Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Improve water and oxygen barrier performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

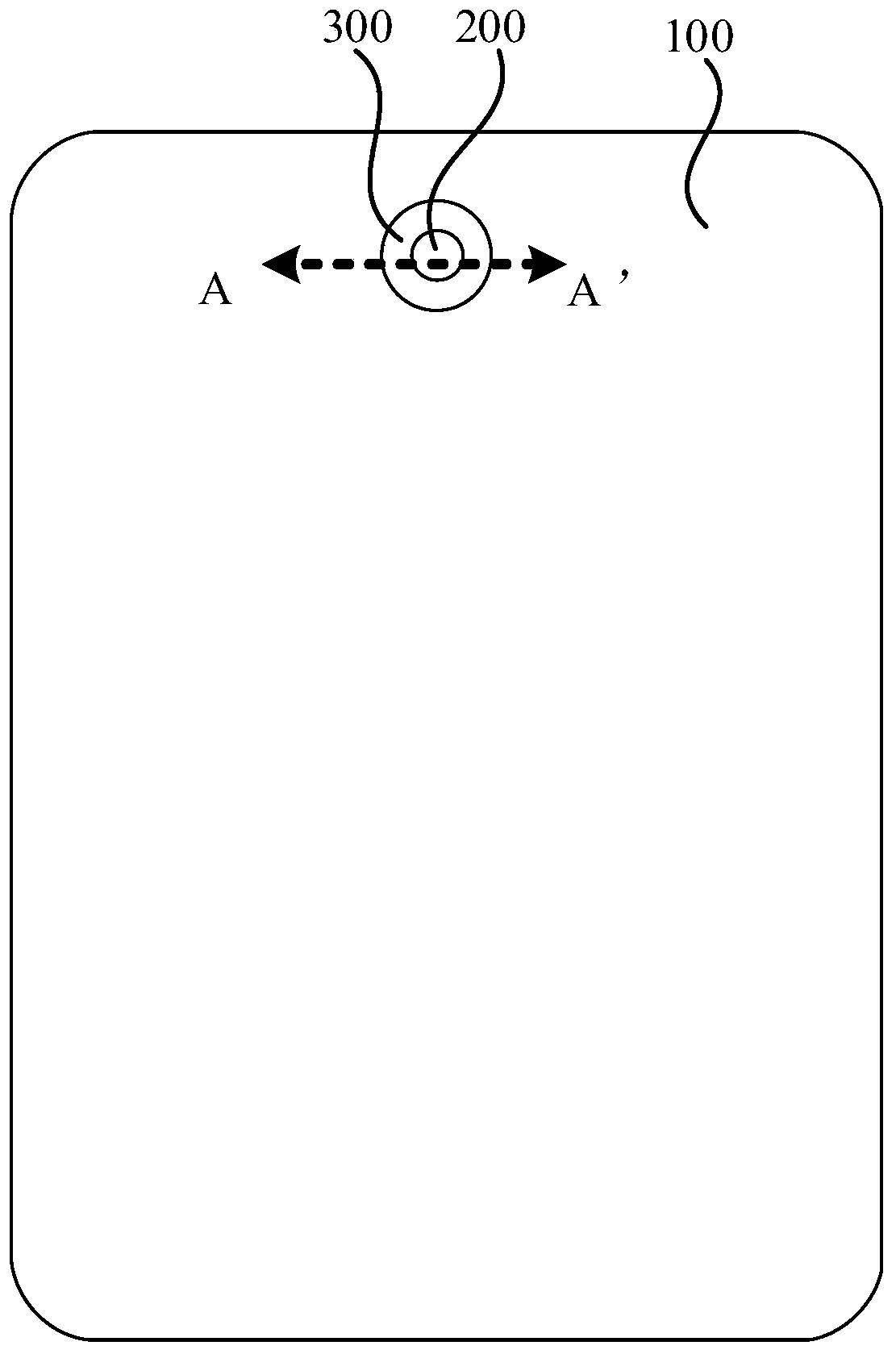

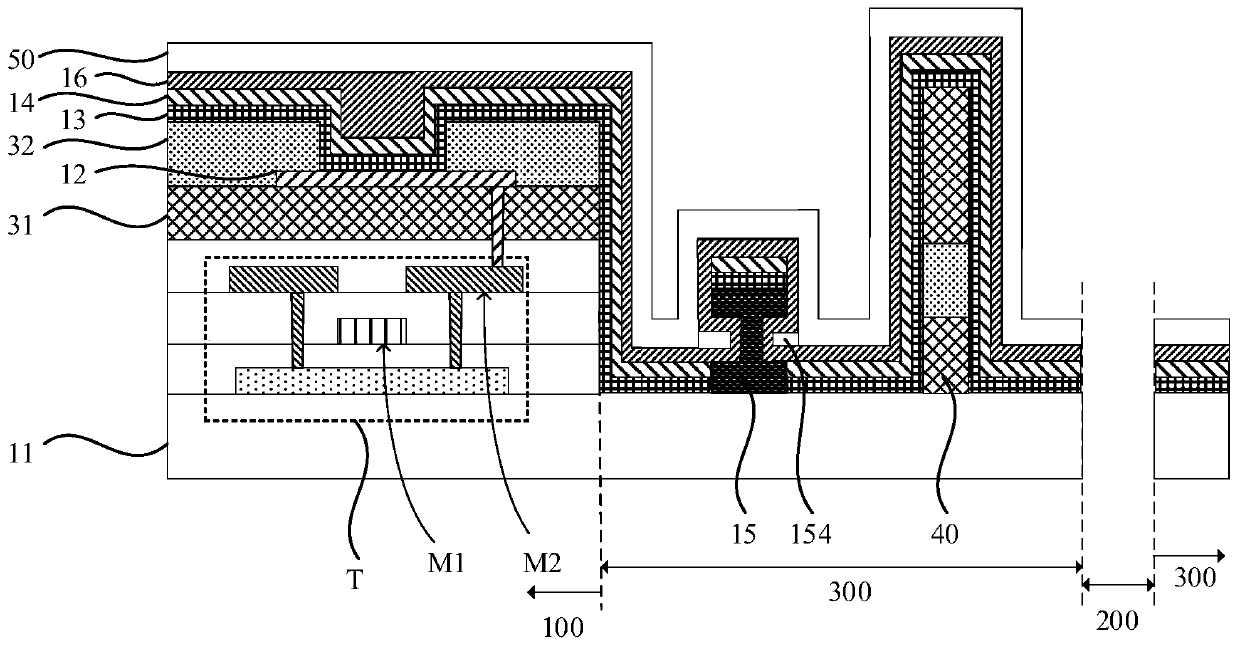

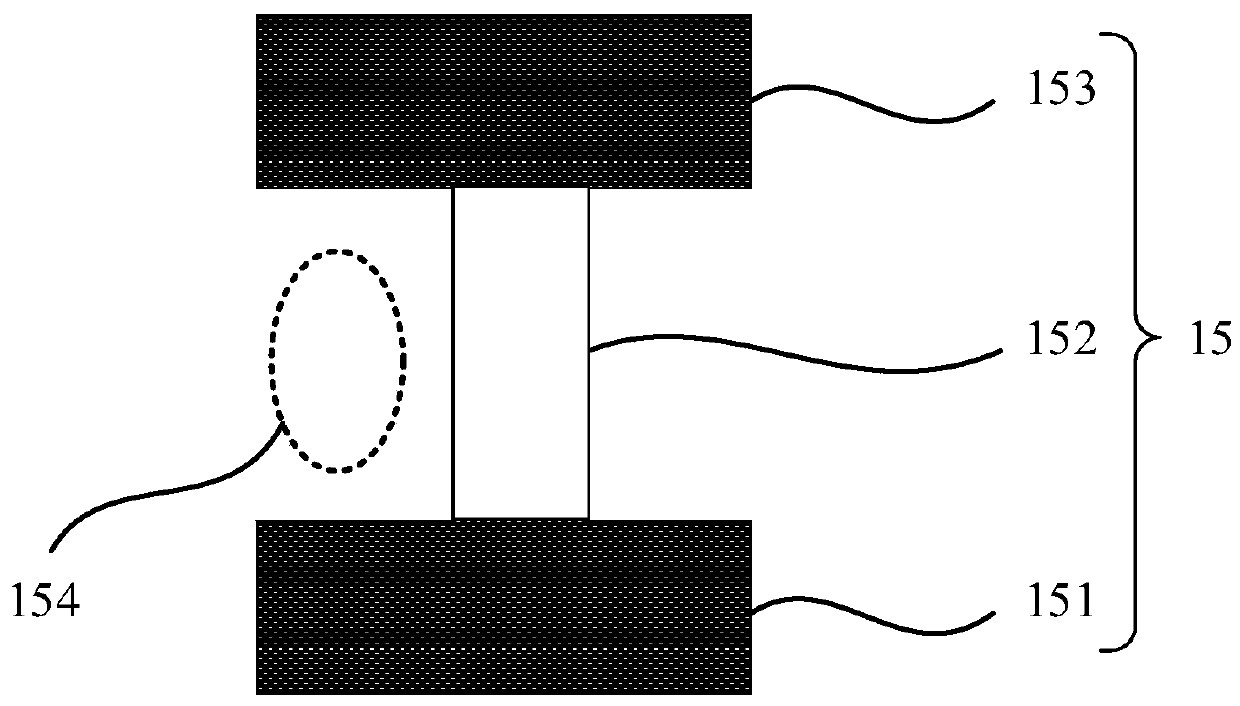

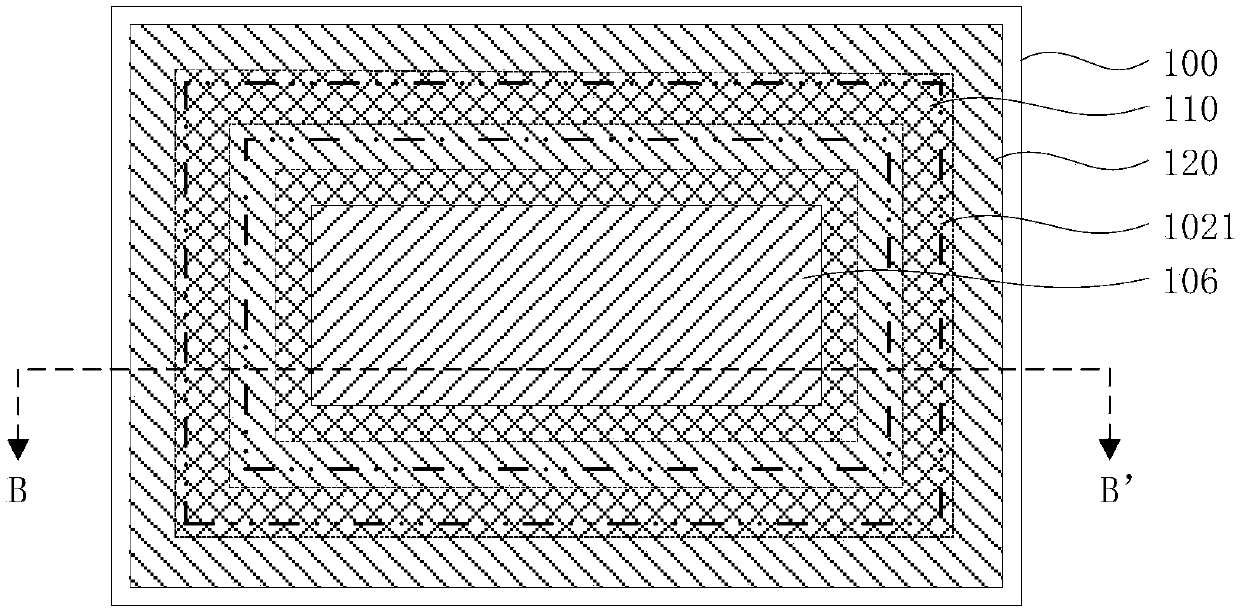

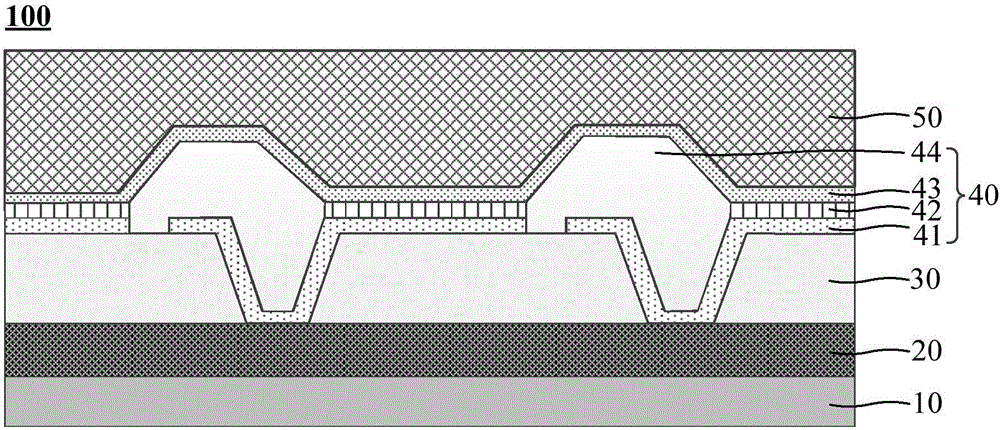

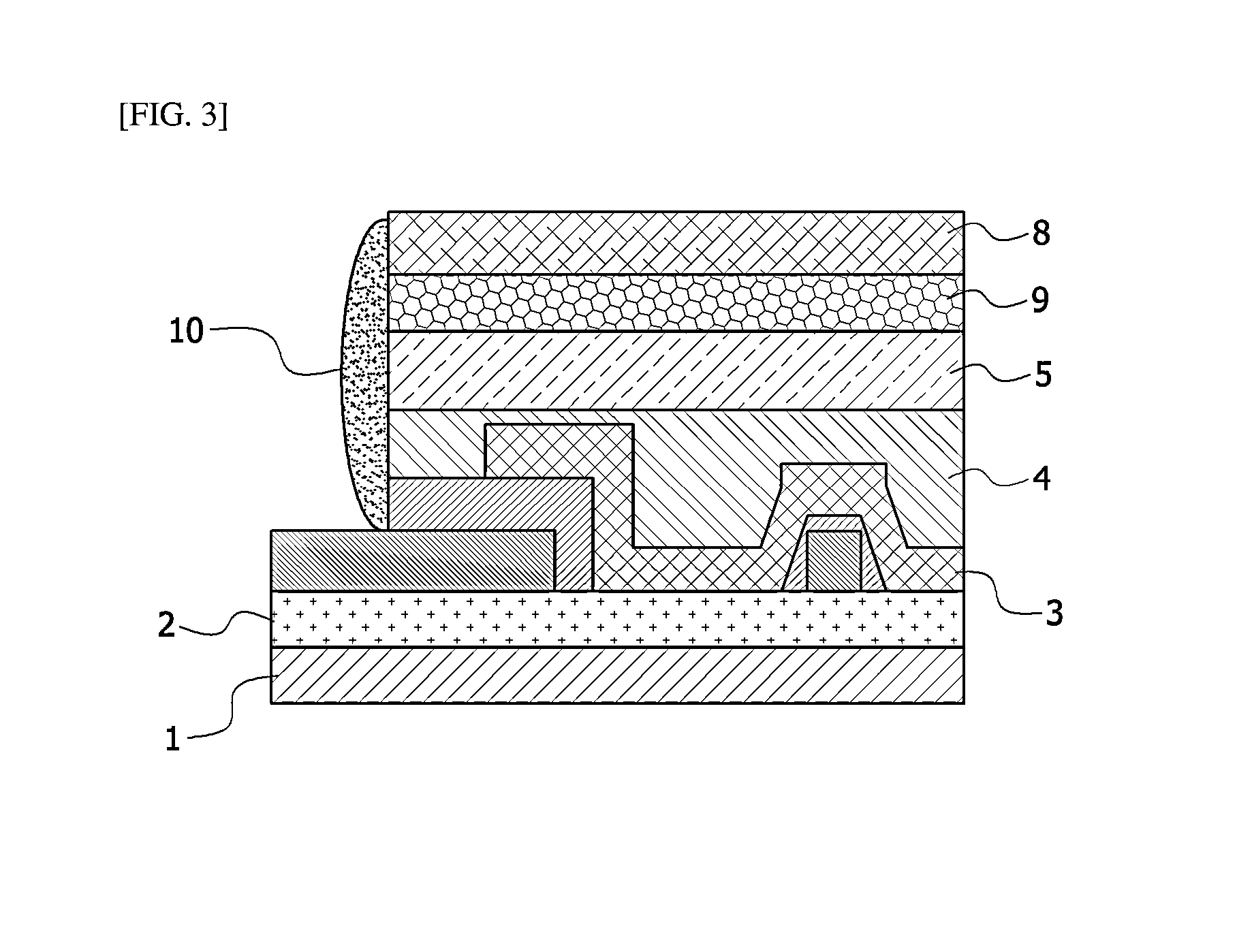

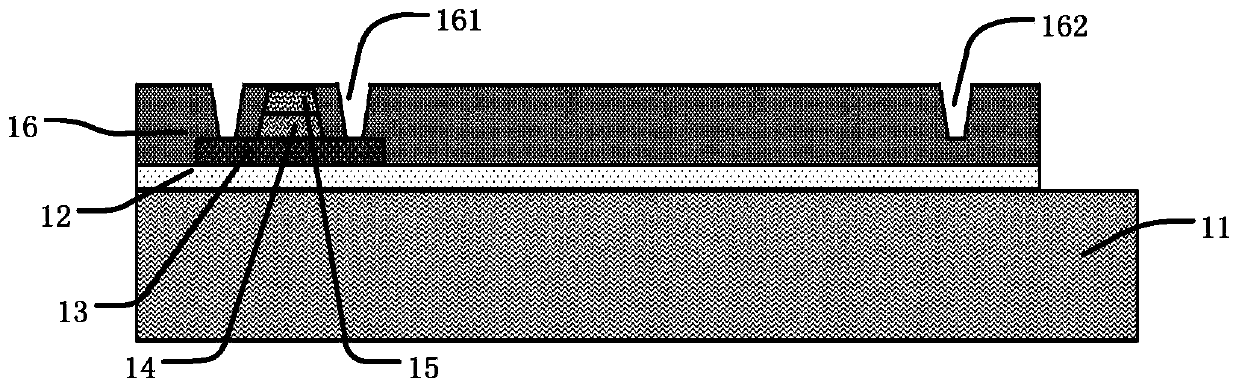

Organic light emitting display panel and manufacturing method thereof

ActiveCN109802052AImprove water and oxygen barrier performanceSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSurface plate

