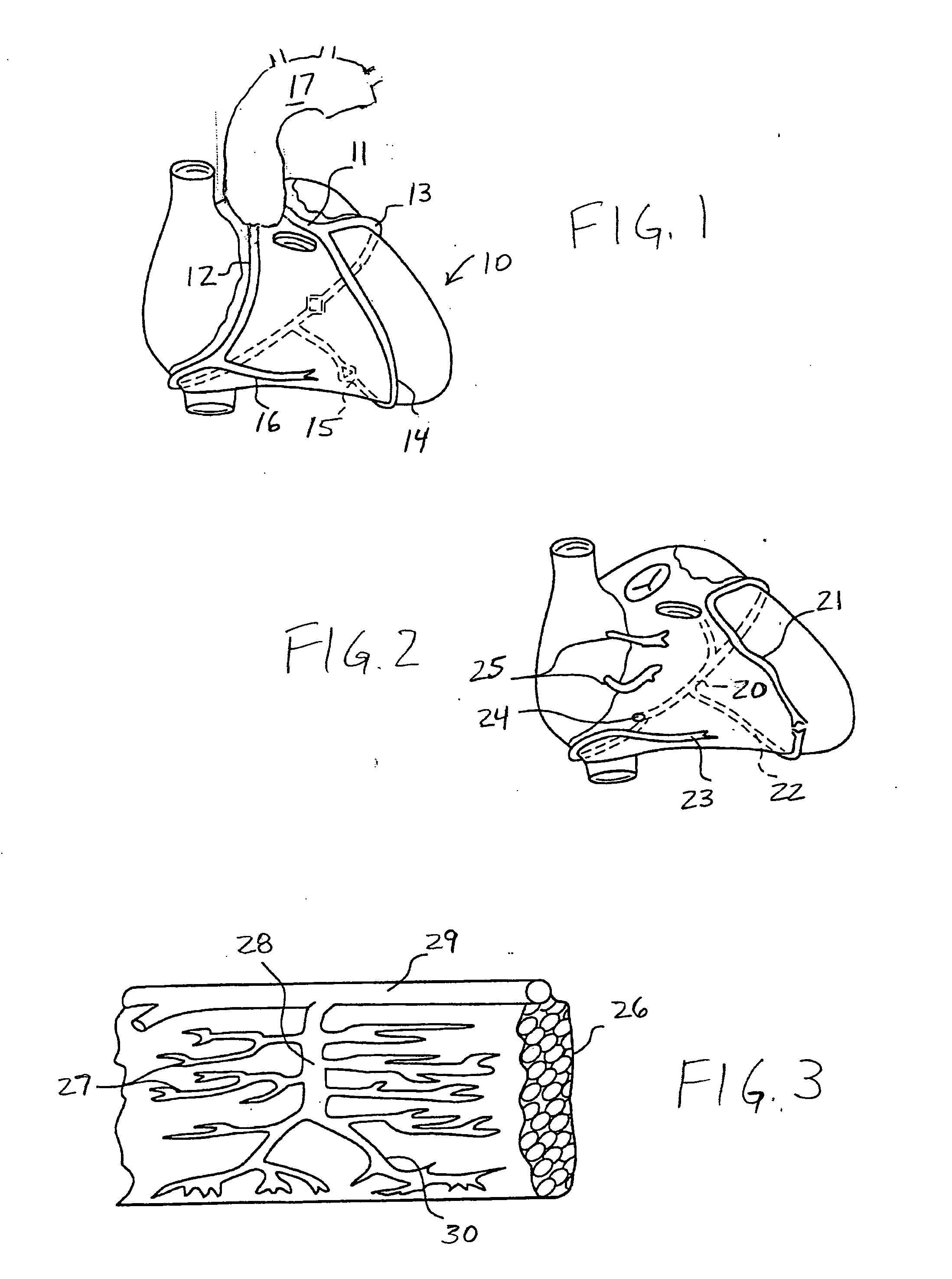

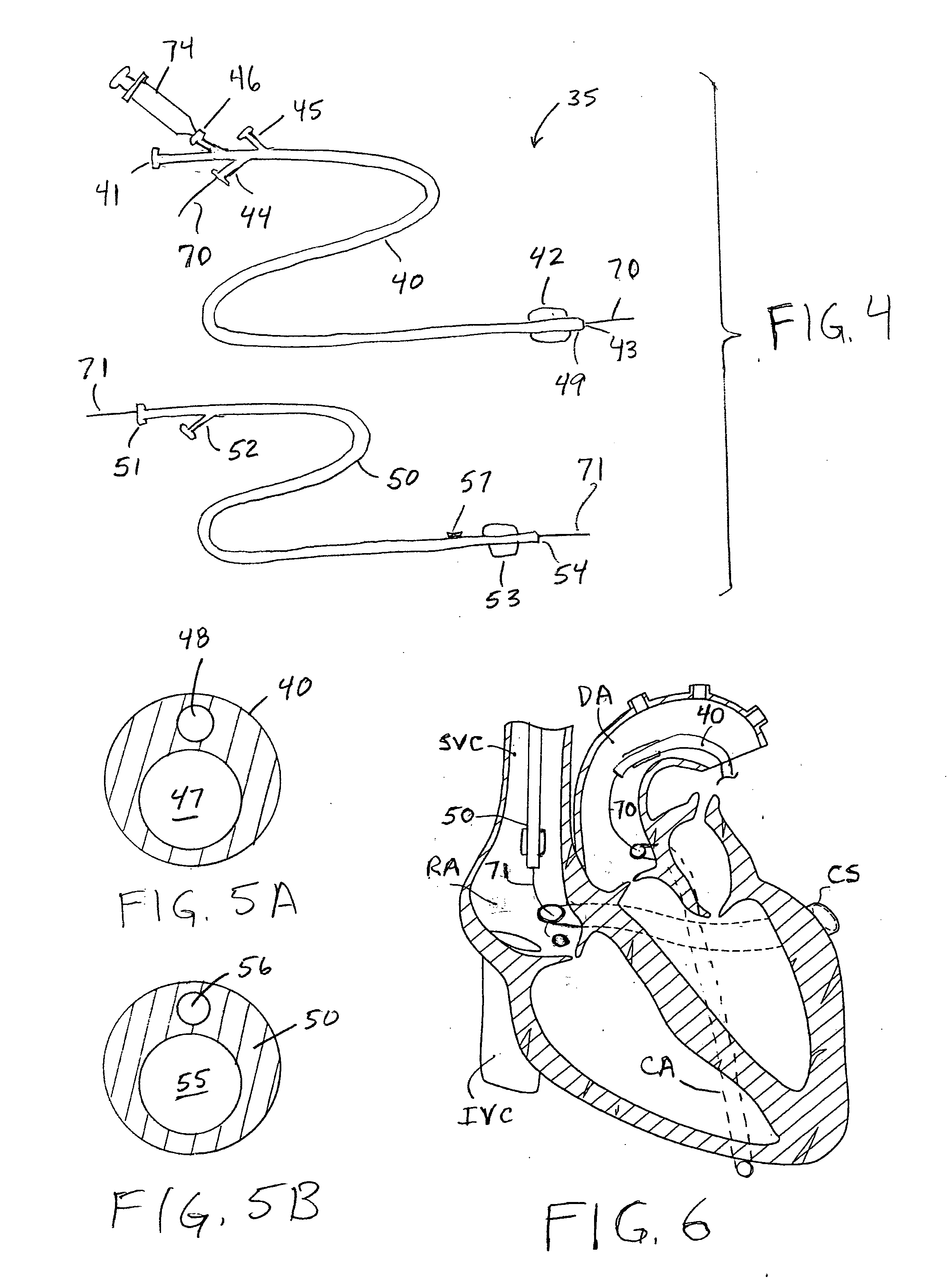

Methods and apparatus for treating infarcted regions of tissue following acute myocardial infarction

ActiveUS20060074399A1Extended stayIncreasing stem cell residence timeBalloon catheterSurgeryProgenitorCoronary arteries

Apparatus and methods are provided for treating an infarcted region of myocardium following acute myocardial infarction by reducing the rate of blood flow through infarcted region, and then injecting a solution containing stem cells, endothelial progenitor cells or mediators of stem cell mobilization, migration and attachment into the effected region so that the stem cells become embedded therein and promote tissue regeneration. In a first embodiment, delivery of the stem cells, endothelial progenitor cells or mediators of stem cell mobilization, migration and attachment is accomplished using a catheter that relies upon antegrade flow through the coronary artery and a flow control catheter placed in the coronary sinus. In an alternative embodiment, the delivery catheter delivers the stem cells in a retrograde manner through the coronary sinus, and the delivery catheter further comprises an occlusion balloon for controlling outflow through the coronary sinus ostium.

Owner:COOK MEDICAL TECH LLC

Intracorporeal Videocapsule With Swiveling Image Pickup

The invention relates to an intracorporeal probe (10), for example preferably for examining hollow organs or natural or artificially created body cavities in the human or animal body, the probe (10) being designed in the form of a capsule that can be introduced into the body without external connecting elements, comprising an elongate housing (16) and an image pickup unit (26) inside the housing (16) that is designed for optically recording a region (pickup region) outside the probe (10). The image pickup unit (26) is held in a fashion capable of moving inside the housing (16) in order to vary the pickup region by means of such a movement (FIG. 1).

Owner:KARL STORZ GMBH & CO KG

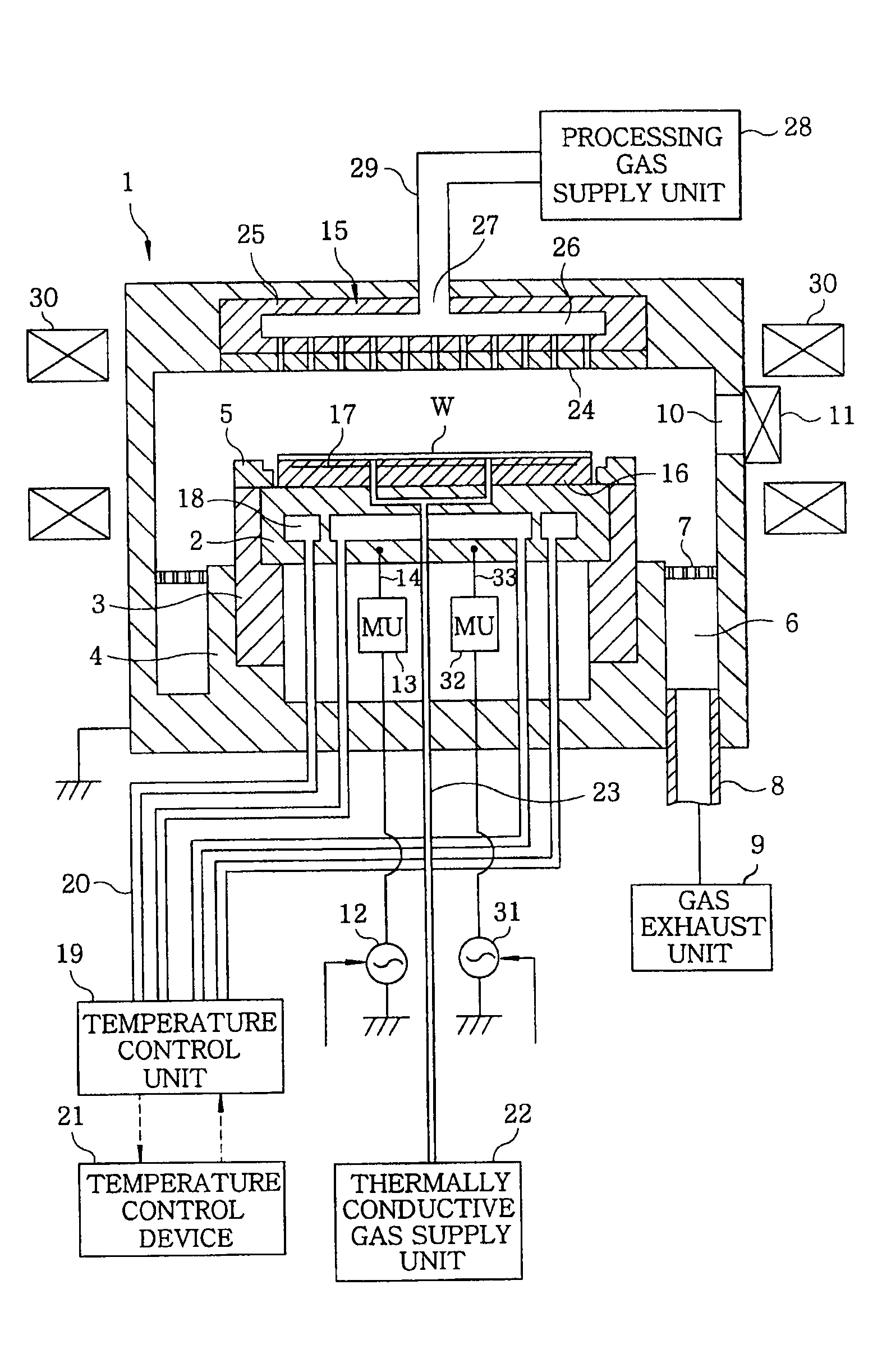

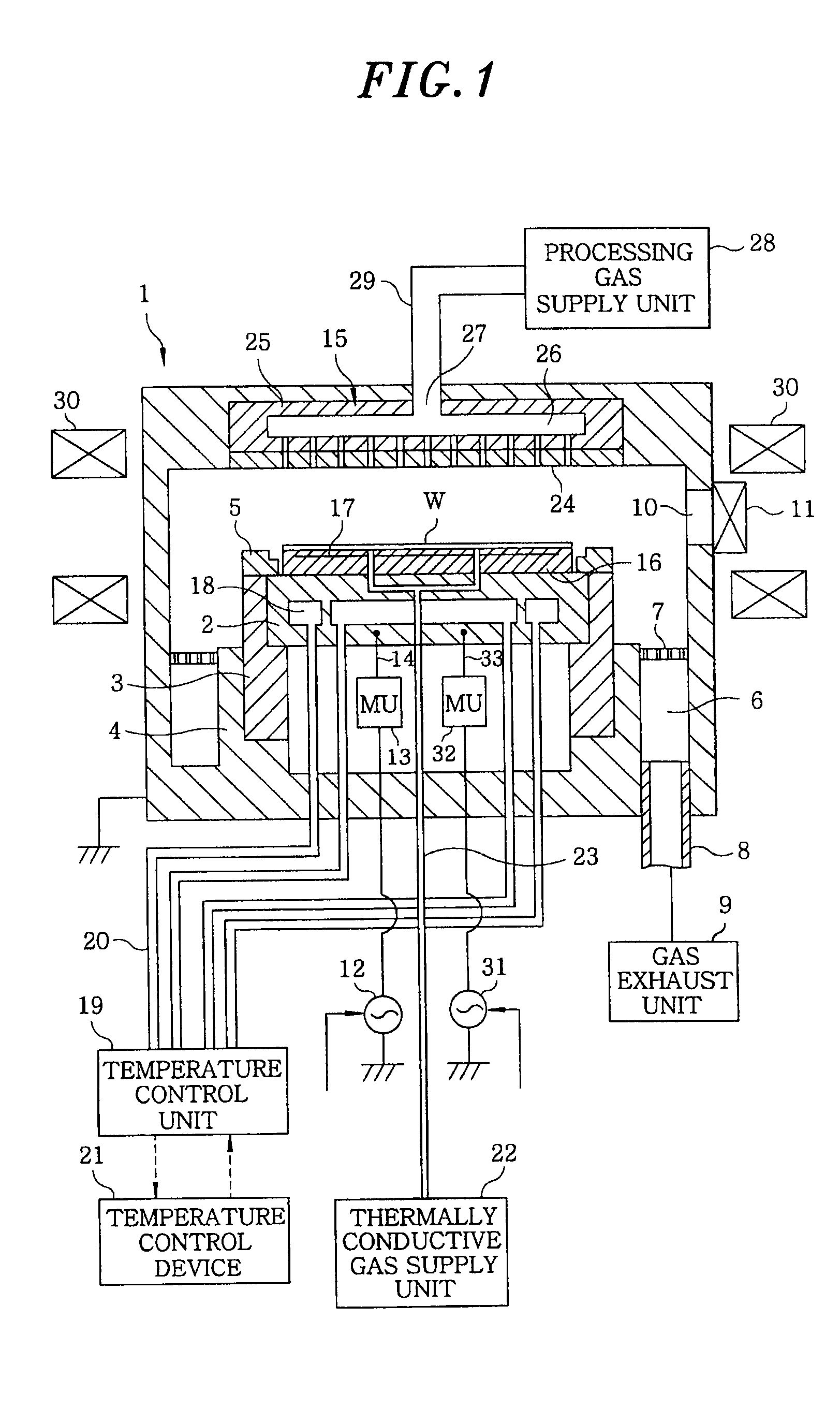

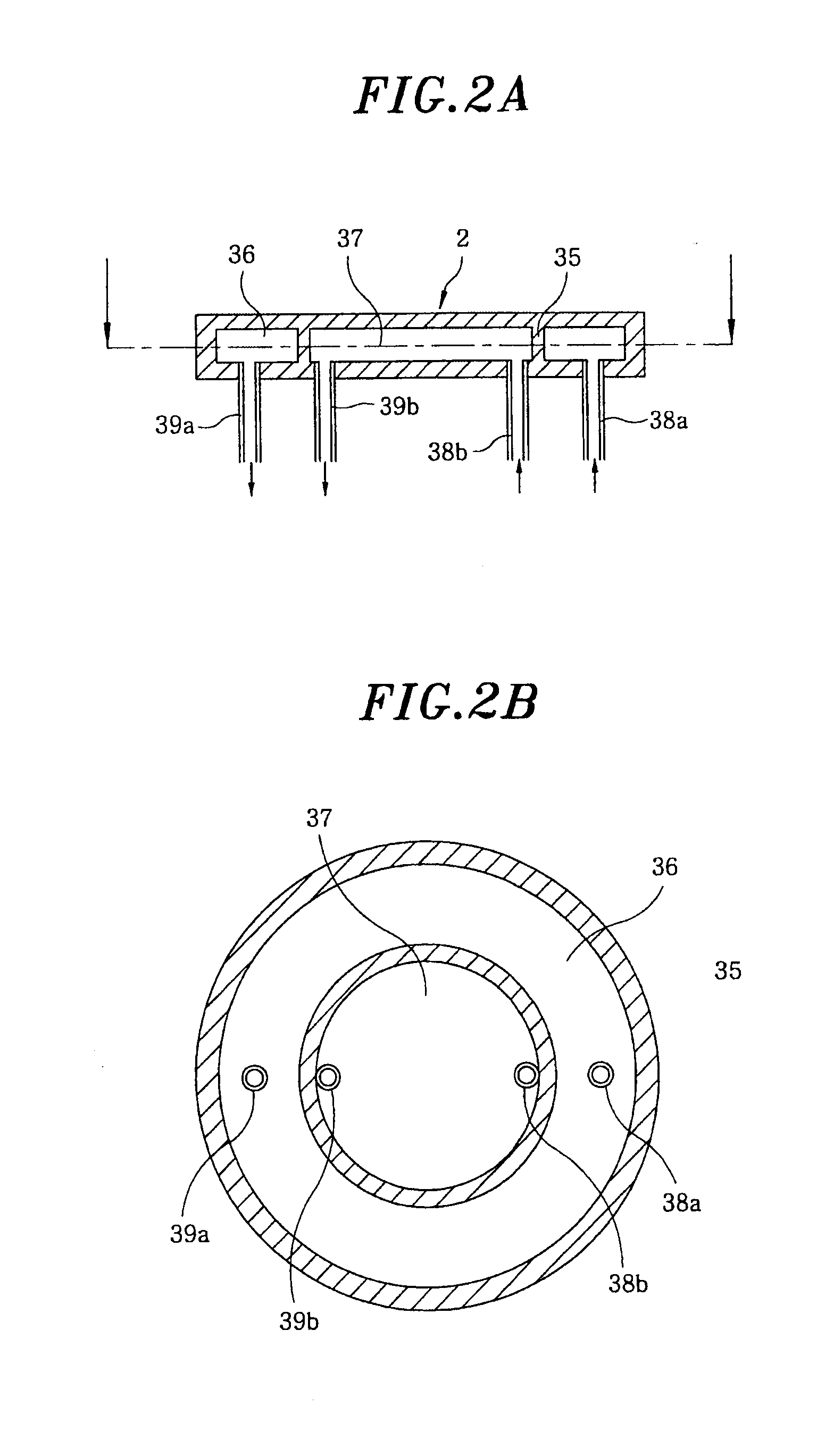

Temperature control device for target substrate, temperature control method and plasma processing apparatus including same

ActiveUS20090118872A1Shorten the time limitUniform temperatureControlling ratio of multiple fluid flowsTemperatue controlPlasma processingCooling channel

A temperature control device for a target substrate includes a mounting table having temperature control members respectively provided in temperature systems to control temperatures of regions of the target substrate to respective predetermined temperature levels; circulation channels through which fluids passing through the temperature control members flow; and heating channels each for flowing therein a heated fluid having a higher temperature compared to the fluids circulating in the circulation channels. The device further includes cooling channels each for flowing therein a cooled fluid having a lower temperature compared to the fluids circulating in the circulation channels; and joining units that join the circulation channels to build the respective temperature control systems, the joining units having flow rate control units that controls flow rate ratios of the fluids supplied from the respective channels to the temperature control members.

