Heat-conducting structure and heat-dissipation device

A heat-conducting structure and heat-dissipating device technology, applied in the direction of modification, heat transfer modification, indirect heat exchanger, etc. through conduction heat transfer, which can solve the problem of large radiator volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The heat conduction structure and heat dissipation device according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

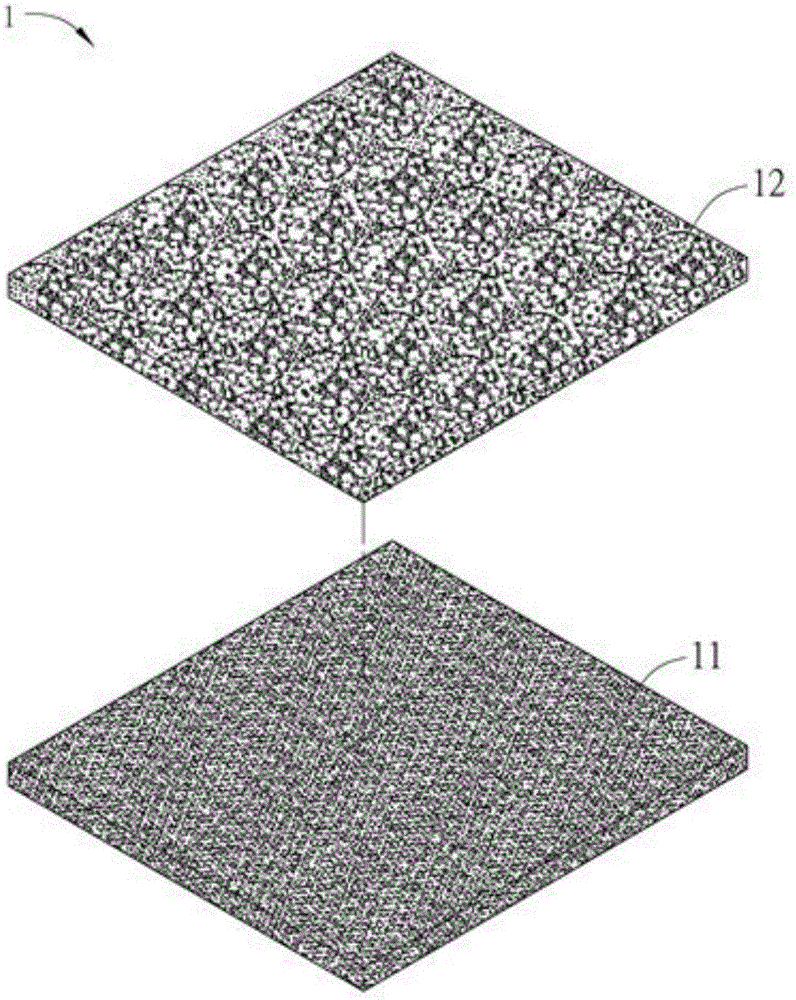

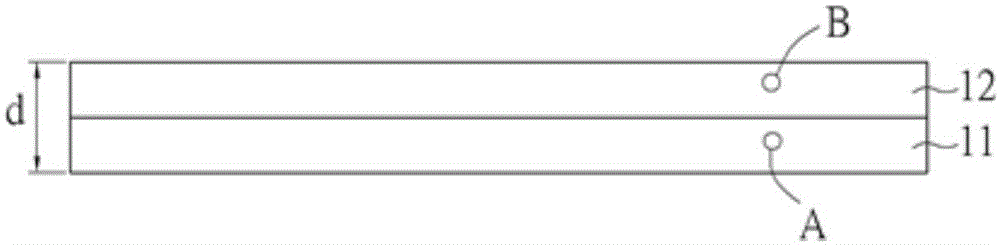

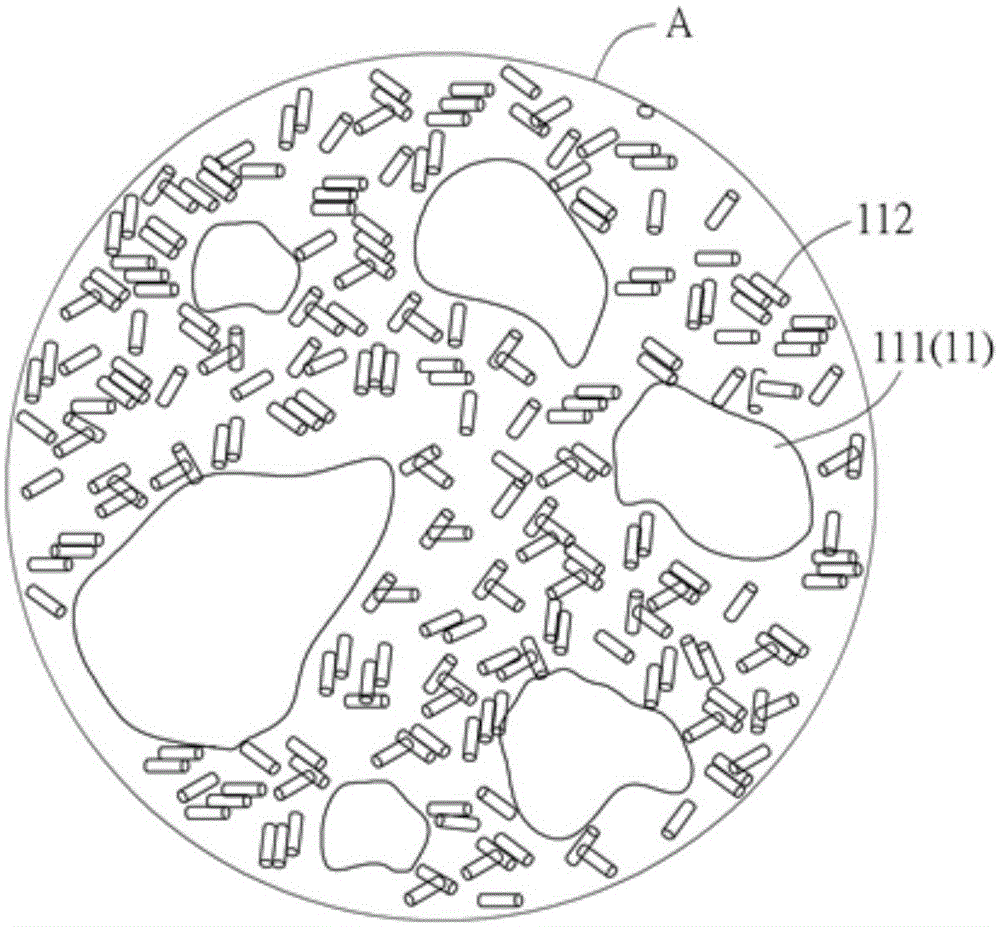

[0029] Please refer to Figure 1A to Figure 1D As shown, among them, Figure 1A and Figure 1B are respectively an exploded schematic diagram and a schematic side view of a heat conduction structure 1 in a preferred embodiment of the present invention, and Figure 1C and Figure 1D respectively Figure 1B The enlarged schematic diagram of area A and area B of . hereby, Figure 1C and Figure 1D They are for illustration only and are not drawn to scale of actual components.

[0030] The heat conduction structure 1 can quickly lead out the heat energy generated by the heat source (such as an electronic component), and includes a first heat conduction layer 11 and a second heat conduction layer 12, and the first he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com