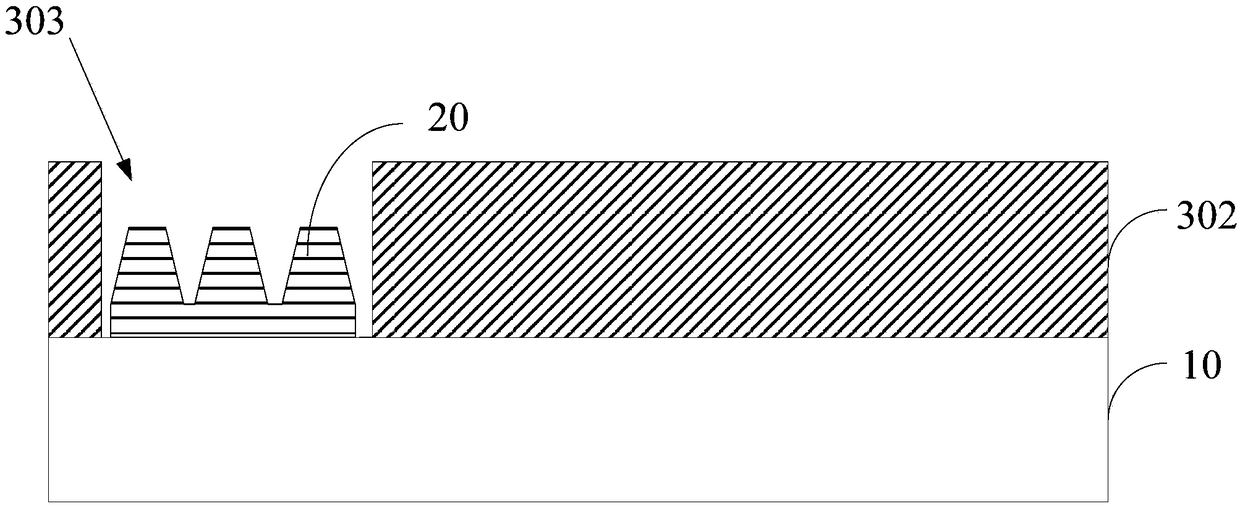

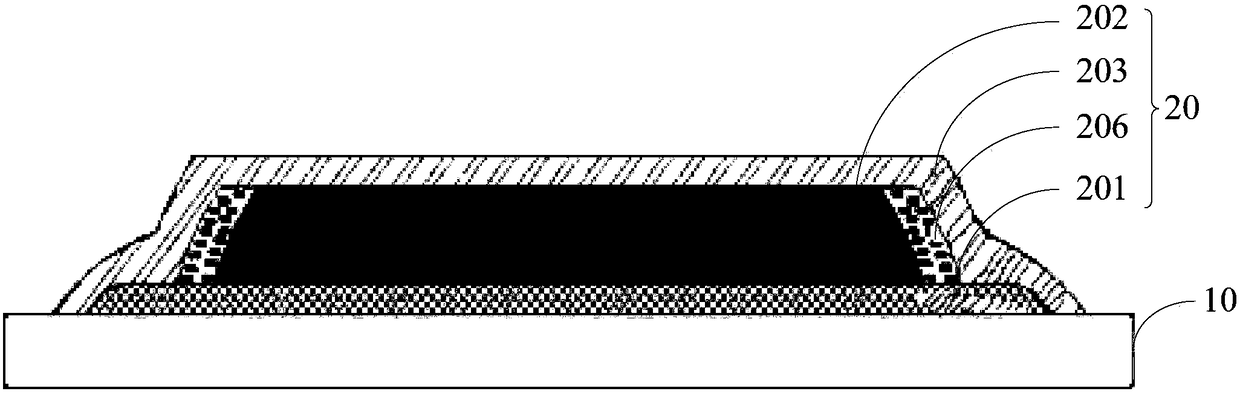

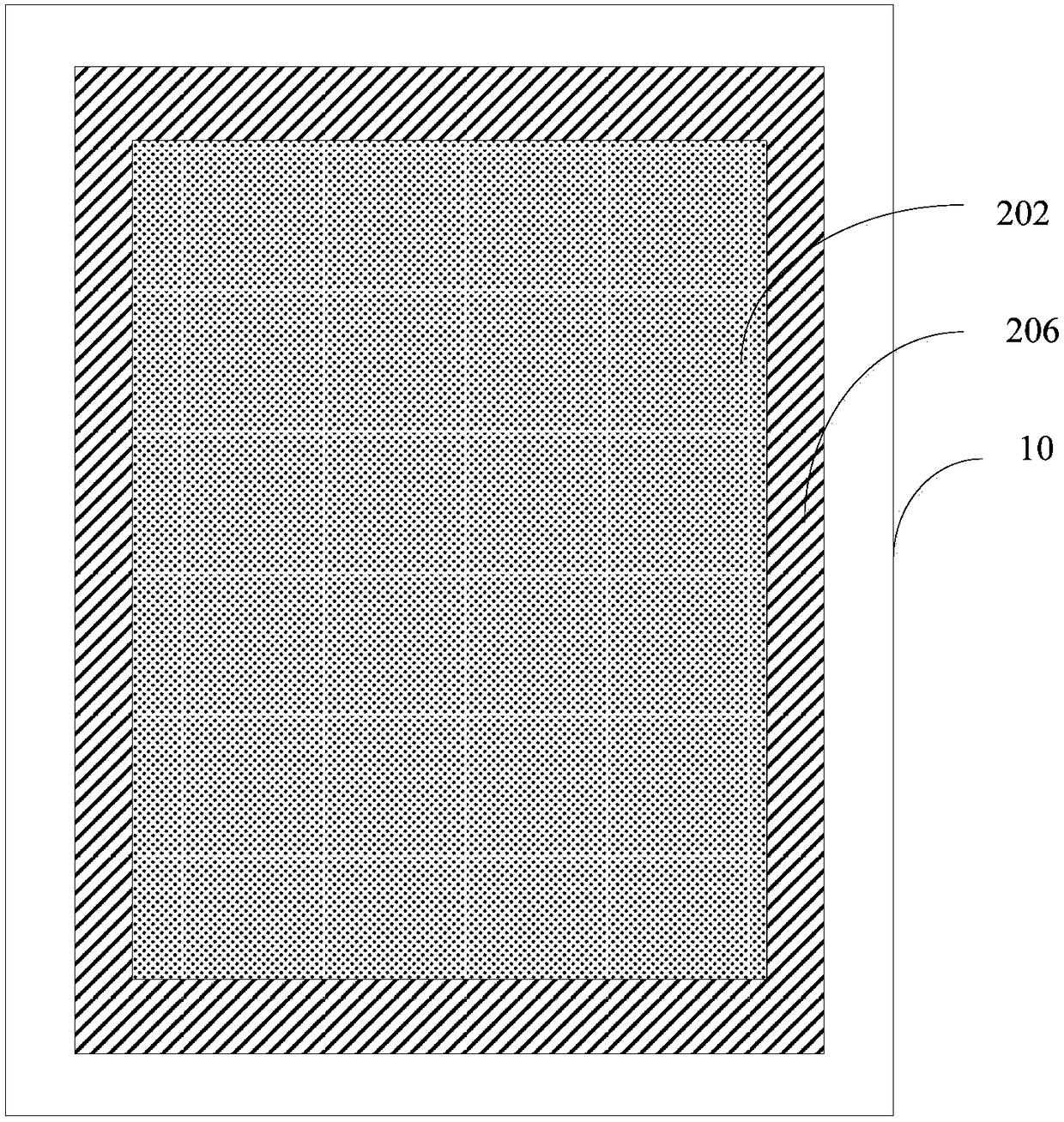

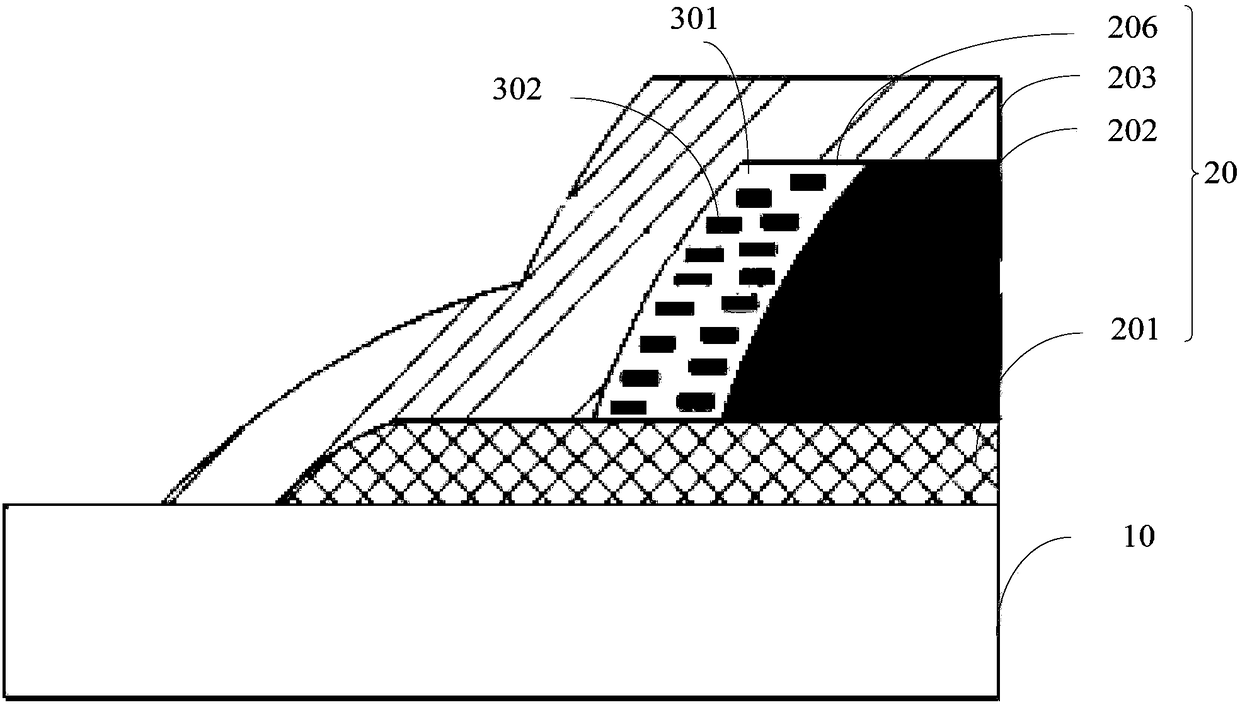

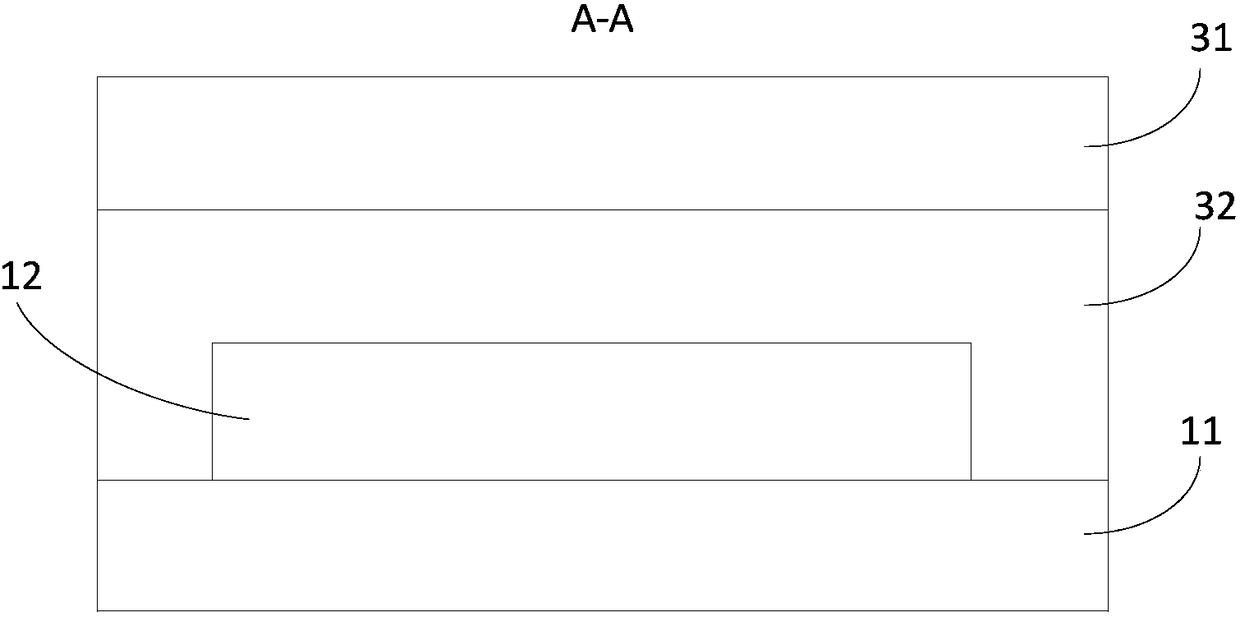

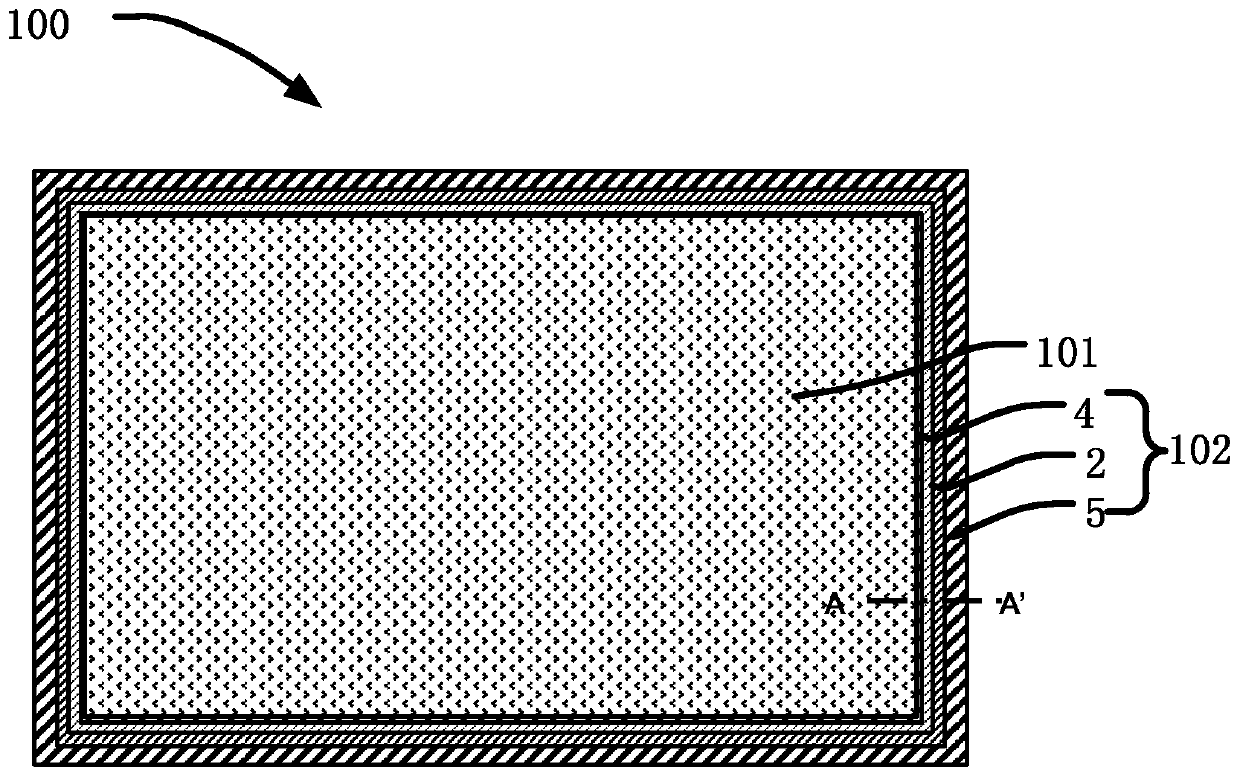

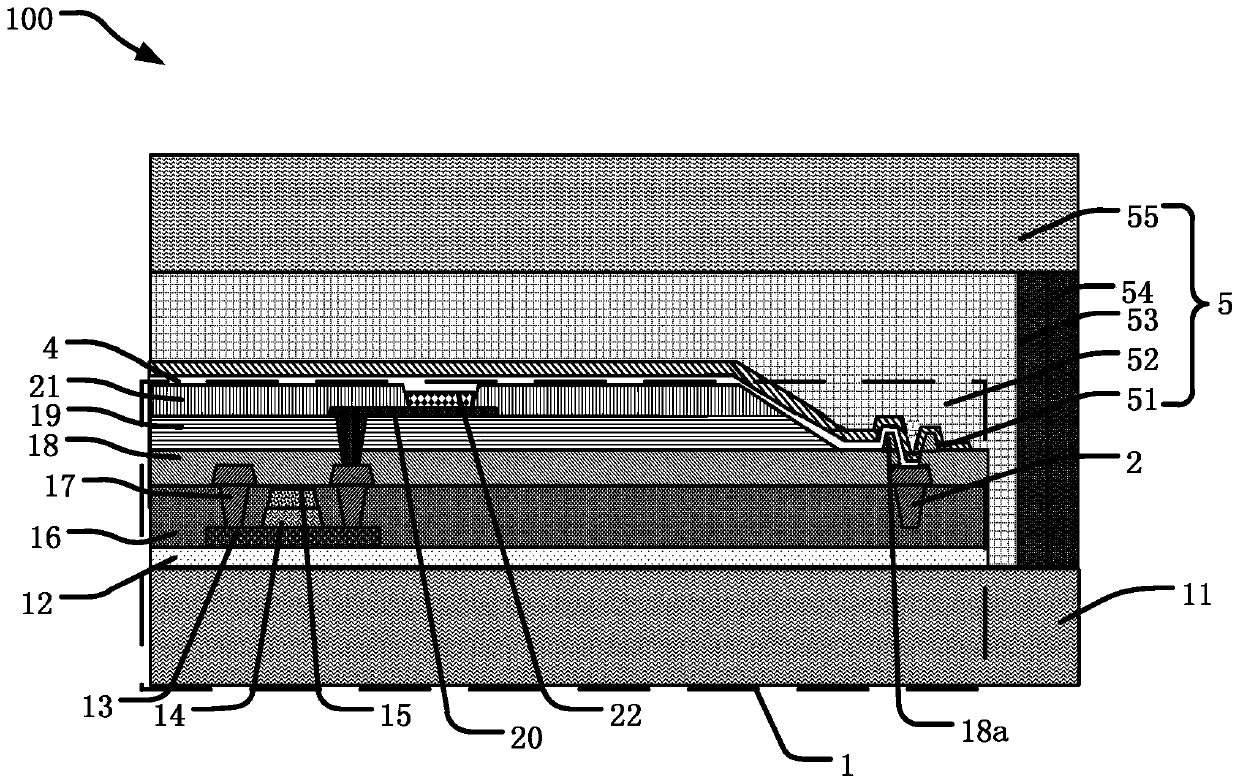

The embodiment of the invention provides an organic light emitting display panel and a manufacturing method thereof. The organic light emitting display panel comprises a display area, a through hole area and a through hole boundary area. The display area at least partially surrounds the through hole area, and the through hole boundary area is located between the display area and the through hole area. The organic light emitting display panel includes a base substrate; a group including a reflective electrode, an organic light emitting structure, and an opposite electrode which are stacked on the base substrate and are located at least in the display area; and a segment portion located on the same side of the base substrate as the organic light emitting structure and located in the throughhole boundary area. A side of the segment portion adjacent to the display area and a side of the segment portion away from the display area have grooves. The organic light emitting structure and the opposite electrode extend from the display area to the through hole boundary area, and are segmented into portions that are not connected to each other by the segment portion. The embodiment of the present invention provides an organic light emitting display panel and a manufacturing method thereof to improve a water oxygen isolation effect.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