Owner:TOKYO ELECTRON LTD

Butler matrix for 3D integrated RF front-ends

InactiveUS8013784B2Reduce lossApparatus is enlargedAntenna arraysSimultaneous aerial operationsElectricityRF front end

A radar apparatus comprises a substrate having first and second sides, an antenna including radiative elements disposed on the first side of the substrate, a Butler matrix supported by the substrate having input and output ports, where each output port of the Butler matrix is electrically connected to a group of radiative elements, and input connections between a radio-frequency (RF) circuit and the input ports of the Butler matrix. The RF circuit may be supported by the second side of the substrate.

Owner:TOYOTA MOTOR CO LTD

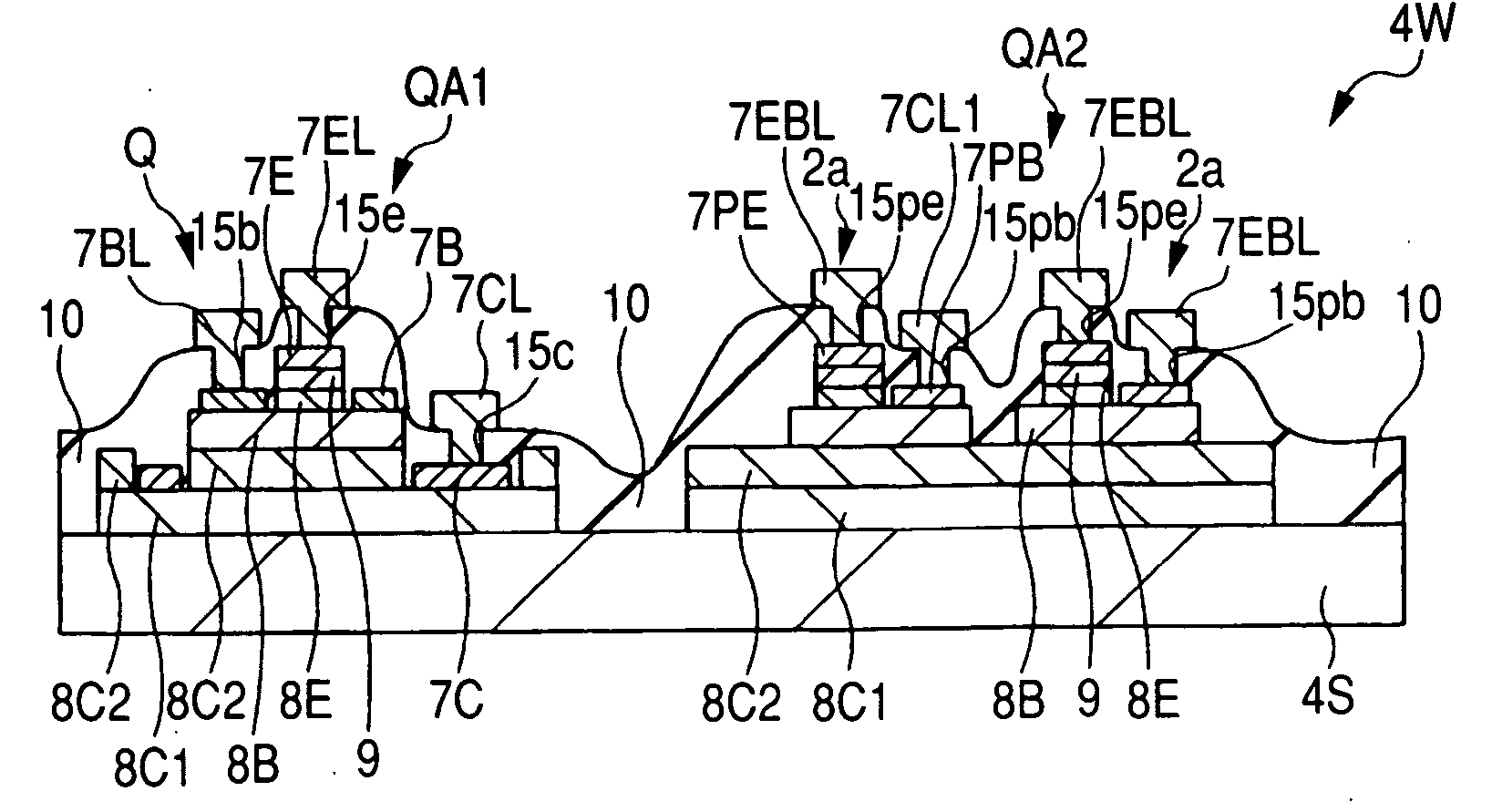

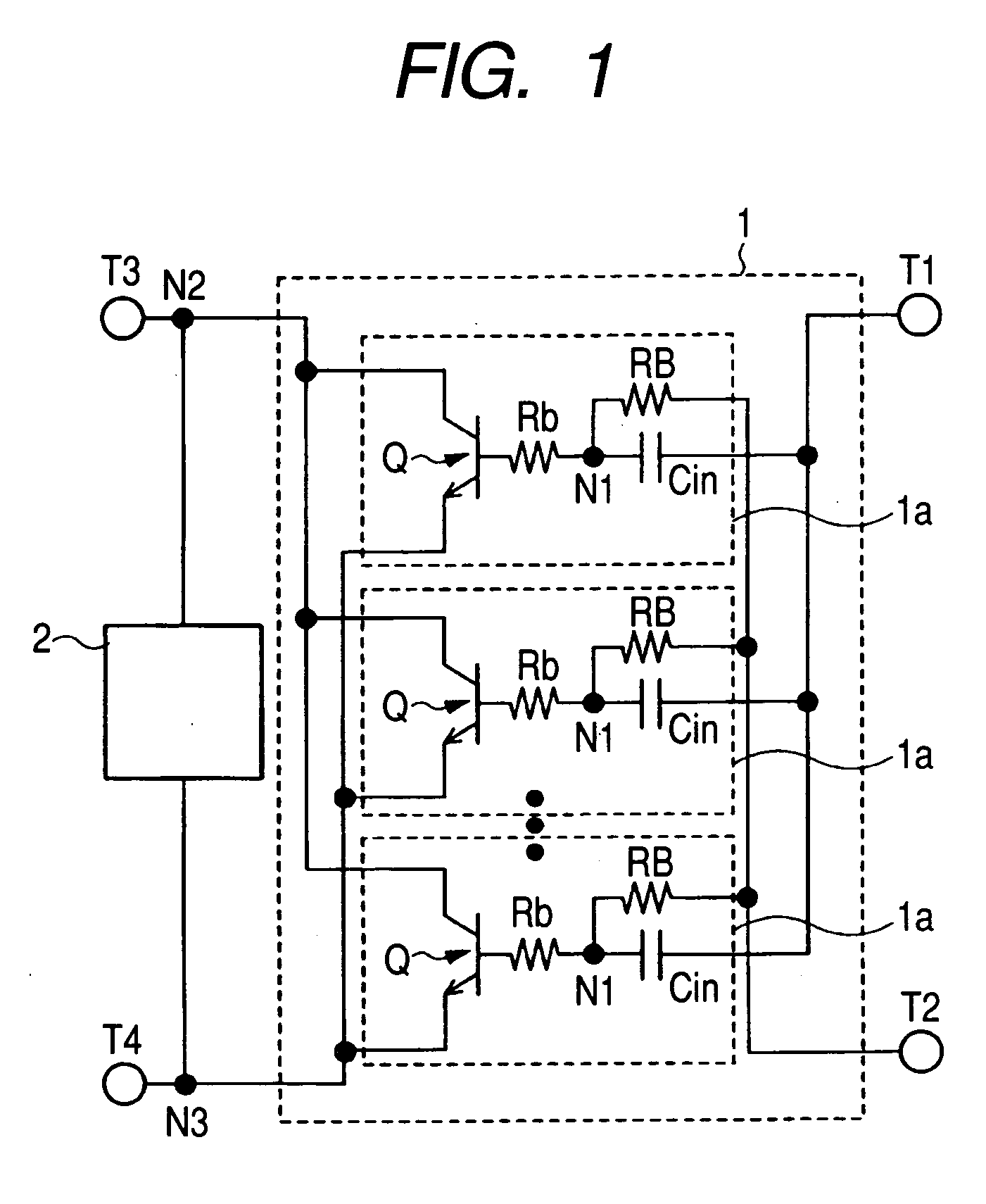

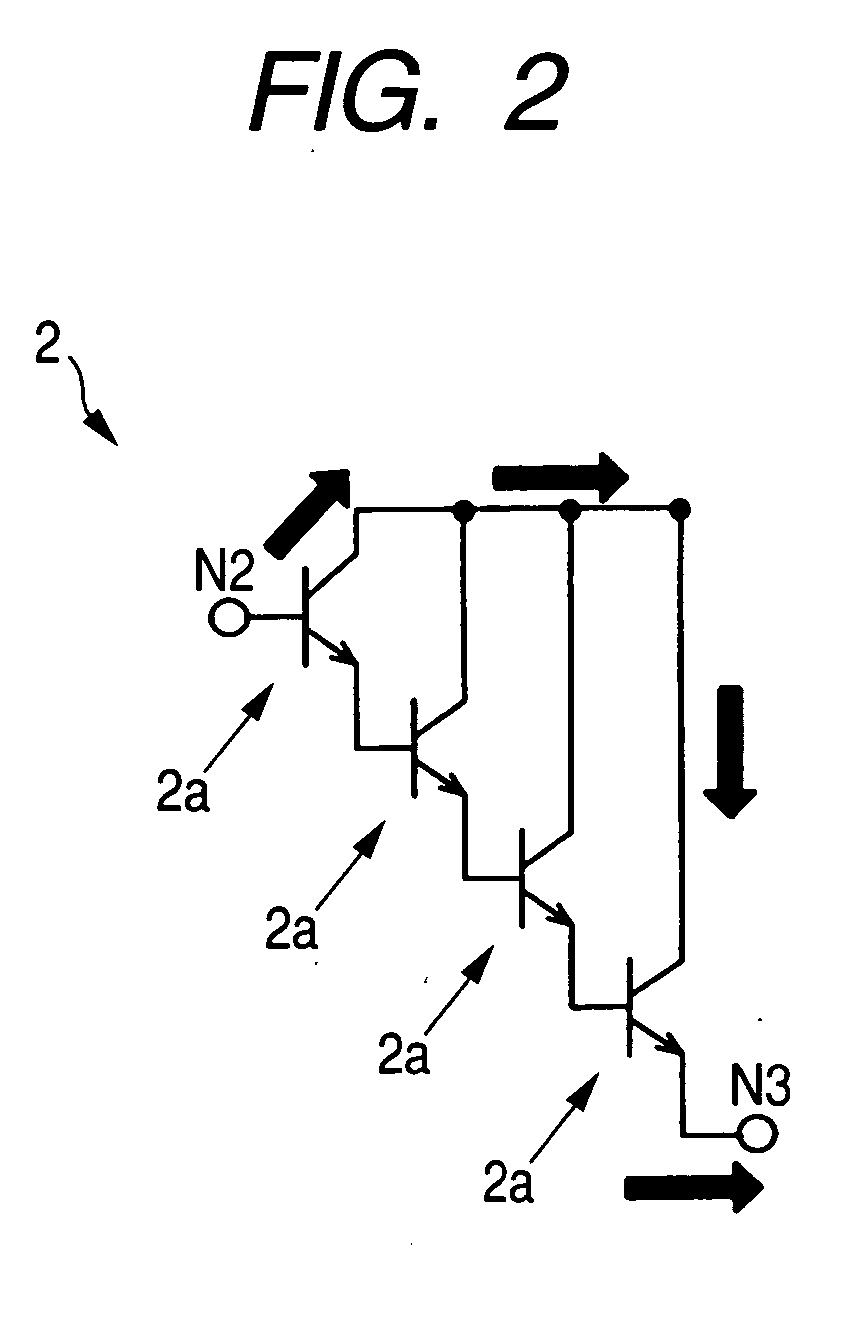

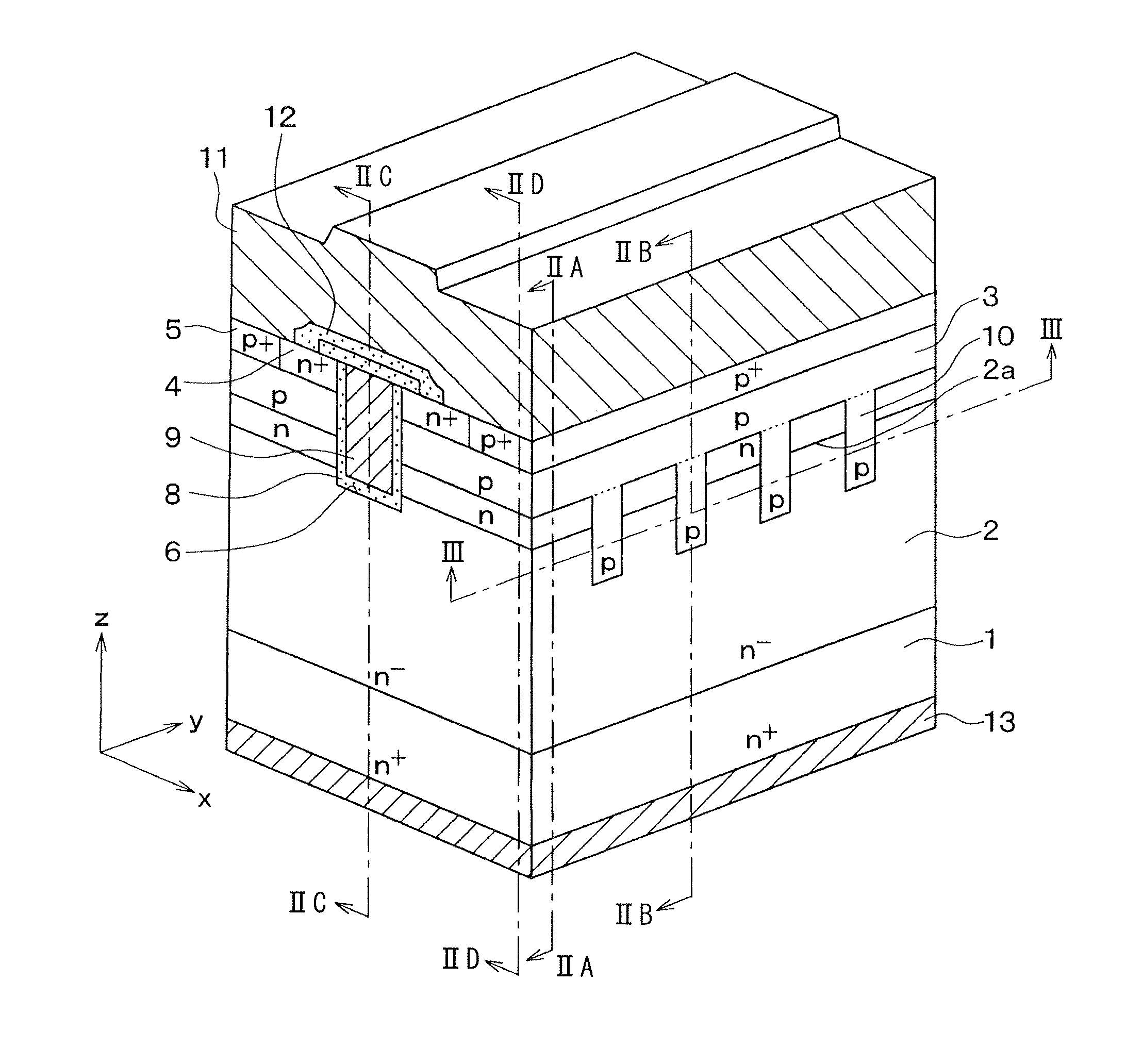

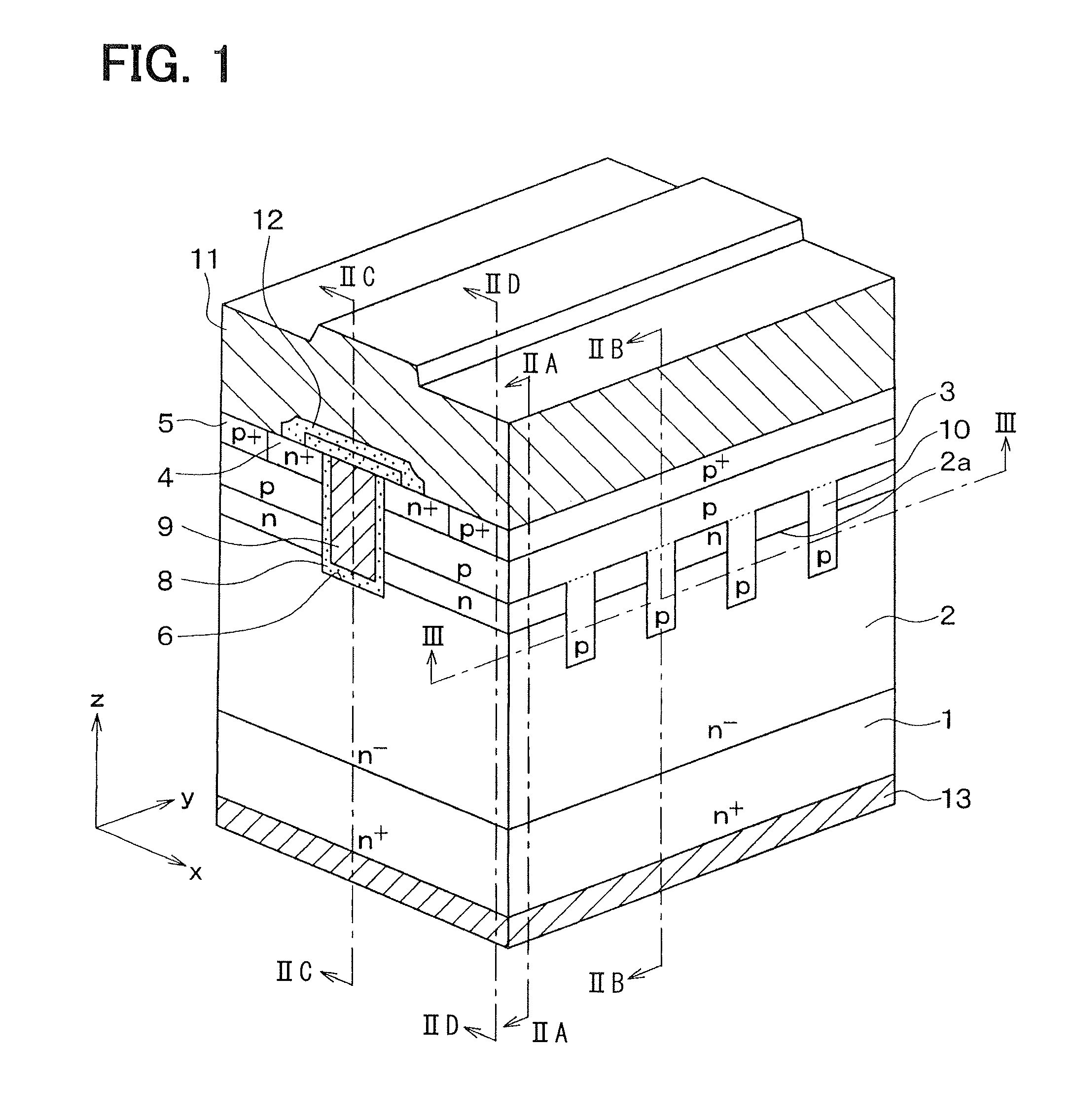

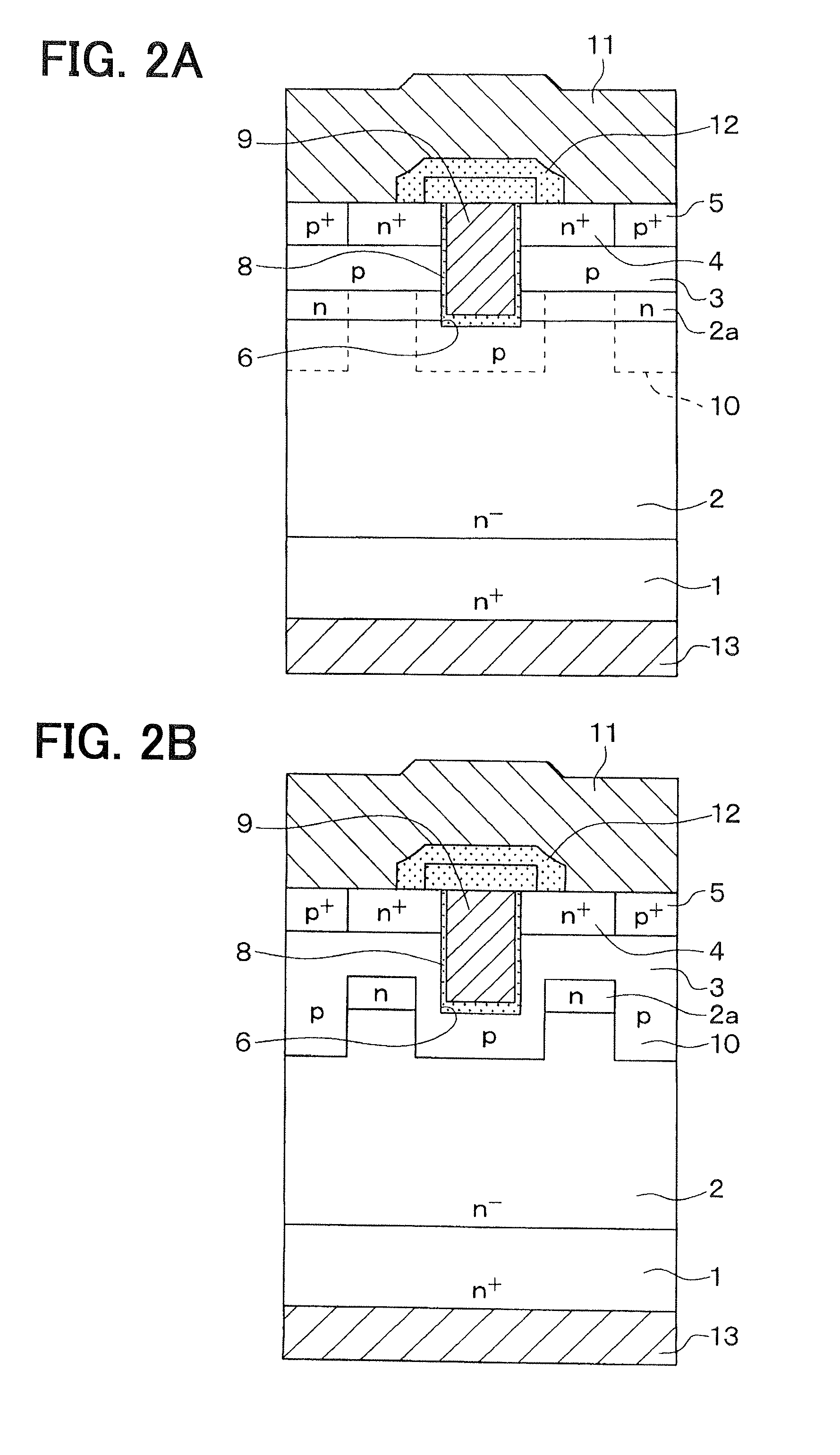

Semiconductor device and radio communication device

ActiveUS20060138460A1Lower temperature riseEnlarge regionTransistorSemiconductor/solid-state device detailsDevice materialMiniaturization

