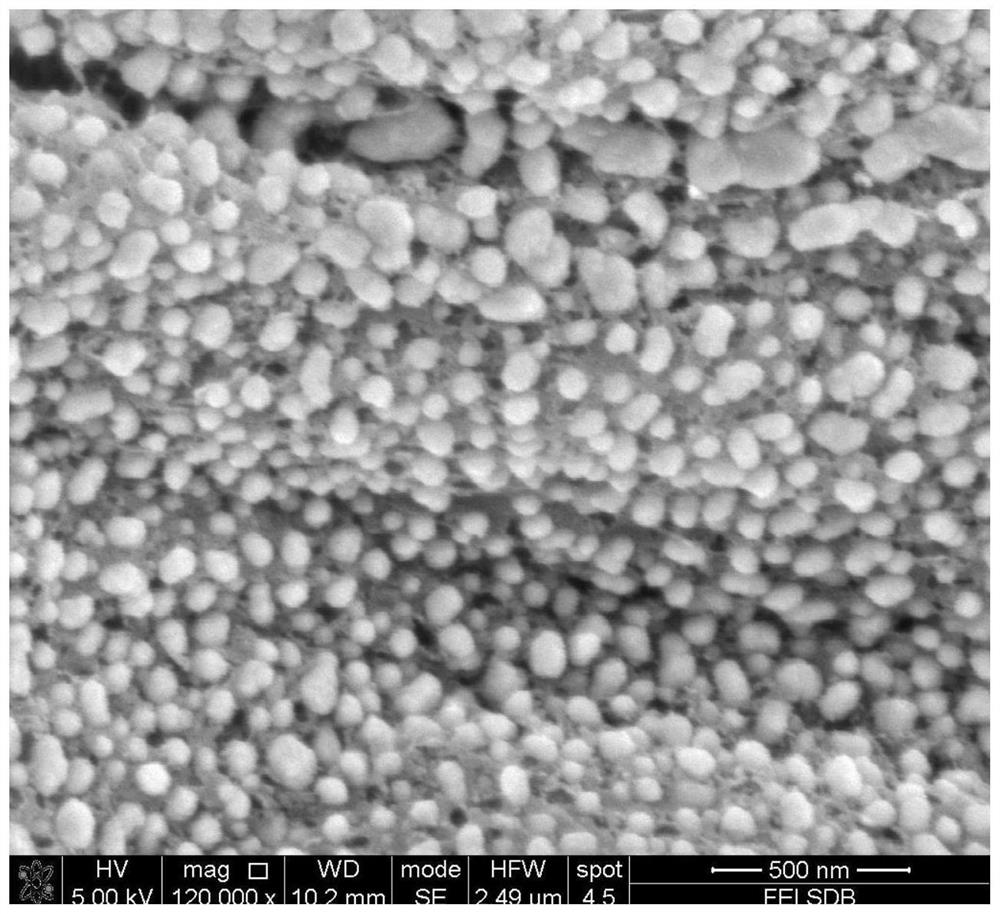

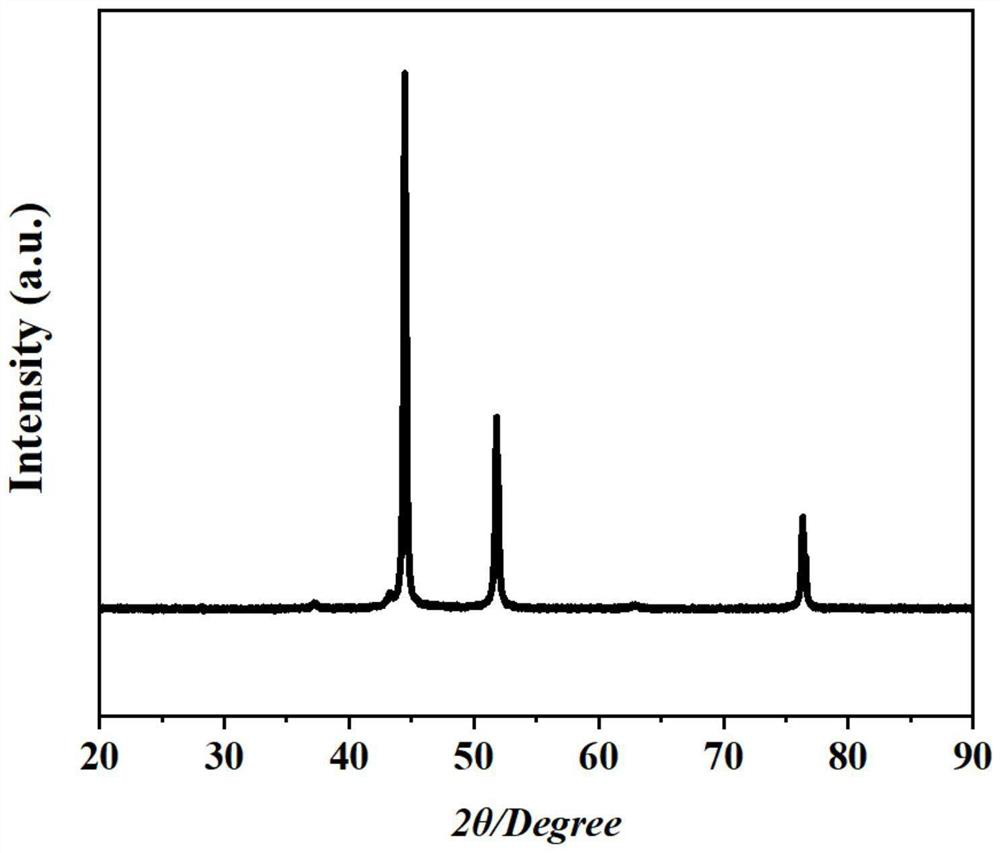

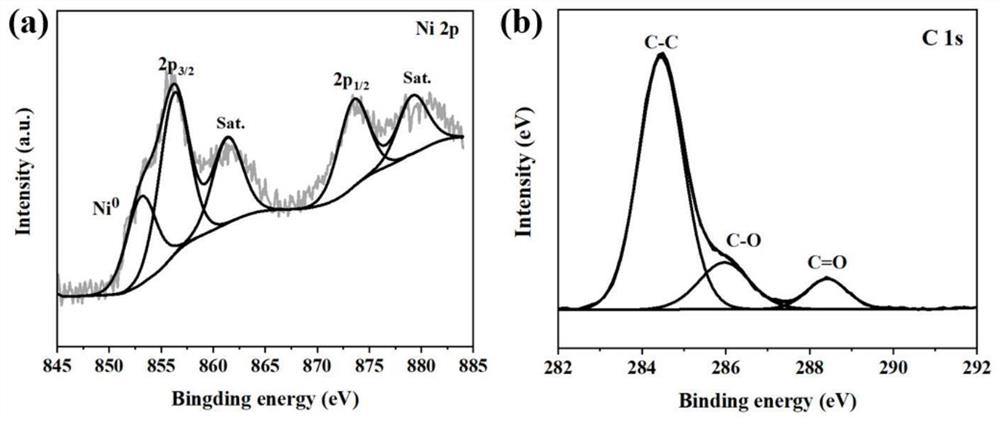

Preparation method of nickel nanoparticle/graphene electromagnetic wave absorbing material

A nanoparticle and absorbing material technology, applied in the direction of magnetic/electric field shielding, electrical components, antennas, etc., to achieve impedance matching, solve easy agglomeration, and high-strength absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Weigh 50 mg of graphene oxide powder into 100 mL of deionized water, and ultrasonically disperse for 60 min to obtain a graphene oxide dispersion with a concentration of 0.5 g / L. 0.01mol of nickel sulfate pentahydrate was weighed, added to 100 mL of graphene oxide dispersion under magnetic stirring, and fully stirred for 30min to obtain a nickel sulfate / graphene oxide mixed solution containing a nickel ion concentration of 0.1mol / L.

[0041] (2) Weigh 0.03 mol of sodium borohydride and add it to 60 mL of deionized aqueous solution under magnetic stirring to obtain a sodium borohydride solution. Then, 40 mL of concentrated ammonia water was added to the sodium borohydride solution to obtain a uniformly dispersed ammonia water / sodium borohydride mixed solution, where the molar concentration of sodium borohydride was 0.3 mol / L. Wherein the molar mass ratio of nickel sulfate and sodium borohydride in step (1) and step (2) is 1:3, and the volume ratio of concentrated amm...

Embodiment 2

[0047] (1) Weigh 50 mg of graphene oxide powder into 100 mL of deionized water, and ultrasonically disperse for 60 min to obtain a graphene oxide dispersion with a concentration of 0.5 g / L. 0.01mol of nickel sulfate pentahydrate was weighed, added to 100 mL of graphene oxide dispersion under magnetic stirring, and fully stirred for 30min to obtain a nickel sulfate / graphene oxide mixed solution containing a nickel ion concentration of 0.1mol / L.