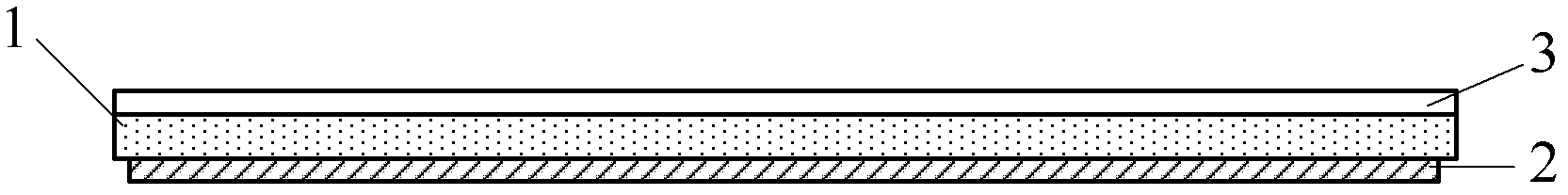

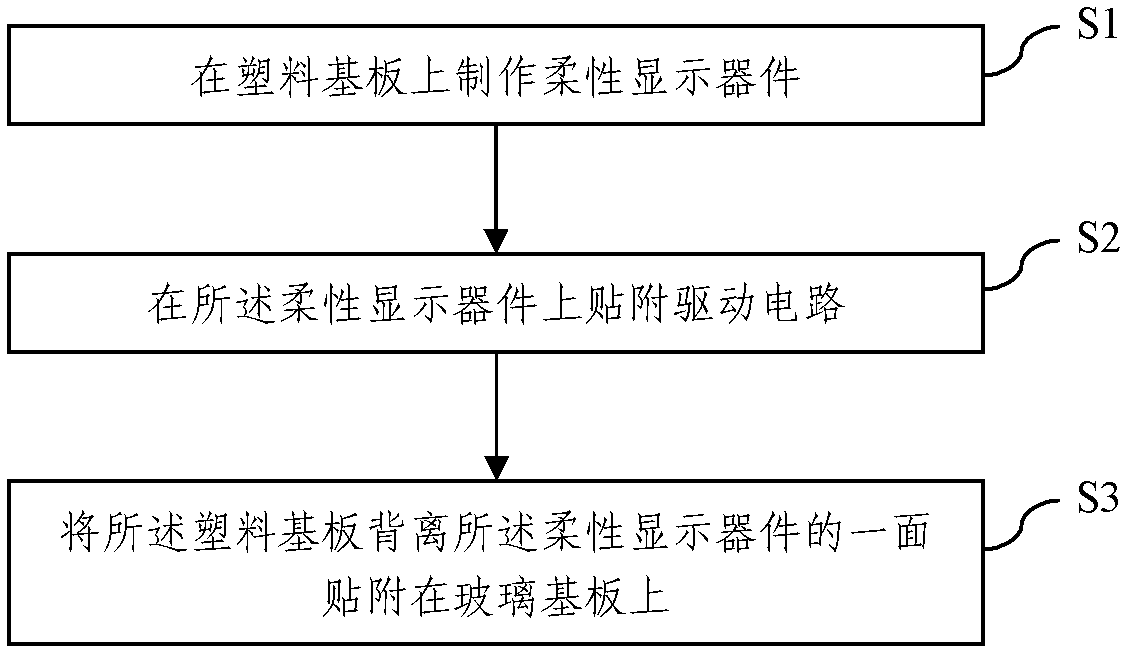

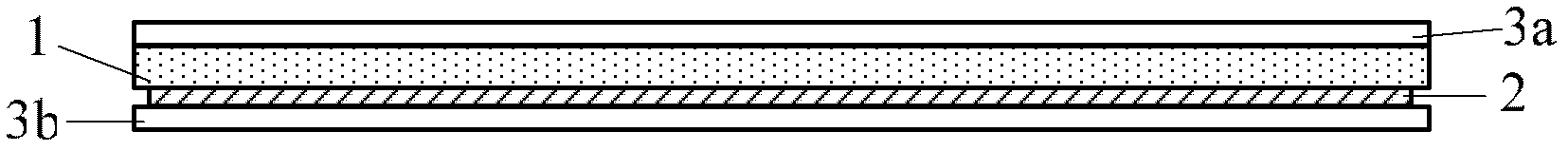

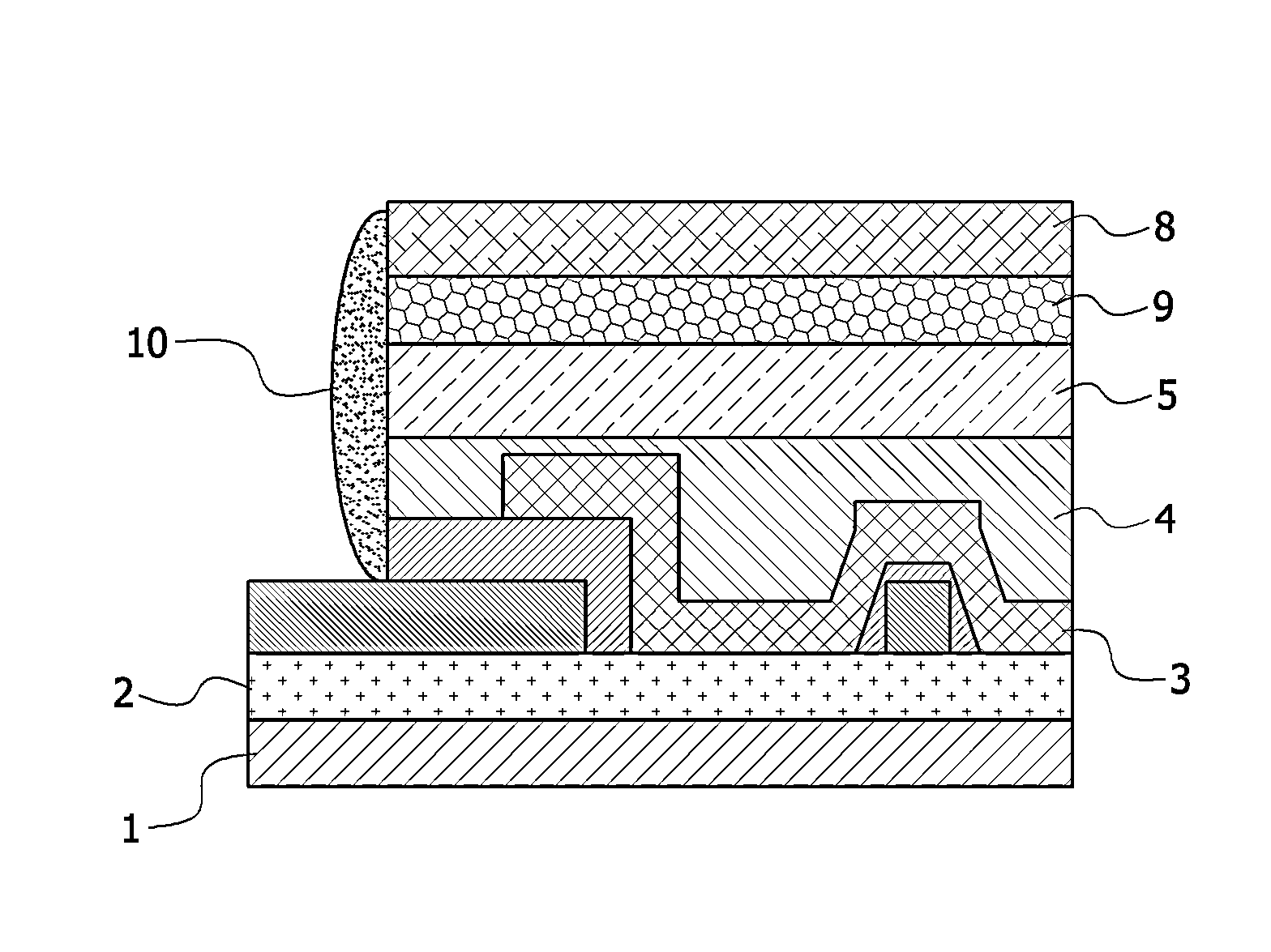

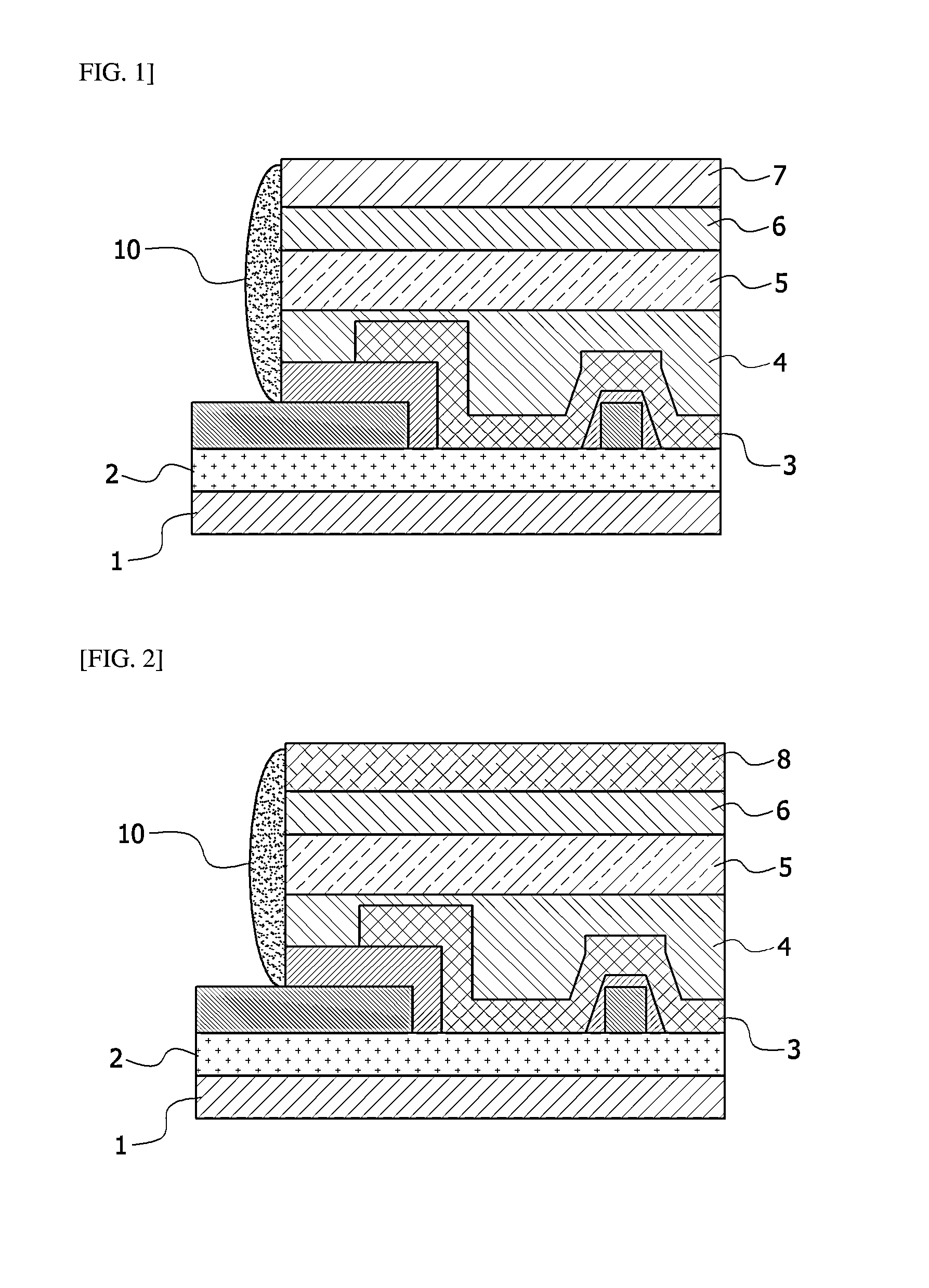

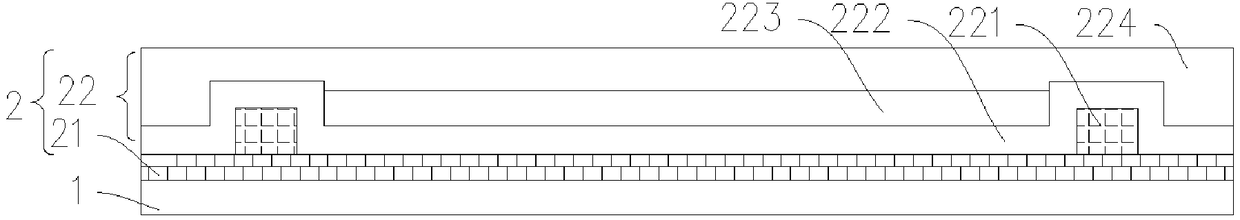

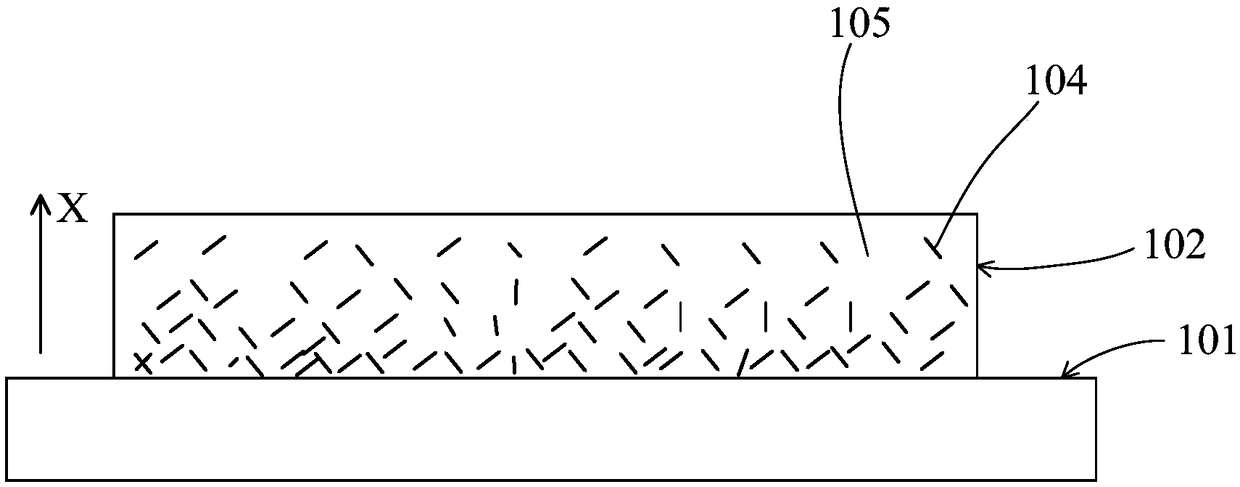

Flexible display device and manufacturing method thereof

InactiveCN102629015AImprove water and oxygen barrier performanceAvoid breakingStatic indicating devicesSolid-state devicesEngineeringOxygen

The invention discloses a flexible display device and relates to the technical field of display. The device comprises a first flexible substrate, a flexible display part and a second flexible substrate, wherein the flexible display part is formed on the surface of the first flexible substrate; the second flexible substrate is positioned at one side of the first flexible substrate, which is deviated from the flexible display part. The invention also provides a manufacturing method of the flexible display device, which comprises the following steps of: manufacturing the flexible display part on the first flexible substrate; and adhering the surface of the first flexible substrate with the flexible display part, which is deviated from the flexible display part, onto the second flexible substrate. According to the flexible display device disclosed by the invention, the flexible display part is packaged by the additional flexible substrate (the second flexible substrate) and particularly the flexible display part formed on a plastic substrate is packaged by adopting an ultrathin glass substrate, so that the flexible display device has better waterproof oxygen-proof property on the basis of keeping the flexibility and the bendable property and is difficult to damage.

Owner:BOE TECH GRP CO LTD

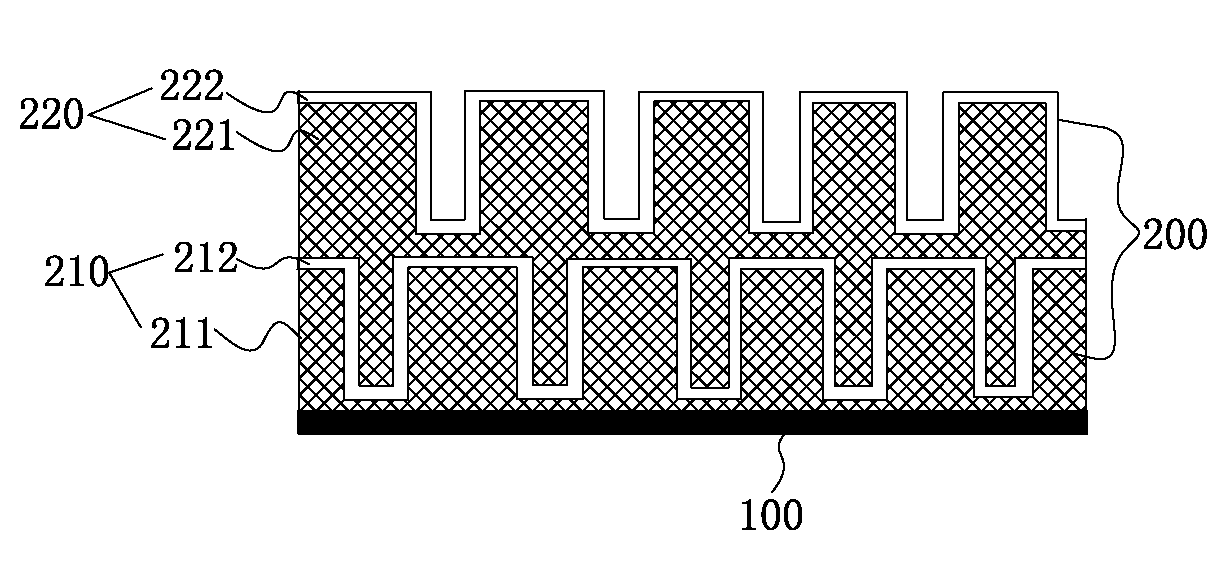

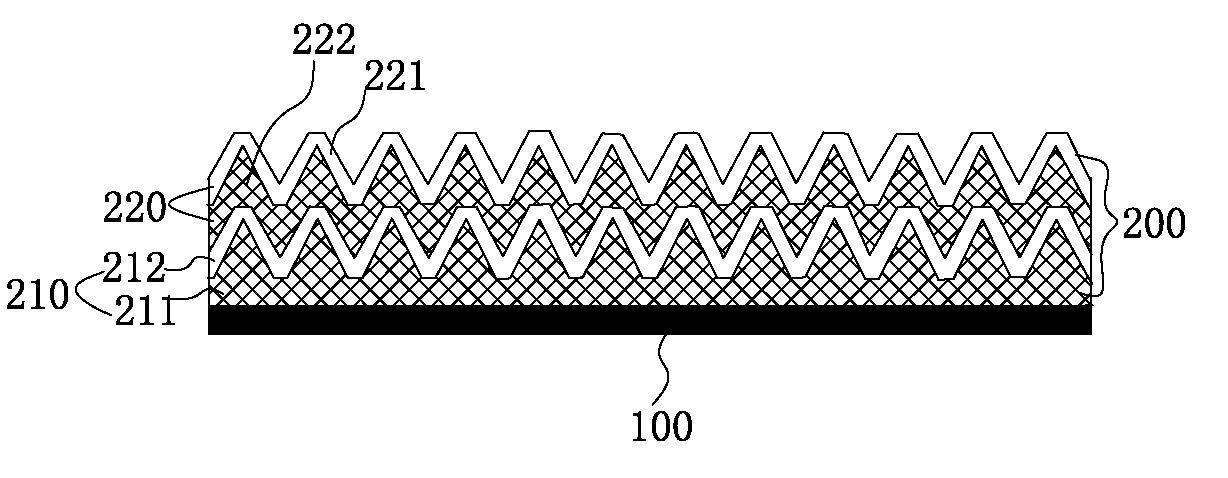

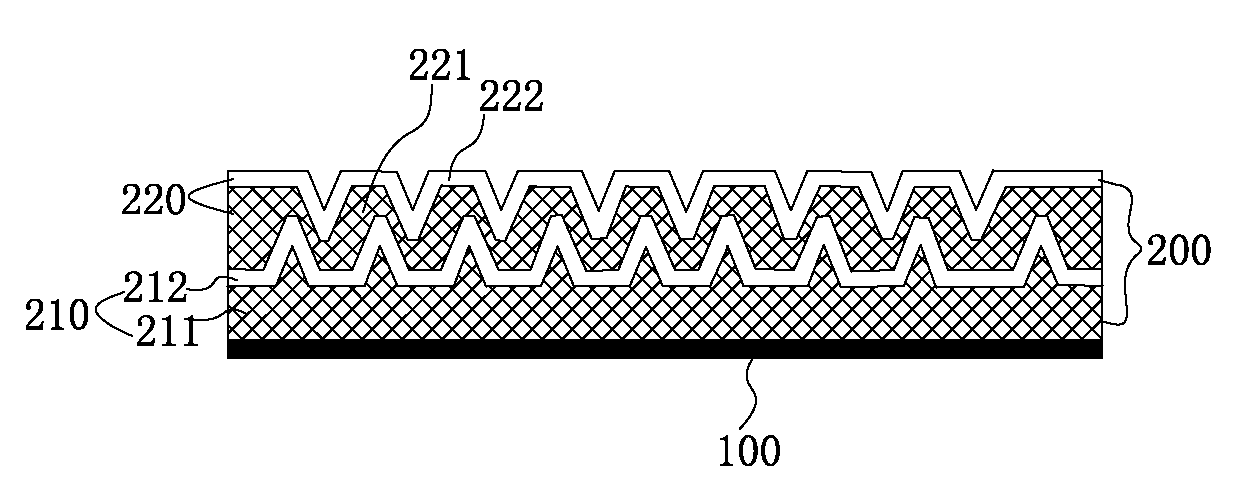

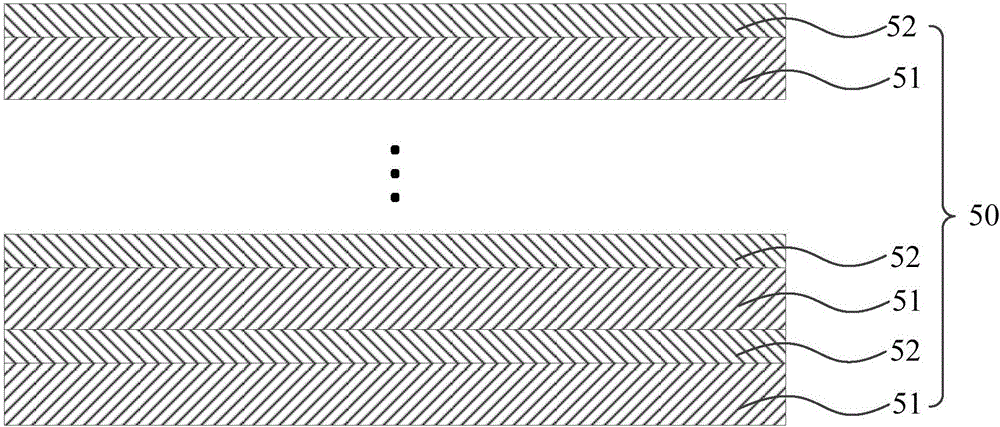

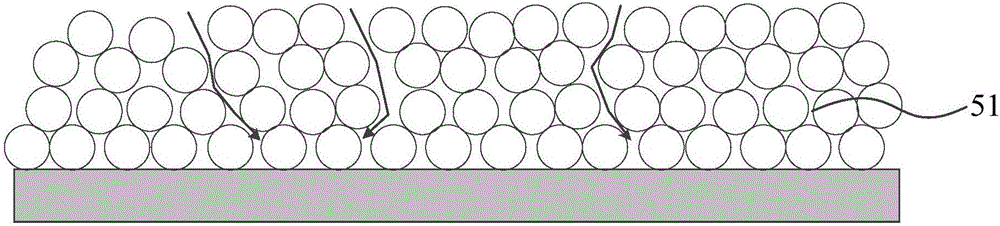

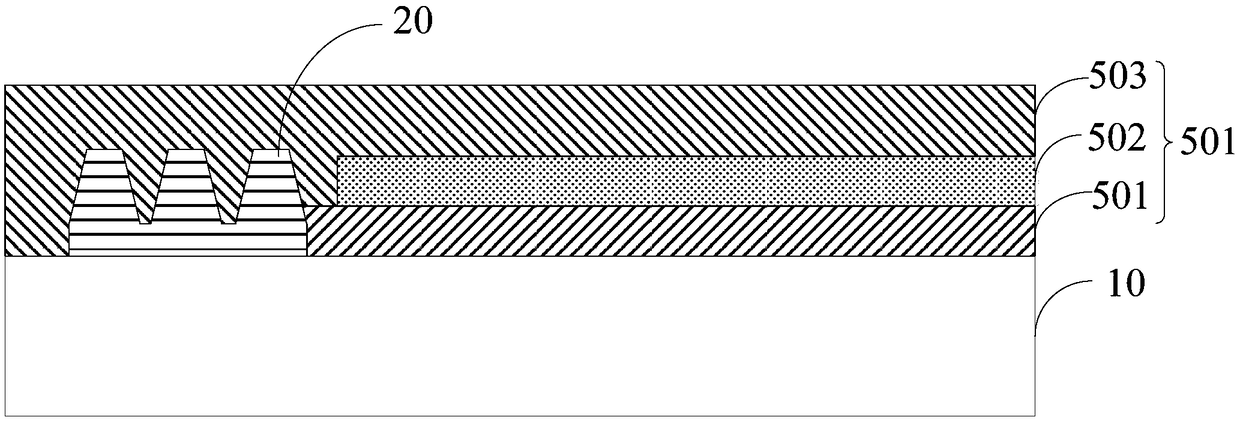

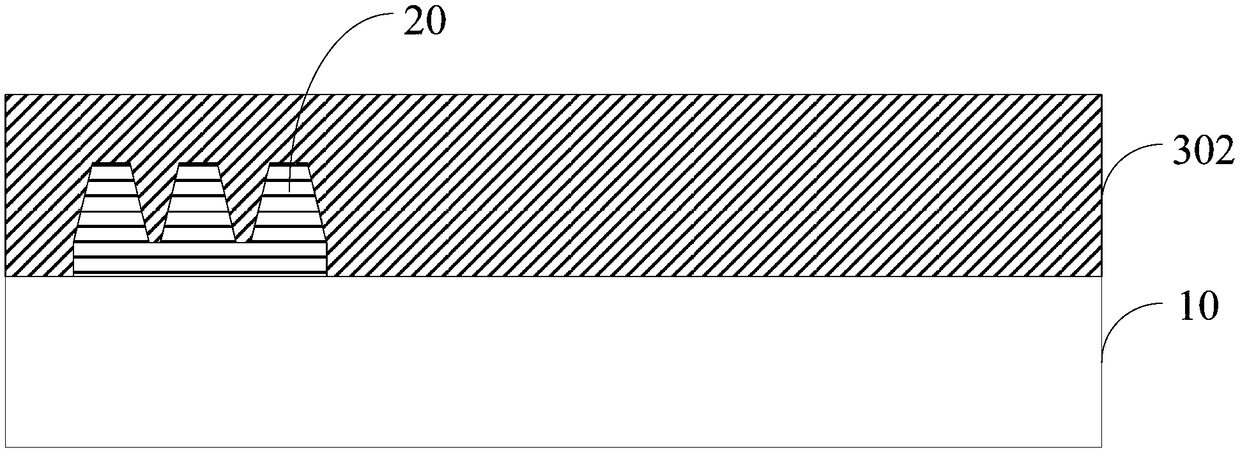

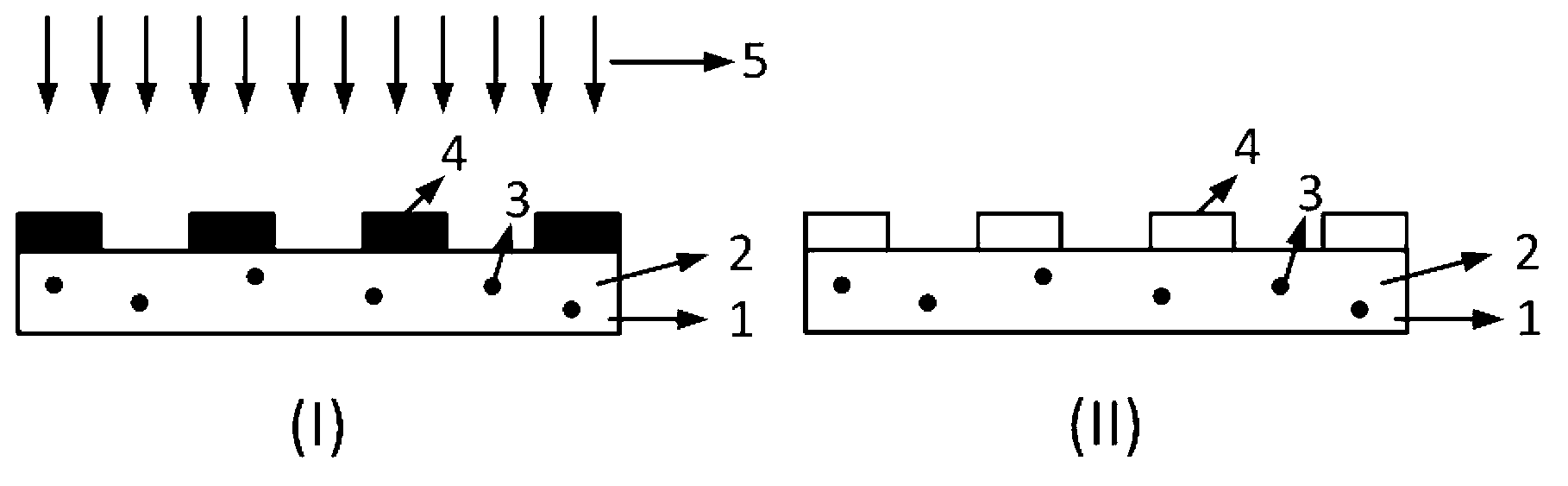

Packaging process of flexible semiconductor film electronic device

ActiveCN103996629AEnhanced scatteringReduce transmittanceSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingThin membraneComposite material