A technology which allows a reduction in the thermal resistance of a semiconductor device and the miniaturization thereof is provided. The semiconductor device has a plurality of unit transistors Q, transistor formation regions 3a, 3b, and 3e each having a first number (seven) of the unit transistors Q, and transistor formation regions 3c and 3d each having a second number (four) of the unit transistors Q. The transistor formation regions 3c and 3d are located between the transistor formation regions 3a, 3b, 3e, and 3f and the first number is larger than the second number.

Owner:MURATA MFG CO LTD

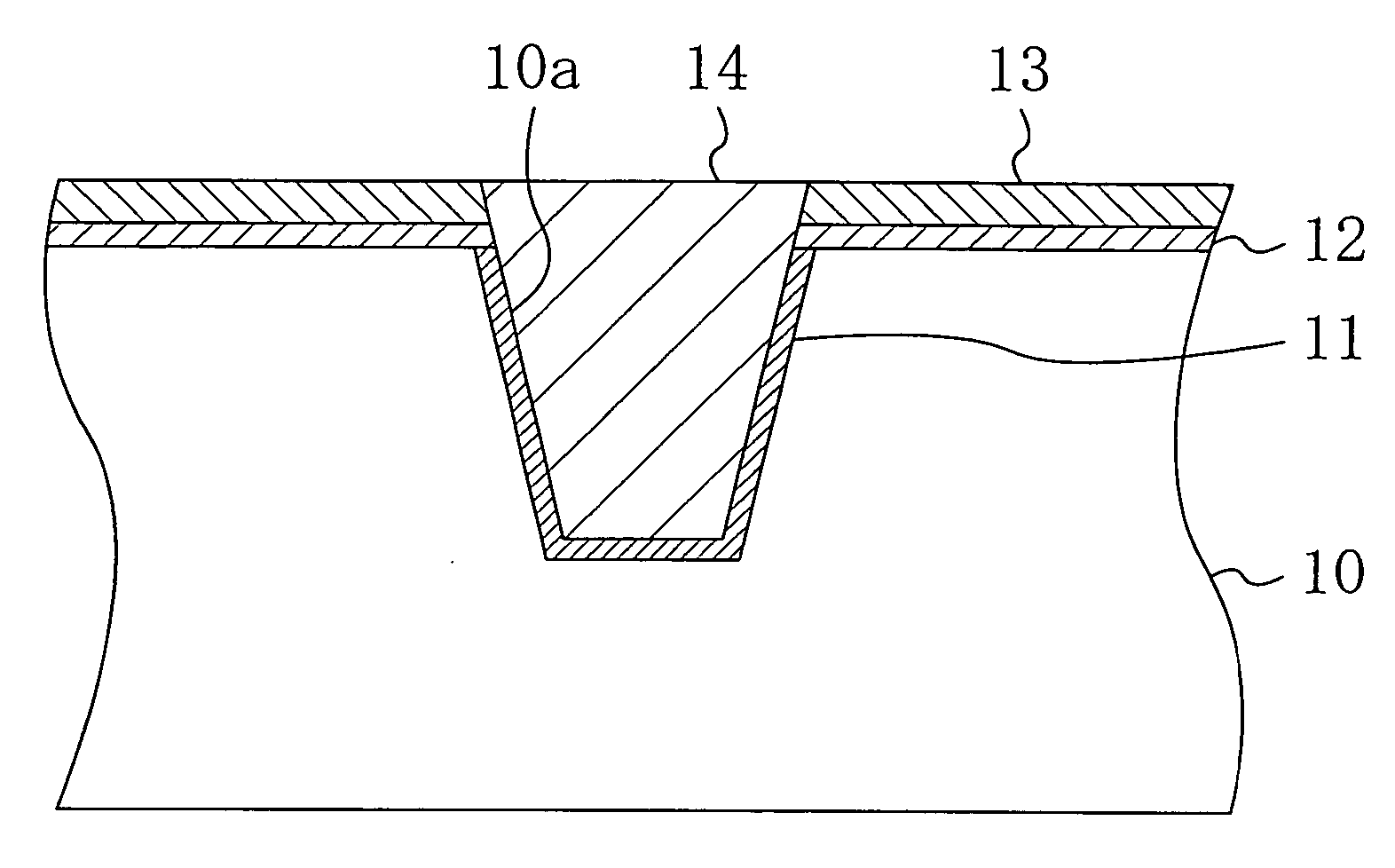

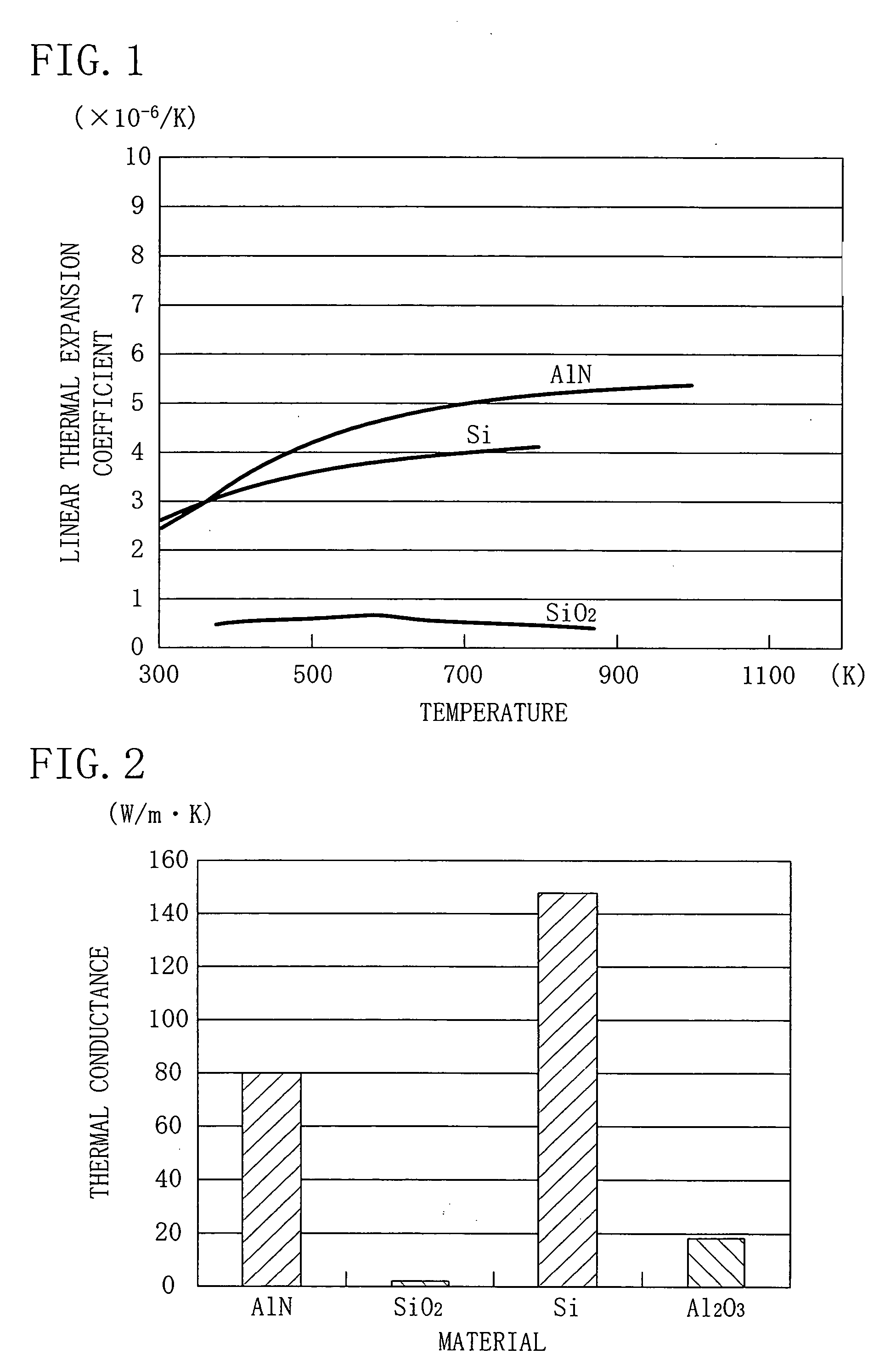

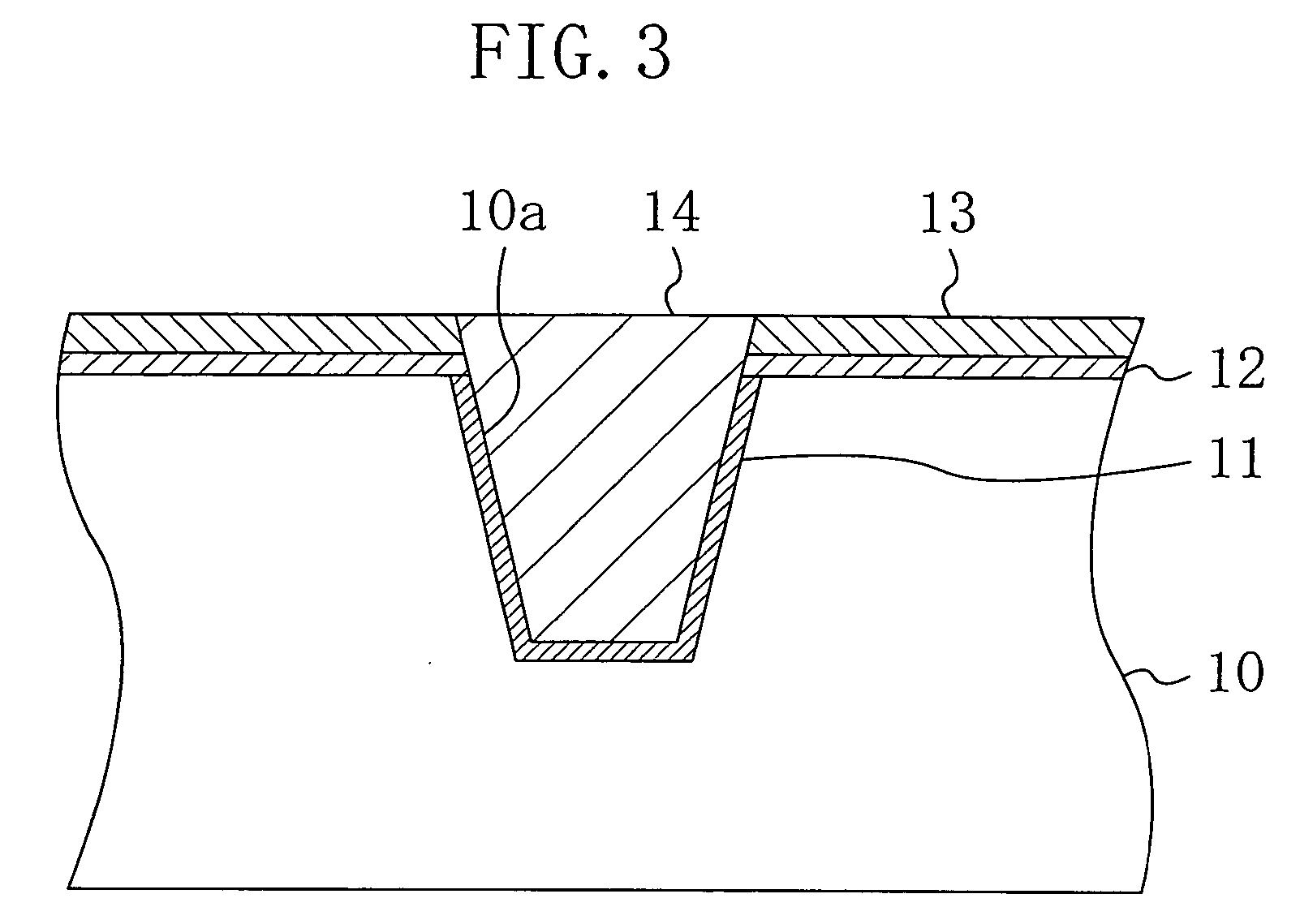

Semiconductor device and manufacturing method thereof

InactiveUS20060087000A1Improve thermal conductivityEnlarge regionSemiconductor/solid-state device manufacturingSemiconductor devicesThermal dilatationDevice material

A semiconductor device has a semiconductor layer of silicon which has a plurality of element formation regions, and a trench isolation region for isolating the plurality of element formation regions from each other. The trench isolation region is formed by filling a trench formed in an upper part of the semiconductor layer with an insulating metal nitride. A thermal expansion coefficient of the insulating metal nitride is closer to that of silicon than a thermal expansion coefficient of silicon oxide is to that of silicon.

