Carbon fiber plate and electronic device

A carbon fiber board, carbon fiber technology, applied in the direction of electronic equipment, electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problem of difficult to meet users' requirements for light and thin electronic equipment, large thickness and weight, etc., to improve rigidity , the effect of reducing thickness and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

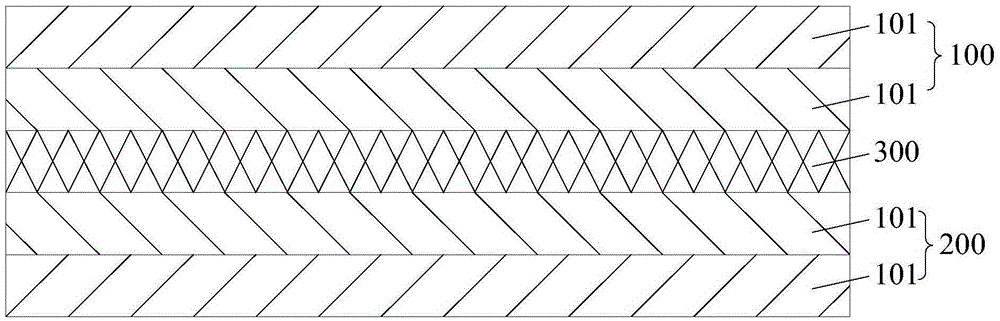

[0024] The embodiment of the present invention discloses a carbon fiber board, the middle layer adopts non-wetting non-woven fabric structure layer, and the carbon fiber arrangement directions of the two adjacent carbon fiber layers in the carbon fiber layer groups on both sides are respectively perpendicular to each other, so that the carbon fiber board The rigidity of the carbon fiber board is improved, which can not only meet the rigidity requirements of electronic equipment, but also set the thickness range of the carbon fiber board to 0.7mm-0.9mm, which not only reduces the thickness and weight of the carbon fiber board, but also facilitates the application of carbon fiber boards. The electronic equipment of the casing realizes thinning and lightening. The embodiment of the present invention also discloses an electronic device, which uses the casing made of the above-mentioned carbon fiber board. The rigidity of the casing can meet the requirements of use, and the casing i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com