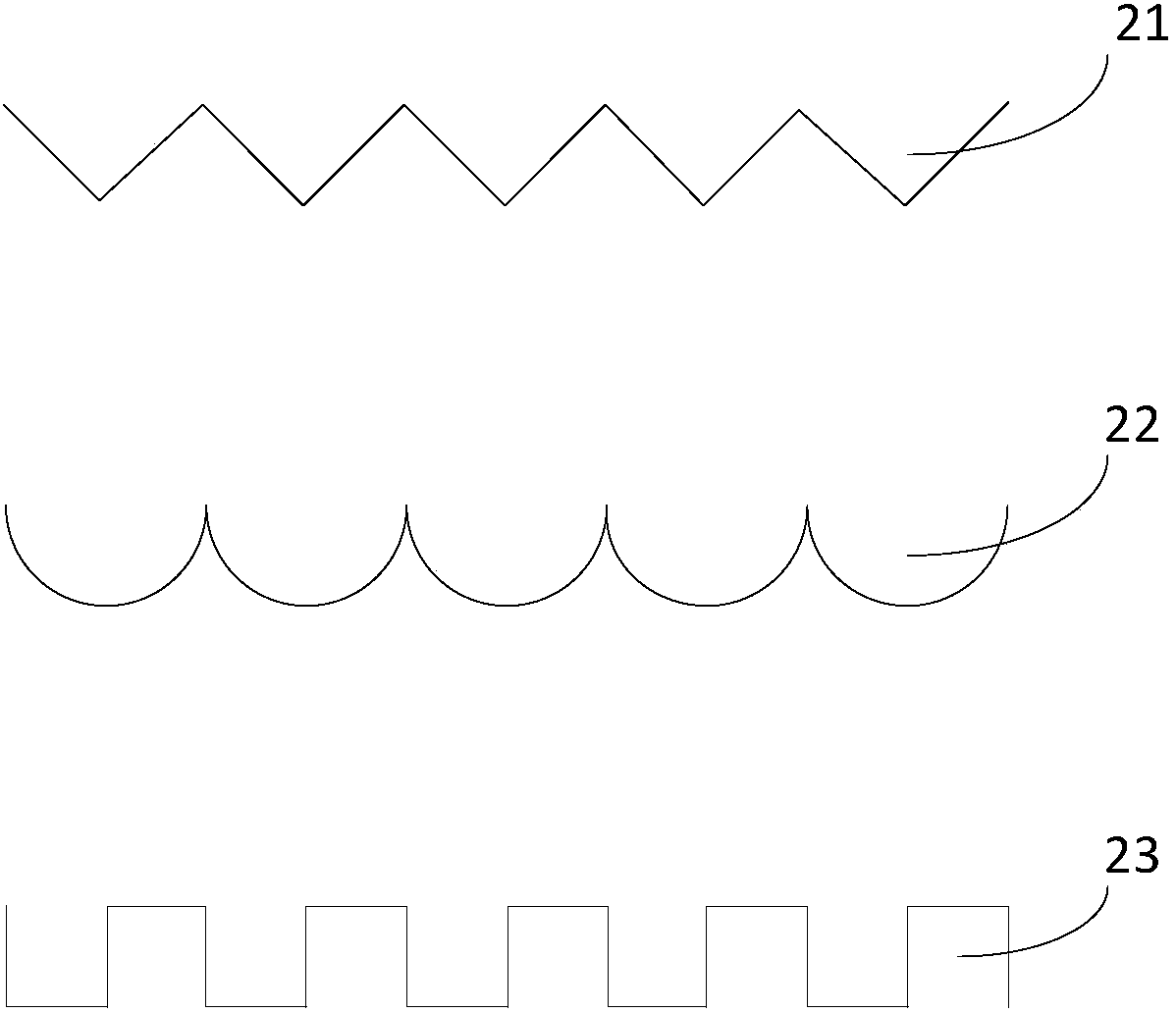

The invention discloses a packaging process of a flexible semiconductor film electronic device. The packaging process comprises a water and oxygen blocking layer preparation working procedure, wherein a water and oxygen blocking layer is formed by one or more water and oxygen blocking units in a stacking mode, each water and oxygen blocking unit comprises an organic blocking layer and an inorganic blocking layer, an uneven morphology structure is arranged on the surface of each organic blocking layer, and each inorganic blocking layer is arranged on the upper surface of the corresponding organic blocking layer. The uneven morphology structure on the surface of an organic film is a regular pattern or an irregular pattern. The uneven morphology structure on the surface of each organic blocking layer is formed in a photoetching mode or physical embossing mode or through particle addition. The uneven morphology structure of the surface of each organic blocking layer is of a rectangular structure or zigzag structure or arc structure. The flexible semiconductor film electronic device is simple in manufacturing process and high in water and oxygen blocking performance, and the device can be kept to be thin while the good water and oxygen isolation performance of the device can be achieved.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

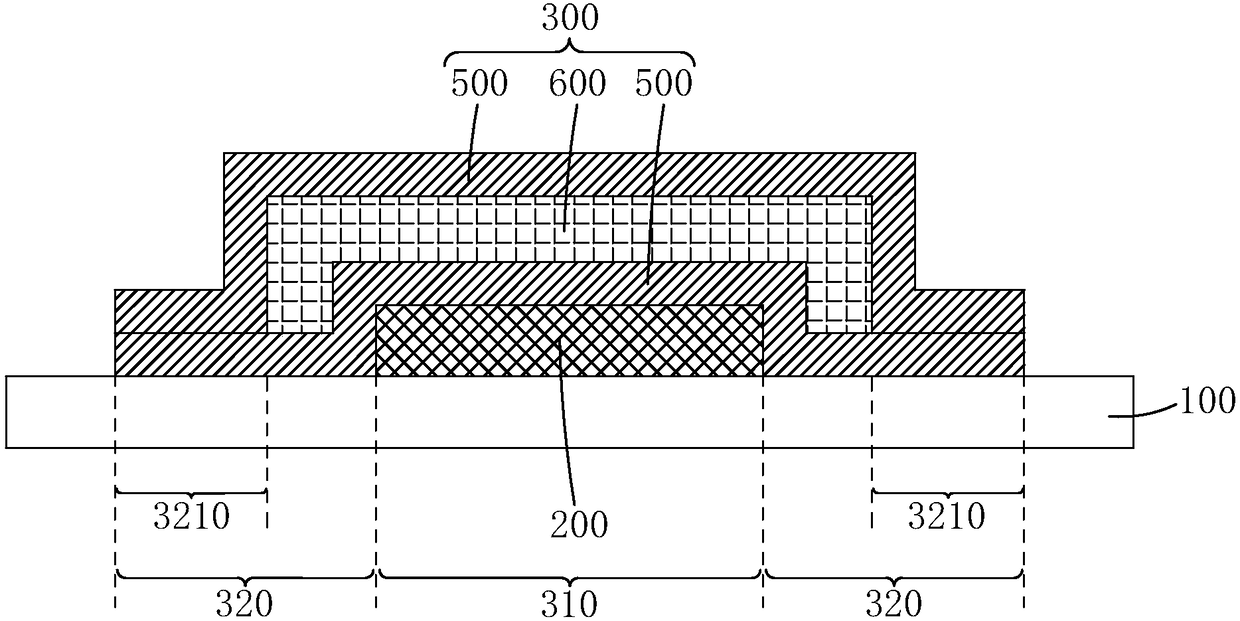

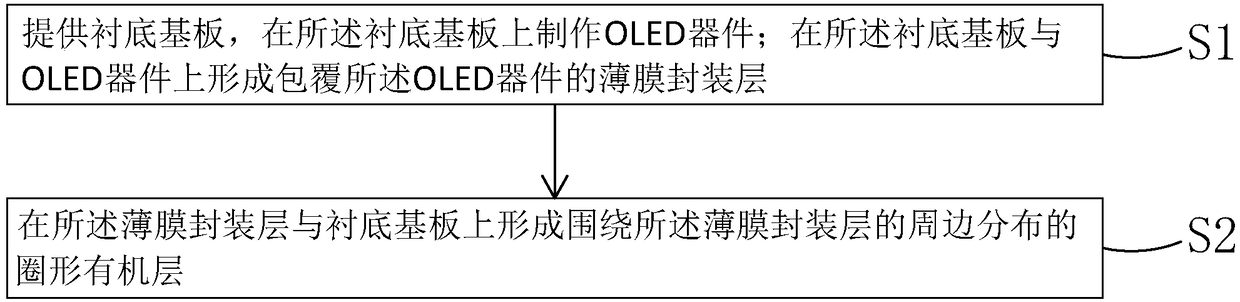

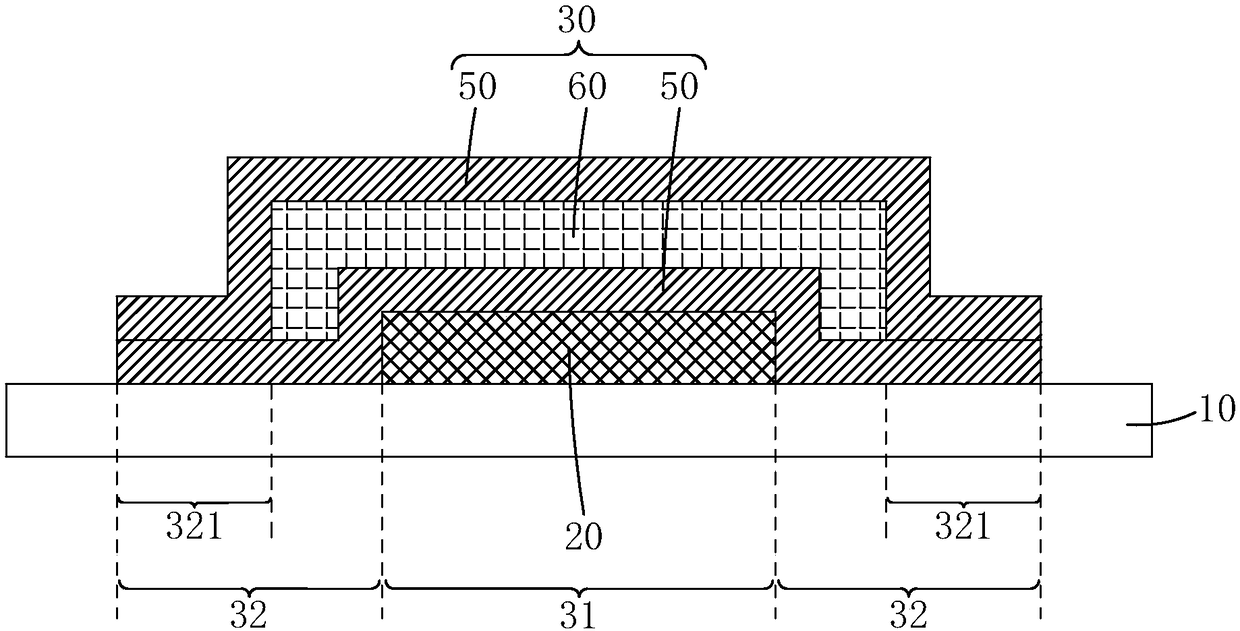

OLED encapsulation method and OLED encapsulation structure

ActiveCN108198953AGood bending resistanceAchieve narrow bezel designSolid-state devicesSemiconductor/solid-state device manufacturingScreen designOrganic layer

The invention provides an OLED encapsulation method and OLED encapsulation structure. The OLED encapsulation method includes the following steps: a first step, providing a substrate, and manufacturingan OLED device on the substrate, and forming a thin film encapsulation layer covering the OLED device on the substrate and the OLED device; and a second step, forming a circular organic layer distributed around the periphery of the thin film encapsulation layer on the thin film encapsulation layer and the substrate. The circular organic layer is arranged on the periphery of the thin film encapsulation layer, and in this way, a hook surface screen design and a narrow frame design of an OLED display device can be achieved, and the ability to block water and oxygen of the OLED encapsulation structure is improved. The OLED encapsulation structure can achieve the hook surface screen design and the narrow frame design of an OLED display device, and has high ability to block water and oxygen.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