Owner:PANASONIC CORP

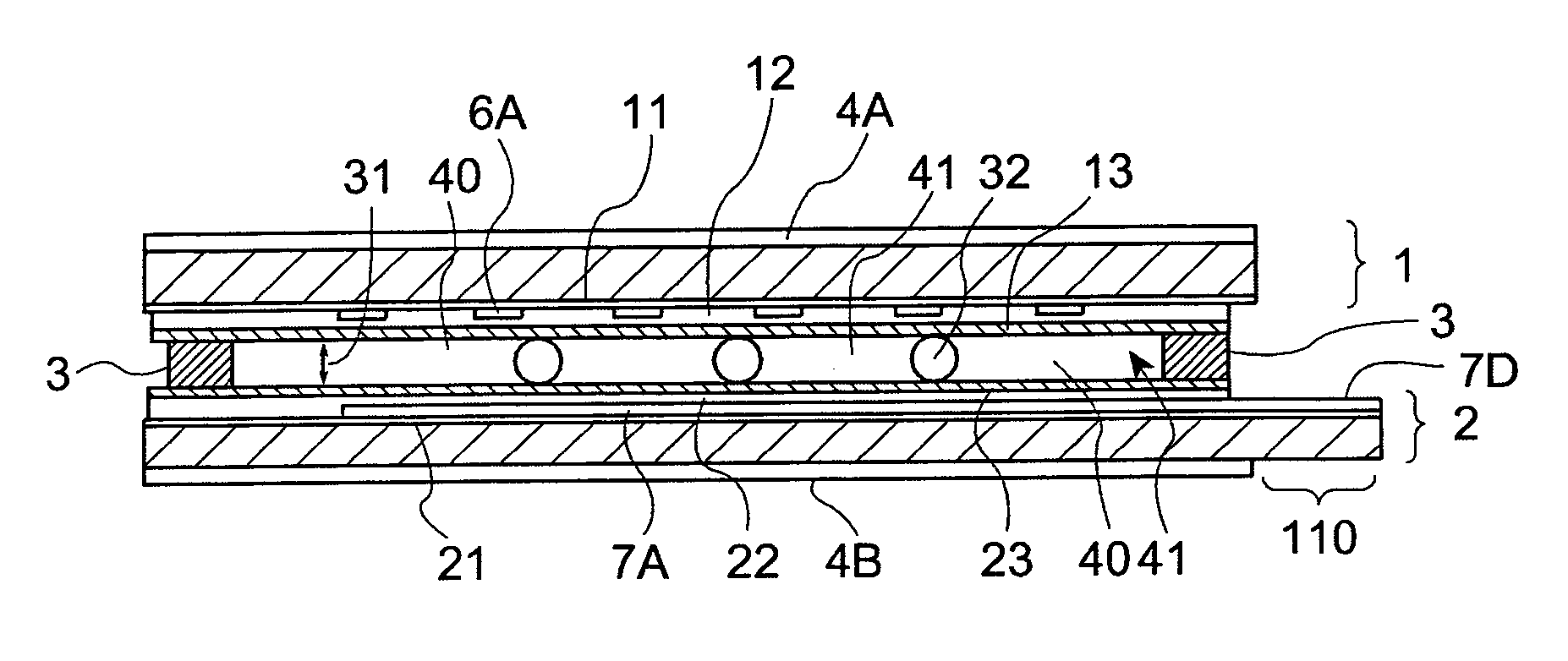

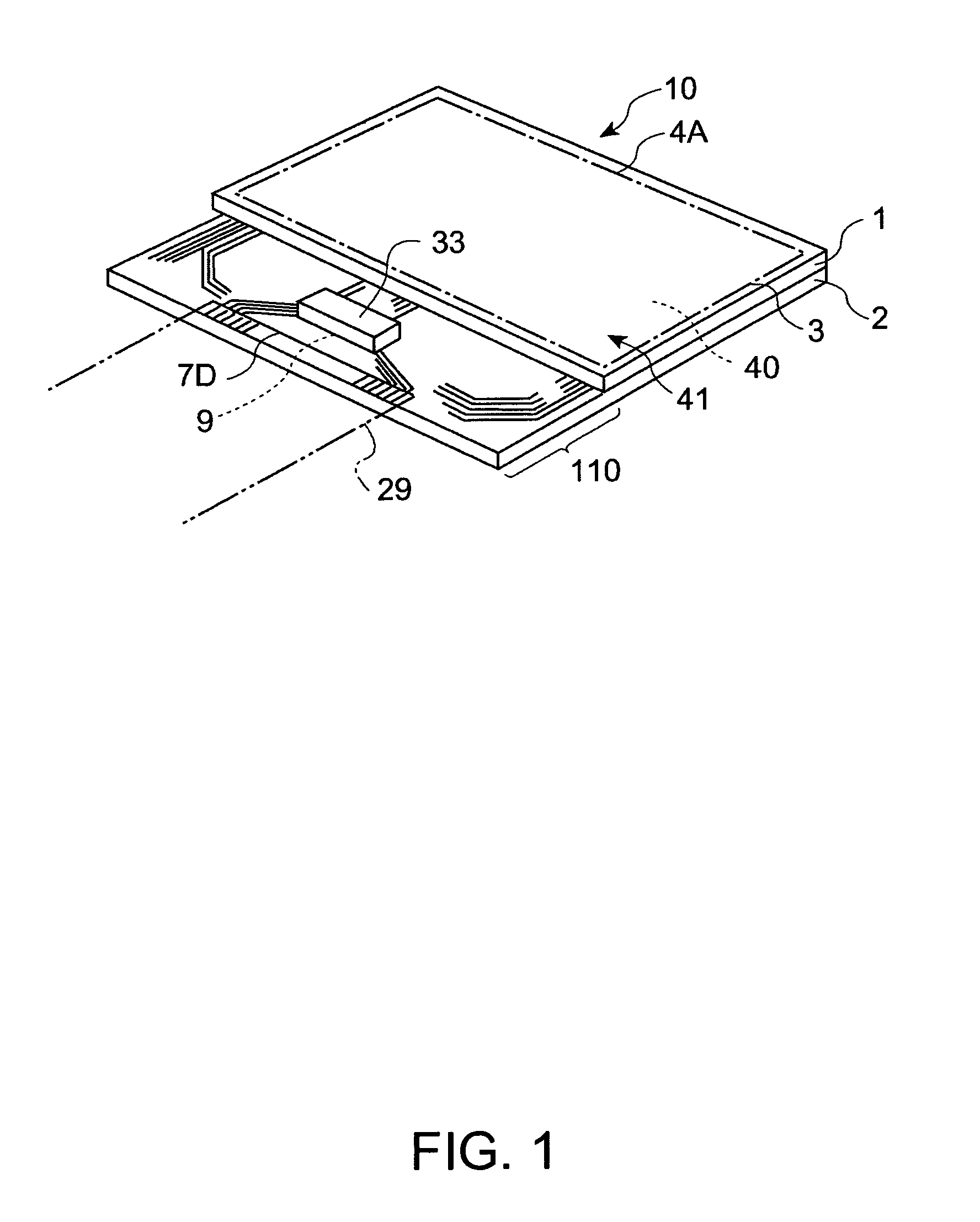

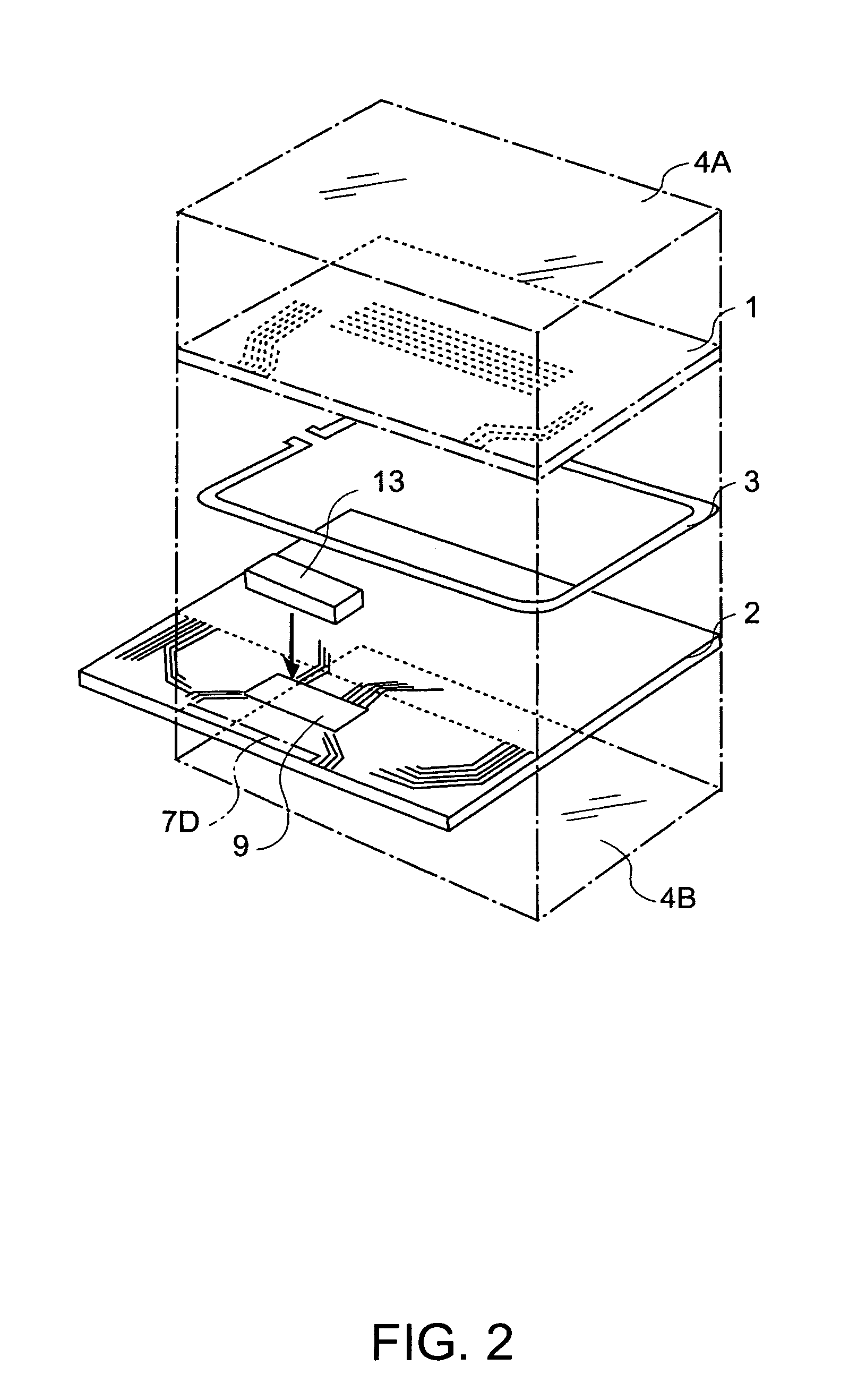

Liquid crystal panel and method of fabricating the same

In a liquid crystal panel 1 provided with first and second substrates 1 and 3 bonded by a sealant 3, alignment layers 13 and 23 for covering electrodes 6A and 7A, respectively, are formed up to the regions overlapping the regions for forming up to 3. Accordingly, since there is no space between the alignment 13 or 23 and the sealant 3, a low twist domain does not occur in a liquid crystal 40. Therefore, the vicinity of the inner periphery of the sealant can also be effectively used as the region for displaying images.

Owner:BOE TECH GRP CO LTD

Silicon carbide semiconductor device and method of manufacturing the same

ActiveUS20110291110A1Lower on-resistanceAmount of electric current that flowsSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor

The silicon carbide semiconductor device includes a substrate, a drift layer, a base region, a source region, a trench, a gate insulating layer, a gate electrode, a source electrode, a drain electrode, and a deep layer. The deep layer is disposed under the base region and is located to a depth deeper than the trench. The deep layer is divided into a plurality of portions in a direction that crosses a longitudinal direction of the trench. The portions include a group of portions disposed at positions corresponding to the trench and arranged at equal intervals in the longitudinal direction of the trench. The group of portions surrounds corners of a bottom of the trench.

Owner:DENSO CORP +1

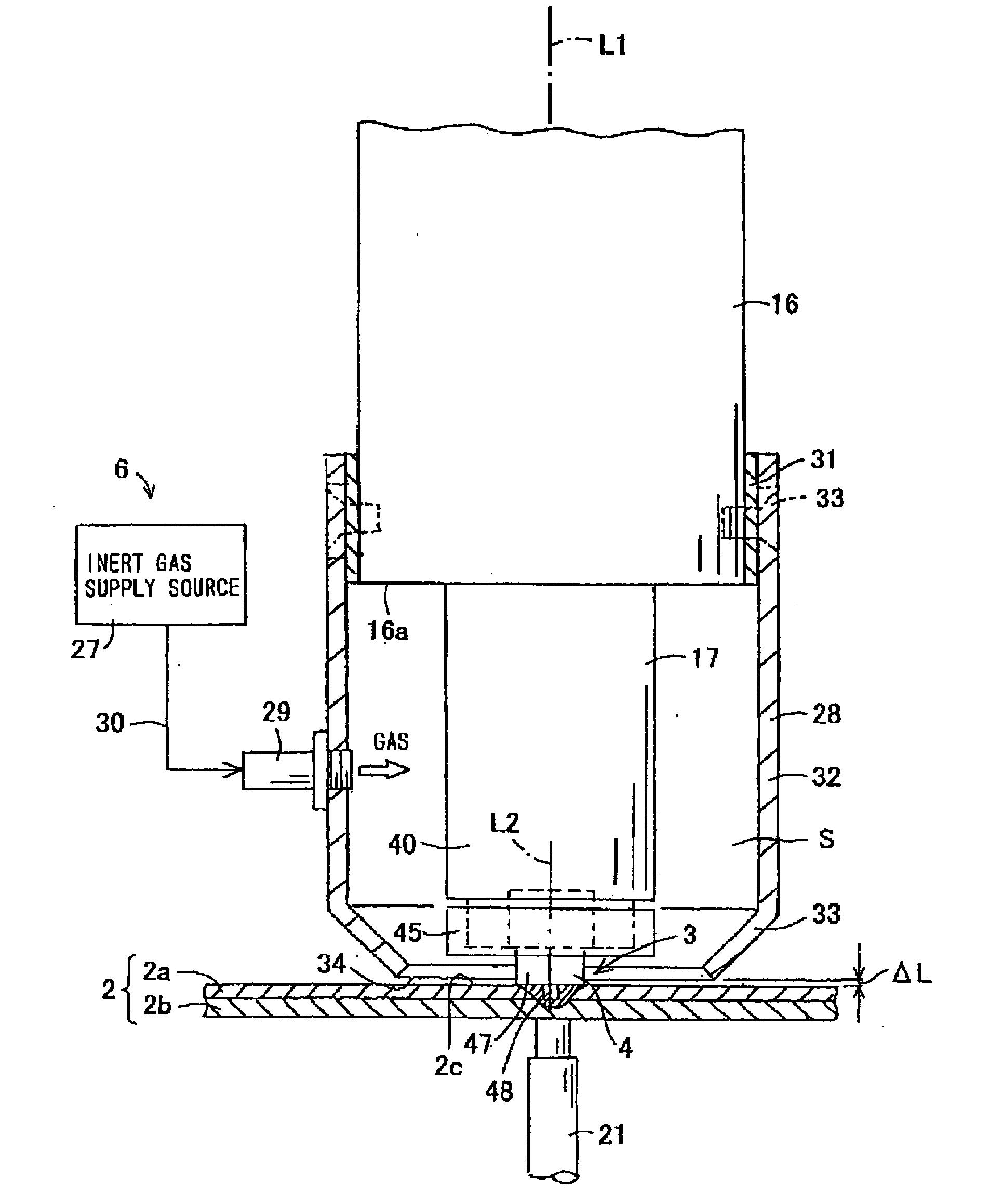

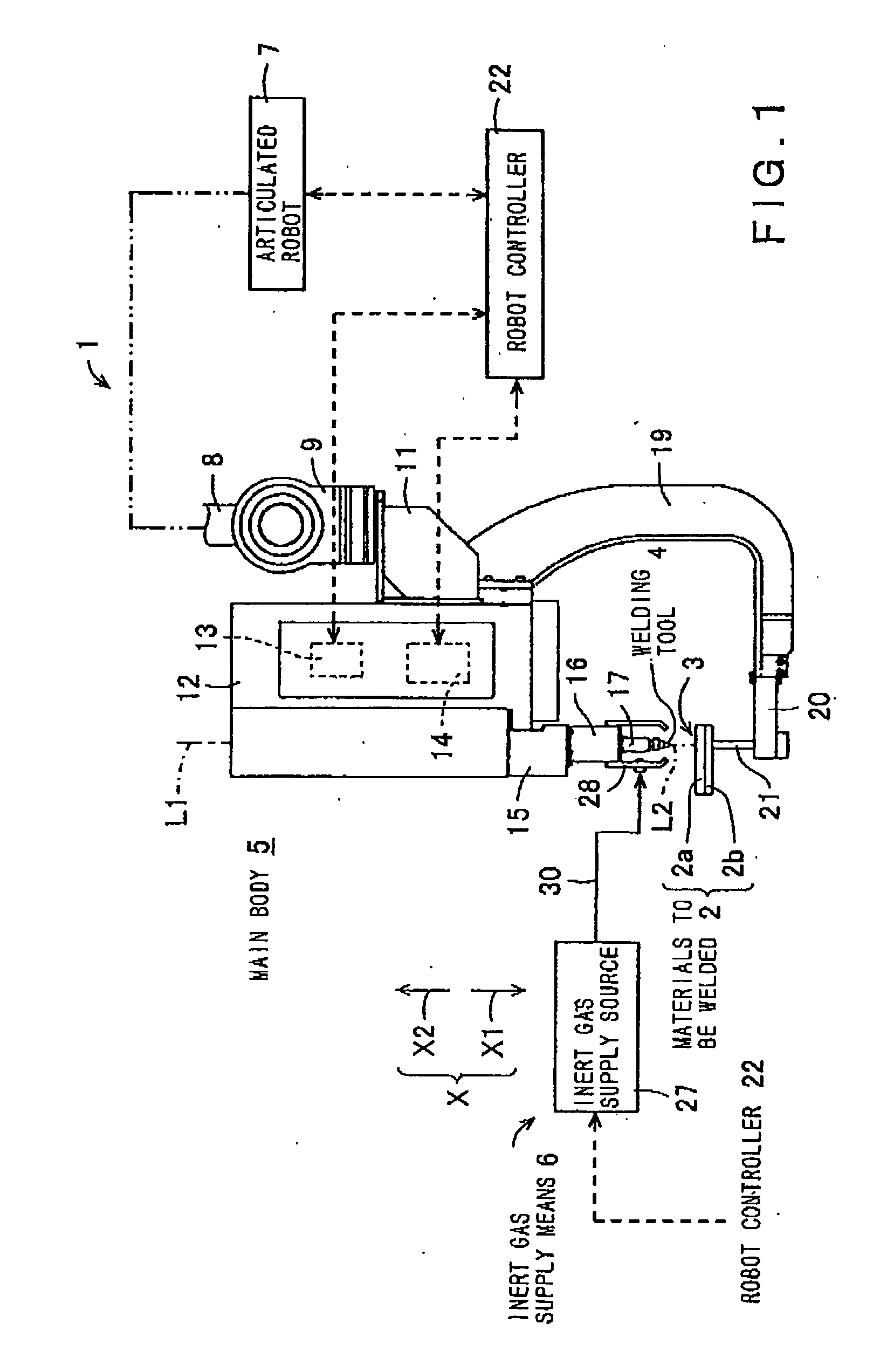

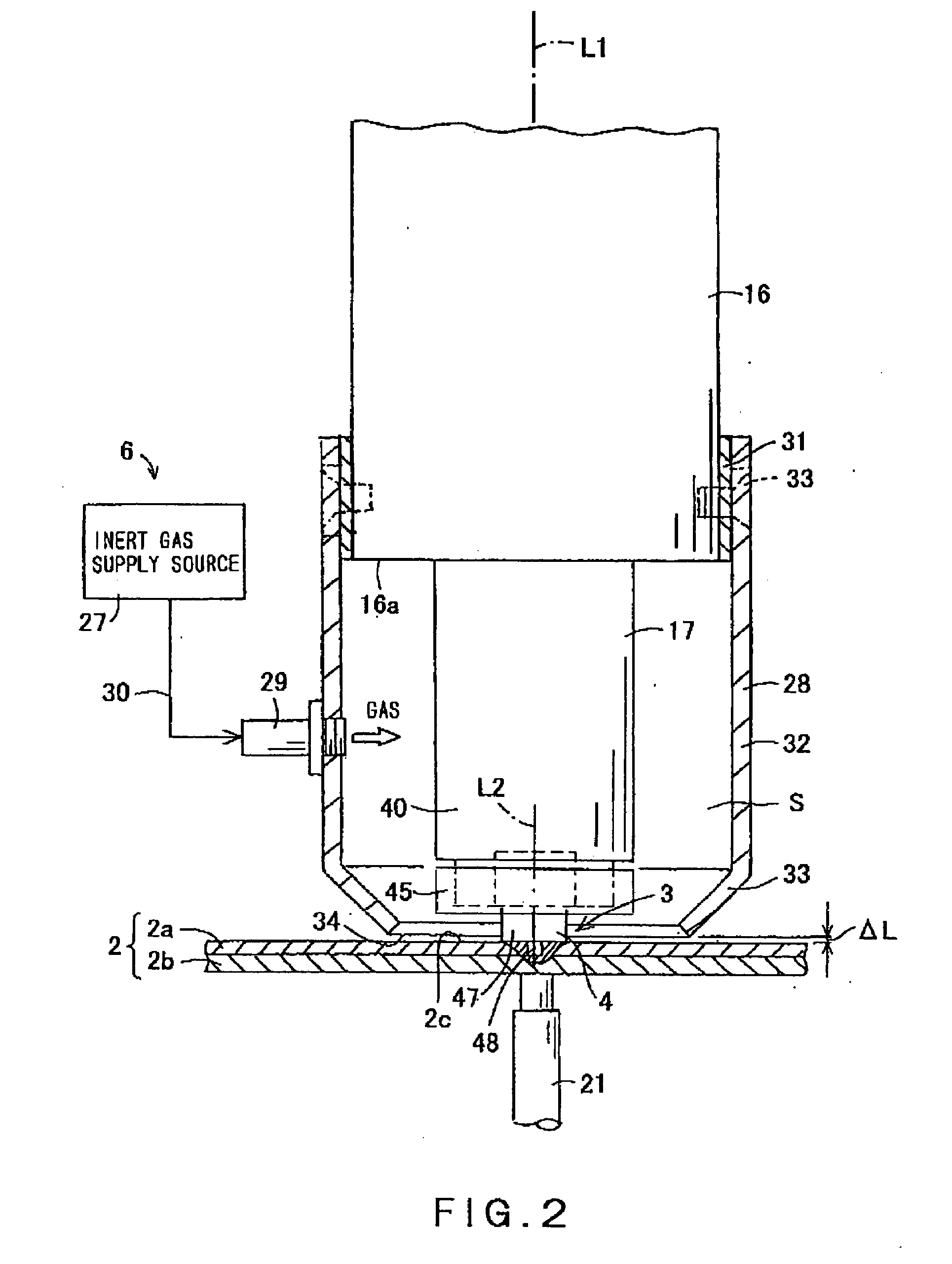

Friction stir welding machine and friction stir welding tool

ActiveUS20080023524A1Prolong lifeInhibit wearWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNitride

The present invention is a friction stir welding machine adapted to perform solid phase welding on a welding portion of materials to be welded, by pressing a welding tool against the welding portion of the materials to be welded while rotating the welding tool, and forcing the welding tool to be advanced into a softened portion which is softened by a frictional heat while stirring the softened portion, wherein a coating made of aluminum nitride is formed on at least a region of the welding tool to be in contact with the materials to be welded.