[0048] (2) Weigh 0.03 mol of sodium borohydride and add it to 60 mL of deionized aqueous solution under magnetic stirring to obtain a sodium borohydride solution. Then, 80 mL of concentrated ammonia water was added to the sodium borohydride solution to obtain a uniformly dispersed ammonia water / sodium borohydride mixed solution, where the molar concentration of sodium borohydride was 0.21 mol / L. . Wherein the molar mass ratio of nickel sulfate and sodium borohydride in step (1) and step (2) is 1:3, and the volume ratio of concentrated...

Embodiment 3

[0053] (1) Weigh 50 mg of graphene oxide powder into 100 mL of deionized water, and ultrasonically disperse for 60 min for 60 min to obtain a graphene oxide dispersion with a concentration of 0.5 g / L. 0.01mol of nickel sulfate pentahydrate was weighed, added to the graphene oxide dispersion under magnetic stirring, and fully stirred for 30min to obtain a graphene oxide mixed solution containing nickel ions.

[0054] (2) Weigh 0.01 mol of sodium borohydride and add it to 60 mL of deionized aqueous solution under magnetic stirring to obtain a sodium borohydride solution. Then, 40 mL of concentrated ammonia water was added to the sodium borohydride solution to obtain a uniformly dispersed ammonia water / sodium borohydride mixed solution. Wherein in step (1) and step (2), the molar mass ratio of nickel sulfate and sodium borohydride is 1:1, and the volume ratio of concentrated ammonia water and the prepared sodium borohydride solution is 4:3.

[0055] (3) the nickel sulfate / graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com