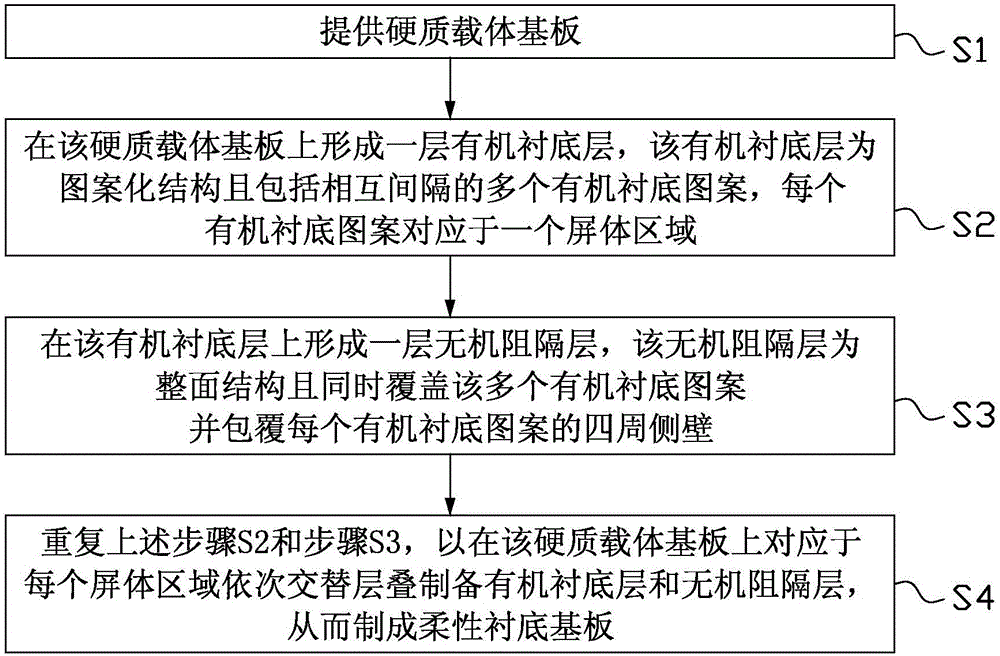

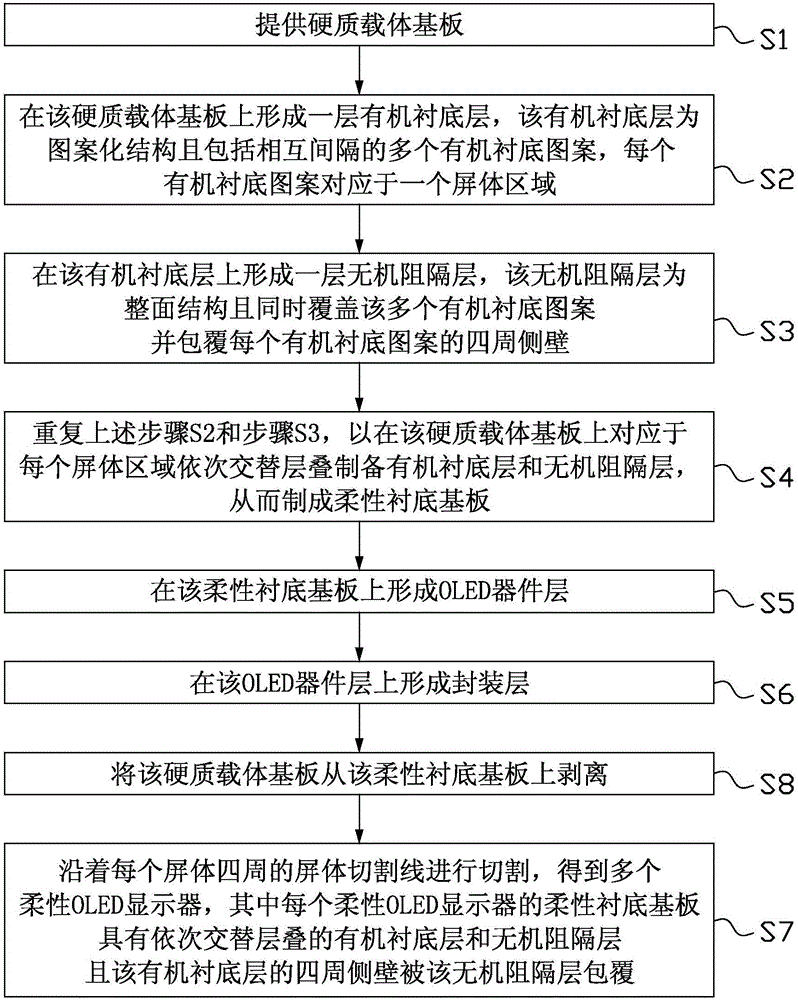

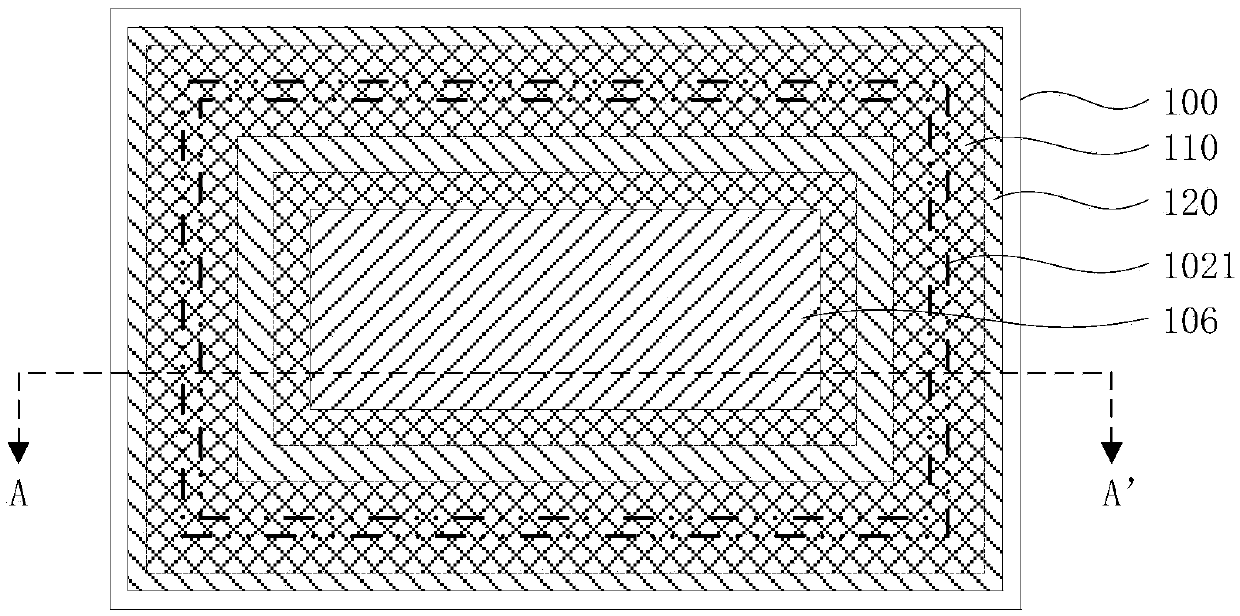

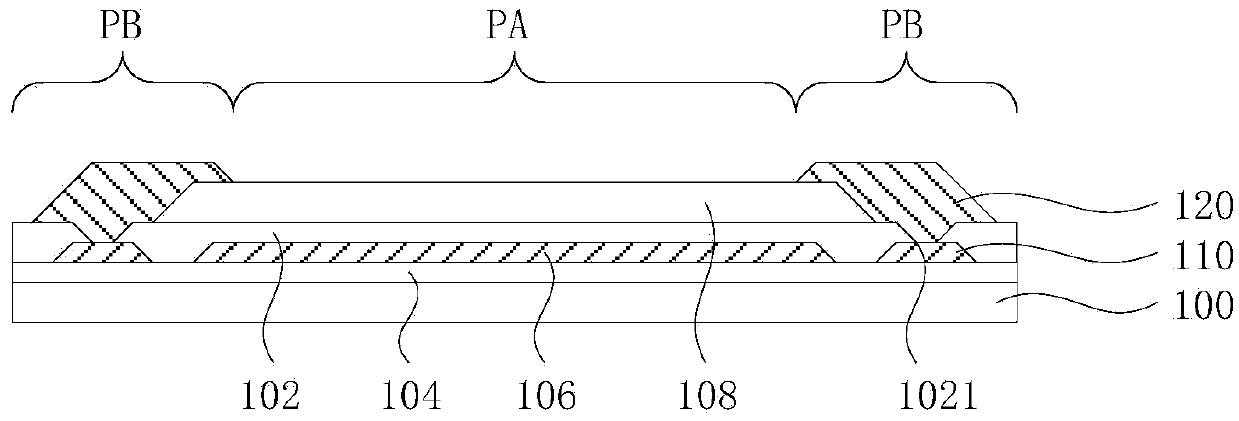

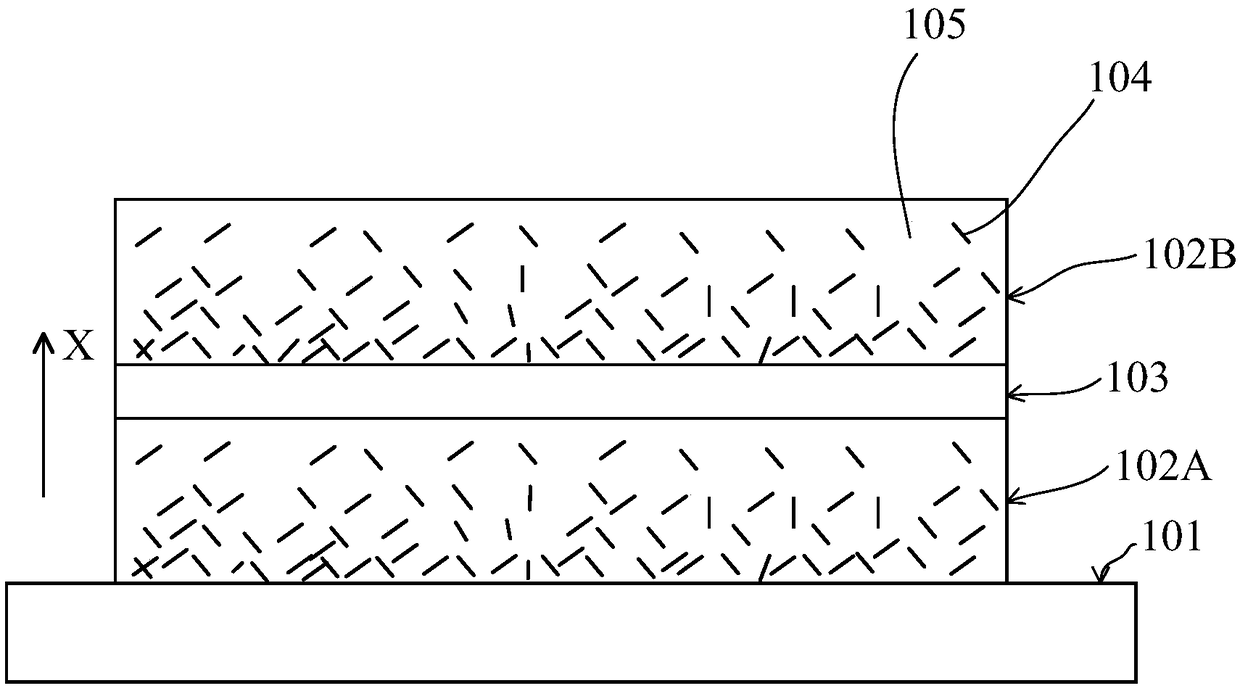

Preparation method of flexible substrate base plate and preparation method of flexible OLED (organic light emitting diode) display

InactiveCN106158740AImprove water and oxygen barrier performanceImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryDisplay device

The invention relates to a preparation method of a flexible substrate base plate and a preparation method of a flexible OLED (organic light emitting diode) display, wherein the preparation method of the flexible substrate base plate comprises the following steps of providing a hard carrier base plate; forming an organic substrate layer on the hard carrier base plate, wherein the organic substrate layer is of a pattern structure and comprises a plurality of mutually separated organic substrate patterns, and each organic substrate pattern corresponds to one screen body region; forming an inorganic blocking layer on the organic substrate layer, wherein the inorganic blocking layer is of an integral surface structure, simultaneously covers the plurality of organic substrate patterns and covers the peripheral side walls of each organic substrate pattern, so that the flexible substrate base plate is prepared. In the preparation method of the flexible substrate base plate, the peripheral side wall of each organic substrate pattern (corresponding to each screen body) is covered by the inorganic blocking layer; the water and oxygen blocking capability of the front side and the lateral side of the flexible substrate base plate can be greatly improved; the water and oxygen blocking performance of the side surface of the flexible display screen body can be effectively improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Flexible display apparatus and preparation method therefor

ActiveCN105374946AGuaranteed display effectImprove Edge ReliabilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The invention discloses a flexible display apparatus and a preparation method therefor. The flexible display apparatus comprises a flexible substrate, a packaging substrate, at least one first display film layer, a thin film packaging layer, and an edge packaging structure, wherein the flexible substrate comprises a display region and a packaging region; the packaging substrate is positioned in the packaging region of the flexible substrate; the at least one first display film layer is positioned in the packaging substrate; a first via hole is formed in the first display film layer on the packaging substrate to expose at least a part of the packaging substrate; the first display film layer is covered with the thin film packaging layer, and the thin film packaging layer extends from the display region to the packaging region; the edge of the thin film packaging layer is closer to the display region than the packaging substrate; the edge packaging structure is arranged along the edge of the thin film packaging layer for covering the edge region and the first via hole of the thin film packaging layer, and the edge packaging structure is in contact with the packaging substrate through the first via hole. According to the flexible display apparatus provided by the invention, the edge reliability in the thin film packaging is improved, so that the water oxygen barrier capability is further improved to ensure the display effect of the display apparatus.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Flexible transparent conductive film preparation method

ActiveCN106601382AEasy to manufactureImprove conductivityMaterial nanotechnologyConductive layers on insulating-supportsTransparent conducting filmOxygen barrier

The invention discloses a flexible transparent conductive film preparation method including the steps of composite conducting layer preparation, water-oxygen barrier layer deposition, flexible substrate applying, and dissociation. The invention further discloses a flexible transparent conductive film, from the bottom to the top, successively includes a flexible substrate, an adhesive layer, a water-oxygen barrier layer, and a composite conductive layer; and the composite conductive layer comprises a transparent polymer support layer and a transparent conductive network from the bottom to the top. The method realizes the preparation of a transparent conductive film having a high conductivity and a flat surface, and the obtained flexible transparent conductive film has a bending-resistant capability.

Owner:王磊

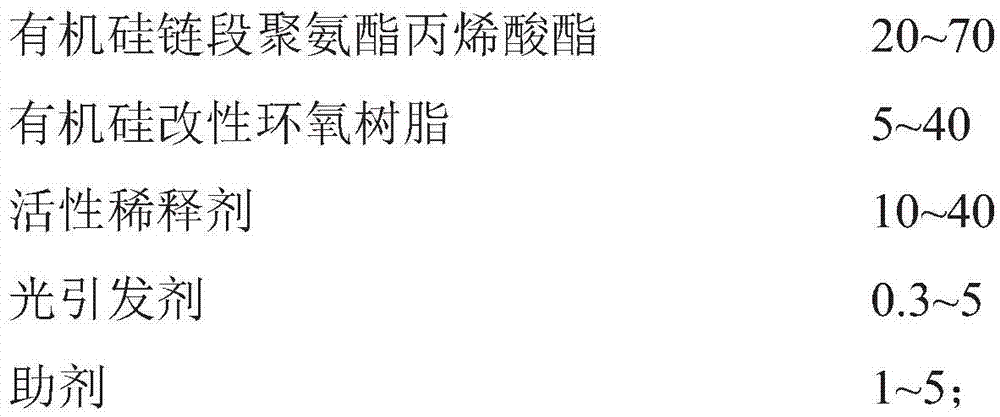

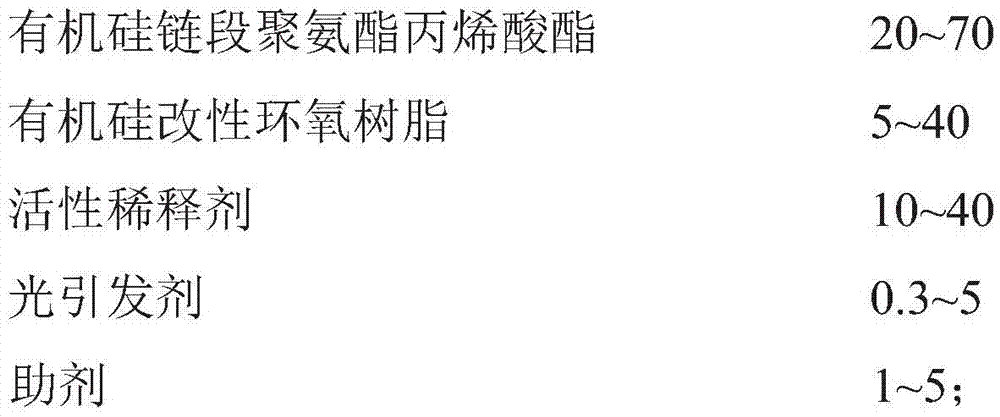

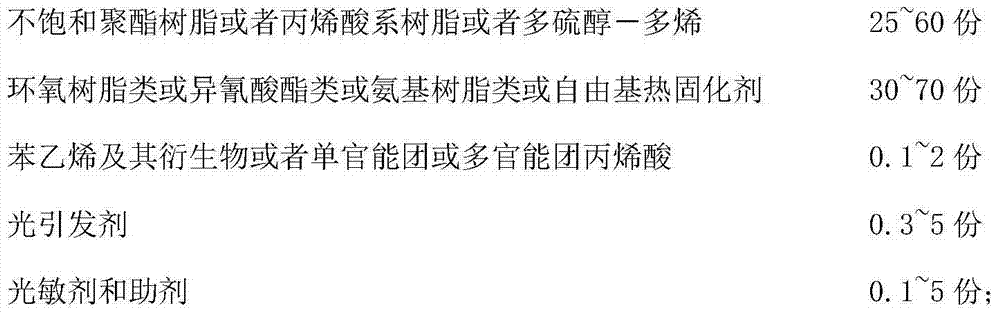

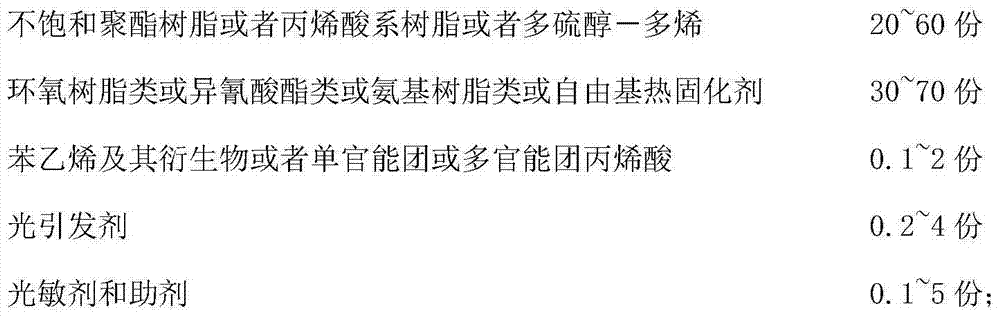

UV adhesive for sealing quantum dot material, and preparation method thereof

ActiveCN105441012ASolve the problem of poor water and oxygen barrier performanceImprove water and oxygen barrier performancePolyureas/polyurethane adhesivesEpoxyMethacrylate

The invention discloses a UV adhesive for sealing a quantum dot material. The UV adhesive is prepared through mixing, by weight, 20-70 parts of organosilicon chain segment polyurethane acrylate, 5-40 parts of organosilicon modified epoxy resin, 10-40 parts of an active diluent, 0.3-5 parts of a photoinitiator and 1-5 parts of an assistant, wherein the organosilicon chain segment polyurethane acrylate is modified polyurethane resin adopting a polysiloxane chain segment as a main chain and a methacrylate double bond function group as an end group; and the organosilicon modified epoxy resin is modified organosilicon resin adopting a polysiloxane chain segment as a main chain and an epoxy function group as an end group. Main resin is based on organosilicon, and the structure and the molecular weight of the resin are controlled, so the UV adhesive has excellent water and oxygen barrier performances, and the problem of poor water and oxygen barrier performances of traditional sealing materials is solved.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Flexible organic electroluminescence display and electronic device

ActiveCN106449709AImprove water and oxygen barrier performanceDenseSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a flexible organic electroluminescence display and an electronic device. The flexible organic electroluminescence display comprises a flexible substrate, a packaging structure and an electroluminescence element, wherein the flexible substrate and the packaging structure are oppositely arranged; the electroluminescence element is located between the flexible substrate and the packaging structure; the packaging structure comprises at least one film packaging layer for covering the electroluminescence element; the film packaging layer is composed of a first inorganic layer and a second inorganic layer which are successively overlapped; the second inorganic layer is made from a nanometer crystal material. The second inorganic layer made from the nanometer crystal material is used for filling the holes, cracks and flaws possibly existing in the surface of the first inorganic layer, so that the defects of the first inorganic layer can be compensated, the performance of separating water and oxygen of the packaging structure can be promoted, the service life of the flexible organic electroluminescence display can be prolonged, and meanwhile, the thickness of the packaging structure can be reduced and the flexible organic electroluminescence display has better bending property.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

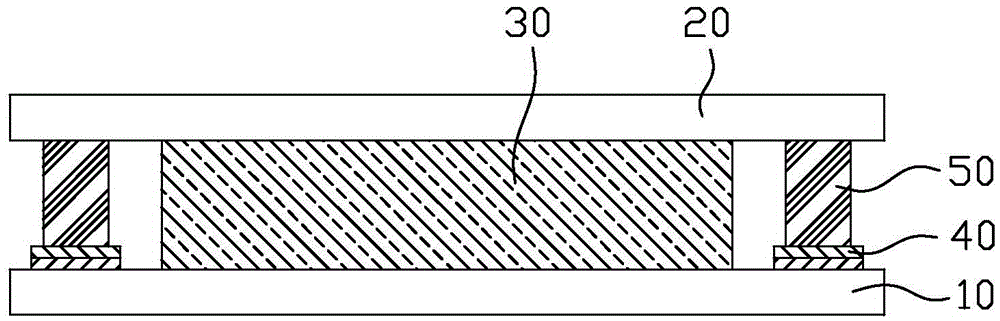

Organic light emitting device comprising encapsulating structure

ActiveUS20130207093A1Good oxygen barrier effectImprove the water effectElectroluminescent light sourcesSolid-state devicesGlass coverMetal foil

Provided is an organic light emitting diode including an organic light-emitting part including a first electrode, an organic material layer having a light-emitting layer, and a second electrode, and an encapsulating layer included on an entire top surface of the organic light-emitting part. Here, the encapsulating layer has a structure in which at least two of a water barrier film, a glass cap, a metal foil and a conductive film are stacked. Accordingly, the diode may have excellent water and oxygen barrier effects, and deterioration of the diode or running failure may be prevented.

Owner:LG DISPLAY CO LTD

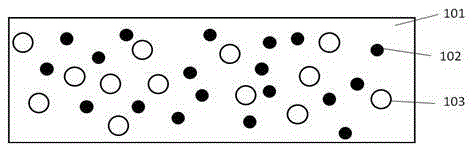

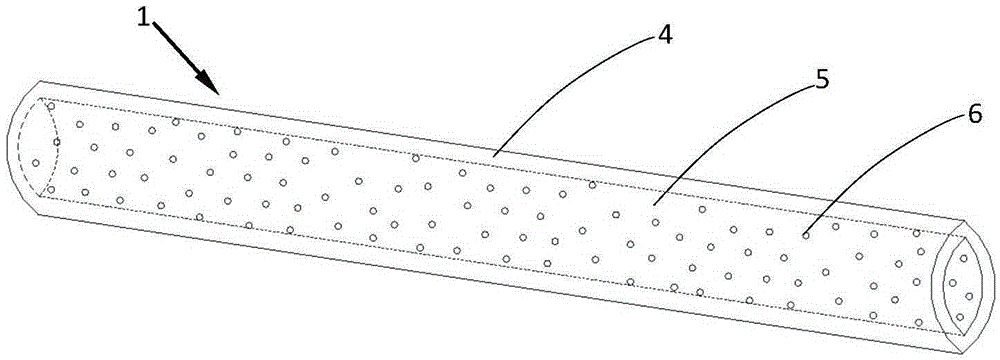

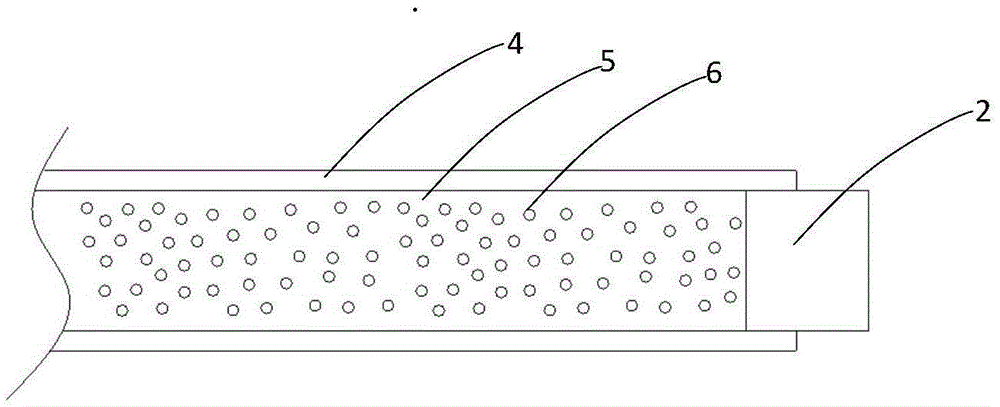

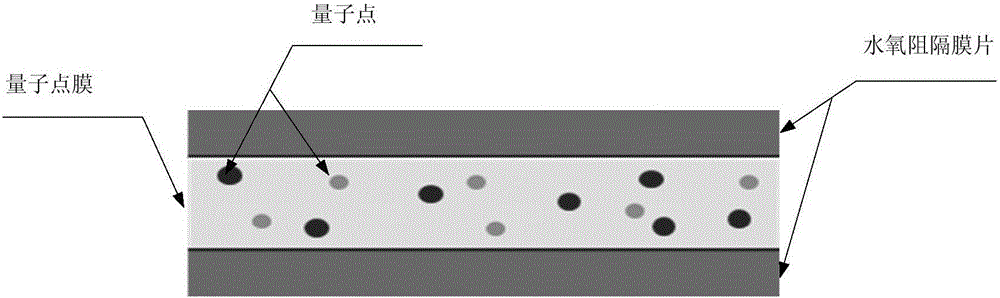

Multi-layer quantum dot film and backlight module group

ActiveCN105259601AImprove color gamutAvoid quenchingDiffusing elementsNon-linear opticsHigh humidityQuantum dot

The invention relates to a multi-layer quantum dot film and a backlight module group. A quantum dot core layer, an upper water and oxygen barrier layer and a lower water and oxygen barrier layer are included. A first quantum dot microcapsule layer is arranged between the quantum dot core layer and the upper water and oxygen barrier layer. A second quantum dot microcapsule layer is arranged between the quantum dot core layer and the lower water and oxygen barrier layer. The first quantum dot microcapsule layer and the second quantum dot microcapsule layer comprise, by weight, 80-110 parts of matrix adhesives, 3-41 parts of quantum dot microcapsules and 1-15 parts of diffusion particles. Luminescence efficiency stability of the multi-layer quantum dot film is good. A test is performed under high temperature and high humidity conditions. Brightness and color gamut attenuation are low and small.

Owner:HEFEI LUCKY SCI & TECH IND

Quantum-dot optical film and backlight module

ActiveCN105259598AImprove color gamutAvoid quenchingNon-linear opticsOptical elementsUltrasound attenuationGamut

The invention relates to a quantum-dot optical film and a backlight module. A quantum dot core layer, an upper water-proof oxygen-insulation encapsulation layer and a lower water-proof oxygen-insulation encapsulation layer are included. The quantum dot core layer comprises, by weight, 80-110 parts of a matrix adhesive, 6-44 parts of a quantum dot microcapsule and 1-15 parts of a diffusion particle. Luminescence efficiency and stability of the quantum-dot optical film are good. A test is performed under high temperature and high humidity conditions. Brightness and color gamut attenuation are low and small.