Owner:KAWASAKI HEAVY IND LTD

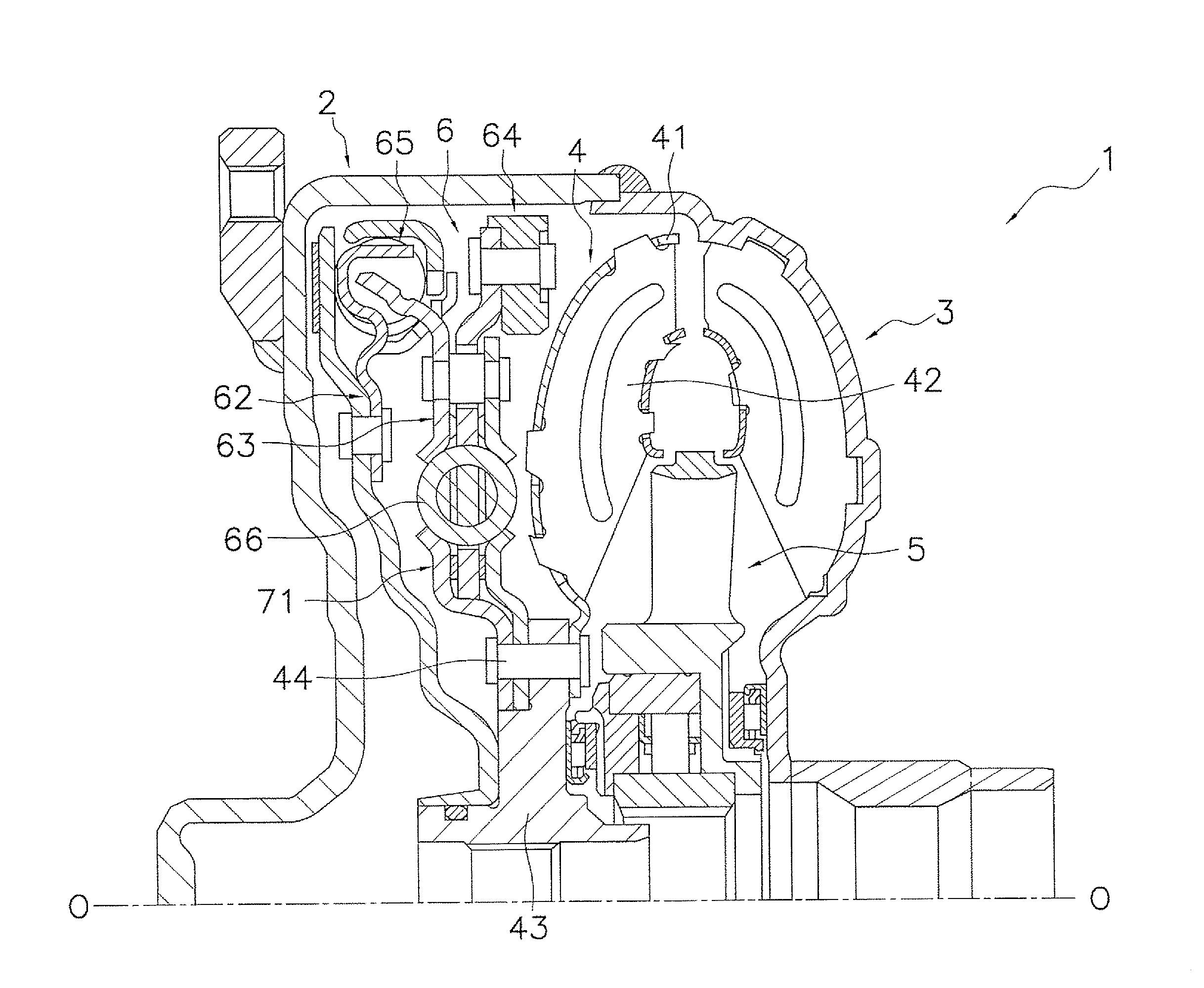

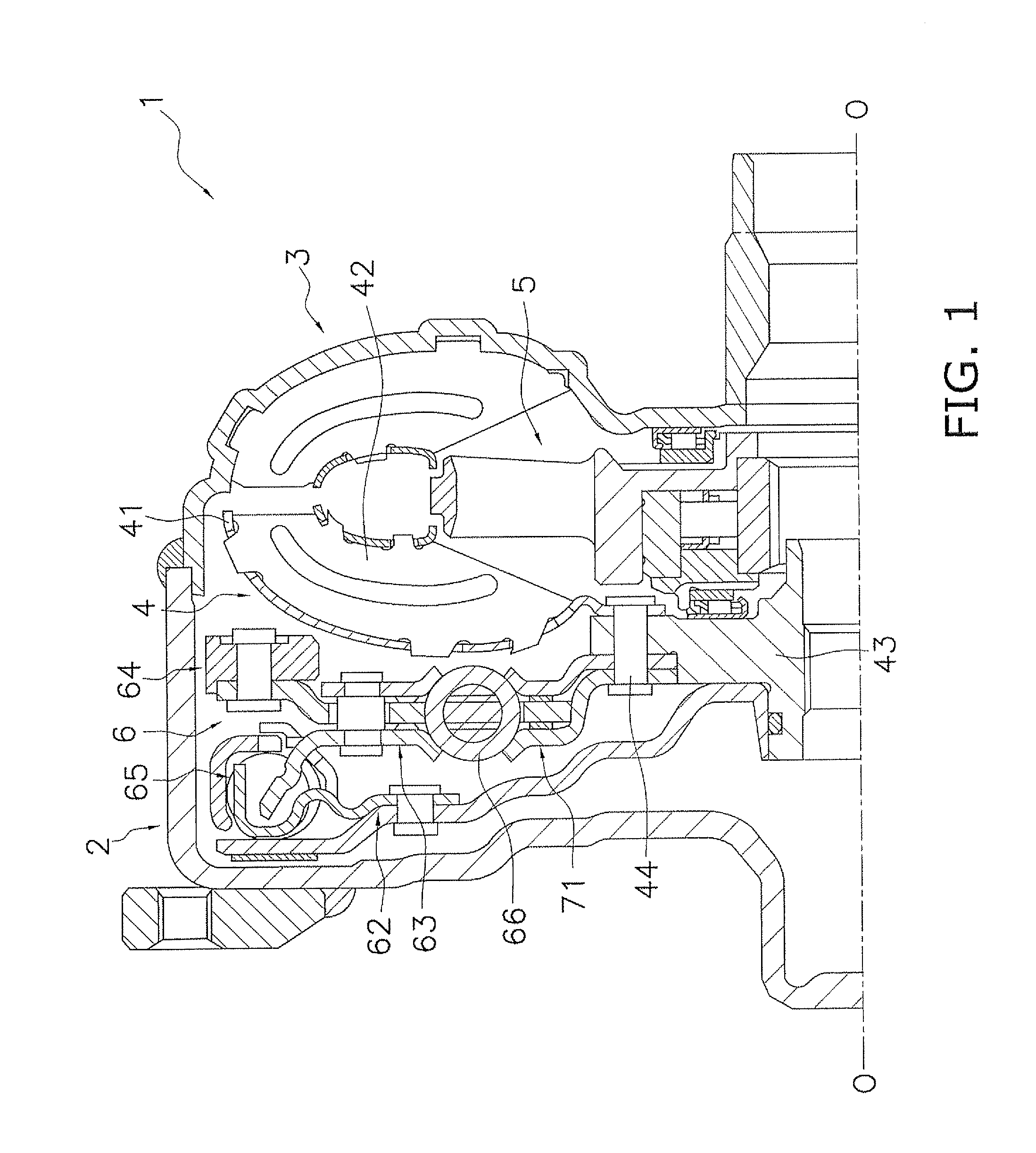

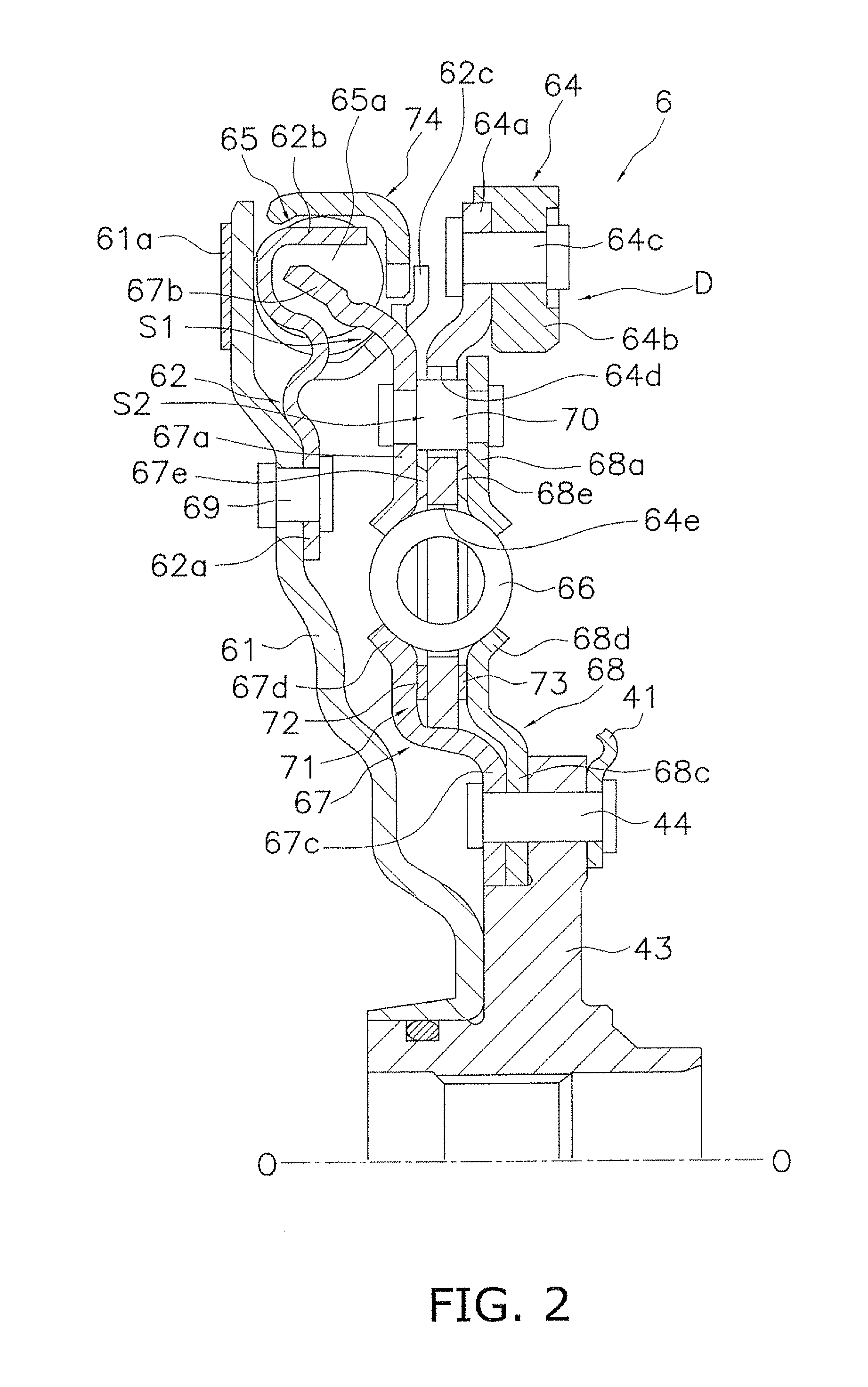

Lockup device and fluid type power transmitting device

ActiveUS20110031083A1Improve fuel efficiencyImprove damping performanceRotary clutchesFluid gearingsCoil springFuel efficiency

The object of the invention is to provide a lockup device that can improve a fuel efficiency of a vehicle. The lockup device (6) has a piston (61), an output plate (63), a first coil spring (65), an inertia member (64), and a second coil spring (66). The output plate (63) is coupled to a turbine (4) such that it can rotate as an integral unit with the turbine (4). The first coil spring (65) elastically couples the piston (61) to the output plate (63) in a rotational direction. The inertia member (64) is provided such that it can rotate relative to the output member (63). The second coil spring (66) elastically couples the inertia member (64) to the output plate (63) in a rotational direction.

Owner:EXEDY CORP

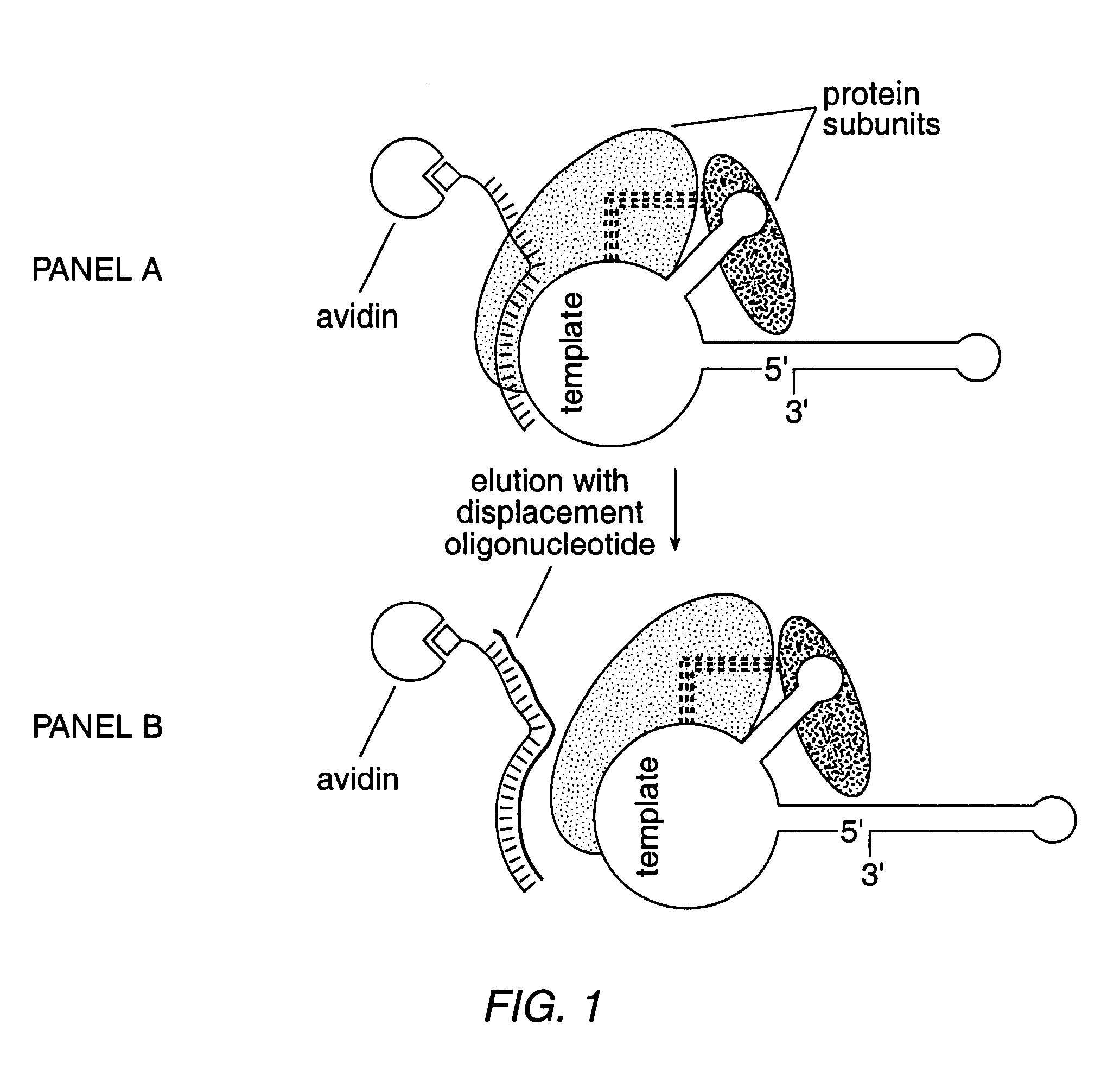

Telomerase

InactiveUS6309867B1Avoid the needEnlarge regionPeptide/protein ingredientsAntibody mimetics/scaffoldsTelomeraseRibonucleoprotein complex

The present invention is directed to novel telomerase nucleic acids and amino acids. In particular, the present invention is directed to nucleic acid and amino acid sequences encoding various telomerase protein subunits and motifs, including the 123 kDa and 43 kDa telomerase protein subunits of Euplotes aediculatus, and related sequences from Schizosaccharomyces, Saccharomyces sequences, and human telomerase. The present invention is also directed to polypeptides comprising these telomerase protein subunits, as well as functional polypeptides and ribonucleoproteins that contain these subunits.

Owner:UNIV OF COLORADO THE REGENTS OF

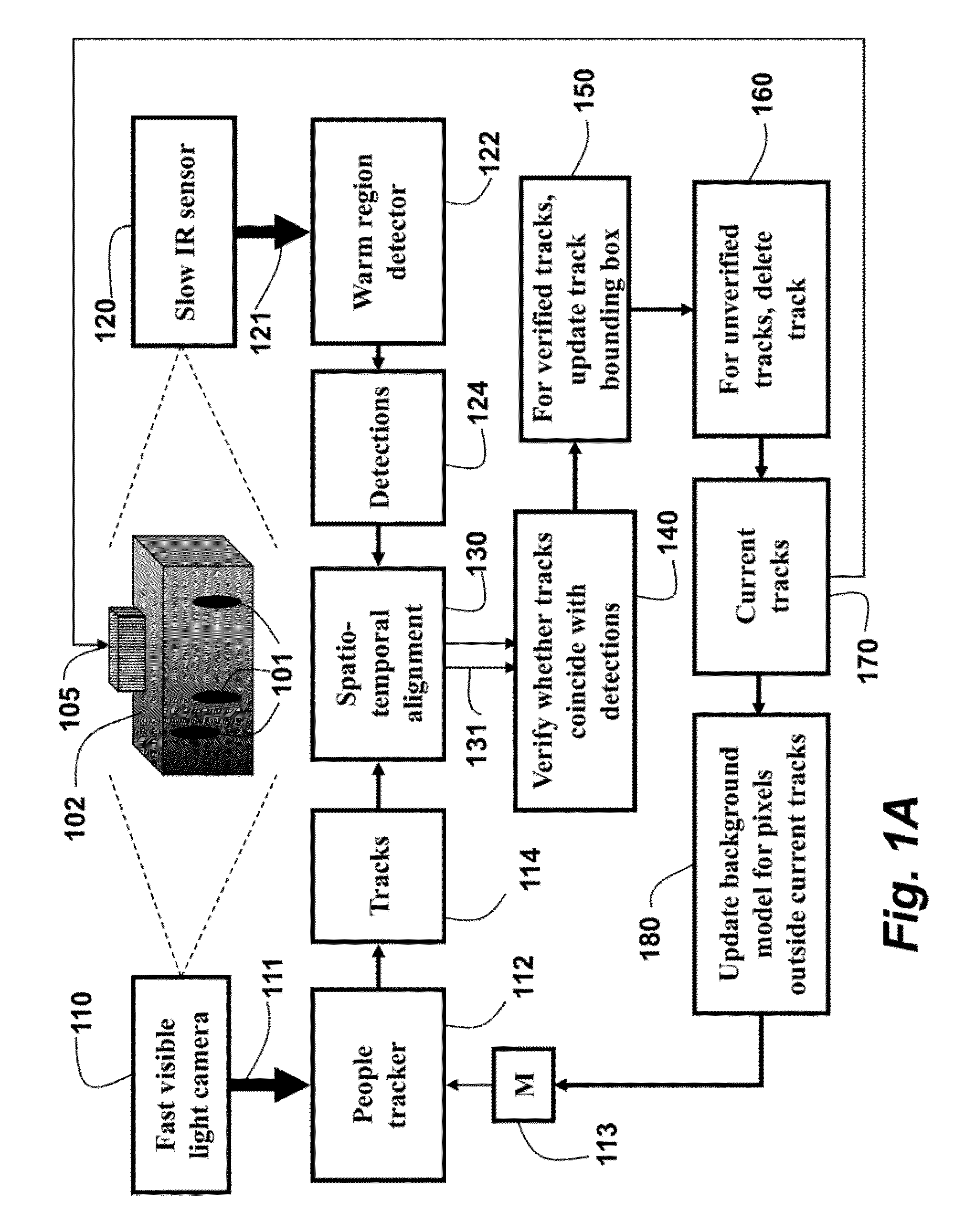

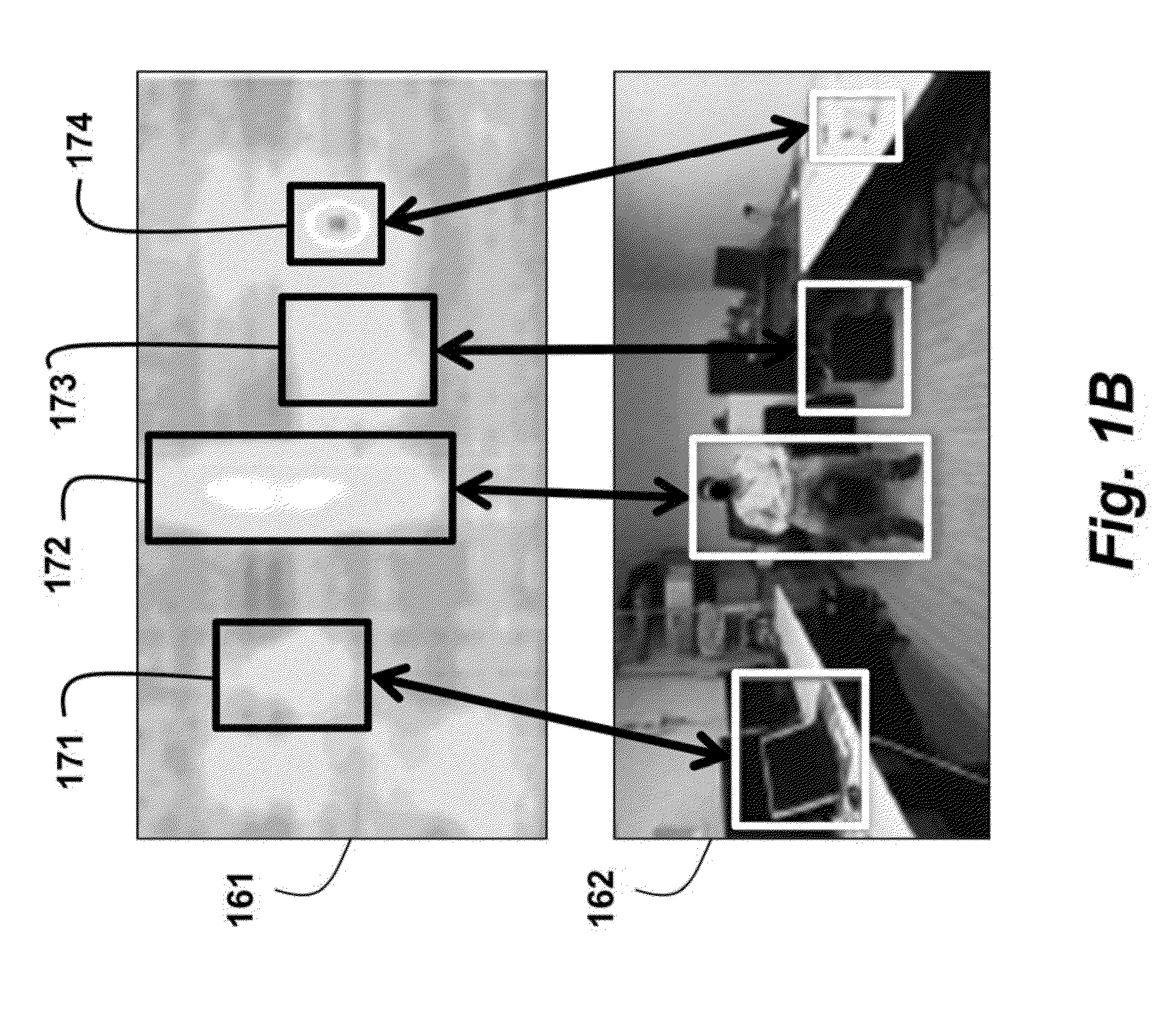

Method and System for Tracking People in Indoor Environments using a Visible Light Camera and a Low-Frame-Rate Infrared Sensor

ActiveUS20150324656A1Easy to controlSlow frame rateTelevision system detailsImage enhancementThermal infraredImage sequence

A method and system tracks objects in an environment by acquiring a first sequence of images of the environment with a visible-light camera having a first frame rate and a second sequence of images with a thermal infrared sensor having a second frame rate. The second frame rate is substantially lower than the first frame rate. The objects are tracked in the first sequence of images to obtain tracks. Warm regions in the second sequence of images are detected to obtain detections. The tracks and the detections are aligned spatially and temporally, and verified to determine whether the tracks and detections coincide after the aligning.

