A kind of preparation method of high-precision ultra-thin PCB

A high-precision, ultra-thin technology, used in printed circuit manufacturing, multi-layer circuit manufacturing, and manufacturing of printed circuit precursors, etc., can solve the problems of poor heat dissipation performance and overall thickness of copper lines, and achieve improved precision. , The width is easy to control, and the effect of strengthening the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

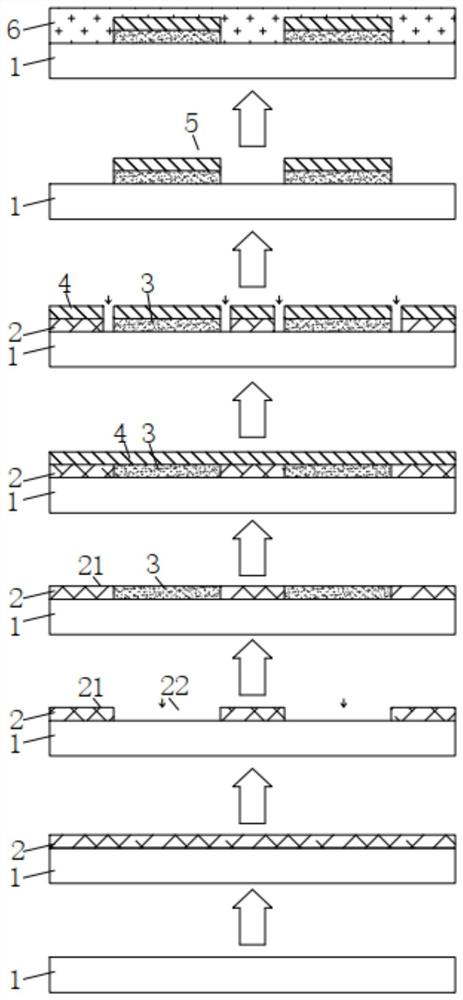

[0052] This embodiment provides a high-precision ultra-thin PCB preparation method, such as figure 1 shown, including the following steps:

[0053] (1) Provide substrate

[0054] The base material 1 is cut according to the preset size, and the purpose is to reduce waste as much as possible; the material of the base material 1 is a copper-free core board with at least one of FR-4, PTFE, PI, and ceramics as the medium. In this embodiment, the substrate 1 adopts a copper-free core board with PTFE as the medium, and the thickness is controlled within the range of 20-25 μm.

[0055] In order to facilitate subsequent processing, the base material 1 needs to be pretreated, such as roughening, cleaning, drying, and punching.

[0056] Wherein, the roughening treatment process is: soaking in lye at 65-70° C. for 40-50 minutes, and the lye includes the following raw materials in parts by weight: 8-10 parts of sodium methoxide and 4-5 parts of potassium tert-butoxide. The purpose is to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com