Owner:HEFEI LUCKY SCI & TECH IND

Quantum dot packaging body and application thereof

InactiveCN105565264AImprove water and oxygen barrier performanceImprove overall lifespanMaterial nanotechnologyIndividual molecule manipulationDisplay deviceQuantum dot

The present invention discloses a quantum dot packaging body which comprises a first packaging medium which is optically transparent and at least two quantum dot glass bodies dispersed in the first packaging medium. Each quantum dot glass body comprises glass located at the outer layer, a second packaging medium which is optically transparent and located at the inner layer, and at least one type of quantum dots dispersed in the second packaging medium. The first packaging medium consists of high polymer materials. By packaging the packaging body quantum dots in the glass body with a certain volume, the fragile disadvantages of glass tubes are avoided, and at the same time, a relative high luminous efficiency is kept. The present invention also discloses a light-emitting device, a backlight module and a display device. The present invention also discloses a preparation method of the quantum dot packaging body.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

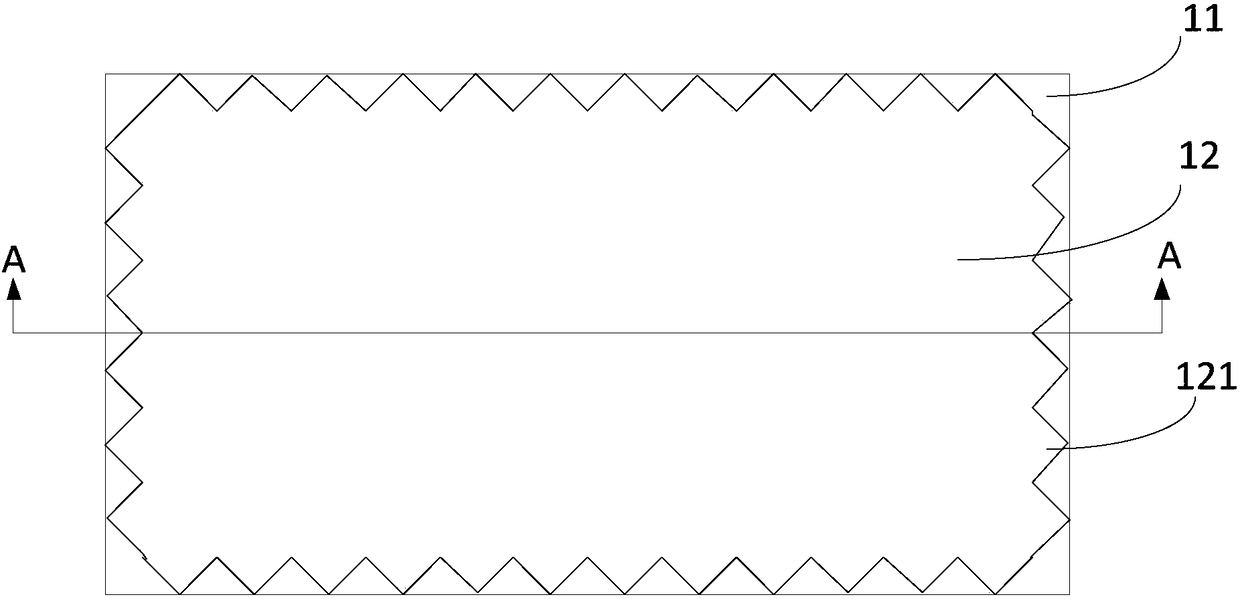

OLED display panel and display device

InactiveCN108832016AHigh water and oxygen barrierImprove water and oxygen barrier performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The OLED display panel provided by the invention comprises a light emitting substrate and at least one group of encapsulation films arranged on the light emitting substrate. Wherein each group of theencapsulation films includes a first inorganic layer disposed on the light emitting substrate, the edge region of the first inorganic layer is provided with a retaining wall, the first inorganic layeris provided with an organic layer and the organic layer is blocked in the retaining wall, and the organic layer is provided with a second inorganic layer covering the first inorganic layer, the organic layer and the retaining wall; wherein the retaining wall is provided with a zigzag structure capable of improving the water-oxygen barrier performance of the OLED display panel. By installing a retaining wall with a zigzag structure on the OLED display panel, not only the ability of the OLED display panel to block water and oxygen can be improved, but also the frame of the OLED display panel can be reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

OLED display panel and packaging method

ActiveCN108598286AImprove water and oxygen barrier performanceExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporOptoelectronics

The invention provides an OLED panel and a packaging method. The OLED panel comprises a light-emitting substrate, and at least one group of packaging films arranged on the light-emitting substrate, wherein each group of packaging films comprise a first inorganic layer arranged on the light-emitting substrate; each first inorganic layer is provided with an organic layer; an organic retaining wall is arranged in an edge region of each organic layer; each organic layer is blocked in the corresponding organic retaining wall and is provided with a second inorganic layer covering the corresponding first inorganic layer, organic layer and organic retaining wall; and each organic retaining wall is filled with a water-absorbing material to improve the water-oxygen blocking ability of the OLED panel. The target of improving the blocking ability on water vapor and oxygen is achieved through arranging one organic retaining wall in the edge region of each organic layer and filling each organic retaining wall with the water-absorbing material, thereby prolonging the service life of the OLED panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

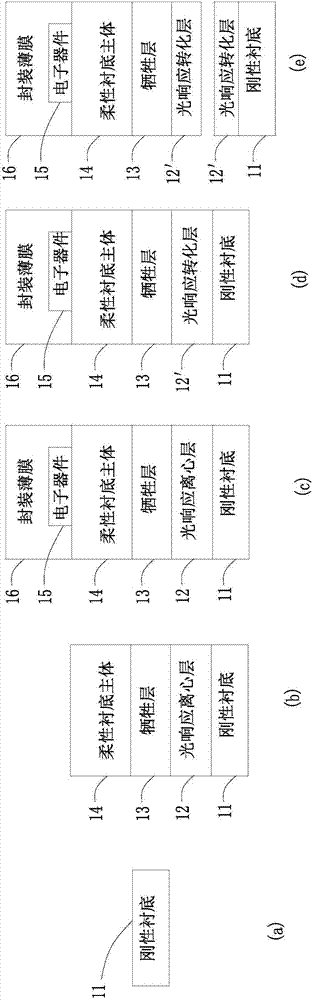

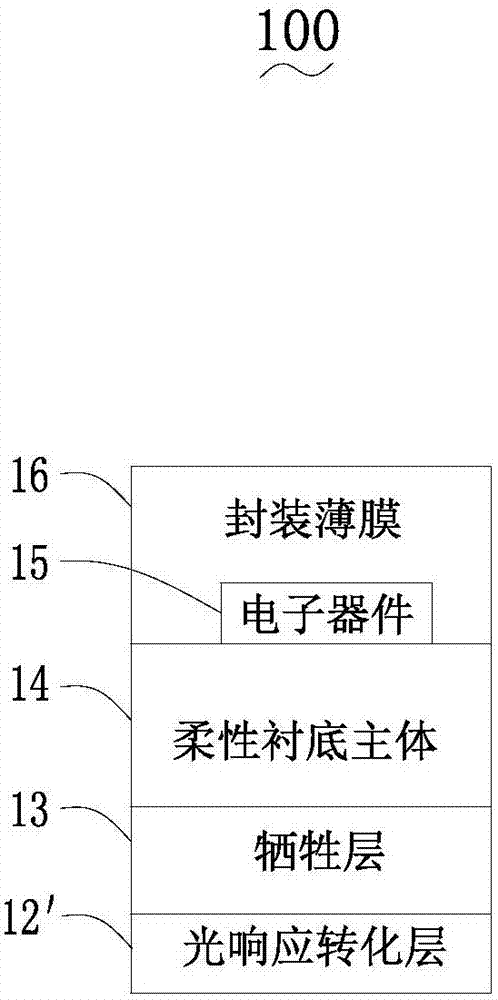

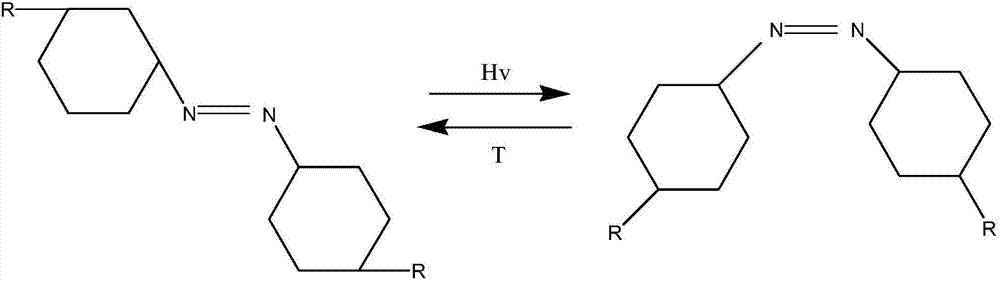

Flexible electronic device and manufacturing method thereof

InactiveCN106887407AImprove performanceImprove water and oxygen barrier performanceSolid-state devicesSemiconductor/solid-state device manufacturingUltraviolet lightsEngineering

The invention discloses a method for manufacturing a flexible electronic device. The method comprises steps of: providing a rigid substrate and successively manufacturing a light-responsive release layer, a sacrificial layer and a flexible substrate body on the rigid substrate; successively forming an electronic device and a packaging film on the flexible substrate body; applying ultraviolet light to a side of the light-responsive release layer so that the light-responsive release layer generates molecular configuration conversion so as to be warped; and stripping the warped light-responsive layer from the rigid substrate, wherein a part of the light-responsive release layer separated from the rigid substrate, the sacrificial layer, the flexible substrate body, the electronic device, and the packaging film form the flexible electronic device. The method for manufacturing the flexible electronic device has no stripping damage and can improve the performance of the electronic device. The invention also provides a flexible electronic device manufactured by the manufacturing method.

Owner:AAC TECH NANJING

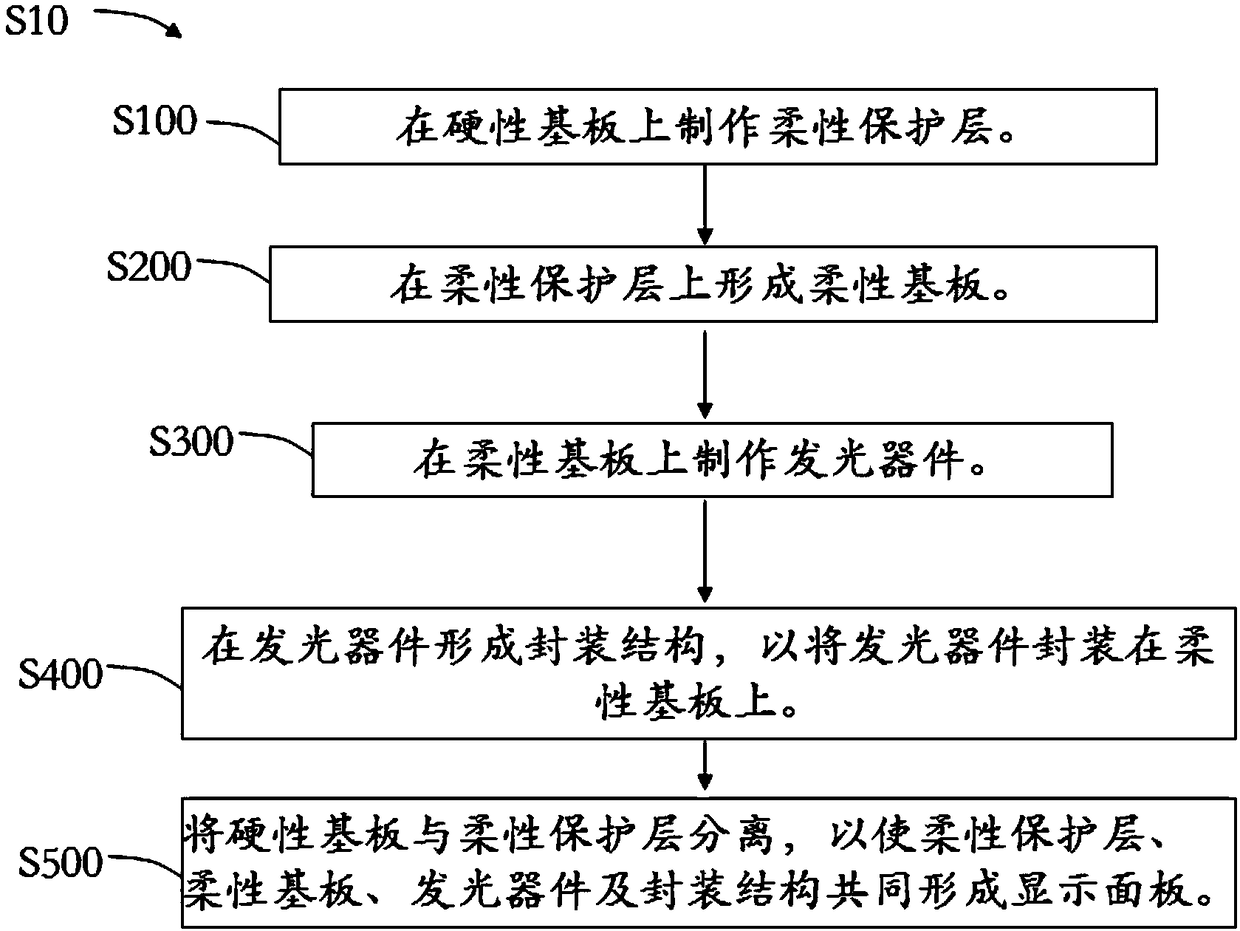

Display panel and manufacturing method therefor

InactiveCN108539051AImprove the ability to block water and oxygenImprove water and oxygen barrier performanceFinal product manufactureSolid-state devicesEngineeringSurface plate

The invention provides a display panel manufacturing method comprising the following steps: a flexible protection layer is made on a rigid substrate, a flexible substrate is formed on the flexible protection layer, an illuminating device is made on the flexible substrate, a packaging structure is formed by the illuminating device, and therefore the illuminating device can be packaged on the flexible substrate; the rigid substrate is separated from the flexible protection layer; the flexible protection layer, the illuminating device and the packaging structure jointly form a display panel. Theinvention also provides the display panel. According to the display panel and the manufacturing method therefor, the flexible substrate can be prevented from being damaged while being peeled off the rigid subtracted, and reliability of the display panel can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

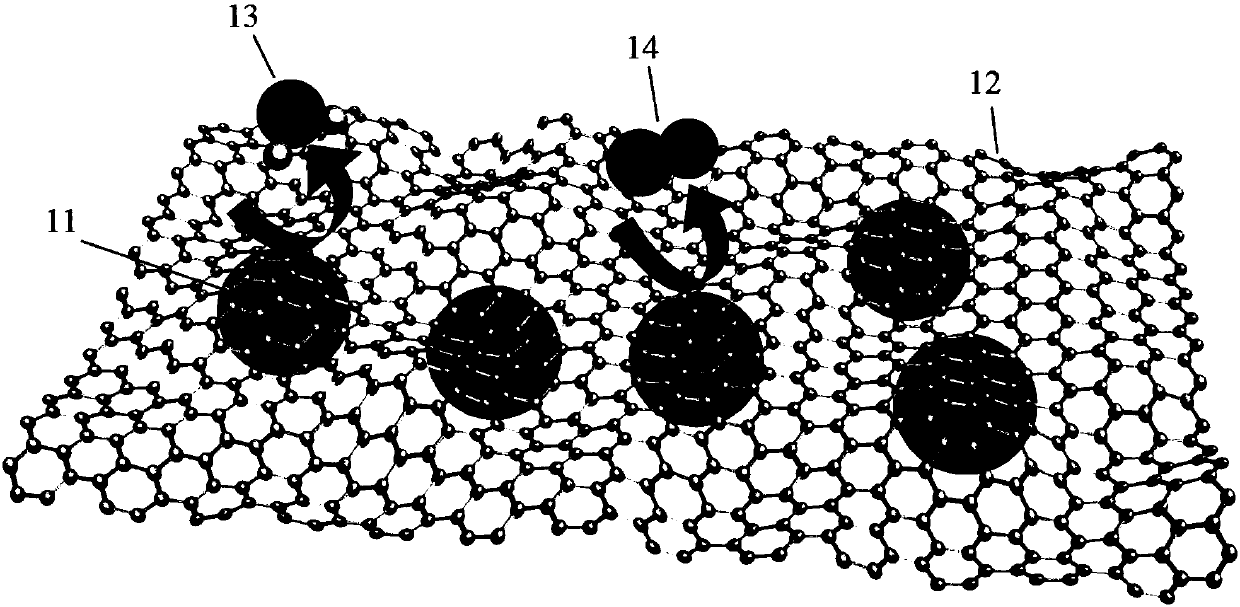

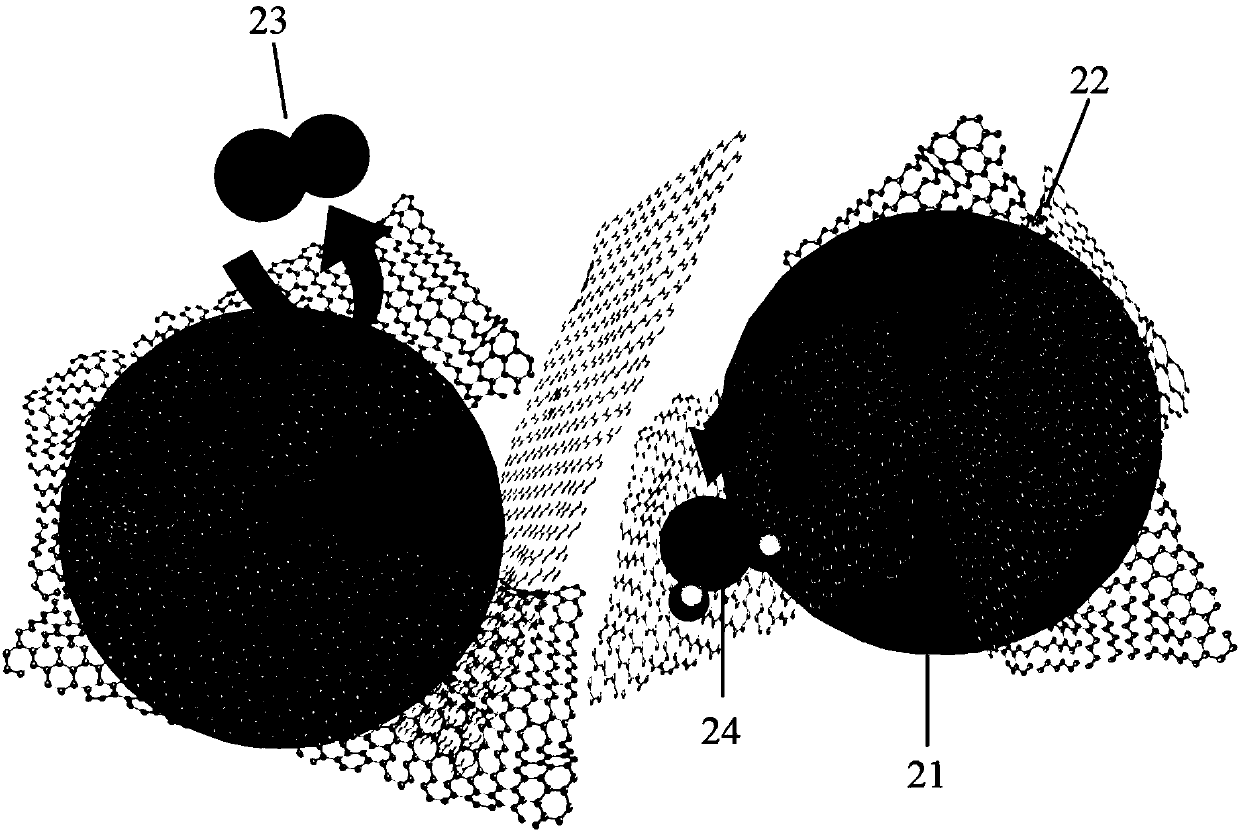

Quantum dot fluorescent composite material as well as preparation method and application thereof

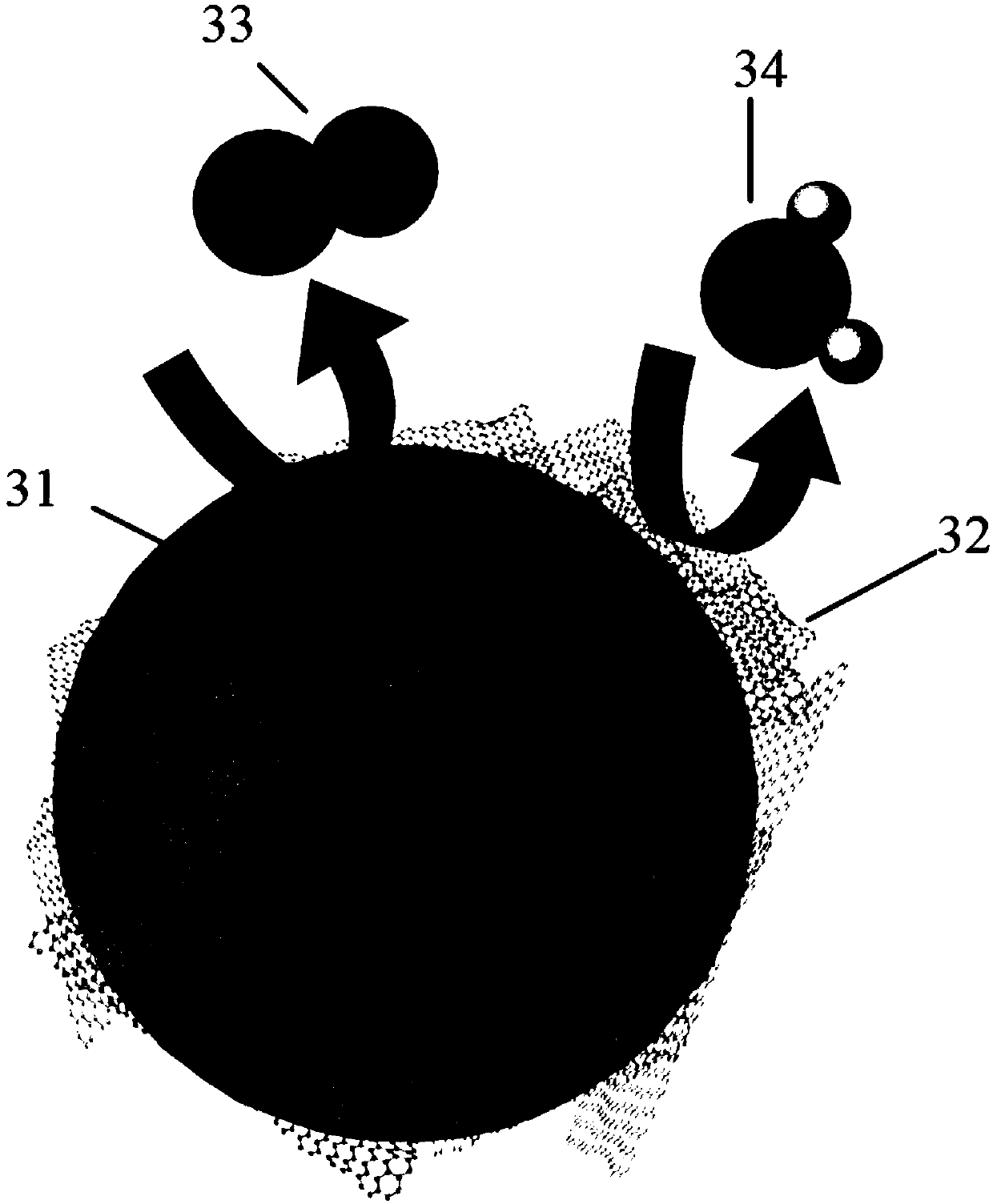

ActiveCN107828416AImprove stabilityReduce leakageMaterial nanotechnologyNanoopticsMicrosphereFluorescence