Owner:MITSUBISHI ELECTRIC RES LAB INC

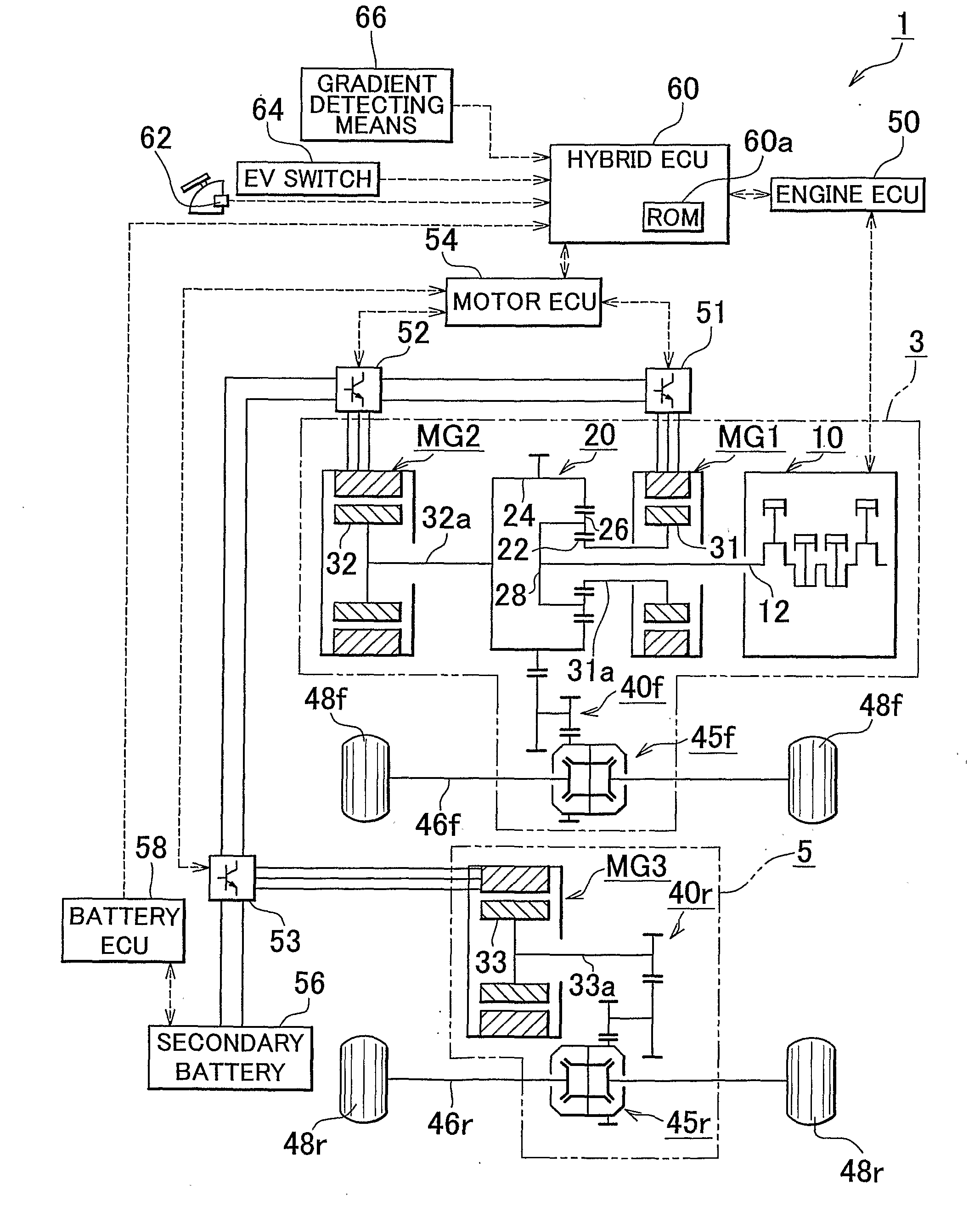

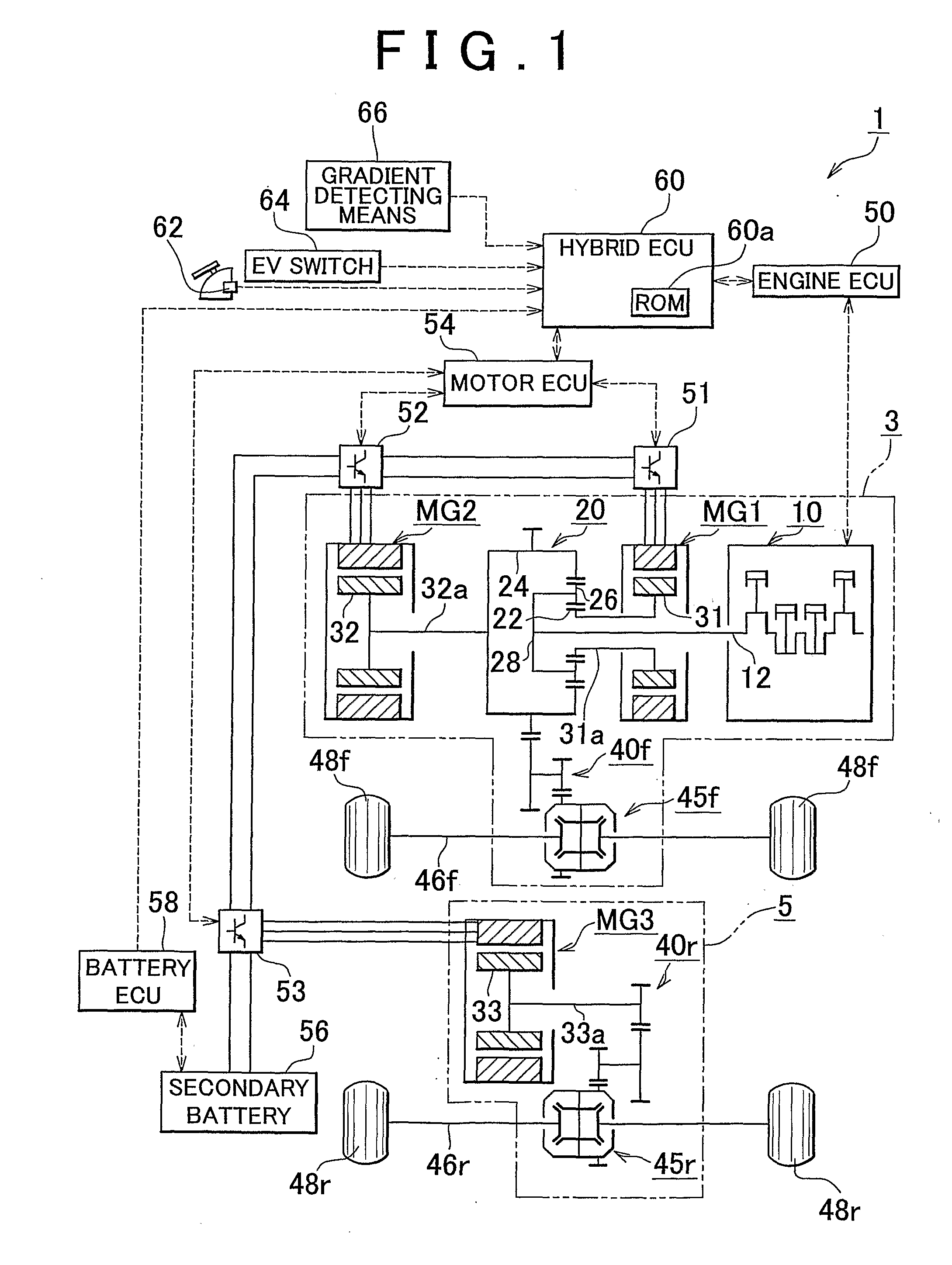

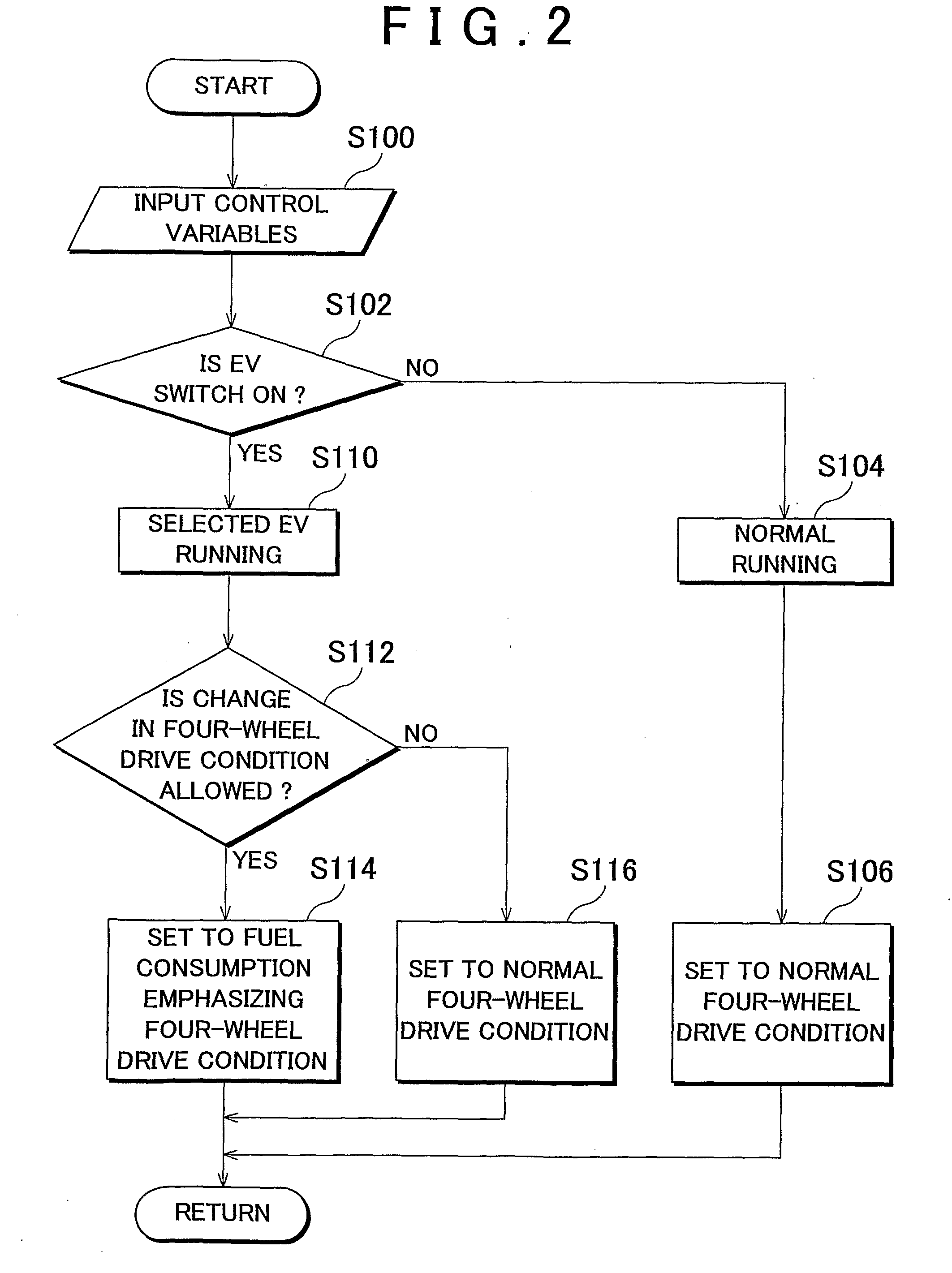

Hybrid Vehicle and Control Method Thereof

ActiveUS20090024262A1Reduce power consumptionReduced areaHybrid vehiclesDigital data processing detailsHybrid vehicleDriving mode

A hybrid vehicle is provided with means for setting a four-wheel drive condition which is a condition for switching from two-wheel drive to four-wheel drive, and an EV switch which, when turned on by an occupant of the vehicle, places the vehicle in an EV driving mode in which only an electric motor is used as the power source. The four-wheel drive condition setting means changes the four-wheel drive condition to reduce a region in which the vehicle operates in four-wheel drive when the EV switch is on as compared to when the EV switch is off. As a result, the vehicle operates in two-wheel drive more frequently, thus reducing power consumption.