The invention relates to a quantum dot fluorescent composite material as well as a preparation method and application thereof. The quantum dot fluorescent composite material is prepared from the following components: graphene and polymer microspheres compounded on the graphene, wherein quantum dots are embedded into the polymer microspheres; the surfaces of the polymer microspheres are bonded withthe surface of the graphene through peptide bonds. On one hand, the compatibility problem of the quantum dots and a polymer material is improved, the shape of the quantum dot polymer composite material is controlled, and the defect that the graphene is easy to quench when being directly combined with the quantum dots is avoided; on the other hand, an excellent water and oxygen blocking capabilityof the graphene is expressed and invasion, caused by water and oxygen, on the quantum dots is reduced; meanwhile, the stability of the quantum dot composite material is further improved by excellentheat conduction performance of the graphene. The quantum dot@PS microsphere@graphene composite material with a stable compound structure is packaged into a quantum dot LED (Light Emitting Diode), so that the water blocking and oxygen blocking stability of the LED can be further improved under the condition that the optical performance of the quantum dots is not remarkably reduced.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

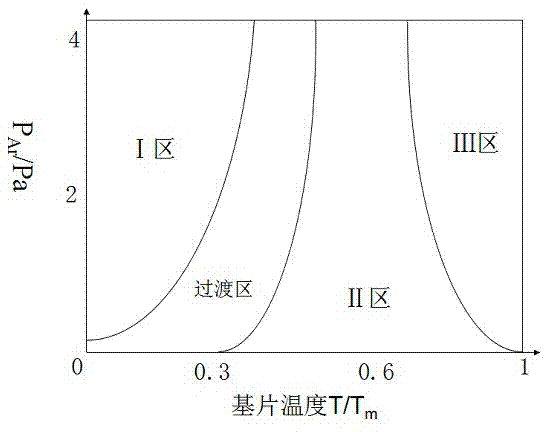

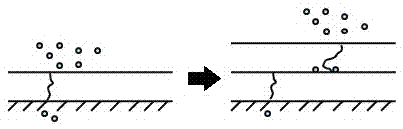

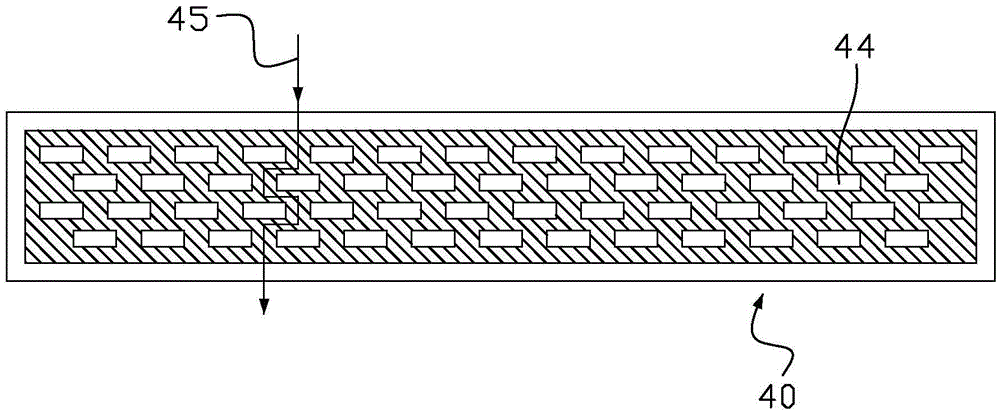

Manufacturing method of water and oxygen barrier layer

ActiveCN105449123AReduce water oxygen transmission rateEffect of mismatchSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporThin membrane

The invention discloses a manufacturing method of a water and oxygen barrier layer. At least two thin film layers are successively manufactured on a substrate to form a water and oxygen composite barrier layer. When each thin film layer is manufactured, manufacturing parameters of at least two any adjacent thin film layers, which are provided and selected during manufacturing, are different so that each thin film layer in the water and oxygen composite barrier layer forms a disconnected mismatch structure of a water and oxygen microchannel. A plurality of thin film layers are manufactured on the substrate to form the water and oxygen composite barrier layer. Through adjusting one or more parameters influencing film deposition, the films can grow with different structures, different properties and even different growth modes so that a water vapor pathway in a previous film layer and a water vapor pathway in a next film layer are mismatched. The water vapor pathways which can not be connected can not conduct the water and oxygen in atmosphere so that water and oxygen barrier performance of the thin films is increased. The method is simple and easy to use. In future industrial production of a flexible display barrier layer, the method possesses considerable popularization potential.

Owner:SHANGHAI UNIV

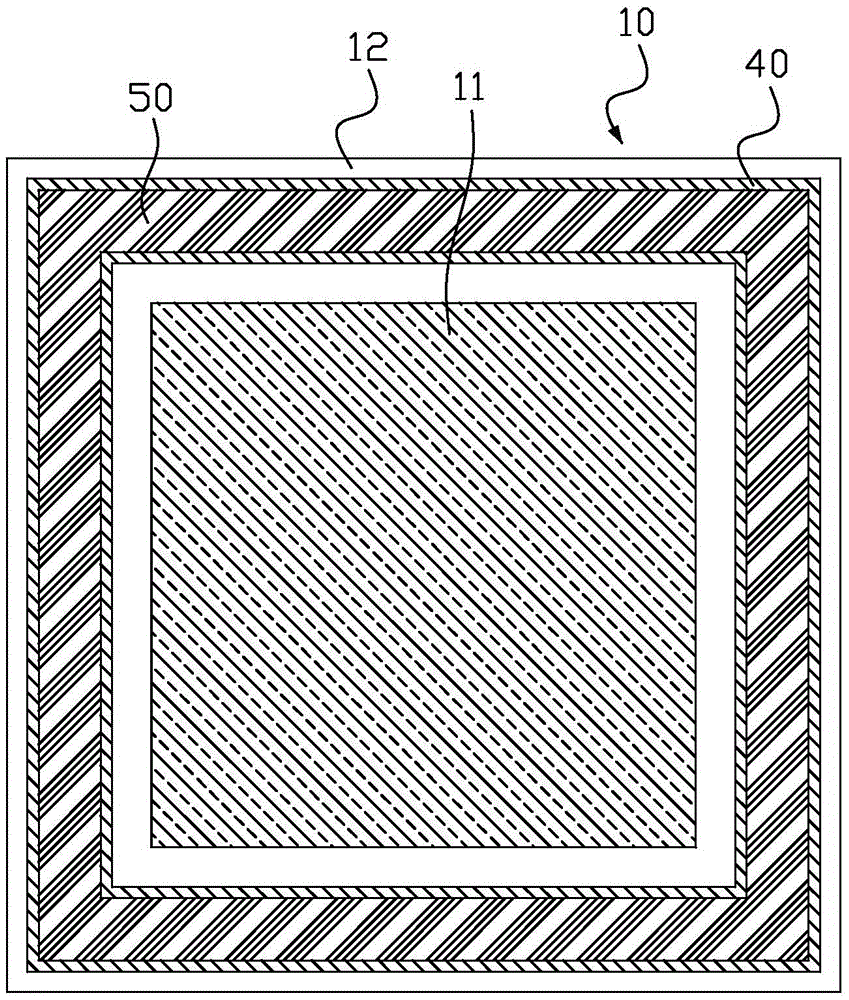

Frit contact membrane layer and OLED packaging structure with frit contact membrane layer

InactiveCN105576149AImprove package strengthImprove water and oxygen barrier performanceSolid-state devicesSemiconductor/solid-state device manufacturingFritOxygen

The invention provides a frit contact membrane layer and an OLED packaging structure with the frit contact membrane layer. The OLED packaging structure comprises a glass substrate, the frit contact membrane layer and a frit, wherein the frit contact membrane layer is positioned on the glass substrate; the frit is in contact with the frit contact membrane layer; the frit contact membrane layer is provided with a plurality of openings in an area corresponding to a frit coating area; the openings are arranged at intervals and arranged into a plurality of rows along the extension direction of the frit; corresponding openings in the adjacent rows are mutually staggered; one part of the frit fills the openings; and one part of the frit is in contact with the upper surface of the frit contact membrane layer. According to the OLED packaging structure disclosed by the invention, the mutually staggered openings are formed in the frit contact membrane layer; therefore, the contact area between the frit and the frit contact membrane layer is increased; the OLED packaging strength is increased; furthermore, a channel for water and oxygen to enter can also be extended through the mutually staggered openings; and the water and oxygen obstructing capability of the frit can be improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Optically-controlled three-dimensional (3D) optical diaphragm and preparation method thereof

ActiveCN103076682AReduce ghostingImprove the display effectSynthetic resin layered productsDiffraction gratingsParallaxGrating

The invention discloses an optically-controlled three-dimensional (3D) optical diaphragm and a preparation method thereof. The optically-controlled 3D optical diaphragm is attached onto any display device capable of displaying a three-dimensional image, and image information with parallax of a left eye and a right eye can be split to the left eye and the right eye of a person to form naked-eye free three-dimensional display. The optically-controlled 3D optical diaphragm comprises a transparent diaphragm material layer and a photochromic grid bar, wherein the transparent diaphragm material layer is doped with zinc oxide nano particles 1,8-diiodooctane additive, the photochromic grid bar is transparent under the non-ultraviolet radiation to display two-dimensional information, the photochromic grid bar turns mazarine under the ultraviolet radiation to realize the grating effect and display the three-dimensional information, through the zinc oxide nano particles in the transparent diaphragm material layer, the transmission rate of the transparent diaphragm material layer is increased by utilizing an optical principle, the viewpoint width of the 3D display is increased, the double-image of the 3D display can be reduced, the 1,8-diiodooctane additive optimizes the dispersibility and uniformity of the zinc oxide nano particles, and the 3D display effect is finally enhanced.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

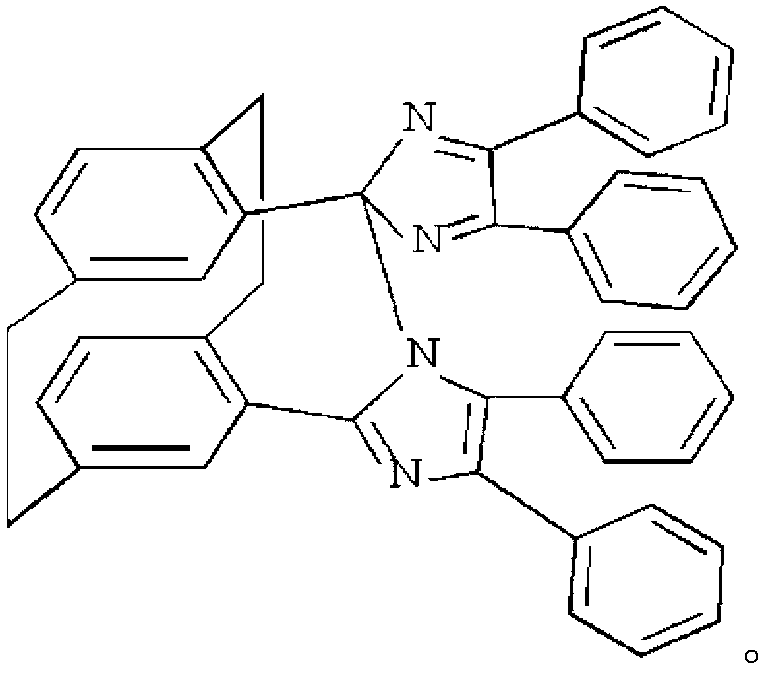

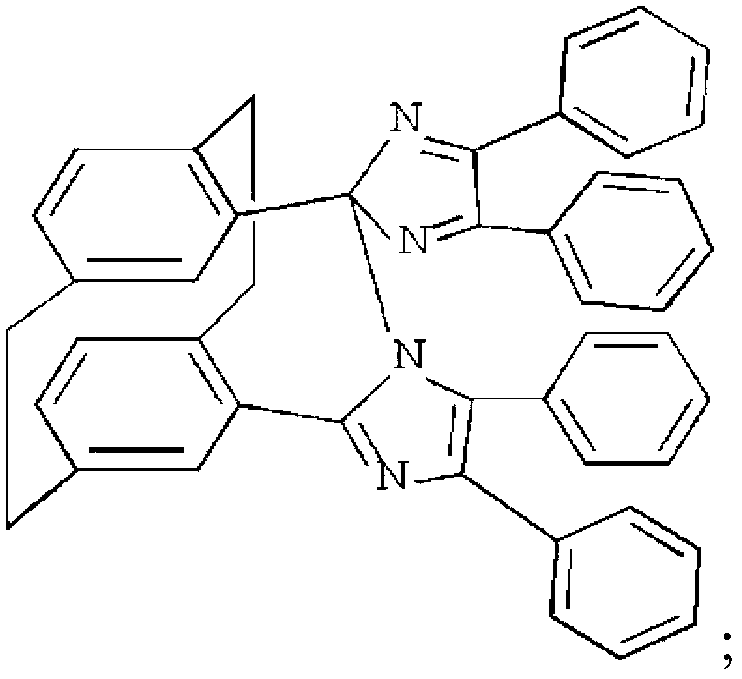

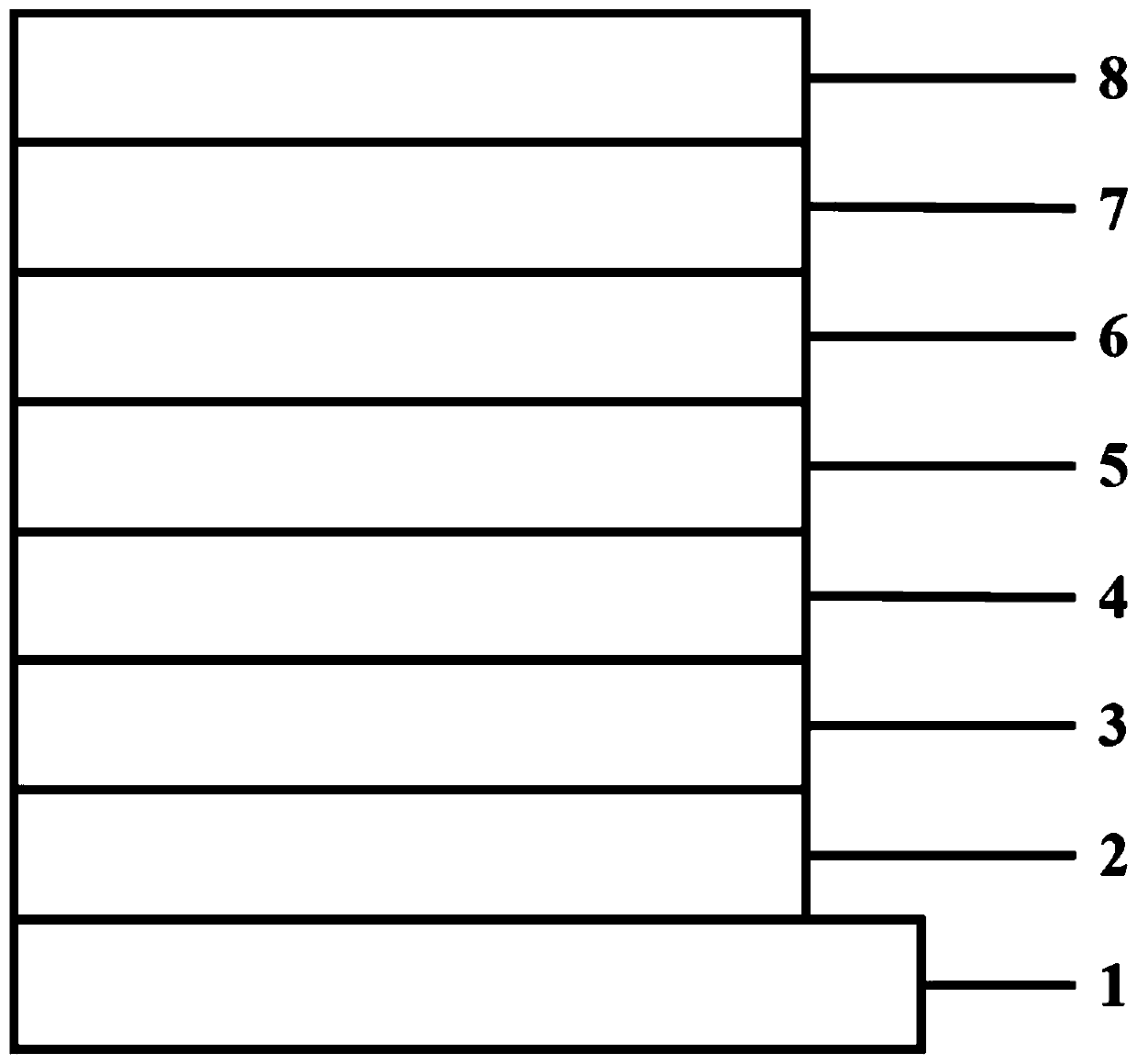

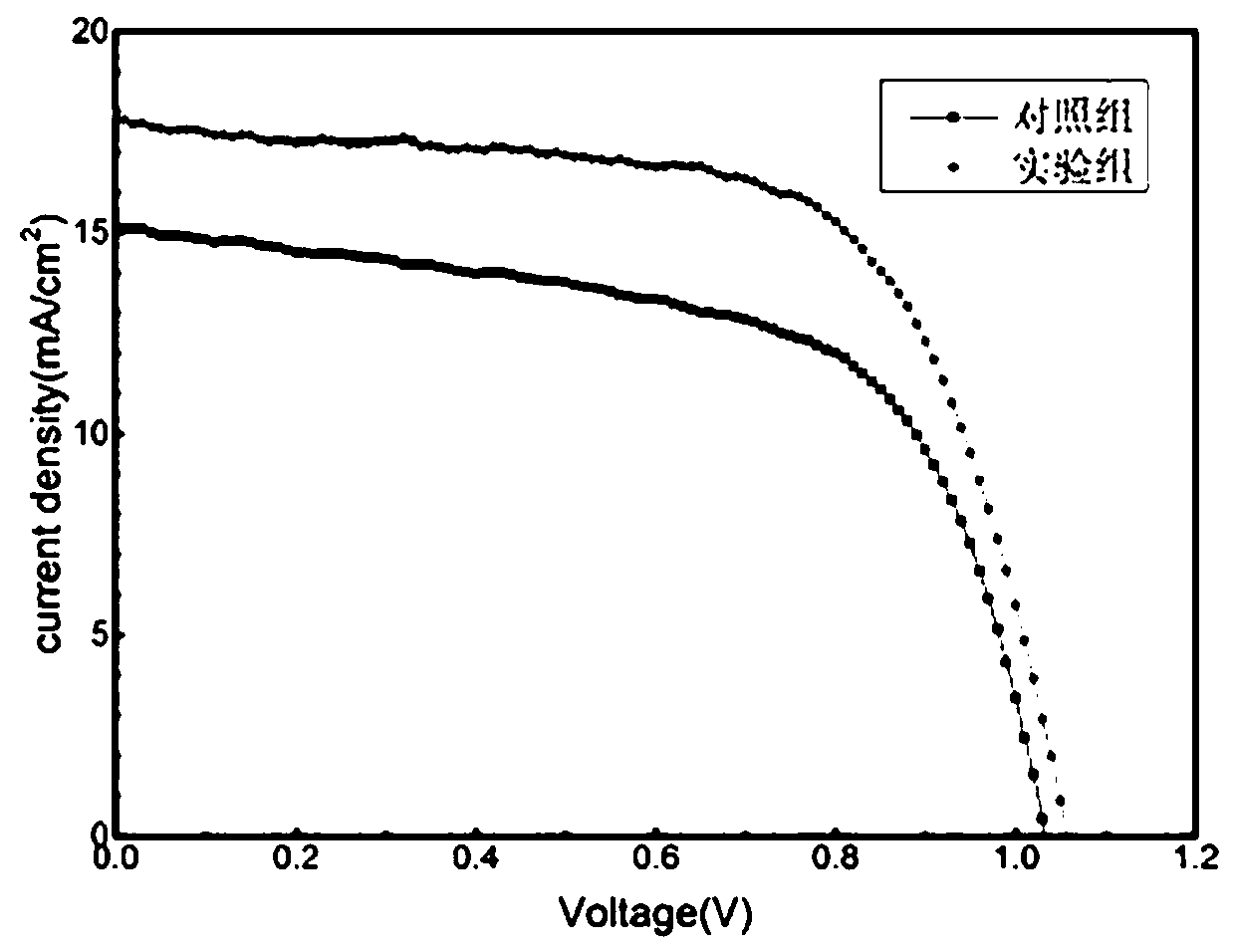

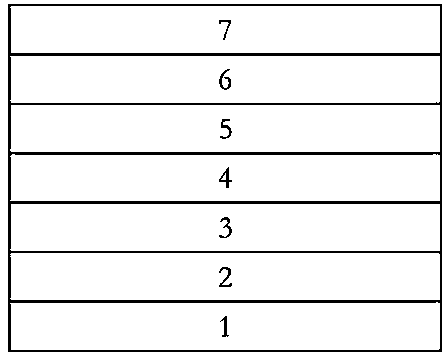

Specially doped perovskite solar cell and preparation method thereof

ActiveCN111180587AFill the crystal gapFill the holeSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerBlocking layer

The invention relates to a specially doped perovskite solar cell and a preparation method thereof. The perovskite solar cell is sequentially provided with a transparent substrate, a conductive anode,a hole transport layer, a passivation doping layer, a perovskite active layer, an electron transport layer, a hole blocking layer and a metal cathode from bottom to top, the passivation doping layer is made of a two-dimensional perovskite precursor material or organic ammonium salt, and the thickness of the passivation doping layer is 0.1-10 nm. Compared with a traditional perovskite solar cell, the photoelectric conversion efficiency is higher, the water and oxygen blocking capacity is better, and the stability of the perovskite solar cell is better.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

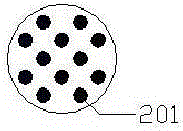

LED coating for encapsulating quantum dots by multiple layers and preparation method thereof

PendingCN108511582ADense high barrier particlesControl glow qualityLuminescent paintsSemiconductor devicesQuantum dotHigh surface

The invention relates to an LED coating for encapsulating quantum dots by multiple layers. The LED coating comprises a traditional encapsulation material layer and a plurality of encapsulation particles of quantum dots and scattered particles, which are scattered in the traditional encapsulation material layer, wherein from inside to outside, the encapsulation particle of the quantum dot and the scattered particle comprises a quantum dot, a compatible polymer layer and a water and oxygen barrier film layer in sequence, and a plurality of inorganic nano scattered particles are scattered in thecompatible polymer layer. The compatible polymer and the quantum dot are highly compatible, so that the high surface energy property of the quantum dot is prevented from damaging colloid crosslinking,and the quantum dot is more stable. According to the LED coating, the quantum dot is wrapped in the compatible polymer and then is crushed into particles, the surface of the particle is encapsulatedby the water and oxygen barrier film layer, and finally, the obtained particles are scattered in another colloid, so as to prepare the quantum dot coating, therefore, the quantum dots are less likelyto gather so as to maintain the luminescence performance; and the multilayer encapsulation structure improves the water and oxygen blocking performance of the quantum dot coating.