Owner:TOYOTA JIDOSHA KK

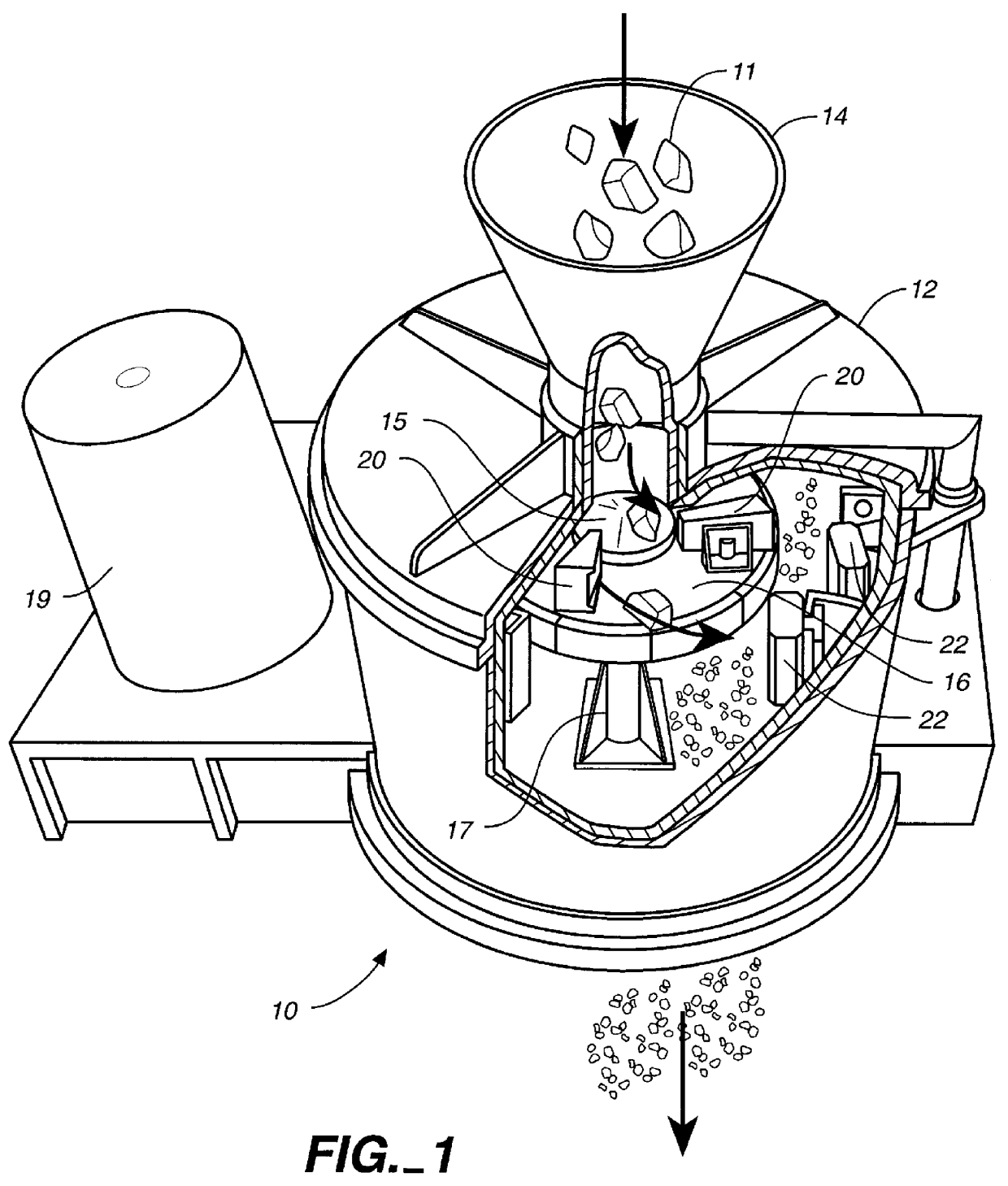

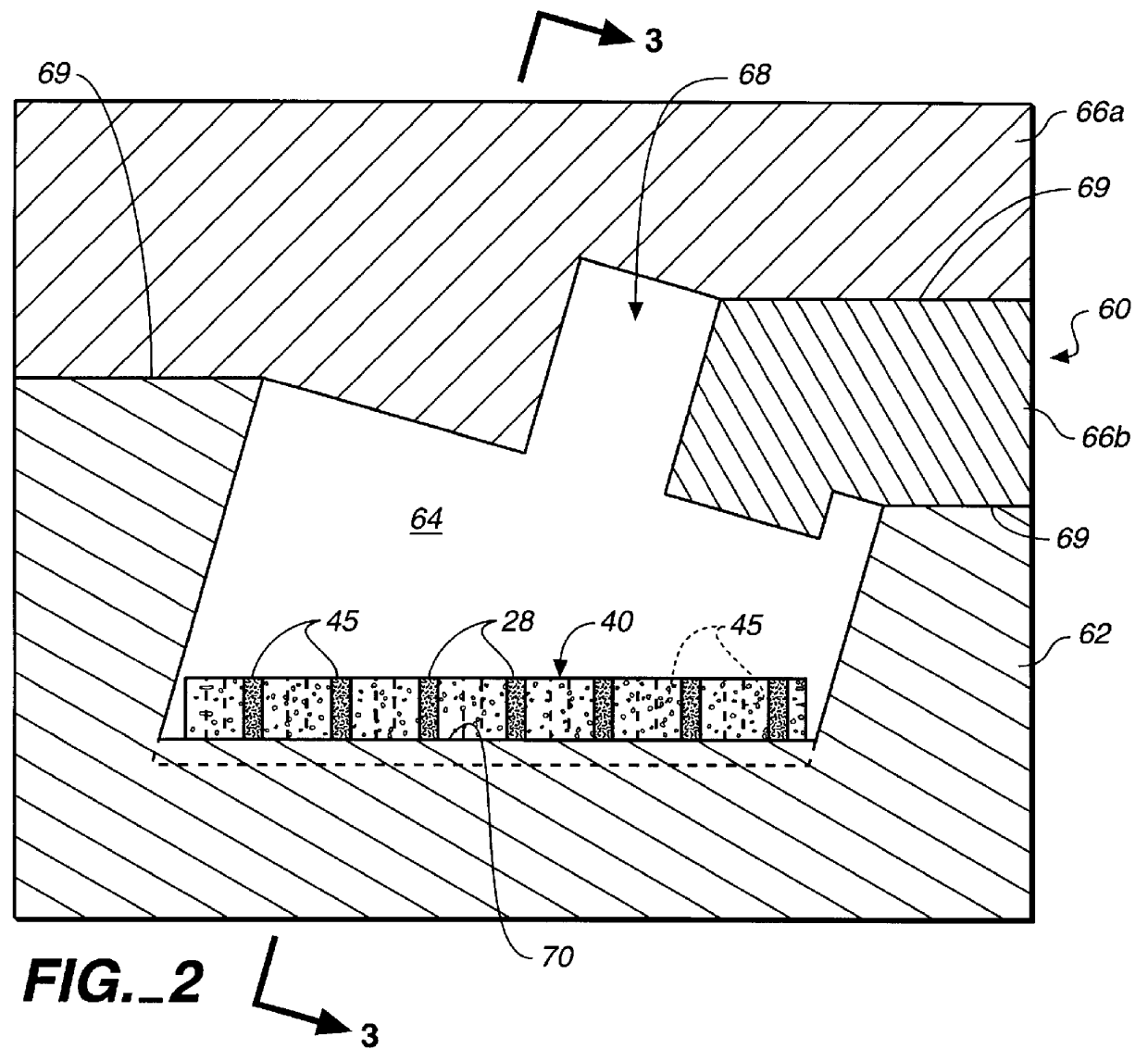

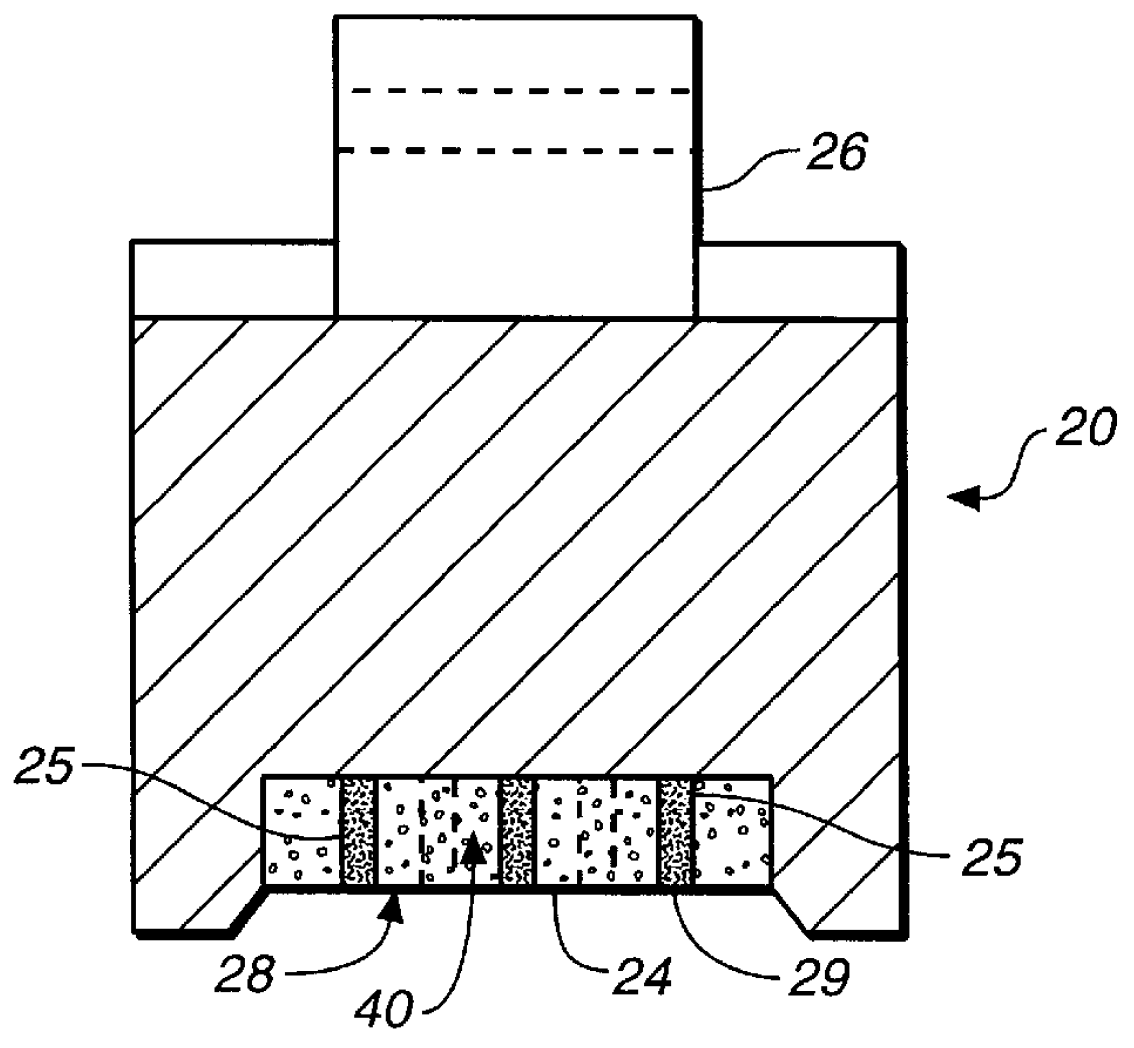

Wear resistant, high impact, iron alloy member and method of making the same

InactiveUS6033791AImprove impact performanceImprove wear resistanceGrain treatmentsThin material handlingShell moldingWear resistant

A wear resistant, high-impact iron alloy member (20,22) suitable for use in an impact rock crusher and a method of making the same. The invention provides a white iron alloy member (20,22) having at least one wear surface (24) with carbide granules encapsulated in a matrix (28) of white iron and contained in a selected region adjacent the wear surface (24) of the member (20,22). The iron alloy member is made by a method of casting comprising the steps of: placing a molding insert (35,40) in a mold (60) at a selected location adjacent the wear surface (24); positioning a quantity of carbide granules (29), most preferably tungsten carbide granules 29, in the molding insert (35,40) before pouring; and pouring molten white iron alloy into the mold (60) to form the casting. The tungsten carbide granules (29) are substantially contained at a selected location by the molding insert (35,40), and the resulting casting (20,22) can be heat treated and cooled to provide a component for a rock crusher or the like which exhibits improved resistance to wear.

Owner:DALLESPORT FOUNDRY

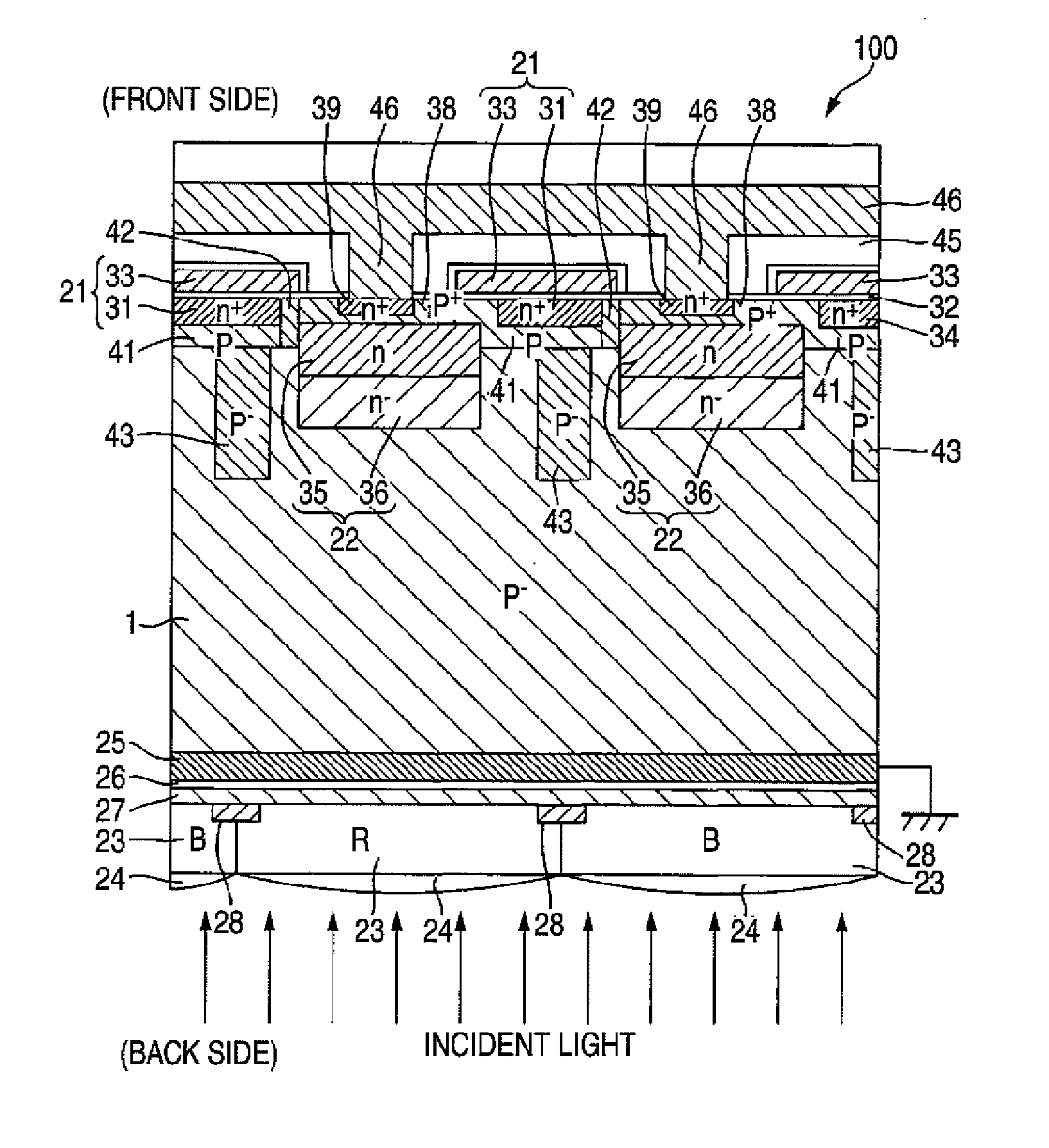

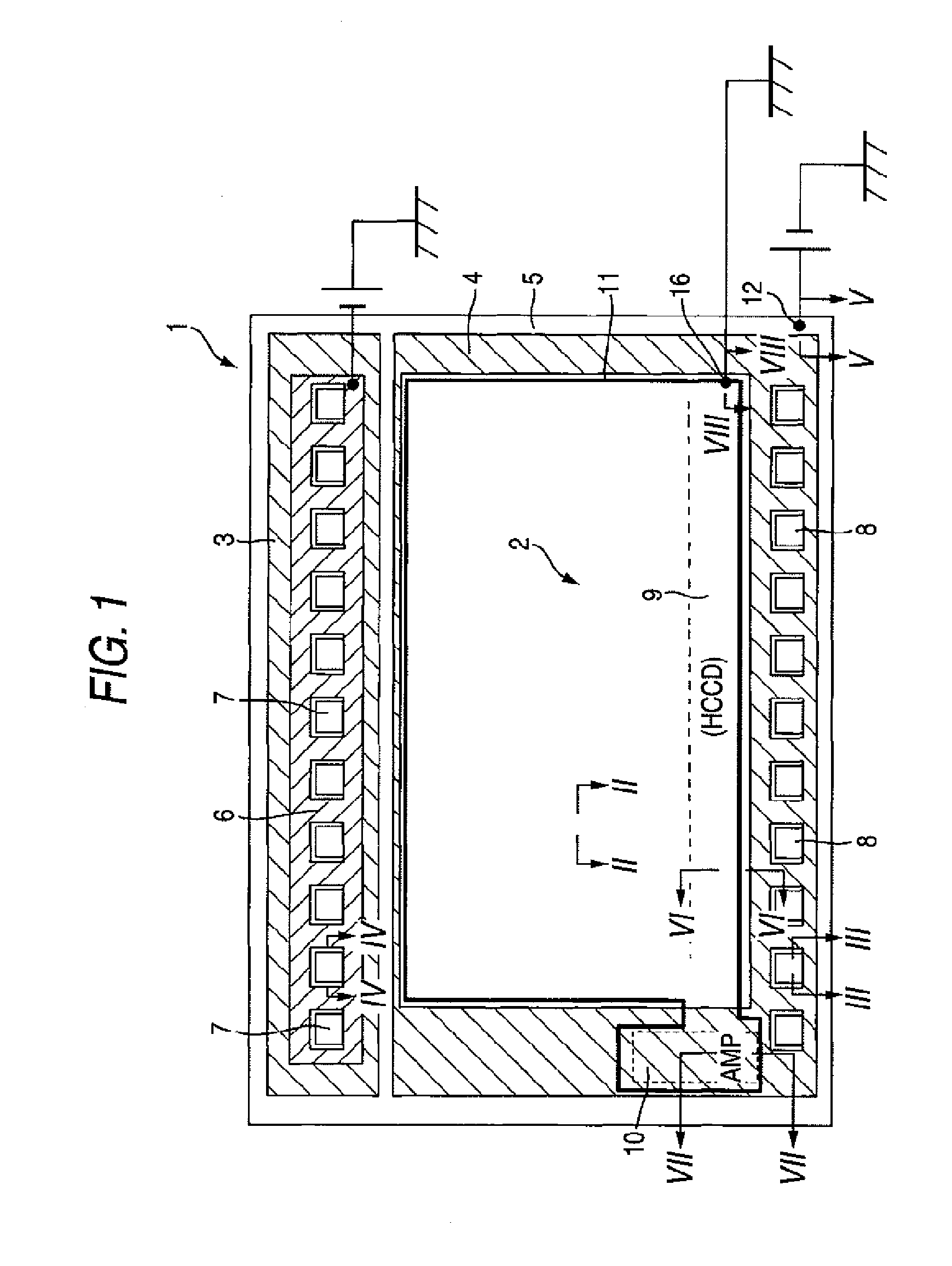

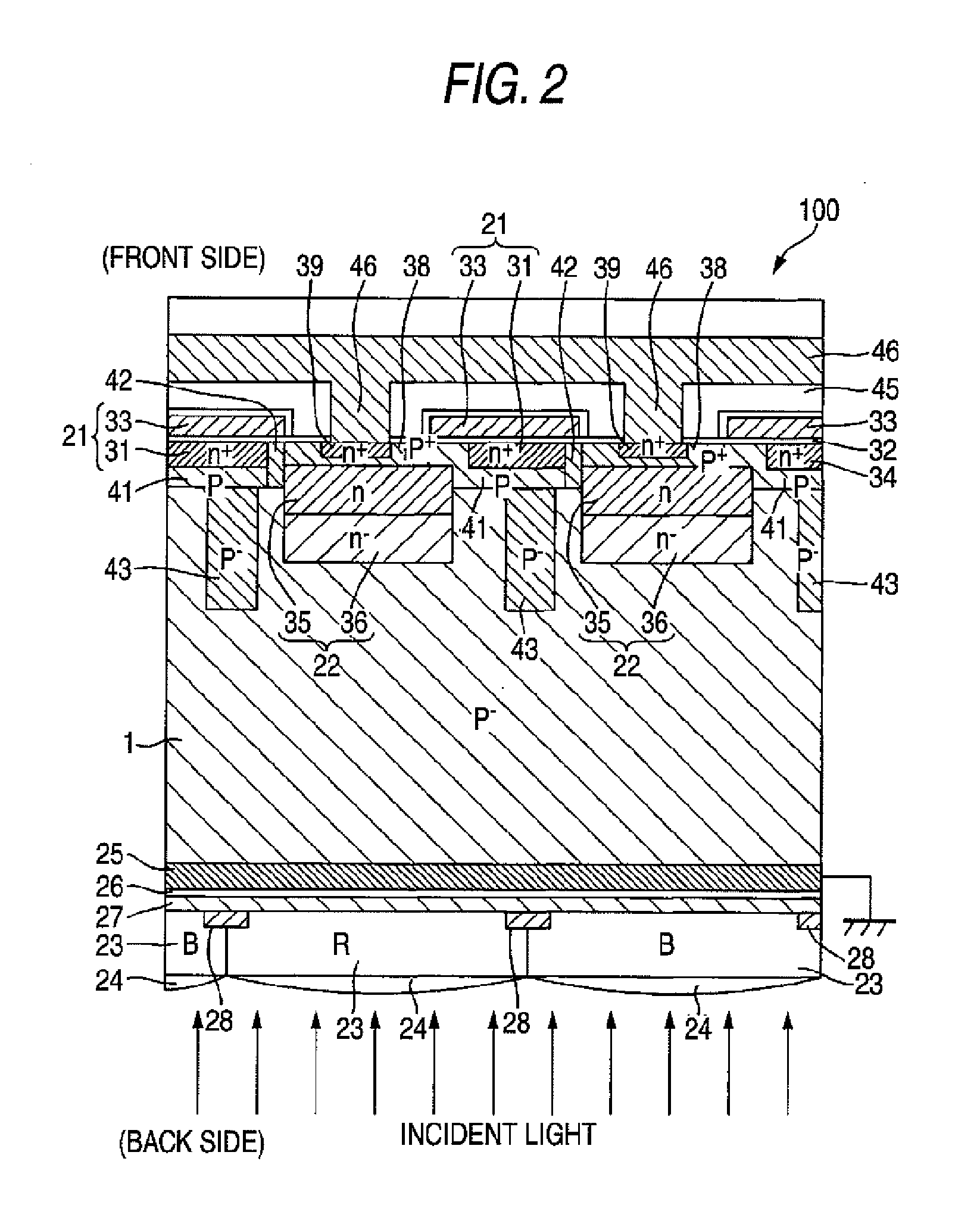

Backside illuminated solid-state imaging device

InactiveUS20080217724A1Reduce resistanceEnlarge regionTelevision system detailsSolid-state devicesSemiconductorVoltage

A backside illuminated solid-state imaging device is provided and includes: a p-type semiconductor substrate; an imaging region that receives a subject light through a back side of the p-type semiconductor substrate to accumulate a signal corresponding to an amount of the received light; a signal reading element disposed in a front side of the p-type semiconductor substrate, the signal reading element reading out the signal from the imaging region; and an n-well region disposed in the front side of the p-type semiconductor substrate and in a periphery of the imaging region, the n-well region being biased to a positive voltage.