Owner:SOUTH CHINA UNIV OF TECH

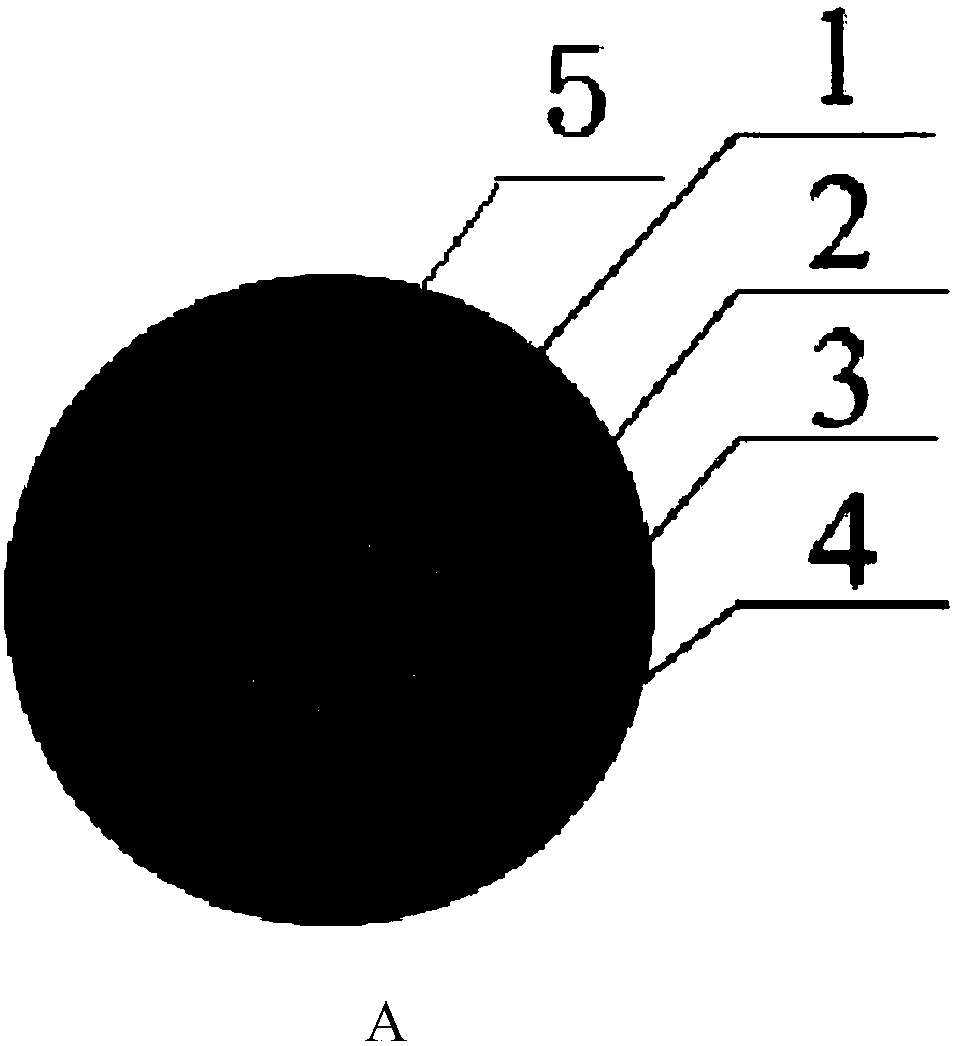

Flexible display device and preparation method

InactiveCN109427996AImprove bending resistanceImprove water and oxygen barrier performanceSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixEngineering

Embodiments of the invention provide a flexible display device and a preparation method, and the problem that a flexible active-matrix organic light-emitting diode module is poor in water oxygen barrier effect on the side surface, and the edge is easy to break or peel off can be solved. According to the flexible display device and the preparation method provided by the embodiment, the flexible display device comprises a display substrate and a packaging film layer which is arranged on the surface of the display substrate, wherein the circumferential edge of the packaging film layer comprises aconcave-convex alternated saw tooth structure.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Display device and preparation method thereof

ActiveCN110993814AImprove water and oxygen barrier performanceImprove sealingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The invention discloses a display device and a preparation method thereof. The display device comprises a display area and a non-display area, and the non-display area surrounds the display area; thedisplay device further comprises a thin film transistor structure layer, an annular metal layer, a light-emitting layer and a first electrode. The display device and the preparation method thereof have the technical effects that the first electrode extends from the display area to the surface of the annular metal layer of the non-display area and completely covers the surface of the annular metallayer, so that metal-to-metal direct contact is formed, and the capacity of an interface for blocking water and oxygen is improved; and when moisture invades laterally, a compact oxidation film is formed on the surface of the first electrode to play a blocking role, and meanwhile, a bulge is formed at the position, corresponding to the annular metal layer, of a passivation layer and plays a role of a small dam to block the moisture layer by layer, so that the sealing performance of a light-emitting element is enhanced, and the life cycle is prolonged.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

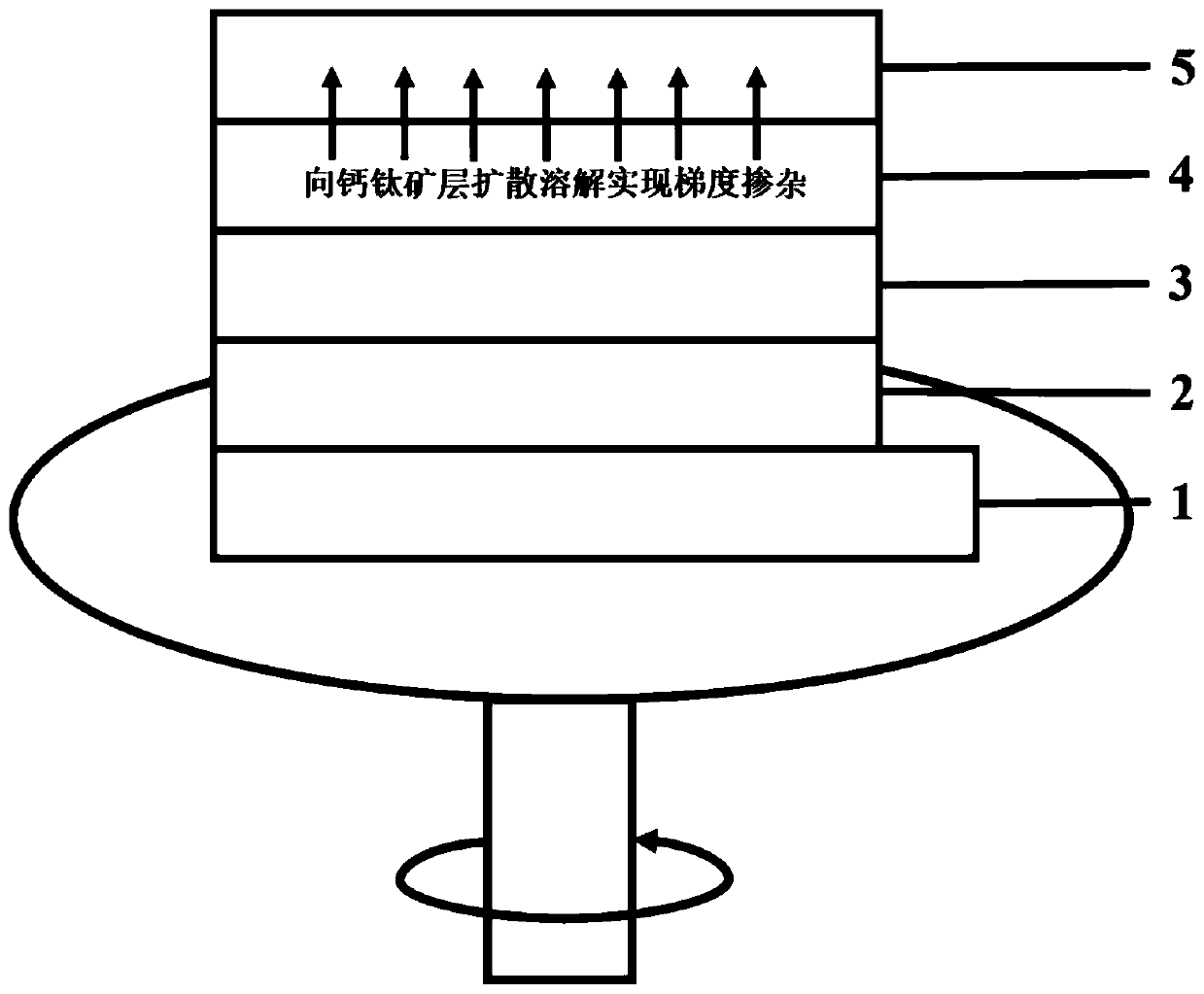

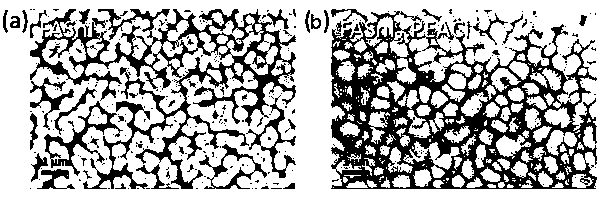

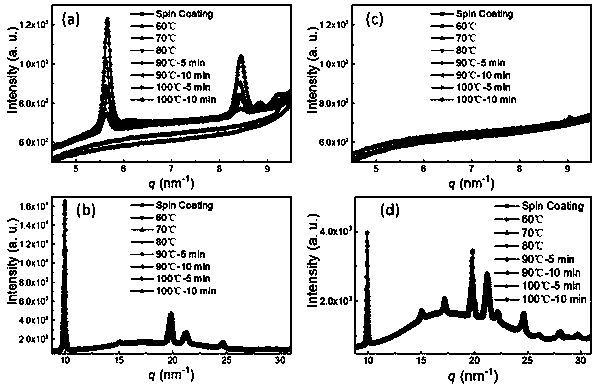

Method for preparing pure-phase high-index vertically-oriented tin-based perovskite thin film based on phenylethyl amine chloride

ActiveCN111180579AImprove stabilityExtended service lifePolycrystalline material growthSolid-state devicesFilm basePerovskite (structure)

The invention belongs to the field of solar cells, and discloses a method for preparing a pure-phase high-index vertically-oriented tin-based perovskite film based on phenylethyl amine chloride. The method is characterized in that by introducing a certain amount of phenethyl amine chloride into a tin-based perovskite precursor solution, high-index and low-index orientation growth is controlled ina two-dimensional structure at different specific temperatures; and through recrystallization induction of phenylethyl amine chloride on tin-based perovskite crystal crystallization and gradient annealing treatment, growth of a low-index structure is effectively inhibited, and the full-coverage and pure-phase high-index two-dimensional crystal tin-based perovskite film growing perpendicular to a substrate is realized. The indoor energy conversion efficiency and the outdoor energy conversion efficiency of the finally prepared photovoltaic device are obviously improved, the tin-based crystal atthe grain boundary achieves a good water-oxygen isolation effect, and the stability of the tin-based device is improved. The method is beneficial to preparation of an efficient and stable tin-based perovskite indoor photovoltaic device, and facilitates energy supply of an intelligent home terminal in the era of internet of things.

Owner:SUZHOU UNIV

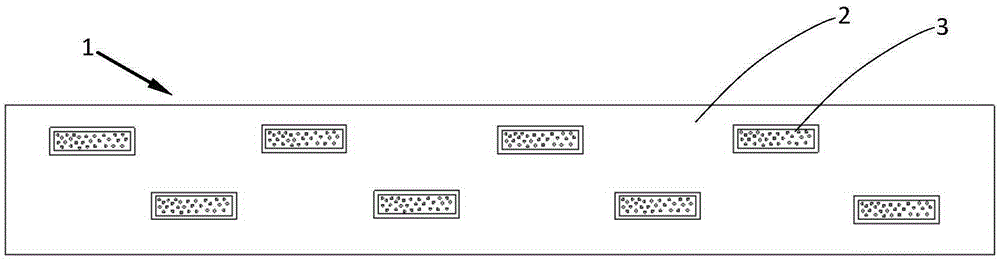

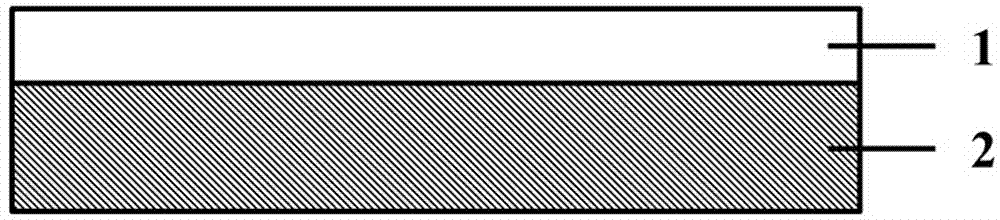

Flexible substrate for display panel and manufacturing method thereof

ActiveCN109244238AImproved optical clarityImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingPolyimideOptoelectronics

The present invention provides a flexible substrate for a display panel. The flexible substrate comprises: a composite film comprising SiO2 nanotubes / polymer matrix, wherein the polymer matrix is polyimide, polyetherimide, polyphenylene sulfide, polyaryl ester, or any combination thereof; Wherein the concentration of the SiO2 nanotubes in the composite film varies in a gradient in an x-axis direction which is a direction perpendicular to the surface of the composite film.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Quantum dot dispersion liquid used for ink-jet printing and color film

The invention discloses quantum dot dispersion liquid used for ink-jet printing and a color film. The quantum dot dispersion liquid comprises 10-40 wt% of quantum dots, 10-30 wt% of fluororesin, 30-70wt% of a reactive diluent and 0.5-5 wt% of an initiator, wherein the viscosity of the quantum dot dispersion liquid is 1-20 cps. The quantum dot dispersion liquid meets the demands of ink-jet printing, and the obtained quantum dot color film is high in luminous brightness and photoconversion efficiency, and shows excellent optical properties.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Biodegradable baseplate used for soft light electron device and manufacturing method thereof

InactiveCN104766932APrevent crystallizationReduce scatterSolid-state devicesSemiconductor/solid-state device manufacturingUV curingUltraviolet

The invention discloses a biodegradable baseplate used for a soft light electron device and a manufacturing method thereof. The baseplate comprises a flexible substrate and a conducting layer, the conducting layer is located on the flexible substrate, the flexible substrate is made of lac mixed with dual curing glue, the mass ratio of the dual curing glue in the lac is 0.3 - 4%, the dual curing glue is composed of a dual curing system, and the dual curing system is an ultraviolet curing-thermocuring system, an ultraviolet curing-micro curing system, an ultraviolet curing-anaerobic curing system or an ultraviolet curing-electron beam curing system. According to the substrate, after the dual curing treatment, the molecules are crosslinked with one another, the resin molecules in the lac are prevented from crystallization, the light scattering is reduced, the light transmittance of the flexible substrate is improved, the performance of the soft light electron device is improved, and meanwhile the problem that the flexibility of the substrate is not high is solved, the obstructing capacity to water radon of the flexible substrate and the smoothness of the surface of the substrate are promoted, and the affinity between a conductive film and the substrate is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

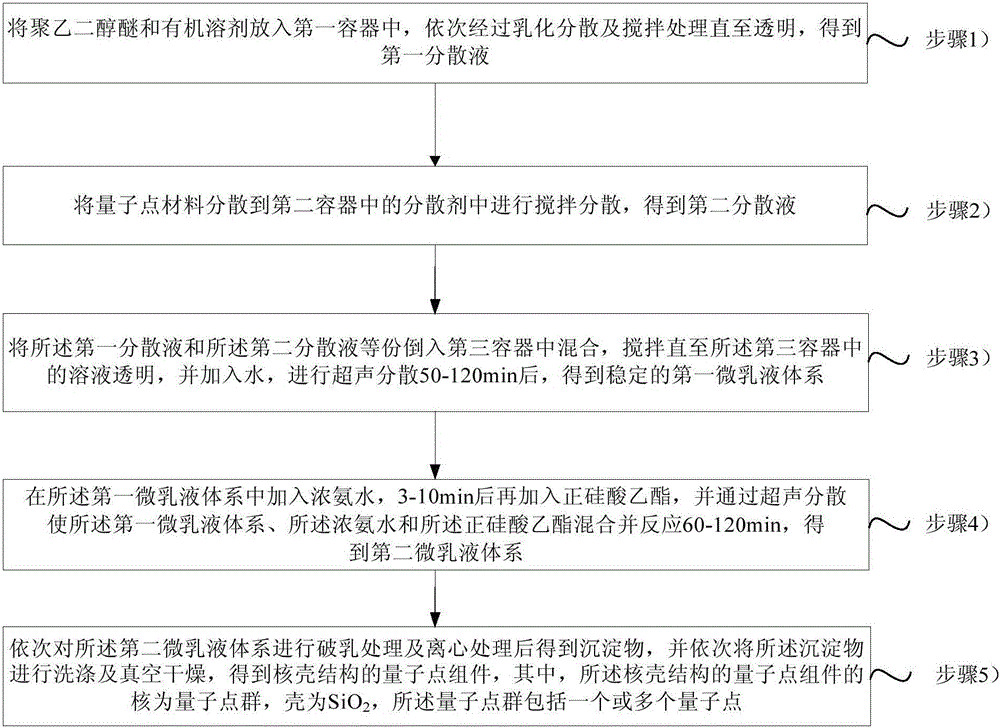

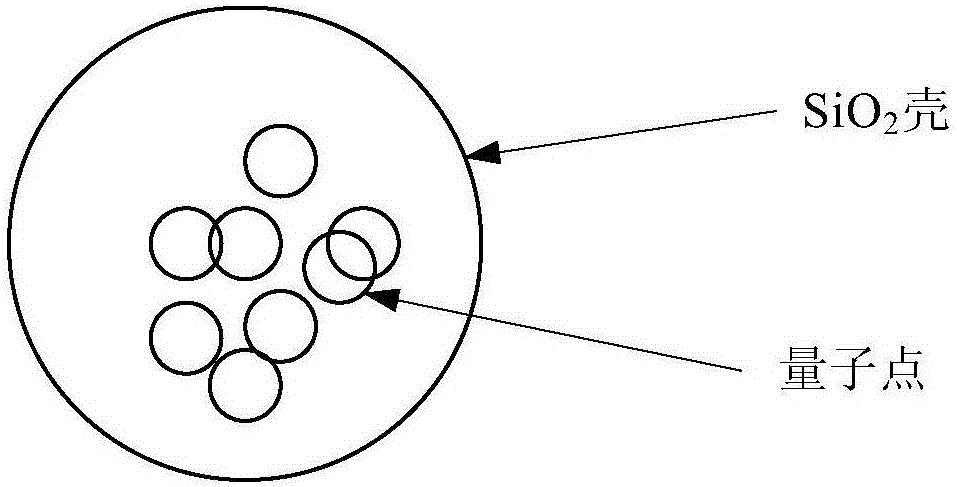

Quantum dot assembly as well as preparation method and application thereof

InactiveCN105754603AReduce water oxygen transmission rateImprove water and oxygen barrier performanceMaterial nanotechnologyNanoopticsTransmittanceChemistry

The invention provides a quantum dot assembly as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) putting polyglycol ether and an organic solvent in a first container, and sequentially performing emulsifying, dispersing, and stirring treatment till a solution is transparent, so as to obtain first dispersion fluid; (2) dispersing a quantum dot material in a dispersing agent in a second container, and performing stirring and dispersing so as to obtain second dispersion fluid; (3) pouring the first dispersion fluid and the second dispersion fluid in a third container, performing mixing and stirring until the solution in the third container is transparent, adding water, and performing ultrasonic dispersion so as to obtain a first microemulsion system; (4) adding strong ammonia water and ethyl orthosilicate to the first microemulsion system, and performing ultrasonic dispersion and mixing and a reaction so as to obtain a second microemulsion system; (5) sequentially performing demulsification treatment and centrifugation treatment on the second microemulsion system so as to obtain precipitates, then sequentially washing the precipitates, and performing vacuum drying on the washed precipitates so as to obtain the quantum dot assembly adopting a nucleocapsid structure. The prepared quantum dot assembly adopting the nucleocapsid structure is high in transmittance.

Owner:HISENSE VISUAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com