Owner:FUJIFILM CORP

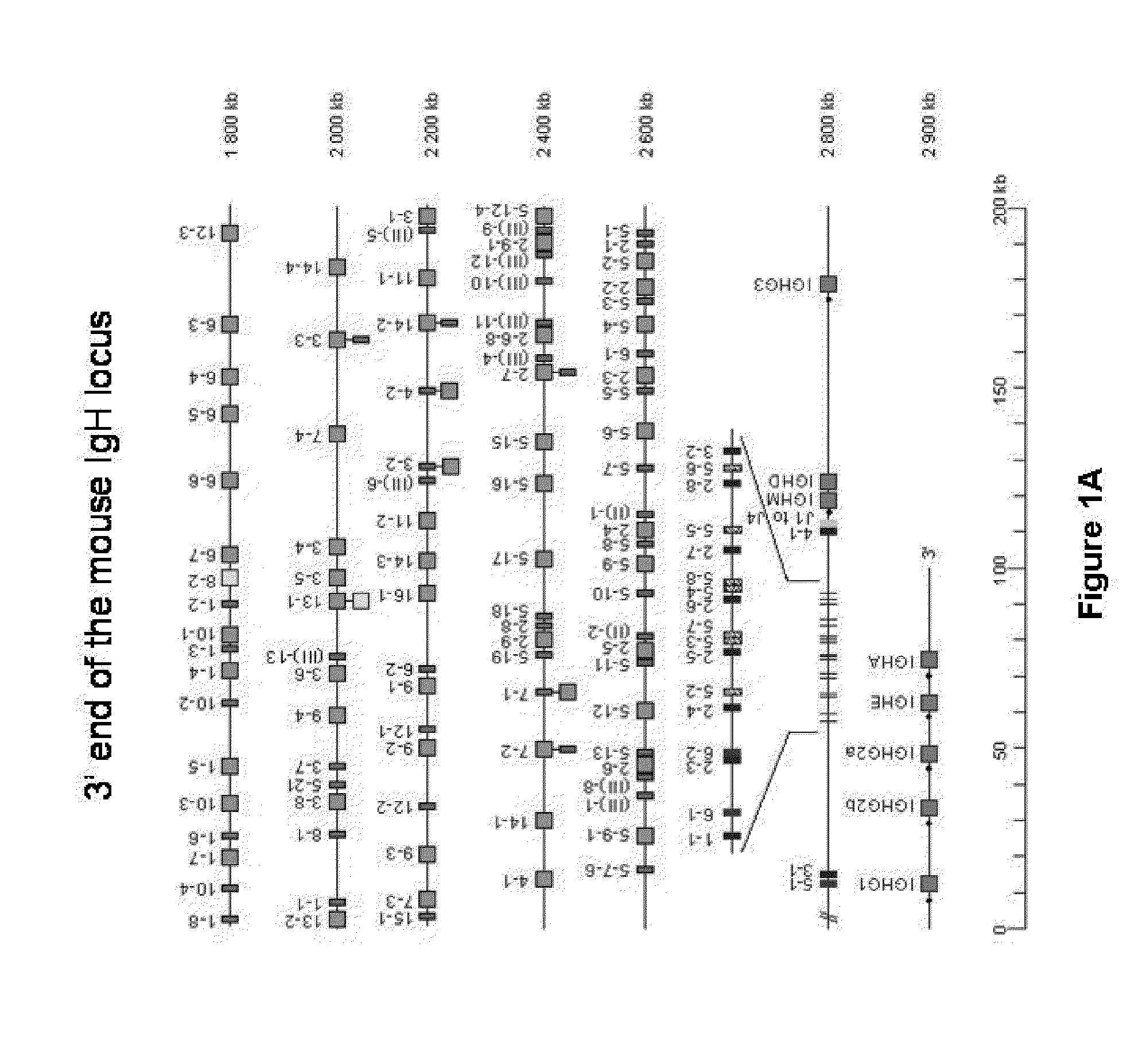

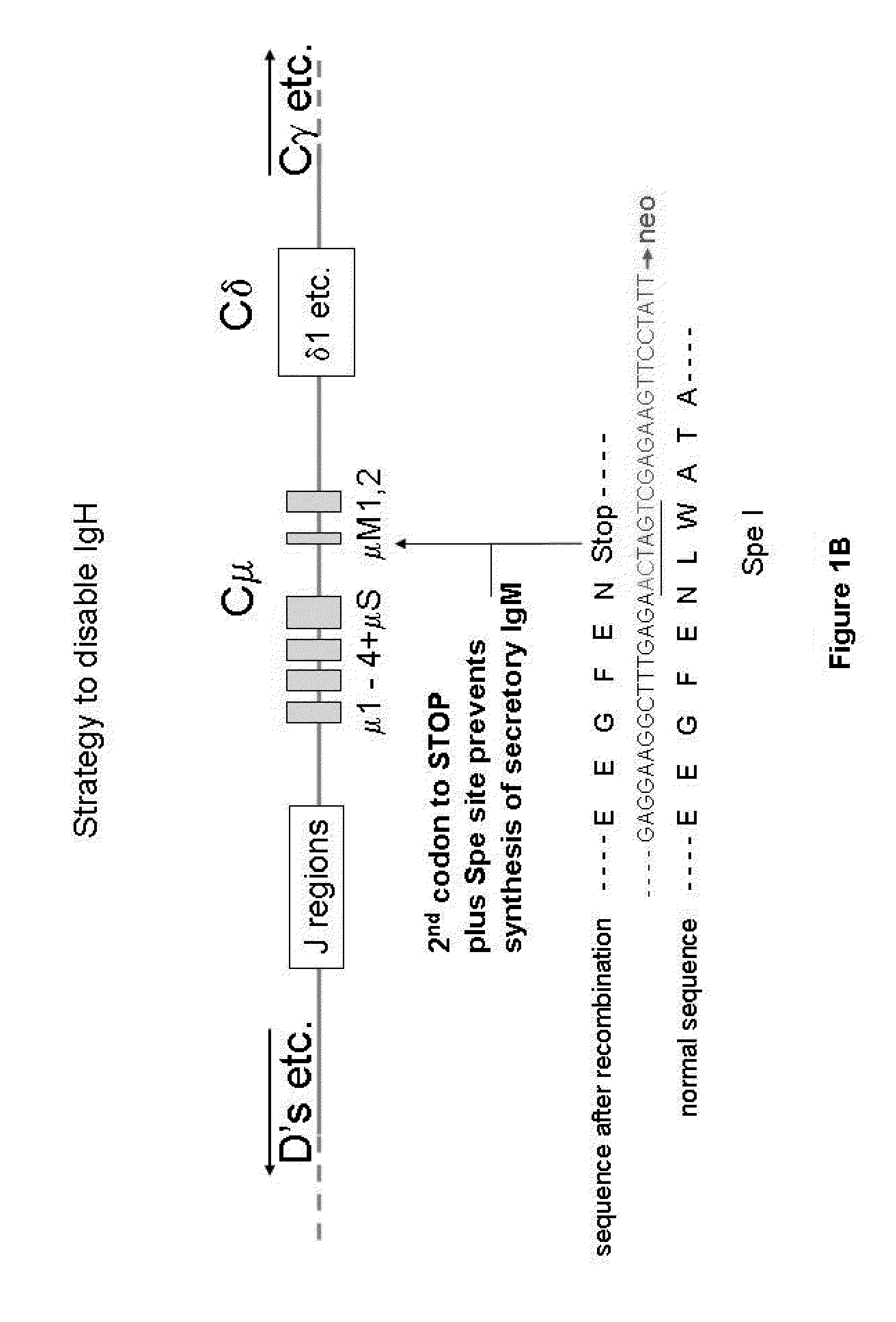

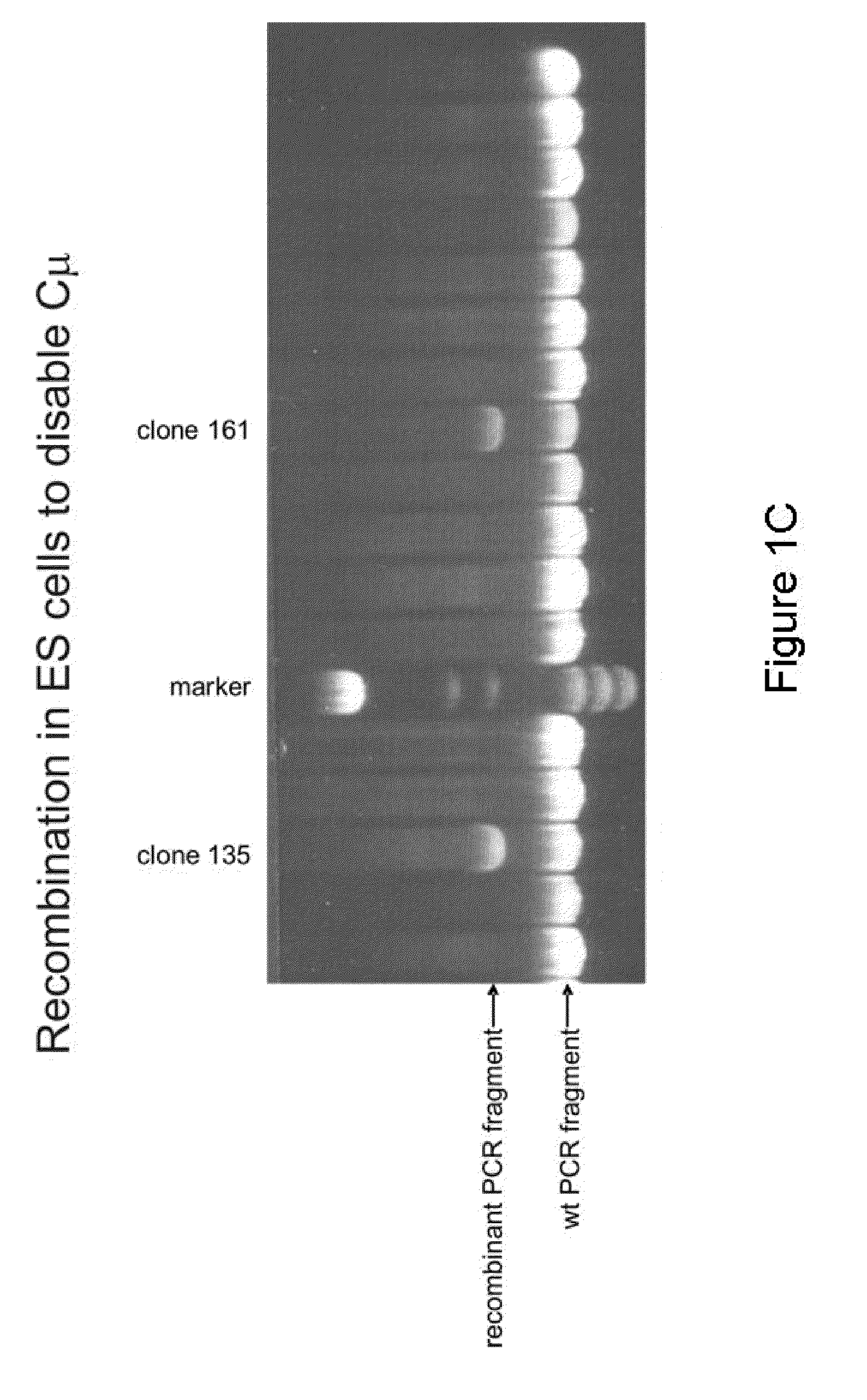

Antibody production

InactiveUS20110314563A1Antibody repertoire and diversityIncrease probabilityImmunoglobulinsImmunological disordersImmunoglobulin heavy chainAntigen challenge

A non-human mammal containing an endogenous lambda light chain gene locus, an endogenous kappa light chain gene locus and an endogenous heavy chain gene locus, each of which can re-arrange so that immunoglobulin heavy and light chain genes are formed and expressed in B-cells following antigen challenge but said loci have been mutated so that the ability to form functional immunoglobulin tetramers comprising re-arranged heavy and light chains produced from said mutated loci has been substantially reduced or eliminated.

Owner:ERASMUS UNIV MEDICAL CENT ROTTERDAM ERASMUS MC

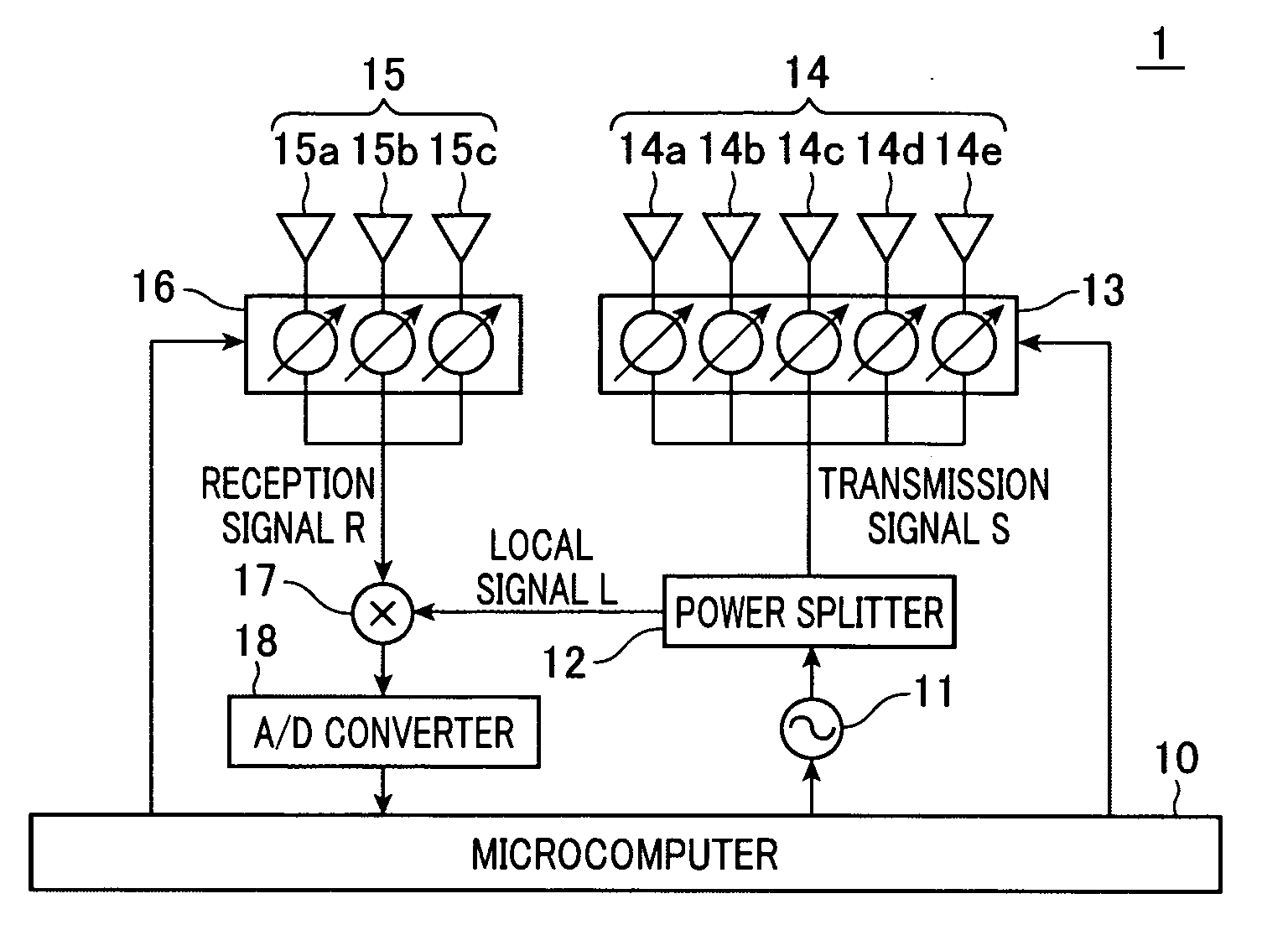

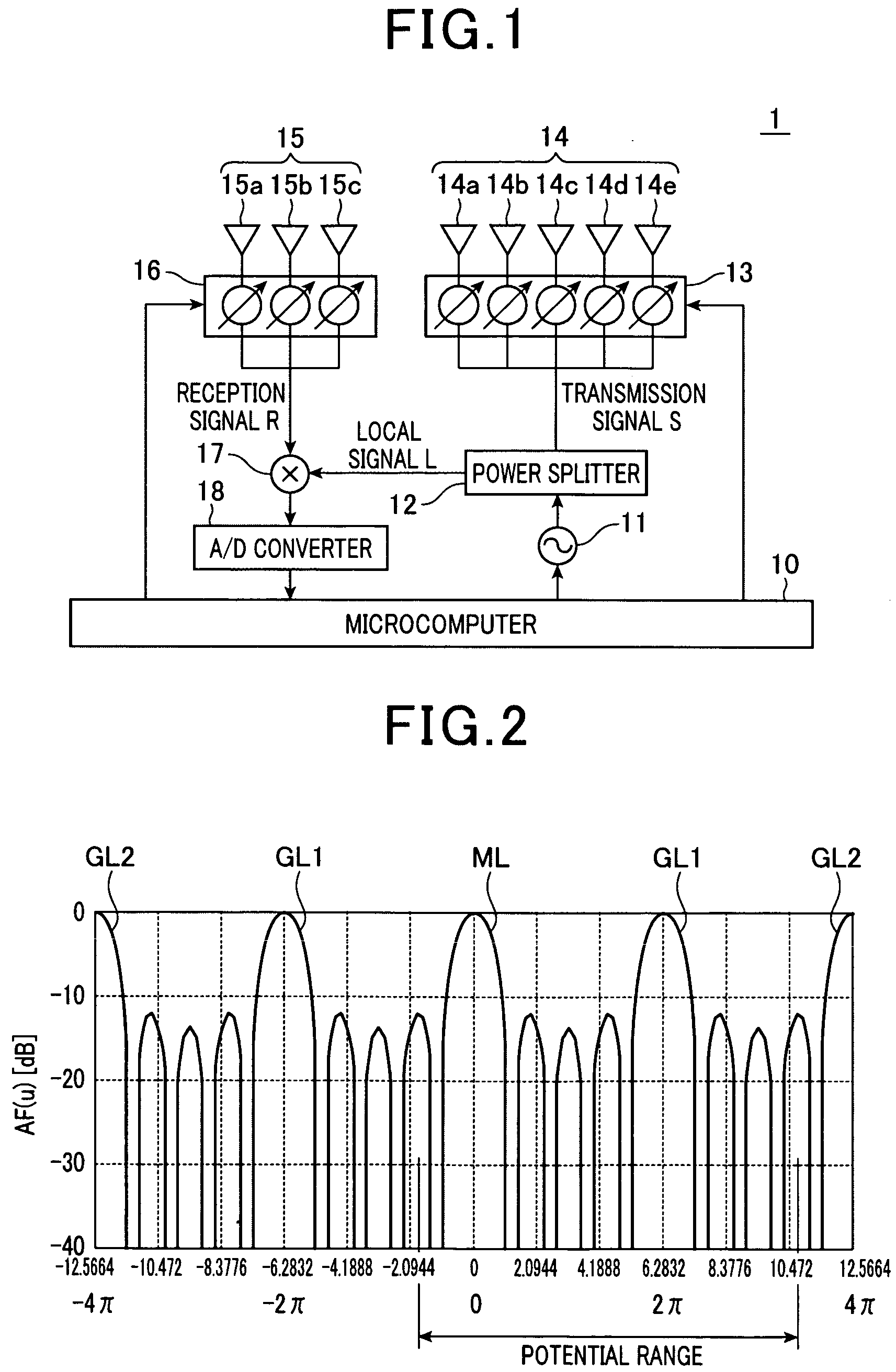

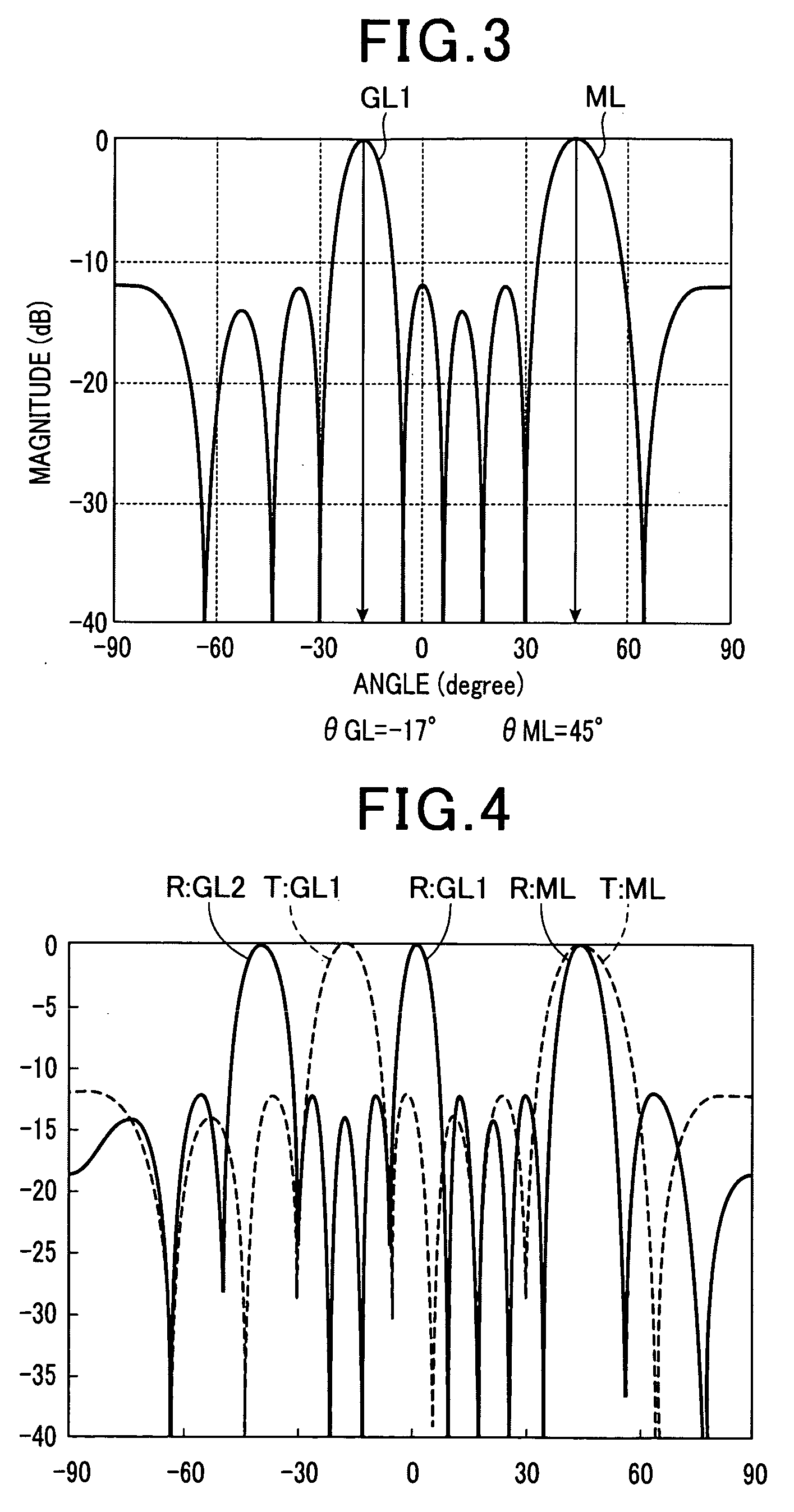

Array antenna apparatus and radar apparatus

InactiveUS20110063158A1Increase heightIncrease intervalAntennasRadio wave reradiation/reflectionNull pointDirectivity

An array antenna apparatus includes a transmission-array-antenna including transmission-antenna-elements, a transmission-side directivity control unit controlling a directivity of the transmission-array-antenna by controlling phases of at least part of the transmission-antenna-elements, a reception-array-antenna including reception-antenna-elements, and a reception-side directivity control unit controlling a directivity of the reception-array-antenna by controlling phases of the reception-antenna-elements. The array antenna apparatus has a composite transmission / reception directivity, in which the direction of a grating lobe of one of the transmission-array-antenna and the reception-array-antenna agrees with the direction of a null point or part of side lobes of the other of the transmission-array-antenna and the reception-array-antenna, and the direction of a grating lobe of the other of the transmission-array-antenna and the reception-array-antenna agrees with the direction of a null point or part of side lobes of the one of the transmission-array-antenna and the reception-array-antenna, and scans in a scanning range with the composite transmission / reception directivity.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com